Page 1

H2O

INDIRECT-FIRED

WATER HEATERS

FOR SINGLE WATER HEATER

INSTALLATIONS

INSTALL ATION, OPER ATION &

MAINTENANCE MANUAL

30, 40, 50, 60, 80, 85, 115

Gallon

L = Low Boy Prole

C = Commercial Pipe

Connections

HO = High Output

XHO = Extra High Output

Conforms to UL STD 174

Certied to CAN/CSA STD C22.2 No. 110-94

Information and specications outlined in this manual in effect at the

time of printing of this manual. ECR International, Inc. reserves the

right to discontinue, change specications or system design at any time

without notice and without incurring any obligation, whatsoever.

ECR International, Inc.

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

An ISO 9001-2008 Certied Company

P/N# 615000054, Rev. C [12/2014]

Page 2

MODELS

H2OI30 H2OI80HO

H2OI40 H2OI80HOC

H2OI40L H2OI85XHOC

H2OI50 H2OI115

H2OI60 H2OI115HO

H2OI60HO H2OI115HOC

H2OI60L H2OI115XHOC

H2OI80

Table of Contents

I. General Information ............................................................................................................... 3

II. Pre-installation Considerations ................................................................................................ 5

III. Piping .................................................................................................................................11

IV. Electrical .............................................................................................................................15

V. Operation ............................................................................................................................15

VI. Maintenance ........................................................................................................................20

VII. Troubleshooting ...................................................................................................................22

SAVE THESE INSTRUCTIONS

Hazard Denitions

The following dened terms are used throughout this manual to bring attention to the presence

of hazards or various risk levels or to important information concerning the life of the product.

!

DANGER

!

WARNING

Indicates a presence of hazards that WILL cause severe personal injury,

death or substantial property damage.

Indicates a presence of hazards that CAN cause severe personal injury,

death or substantial property damage.

!

CAUTION

NOTICE

Indicates a presence of hazards that will or can cause minor

personal injury, or property damage.

Indicates special instructions on installation, operation or

maintenance that are important but not related to personal injury

or property damage.

2

Page 3

I. General Information

IMPORTANT INFORMATION – READ CAREFULLY

NOTE: The equipment shall be installed in accordance with those installation regulations required in the area where the

installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction shall be

consulted before installations are made.

All wiring on water heaters shall be in accordance with the National Electrical Code and/or local regulations.

!

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury, or loss

of life. Read and understand the entire manual before attempting installation, start-up, operation, or service. Installation

and service must be performed only by an experienced, skilled installer or service agency.

This water heater contains very hot water under high pressure. Do not unscrew any pipe ttings or attempt to disconnect

any components of this water heater without positively assuring that the water is cool and has no pressure. Always wear

protective clothing and equipment when installing, starting up or servicing this water heater to prevent scalding injuries.

Do not rely on the pressure and temperature gauges to determine the temperature and pressure of the water heater.

This water heater contains components that become very hot when the boiler is operating. Do not touch any components

unless they are cool.

Failure to follow all instructions in the proper order can cause personal injury or death. Read all instructions, including all

those contained in component manufacturers’ manuals before installing, starting up, operating, maintaining, or servicing

the water heater.

!

CAUTION

To reduce the risk of excessive pressures and temperatures in this water heater, install temperature and pressure

protective equipment required by local codes but no less than a combination temperature relief valve certied by a

nationally recognized testing laboratory that maintains periodic inspection of production of listed equipment or materials,

as meeting the requirements for Relief Valves and Automatic Shutoff Devices for Hot Water Supply Systems, ANSI Z21.22latest edition. This valve must be marked with a maximum set pressure not to exceed the marked working pressure of

the water heater. Install the valve into an opening provide and marked for this purpose in the water heater, and orient it

or provide tubing so that any discharge from the valve will exit only within 6 inches above, or at any distance below, the

structural oor, and cannot contact any live electrical part. The discharge opening must not be blocked or reduced in size

under any circumstances.

These water heaters with single-wall stainless steel heat exchangers meet the Uniform Plumbing Code for installation in

potable water systems provided that:

• The boiler water, including additives, is practically non-toxic, having a toxicity rating of class 1 as listed in Clinical

Toxicology of Commercial Products, latest edition.

• The boiler water pressure is limited to maximum 30 psig by an approved safety or relief valve.

• The heat transfer medium is potable water or contains only substances that are recognized as safe by the U.S. Food

and Drug Administration. (FDA)

• The pressure of the heat transfer medium is maintained less than the normal minimum operating pressure of the

potable water system.

The maximum boiler water supply temperature to the indirect heat exchanger must not exceed 240 deg. F (115 deg. C).

Improper water quality will reduce the life of the water heater. Hard water, sediment, high or low PH and high levels of

chlorides in the domestic water should be avoided. Be sure that PH levels fall between 6 and 8 and dissolved chlorides

are less than 100 ppm. A lter must be used where sediment is greater than 5 microns in size in the water supplied to

the unit. A water softening system is recommended for areas with hard water. In cases where water quality is unknown, a

qualied water treatment expert should be consulted.

NOTICE: Damage to tanks caused by improper water quality is not covered under the warranty.

3

Page 4

!

DANGER

DO NOT store or use gasoline or other ammable vapors or liquids in the vicinity of this or any other appliance.

If you smell gas vapors, DO NOT try to operate any appliance - DO NOT touch any electrical switch or use any phone in

the building. Immediately, call the gas supplier from a remote located phone. Follow the gas supplier’s instructions or if

the supplier is unavailable, contact the re department.

!

DANGER

This water heater is supplied with an adjustable thermostat to control the water temperature. Hot water temperatures

required for automatic dishwashers and laundry use can cause scald burns resulting in serious personal injury and/or

death. The temperature at which injury occurs varies with the person’s age and the time of exposure. The slower response

time of disabled persons increases the hazard to them. NEVER allow small children to use a hot water tap or to draw their

own bath water. NEVER leave a child or disabled person unattended in a bathtub or a shower.increases the hazard to

them. NEVER allow small children to use a hot water tap or to draw their own bath water. NEVER leave a child or disabled

person unattended in a bathtub or a shower.

II. IMPORTANT SAFETY INSTRUCTIONS

!

WARNING

– When using electrical appliances, basic safety precautions to reduce the risk of re,

electric shock, or injury to persons should be followed, including:

READ ALL INSTRUCTIONS BEFORE USING THIS INDIRECT WATER HEATER.

1.

Install or locate this water heater only in accordance with the provided installation instructions

2.

Use this water heater only for its intended use as described in this manual.

3.

As with any appliance, close supervision is necessary when used by children.

4.

Do not operate this water heater, if it is not working properly, or if it has been damaged or dropped.

5.

This water heater should be serviced only by qualied personnel. Contact nearest authorized service facility for

examination, repair, or adjustment.

4

Page 5

II. Pre-installation Considerations

Inspect shipment carefully for signs of damage. All equipment is carefully inspected and packed. Manufacturer’s

responsibility ceases upon delivery of the water heater to the carrier in good condition. Any claims for damage or

shortage, must be led immediately against the carrier by the consignee. No claims for variances or shortages will be

allowed by the Manufacturer, unless they are presented within sixty days after receipt of the equipment.

Installation must conform to the requirements of the authority having jurisdiction. In the absence of such requirements,

installation must conform to the National Plumbing Code and the National Electrical Code ANSI/NFPA No. 70, current

edition.

IMPORTANT CONSIDERATIONS BEFORE INSTALLATION

1.

Water Heater Sizing.

Choose the water heater model based on the expected water usage for the given site. The average residence

with one shower or more will require a Model 40 or larger. The Model 30 should only be considered for

residences with minimal water demand, or for commercial applications without showers. See Tables 2 and 3.

Consult ASHRAE sizing guides and other references.

Factors that increase water demand dramatically include high ow shower heads, hot tubs, and the use of more than one

shower at a time. Increase the tank size if these factors are present. Consult ASHRAE sizing guides and other references.

Dimensions, weights, ratings, and capacities are outlined in Table 1.

2.

Boiler Sizing.

The water heater will provide the rated performance only if it is used with a boiler with a heating capacity of at least as

much as the capacity ratings in Tables 2 and 3. If the boiler has less capacity, the water heating output will be reduced.

NOTICE

If the boiler takes longer to heat up from a cold start, hot water shortage may occur.

The maximum heat transfers through the coil (heat input) of the water heaters at 240 deg.

F boiler supply temperature and 210 deg. F potable water temperature are as follows:

• Models 30 – 115 single coil units and models 60-D, 80-D, and 115-D dual coil units

are less than 96,000 BTU/HR.

• Models 80-HO, 115-HO, 80-HO-C, and 115-HO-C high output units are less than

84,000 BTU/HR.

• Models 85-XHO and 115-XHO, the extra high output series, are less than 175,000

BTU/HR.

Potable water temperature is limited to below 210 deg. F and nominal water containing

capacity is below 120 gallons for all indirect models.

Accordingly, per Part HLW-101.2, Section IV of the ASME Boiler and Pressure Vessel Code,

all indirect water heater products are exempt from compliance with the code.

Check with local codes for applicability

5

Page 6

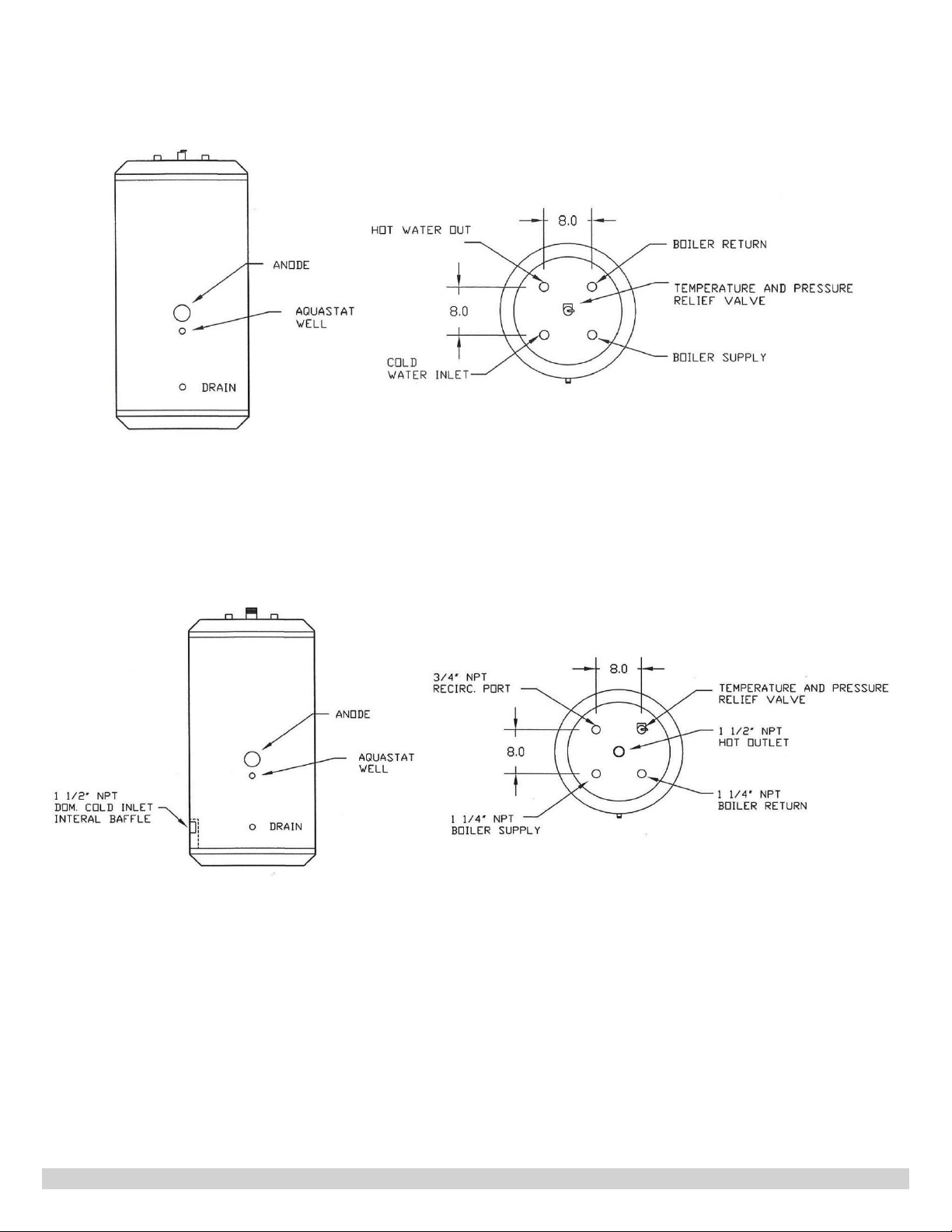

STANDARD AND HO UNITS

HOC UNITS

6

Page 7

XHOC EXTRA HIGH OUTPUT UNITS

XHOC HIGH OUTPUT INDIRECTS

MODEL 115-XHOC - HEIGHT = 74" - 115 GAL.

MODEL 85-XHOC - HEIGHT = 64" - 86 GAL.

COLD AND HOT DOMESTIC - 1 ½" NPT CONNECTIONS

COIL SUPPLY AND RETURN - 1 ½" NPT CONNECTIONS

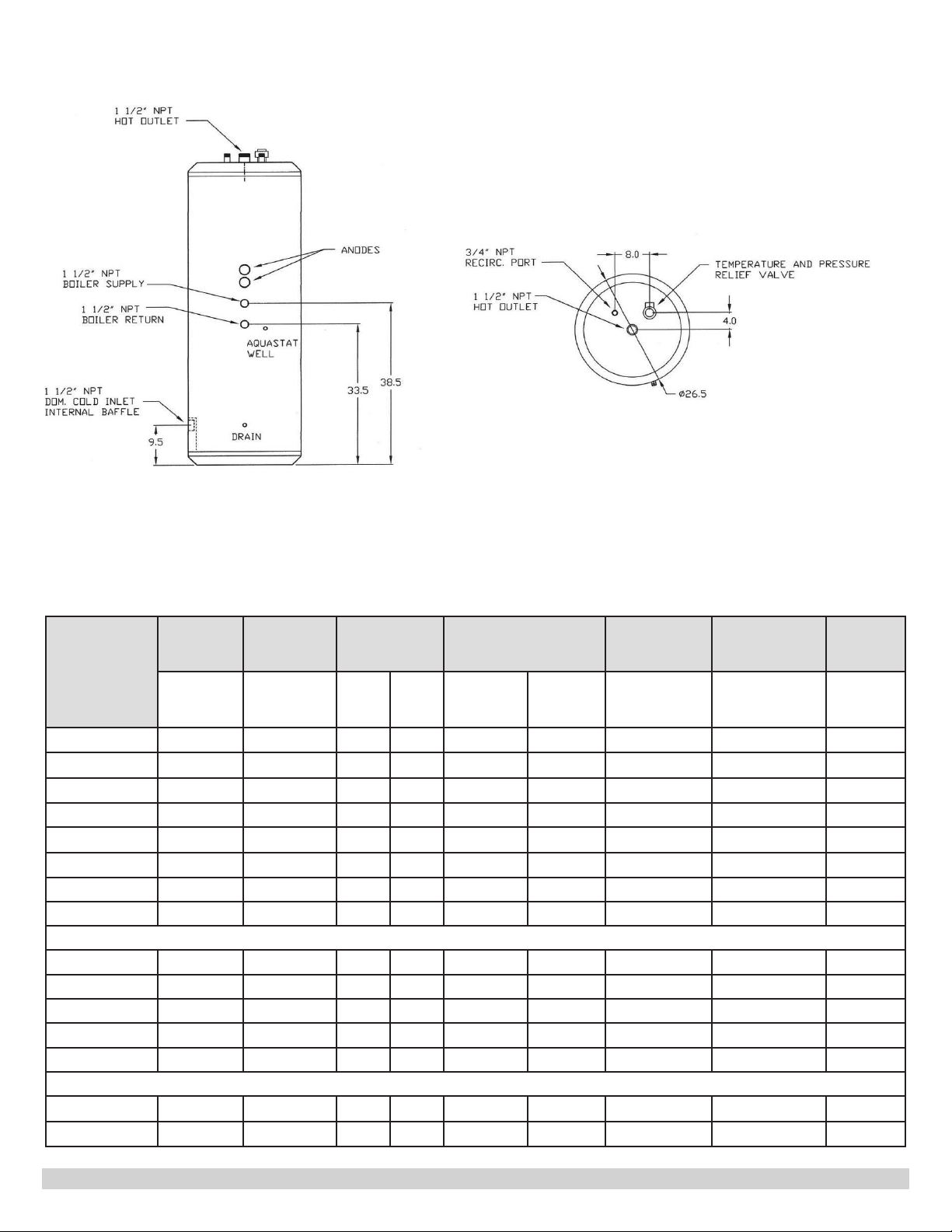

TABLE 1- Dimensions and Capacities

Model

Storage

Volume

Coil

Heating

Surface

Dimensions

(Inches)

Gals. Sq. Ft. Ht. Dia.

Piping Connections

N.P.T

Domestic

Water

In/Out

Boiler

Water

In/Out

Max. Tank

Working

Pressure

Max. Coil

Working

Pressure

shipping

(psi) (psi) Lbs.

Approx.

H2OI30 30 7.3 34.0 23.5 3/4 1 150 90 85

H2OI40 40 7.7 44.0 23.5 3/4 1 150 90 100

H2OI40L 42 7.4 36.0 28.0 3/4 1 150 90 100

H2OI50 50 8.2 54.0 23.5 3/4 1 150 90 110

H20I60 60 8.6 62.0 23.5 3/4 1 150 90 125

H2OI60L 60 7.7 46.0 28.0 3/4 1 150 90 120

H2OI80 80 8.2 56.0 28.0 1 1 150 90 140

H2OI115 115 9.1 74.0 28.0 1 1 150 90 175

High Output Units

H2OI60HO 60 15.1 62.0 23.5 1 1 150 90 145

H2OI80HO 80 14.8 56.0 28.0 1 1 150 90 155

H2OI8H0C 80 14.8 56.0 28.0 1½ 1¼ 150 90 155

H2OI115HO 115 15.6 74.0 28.0 1 1 150 90 190

H2OI115HOC 115 15.6 74.0 28.0 1½ 1¼ 150 90 190

Extra High Output Units 85-XHO and 115-XHO

H20I85XHOC 87 28.7 64.0 28.0 1½ 1½ 150 90 215

H20I115XHOC 115 28.7 74.0 28.0 1½ 1½ 150 90 240

Wt.

7

Page 8

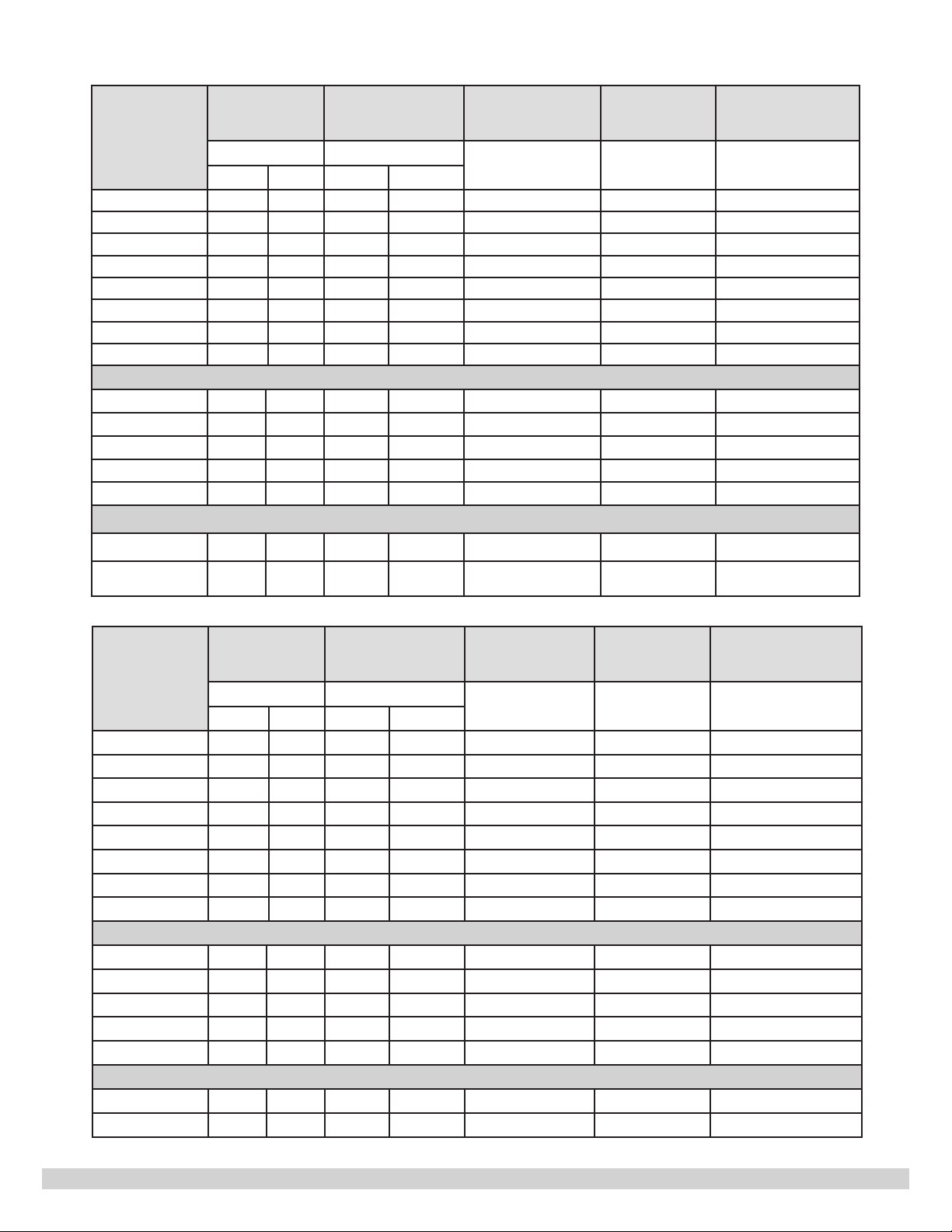

Table 2 - 200 deg F Boiler Supply Ratings

Max. First

Hour Rating

Continuous

Rating

Boiler Output

Needed

Model

Gal/Hr. @ Gal/Hr @

140 F 115 F 140 F 115 F

H20I30 202 269 175 242 131,250 14.0 5.3

H2OI40 221 292 185 256 138,670 14.0 5.7

H2OI40L 212 251 176 215 132,000 14.0 5.3

H2OI50 223 291 178 246 133,280 14.0 6.0

H20I60 262 342 208 288 155,700 14.0 6.2

H20I60L 239 310 185 256 138,570 14.0 5.7

H2OI80 271 248 199 276 149,390 14.0 6.0

H2OI115 324 409 221 306 165,750 14.0 6.6

(BTU/Hr) Gal/Min (Ft. Water)

Boiler Water

Flow Through

Coil

Pressure

Drop

Through Coil

High Output Units 60-HO, 80-HO, and 15-HO

H2OI60HO 406 541 352 478 263,600 14.0 10.1

H2OI80HO 418 551 346 479 259,340 14.0 9.9

H2OI80HOC 442 584 370 512 277,070 21.0 10.5

H2OI15HO 467 607 364 504 273,100 14.0 15.8

H2OI115HOC 479 623 376 520 281,800 21.0 16.7

Extra High Output Units 85-XHO and 115-XHO

H2OI85XHOC 738 992 660 914 495,000 28.0 13.0

H2OI115XHOC 763 1017 660 914 495,000 28.0 13.0

Table 3 - 180 deg F Boiler Supply Ratings

Max. First

Hour Rating

Model

Gal/Hr. @ Gal/Hr @

140 F 115 F 140 F 115 F

H20I30 176 233 149 206 111,560 14.0 5.3

H2OI40 193 254 157 218 117,870 14.0 5.7

H2OI40L 186 251 150 215 223,300 14.0 5.3

H2OI50 196 254 151 209 113,290 14.0 6.0

H20I60 231 298 177 244 132,340 14.0 6.2

H20I60L 211 272 157 218 117,785 14.0 5.7

H2OI80 241 306 169 234 126,980 14.0 6.0

H2OI115 291 363 188 260 140,890 14.0 6.6

High Output Units 60-HO, 80-HO, and 15-HO

H2OI60HO 353 468 299 414 224,200 14.0 10.1

H2OI80HO 366 479 294 407 220,440 14.0 9.9

H2OI80HOC 386 507 314 435 235,510 21.0 10.5

H2OI15HO 413 532 310 429 232,135 14.0 15.8

H2OI115HOC 423 545 320 442 239,530 21.0 16.7

Extra High Output Units 85-XHO and 115-XHO

H2OI85XHOC 649 868 571 790 428,000 28.0 13.0

H2OI115XHOC 674 893 571 790 428,000 28.0 13.0

Continuous

Rating

Boiler Output

Needed

Boiler Water

Flow Through

Coil

Pressure

Drop

Through Coil

(BTU/Hr) Gal/Min (Ft. Water)

NOTE: All ratings are based on 50 deg. F cold water inlet.

8

Page 9

3.

Circulator Sizing.

Refer to Tables 2 and 3 for the minimum ow through the water heater coil and the pressure drop at minimum ow.

Calculate the pressure drop across all piping and ttings connected to the water heater zone. Be sure to include all zone

valves, check valves, and shut-off valves. It is recommended that the water heater zone be piped with 1” pipe around the

entire loop on typical residential sites.

A. System Zone Control

The water heater must be installed as a separate zone from the space heating system. The water heating zone’s piping

and circulator must be sized for the minimum ow rate with all the zones in use and a maximum ow with only the water

heater in use. Best performance is normally achieved using zone control with circulators.

The three most common systems are:

1.

Zone Circulators- Space heating zones use a circulator for each zone. The water heater is controlled with an

additional circulator.

2.

Hybrid System- Space heating zones use zone valves for each zone. The water heater is controlled with an

additional circulator.

3.

Zone Valves – Space heating zones use zone valves for each zone. The water heater is controlled with an

additional zone valve. Select a valve with a low pressure drop, and assure minimum ow with adequate pipe

sizing.

B. Priority or Non-Priority for Hot Water

1.

Option 1 – Priority. The demand for space heating is interrupted until the hot water demand is satised. This

option provides the maximum delivery of hot water.

Priority is recommended when:

A. The boiler output is less than 100,000 Btu per hour, or

B. The boiler output required to satisfy the hot water demand is more than 50% of the boiler output needed to

satisfy the space heating demand, or

C. When an interruption in space heating can be tolerated during long domestic hot water draws.

In most cases the delay in space heating will not be noticed because of the rapid recovery of the water

heater. It must be recognized however that certain water heater malfunctions, such as a failed thermostat or

circulator, could delay space heating indenitely.

2.

Option 2 – Non-Priority. The boiler output is divided between space heating and water heating. Heating of

domestic hot water can be reduced during simultaneous space and water heating demands. The amount of

reduction depends on the boiler output, the number of space heating zones calling, and the amount of boiler

water ow split between the space heating and zones and the water heater zone.

9

Page 10

C. Locating the water heater.

1”

1”

1”

1”

1”

Water heater should be located in an area where water leakage from the tank or connections will not result in damage to

areas adjacent to the water heater or to lower oors of the structure. When such a location can not be avoided, a suitable

drain pan must be installed under the water heater, and the drain pan must be connected to a drain.

Water heater should be installed as close to the boiler as is practical for easy access for service. Unit is designed for

installation on combustible ooring and in alcoves, closets, etc.

The minimum clearances from combustible surfaces are:

Bottom-------------------------0”

Left, right, and rear sides -- 1”

Front---------------------------1”

Top-----------------------------6”

The minimum clearances for service are:

Bottom-------------------------0”

Left, right, and rear sides -- 3”

Front--------------------------30”

Top-----------------------------6”

D. Additional components

1.

Shut-off valves. Allows the isolation of the water heater from the boiler system during service.

2.

Unions. Allows for easy locating or removal. Use dielectric unions or couplings to protect hot and cold water

Front View Top View

ttings from corrosion when connecting dissimilar materials such as copper and galvanized pipe.

3.

Vacuum breaker. Protects the water heater from collapse if a hot tank is valved off to service other components

in the system. Required for Commonwealth of Massachusetts.

4.

Thermal expansion tank. If the water heater is installed in a closed water supply system, such as a system

having a back ow preventer in the cold water supply line, the installation of a thermal expansion tank is

required.

5.

Water hammer arrester. Dishwashers, clothes washers, and fast-closing positive shutoff valves incorporated

in the system all contribute to creating water hammer. Install a water hammer arrester to prevent damage to

pipes and appliances. See control manufacturer's instructions for application and installation.

6.

Backow preventer. Protects potable water supplies from contamination due to backow. Required for

Commonwealth of Massachusetts.

E. Removing the Existing Domestic Water Heating System

1.

External Tankless Heater- Disconnect all lines to the boiler and plug the boiler ttings. Disconnect the external

heater from the boiler piping, and the domestic piping systems.

2.

Internal Tankless Heaters- Disconnect the domestic piping. Do not plug the cold water or the hot water ttings

in the internal tankless coil. Leave the coil in the boiler with the cold and hot water ttings open to prevent

pressure build-up in the coil.

For California installation this water heater must be braced, anchored, or stapped to avoid falling or

NOTICE

moving during an eathquake. See instructions for correct installation procedures. Instructions may

be obtained from California Ofce of the State Architect.

10

Page 11

F. Water Quality

Improper water quality will reduce the expected life of the water heater. Hard water, sediment, high or low Ph, and high

levels of chlorides in the domestic water should be avoided. Sediment and hard water will eventually coat the heating coil

inside the water heater and reduce the rate of hot water production and may, eventually cause a failure. High or low Ph

and/or high chloride concentrations will cause corrosion and eventually failure. A lter is strongly recommended where

sediment is present in the water. A water softening system is recommended for areas with hard water.

In an area where the water quality is not known, a water quality test should be performed.

WARNING:

Do not operate the water heaters in areas where the Ph is above 8.0 or below 6.0, and/or with chloride concentrations

greater than 100 parts per million (ppm). ECR’s standard warranty does not cover problems caused by improper water Ph

or excessive levels of chlorides.

NOTICE

Damage to tanks caused by improper water quality is not covered under the warranty.

III. Piping

A. Domestic water piping. See Figure 1.

1.

Shut off the cold water supply at the main shutoff valve.

Open one or more faucets to relieve the pressure. Open the system drain, leaving the faucets open.

Drain the domestic water system.

2.

Position the water heater in the nal location.

3.

Connect the cold water supply piping.

• Install piping onto cold inlet connection.

• Connect to cold water supply connection using a union, a heat trap, a shut-off valve, a vacuum breaker, an

expansion tank (where required), and a lter (recommended to prevent sediment buildup).

NOTICE

If installing on a city supply, a properly sized thermal expansion tank is required and should be installed in

accordance with the product installation manual.

If a water heater is installed in a closed water supply system, such as one having a backow preventer in the cold

water supply, a check valve in the cold water supply, or a pressure reducing valve in the cold water supply means

shall be provided to control thermal expansion.

The appliance, when installed, must be grounded in accordance with the local codes, or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70.

WARNING

If this product is connected to a cold water supply line that has a check valve, a backow preventer, a pressure

reducing valve, or a check valve in the water meter, it is a requirement that a properly sized thermal expansion

tank be installed in the cold water inlet line. There will be no warranty on applications where there is no pressure

control.

4.

Connect the domestic hot water piping.

Install piping on to hot water supply connection using a union, a heat trap, a vacuum breaker, and a shut-off

valve.

11

Page 12

5.

Pipe the relief valve discharge so that the discharge from the valve will exit only within 6 inches above, or at

any distance below, the structural oor, and cannot contact any live electrical part. The discharge opening must

not be blocked or reduced in size under any circumstances.

WARNING

Install a discharge line so that water discharged from the temperature and pressure relief valve will exit within

six (6) inches above, or any distance below, the structural oor and cannot contact any live electrical part. The

discharge line is to be installed to allow for complete drainage of both the temperature and pressure relief valve

and the discharge line. The discharge opening must not be subjected to blockage or freezing.

DO NOT thread, plug, or cap the discharge line. It is recommended that a minimum clearance of four (4) inches

be provided on the side of the water heater for servicing and maintenance of the combination temperature and

pressure relief valve.

Do not place a valve between the combination temperature and pressure relief valve and the tank!

6.

Fill the water heater tank.

Open all faucets to allow air to purge from the tank and piping. Remove screens on faucets.

Open domestic hot water shut-off valve.

Open cold water inlet shut-off valve.

Purge all of the air from the domestic water system. Allow water to run so the tank is completely purged of any

debris. Run the water long enough to change at least ve tank volume changes. Close all faucets. Reinstall all of

the screens in the faucets.

Check the system for leaks. Repair as required.

B. Water boiler piping. See Figures 3 and 4.

1.

Determine where the boiler, the space heating, and the water heater connections should be made based on the

type of piping system that is either in place, or is to be installed for a new hydronic system installation. See

Figure 3, Boiler Water Piping with Zone Circulators, and Figure 4, Boiler Water Piping with Zone Valves.

2.

It is recommended that 1” pipe and 1” zone valves be used on the water heater zone on residential site and 1¼"

and 1½" pipe be used on High Output units on commerical sites.

Zone Circulator System

For space heating systems that use Zone Circulators, refer to Figure 3. The water heater connection labeled

“BOILER SUPPLY” should be piped to the boiler supply piping after the air purger and before the space heating

takeoffs. Mount the water heater circulator as close as possible to the water heater, and make sure the ow

arrow points toward the water heater. The use of shut-off valves is recommended for future service convenience.

The water heater connection labeled “BOILER RETURN” should be piped to the boiler return piping as close to

the boiler as possible and after any ow control or check valves in the space heating return piping. The use of a

union and a shut-off valve is recommended. The use of a check valve is required to prevent back ow through

the water heater during operation of the space heating system.

Zone Valve System

For a space heating system that uses Zone Valves, refer to Figure 4. The water heater connection labeled

“BOILER SUPPLY” should be piped to the boiler supply piping after the air purger and before the space heating

circulator. Mount the water heater circulator as close as possible to the water heater, and make sure the

ow arrow points toward the water heater. The use of a shut-off valve is recommended for future service

convenience.

The water heater connection labeled “BOILER RETURN” should be piped to the boiler return piping as close to

the boiler as possible and after any ow control or check valves in the space heating return piping. The use of a

union and a shut-off valve is recommended. The use of a check valve is required to prevent back ow through

the water heater during operation of the space heating system.

12

Page 13

NOTICE

Hot Water Supply

Figures 1, 2, 3 and 4 are meant to illustrate system piping only. The Installer is responsible for

conforming to the Local Codes. In Massachusetts, you must install a vacuum relief valve per 248 CMR.

See local code requirements.

Figure 1 - Domestic Water Piping

Pipe relief valve discharge to

within 6" of oor. See Section

III, item #5.

Figure 2 - Typical Mixing Valve Install

Shut off

Valve

Cold Water Supply

Cold

Inlet

Expansion

Tank

Solar

Water

Heater

with

boiler

indirect

or

electric

back up

Check

Valve

Hot

Outlet

Temperature

& Pressure

Relief Valve

Drain Valve

Anti-

scald

valve

Pipe relief valve discharge

to within 6" of oor. See

Section III, item #5.

Single Tank

Installation

13

Page 14

Figure 3 - Boiler Water Piping with Zone Circulators

Pipe relief valve discharge

to within 6" of oor. See

Section III, item #5.

Figure 4 - Boiler Water Piping with Zone Valves

Pipe relief valve discharge

to within 6" of oor. See

Section III, item #5.

14

Page 15

IV. Electrical

1.

Install electric wiring and grounding in accordance with the National Electrical code and local regulations.

2.

All water heaters are supplied with a thermostat.

3.

Refer to schematics for separate circulator wiring.

Refer to schematics for zone valve wiring.

Reference should be made to the Installation Manual for the boiler as well.

V. Operation

Startup

After the water heater has been plumbed and wired, and the boiler water piping is purged of air, the water heater is ready

to be started.

1.

Follow the boiler installation instructions to place the boiler in operation.

2.

The tank thermostat is factory pre-set to 125 degrees F and will call for heat if the water in the tank is lower

than 125.

3.

On a call for heat, the tank thermostat contacts close to start the water heater zone circulator and the boiler.

4.

After the tank has reached the temperature setting, the tank thermostat opens and de-energizes the circulator

and the boiler. If there is a call for space heating, the boiler will continue to run until the room thermostats are

satised.

WARNING

This water heater can deliver scalding temperature water at any faucet in the system. Be careful when

using hot water to avoid scalding injury. By setting the thermostat on this water heater to obtain an

increased water temperature, you create the potential for scald injury. To protect against injury, you

should install an ASSE approved mixing valve ( a device to limit the temperature of water to protect

against scald injury via mixing hot and cold water supply) in the water system. This valve will reduce

point of discharge temperature in branch supply lines. Such valves are available from a local plumbing

supplier. Please consult with a plumbing professional.

15

Page 16

Temperature Adjustment

The tank thermostat controls the maximum water temperature in the water

heater. If it is set too high, the resulting hot water can cause painful scalding

with possible serious and permanent injury. The temperature at which this

occurs varies with a person’s age, and the length of time in contact with the

hot water. The slower response time of infants, older, or handicapped people

increases the hazard for them.

It is recommended that the thermostat be set for the lowest possible

temperature that satises your needs. This will also provide you with the

lowest energy consumption and cost.

Check the water temperature at a hot water faucet soon after the tank

thermostat has satised, and the circulator and the boiler have turned off.

Adjust as needed.

Lowering the thermostat setting will not have an immediate effect on the

water temperature because the stored water will have to be used and the

thermostat must go through the cycle of heating cold water and satisfying at

the new, lower temperature. Additional temperature checks should follow the

completion of a heating cycle. Further adjustments may be required after you

have used the water heater.

The table below details the approximate relationship of water

temperature and time with regard to scald injury and may be used

as a guide in determining the safest water temperature for your

applications.

Approximate Time/Temperature

Relationships in Scalds

120°F (52°C) More than 5 Minutes

125°F (52°C) 1½ to 2 Minutes

130°F (54°C) About 30 Seconds

135°F (57°C) About 10 Seconds

140°F (60°C) Less Than 5 Seconds

145°F (63°C) Less Than 3 Seconds

150°F (66°C) About 1½ Seconds

155°F (68°C) About 1 Second

The scald label show to the right can be found on all Indirect

Water Heaters and Storage tanks. Take note and use caution when

adjusting the temperature settings with your water system. Be sure

to always feel the water before bathing or showering, especially

when drawing a bath for an infant or elder.

Hot Water Can Scald!

Water heated to temperature for

clothes washing, dish washing and

other sanitizing needs can scald

and cause permanent injury.

Children, elderly, and inrm or

physically handicapped persons

are more likely to be permanently

injured by hot water. Never leave

them unattended in bathtub or

shower. Never allow small children

to use a hot watertap or draw their

own bath.

If anyone using hot water in the

building ts the above description,

or if state laws or local codes

require certain water temperatures

at hot water taps, you must take

special precautions:

• Use lowest possible temperature

setting.

• Install some type of tempering

device, such as an automatic

mixing valve, at hot water tap

or water heater. Automatic

mixing valve must be selected

and installed according to

manufacturer's recommendations

and instructions.

16

Water passing out of drain valves

may be extremely hot. To avoid

injury:

• Make sure all connections are

tight.

• Direct water ow away from any

person.

Page 17

WARNING

It is the responsibility of the installing contractor to see that all controls are correctly installed and are

operating properly when the installation is complete.

DO NOT operate the water heater with jumpered or absent controls or safety devices.

DO NOT tamper with or alter the water heater and /or controls.

DO NOT operate the water heater if any external part has been under water. Immediately call a

qualied service technician to inspect the appliance and to replace any part of the control system that

is or had been under water.

DO NOT install this water heater on carpeting. This water heater is suitable for installation on

combustible ooring.

DO NOT operate this water heater without rst being certain it is lled with water.

17

Page 18

Argo offers a broad line of controls for water heating and multiple zone boiler heating applications.

Please check out our web site at http://www.argoindustries.com for applications information and comprehensive wiring

diagrams.

A typical wiring diagram is shown below. This is a multi-zone application using zone pumps with programmable domestic

hot water priority using our ARM-4P Panel.

Product features include:

1.

Built in transformer that will support up to 15 zones. Transformer has electronic fuse protection to prevent

transformer overloading.

2.

Data Port Terminal for easy connection to other Argo control products.

3.

Expansion module plug-in allowing easy expansion to more zones.

4.

Priority Zone Safety Timer. If the priority zone calls for more than 30 minutes the priority zone feature will turn

off allowing all zones to operate independently preventing freeze ups if water heater has a problem.

5.

Plug in replacement relays for long life and easy servicing with 1/3 HP pump motor ratings.

INDIRECT WATER TANK TO ARM-4P CONTROL

Class 2

Terminals

To Boiler T-T

Terminals

Primary

Terminals

18

Page 19

19

Page 20

VI. Maintenance

The water heater is intended to provide many years of reliable service. Components, such as thermostats and relief

valves, may be subject to failures that require service. Depending on the quality of the water supply, sediment and/or

scale may coat the heating coil in the tank and reduce hot water recovery rate. Failure to use the correct procedures or

parts can result in unsafe operation.

The owner should arrange to have the following inspections and simple maintenance procedures done at the suggested

frequencies.

1.

Boiler and Domestic Water Piping (Annual)

Check all piping for signs of leakage at the joints, unions and shut-off valves. Repair as required.

2.

Temperature and Pressure Relief Valve (Annual)

• The temperature and pressure relief valve should be checked to ensure that it is in operating condition. To

check the relief valve, lift the lever at the end of the valve several times. The valve should seat properly and

operate freely. If water does not ow, remove and inspect for obstructions or corrosion. Replace with a new

valve of the recommended capacity as necessary. Do not attempt to repair the valve, as this could result in

improper operation and a tank explosion. In areas with poor water conditions, it may be necessary to inspect

the temperature and pressure relief valve more often than once a year.

CAUTION

Before manually operating the valve, make sure that a drain line has been attached to the valve to direct the

discharge to an open drain. Failure to take this precaution could mean contact with extremely hot water discharging

from the valve during this checking operation.

If the temperature and pressure relief valve on the heater discharges periodically or continuously, it may be due

to thermal expansion of water in a closed water supply system, or it may be due to a faulty relief valve. Thermal

expansion is the normal response of water when it is heated. In a closed system, thermal expansion will cause the

system pressure to build until the relief valve actuation pressure is equaled. Then the relief valve will open, allowing

some water to escape, slightly lowering the pressure. Contact your water supplier or local plumbing inspector on

how to control this situation.

3.

Sediment (Annual except where harsh water quality may require more frequent service)

Depending on water conditions, a varying amount of sediment may collect in the tank. Levels requiring service

are indicated by a small temperature difference between the boiler supply and return lines, and a reduced

recovery rate. Repeated ushing usually clears such material. As a preventive measure, water should be drawn

from the drain valve until it runs clear and the installation of a water lter should be considered.

4.

Scale (Annual)

Hard water may cause scale buildup on the outside of the heating coil inside the tank. A water softener will

prevent this problem. Symptoms are identical to sediment buildup. If repeated ushing does not resolve the

problem, chemical cleaning may be required. Contact a qualied contractor.

20

Page 21

5.

Inspect Anode (annual)

• The purpose of the magnesium anode is to reduce the damaging effects of aggressive water on the water

heater. Aggressive water will cause the anode(s) to erode. The anode(s) must be inspected at least annually

to determine whether a new anode should be installed. Use anode replacement parts supplied by ECR only.

ECR anodes are 1-1/4 NPT and are made with magnesium, brass, and stainless steel. There is no steel in a

ECR anode. Severe or rapid deterioration of the anode indicates very aggressive water. If this occurs, have

the water tested to verify whether it is within the limits outlined on page 11. Failure to inspect the anode

regularly and replace if necessary could result in damage to the water heater. If this unit is installed and

maintained according to the instructions and conditions in this manual, this product will last for a long time.

1.

Close domestic water isolation valves.

2.

Drain the water heater completely and allow it to cool off.

3.

Remove the anode cover on the front of the unit. See gures on pages 6 and 7. The temperature control

can be turned to the side to allow easier access.

4.

After the water heater has drained and cooled, remove the anode using a 1¾” 6-point socket and a

breaker bar.

5.

Inspect the anode and replace if needed. The anode should be replaced when more than 6” of core wire is

exposed. The anode should be replaced with a ECR supplied anode only. See above. The brass hex on the

anode is 1¼ NPT and installs into a 1¼ stainless half coupling on the shell of the tank. This part will need

to be properly Teon taped and coated with a quality Teon based pipe sealant.

6.

Replace the inspection cover.

7.

Rell the water heater, and restore to operation.

8.

Verify operation of boiler and water heater.

21

Page 22

VII. Troubleshooting

PROBLEM CAUSE SOLUTION

No hot water at faucets

Insufcient or runs out of hot water

at the faucet

Press reset button

Boiler does not operate.

Circulator does not operate Check shaft coupling

Improper thermostat setting Turn thermostat to a higher setting.

Zone valve does not open Check power supply and valve

Electrical problem Check fuses and replace.

Sediment and/or scale buildup If boiler, circulator, and thermostat are

Clogged lter Clean or replace lter.

Thermostat setting too low. Turn the thermostat to a higher setting.

Undersized boiler with no priority to

domestic water heating.

Peak draw of hot water is greater than

the tank storage.

Sediment and/or scale buildup Clean coil

Faulty water heater thermostat Replace thermostat

Thermostat set to high Lower thermostat setting.

Check main cut-off switch

Check fuses or breakers.

Check power supply

Check shaft coupling

Check circuit breaker and reset.

Check power supply

operating properly, and the boiler is cycling

on the high limit several times before the

tank thermostat is satised, the coil may

have a coating of sediment and/or scale.

Rewire for priority.

Determine peak usage and compare to tank

volume.

Water at faucet too hot

Boiler cycles more than 5 times per

day in summer

Improper system plumbing

Improper wiring. Compare wiring to installation guide.

Excessive demand Reduce demand or consider larger boiler

Faulty thermostat Replace thermostat

Boiler high limit set to low Increase boiler hi-limit setting

Sediment and or scale buildup Clean coil.

Compare plumbing to installation guide.

Inspect check valves.

and/or water heater.

22

Page 23

REPLACEMENT PARTS LIST

Description Part Number

Temperature and Pressure Relief Valve

1

(for all models except XHOC)

Temperature and Pressure Relief Valve

2

(for XHOC models only)

3 Aquastat Well, Stainless Steel 240009522

4 Aquastat 240009521

5 Drain Valve Nipple, ½" x 3½" Stainless Steel 240010930

6 Drain Valve 240010928

7 Anode Rod 240010929

240010926

240010927

XHOC HIGH OUTPUT INDIRECTS

STANDARD AND HO UNITS HO-C UNITS

23

Page 24

242526

Page 25

Page 26

NOTES

Page 27

NOTES

27

Page 28

H

O

2

ECR International, Inc

2201 Dwyer Avenue, Utica NY 13504-4729

web site: www.ecrinternational.com

Loading...

Loading...