Duke 1104 Operators Manual

ELECTRIC FOOD WARMERS

Installation

Operation

& Maintenance

Manual

DUKE MANUFACTURING CO.

2305 N BROADWAY • ST. LOUIS, MO 63102

800.735.3853 • 314.231.1130 • 314.231.5074 Fax

www.dukemfg.com

201351K

INDEX

PAGE

Principles of Operation 3

Installation Instructions 3

Cord & Plug Schedule 4

Electrical Connection Diagram 5

Operating Instructions 6-7

Care of Equipment 7

A. Heating Elements 7-9

B. Pilot Lights 9

C. Hinge and Door Adjustments 9-10

D. Damper Assembly 11

E. Replacement of Pilots Lights or Thermostats 11

Troubleshooting 12

Recommended Food Storage Periods 13

Parts List 14-15

Unitrack Assembly 16

Door Styles 17

Angle Slides 18-19

Number of Elements per Unit 20

Please supply the ID Number and the Serial Number when ordering

replacement parts or requesting service.

We recommend service by Duke Authorized Service Agencies during and

after the warranty period.

2 of 20

PRINCIPLES OF OPERATION

The Thermotainer has been designed to preserve hot food at its proper temperature in its own moisture, without the

addition of water, steam or circulating fans. The hot air surrounding the food compartment is electrically heated and

automatically controlled to maintain the desired temperature. Each cabinet has one or more thermostats depending

upon its design and model number. Each compartment has a vent or damper for the control of moist or dry foods.

The primary function of a Thermotainer is for the intermediate storage of hot food after it leaves the cooking unit

until it is ready to serve. Thermotainers are not designed to reheat food that has cooled, thawing frozen food, or for

cooking. These uses are not recommended.

INSTALLATION

The Thermotainer, when it leaves the factory, is assembled and ready for Installation. The nameplate on the

thermostat side of the cabinet contains model number, serial number, volts, hertz, wattage and instructions on the

damper operation. The Thermotainer must be connected to the proper electrical power source as indicated on the

nameplate. Failure to do this may cause serious damage, prevent proper operation and void the manufacturer's

warranty.

The access to the electrical connection box is normally located at the lower front (thermostat side) bottom. It is

covered with an access cover panel that is held in place by two screws. Concealed, but adjacent to the right side of

the electrical connection box is a wire chase that runs front to back. It is visible by looking underneath the unit. The

wire chase permits access to the side knockout of the electrical connection box and to "stub up" or rear connects the

electrical power source. Some Thermotainers may be equipped with cords and plugs or the electrical connection box

may be in another location depending upon the design and location that may have been specified. It is not necessary

to disassemble any part of the Thermotainer to make the electrical connection.

Thermotainers should be moved by carefully lifting underneath and placed in the desired location. They should not

be pushed or shoved as this may damage the legs, the hardware, or the electrical components. After setting in place,

the Thermotainer must be leveled. If equipped with legs, the adjusting feet should be turned to level the cabinet.

3 of 20

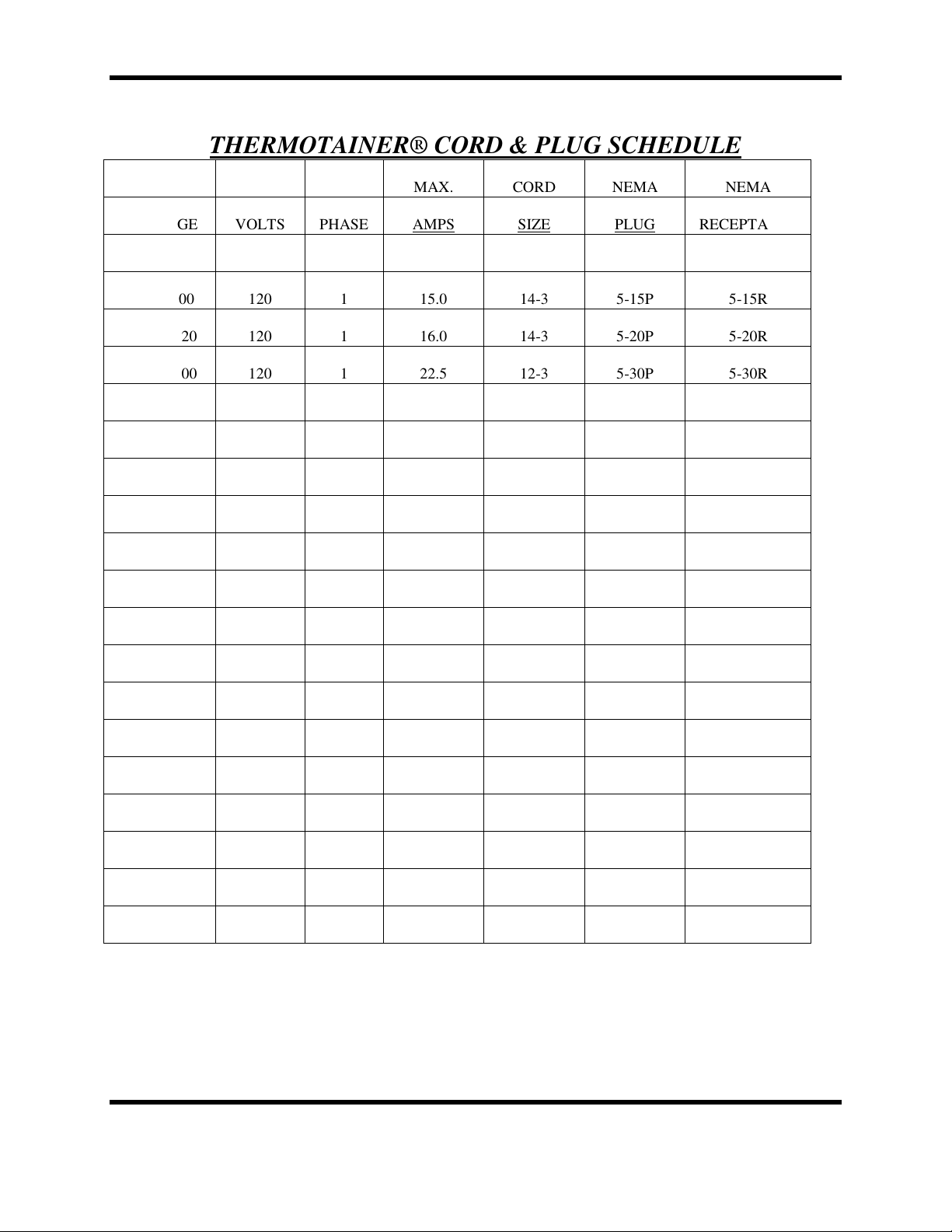

THERMOTAINER® CORD & PLUG SCHEDULE

MAX. CORD NEMA NEMA

WATTAGE VOLTS PHASE AMPS SIZE PLUG RECEPTACLE

Up to 1800 120 1 15.0 14-3 5-15P 5-15R

1800 - 1920 120 1 16.0 14-3 5-20P 5-20R

1920 - 2700 120 1 22.5 12-3 5-30P 5-30R

2700 – 4500 120 1 37.5 8-3 5-50P 5-50R

Up to 3120 208 1 15.0 14-3 6-15P 6-15R

3120 – 3328 208 1 16.0 14-3 6-20P 6-20R

3328 – 4680 208 1 22.5 12-3 6-30P 6-30R

4680 – 7800 208 1 37.5 8-3 6-50P 6-50R

Up to 5757 208 3 16.0 12-4 15-20P 15-20R

5757 – 8096 208 3 22.5 10-4 15-30P 15-30R

8096 – 13493 208 3 37.5 6-4 15-50P 15-50R

Up to 3600 240 1 15.0 14-3 6-15P 6-15R

3600 – 3840 240 1 16.0 14-3 6-20P 6-20R

3840 – 5400 240 1 22.5 12-3 6-30P 6-30R

5400 – 9000 240 1 37.5 8-3 6-50P 6-50R

Up to 6643 240 3 16.0 12-4 15-20P 15-20R

6643 – 9342 240 3 22.5 10-4 15-30P 15-30R

9342 – 15570 240 3 37.5 6-4 15-50P 15-50R

4 of 20

MODEL NUMBER

"A" DIM.

"B" DIM.

"C" DIM.

1101

-

1101P

1154

-

1154P

1453

-

1453P

1553

-

1553P

1102

-

1102P

1454

-

1454P

1554

-

1554P

1103

-

1103P

1455

-

1455P

1571

-

1571P

1104

-

1104P

1456

-

1456P

1572

-

1572P

16- 32" 12"

1151

-

1151P

1458

-

1458P

1573

-

1573P

1152

-

1152P

1262

-

1262P

1551

-

1551P

1574

-

1574P

1153

-

1153P

1452

-

1452P

1552

-

1552P

1202

-

1202P

1302-1302P

1305

-

1305P

1309

-

1309P

11-

1/2" 27" 7-12"

1203

-

1203P

1303

-

1303P

1306

-

1306P

1353

-

1353P

1351

-

1351P

2352

-

2352P

21-

1/2" 27" 17-1/2"

2353

-

2353P

1602

-

1602P

1651

-

1651P

2103

-

2103P

2454

-

2454P

2466

-

2466P

1652

-

1652P

2104

-

2104P

2456

-

2456P

2468

-

2468P

1653

-

1653P

2452

-

2452P

2458

-

2458P

2652

-

2652P

18" 32-

14"

2101

-

2101P

2453

-

2453P

2464

-

2464P

2653

-

2653P

2102

-

2102P

1652A

18" 23-1/2" 14"

2201

-

2201P

2302

-

2302P

2308

-

2308P

2318

-

2318P

2202

-

2202P

2303

-

2303P

2309

-

2309P

2602

-

2602P

13-

1/2" 27-

91/9"

2203

-

2203P

2304

-

2304P

2314

-

2314P

2603

-

2603P

2204

-

2204P

2306

-

2306P

2316

-

2316P

1253

-

1253P

16" 34" 12"

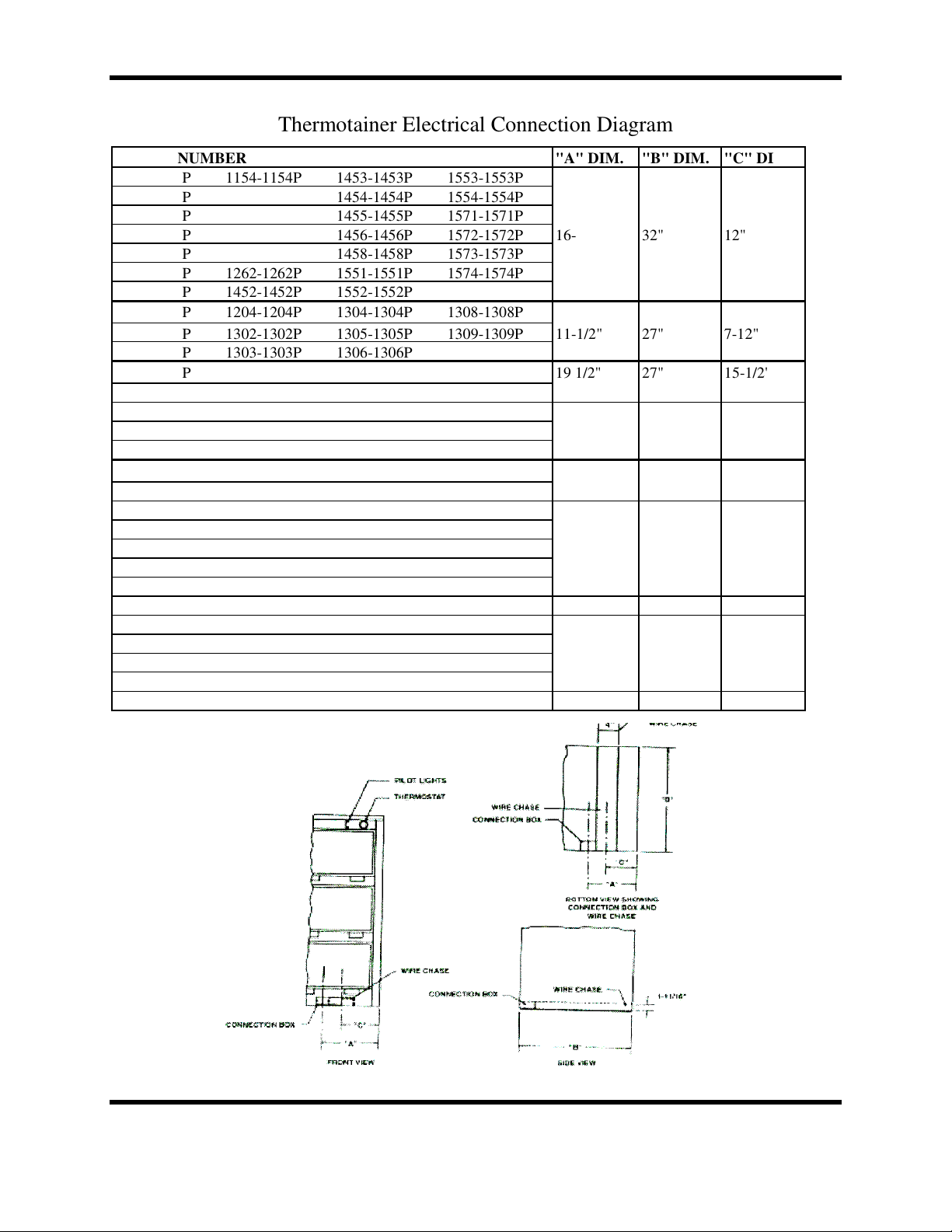

Thermotainer Electrical Connection Diagram

1201-1201P 1204-1204P 1304-1304P 1308-1308P

1352-1352P 19 1/2" 27" 15-1/2'

1601-1601P 1603-1603P 13-1/2" 27-1/2" 9 1/2"

5 of 20

If legs were not supplied, it may be necessary to shim

under the bottom to level. After leveling, with the

thermostat (s) in the off position, the Thermotainer

can be connected to the electrical power source.

Installation must be in accordance with national or

local electrical and sanitation codes. In order to

remain in compliance with NSF standards, the base

must be sealed to the counter or floor. Use General

Electric RTV-102, Dow Corning 781 Building

Sealant or any silicone based product, which is

approved and acts as an adhesive/ sealant.

When the electrical connection is completed, install

the stainless steel angle slides inside the

compartments. Clean and polish the inside and

outside before preheating for the first time. This will

assure the factory finish remaining bright for years.

See Care of the Equipment section of this manual.

Electrical Control

The temperature is maintained by a thermostat (s)

that can be adjusted to the desired temperature. The

thermostat is directly connected to the heating

elements, which in turn heat the air space

surrounding each compartment. A thermostat may

control one or more compartments depending upon

the design.

Each Thermotainer is carefully inspected and tested

at the factory. The thermostat (s) are adjusted and

calibrated with precision temperature indicating

instruments.

To prevent food spoilage and harmful bacteria

growth, food should not be placed in a cold

Thermotainer. Preheat by turning the thermostat knob

to the desired temperature setting. Allow at least 11/2 hours to reach the set temperature.

In heating a cold unit, set the thermostat to the desired

temperature. Do not turn to a higher setting as this

will waste energy, cause the Thermotainer to be

heated above the desired temperature and will not

increase the speed of preheating.

OPERATING INSTRUCTIONS

When the operating temperature has been reached,

the red pilot light will go out. (It cycles on and off as

the temperature varies in the compartment.) The

Thermotainer is now ready to accept food for storage.

If the food is to be served in the same pan in which it

was cooked, it may be left in this pan and placed in

the compartment. Otherwise pan food immediately

after cooking into another utensil and place in the

compartment. The Thermotainer keeps the food in

perfect condition during the interval between cooking

and serving.

All foods should be placed in the compartment while

hot. The use of the Thermotainer for reheating or

warming cold food is not recommended. If the

Thermotainer is to be used for reheating food, consult a

competent food or health authority for information

concerning which foods may be cooled and reheated

safely.

The thermostat dial temperature numbers may not

necessarily indicate the exact compartment

temperature. After it has been determined by use at

which setting food keeps best, the thermostat should

be kept at this setting to maintain this temperature.

Your own experience will be the best guide. Do not

constantly change the thermostat setting once it has

been determined unless the foods being stored require

different temperatures.

NOTE: Thermostats are factory calibrated. Field

calibration of the thermostat is not covered by

warranty. Preheating

Most foods can be kept in their best condition at a

temperature of approximately 175°F (79.4°C), but the

exact temperature will vary with the kind of food and

the method of preparation. Minor temperature

fluctuations will not affect the quality of most foods.

It is not possible to give exact instructions that will fit

all conditions. It is suggested that you experiment by

increasing or decreasing the temperature until you

find the most suitable temperatures for various types

of foods. For suggested temperature settings, consult

the food storage instruction sheet on page 16.

6 of 20

Loading...

Loading...