USER GUIDE

Please read this user guide

for important health & safety

instructions and to get the best

results every time. Retain it for

future reference.

IMPORTANT INFORMATION –

please read before you start

• Carefully read the complete user guide before use and

always follow instructions including those on the paint

pack packaging.

• Keep user guide in a safe place for future reference.

• Dispose of all waste packaging properly.

• The PaintPod is for indoor use only.

• Only use PaintPod paint packs, parts, products

and accessories.

• Always wear protective clothing and as with all

decorating, cover furnishings, ooring etc.

• Keep area around your work place clean and tidy to

help avoid accidents.

• Ensure children and animals are kept away at all times

whilst operating the PaintPod.

• Always place and use the PaintPod on a at, stable

and horizontal surface.

• Always unplug the PaintPod after use.

• Keep power lead away from water, heat, oil, sharp

edges and moving parts.

• Keep the PaintPod away from sources of heat, naked

ames or ignition.

• Only use clean warm water to clean the PaintPod.

• Clean the PaintPod thoroughly after each use to

ensure it works effectively next time.

• Only store the PaintPod when clean and dry.

• Dispose of waste water by pouring down the sink.

• DO take care not to trip over the power lead or

delivery tube.

• ONLY USE a CR2032 3v battery in the roller handle.

• WARNING Fire Hazard! DO NOT incinerate waste

batteries.

• DO NOT dispose of batteries as household waste.

Dispose of or recycle according to local authority

guidelines.

• DO NOT store batteries in any location where

temperatures may exceed 40°C.

• DO NOT tamper with the battery.

• When replacing battery, follow manufacturer

instructions.

DO

DO NOT

BATTERIES

MAINS CONNECTION

DISPOSAL

• DO NOT use any other paint with the PaintPod.

Dulux PaintPod paint is specially formulated.

• DO NOT modify the PaintPod.

• DO NOT place PaintPod on ladders or on stair treads.

• DO NOT use hot or boiling water to clean the

PaintPod.

• DO NOT use solvents, detergents chemical or abrasive

cleaners to clean the inside or outside of the PaintPod.

• DO NOT pour paint directly into the PaintPod.

• DO NOT use the PaintPod if any parts of it are

damaged, excessively worn, faulty or missing.

• DO NOT put any object or part of your body near any

moving parts of the PaintPod.

• DO NOT use the PaintPod with wet hands.

• DO NOT use the PaintPod in explosive atmospheres.

• DO NOT pour waste water into rain water drains, natural

water courses or on to land.

• DO NOT pull the unit by either the power lead or

delivery tube.

The PaintPod is supplied with a power lead and a tted

3 amp fused plug. It operates at low voltage

and is connected to a separate power supply unit.

IMPORTANT: Please read the following safety

instructions carefully before use.

• DO only use the PaintPod power supply provided.

• If a replacement plug is tted, dispose of the old

plug safely.

• DO NOT use the PaintPod if the power lead

is damaged.

• DO NOT use the PaintPod or power lead without the

plug’s top cover tted.

• ONLY USE 3 amp replacement fuses. Replacement

fuses must conform to BS1362.

• WARNING: IF IN ANY DOUBT PLEASE CONSULT

A QUALIFIED ELECTRICIAN.

Once the product has reached the end of its useful life

or if it has become damaged outside of the one year

guarantee, please dispose of the PaintPod roller system

correctly. Do not dispose of the PaintPod roller system

as household waste. Take to your local authority waste

electrical equipment disposal centre.

1

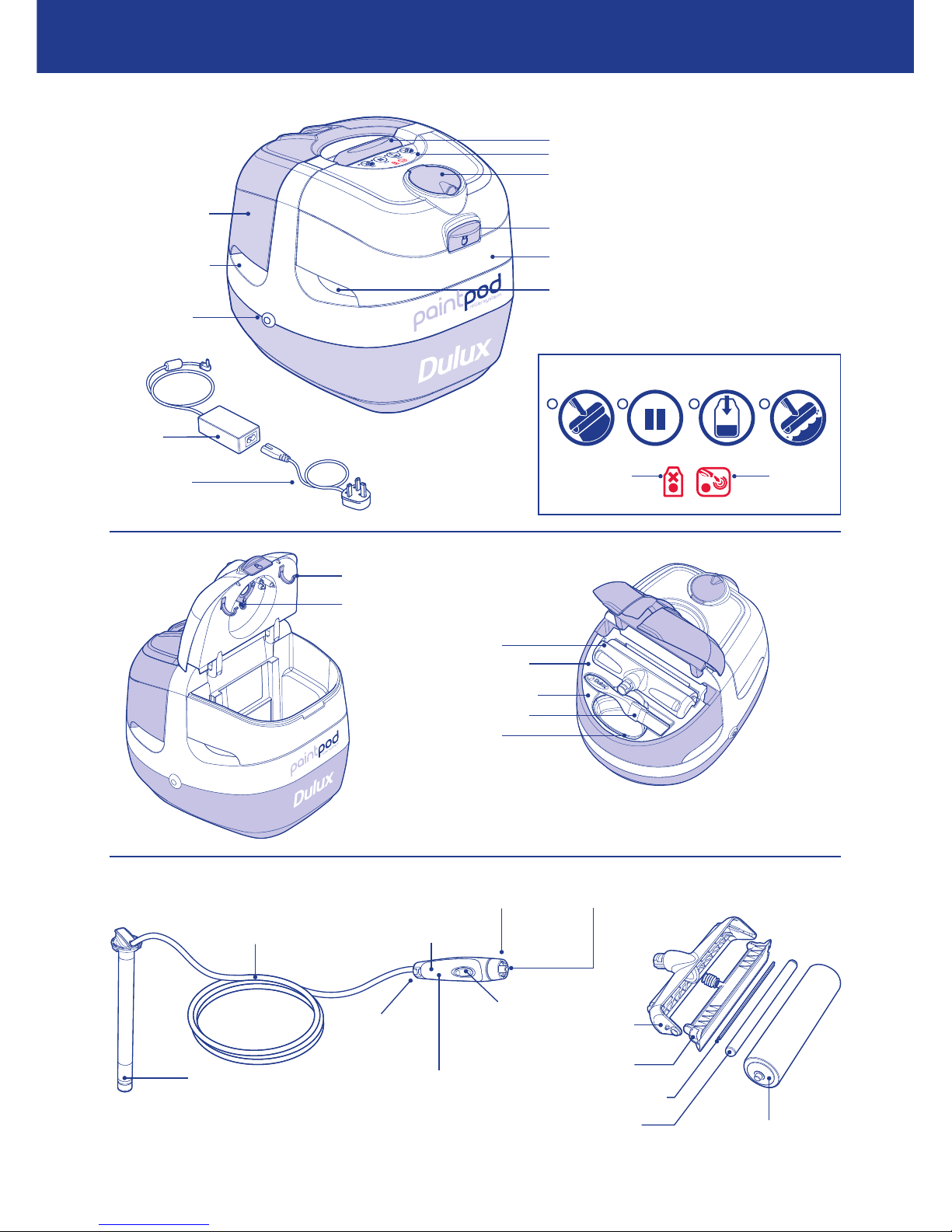

GETTING TO KNOW YOUR PAINTPOD

Dip tube rest

Dip tube wipe

2

Battery

compartment

Paint loading

trigger

Roller handle

Roller head

release button

Roller head

connector

Dip tube

Delivery tube

Battery

compartment

release button

Feeder tray

Roller head

Distribution plate

Feeder roller

Roller sleeve

Control panel

Clean

warning

Paint pack

warning

CLEANDRAINPAUSEPAINT

Blue chamber

Blue chamber

handle

Power lead

input

Carry handle

Dip tube cover

Lid release

White chamber (front)

White chamber handle

Control panel

Power lead

Power

supply unit

IMPORTANT: The dip tube and delivery tube

are a single unit. DO NOT pull apart.

Roller head

Docking station

Spout

(hidden by brush)

Triangular brush

Edging cup

The PaintPod is a power assisted roller system that enables you to control the

flow of paint onto the roller at all times. It has a unique triangular edging brush

which makes light work of edges and corners before walls are painted with the

roller. Finally, when you have finished, it cleans itself whilst you stand back and

admire your work!!

Visit either www.dulux.co.uk/paintpod or www.dulux.ie/paintpod for a step

by step product demonstration.

If you are experiencing technical difculties or need

product advice, visit our web site or Customer Advice

Centre.

UK

ICI Paints, Wexham Road, Slough, SL2 5DS

Tel: 0870 444 1111

www.dulux.co.uk/paintpod

ROI

ICI Dulux Paints Ireland, Commons Road, Cork

Tel: 021 422 0222

Fax: 021 422 0205

www.dulux.ie/paintpod

The guarantee is valid for one year from date of

purchase and covers the complete PaintPod roller

system, with the exception of the dip tube and

delivery tube.

This guarantee does not cover rectication or any

other costs.

We will repair the PaintPod roller system or replace

free of charge the complete unit or parts of, if it is

faulty due to a manufacturing or material fault.

The guarantee does not cover the application of the

PaintPod emulsion.

Nothing in this clause is deemed to exclude or restrict

liability for death or personal injury resulting from the

negligence of the manufacturer.

The following are specifically excluded from the terms

and conditions of this guarantee:

• Damage caused by misuse or improper handling

of the PaintPod roller system or damage due to

incorrect use in accordance with the instructions.

• Normal ‘wear and tear’.

• Damage suffered through negligence, wilful damage,

improper use or accidental damage.

• Any modications made by the purchaser to the

PaintPod roller system or repairs carried out by an

unauthorised service agent.

• Damage caused by immersion in water, damp, re,

natural light and atmospheric conditions.

This guarantee does not affect your statutory rights.

For advice on returns, contact the ICI Customer

Advice Centre in your country.

TECHNICAL PRODUCT ADVICE

EU STATEMENT OF COMPLIANCE

PRODUCT SPECIFICATION

GUARANTEE

3

The PaintPod unit conforms to:

This product complies with WEEE Directive 2002/96/

EC and ROSH Directive 2002/95/EC

EMC EN 301 489-3 v1.4.1 (2002-08)

Radio frequencey EN 300 220-2 v2.1.1 (2004-06)

Power supply unit EN 60950

Model No: A466000150N

Voltage: 240v – 12v – 3 amps

Length: 450mm

Width: 340mm

Depth: 350mm

Unit weight: up to 12.5kgs

including paint

THE FAST, EASY AND CLEAN WAY TO DECORATE

CONTENTS

4

SECTIONS PAGES

IMPORTANT INFORMATION

GETTING TO KNOW YOUR PAINTPOD

USING YOUR PAINTPOD

Setting up

Painting edges and corners

Painting walls and ceilings with the roller

Taking a break

Moving to a new location

Inserting a new paint pack

CARING FOR YOUR PAINTPOD

Draining and cleaning

Storage

Replacing the dip tube and delivery tube

Removing and replacing the roller sleeve

Replacing the battery

TROUBLE SHOOTING

Accessories

Spare parts

Dip tube replacement chart

1

2 – 3

5

6

7

8

8

9

10 – 12

12

13

13

14

15 – 16

16

16

Back cover

USING YOUR PAINTPOD

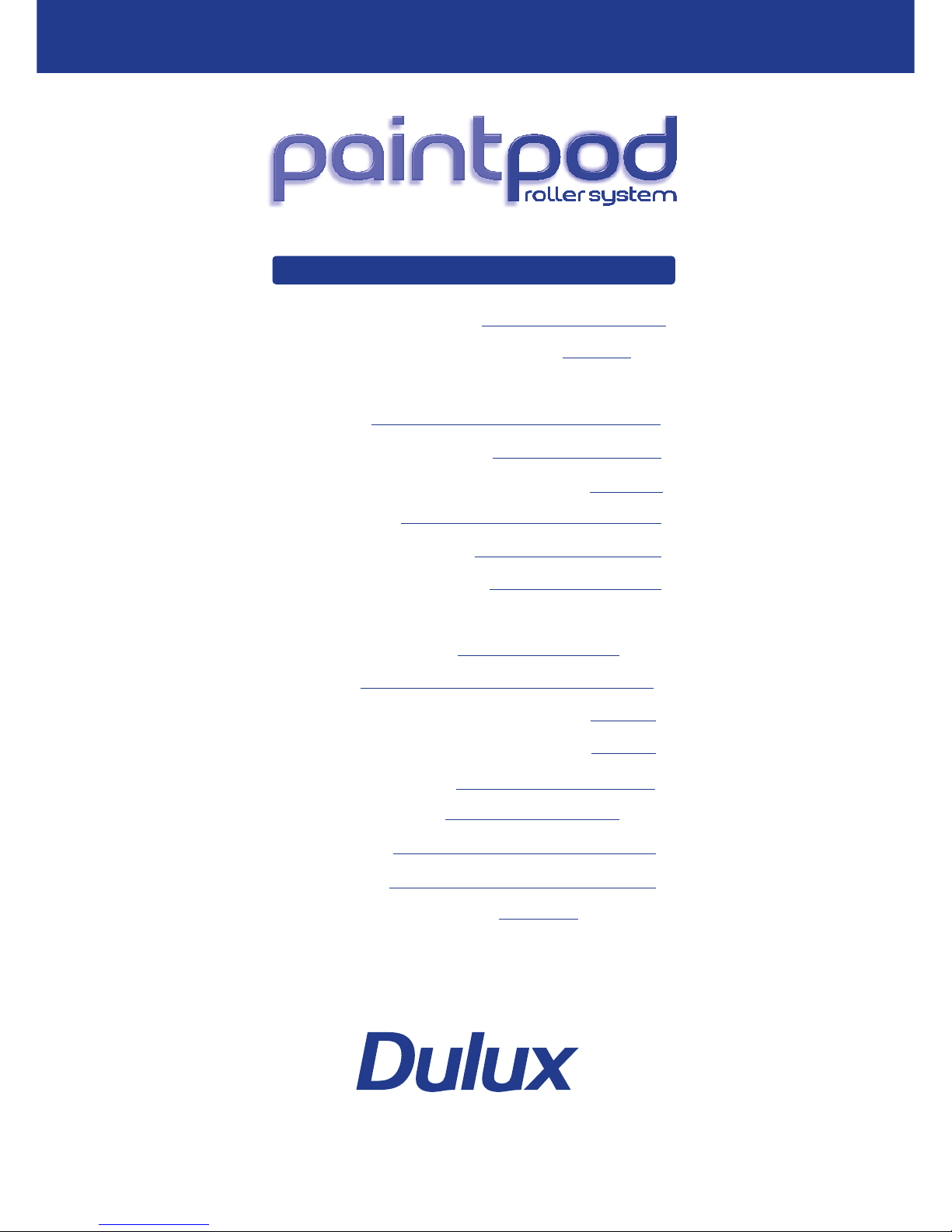

SETTING UP

a

Plug mains power lead into power

supply unit. Connect one end

of the power lead to power lead

input on the PaintPod and the

other to a mains socket. The lights

on the PaintPod will ‘ash’ twice

and make a noise to show it is

connected to the mains

power supply.

Always set up the PaintPod in the room to be painted.

Lift the lid release of the white chamber and remove the contents.

Gently shake the paint pack

(not supplied) for approximately

10 seconds before unscrewing

the lid.

Peel off the foil seal.

Lift lid release of white chamber

and place paint pack inside.

Ensure paint pack is facing the

right direction – the dip tube hole

on the paint pack must face the

front of the white chamber.

IMPORTANT: If dip tube hole on the paint pack is NOT facing the front of the white chamber the paint pack

warning light will illuminate when the ‘paint’ button is pressed and the PaintPod will not operate. If this

happens, lift lid and re-insert paint pack in the correct position.

d

e

f

Fold down paint pack handle and

close the white chamber lid.

IMPORTANT: Check paint pack

warning light is NOT illuminated

then lift dip tube cover and fully

insert dip tube into PaintPod.

Twist dip tube clockwise to lock

and ‘click’ into position. Ensure

dip tube is locked correctly

otherwise pump will not work

Close dip tube cover.

for wall and ceilings

I

M

P

O

R

T

A

N

T

I

N

F

O

R

M

A

T

I

O

N

PLEASE READ

THEN REMOVE BEFORE

INSERTING PACK

PAINTPOD emulsion pask MUST be

placed into the PaintPod rooler system

with the drip tube hole facing

the front of the unit

b

c

for wall and ceilings

emulsion

White

Chamber

Dip

tube

hole

When ready to paint

Press ‘paint’ button. The blue light

will illuminate.

for wall and ceilings

splatter free ultra smooth finish

5

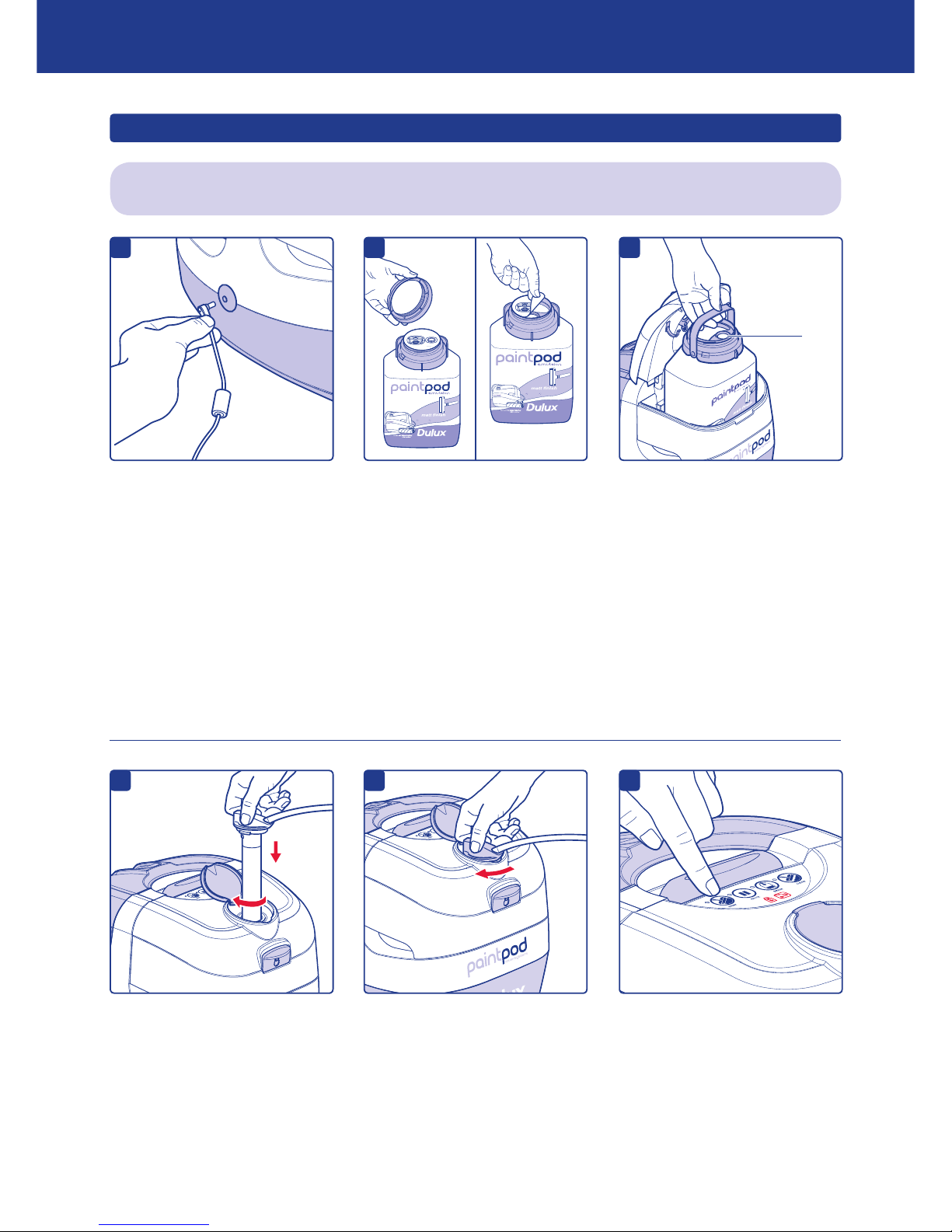

PAINTING EDGES AND CORNERS

d

Remove spout, triangular brush

and edging cup from docking

station.

Using both hands lift blue lid as

shown.

For best results use the triangular brush to paint the edges and corners before using the roller.

Insert the spout onto roller handle.

It will ‘click’ when tted.

Ensure ‘paint’ button is

illuminated. Squeeze paint loading

trigger to pump paint into edging

cup. Release trigger to stop

paint ow.

IMPORTANT: When paint loading

trigger is released the sound will

change. This is normal.

f

Using the triangular brush paint

the edges and corners.

Rell edging cup if necessary.

b

Triangular

brush

Spout

(hidden

by brush)

Edging

cup

a

USING YOUR PAINTPOD

Press ‘pause’ button.

e

When nished remove the spout

by pressing the handle release

button on the handle. Wipe roller

head connector thoroughly, rinse

the edging cup, triangular brush

and spout thoroughly with warm

water and allow to dry.

c

Spout ridge

6

USING YOUR PAINTPOD

7

PAINTING WALLS AND CEILINGS

d

Ensuring roller head connector is

free from paint, push t the handle

securely onto the roller head.

Lift the handle upwards and

remove the roller head from the

docking station.

Remove the paper label.

The PaintPod makes painting easy, fast and clean. However it may take a little time to perfect your

painting technique. Practice using the roller before starting.

Ensure ‘paint’ button is illuminated.

Start rolling the dry roller on the

wall and whilst in motion squeeze

paint loading trigger to load paint

onto roller.

Keep squeezing paint loading

trigger AND keep roller in motion

until it begins to load with paint.

When sufciently loaded, release

trigger and roll out paint to an

even nish.

IMPORTANT: Do not continually

squeeze the trigger, this will

overload the roller with paint

and may cause dripping. To

avoid, squeeze the trigger

INTERMITTENTLY and ONLY

when roller is in motion.

e

As paint is rolled onto the wall, the

roller will need to be reloaded with

more paint. WHILST CONTINUING

TO ROLL, squeeze paint loading

trigger to load paint onto roller.

When sufciently loaded, release

trigger and continue painting.

To keep your work area clean

and safe, place roller head in

the docking station in the blue

chamber when pausing.

IMPORTANT: The roller head

MUST be lowered down into the

cleaning station as shown so

it sits correctly when the lid is

closed.

c

a

Hold the delivery tube away

from the wall with your free

hand so it does not ‘brush’

against the wet paint.

b

1

2

f

1

2

7

TAKING A BREAK

To take a break during painting,

press ‘pause’ button.

Place roller head correctly in

docking station, close lid and

‘click’ shut.

IMPORTANT: If leaving for more

than 4 hours clean system

completely.

Follow instructions in

‘DRAINING AND CLEANING’.

a

b

Press ‘pause’ button and unplug

power lead from mains socket.

IMPORTANT: The PaintPod

and paint pack can weigh up to

12.5kgs. LIFT WITH CARE.

Press centre of carry handle to

release it and pull up.

Carry PaintPod to new location

and push handle down.

IMPORTANT: Lids cannot be

opened whilst carry handle is

raised.

Plug power lead into the mains

socket in the new location and

press ‘paint’ button to continue.

a

MOVING TO A NEW LOCATION

c

USING YOUR PAINTPOD

b

1

2

IMPORTANT:

The PaintPod and paint pack can weigh up to 12.5kgs. LIFT WITH CARE.

8

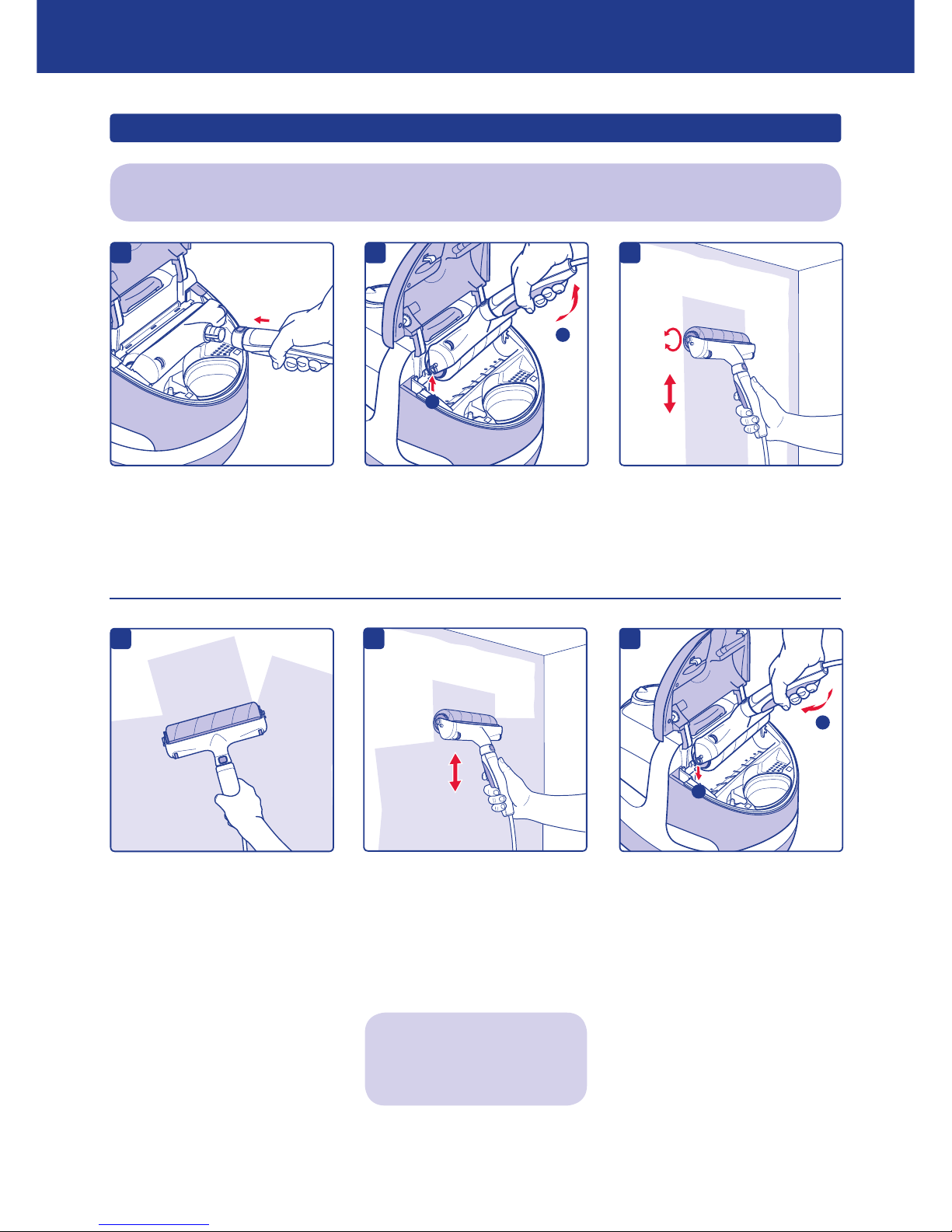

INSERTING A NEW PAINT PACK

d

Press ‘pause’ button on control

panel.

Place roller head correctly in the

docking station, close lid and

‘click’ shut.

9

Lift dip tube cover and twist dip

tube cap anti-clockwise to unlock.

Carefully remove dip tube from

PaintPod.

Any excess paint on dip tube will

be removed by dip tube wipe.

Whilst holding dip tube in one

hand, open lid of white chamber

and place dip tube onto dip tube

rests.

for wall and ceilings

emulsion

e

Remove empty paint pack and

replace with a new one. Follow

instructions in ‘SETTING UP’

(page 5).

IMPORTANT: Ensure paint pack

is facing the right direction.

Remove dip tube from resting

position, close lid and insert dip

tube back into PaintPod, locking

it into position. Follow instructions

in ‘SETTING UP’.

Press ‘paint’ button to resume

painting.

If a different paint colour is to be used, the PaintPod should be drained and cleaned. Follow instructions on

pages 10, 11 and 12.

USING YOUR PAINTPOD

c

Paint on the end of dip tube will

need to be removed with a rag.

a

1

2

b

1

2

f

1

2

CARING FOR YOUR PAINTPOD

DRAINING AND CLEANING

Draining

Leaving paint pack in PaintPod,

place roller head and roller handle

correctly in docking station, close

lid and ‘click’ shut.

As with a normal roller, clean as much excess paint as possible before cleaning by rolling on the wall or on

waste paper. Remove the triangular brush, edging cup and spout and rinse separately.

IMPORTANT: Ensure drain cycle is completed before paint pack is removed or before starting cleaning process.

Press ‘drain’ button to drain paint

back into paint pack – this takes

about 30 seconds and stops

automatically.

IMPORTANT: Paint residue will

still be visible on inside surface

of delivery tube.

Cleaning

Lift dip tube cover and twist dip

tube anti-clockwise to unlock.

Carfully remove dip tube from

PaintPod.

d

f

e

Any excess paint on dip tube will

be removed by dip tube wipe.

Paint on the end of dip tube will

need to be removed with a rag.

Using the handles, remove white

chamber and carry it to sink.

Whilst holding dip tube, open lid

of white chamber and place dip

tube onto dip tube rests.

Remove paint pack and replace

screw cap.

b

a

1

2

c

1

2

10

CARING FOR YOUR PAINTPOD

DRAINING AND CLEANING

Fill white chamber to level

indicated with 5 litres of warm

water and return it to the

PaintPod.

Remove dip tube from dip tube

rests and close lid.

Lift dip tube cover and insert dip

tube into PaintPod.

Twist dip tube clockwise to lock

and ‘click’ into position.

Close the dip tube cover.

Press ‘clean’ button to activate

cleaning cycle – this takes

about 10 minutes and stops

automatically when completed.

IMPORTANT: If ‘clean’ warning

light illuminates, check roller

head and handle are correctly

placed in the docking station.

j

Lift blue chamber lid and remove

roller handle from roller head

by pressing roller head release

button.

Hold delivery tube above

PaintPod and press ‘drain’ button

again to remove any excess water.

IMPORTANT: If roller contains

excessive paint, it may be

necessary to repeat the cleaning

cycle, using clean warm water.

To prevent spilling dirty water on

oor – DO NOT lift roller head from

docking station.

Remove roller head from docking

station. Remove roller sleeve from

roller head. Squeeze out excess

water and leave out to dry.

IMPORTANT: The roller fibres will

permanently adsorb some dye

from the colour of the paint being

used. This is more noticeable

with stronger colours.

IMPORTANT: In some instances

(e.g. if roller has been overloaded)

it may be necessary to give the

roller head components a more

thorough clean as described on

page 12. This will ensure that you

get maximum performance from

your PaintPod.

h

g

Using handles, lift blue chamber

out of the PaintPod and take to

the sink to empty the waste water.

DO NOT pour into rain water

drains, natural water courses or

onto land.

Any paint left on the roller head

connector should be removed

with a rag.

If necessary remove and clean

the roller head connector as

described on page 13.

k

Roller

head

connector

i

1

2

11

12

CARING FOR YOUR PAINTPOD

DRAINING AND CLEANING

STORAGE

Remove white chamber and

dispose of any water.

Dry and replace white chamber.

Ensure PaintPod and all parts

are completely clean and dry

before storage.

Do not store in moist or damp

environments.

The delivery tube should be stored

in the white chamber, taking care

that it is not kinked.

After storing PaintPod in

extremely cold temperatures,

allow it to reach room temperature

before use.

Remove dip tube wipe (by pushing

up) and rinse separately.

Ret the dip tube wipe by placing

over the lugs and pulling down.

n

Dip tube

wipe

Lug

m

Remove feeder roller from the

feeder tray and clean.

Ret feeder roller and roller sleeve

into roller head, (note: the roller

sleeve will only t one way into the

roller head).

If roller head needs extra cleaning

remove the roller head from the

handle. Wipe and dry the roller

head inlet.

Carefully pull out at one end of the

‘roller head’ and remove the roller

sleeve and clean.

l

Roller sleeve

Roller head inlet

a

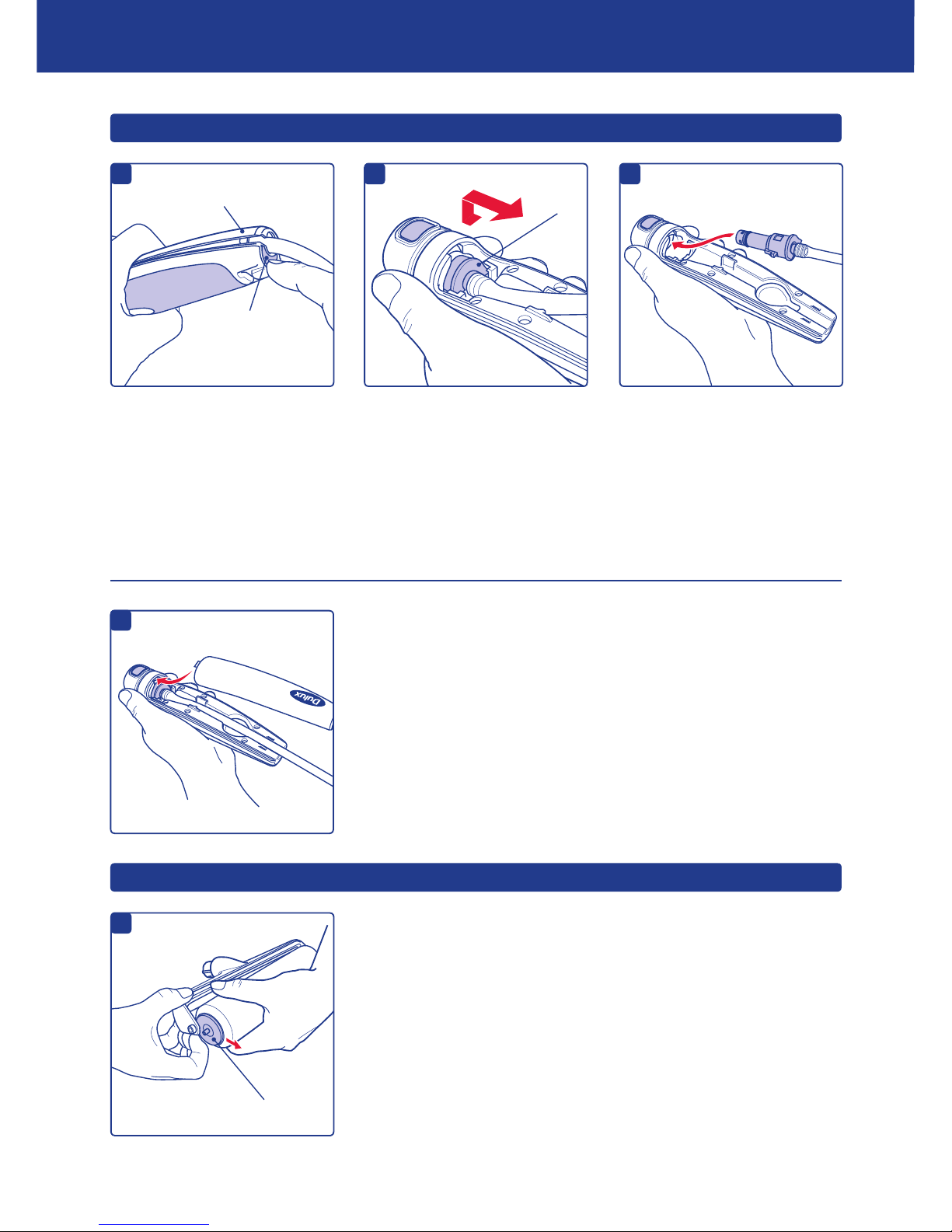

CARING FOR YOUR PAINTPOD

REPLACING THE DIP TUBE AND DELIVERY TUBE

REMOVING AND REPLACING THE ROLLER SLEEVE

c

Remove the battery compartment

cover by pressing the battery

compartment release button on

the end of the handle assembly.

Remove the roller head from the

handle.

Carefully pull out at one end of the

‘roller head’ and remove the roller

sleeve.

Clean or replace the roller sleeve

and ret into the roller head. The

roller sleeve will only t one way

into the roller head. Make sure the

distribution plate and feeder roller

are in position.

Whilst holding the delivery tube,

gently push forward and lift the

roller head connector upwards to

remove from handle.

Insert the new roller head

connector (attached to delivery

tube) back into handle and gently

push forwards and down. It will

‘click’ when inserted correctly.

IMPORTANT: DO NOT force the

roller head connector, it will only

go in one way.

d

Place the delivery tube into its

holding position (in handle) and

replace the white handle cover. It

will ‘click’ when replaced correctly.

The replacement dip tube and

delivery tube are now ready for use.

Please dispose of the used dip

tube and delivery tube with normal

household waste.

a

Battery compartment cover

Battery compartment

release button

a

Roller sleeve

b

Roller

head

connector

13

CARING FOR YOUR PAINTPOD

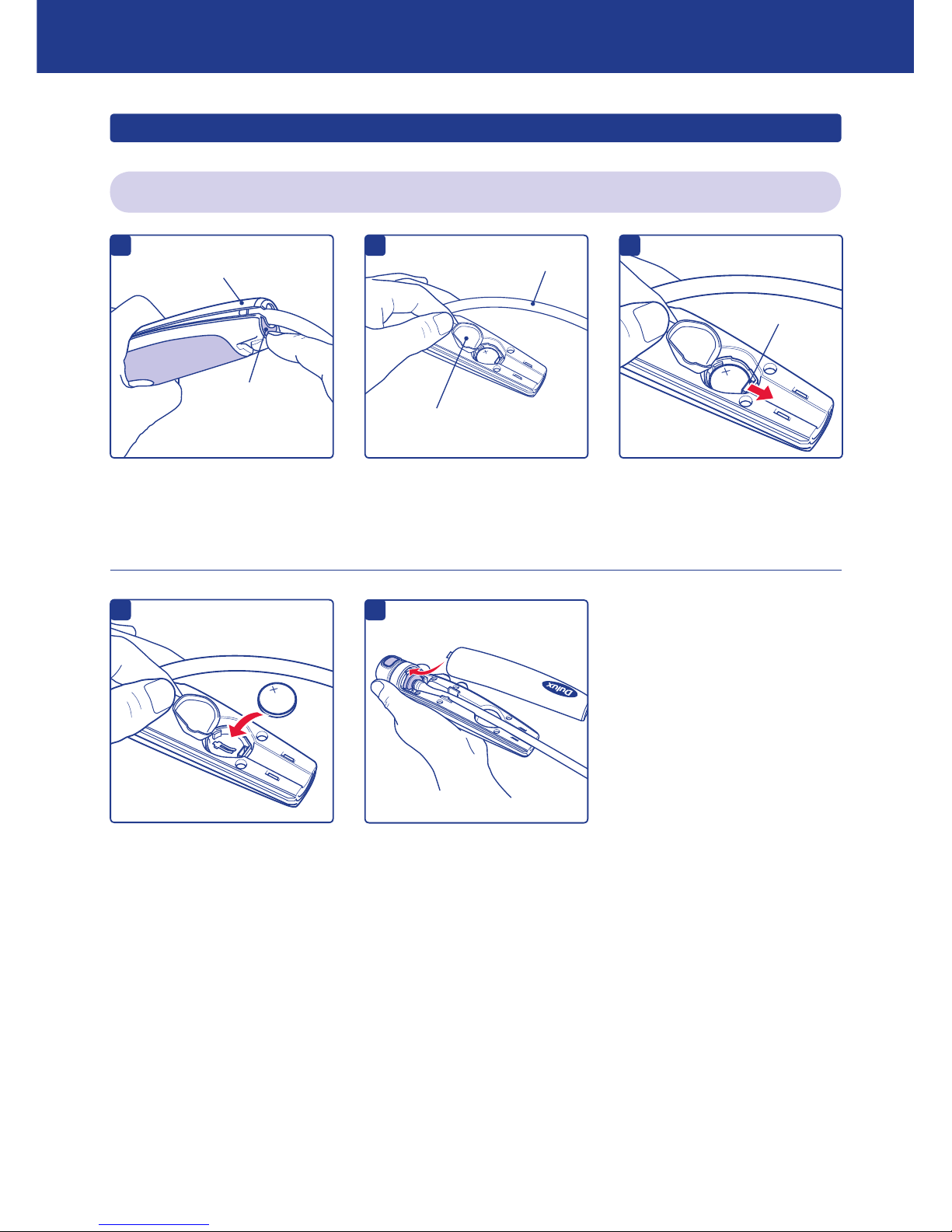

REPLACING THE BATTERY

Remove the battery compartment

cover by pressing the battery

compartment release button on

the end of the handle assembly.

Move the delivery tube aside.

Pull the tab of the rubber cover up

to expose the CR2032 3v battery.

Release the battery by pushing

the metal holding clip down.

CR2032

3V

d

Replace the battery the correct

way up and ensure the metal

holding clip keeps the battery in

place. Reposition the rubber cover

and delivery tube.

Replace the battery compartment

cover. It will ‘click’ when replaced

correctly.

Please dispose of the used battery

as stated in the BATTERIES

section on page 1.

CR2032

3V

b

Delivery tube

Rubber cover

CR2032

3V

c

Metal holding clip

e

a

Battery compartment cover

Battery compartment

release button

Replacement CR2032 3v batteries can be purchased from leading retailers.

14

TROUBLE SHOOTING

15

SYMPTOM POSSIBLE CAUSES ACTION

Unit does not power up and/

or cuts out during use.

Paint pack warning light

illuminated.

Unit does not start pumping

paint or occasionally cuts out

during painting.

Insufcient/no paint owing

onto roller sleeve.

Paint dripping/splatter during

painting.

Roller handle is difcult to

insert into roller head.

Roller will not rotate during

painting.

Power lead not inserted correctly. Insert power lead correctly (page 5).

Power lead has been pulled out of

PaintPod unit.

Reinsert power lead (page 5).

Power lead is not plugged into

mains socket.

Plug 3 pin plug into mains socket (page 5).

Mains power is not turned on. Turn on mains socket (page 5).

Power lead is damaged. Replace power lead.

No paint pack in the PaintPod. Place paint pack into the white chamber and follow user

guide (page 5).

Paint pack is inserted into white chamber

the wrong way around.

Remove paint pack and replace ensuring dip tube hole inside

the pack is facing the correct way (see foil lid or user guide

– page 5).

The white chamber lid is not closed

properly.

Open and reclose the lid ensuring that it clicks closed.

Paint pack still present in white chamber

whilst trying to clean.

‘Drain’ the paint back into the pack. Remove pack from white

chamber before starting the cleaning program (page 10).

Battery in handset is at. Replace battery in roller handle (page 14).

Battery missing from handset. Replace battery in roller handle (page 14).

Two or more PaintPods in the same room. The rst time the trigger on the roller handle is pressed its

identity (ID) is transmitted from the handle and stored in the

unit. This occurs each time the unit is powered up. Pairing of

the handle and the unit occurs after pressing the paint button

once on the control panel. Ensure you only ‘pair’ ONE unit at

a time.

Dip tube pump wear. Replace dip tube.

Tube twisted, kinked or pinched off. Straighten, or replace dip tube.

Inadequate cleaning on previous use

(instructions not followed) leading to

blocked dip tube.

Replace dip tube.

Dip tube not engaged correctly. Check orientation of dip tube (page 5).

Battery in handset at. Replace battery in roller handle (page 14).

Paint pack empty. Replace paint pack (page 9).

Not using paint loading trigger sufciently to

load paint.

Use paint loading trigger whilst rolling roller to load paint

onto roller.

Constant pressure on paint loading trigger

leading to overloading of paint into feeder

tray during painting and not rolling/rolling

fast enough to distribute paint.

Immediately release paint loading trigger and roll out excess

paint onto wall/ceiling. Then use paint loading trigger as

directed in user guide (page 7).

Roller sleeve old and worn. Replace roller sleeve (page 13).

Roller sleeve is wet from previous use. Remove sleeve from roller head, squeeze out excess water

and allow to dry.

Water in tube from previous cleaning cycle. Roll roller onto dry cloth to remove excess water before

painting. If you notice water in the tube before painting then

excess water can be drained by using the drain cycle.

Feeder roller not in place. Correctly place feeder roller into feeder tray.

Feeder tray has become detatched from

roller head.

Reassemble feeder tray.

Paint contamination of either handle

coupling or roller head connector.

Remove any paint contamination or replace dip tube if

contamination is excessive (page 12).

Constant pressure on paint loading trigger

leading to overloading of paint into feeder

tray during painting and not rolling/rolling

fast enough to distribute paint.

Immediately release paint loading trigger and roll out excess

paint onto wall/ceiling. Then use paint loading trigger as per

instruction.

16

A range of spare parts are available for you to order

either on line or by telephone.

If the item required is claimable under the guarantee

(within 12 months of purchase) then please phone:

UK: 0870 444 1111

ROI: 021 422 0222

If the item required is not under guarantee then

please order on:

UK: 0844 844 2625 or www.dulux.co.uk/paintpod

ROI: 01 459 6021 or www.dulux.ie/paintpod

White chamber (A466900050P)

Blue chamber (A466900150P)

Docking station (A466900250P)

Edging cup (A466900350P)

Edging spout (A466900450P)

Roller cage (A466900550P)

(Including: Roller head, Feeder tray,

Distribution plate and Feeder roller)

Dip tube wipe (5 per pack) (A466900650P)

Roller handle (A466900750P)

Dip tube rest (2 per pack) (A466900850P)

Power supply unit (A466900950P)

SPARE PARTS

Visit either www.dulux.co.uk/paintpod or www.dulux.ie/paintpod for more technical advice.

Cleaning button does not

activate cleaning cycle.

Cleaning cycle does not

clean/effectively clean tube.

Cleaning cycle does not

clean/effectively clean roller.

Drain cycle has not been carried out. Carry out drain cycle (page 10).

Paint pack still in place. Carry out draining and cleaning cycle (page 10).

Roller not docked in docking station

correctly (clean warning light will be

illuminated).

Place in docking station according to user guide

(page 10).

Dip tube pump wear resulting in slow/no

pumping of water.

Replace dip tube.

Inadequate cleaning on previous use

leading to blocked dip tube.

Replace dip tube.

Delivery tube twisted, kinked or otherwise

damaged.

Straighten, or replace delivery tube.

Cold water used. Repeat cleaning cycle using warm water (page 11).

Roller handle not attached to roller head. Ensure handle is completely engaged.

Dip tube not engaged properly. Check orientation of dip tube (page 5).

Roller sleeve old and worn. Replace roller sleeve (page 13).

Blue chamber lid not closed. Check and close completely until ‘clicked’ into position.

Docking station not correctly located. Check location and ensure that lid closes completely.

Roller not engaged in correct position. Ensure roller is placed in position as per user guide.

Dip tube pump wear resulting in slow/no

pumping of water.

Replace dip tube.

Cold water used. Repeat cleaning cycle using warm water (page 11).

SYMPTOM POSSIBLE CAUSES ACTION

For convenience when painting ceilings and other high

areas, an Extra reach handle and 2 Metre extension

tube are available. These items plus the accessories

listed below are available from your local DIY retailer.

ACCESSORIES

Roller sleeve

(A466000250N)

Dip tube and delivery

tube (4 metre)

(A466000350N)

2 Metre

extension tube

(A466000450N)

Extra reach handle

(A466000550N)

Edging brush

(A466000650N)

TROUBLE SHOOTING

Dulux, PaintPod and the distinctive

livery are trademarks of ICI.

A466000150N. DATE: FEBRUARY 2008

IMPORTANT: The dip tube contains a pump which

has an optimum performance life of 10 packs

(approximately 50 litres of paint). After this time,

the pump performance will begin to deteriorate and

should be replaced.

Use the chart below to record the number of paint

packs you have used so you know when to replace

dip tube.

To replace see: ‘REPLACING THE DIP TUBE AND

DELIVERY TUBE’ on page 13.

DIP TUBE REPLACEMENT

PaintPod roller system record 1

Time to replace

Dip tube

PaintPod roller system record 1

Time to replace

Dip tube

PaintPod roller system record 2

Time to replace

Dip tube

PaintPod roller system record 3

Time to replace

Dip tube

Loading...

Loading...