Duke Manufacturing FLEXIBLE BATCH BROILER - CE Operation Manual

Installation & Operation Manual

FLEXIBLE BATCH BROILER - CE

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, Missouri

800-735-3853 • 314-231-1130 • Fax 314-231-5074

www.dukemfg.com

175820D

AS OF: 2/15/08

FLEXIBLE BATCH BROILER

RESTAURANT

EQUIPMENT MANUAL

Page 2 of 31

INDEX

PAGE

I. General Information ..........................................................................3

A. Batch Broiler Specifications................................................................................. 3

A-1.0 Model Number Key .................................................................................. 4

A-2.0 Broiler Dimensions ................................................................................... 4

II. Installation Instructions....................................................................5

A. Qualified Personnel ...........................................................................................5

B. Delivery and Inspection .....................................................................................5

C. Broiler Assembly................................................................................................ 6

D. Adjustments at Installation…………………………………………………………..7

E. Location of the Broiler........................................................................................ 8

F. Gas Piping ......................................................................................................... 8

G. Electrical Connections....................................................................................... 8

H Ventilation.......................................................................................................... 8

III. Operation Instructions.....................................................................9

A. Broiler Controls .................................................................................................. 9

B. Cooking Product ................................................................................................ 10

B-1.0 Lighting the Broiler ................................................................................... 10

B-2.0 Cook Product ........................................................................................... 10-11

B-3.0 Cook Cycle Complete .............................................................................. 11

B-4.0 Fine Cooking Adjustment......................................................................... 11

B-5.0 Cancel a Cook Cycle ............................................................................... 11

B-6.0 Checking the Broiler Temperature........................................................... 11

B-7.0 Checking the Set Point Temperature....................................................... 11

B-8.0 Shutdown the Broiler................................................................................ 11

C. Cleaning............................................................................................................. 12

C-1.0 Four (4) Hour Cleaning ........................................................................... 14

C-2.0 Daily Cleaning.......................................................................................... 15-16

C-3.0 Weekly Cleaning ...................................................................................... 17-21

C-4.0 Monthly Cleaning ..................................................................................... 22-23

D. Troubleshooting................................................................................................. 24-26

IV. Service and Repair ..........................................................................27

V. Replacement Parts List ...................................................................28-29

VI. Wiring diagram.................................................................................30

VII. Customer Assistance .....................................................................31

FLEXIBLE BATCH BROILER

POST IN A PROMINENT LOCATION

vicinity of this or any other appliance.

RESTAURANT

EQUIPMENT MANUAL

Instructions to be followed in the event the user smells gas. This

information shall be obtained by consulting the local gas supplier.

Do not store or use gasoline or other flammable vapors or liquids in the

FOR YOUR SAFETY:

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating

and maintenance instructions thoroughly before installing or servicing this

WARNING:

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

I. General Information

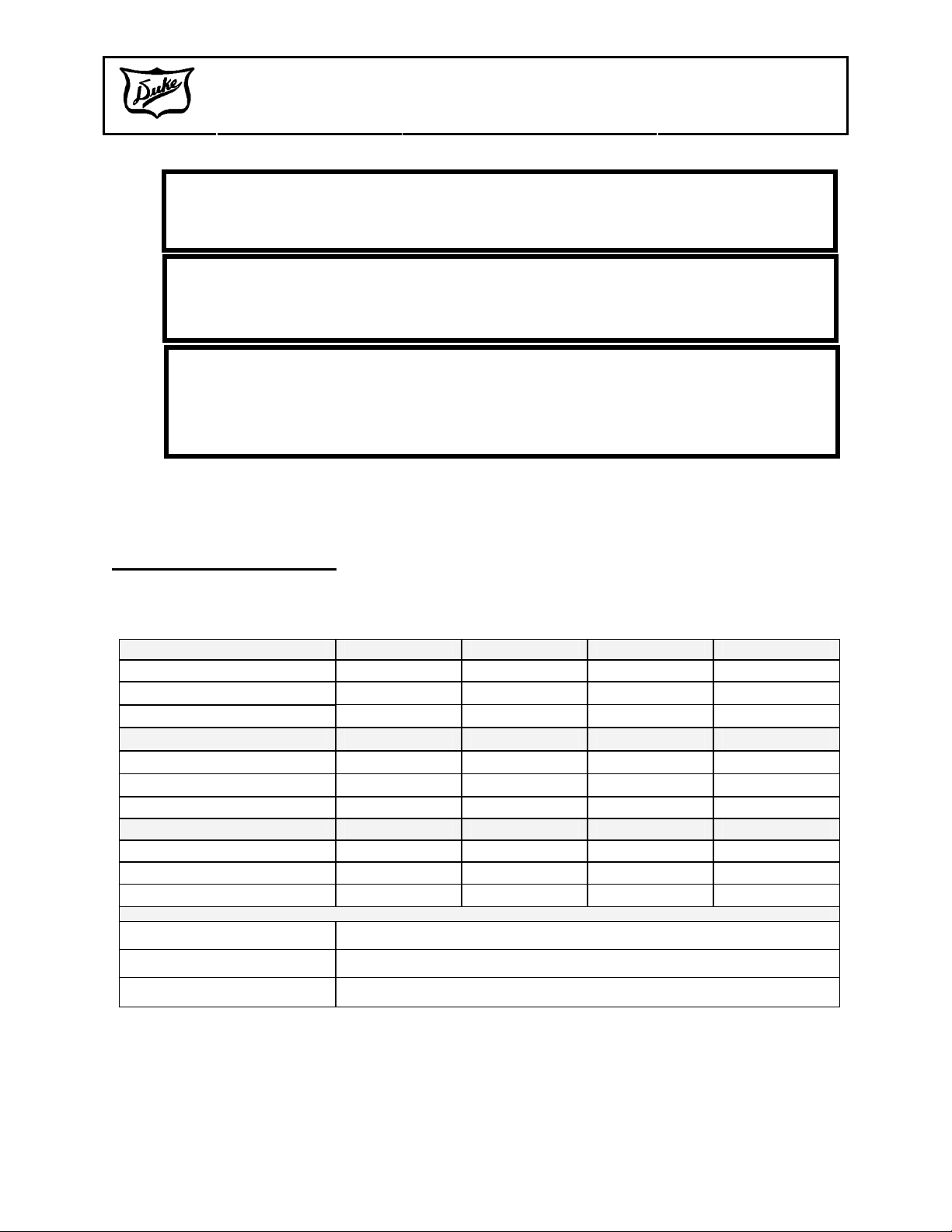

A. Batch Broiler Specifications

ALTITUDE (MAXIMUM) 607 m 607 m 607 m 607 m

GROSS HEAT INPUT 29.4 KW 29.4 KW 25.2 KW 25.2 KW

GAS PIPE CONNECTION 12.7mm BSPT 12.7mm BSPT 12.7mm BSPT 12.7mm BSPT

Supply Pressure 20 mbar 25 mbar 28-30 mbar 37/50 mbar

IR Burner Pressure 9.34 mbar 12.95 mbar 19.93 mbar 19.93 mbar

Lower Burner Pressure 9.34 mbar 12.95 mbar 19.93 mbar 19.93 mbar

ORIFICE – Front IR Burner 2.35 2.35 1.40 1.55

ORIFICE – Rear IR Burner 2.50 2.50 1.51 1.61

ORIFICE – Lower Burner 3.05 3.05 1.70 1.85

SHIPPING WEIGHT

I2H/I2E(G20) I2L(G25) I3B/P(G30) I3P(G31)

I2H/I2E(G20) I2L(G25) I3B/P(G30) I3P(G31)

I2H/I2E(G20) I2L(G25) I3B/P(G30) I3P(G31)

204 Kg (450 lbs)

Page 3 of 31

SHIPPING DIMENSIONS

ELECTRICAL RATING

121.9 cm x 99.1 cm x 172.7 cm (48” x 39” x 68”)

230V~ 50Hz 1.1A 250W

FLEXIBLE BATCH BROILER

RESTAURANT

EQUIPMENT MANUAL

A-1. Model Number Key

FBB- X Y- 230

X identifies Gas Configuration

Description Model Description Model

X = 1 I3P(G31) gas w/o Catalyst

X = 2 I2H/I2E(G20) gas w/o Catalyst

X = 3 I3B/P(G30) gas w/o Catalyst

X = 5 I2L(G25) gas w/o Catalyst

Y = O without Catalyst

FBB-10-230

FBB-20-230

FBB-30-230

FBB-50-230

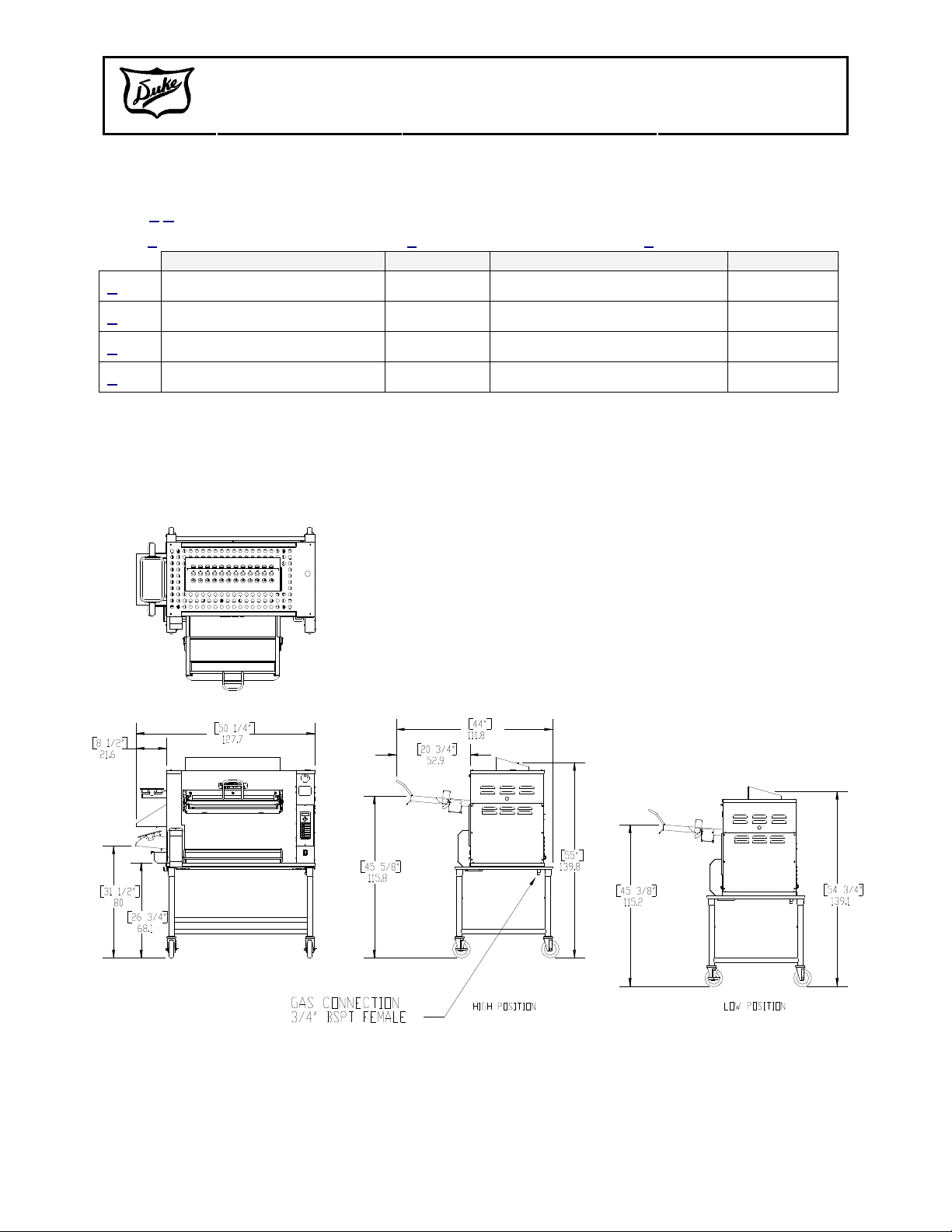

A-2. Broiler Dimensions

Dimension shown in centimeters, bracketed [ ]are in inches

Note:

Y = C with Catalyst

I3P(G31) gas with Catalyst

I2H/I2E(G20) gas with Catalyst

I3B/P(G30) gas with Catalyst

I2L(G25) gas with Catalyst

Page 4 of 31

FBB-1C-230

FBB-2C-230

FBB-3C-230

FBB-5C-230

FLEXIBLE BATCH BROILER

RESTAURANT

EQUIPMENT MANUAL

II. Installation Instructions

A. Qualified Personnel

These installation instructions are for the use of

qualified installation and service personnel

only. Installation or service by other than

qualified personnel may result in damage to the

broiler and/or injury to the operator.

Qualified installation personnel are those

individuals, firms, companies or corporations

which either in person or through an agent is

engaged in and responsible for:

Compliance with the installation in force in

the country in which the appliance is to be

installed

This appliance shall be installed with

sufficient ventilation to prevent the

occurrence of unacceptable concentrations

of substances harmful to health in the room

in which the appliance is installed

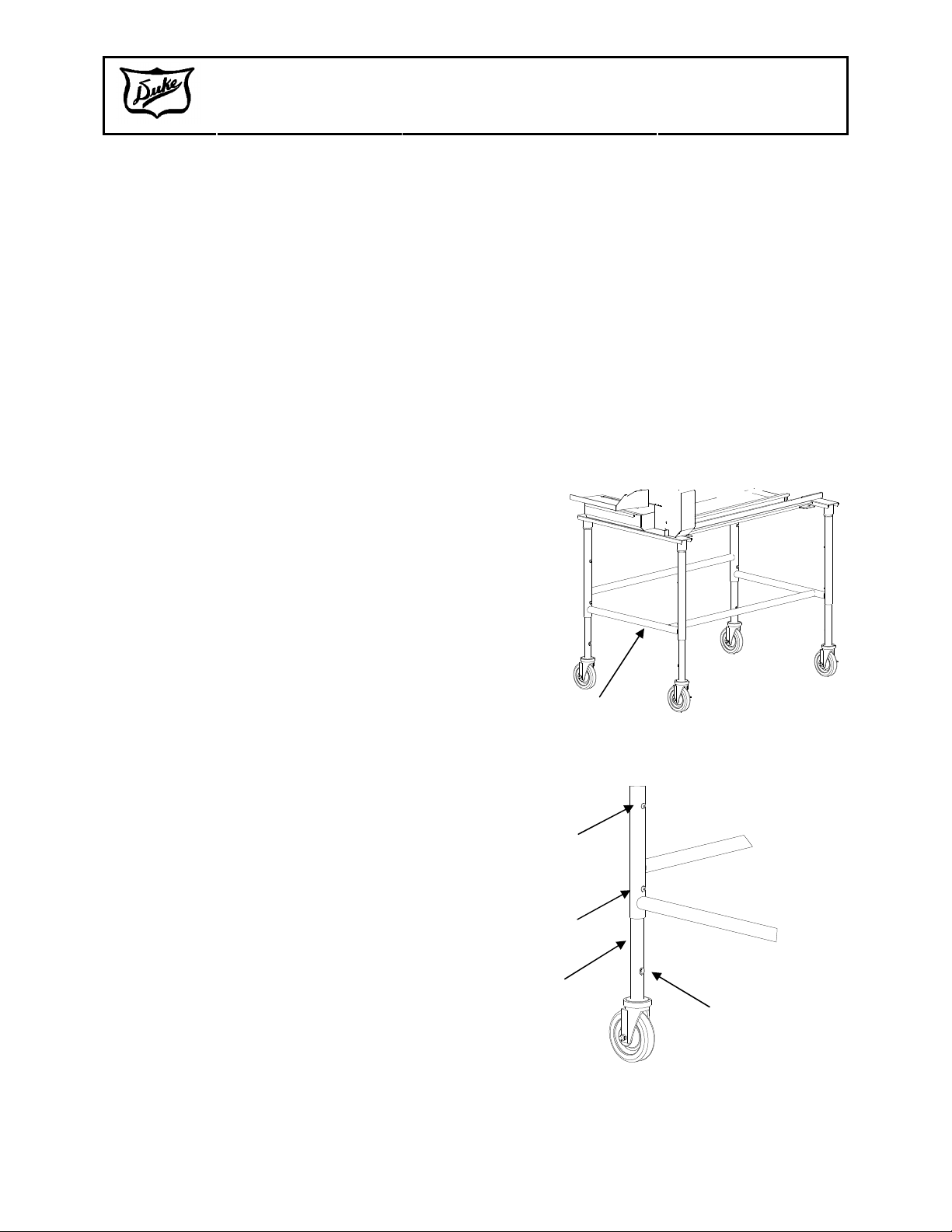

Caution - the appliance is mounted on 4

wheels. Care must be taken not to hit

kitchen walls or similar hard objects while

moving or installing the appliance.

Parts protected by the manufacturer,

agent, or assignee shall not be adjusted by

the installer

B. Delivery and Inspection

Duke Manufacturing Co. does everything within

its power to insure you received your broiler in

good condition. They are strapped down on

heavy wooden skids and packed to prevent

shipping damage. They have all been carefully

inspected before they were packaged and

consigned to the carrier.

Upon delivery of your Duke broiler:

Look over the shipping container, carefully

noting any exterior damage on the delivery

receipt, which must also be signed by the

driver/ delivery person.

Unpack and check for any damage, which

was not evident on the outside of the

shipping container.

Page 5 of 31

Caution: The Broiler is very heavy!

Use adequate help for lifting.

1. Using a utility knife, cut away plastic wrap

(Not shown).

2. Remove the top cardboard and inner cap

3. Remove cardboard from the corners (4

places).

4. Remove cardboard on the ends (2 places)

5. Remove banding straps (Cut with utility knife

or scissors: 5 places)

6. Remove box of attachable parts &

accessories from the front

7. Safely lift one end of broiler and tap block

towards center and then sideways to

remove. Repeat for remaining blocks. This

allows casters to touch the pallet

8. While carefully supporting broiler, slowly roll

it off the pallet taking care not to damage the

casters

9.

Remove blue tape from broiler panels.

Check for concealed damage. The carrier

must be notified within fifteen (15) days of

the delivery of the broiler and the carton,

skid and all packaging materials must be

retained for inspection.

Duke Manufacturing Co. cannot assume

liability for loss or damage suffered in

transit. The carrier assumes full

responsibility for delivery in good order

when the shipment was accepted.

However, we are prepared to assist you

with filing your claim.

FLEXIBLE BATCH BROILER

RESTAURANT

EQUIPMENT MANUAL

Page 6 of 31

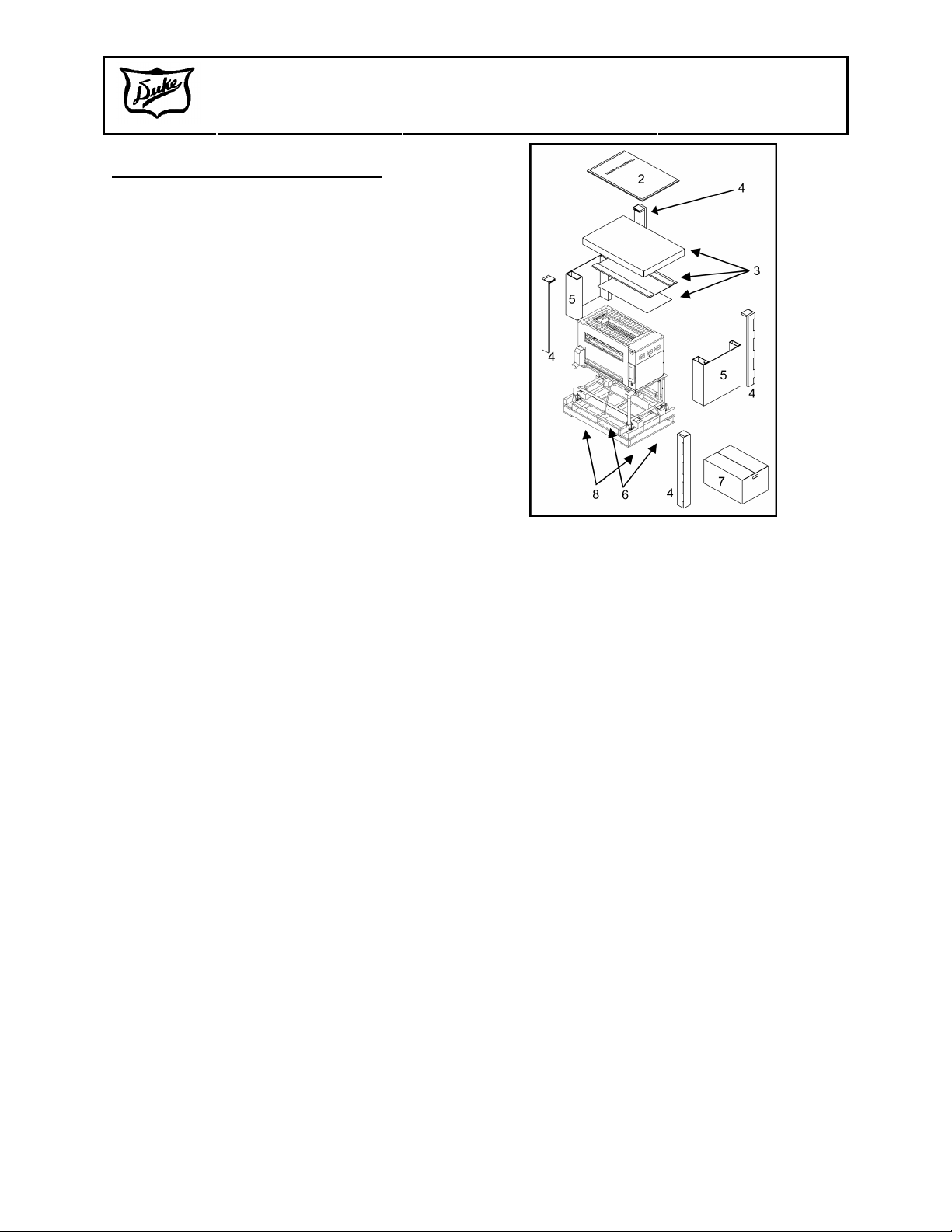

C. Broiler Assembly

Before assembling and installing the broiler, please check to make sure that all necessary parts are present.

Item # Part Name Part #

1 PRODUCT PAN SHELF 175353

2 DISCHARGE CHUTE 175340

3 DISCHARGE HOOD 175362

4 DISCHARGE PAN HOLDER 175358

5 DISCHARGE GREASE PAN 175357

6 “V” GREASE PAN 175325

7 MAIN GREASE PAN 175329

8 LOADER 175444

9 LOADER TRAY 175430

10 LOADER BRACKET 175438

11 DOOR 175429

12 LOADER RAMP 175741

13 IMPEDANCE PAN 175226

14 CATALYST (OPTIONAL) 175480

15 CATALYST GUARD (OPTIONAL) 175482

16 SANITATION PAIL 175842

OPTIMAL Service Parts & Accessories

PARTS KIT – I2H/I2E(G20) (w/ Controller & Cook

Chain)

PARTS KIT – I2L(G25) (w/ Controller & Cook

Chain)

PARTS KIT – I3B/P(G30) & I3P(G31) (w/ Controller

& Cook Chain)

PARTS KIT - I2H/I2E(G20), I3B/P(G30) & I3P(G31)

(Burner & Flame Arrestor)

PARTS KIT - I2L(G25) (Burner & Flame Arrestor)

175850

175851

175852

175520

175854

Loader Install Tool

(Included with Broiler Tools Kit)

PARTS KIT - I2H/I2E(G20), I3B/P(G30) & I3P(G31) (Burner,

Arrestor, Loader, & Burner Shield)

PARTS KIT - I2L(G25) (Burner, Arrestor, Loader, & Burner

Shield)

KIT – CE GAS HOSE CONNECTOR 175831

KIT – CE GAS HOSE CONNECTOR - UK 175827

175526

175853

Setup: Install all items as shown below.

Note: Install loader bracket with (4) ¼-20 nuts. Use supplied extension tool to remove and reinstall nuts.

(Nuts are shipped installed on loader mounting studs.)

FLEXIBLE BATCH BROILER

RESTAURANT

EQUIPMENT MANUAL

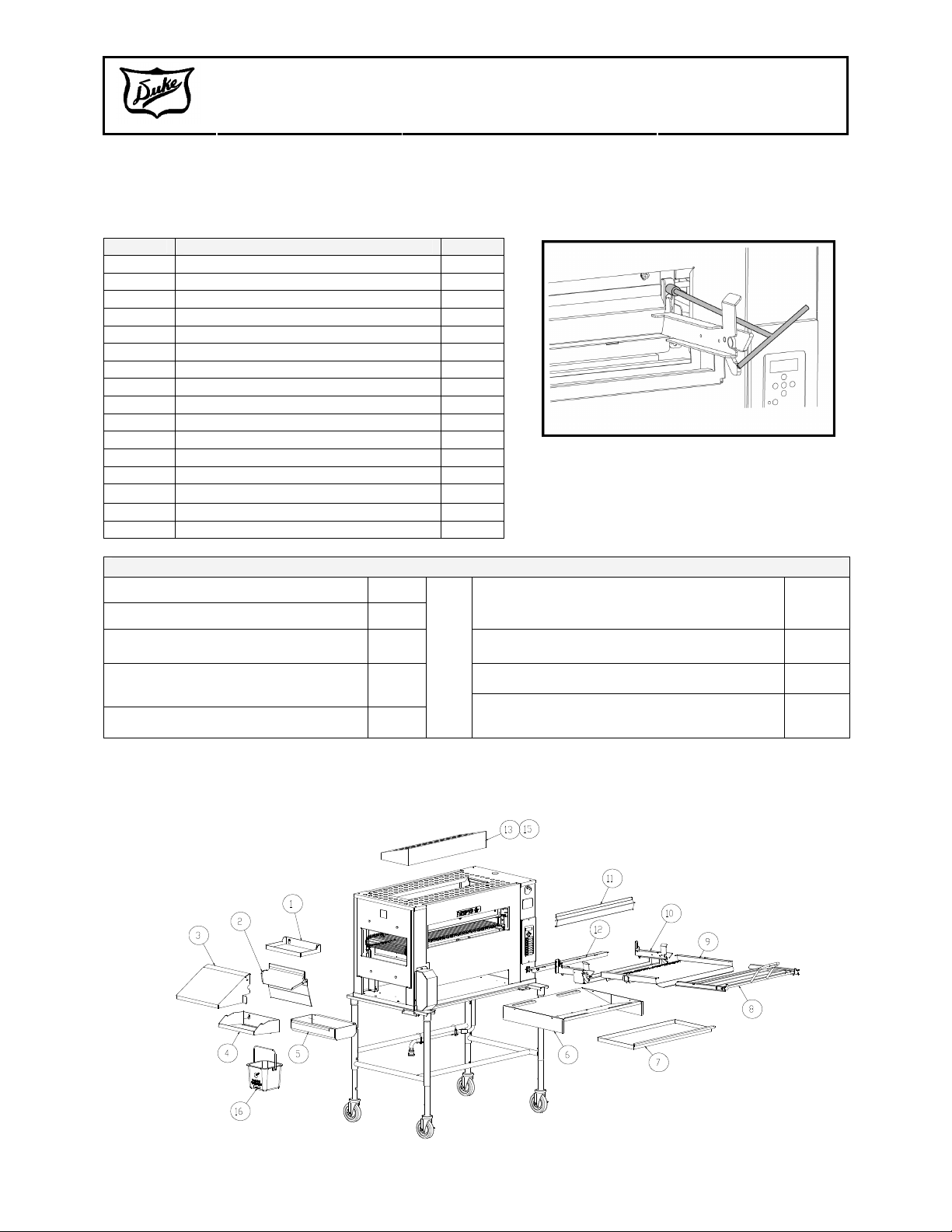

D. Adjustments at Installation

Each broiler section and all its component parts

have been tested thoroughly and inspected

before your broiler was shipped from the factory.

However, it is sometimes necessary to further

test or adjust the broiler once it has been

installed. Such adjustments are the responsibility

of the Dealer or Installer. These types of

adjustments are not considered defects, rather a

normal and routine part of the proper installation

of the equipment.

These adjustments include but are not limited to:

• Adjustments to the gas pressure regulator

• Broiler height adjustment (if required)

No installation should be considered complete

without proper inspection and, if necessary, any

adjustments by qualified service or installation

personnel.

It is also important not to obstruct the natural flow

of combustion and ventilation air if the broiler is to

operate properly. This broiler should not be

installed on a curb base or sealed to the wall.

Either condition can restrict the flow of air to the

combustion compartment or prevent proper

ventilation of the unit. Before making any

connections to the broiler, check the ratings plate

to be sure the broiler specifications concur with

the type of gas and voltage to be supplied to the

broiler.

The rating plate is located on the back of the

control compartment cover panel on the right end

of the unit.

The plate bearing the broiler’s model number and

serial number is attached to the back side of the

unit.

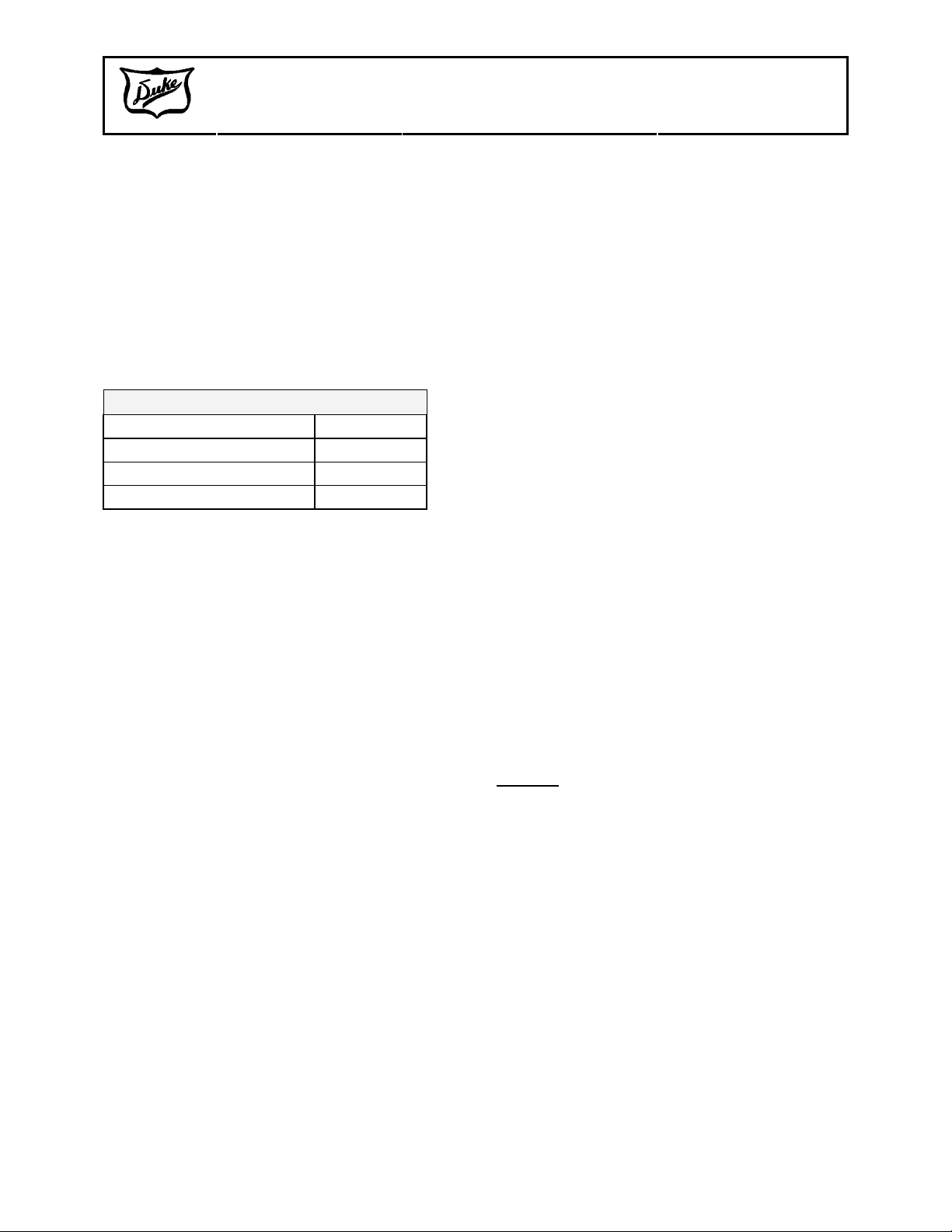

Raise or Lower Broiler

The broiler height can be adjusted via two

screws on each leg.

Caution: The Broiler is very heavy!

Use adequate help for lifting.

1. Lift one end of the broiler onto a wide,

sturdy stand (not supplied).

2. Remove (2) screws per leg and

raise/lower to threaded holes. Reinstall

screws.

3. Remove stand and safely raise/lower

broiler.

4. Place plastic hole plugs (supplied attach

to stand) in any unused holes.

Support broiler here

Screw

Screw

Slide Leg.

Reinstall screws.

Plastic Hole

Plug

Page 7 of 31

FLEXIBLE BATCH BROILER

RESTAURANT

EQUIPMENT MANUAL

E. Location of the Broiler

Proper placement of the broiler will give you the

best results long-term user convenience. We

urge you to give adequate thought in the

placement of your broiler prior to its arrival.

The broiler should be placed in an area that

is free from drafts and accessible for proper

operation and servicing.

The area around the broiler must be kept

clear of combustible materials as specific

below:

Combustible Surface Spacing

305 mm

76 mm

102 mm

0 mm

Discharge End (left side)

Access Panel End (right side)

Rear

Floor/Table

F. Gas Piping

The standard broiler consumes gas at a total of

100,000 BTU/hr, 29.4 KW. The overall piping

plan of the kitchen must support the supply

rating to support appliance to achieve the

performance rating.

Generally, piping should be sized to provide a

gas supply sufficient to meet the maximum

demand of all gas appliances on a line without

undue loss of pressure to the equipment. The

total BTU requirements of all equipment being

served and the piping length from the meter are

major considerations in the proper design of the

gas supply system.

NOTE: A fixed restraint of the proper length must

be incorporated to secure the broiler to a nonmovable surface to eliminate strain on the gas

connector.

G. Electrical Connections

Page 8 of 31

H. Ventilation

This appliance shall be installed with sufficient

ventilation to prevent the occurrence of

unacceptable concentrations of substances

harmful to health in the room in which the

appliance is installed.

Venting to a Canopy Exhaust Hood

A mechanically driven exhaust hood must have

a minimum capacity of 1700 m3/hr (1000 cfm)

with a minimum 100cm by 130cm (39.4 in by

51.2 in) opening to adequately vent this

appliance. The specified capacity and opening

is required in a dedicated hood for this appliance

or in addition to other appliance vented through

a common canopy exhaust hood.

Maintenance of Ventilation System

The ventilation system must be maintained and

annually inspected by Qualified Personnel

concurrent as part of or in addition to

governmental requirements.

This inspection/maintenance should consist of,

but not be limited to:

Inspection for blockages or build up

which might interfere with the venting of

the broiler.

Repair of such blockages.

Inspection of the venting canopy, its drive

motors and bells, etc.

Warning:

sheet pans, food containers or aluminum foil on

the top of the broiler. This will obstruct the

venting of cooking vapors and airflow through

the unit—resulting in poor cooking performance.

Do not place any objects such as

Your broiler must be supplied from a 230 Volt 50

Hertz, grounded circuit with a detachable line

cord for each country’s requirements. A wiring

diagram is attached to the broiler control

compartment and with this manual.

WARNING: This appliance employs an

earthed, safety ground electrical supply

system. DO NOT cut or modify the earthing

provisions of this appliance.

FLEXIBLE BATCH BROILER

RESTAURANT

EQUIPMENT MANUAL

III. Operation Instructions

The information in this section is intended for the

use of qualified operating personnel. Qualified

Operating Personnel are those individuals who

have carefully read the information contained in

this manual, are familiar with the function of the

broiler and/or have had experience with operating

the equipment described. We recommend

following these instructions to insure optimum

performance, long life and trouble-free service

from your broiler.

The controller is pre-programmed at the factory

for known recipes at the time of manufacture.

The product keys must be programmed with an

approved recipe and the broiler properly

calibrated prior to use.

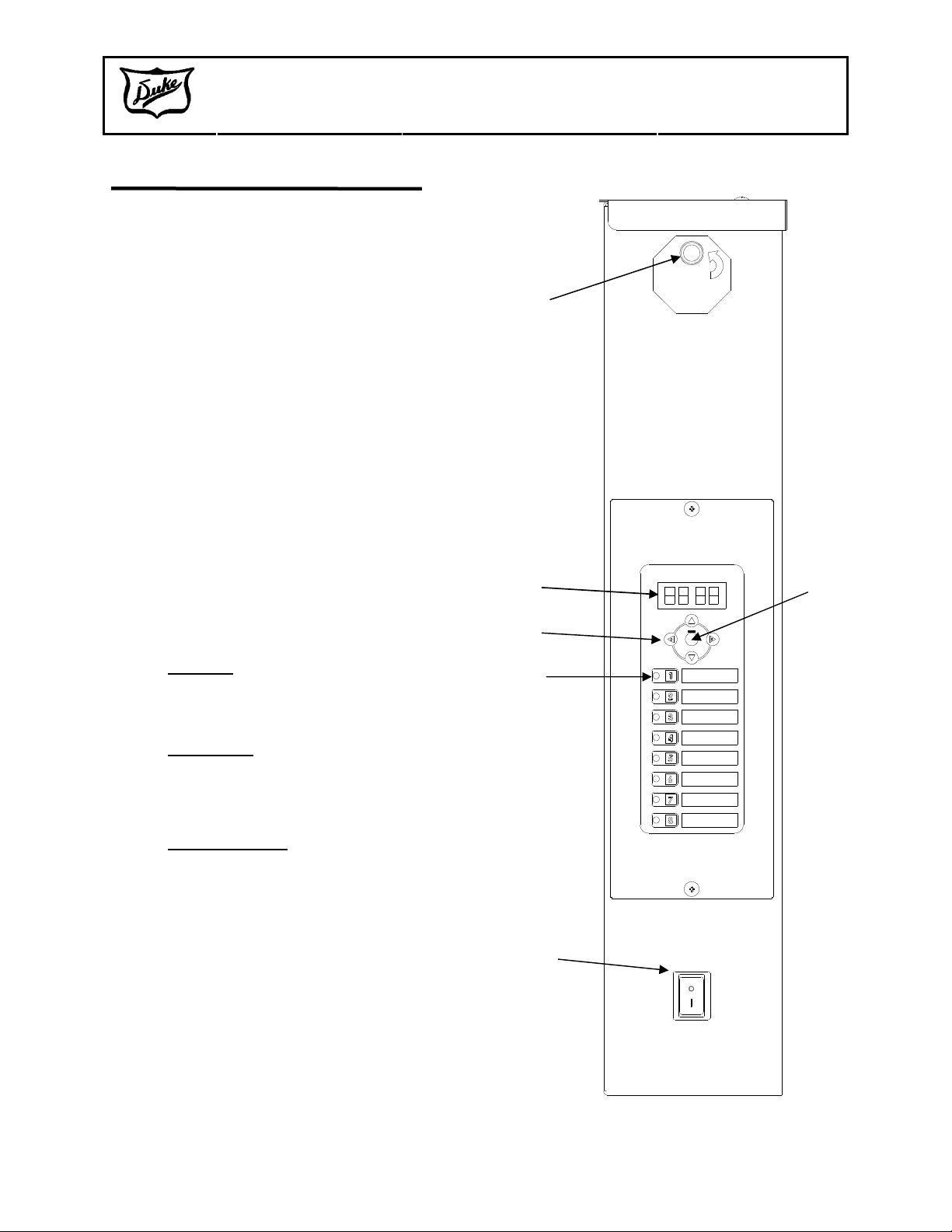

A. Broiler Controls

1. Power Switch – Turns the broiler ON or

OFF. The broiler is self-lighting.

2. Product Selection Keys – Selects the

product recipe to run. Also functions as

number keys 1-8 in programming mode.

3. Arrow Keys

Up-Arrow: Displays the current broiler

temperature when pressed in run mode.

Scrolls backward through parameters

when pressed in program mode.

Down-Arrow: Displays the broiler setpoint temperature when pressed in run

mode. Scrolls backward through

parameters when pressed in program

mode.

Left-Right Arrows: Moves between

characters or parameters in program

mode. Also used as numerals 0 and 9

keys.

4. Display

5. Enter Key – Press and hold for 5

seconds to enter program mode. Also

used to move though and enter

parameters in programming mode.

6. Cook Light – This light is lit during

preheat and the entire cook. The

operator should not load the broiler while

the light is lit.

3

6

4

2

Page 9 of 31

5

1

FLEXIBLE BATCH BROILER

RESTAURANT

EQUIPMENT MANUAL

B. Cooking Product

B-1.0 Lighting the Broiler

• Start Ventilation System.

• Turn ON/OFF switch to the ON (1)

position.

• The control will display PrE during the

pre-heat cycle.

• The LED's next to all product keys with

non-zero cook times will be red.

• The control will display rdY at the

completion of the pre-heat cycle and the

LED’s next to all product keys with nonzero cook times will be green.

• (To shutdown the broiler, see section B-

8.0)

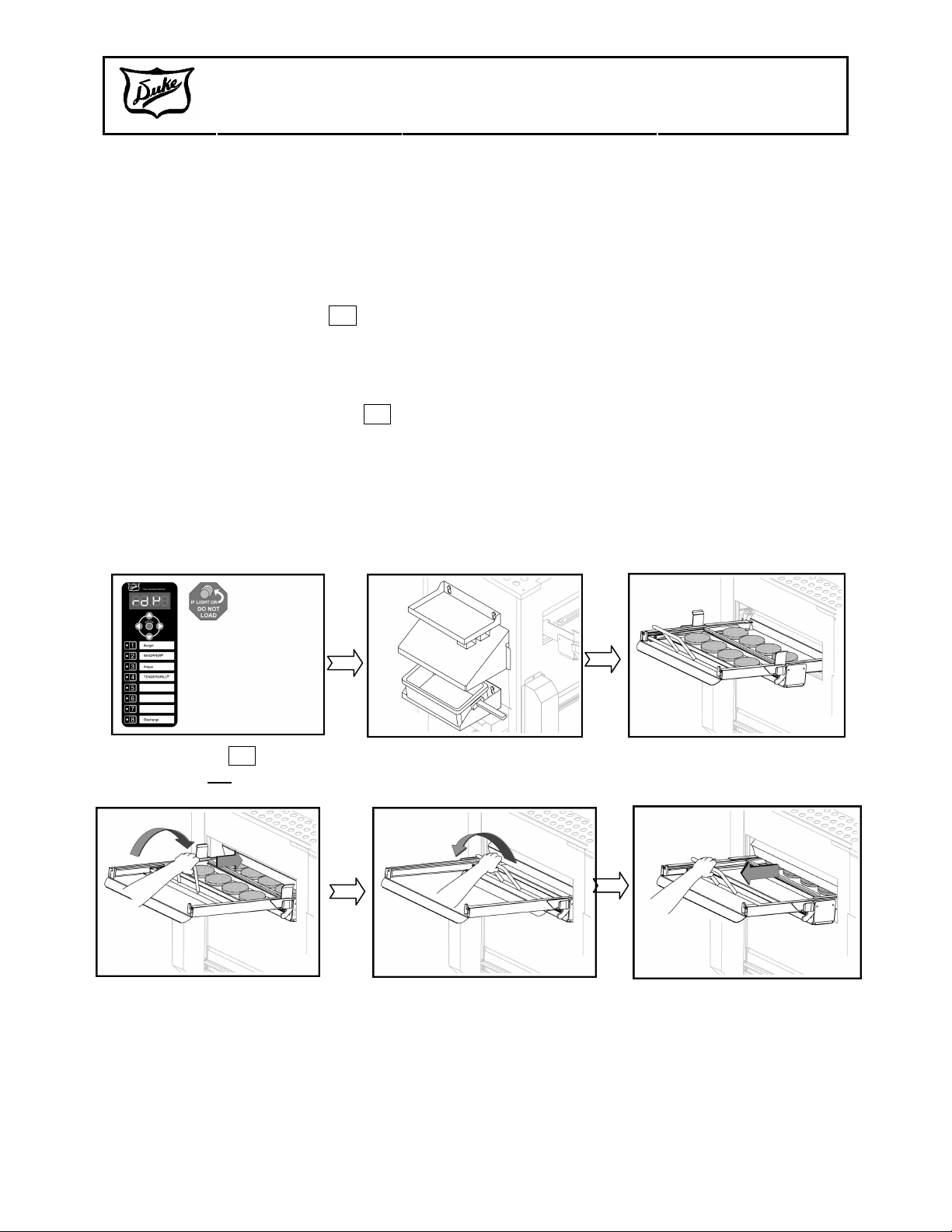

B-2.0 Cook Product

Page 10 of 31

Broiler displays rdY and

Cook light is not on.

Load product. Push forward

as shown.

Place holding pan at

discharge.

Rotate handle down to lift

inside bar over product.

Place product in front and

back rows.

Pull out loader with handle

rotated.

Loading...

Loading...