Page 1

Owners Manual

Head Office:

P.O. Box 2018

Hilton Highway, Washdyke

Timaru, New Zealand

Telephone (03) 688 2029

Facsimile (03) 688 2821

Australian Branch:

4B Silverton Close

Laverton North 3026

Melbourne, Australia

Telephone (03) 9314-9666

Facsimile (03) 9314-6810

Renovator TFD 3m & 3.5m

ORIGINAL INSTRUCTIONS

Pt. No. 67415

Issue 0517

Page 2

ii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Acquisition & Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Description of Machine Working Principle. . . . . . . . . . . . . . . . . . . . . . . 3

Dimensions & Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY - General Safety Symbols on Machine . . . . . . . . . . . . . . 6

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . 7

Be Prepared for Emergencies . . . . . . . . . . . . . 7

Appropriate Dress . . . . . . . . . . . . . . . . . . . . . . 8

Transport This Machine Safely . . . . . . . . . . . . 8

Handle Agricultural Chemicals Safely . . . . . . . 9

Avoid High Pressure Fluids . . . . . . . . . . . . . . . 9

Safe Work Practices . . . . . . . . . . . . . . . . . . . . 9

Practise Safe Maintenance . . . . . . . . . . . . . . . 10

SAFETY - Machine Specific Hazard Points . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Decals & Safety Guards. . . . . . . . . . . . 13

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Read Before Calibration Setting Seeder Shutter Slides. . . . . . . . . . . . . 18

Bottom Flap Settings . . . . . . . . . . . . . . . . . . . . 18

Sowing Fine Seeds . . . . . . . . . . . . . . . . . . . . . 18

General Controls & Main Operating Screen . . 19

Priming Switch Buttons . . . . . . . . . . . . . . . . . . 20

Power On Routine . . . . . . . . . . . . . . . . . . . . . . 21

Main Operating Screen . . . . . . . . . . . . . . . . . . 22

Calibration Procedures . . . . . . . . . . . . . . . . . . 24

Calibration Chart, Default Calibration Factors. 28

Maintenance & Care General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lubrication Instructions . . . . . . . . . . . . . . . . . . 31

Maintenance Schedule . . . . . . . . . . . . . . . . . . 32

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Maintenance Notes . . . . . . . . . . . . . . . . . . . . . 34

Parts List Complete Assembly . . . . . . . . . . . . . . . . . . . . 36

Mainframe & Drawbar . . . . . . . . . . . . . . . . . . . 38

Wheel Leg . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Wheel Hydraulics. . . . . . . . . . . . . . . . . . . . . . . 44

Adjustable Toolbars . . . . . . . . . . . . . . . . . . . . . 46

Fixed Toolbars . . . . . . . . . . . . . . . . . . . . . . . . . 50

Tine, Boot & Point . . . . . . . . . . . . . . . . . . . . . . 52

Hose Supports. . . . . . . . . . . . . . . . . . . . . . . . . 54

Footboard, Ladder & Handrail. . . . . . . . . . . . . 56

Dual Seedbox Assembly . . . . . . . . . . . . . . . . . 60

Agitator Shaft Assembly . . . . . . . . . . . . . . . . . 64

Renovator TFD Contents

Page

Page 3

1

Pt. No. 67415

Issue 0517

Parts List (continued)

Gearmotor Drives Front/Rear . . . . . . . . . . . . . 67

Electric Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Rear Tow Hitch . . . . . . . . . . . . . . . . . . . . . . . . 76

Tine Harrow . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Uni-Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Electric Drive (detailed manual) Electric Drive detailed operation and setup . . 83

Renovator TFD Contents (continued)

Page

Page 4

2

Introduction

Acquisition & Warranty

On delivery of your new Duncan Renovator TFD please

check that the machine is not damaged. In cases of shipping

damage, please ask your dealer to arrange for the appropriate

claim to be lodged immediately. Assemble any parts supplied

loose and inspect your machine with the aid of this manual to

familiarise yourself with its features. If you have any queries

ask your dealer straight away. The machine is covered by our

12 month warranty on faulty parts, subject to normal use.

Record below the serial number of your machine and keep

it in a secure place to help trace the machine and assist

us when you order parts.

The Owner’s Manual

Your new Duncan Renovator TFD will give long and efficient

service if given normal care and operated properly.

This owner’s manual is provided so that you can become

thoroughly familiar with the design of the machine and to

furnish information on correct operation, adjustment and

maintenance. Only persons well acquainted with these

guidelines should be allowed to use the equipment.

A separate illustrated parts section has been provided so that

if any parts are required your dealer will be able to supply

them by reference to part numbers.

The manual is considered as part of your machine and must

remain with the machine when it is sold.

Right and left hand references in this manual are

determined by standing behind the machine and facing in

the direction of travel.

Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial No:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Owner:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delivery Date:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disclaimer

Every effort has been made to

ensure that the information in this

manual was accurate and up to

date at the time of going to press.

Clough Agriculture reserves the

right to make subsequent changes

to the machine, where necessary,

without notification.

The Company will not be

responsible for any damage or

consequential loss arising out of

misinterpretation or failure to follow

recommended procedures. Nor will

it be liable for any damage caused

by or arising out of modification or

misuse of its product.

The owner has a responsibility to

protect himself and others by

observing all safety information

and by ensuring all operators are

well acquainted with the safety

information, trained in the correct

use of the machine and applying

safe work practices.

This Document contains the Original

Operating Instructions for this machine

and are verified by the Manufacturer,

Signed:...........................................

Product Development Manager

Page 5

3

Pt. No. 67415

Issue 0517

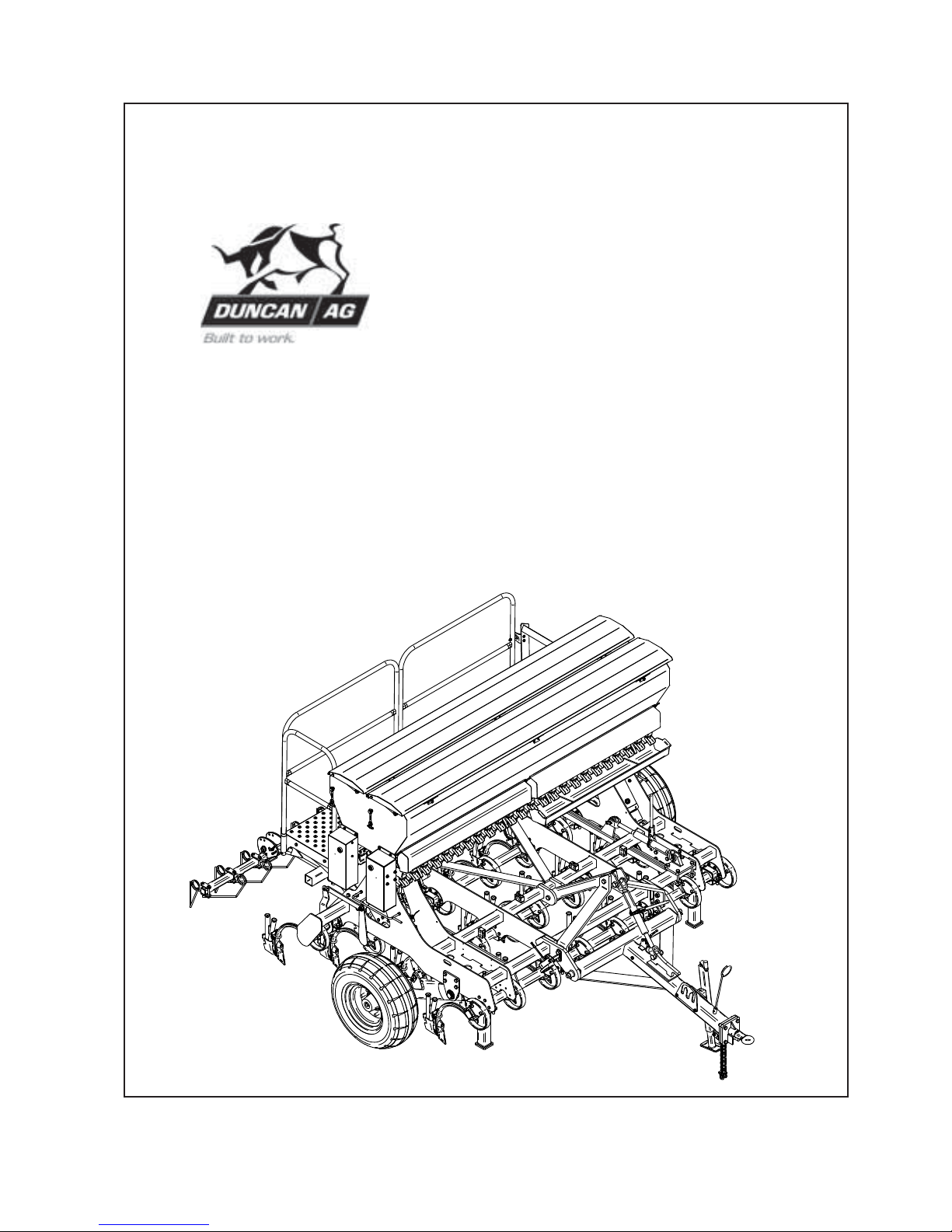

Description of Machine

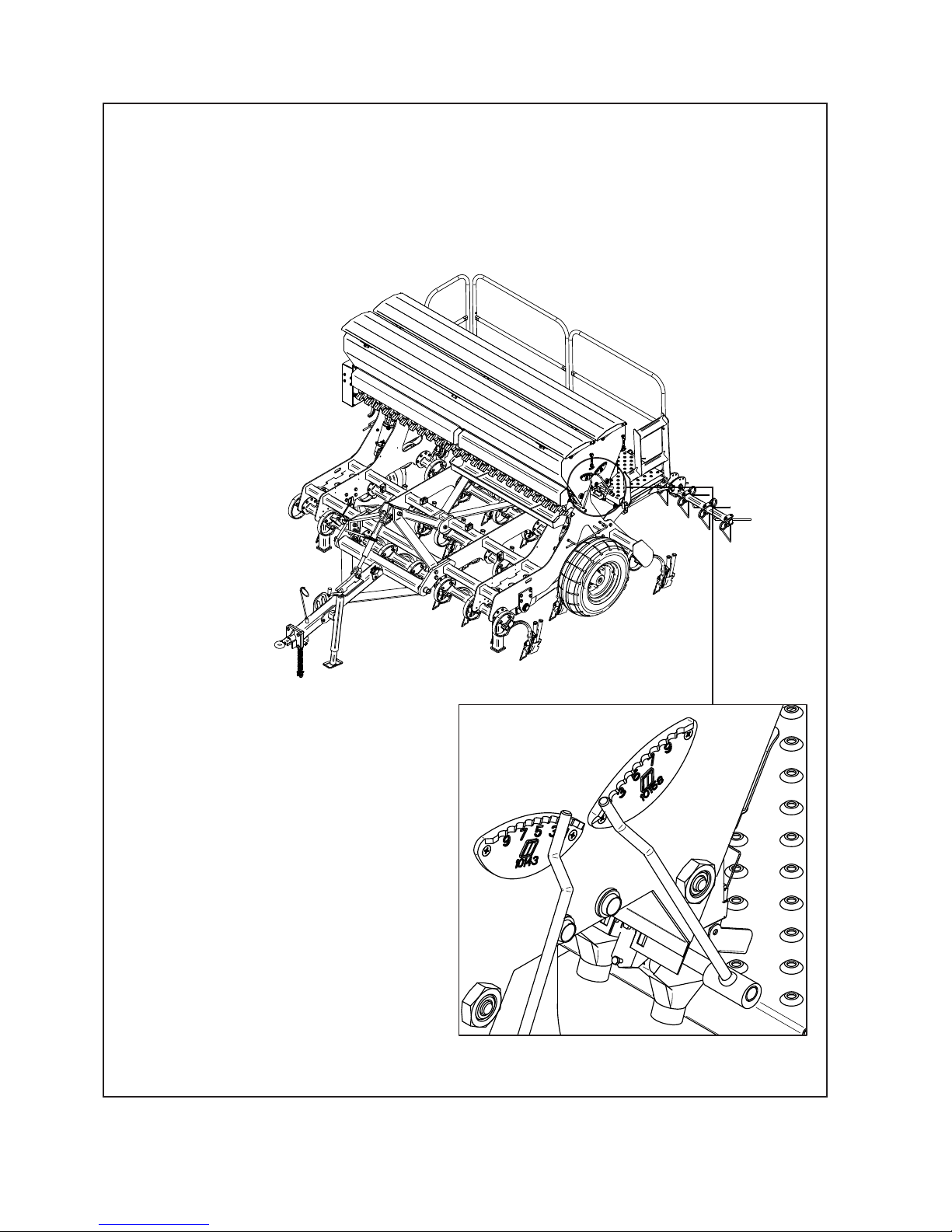

The Duncan Renovator TFD is an S-tine drill with

narrow points. The box is mounted on a robust frame

accommodating large diameter tyres. The ground

engaging components are controlled by a hydraulic

ram system, giving ample control on ground pressure,

good transport clearance and contour following ability.

Sowing depth is controlled by adjusting the hydraulic

rams. Optionally, the angle of the points are adjustable

via rotating tool bars for optimum ground following and

penetration.

The quality European type peg roller seeder system

handles all seeds from turnip and rape through to peas

and maize. The seeder drive is electric via a reduction

gearbox to the seeder shaft. Ground speed is sensed via

ground radar with seed rates controlled proportionally to

ground speed. Seeding ceases automatically when the

machine is raised into the transport position.

Working Principle

The seeder drive, pegged seed rollers and seeder flaps

are set to give the desired seed rate. The S-tine and

narrow point, create the seed bed. Seed flows down the

flexible tubes between seeder and boot units, and drops

into the prepared seed bed.

Renovator TFD

Page 6

4

Page 7

5

Pt. No. 67415

Issue 0517

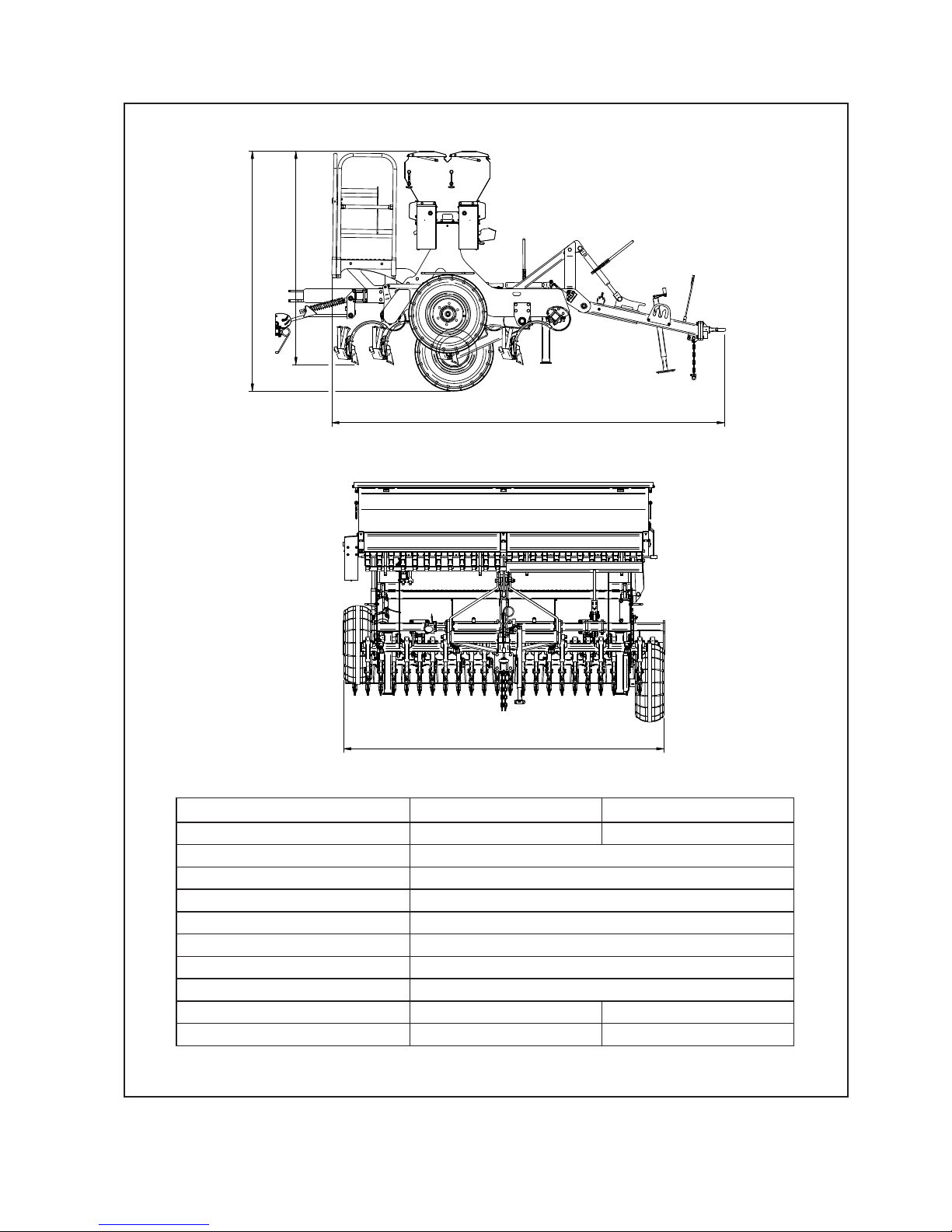

Dimensions & Capacities 24Run 28Run

Width (over wheels /mm) 3100 3600

Working Height (mm) 2060

Transport Height (mm) 2320

Overall Length (mm) 3790

Tyre Size 10.0/75-15.3 (18 ply AW702)

Recommended Tyre Pressure 7 Bar (101psi)

Maximum speed (km/hr) 40 km/hr

Row Spacing (mm) 125

Effective Sowing Width (mm) 3000 3500

Box Capacity (litres per box) 500 600

‘Renovator TFD’ Dimensions & Capacities

:,'7+29(5:+((/6

Page 8

6

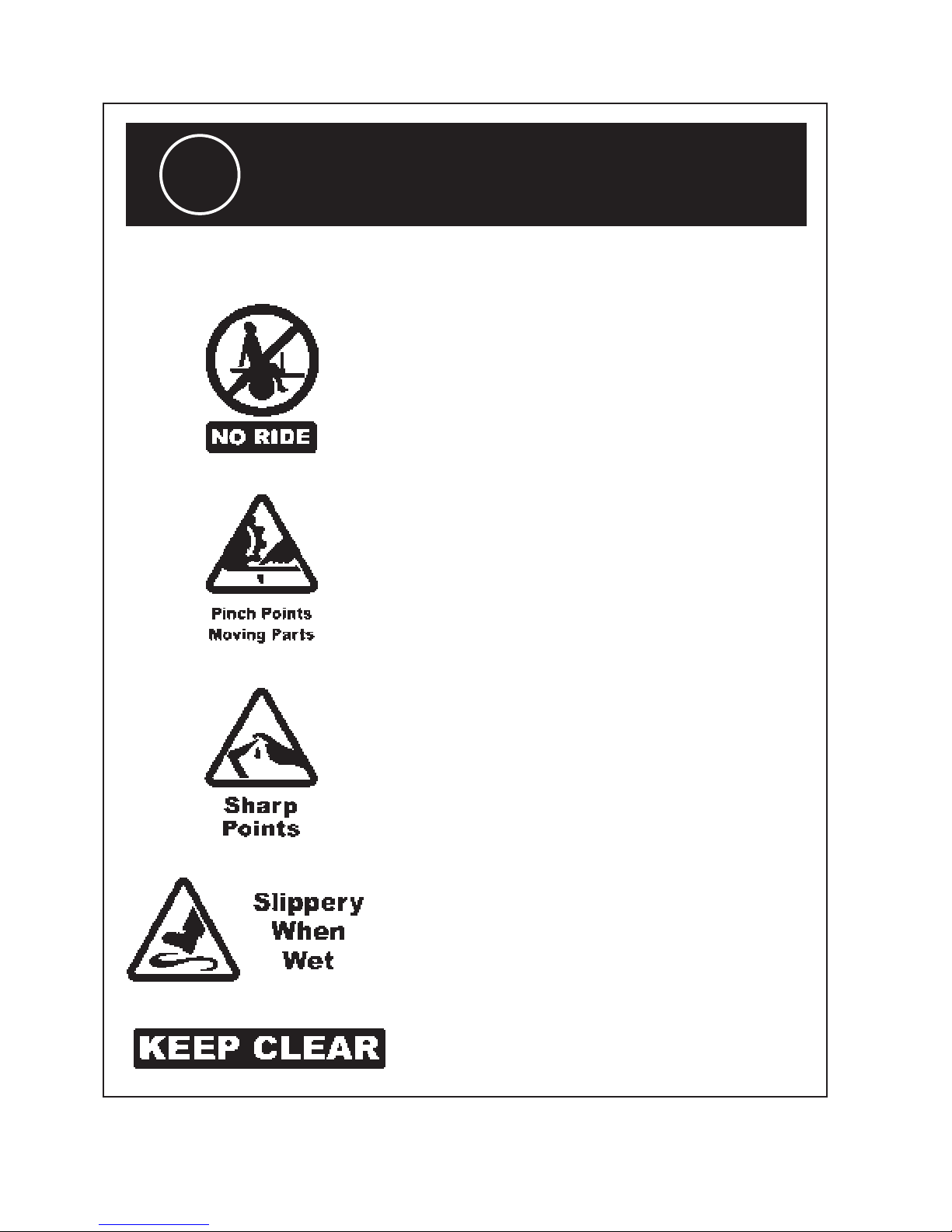

Do not ride or allow passengers on the machine.

Under no circumstances are passengers to be permitted

on the machine while it is in operation or being transported.

Any footboards and/or footsteps are provided solely for the

purpose of preparing the machine for use.

Keep clothing and body extremities well clear of pinch

points while the machine is operating (seeding or

calibrating). Keep well clear of moving parts at all times.

These signs typically occur wherever trapping points exist.

These include drive chains, sprockets, shafts, wheels, discs,

pivot points, etc. Guards are provided with the machine

for safety reasons (where practical without compromising

machine performance). Ensure these are always fitted

during operation.

Always exercise extreme caution in the vicinity of sharp

edges and points.

Where possible guards are provided with the machine

for safety reasons (where practical without compromising

machine performance). Ensure these are always fitted

during operation.

Footboards, footsteps, drawbars and other machine

surfaces may be slippery when wet.

Apply extra caution in wet conditions and in the early

morning when surfaces are wet.

Keep Clear. (It is dangerous to be in this area when the

machine is operating.)

!

ATTENTION

On the machine important safety information is indicated by these symbols.

These highlight general safety aspects in regard to the machine rather than specific hazards.

‘Renovator TFD’ Safety

Page 9

7

Pt. No. 67415

Issue 0517

SAFETY - General

This section of the manual offers general guidelines

for the safe operation of machinery. It does not replace

local safety regulations.

These guidelines were current at

the time of publication, but may be superseded by later

regulations.

Clough Agriculture has made every effort to highlight all

risks to personnel or property. Owners and operators have

a responsibility to exercise care and safe work practices at

all times in the vicinity of the machine.

Owners are advised to keep up to date on safety issues

and to communicate these to all users of the machine.

Contact the Occupational Safety and Health Service

(OSH) for further information about general safety aspects.

If you have safety concerns specifically related to this

machine, contact your dealer immediately.

Operator Safety

Read this manual carefully before operating new

equipment. Learn how to use this machine safely.

Be thoroughly familiar with the controls and the proper use

of the equipment before using it.

Take careful note of all safety instructions both in this

manual and on the machine itself. Failure to comply with

instructions could result in personal injury and/or damage

to the machine.

Replace missing or damaged safety signs on the machine

and ensure that these remain clearly visible.

It is the owner’s responsibility to ensure that anyone

who operates, adjusts, lubricates, maintains, cleans

or uses the machine in any way has had suitable

instruction and is familiar with the information in this

manual (particularly with regard to safety aspects).

Operators and other users of the machine should be

aware of potential hazards and operating limitations.

Be Prepared for Emergencies

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance,

hospital and fire department near your telephone.

N.B. Throughout this

manual important safety

information is indicated

by these symbols in the

margin:

A prohibition should

be observed under all

circumstances.

A warning indicates a

hazard that could cause

death or injury if the

warning is ignored.

A caution indicates a

hazard that may cause

damage to property if

the caution is ignored.

‘Renovator TFD’ Safety

Page 10

8

SAFETY - General (Continued)

Appropriate Dress

Wear close fitting clothing and avoid rings or other forms of

jewellery which could become caught in the machinery.

People with long hair must have it securely fixed and confined

close to the head.

Refer to local safety standards for protective clothing and

recommended safety equipment.

Adequate protection, such as a face mask, should be worn if

operating this machine in dry and dusty conditions.

Transport This Machine Safely

Ensure that all linkage pins and security clips are fitted correctly.

With trailing machines tow with the drawbar only, as this is the

only safe towing point on the machine.

Always check that bystanders (especially children) are well clear

(front and rear) before starting and moving the tractor and the

machine.

Plan safe routes of travel, and be aware of power lines and

other roadside hazards. Take particular care when towing

implements on hillsides.

Do not ride or allow passengers on the machine.

This machine is not designed to carry passengers, and no riders

are permitted.

Road transport

On public roads,

• A speed of 40km/h must not be exceeded.

• Do not operate during the hours of darkness unless standard

lights are fitted and clearly visible. (This also applies when

visibility is limited, e.g., in foggy conditions.)

See the guidelines in the Vehicle Dimensions and Mass Rule,

issued by the Land & Transport Safety Authority.

Avoid tip-overs

Avoid holes, ditches and obstructions which may cause the

machine to tip over, especially on hillsides. Never drive near the

edge of a gully or steep embankment - it might cave in. Slow

down for hillsides, rough ground and sharp turns.

‘Renovator TFD’ Safety

Page 11

9

Pt. No. 67415

Issue 0517

SAFETY - General (Continued)

Handle Agricultural Chemicals Safely

All farm chemicals should be stored, used, handled and

disposed of safely and in accordance with the supplier’s/

manufacturer’s recommendations.

Read the product label before using, noting any warnings

or special cautions, including any protective clothing or

equipment that may be required, ie. respirator.

Do not eat or smoke while handling sprays, fertilisers, coated

seeds, etc. Afterwards, always wash your hands and face

before you eat, drink, smoke, or use the toilet.

Store sprays, fertilisers, coated seeds, etc. out of reach of

children and pets, and away from food and animal feeds.

Any symptoms of illness during or after using chemicals

should be treated according to the supplier’s/manufacturer’s

recommendations. If severe, call a physician or get the

patient to hospital immediately. Keep the container and/or

label for reference.

Avoid High Pressure Fluids

Avoid any contact with fluids leaking under pressure, because

the fluids can penetrate the skin surface.

Any fluid which penetrates the skin, will need to be removed

immediately by a medical expert. Seek specialist advice on

this type of injury.

Relieve the pressure before disconnecting any hydraulic or

other lines. Make all repairs and tighten all fittings before

re-connection to pressurised fluid.

Keep your hands and body away from any pinholes or high

pressure jets. Search for leaks with a piece of cardboard

instead of using your hand directly.

Safe Work Practices

All farm machinery is potentially dangerous and should be

treated with caution and respect.

Before starting the machine, ensure that all controls are placed

in neutral and that bystanders are well clear. Check that the

guards have been securely fitted and that any adjustments

have been made correctly.

Where possible, disconnect or isolate the drive mechanism to

the implement. Lower the machine onto the ground when not

in use.

Do not operate this equipment when severe weather

conditions appear imminent.

‘Renovator TFD’ Safety

Page 12

10

SAFETY - General (Continued)

Practise Safe Maintenance

Keep the machine in safe working condition. Routine maintenance

and regular servicing will help reduce risks and prolong the life of the

machine.

General Maintenance

Accidents occur most frequently during servicing and repair. The

following general rules must be followed when maintaining or working

with machinery:

• All operating and maintenance manuals must be

read before and referred to while using or servicing any

piece ofequipment.

• Turn off all machinery power sources and isolate the

machine before making adjustments, doing lubrication,

repairs or any other maintenance on the machine.

• Ensure that the machine hydraulics are disconnected from

the power source.

• Wear gloves when handling components with cutting

edges, such as any ground cutting components.

• Beware of hazards created by springs under tension

or compression when dismantling or maintaining the

machine.

• It is recommended that you clean the machine with a water

blaster or similar apparatus before commencing

maintenance.

Make Sure the Machine is Well Supported

When machinery is fitted with hydraulics, do not rely on the

hydraulics to support the machine. During maintenance or while

making adjustments under the machine, always lock the hydraulics

and support the machine securely. Place blocks or other stable

supports under elevated parts before working on these.

Electrical Maintenance

Disconnect the electrical supply from the tractor before doing any

electrical maintenance.

Welding

With electronic equipment in modern tractors it is advisable to disconnect

the machine from the tractor, or at least disconnect the alternator and

battery before attempting any welding.

Use Only Genuine Spare Parts

Unauthorised modifications or non-genuine spare parts may be

hazardous and impair the safe operation and working life of the machine.

Excess lubricants must be disposed of safely so as not to become a

hazard.

‘Renovator TFD’ Safety

Page 13

11

Pt. No. 67415

Issue 0517

SAFETY - Machine Specific

This section of the manual gives specific guidelines for

the safe operation of the Renovator TFD.

These guidelines were current at the time of publication, but

may be superseded by later circumstances. They do not

necessarily cover every possible hazard and must be read in

conjunction with the SAFETY - General section (Page 6-10).

Hazard Points on the Renovator TFD

The lists below are not all-inclusive and serve only to highlight

the more obvious areas of risk.

The decals attached to the machine are a general reminder

that there are hazardous areas on the machine, rather than

specifically highlighting all possible hazards.

For decal locations on machine, refer Page 13.

No Ride

Passengers are not permitted anywhere on the machine.

Pinch Points/Moving Parts

Hazardous areas include:

• Drive chains.

• Sprockets between the drive motor, the box shafts and the

agitator shafts.

• Agitator shaft inside the boxes.

• Seeder units, box shaft and shaft connectors.

• Wheel legs and main frame assemblies

• Between tines and the adjuster mechanism.

• Finger tine assemblies (where fitted).

Slippery When Wet

Hazardous areas include:

• Footboards and footstep.

• All smooth surfaces on the frame structure.

Keep Clear

Hazardous areas include:

• Between the tractor and Renovator TFD.

• Immediately adjacent to the Renovator TFD side.

‘Renovator TFD’ Safety

Page 14

12

SAFETY - Machine Specific

(Continued)

Hazard Points on the Renovator TFD

(Continued)

Calibrating

Be particularly careful when calibrating the seeding rate. At

this time, the calibration trays have been removed and are no

longer covering the rotating seeder units. See Pinch Points/

Moving Parts (Page 11) for hazardous areas.

Transport

The two wheels located at the sides of the machine are for the

purpose of controlling sowing depth. These are also used to

support the machine weight during transport (while linked to

the tractor).

Important - Refer to safety cautions in the Transport section,

page 8 of the manual. Ensure that all linkage pins and security

clips are fitted correctly.

Maintenance

Refer Page 28 for reference to the Maintenance and Care

section of the manual.

Lubrication

Refer Page 30 for reference to the Maintenance and Care

section of the manual.

‘Renovator TFD’ Safety

Page 15

13

Pt. No. 67415

Issue 0517

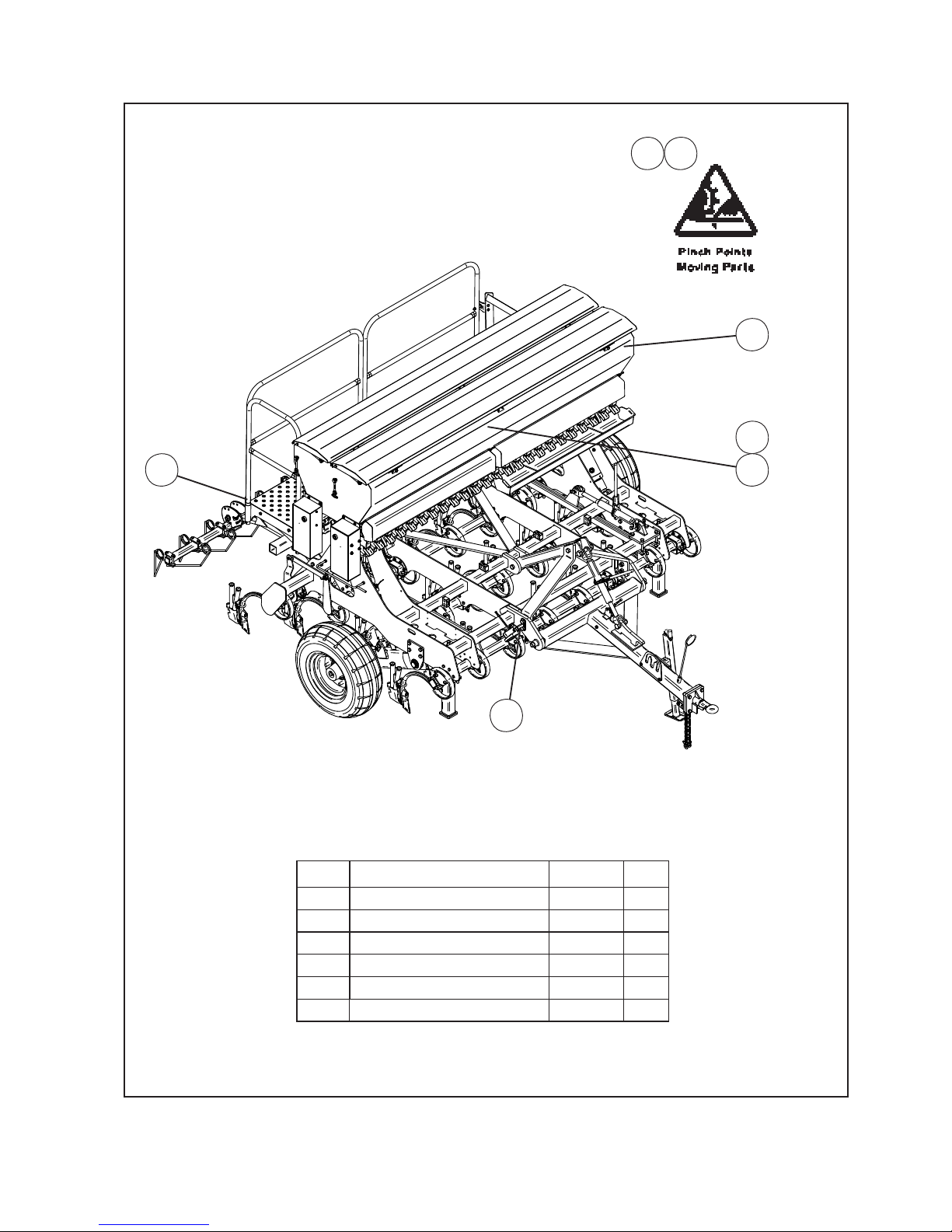

SAFETY - Machine Specific

(Continued)

Inside Box Lid

25

Item Decal/Guard Pt. No. Qty

1 ‘No Ride’ 43900 2

2 ‘Pinch Point/Moving Parts’ 43901 3

3 ‘Slippery When Wet’ 43902 2

4 ‘Keep Clear’ 43909 2

5 Arrows (inside box lid) 43905 2

6 ‘40 km/hr’ 43912 2

4

‘Renovator TFD’ Safety

1

23

6

Both Ends

Page 16

14

Transport

1 Raise the drill into the transport position and hold at the full

extent of the rams for a few seconds to allow cylinders to

equalise.

2

Important - To avoid machine damage due to drill

lowering during transport, always close the hydraulic

valve at the quick release coupling. Move the handle to a

position at 90

0

to the hydraulic line

3

Maximum towing speed 40 km/hr.

For countries other than New Zealand greater speed

restrictions may apply, please refer to your local

transport authority.

Ensure towing vehicle requirements are adequate

for the towed vehicle e.g. mass, brakes. Refer to

recommendations published by the local Land Transport

Authority or equivalent.

Braking when towing can cause the load to jackknife. Use

extra care when towing in adverse conditions such as mud,

inclines and sharp bends.

Lower towing speeds are recommmended on farm roads/

tracks and where one wheel is on or over a road verge.

‘Renovator TFD’ Operation

Page 17

15

Pt. No. 67415

Issue 0517

Operation

General Operation Guidelines

1 Use a sufficiently powerful tractor which is heavy enough to tow the drill safely.

2 Operate the drill at a speed of 6-12 km/hr (4-8 mph).

In stony and uneven ground conditions a lower speed is more appropriate

3 Check that the drill is level during calibration and while seeding.

4 Check tyre pressure before seeding. Refer page 5.

5 Double check seed rates before seeding.

6 Raise the drill out of the ground when making any turns.

7 Raise the drill out of the ground before backing up.

8 Stretched sagging hoses disrupt seed flow. Slight tension may be restored by carefully shortening

the affected hose; remove from the tube at ground level and cut accordingly.

Care must be taken not to shorten too much as the tension will pull the hose from the ground tube

or damage the plastic metering funnel.

9 After prolonged storage, check to see that all drive mechanisms and hydraulic equipment are functioning

correctly. Check that the seed/fertilizer tubes are not perished or blocked.

Sowing Speed

Typical travel speeds when sowing range from 6-12 km/hr in good conditions. In stony and uneven

ground conditions a lower speed is recommended to minimise rapid part deterioration. Sowing too fast

can result in:

1 Poor contour following and uneven sowing depth.

2 Impact damage to:

a Ground engaging components.

b Bearings, housings & axles.

c Fasteners & structural components.

3 More extreme conditions will result in greater vibration

and uneven seed flow at low seeding rates.

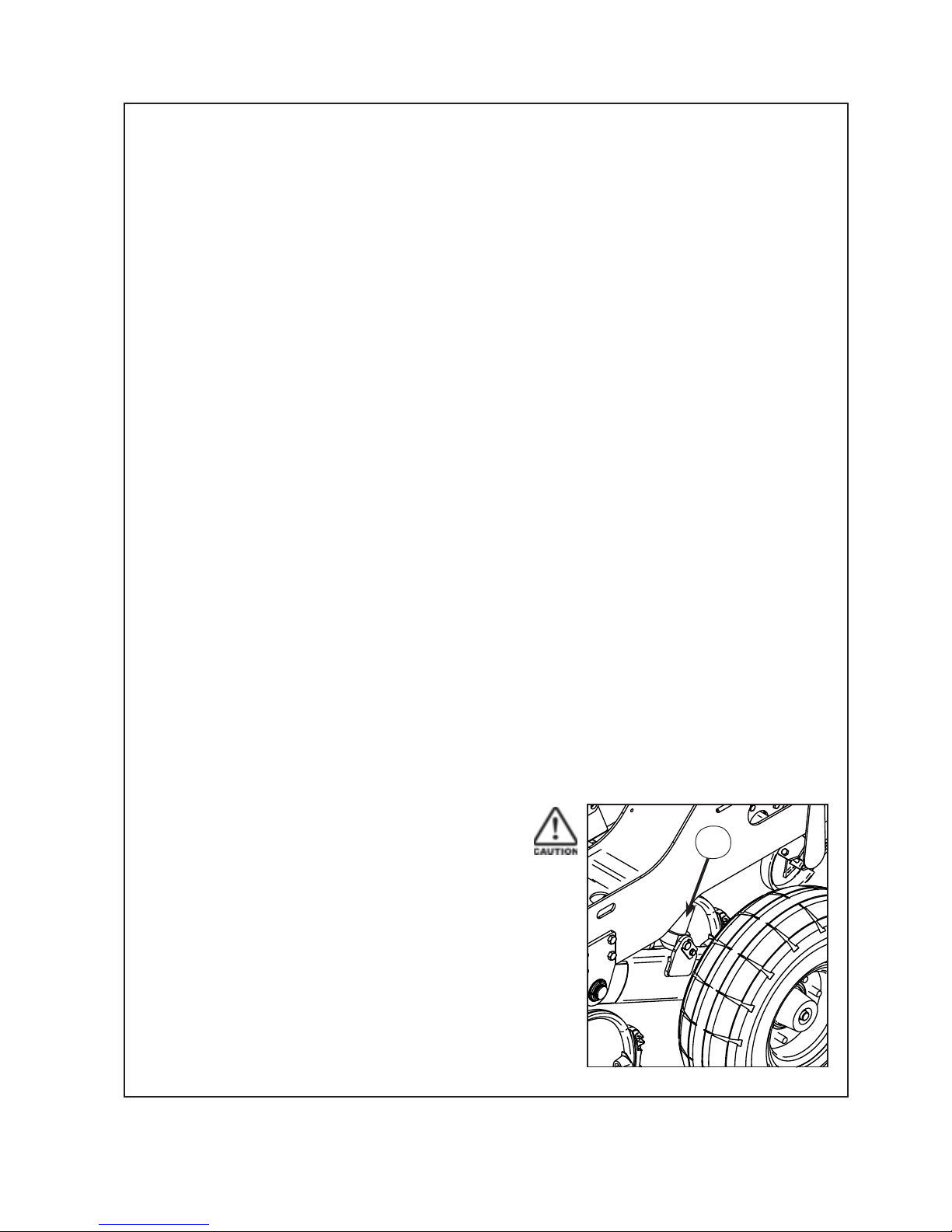

Sowing Depth Control

The sowing depth is dependent on:

1 The wheel height in relation to the chassis

2 Tyre pressure

3 Ground condition i.e. hard or soft

The wheel height in relation to the chassis is controlled using the

threaded depth adjustment collar (1) on the left hand wheel leg

ram. The rams are phasing and the left hand ram controls the

overall depth. The threaded collar on the right hand ram can be

adjusted to take up the clearance on this side. In this way, in the

event of hydraulic failure the preset depth is maintained.

Caution: Do not over-extend the thread depth adjustment. Clip on

depth stop collars may be added to both sides if more control is

required.

‘Renovator TFD’ Operation

1

Page 18

16

Magnetic Cut-out Sensor

To enable seeding to start and when the machine is

lowered into and lifted out of the ground, a magnetic

sensor is fitted on the RH wheel leg hydraulic ram. The

sensor position may be adjusted to suit the ground and

sowing conditions.

Level Drill

Use the drawbar turnbuckle to tilt the drill so it is sitting

level. Ensure that the front and rear rows are at an even

depth.

Transport Position

When in the transport position the hydraulic cylinders are

fully extended.

‘Renovator TFD’ Operation

Page 19

17

Pt. No. 67415

Issue 0517

‘Renovator TFD’

Page 20

18

‘Renovator TFD’ Read Before Calibration

Components Referred to in the Pre-Calibration Setup and Calibration Process

The following pages describe how to set the machine up for calibration, the calibration process and

subsequent adjustments to obtain the desired seed and/or fertilizer output.

Terms and words used in those instructions are shown below:-

‘Left’ and ‘Right’ on the machine are with respect to the direction of forward travel.

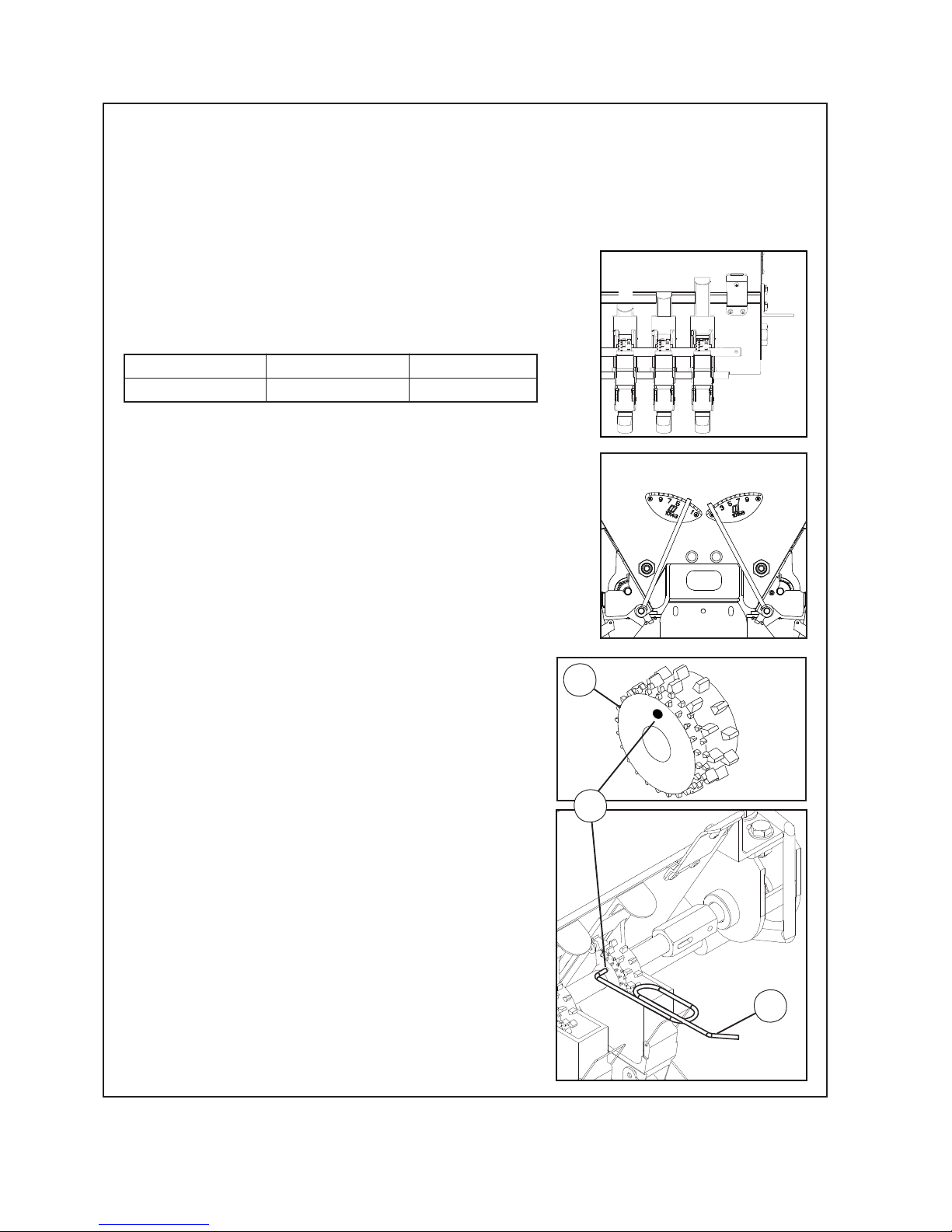

Shutter Slides

The varying flow properties of seeds require different shutter

slide positions which may be found in the Sowing Chart for the

individual type of seed or fertilizer. This corresponds to one of

the three settings as shown.

Bottom Flap Settings

The various seed sizes require matching bottom flap clearances

below the metering wheel. The adjusting plate allows for 10

different settings. The required position for the seed type may

be found in the Sowing Chart. The control levers are located

on the LH end of the seedbox, (opposite end to the electric

motors).

Number “1” corresponds to the minimum (closed) position and

“10” the maximum gap.

A B C

Closed 3/4 Open Fully Open

A

B

C

10

1

10

1

3

2

Metering Wheel - Sowing Fine Seeds

For sowing fine seeds the Renovator TFD is equipped as

standard with a combined normal and fine seed

“Elite” metering

wheel, 1.

During grain sowing and other larger varieties of seed both the

normal and fine seed metering wheels are coupled and both rotate.

In order to convert the seed drill to sow fine seed, rotate the box

shaft clockwise until the holes

of the fine seed wheel, 2, are

visible. This is achieved by pressing and releasing the priming

switch thus instructing the electric motors to rotate the seed

shaft. By trial and error the holes can be located.

Using the tool supplied, 3, disengage the the pin inside the

hole so that the normal metering wheel rotates freely on the

metering shaft.

At this time it would be advisable to close any shutter slides

not required for the fine seed sowing.

When seed is to be sown again using the normal metering wheel

press the pin, from the normal metering wheel side (opposite

direction to before), using the tool, back into the hole of the fine

seed wheel thus reconnecting the drive between the two.

Page 21

19

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Read Before Calibration

Components Referred to in the Pre-Calibration Setup and Calibration Process

The following pages describe how to set the machine up for calibration, the calibration process and

subsequent adjustments to obtain the desired seed and/or fertilizer output.

Terms and words used in those instructions are shown below:-

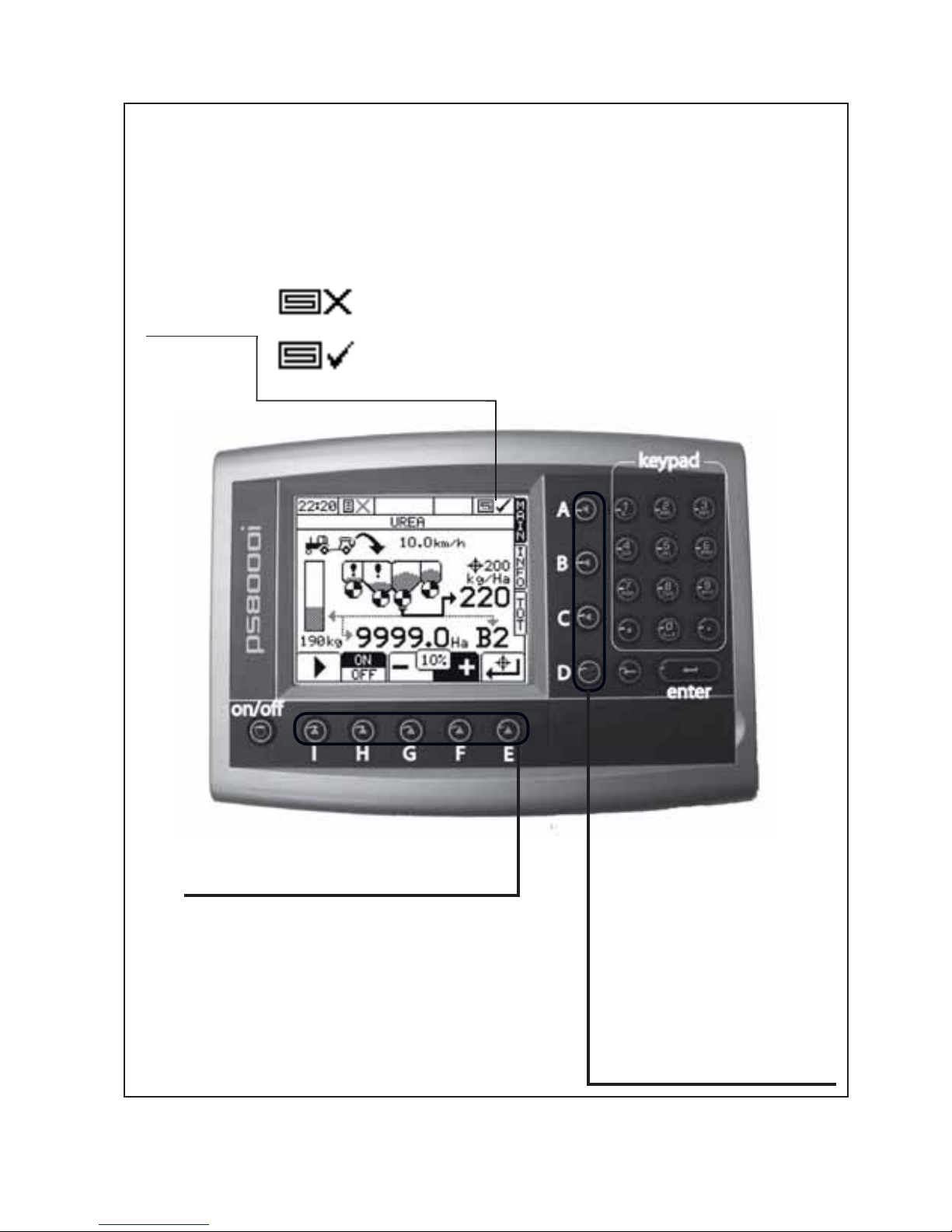

General Controls and Main Operating Screen

OUT OF WORK- the machine is raised up for turning or transport

‘AREA CUTOUT’

IN WORK- the machine is lowered ready for drilling

‘MENU KEYS’

A ‘MAIN’ The default screen as

shown above.

B ‘INFO’ Access and edit

information regarding bin

contents.

C ‘TOT’ Displays the amount of

product dispensed and the area

covered.

D ‘MENU’ Machine setup and

diagnostics access screen.

‘SUB-MENU SOFT KEYS’ -the function

changes for each screen. The icon above each

button is the function.

Page 22

20

‘Renovator TFD’ Read Before Calibration

Components Referred to in the Pre-Calibration Setup and Calibration Process

The following pages describe how to set the machine up for calibration, the calibration process and

subsequent adjustments to obtain the desired seed and/or fertilizer output.

Terms and words used in those instructions are shown below:-

Priming Switch Buttons

Priming Switch Operation

The priming switches are located on the left

hand end of the dualbox. There is one switch per

box.

Priming switches are used to start the calibration

process. Pressing the button for about 1 second

then releasing will start the appropriate seeder

shaft. Pressing the button again for about 1

second will stop the rotation.

Whilst this is mainly used for calibration it is also

useful for priming the seeder units and testing

motor operation. The Main Operating Screen will

change to calibration mode when the Priming

Switches are pressed. The operator can exit

this mode without affecting any settings. More

information and operating screen pictures are

shown in the calibration section.

Page 23

21

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Read Before Calibration

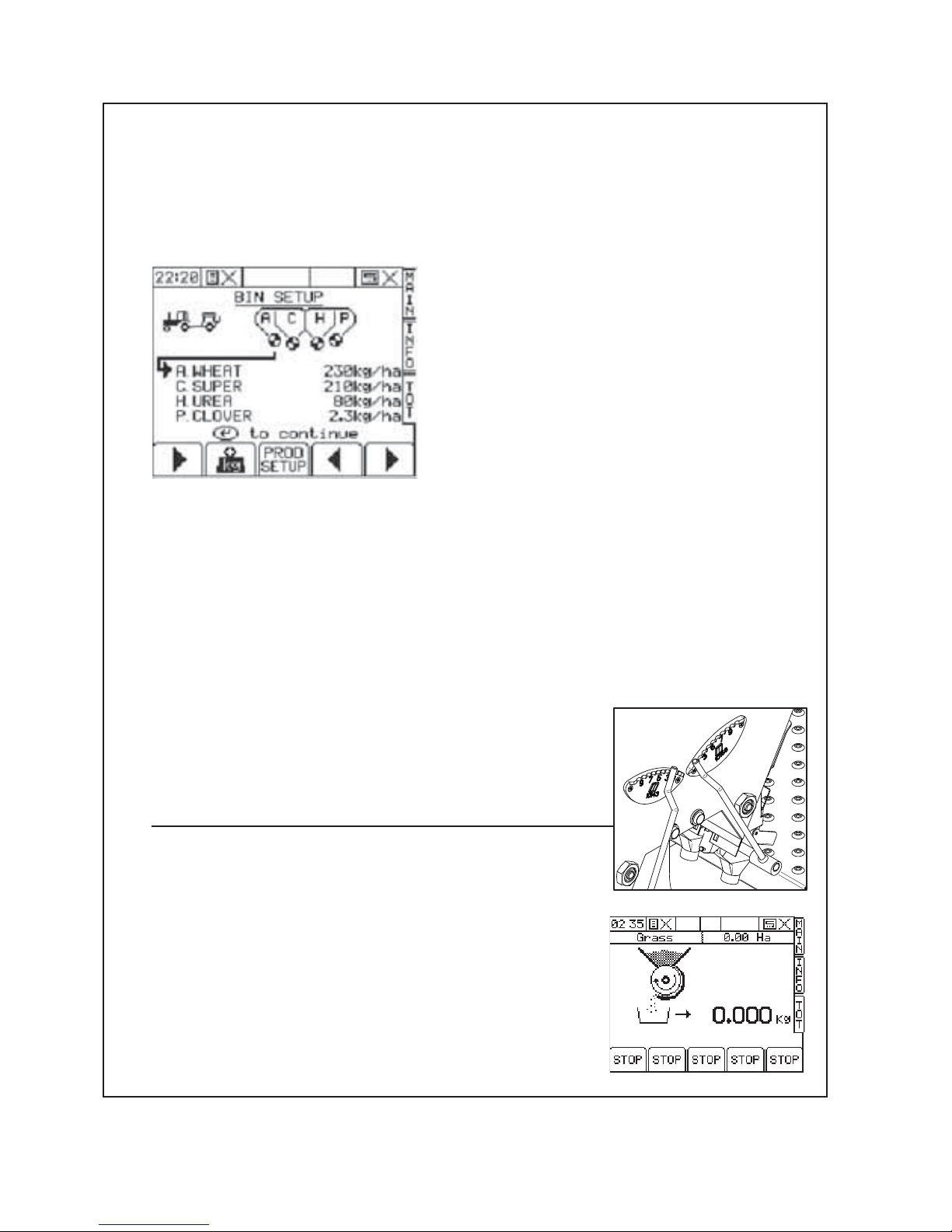

Power On Routine

Note: The machine must be up in the Transport Position for the ‘Power On Routine’ to work.

When the instrument is first turned on the instrument will enter a short routine to remind the operator

of the previous setup. The set up can be changed and then accepted by pressing the ENTER key or

alternatively, the routine can be skipped by pressing the MAIN button (Key A).

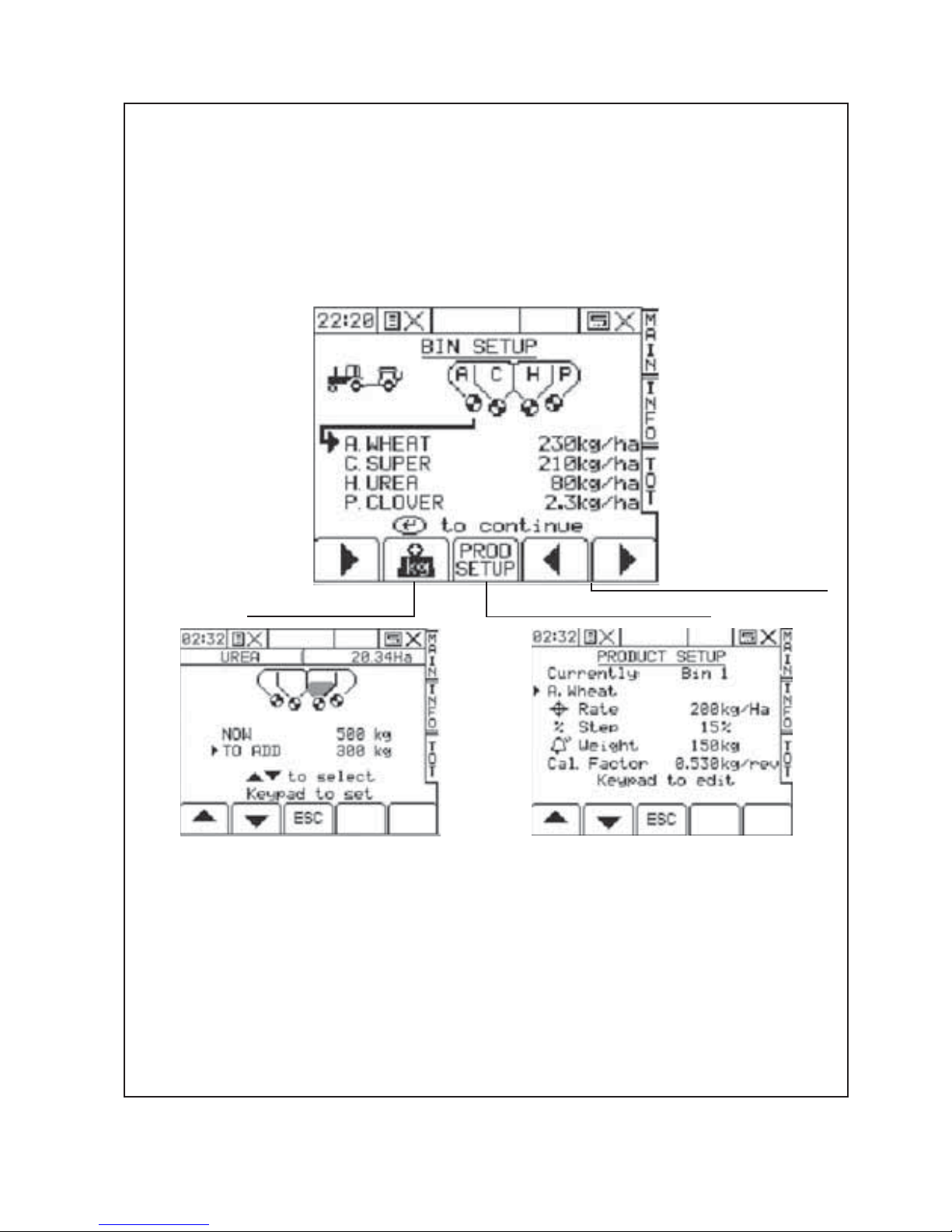

The first screen on start up is the BIN SETUP screen. This screen advises the operator which products are

defined to which bin. On the screen format shown below the operator can use the ‘PRODUCT LIST’ keys

to cycle through the list of products. The application rate saved against that product will also be shown.

The letter shown in the graphic will also change to reflect the product selected.

‘PRODUCT LIST’

‘PROD SETUP’‘BIN CONTENTS’

Startup Screen Display Features

The ‘BIN CONTENTS’ button enables the operator to program the contents of the bin. The ‘NOW’ value

refers to the calculated current contents of the bin based on the work done. This value can be changed

directly by selecting ‘NOW’ and using the key pad and pressing enter. Alternatively, when a specific

amount of product is being added to the bin, select ‘TO ADD’ and use the key pad and press enter to add

to the ‘NOW’ total. Pressing the ‘ESC’ (escape) key returns to the previous ‘INFO’ screen.

The ‘PROD SETUP’ screen allows the operator to change the details of the products in the directory.

There is a directory of 16 products and against each of these 4 factors are recorded. These factors are

target rate, step size, alarm weight and calibration factor. Note: the calibration factor is calculated by the

machine during the calibration process. The only reason to alter this setting manually is when the user

enters wrong information during the calibration process which can stop the motors from working. A list of

default Cal Factors are shown in the calibration section.

Page 24

22

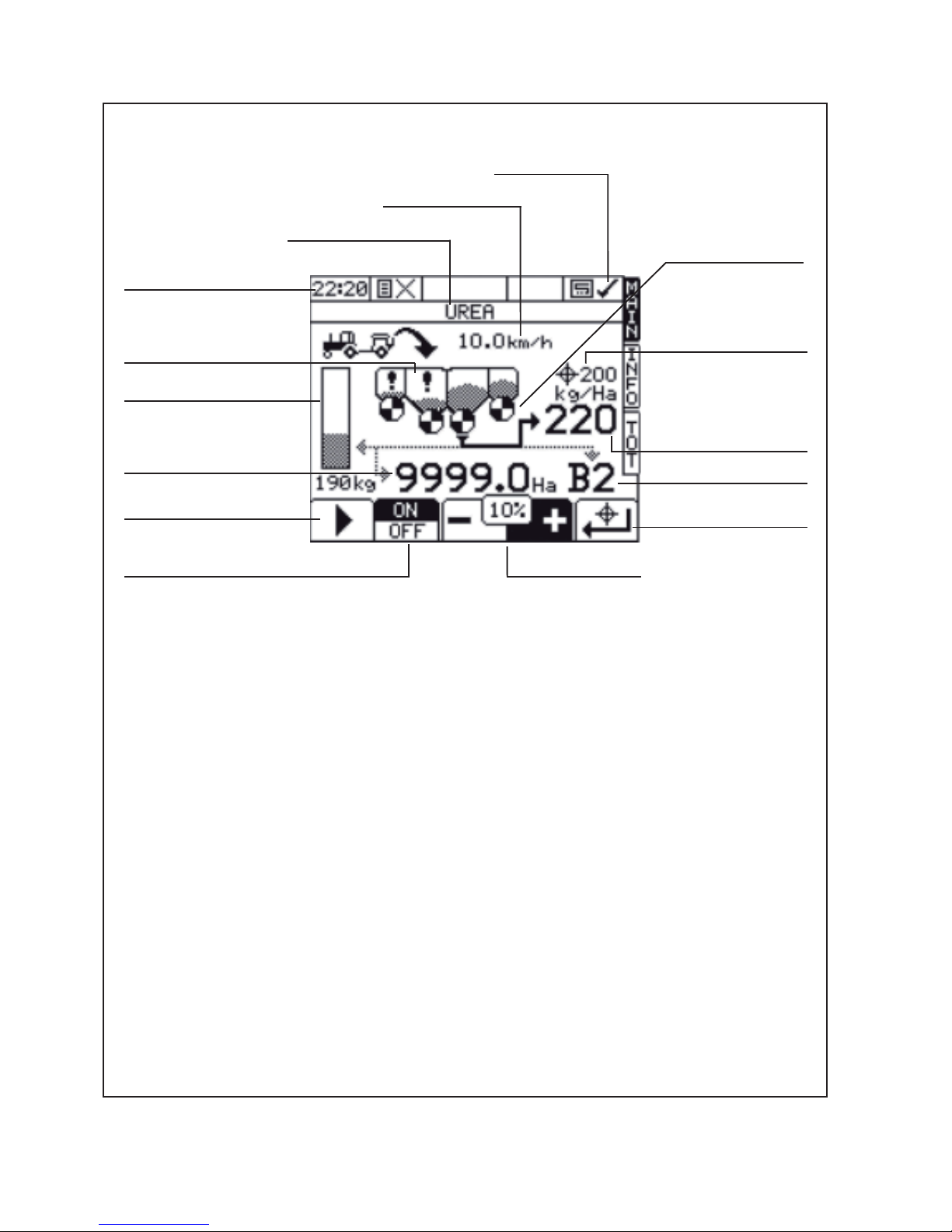

Main Operating Screen

‘Renovator TFD’ Read Before Calibration

Main Screen Display Features

The screenshot above shows the status of Bin 2 (Rear Bin). The ‘BIN SELECTION’ button cycles through

the bins. The line under the metering roll will move to the next bin and the details for that bin will be shown.

When the machine is in use, the metering roll animates to show the bin motor is rotating. The ‘CURRENT

RATE’ is shown. ‘TARGET RETURN’ resets the ‘CURRENT RATE’ to the ‘TARGET RATE’ and cancels

and ‘STEP CHANGE’ applied.

If the ‘BIN MOTOR ON/OFF’ is pressed the bin motor will toggle between these on and off. The metering

roll animation will be replaced with a cross to indicate the bin has been switched off.

Note: The TFD has bins 1 (front) & 2 (rear) as standard. A Small Seed box is optional and is designated

bin 3 when fitted.

Whilst the MAIN screen is displayed, an alternative MAIN SUMMARY screen may be displayed by

pressing the MAIN button. You may cycle betwen the two MAIN screens by pressing the MAIN button.

Clock

‘AREA CUTOUT’

‘FORWARD SPEED’

‘PRODUCT SELECTED’

‘LOW LEVEL

REMINDER’

‘BIN CONTENTS LEVEL’

‘TARGET RATE’

‘CURRENT RATE’

‘STEP CHANGE’

the current rate

can be increased

or decreased by

the % shown from

the target rate.

‘BIN NUMBER’

‘BIN SELECTION’

‘BIN MOTOR ON/OFF’

‘P ART AREA’ SOWN FOR

SELECTED PRODUCT

‘METERING ROLL’

‘TARGET RETURN’

Page 25

23

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Read Before Calibration

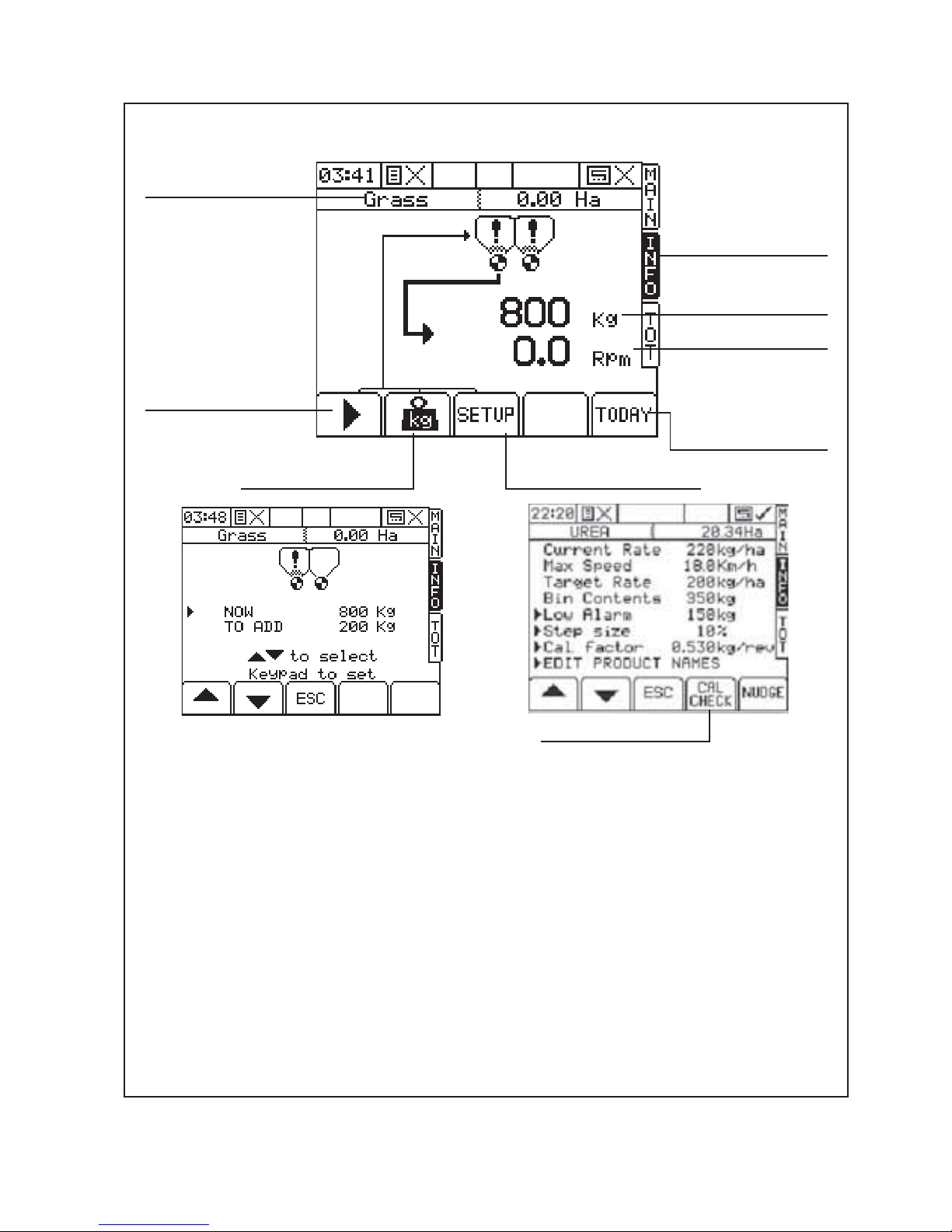

Info Screen -Individual Info Screen shown below.

Info Screen Display Features

The ‘BIN SELECTION’ button cycles through the bins. The line under the metering roll will move to the

next bin and the details for that bin will be shown. The ‘PRODUCT’ shows the product for the bin selected.

The ‘BIN CONTENTS’ button enables the operator to program the contents of the bin. The ‘NOW’ value

refers to the calculated current contents of the bin based on the work done. This value can be changed

directly by selecting ‘NOW’ and using the key pad and pressing enter. Alternatively, when a specific

amount of product is being added to the bin, select ‘TO ADD’ and use the key pad and press enter to add

to the ‘NOW’ total. Pressing the ‘ESC’ (escape) key returns to the previous ‘INFO’ screen.

The ‘INFO SETUP’ screen allows changes to the items marked with a cursor arrow. Changes to these

settings will change the settings for the product.

The ‘CALIBRATION CHECK’ is one way to start the calibration procedure. Refer to the following section.

‘BIN SELECTION’

‘PRODUCT

REMAINING’

‘SHAFT SPEED’

‘INFO’- cycle between

individual and

summary info

screens.

‘PRODUCT’

‘BIN CONTENTS’ ‘INFO SETUP’

‘TODAY’-shows

the qty of product

metered and duration

for today only.

‘CALIBRATION CHECK’

Page 26

24

‘Renovator TFD’ Calibration

Calibration Procedures

The calibration test should be done to confirm the settings of the required seed rate and is done with the

drill stationary and level. Please ensure that you have read the previous section.

1 Power On the console.

2 You will be presented with the BIN SETUP screen. Make any changes to product or target sowing

rates now.

3 Prepare a suitable area for weighing and setup the scales. Tare the scales with the same container

that will be used to weight the product. Scales must be accurate to 2 grams

4 Refer to the sowing chart (page 28) for the chosen product. Set the Shutter Slides, Bottom Flaps and

Metering Wheels in accordance with the sowing chart.

5 Remove the calibration trays from the bracket on the seedbox. Place the trays on the calibration tray

brackets on the seedbox.

6 Push down all the clear plastic seed directors to redirect seed into the calibration trays.

7 For the calibration check, half fill the appropriate box with product. If this is not possible, make sure

the product is evenly distributed over all the seeder units in the box.

8 The calibration process can be in initiated in two ways:

(i) By pressing the appropriate ‘PRIMING SWITCH’

(ii) Via the SETUP menu.

Each of these methods are described in the next few pages.

The PRIMING SWITCH method is easier and more convenient.

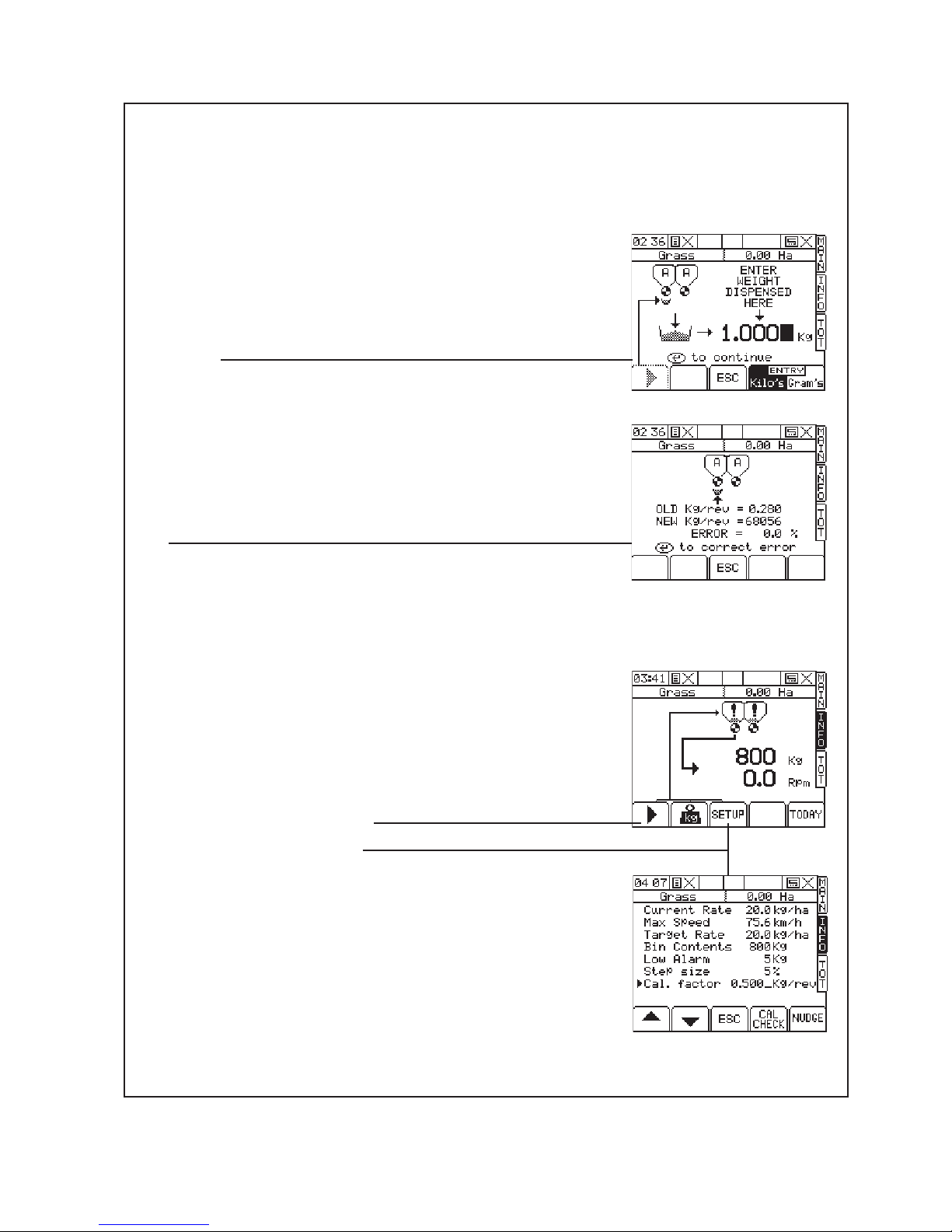

(i) Calibration via PRIMING SWITCH (recommended)

1 Press and hold the appropriate ‘PRIMING SWITCH’ for 1

second then release.

2 The Operating Screen will change as shown. It is likely the

operator will be standing near the priming switches at this

time so will not see the display. It is only after weighing the

dispensed product that the operator need visit the tractor cab.

If the operator presses ‘STOP’ the calibration will be cancelled;

no seting will be altered. This may occur if the priming switch is

pressed to just prime the seeder units or test the motor drive.

Page 27

25

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Calibration

Calibration via PRIMING SWITCH (continued)

3 The appropriate metering unit will run until the PRIMING

SWITCH is pressed again. Product is collected in this

time. The operator is in control of the amount of product

metered out so is able to stop the metering unit when

the calibration trays are at a suitable fill level.

4 Weigh the contents of the calibration trays. Write down

the amount exactly as displayed. Do not round up or

round down the value measured. Scales must be

accurate to 2 grams.

5 Enter the recorded value into the Operating Screen as

shown. Press ‘ENTER’ to confirm as requested.

Always use consistant units of measure ie grams or

Kilograms.

6 Press ‘ENTER’ again. The instrument will then calculate

the settings in order to correctly deliver the product. The

‘error’ value is only the difference between the new and

old settings. Subsequent recalibrations with the same

product will only report small differences.

7 Press ‘ENTER’ again to confirm and store the new

settings.

8 Repeat the calibration process. In this case, the ‘Error’

reported will be very small if any. Remember to press

the ‘ENTER’ key to accept the settings. This repeat

calibration is especially important if the metering units

have been adjusted from very different values since the

last time the machine was used.

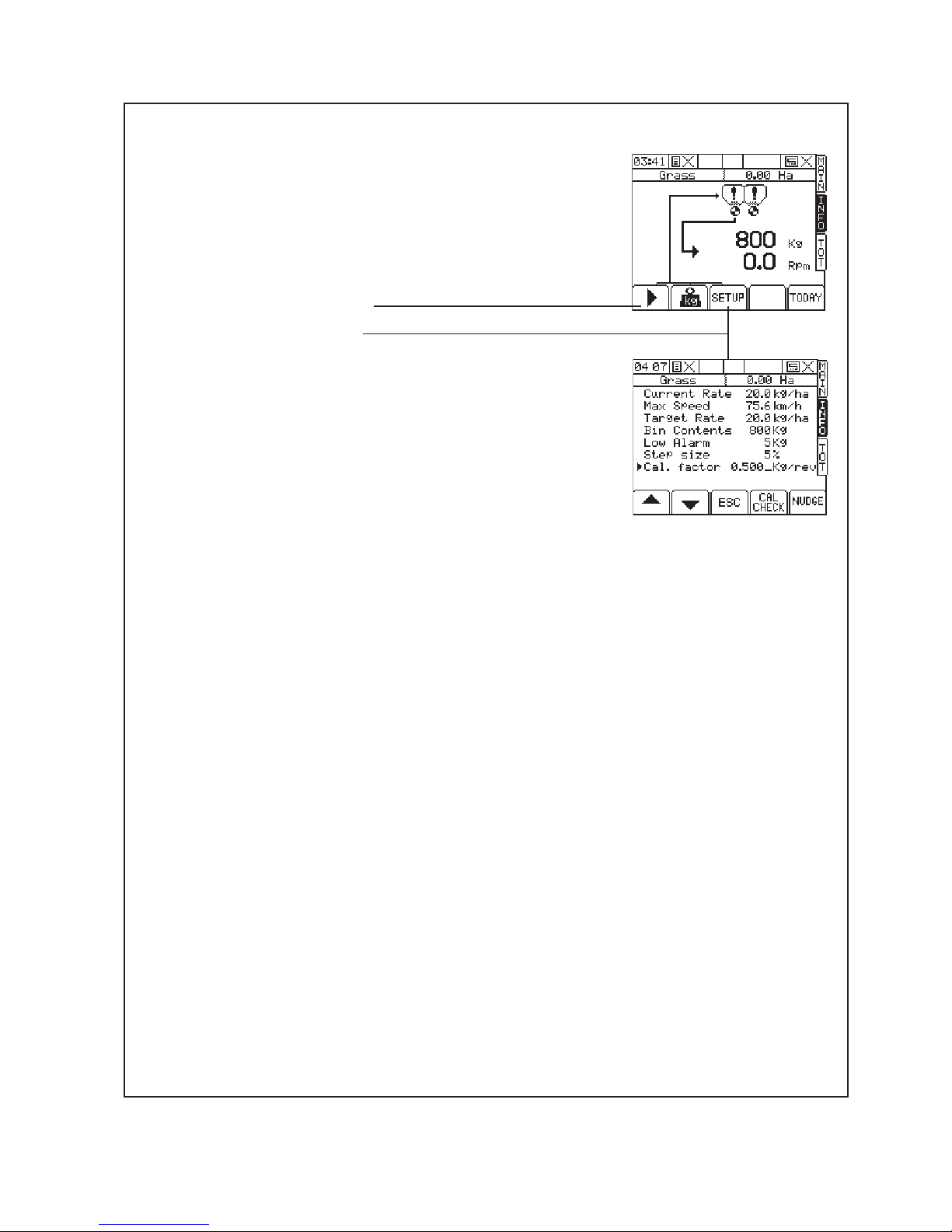

9 NOTE: If, when presing the priming switch the motors

do not turn but there are no other errors, it could be

that the previous calibration was wrongly entered. The

metering speed is out of the range of the motor speed.

This can be corrected by manually entering a ‘calibration

factor’ as follows:

(i) Press the ‘INFO’ menu key.

(ii) Select the appropriate bin.

(iii) Press the ‘SETUP’ key.

(iv) Use the up down arrows to select the ‘Cal. factor’

line.

(v) Type 0.500 and hit the ‘ENTER’ key. (You need to

enter the leading zero as the machine will not accept

the ‘.’ as a first character.) Note that although the default

calibration factor for Grass is 0.28 kg/rev resetting to

0.500kg per rev gets the machine working again for

re-calibration.

(vi) Hit the ‘ESC’ key to return to the ‘SETUP’ menu or

hit the ‘MAIN’ key to return to the ‘MAIN’ menu.

(vii) Repeat the calibration process from step 1.

Page 28

26

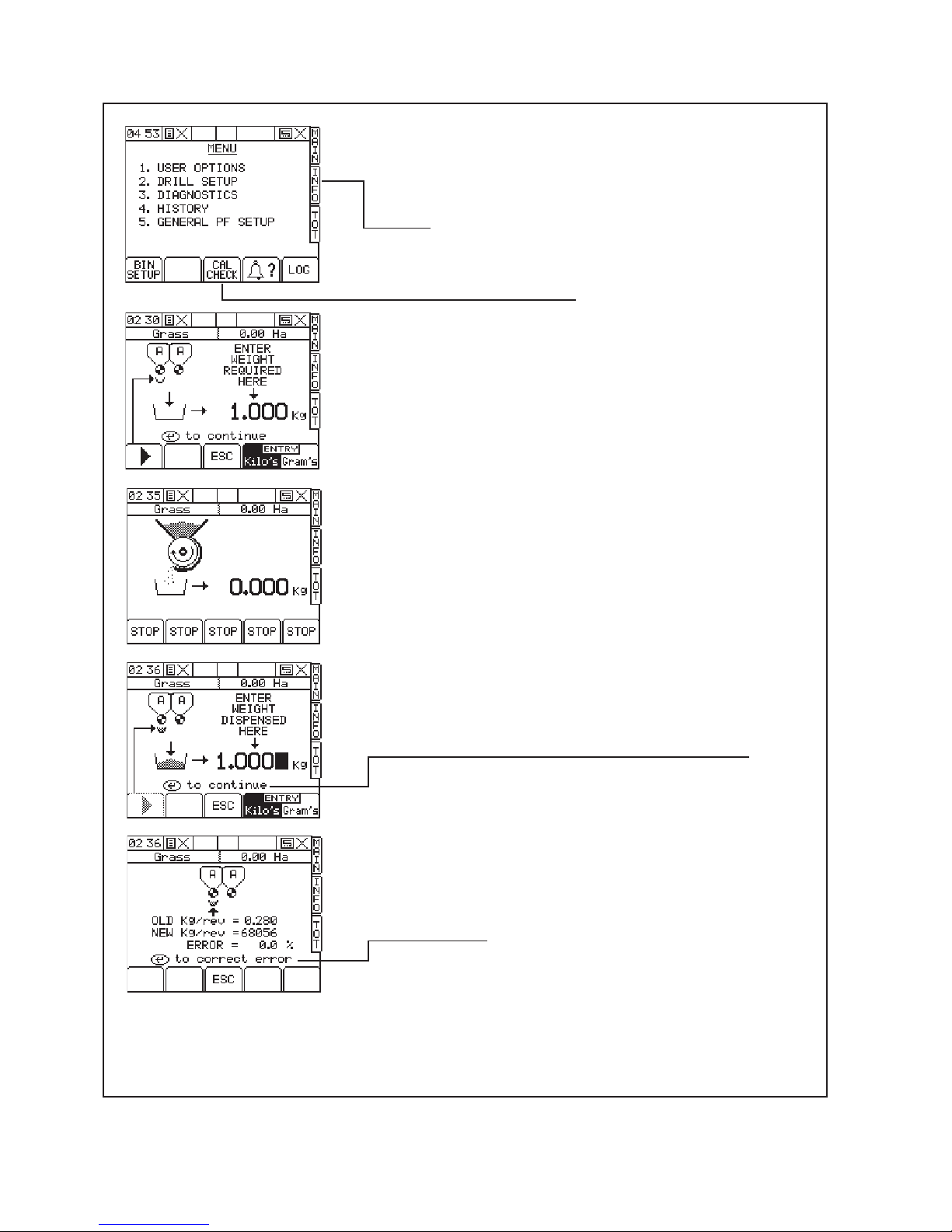

(ii) Calibration via ‘SETUP’ MENU

1 Ensure that steps 1 to 8 on page 22 have been carried

out prior to actual calibration.

2 Navigate to the ‘MENU’ screen by pressing the ‘MENU’

key.

3 Access the ‘Calibration Check’ screen by hitting the

‘CAL CHECK’ button.

4 The screen will then prompt, “Enter weight required

here”. Select the bin that you want to calibrate by

pressing the arrow key.

Enter the amount required. Hit ‘ENTER’ to continue

Remember to set and keep to consistant units.

Note that this is is only related to calibration and

weighing; it is not related to the sowing rate entered

on the startup screen earlier.

6 The machine will dispense the amount you entered

based on the current settings. If the product or seeding

rates are different from the last time the machine was

used then the amount metered may not be as expected.

If you suspect that the calibration container will overflow

then you can stop metering process by hitting one of the

5 keys along the bottom of the screen.

7 Once the machine has stopped the calibration delivery,

either because it has reached the amount you entered

or you forced it to stop, weigh the contents of the

container. Write down the amount exactly as displayed.

Do not round up or round down the value measured.

Scales must be accurate to 2 grams.

8 Enter the recorded value into the Operating Screen as

shown. Press ‘ENTER’ to confirm as requested.

Always use consistant units of measure ie grams or

Kilograms.

6 Press ‘ENTER’ again. The instrument will then calculate

the settings in order to correctly deliver the product. The

‘error’ value is only the difference between the new and

old settings. Subsequent recalibrations with the same

product will only report small differences.

7 Press ‘ENTER’ again to confirm and store the new

settings.

8 Repeat the calibration process. In this case, the ‘Error’

reported will be very small if any. Remember to press

the ‘ENTER’ key to accept the settings. This repeat

calibration is especially important if the metering units

have been adjusted from very different values since the

last time the machine was used.

‘Renovator TFD’ Calibration

Page 29

27

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Calibration

(ii) Calibration via ‘SETUP’ MENU continued

9 NOTE: If, when presing the priming switch the motors do

not turn but there are no other errors, it could be that the

previous calibration was wrongly entered. The metering

speed is out of the range of the motor speed.

This can be corrected by manually entering a ‘calibration

factor’ as follows:

(i) Press the ‘INFO’ menu key.

(ii) Select the appropriate bin.

(iii) Press the ‘SETUP’ key.

(iv) Use the up down arrows to select the ‘Cal. factor’

line.

(v) Type 0.500 and hit the ‘ENTER’ key. (You need to

enter the leading zero as the machine will not accept

the ‘.’ as a first character.) Note that although the default

calibration factor for Grass is 0.28 kg/rev resetting to

0.500kg per rev gets the machine working again for

re-calibration.

(vi) Hit the ‘ESC’ key to return to the ‘SETUP’ menu or

hit the ‘MAIN’ key to return to the ‘MAIN’ menu.

(vii) Repeat the calibration process from step 1.

Page 30

28

‘Renovator TFD’ Calibration Sowing Chart

Settings for Seed Type

Seed Type

Default Calibration

Factor (kg/rev)

Shutter Slide1Bottom Flap2Metering Wheel

3

Wheat 0.70 3/4 3 N

Oats 0.69 Full 3 N

Barley 0.69 Full 3 N

Ryecorn

- Full 3 N

Peas 1.00 3/4 3 N

Grass 0.28 Full 3 N

Grass Mix 0.30 Full 3 N

DAP Granules 0.94 Full 3 N

Super Phosphate 1.20 Full 3 N

Lucerne/Alfalfa 0.10 3/4 1 F

Turnip 0.093 3/4 1 F

Kale 0.092 3/4 1 F

Swede 0.093 3/4 1 F

Canola/Rape 0.09 3/4 1 F

White Clover 0.094 3/4 1 F

Red Clover 0.094 3/4 1 F

NOTES

1. SHUTTER SLIDE

For grain, opening the shutter slide to Full gives 10-15% more flow.

2. BOTTOM FLAP

The values shown were the optimum test settings.

Decreasing the gap may cause seed damage.

Too large a gap will give intermittent flow rates.

Flaps are spring loaded to cope with small variations in seed/granule size.

3. METERING WHEEL

N = Normal metering wheel

F = Fine metering wheel only

TSW: TSW(gm) x Desired Plants/m

2

= Sowing Rate (Kg/Ha)

Germination %

Page 31

29

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Calibration Notes

Page 32

30

General Safety and Accident Prevention Advice

1 Make sure that if the tractor remains attached to the drill

that the ignition key is removed.

2 During maintenance the drill should be supported in such

a manner that if hydraulic failure was to occur the machine

would still be adequately supported.

3 Wear gloves when handling components with cutting

edges such as worn discs etc...

4 Disconnect the electrical supply from the tractor before

doing any electrical maintenance.

5 Refer to safety sections for more safety information.

General Cautionary Maintenance Advice

1 Electric Welding - With the electronic equipment in

modern tractors it is advisable to completely disconnect the

implement from the tractor, or at the very least disconnect

the alternator before attempting any welding.

2 Hydraulics - Ensure hydraulic couplings (male & female)

are clean before connecting. Dirty couplings will result

in hydraulic oil contamination and hydraulic cylinder seal

damage and bore scores. This in turn will result in oil

leakage past the piston seals.

No filter is fitted to the hydraulic system. If hydraulic

fittings and oil supply are not going to be kept clean it is

recommended that a filter be fitted to prevent hydraulic

cylinder damage.

3 Water Blasting - Water blasting, steam cleaning or other

pressurised cleaning processes can force dirt etc. into

undesirable places that may cause damage or rapid part

wear to items such as bearings, seals, chains, bushes etc.

Caution must be exercised.

‘Renovator TFD’ Maintenance & Care

Page 33

31

Pt. No. 67415

Issue 0517

Lubrication Chart

Maintenance & Care - Lubrication Instructions

* The lubrication frequencies are only a guide. Actual frequency will be dependent on extent of use and ground conditions.

Precautions with Grease

Greases should not be mixed as the structure may be weakened by the

mixes of different types of thickener, which may cause softening and loss of

grease from the bearings by running out.

Item Components Lubricant Frequency*

1 Wheel Bearings Castrol LMX Grease Annually

2 Wheel Leg Pivots Castrol LMX Grease Weekly

3 Drive Chains Suitable Roller Chain Lubricant See Maintenance Schedule

4 Turnbuckles Castrol LMX Grease Monthly

5 Coupling Castrol LMX Grease Monthly

Your new Duncan Renovator TFD will

give long and efficient service if given

normal care and maintained properly.

1

2

4

5

3

‘Renovator TFD’ Maintenance & Care

Page 34

32

Maintenance Schedule

(

Refer also to Summary Chart, above)

1. Bolted Connections

All bolted connections of the machine should be checked after the first 3 to 5 hours of operation and

retightened if necessary and thereafter at regular intervals. It is suggested that this is done every 500

hectares or annually, whichever occurs first.

2. Hydraulics

Ensure hydraulic couplings (male & female) are clean before connecting. Dirty couplings will result in

hydraulic oil contamination and hydraulic seal and bore damage which will cause oil leakage past the

seals.

No filter is fitted to the hydraulic system. If the hydraulic fittings and the oil supply are not going to

be kept clean then it is recommended that a filter be fitted to prevent hydraulic cylinder damage.

3. Drive Chains

All drive chains (1) should be checked after every 20 hours of operation and weekly thereafter or

after 75Ha of operation.

The metering wheels of the seed drill are driven via roller chains from the gearmotor.

4. Wheel Arm Pivots

Wheel arm pivots must be greased regularly (weekly or after every 75Ha) to provide lubrication and

flush out any dirt.

6. Tyre Pressure

The recommended tyre pressures may be found on page 5. Check the tyre pressure regularly to

ensure correct pressure is maintained. Weekly checks are recommended.

7. Length of Seed/Fertiliser Tubes

These tubes can stretch over a period of time and require checking at approximately six monthly

intervals. Shorten if necessary to avoid bends which will restrict the flow of seed/fertiliser.

8. Framework

The framework structure should be inspected annually for defects, i.e., cracks in members or welded

connections. The framework should be cleaned prior to the inspection.

Maintenance & Care - continued

Components

Daily Weekly Pre Season

(or after 20Ha) (or after 75Ha) (or 500 Ha)

Seeders/Agitators/Bottom Flaps ●●●

Pivot Pin Fasteners ●●

Roller Chains ●●

Hydraulics (Oil Leaks) ●●

Tyre Pressures ●●

Bolted Connections ●

‘Renovator TFD’ Maintenance & Care

Page 35

33

Pt. No. 67415

Issue 0517

9. Bottom Flaps

The required seed rate is controlled by both the metering

wheels and the bottom flaps. The seed flows from the seed

box into the metering wheel housings. Inside the metering

wheel housing (1) the seed is caught between the metering

wheel (2) and the bottom flap (3). The metered amount

of seed is transported by the metering wheel to the edge

of the bottom flap where it drops off into the seed guide

tube which leads to the coulter. Varying grain sizes require

the matching of the flap clearance to the different grain

sizes. This matching is done by raising or lowering the

bottom flaps by using the flap adjusting lever on the LH

end of the seed box. If larger foreign particles, e.g. stones

get between the metering wheel and the bottom flap, the

bottom flap can give way downwards. A strong return

spring (4) brings the bottom flap immediately back into the

working position.

The metering system should be checked every 1/2 year

or before any sowing period with an empty seed box

and empty metering housings.

Use the following procedure:

Put the bottom flap setting levers (6) (located on the LH

end of the seed boxes) in position “1” for the front box and

position “1” for the rear box.

By turning the metering wheel shaft by hand check the

flaps are all set to a gap of 0.1 to 0.5mm.

To adjust individual flaps use the spring tensioning screw

(5) .

Note: Maintenance Schedule (page 32)

Where the frequency is given in terms of use (eg. weekly)

or area covered (eg. 75 Ha) perform the maintenance task

based on whichever occurs first.

Preparing the Machine for Storage.

Locate on a dry level surface. The machine should be

stored wherever possible so the rams are not supporting

any weight. The drive chains should be lubricated with

suitable roller chain lubricant before prolonged periods of

storage.

For longer term storage remove seed/fertiliser tubes

from the boot assembly and allow to hang without

deformation. Check tube lengths when replacing.

It is recommended that maintenance be carried out

at the end of the season, giving sufficient time to

obtain spare parts and/or carry out repairs if required.

Important !

1

3

4

5

2

10

1

10

6

Page 36

34

Page 37

35

Pt. No. 67415

Issue 0517

Parts List

‘Renovator TFD’ Seed Drill

Head Office:

P.O. Box 2018

Hilton Highway, Washdyke

Timaru, New Zealand

Telephone (03) 688 2029

Facsimile (03) 688 2821

Australian Branch:

4B Silverton Close

Laverton North 3026

Melbourne, Australia

Telephone (03) 9314-9666

Facsimile (03) 9314-6810

Page 38

36

‘Renovator TFD’ Complete Assembly

3

1

2

7

8

6

4 5

9

Page 39

37

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Complete Assembly

ITEM PART No. DESCRIPTION QTY

1 Refer Page 38 Main Frame & Drawbar Assembly -

2 Refer Page 42 Wheel Leg (including hydraulics) -

3 Refer Page 46 Adjustable Toolbars -

4 Refer Page 50 Fixed Toolbars -

5 Refer Page 52 Tine, Boot & Point -

6 Refer Page 54 Hose Supports -

7 Refer Page 56 Footboard, Ladder & Handrail -

8 Refer Page 60 Seed Box & Metering Units -

9 Refer Page 67 Electric Drive (parts) -

10 Refer Page 76 Rear Tow Hitch & Tine Harrow Mount (Optional) -

11 Refer Page 78 Tine Harrow (Optional) -

12 Refer Page 80 Uni-Roller (Optional) -

13 Refer Page 83 Electric Drive (detailed instructions & setup) -

Page 40

38

‘Renovator TFD’ Mainframe and Drawbar

1

2

5

6

6

7

89

10

10

11 1213

14

15

3

3

7

16

17

21

19

22

24 25 26 27

20

23

4

1228

29

18 20

Page 41

39

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Mainframe and Drawbar

ITEM PART No. DESCRIPTION QTY

1 72001 Mainframe Welded Assembly (3m 24R) 1

1 72046 Mainframe Welded Assembly (3.5m 28R) 1

2 60033 Drawbar Welded Assembly 1

3 4800315 Hose Support 1

4 60094 Drawbar Axle 1

5 45285 Roll Pin 2

6 72014 Centre Hitch Welded Assembly 1

7 60405 Towing Eye Assembly 1

8 26577 LH Support Stay 1

9 26578 RH Support Stay 1

10 43832 Safety Chain Assembly 2

11 45066 M20 x 70 Grade 8.8 Bolt 2

12 45141 M20 Nyloc Nut 6

13 47244 7/8” UNF Bolt x 6.5” 1

14 47548 7/8” UNF Nut 1

15 45181 M8 x 12 S/H Grub Screw 1

16 45042 M16 x 60 Grade 8.8 Bolt 4

17 45140 M16 Nyloc Nut 4

18 45033 M12 x 120 Grade 8.8 Bolt 1

19 45034 M12 x 120 Grade 8.8 Bolt 2

20 45139 M12 Nyloc Nut 3

21 60409P Hose Rack 1

22 26850k Stand Kit 1

23 43007 Grease Nipple 1

24 22262 Clevis Pin Tabbed 1

25 45001s M10 x 20 S/Screw Grade 8.8 ZP 1

26 45152 M10 Light Flat Washer 1

27 45166 M10 Spring Washer 1

28 45068 M20 x 80 Grade 8.8 Bolt 2

29 72210k Transport Stand Kit 1

Page 42

40

‘Renovator TFD’ Mainframe and Drawbar

Note: Drawbar hydraulic parts can be

purchased as a kit.

The part number is 26720K.

6

7

9

11

8

10

5

12

13

15

14

13

4

2

1

4

3

Page 43

41

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Mainframe and Drawbar

ITEM PART No. DESCRIPTION QTY

Drawbar Turnbuckle Parts

1 43395 H/D Ratchet Turnbuckle 1

2 47254 Bolt 1” UNF x 5” HT 1

3 47251 Bolt 1” UNF x 3.5” HT 1

4 47552 1” UNF Nyloc Nut 2

Drawbar Hydraulic Parts

5 43852 Hydraulic Cylinder 1

6 26723 Hydraulic Hose 2.80m 1

7 26724 Hydraulic Hose 2.50m 1

8 43496 3/4” UNO to 3/8”BSPT Elbow 1

9 43393 3/8” BSP S/S Ball Valve 1

10 43147 1/2” BSP Quick Release Coupling 2

11 43617 Dust Cover 2

12 43280 3/4” UNO to 3/8” BSPM Nipple 1

13 47552 1” UNF Nyloc Nut 2

14 47254 Bolt 1” UNF x 5” HT 1

15 47251 Bolt 1” UNF x 3.5” HT 1

Page 44

42

‘Renovator TFD’ Wheel Leg

2

10

11

12 13 14 15

1

9

7

8

3

4

365

16

17

Page 45

43

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Wheel Leg

ITEM PART No. DESCRIPTION QTY

1 72020 Left Hand Wheel Leg Welded Assembly(not shown) 1

1 72031 Right Hand Wheel Leg Welded Assembly 1

2 72032 Pivot Pin 2

3 72017 Wheel Leg Mount 2

4 43426 Glacier Bush Ø45 4

5 45618 Lock Nut 2

6 45619 Lock Washer 2

7 45038S M16 X 40 Grade 8.8 Z/P S/Screw 16

8 45140 M16 Nyloc Nut 16

9 43010 90° Grease Nipple 2

10 26558 Clevis Pin 90mm long 2

11 45272 R Clip (S12 or AG7) 4

12 45002S M10 X 25 Grade 8.8 Z/P S/Screw 2

13 45166 M10 Spring Washer Z/P 2

14 45158 M10 H/D Flat Washer Z/P 2

15 22262 Clevis Pin Assembly 2

16 60245 Hub (6 Stud) 2

17 45638 10.0/75-15.3 Wheel Assy 6 Stud (18 Ply) 2

Page 46

44

‘Renovator TFD’ Wheel Hydraulics

20 - 22

23, 24

4 8

10 17

9

11

19

9

10

5

18

12

16

2

5

1

4

7

13, 14

Slave

Cylinder

Master

Cylinder

Direction of travel

15

15

3 3

Right Hand SideLeft Hand Side

6

Page 47

45

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Wheel Hydraulics

ITEM PART No. DESCRIPTION QTY

1 26702 3.5” x 6.5” Master Rephasing Cylinder (Includes pin) FIT TO RIGHT HAND SIDE 1

2 26703 3.25” x 6.5” Slave Rephasing Cylinder (Includes pin) 1

3 43848 Stroke Limiting Collar 7/8” (where fitted) 1

4 60866 Hydraulic Hose, 2.70m (Tractor to Ball Valve) 3m & 3.5m 1

5 60864 Hydraulic Hose, 2.70m (B.Valve to Master Cyl Base) 3m 1

5 60869 Hydraulic Hose, 2.80m (B.Valve to Master Cyl Base) 3.5m 1

6 60864 Hydraulic Hose, 2.70m (Master to Slave Cyl Base) 3m 1

6 60868 Hydraulic Hose, 3.10m (Master to Slave Cyl Base) 3.5m 1

7 60863 Hydraulic Hose, 5.45m (Slave Cylinder Head to Tractor) 3m 1

7 60867 Hydraulic Hose, 5.70m (Slave Cylinder Head to Tractor) 3.5m 1

8 43028 3/8” Flow Control 1

9 43391 3/8” Dowty Washer 3

10 43392 3/8” BSPP Male Nipple 2

11 43393 3/8” BSP S/S Ball Valve 1

12 60856 Hydraulic Valve Support Assy 1

13 43147 1/2” BSP Quick Release Coupling 2

14 43617 Dust Cover 2

15 43280 3/4” UNO to 3/8” BSP Nipple 4

16 45033 M12 x 120 Bolt 1

17 45139 M12 Nyloc Nut 1

18 44957 M6 X 50 Bolt 2

19 45136 M6 Nyloc Nut 2

20 22262 Clevis Pin Assembly 2

21 45418s M10 x 25 Set Screw 2

22 45166 M10 Spring Washer 2

23 26558 Clevis Pin 2

24 45272 R Clip 2

Page 48

46

‘Renovator TFD’ Adjustable Toolbars

5

4

3

2

4

1

6

Page 49

47

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Adjustable Toolbars

ITEM PART No. DESCRIPTION QTY

24R 28R

1 72168 TFD 3.0m Front Beam Welded Assembly 1 -

1 72230 TFD 3.5m Front Beam Welded Assembly - 1

2 72169 TFD 3.0m Middle Beam Welded Assembly 1 -

2 72231 TFD 3.5m Middle Beam Welded Assembly - 1

3 72170 TFD 3.0m Rear Beam Welded Assembly 1 -

3 72232 TFD 3.5m Rear Beam Welded Assembly - 1

4 72175 TFD Rear Beam (Short) Welded Assembly 2

5 Refer Page 48 Toolbar adjust components -

6 Refer Page 52 Tine, Boot & Point Components -

Page 50

48

‘Renovator TFD’ Adjustable Toolbars

1819

15

16

17

14

5

6

1 2

43

12

1310 14

758

9

1011

Page 51

49

Pt. No. 67415

Issue 0517

ITEM PART No. DESCRIPTION QTY

1 72174 Rear Link Arm TFD 2

2 72165 Rear Adjusting Bush TFD 4

3 45020 M12 x 35 Grade 8.8 Z/P Bolt 4

4 45159 M12 HD Flat Washer 4

5 45139 M12 Nyloc Nut 60

6 43395 HD Turnbuckle 1

7 26558 Clevis Pin 90mm long 2

8 45272 R Clip (S12 or AG7) 4

9 72162 TFD Link Arm W/Assembly (attached to Turnbuckle) 1

10 72166 Adjusting Bush TFD 6

11 72160 Link Arm TFD 1

12 45040 M16 x 50 Grade 8.8 Z/P Bolt 6

13 45160 M16 H/D Flat Washer Z/P 6

14 45140 M16 Nyloc Nut 34

15 72036 TFD Upper Clamp Body W/Assy 14

16 72155 Rubber Cord 56

17 72040 TFD Lower Clamp Body W/Assy 14

18 45019S M12 x 30 Grade 8.8 Z/P S/Screw 56

19 45040S M16 x 50 Grade 8.8 Z/P S/Screw 28

‘Renovator TFD’ Adjustable Toolbars

Page 52

50

‘Renovator TFD’ Fixed Toolbars

1

7 6

8

35 2

4

Page 53

51

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Fixed Toolbars

ITEM PART No. DESCRIPTION QTY

24R 28R

1 72060 TFD 3.0m Front Beam W/Assy Fxd 1 -

1 72066 TFD 3.5m Front Beam W/Assy Fxd - 1

2 72161 TFD 3.0m Mdl Beam W/Assy Fxd 1 -

2 72067 TFD 3.5m Mdl Beam W/Assy Fxd - 1

3 72162 TFD 3.0m Rear Beam W/Assy Fxd 1 -

3 72068 TFD 3.5m Rear Beam W/Assy Fxd - 1

4 72063 TFD R Beam LH Short W/Assy Fxd 1

5 72064 TFD R Beam RH Short W/Assy Fxd 1

6 45019s M12 x 30 Grade 8.8 Z/P S/Screw 56

7 45139 M12 Nyloc Nut 56

8 Refer Page 52 Tine, Boot & Point Components -

Page 54

52

‘Renovator TFD’ Tine, Boot & Point

8

1

10

2

65

2 clamps

per tine

7

11

3

4

9

12

13

Page 55

53

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Tine, Boot & Point

ITEM PART No. DESCRIPTION QTY

24R 28R

1 43159 “S” Tine Bellota 45x12 2476 24 28

2 44346 BH1 Tip Tiled Flexiseeder 24 28

3 44347 BH2 Clamp for BH1 Flexiseeder 24 28

4 72196C Seeding Boot TFD 15 17

5 72151P TFD ‘S’ Tine Clamp 48 56

6 45032 M12 x 110 Grade 8.8 Z/P Bolt 72 84

7 45139 M12 Nyloc Nut 72 84

8 72194 M12 ‘U’Bolt Flexiseeder Point 24 28

9 45126 M12 1.75p Conelock Nut 72 84

10 44923 M12x75 Grade 10.9 Z/P Bolt 24 28

11 45222 M8x35 Skt Hd Cap Screw 10.9 Z/P 48 56

12 45128 M8 Conelock Nut 10.9 48 56

13 72218C Seeding Boot Curved TFD 9 11

Page 56

54

‘Renovator TFD’ Hose Supports

3 4 2

1

1

5 6 7 8

9

Not Shown

Page 57

55

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Hose Supports

ITEM PART No. DESCRIPTION QTY

24R 28R

1 74041 3.0m Hose Support Frame 2 -

1 74046 3.5m Hose Support Frame - 2

2 74071 Hose Support Bracket 4

3 44962 M8 x 30 Grade 8.8 Z/P S/Screw 8

4 45151 M8 Light Flat Washer 8

5 45137 M8 Nyloc Nut 8

6 45004s M10 x 35 Grade 8.8 Z/P S/Screw 8

7 45152 M10 Light Flat Washer 8

8 45138 M10 Nyloc Nut 8

9 43817 Dia. 32/50mm Hose Clip 48 56

Page 58

56

‘Renovator TFD’ Footboard, Ladder & Handrail

1

2

3 5

7

4

4

12

9

1011

98

10

6 7

15

1413

Page 59

57

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Footboard, Ladder & Handrail

ITEM PART No. DESCRIPTION QTY

24R 28R

1 60160 Rear Guard Rail W/Assy (3.0m) 2 -

1 60360 Rear Guard Rail W/Assy (3.5m) - 2

2 60163 End Guard Rail W/Assy 1

3 60150 3.0m Footboard Assembly 1 -

3 60350 3.5m Footboard Assembly - 1

4 72035 TFD Outer F/Board Mntg Profile 2

5 72034 TFD Inner F/Board Mntg Profile 2

6 45040S M16 x 50 Grade 8.8 Z/P S/Screw 8

7 45140 M16 Nyloc Nut 16

8 45021 M12 x 40 Grade 8.8 Z/P Bolt 6

9 45159 M12 H/D Flat Washer Z/P 8

10 45139 M12 Nyloc Nut 8

11 45023 M12 x 50 Grade 8.8 Z/P Bolt 2

12 45038S M16 x 40 Grade 8.8 Z/P S/Screw 8

13 43757 Drop Lock 1

14 45138 M10 Nyloc Nut 1

15 Refer Page 58 Ladder Components -

Page 60

58

‘Renovator TFD’ Footboard, Ladder & Handrail

54

2

3

1

6

7 8 9

10

Page 61

59

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Footboard, Ladder & Handrail

ITEM PART No. DESCRIPTION QTY

1 60170 Footboard Step Bracket W/Assy 1

2 72143 TFD Ladder W/Assembly 1

3 45062 M20 x 50 Grade 8.8 Z/P Bolt 2

4 45155 M20 Light Flat Washer Z/P 2

5 45141 M20 Nyloc Nut 2

6 45023 M12 x 50 Grade 8.8 Z/P Bolt 2

7 45002S M10 x 25 Grade 8.8 Z/P S/Screw 2

8 45152 M10 Light Flat Washer Z/P 2

9 45138 M10 Nyloc Nut 2

10 63220 Ladder Securing Bracket 1

Page 62

60

‘Renovator TFD’ Dual Seedbox Assembly

1 2 3

6

5

4

11

7

10

98

12

13

14

Page 63

61

Pt. No. 67415

Issue 0517

ITEM PART No. DESCRIPTION QTY

24R 28R

1 72100

Dual Box Assembly & Lid 24 Run (with seeder

hardware) 1 -

1 72233

Dual Box Assembly & Lid 28 Run (with seeder

hardware) - 1

2 74002 Dual Box/Dual Lid 24 Run (painted sheetmetal) 1 -

2 72234 Dual Box/Dual Lid 28 Run (painted sheetmetal) - 1

3 74006 Lid Only 3m 2 -

3 72282 Lid Only 3.5m - 2

4 26599 Calibration Tray Bracket 8

5 72139 Calibration Tray 3m 4 -

5 72275 Calibration Tray 3.5m - 4

6 Refer Page 61 Seeder Mechanism 48 56

7 Refer Page 60 Agitator Drive Assembly 2

8 23633 Box Shaft Short Connect Sleeve 2

9 72130 Flap Shaft 3m 2 -

9 72271 Flap Shaft 3.5m - 2

10 72129 Box Shaft 3m 2 -

72270 Box Shaft 3.5m - 2

11 45002S M10 X 25 Grade 8.8 Z/P S/Screw 4

12 45138 M10 Nyloc Nut 4

13 Refer Page 64 Rear Motor Drive 1

14 Refer Page 63 Front Motor Drive 1

‘Renovator TFD’ Dual Seedbox Assembly

Page 64

62

‘Renovator TFD’ Dual Seedbox Assembly

32

1

5

6

2

25

4

4

27

26

4

22 23

4

24

14

18

17

16

13

7 98

11 12 10 13

14

15

Page 65

63

Pt. No. 67415

Issue 0517

ITEM PART No. DESCRIPTION QTY

1 29163 Hinge Assembly 6

2 45908 M6 X 16 Pan Pozi Z/P M/C Screw 24

3 45150 M6 Light Flat Washer Z/P 12

4 45136 M6 Nyloc Nut 34

5 27599 Hinge Pin Spring Clip 6

6 22491 Hinge Pin 6

7 45632 M4 Nyloc Nut 4

8 45646 Rubber Tensioner Hook 4

9 45633 M4 x 25 Pan Head Screw 4

10 45644 Gas Strut 100N 4

11 45005 M10 x 40 Grade 8.8 Z/P Bolt 8

12 45152 M10 Light Flat Washer Z/P 16

13 45130 M10 Grade 8.8 Hex Nut Z/P 12

14 45138 M10 Nyloc Nut 12

15 45654 M10 Dome Nut Stainless 4

16 45661SS M10x50ss Button Head Skt Screw 4

17 45158 M10 H/D Flat Washer Z/P 8

18 45645 T-Pull Rubber Rope Tensioner 4

19 72137 Rear Flapshaft Handle W/Assy 1

20 72134 Front Flapshaft Handle W/Assy 1

21 45186 M10 x 12 Socket Head Grubscrew 4

22 10143 Quadrant Plate Cast (9-7-5-3-1) 2

23 10158 Quadrant Reverse (1-3-5-7-9) 2

24 45758 M6 x 16 C/Sunk Posi Z/P Screw 4

25 45122 M6 Grade 8.8 Hex Nut 6

26 22568 Location Tab Calibration Tray 6

27 45907 M6 X 12 Pan Pozi Z/P M/C Screw 6

‘Renovator TFD’ Dual Seedbox Assembly

Page 66

64

‘Renovator TFD’ Agitator Shaft Assembly

ITEM PART No. DESCRIPTION QTY

24R 28R

1 72141 3.0m 24R TFD Agitator Shaft 2 -

1 72274 3.5m 24R TFD Agitator Shaft - 2

2 72131 Joining Collar/Agitator Shaft 2

3 45185ss M10 x 10 St Stl Skt/Hd G/Screw 4

4 22423 Agitator Bearing Support Short 4

5 47600 M30 Iso Fine Hex Lock Nut Z/P 4

6 22428 Support Cap 2

7 45410sss M8 x 16 Grade 316 S/S S/Screw 4

8 45137ss M8 Nyloc Nut Grade 316 S/S 4

3

6

7

812

45

4 5

Page 67

65

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Seeder Mechanism

ITEM PART No. DESCRIPTION QTY

24R 28R

1 43375 Metering Housing 48 56

2 43376 Shutter Slide 48 56

3 43377 Seed Metering Wheel Assembly (Includes item 4) 48 56

4 43374 Fine Seed Wheel (For Spares Ordering Only) -

5 43378 Bottom Flap & Bolt Assembly 48 56

6 22550 Seeder Extension Funnel 48 56

7 22551 Seed Diverter 48 56

8 22548 Spring Clip, S/S 48 56

9 43379 Seed Shaft Guide Bearing 6

10 43380 Guide Bearing Tension Spring 6

11 43382 Metering Wheel Clutch Hook 1

12 43362 Fine Seed Wheel Brush (Optional Extra) -

8

1

6

5

42 3

7

9

1011

Page 68

66

‘Renovator TFD’ Blank Page

Page 69

67

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Gearmotor Drive - Front Bin

1

234

798

5

19

10 12

13

15 16 17

18

Refer to parts list on Page 69

11

6

14

Page 70

68

‘Renovator TFD’ Gearmotor Drive - Rear Bin

2 3 4 5

1

21

8

9

7

13

1012

15

20

Refer to parts list on Page 69

17 16

11

6

14

Page 71

69

Pt. No. 67415

Issue 0517

ITEM PART No. DESCRIPTION QTY

1 43943 450w Electric motor c/w 100:1 gbox 2

2 72125 15T Sprocket 3/8”P x 19mm Bore 2

3 45179 M8 x 8 Socket/Hd Grub Screw 2

4 44993S M8 X 25 Grade 8.8 Z/P S/Screw 8

5 72156 Seed Drive Shaft TFD 2

6 29146 Key 6 x 6 x 65 2

7 45150 M6 Light Flat Washer Z/P 6

8 45164 M6 Spring Washer Z/P 6

9 44951S M6 x 16 Grade 8.8 Z/P S/Screw 6

10 22413 3/8” B.S.Chain X 35 Links 2

11 43396 3/8” Pitch Joiner Link 2

12 22418 21T Sprocket 3/8”p X 20mm Bore 2

13 45187 M10 x 16 Socket/HD Grub Screw 4

14 43428 Nylon Bush 2

15 72123 Agitator Shaft Extension 2

16 45157 M8 H/D Flat Washer Z/P 8

17 45137 M8 Nyloc Nut 8

18 72118 Motor Mount W/Assy Front Drive 1

19 72128 Motor Guard Front Drive 1

20 72132 Motor Mount W/Assy Rear Drive 1

21 72187 Motor Guard Rear Drive 1

‘Renovator TFD’ Gearmotor Drive - Front / Rear Bin

Page 72

70

‘Renovator TFD’ Electric Drive

TO MOTOR

TO LOOM

TO LOOM

60 AMP

60 AMP

1

2 3 4

5

6

7

BOX 1 LEVEL

RIGHT

BOX 1 LEVEL

LEFT

AREA

CUT-OUT

MCM 1

FORWARD

SPEED RADAR

MCM 2

BOX 1 PRIME

SWITCH

BOX 1 SHAFT

CONFIRMATION

MOTOR/GEARBOX

MOTOR/GEARBOX

BOX 2 LEVEL

RIGHT

BOX 2 LEVEL

LEFT

BOX 2 PRIME

SWITCH

BOX 2 SHAFT

CONFIRMATION

8

9

11 12

13

14

16

17

17

18

15

7

2419

Page 73

71

Pt. No. 67415

Issue 0517

ITEM PART No. DESCRIPTION QTY

1 43952 Tractor Power Lead c/w Fuse Assembly 1

2 44040 Drill Power Lead 1

3 44041 Fuseholder with fuse -60 Amp 1

4 43984 60Amp Maxi Fuse (Blue) 2

5 44042 Red power cable 250mm long. M5 Ring 12-10 AWG 2

6 44043 Yellow/Green earth cable 250mm long. M5 Ring 12-10 AWG 2

7 44025 Motor Control Module (Cinch Connector) 2

8 43943 450watt, 100:1 g/box & 100ppr Encoder 2

9 44047 Duncan PSi Console 1

10 43983 PS Console Mounting Bracket (In cab) 1

11 43982 Duncan PS Instrument Lead 1

12 44048 Drill Harness to Tractor 1

13 44049 Box 1 Harness 1

14 44050 Box 2 Harness 1

15 43948 0.5m Level Sensor c/w Connector 4

16 43950 0.5m Priming Switch c/w Connector 2

17 43949 0.5m Shaft Speed Sensor c/w Connector 2

18 44054 Area cutout sensor 2.2m 1

19 44053 Radar extension lead 2.2m 1

20 43958 Magnet Ring 2

21 45368SS M10 Starlock Fixing Washer 2

22 45158 M10 Heavy Duty Flat Washer 2

23 29339 Shaft Confirmation Sensor Bracket 2

24 44111 Radar 1

‘Renovator TFD’ Electric Drive

Sensor includes nut

& lock washers

20

22

21

23

17

Page 74

72

‘Renovator TFD’ Electric Drive (continued)

Sensor includes nut

& lock washers

1

2

3

8

7

6

4

5

4 9

13

10

12

14

1615

18

11

17

Page 75

73

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Electric Drive (continued)

ITEM PART No. DESCRIPTION QTY

1 26702 3.5” x 6.5” Master Rephasing Cylinder (Includes pin) 1

2 72207 Activator Arm TFD 1

3 43956 Bar Magnet (Wheel Ram Sensor) 2

4 44954S M6 x 25 Grade 8.8 Z/P S/Screw 6

5 45164 M6 Spring Washer 2

6 44082 Hose Clamp St Stl 82-108 Dia 1

7 44054 Shaft Sensor M12 2.2m Lead 1

8 29129 Wheel Sensor Mount 1

9 45122 M6 Grade 8.8 Hex Nut Z/P 4

10 45150 M6 Light Flat Washer 4

11 45136 M6 Nyloc Nut 4

12 63160 MCM Bracket 2

13 44041 Fuseholder with fuse -60 Amp 1

14 43984 60Amp Maxi Fuse (Blue) 1

15 45146 M5 Nyloc Nut 8

16 45124 M5 Flat Washer 8

17 45142 M5 x 25 25 Grade A2-70 Set Screw 8

18 44025 Mk2 Motor Control Module 2

Page 76

74

‘Renovator TFD’ Electric Drive (continued)

1 2

3

4

5

Radar includes

mounting screws

& washers

6

Page 77

75

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Electric Drive (continued)

ITEM PART No. DESCRIPTION QTY

1 44111 Radar 1

2 72150 Radar Mounting Bracket 1

3 45068 M20 x 80 Grade 8.8 Z/P Bolt 2

4 45141 M20 Nyloc Nut 2

5 45053 Radar Extension lead 3m 1

6 43950 Priming Switch c/w 2way Amp ss (0.5m lead) 2

Page 78

76

‘Renovator TFD’ Rear Tow Hitch

3

5

4

2

1

6

Page 79

77

Pt. No. 67415

Issue 0517

‘Renovator TFD’ Rear Tow Hitch

ITEM PART No. DESCRIPTION QTY

72220k Rear Tow Kit (Plain) comprises items 1 to 3 below:- -

1 63035 Rear Towhitch Welded Assembly 1

2 45140 M16 Nyloc Nut 8

3 45047 M16 x 90 Grade 8.8 Z/P Bolt 8

4 63297 Tine Harrow Stub Assembly 2

5 45040 M16 x 50 Grade 8.8 Z/P Bolt 8

6 45140 M16 Nyloc Nut 8

7 72221k Rear Tow Kit (Tine Harrow) TFD 1

Note: Item 7 contains all parts shown (1 to 7) above

See Page 79 for configurations for fitting Tine Harrow

Page 80

78

‘Renovator TFD’ Tine Harrow (Optional)

25

13

3

12

2

6

14

16

9

11

12

8

5

4

18

15

14

19

17

24

23

11

212220

7

8

10

15

27

26

11 28

11

9

15

1

Page 81

79