Dukane 9001-2000 User Manual

04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

User’s Manual

Dukane Corporation • Ultrasonics Division • 2900 Dukane Drive • St. Charles, Illinois 60174 USA • TEL +1–630–797–4900 • FAX +1–630–797–4949

Dukane products are manufactured

ISO 9001:2000

in ISO registered facilities

Dukane Part No. 403–566-01

www.dukcorp.com/us

DPC II Plus and EZ Welder System – User’s Manual

Copyright © 2003—2004 Dukane Corporation

Ultrasonics Division

2900 Dukane Drive

St. Charles, IL 60174 USA

Notice of Rights:

All rights reserved. No part of this manual including the interior design, cover design and icons may be reproduced, transmitted or utilized in any form or by any means, electronic,

mechanical, photocopying, recording, or by any information

storage and retrieval system, without written permission from

Dukane Corporation.

Notice of Liability:

The information contained is this manual is distributed on an

“As is” basis, without warranty. While every precaution has

been taken in the preparation of this manual, Dukane Corporation shall not have any liability to any person or entity with

respect to any liability, loss, or damaged caused or alleged to

be caused directly or indirectly by the instructions contained

in this manual, or by the hardware and software products described herein.

Printed in the United States of America.

PRINTED ON RECYCLED PAPER

Dukane Part Number: 403–566–01

Dukane ultrasonic equipment is manufactured under one or more of the following

U.S. Patents:

3,780,926 3,825,481 4,131,505 4,277,710 5,798,599 and 5,880,580.

DPC™ is a trademark of Dukane Corporation

EZ Welder™ is a trademark of Dukane Corporation

ii Dukane Manual Part No. 403–566–01

Table of Contents

DPC II Plus & EZ Welder Manual Revision History

Revision Revision

Number History Date

–00

–01 Modify Table 5—V on page 48 (Pin 9 is +22V DC) 2004–Dec–07

Add information for EZ–Series Generator to DPC II Plus Manual.

Added EZ Welder™ Key Features to Section 1.

Table 3—1 references new DPC II Plus/EZ Welder manual.

Figure 4–1B shows EZ Generator w/o Hot Key for P2.

Figure 4–8B added to show current software revision for

EZ Generator. Figure 4–8A shows DPC II Plus version.

Figure 5–1 notes Multi–Probe modules are for DPC II Plus only.

Added note that photo on page 49 does not apply to EZ system.

Added note to Figure 7–30 that P2 branch is for DPC II Plus

systems only. EZ Series are single pressure.

Updated Dukane’s telephone numbers on pages 143–144.

Added Table 15—II for EZ Generator Part Number.

Clarify AFTERBURST option bypass on page 73 and 80.

Emergency Stop Switch Interface Diagram on page 25

New consolidated warranty.

2003–Sept–25

Dukane Corporation • • Ultrasonics Division

Dukane Manual Part No. 403-566-01 iii

DPC II Plus and EZ Welder System – User’s Manual

This page intentionally left blank

iv Dukane Manual Part No. 403-556-01

Table of Contents

TABLE OF CONTENTS

Section 1 – Introduction........................................................... 1

Before Operating ................................................................................... 3

Read The Manual First ...................................................................................3

Caution and Warnings................................................................................... 3

Drawings Labels ............................................................................................. 3

Manual Organization............................................................................. 4

DPC–II Plus Overview.............................................................................. 6

EZ Welder Overview............................................................................... 6

Key DPC–II Plus Features ........................................................................ 7

Key EZ Welder Features ......................................................................... 8

Section 2 – Safety Tips.............................................................. 9

Health & Safety Tips............................................................................. 11

Plastics Health Notice .................................................................................. 12

Electrical Grounding Safety ........................................................................ 12

RFI Considerations................................................................................ 13

Section 3 – Unpacking & Installation .................................... 15

Shipping Carton Contents ................................................................... 17

DPC Placement ..................................................................................... 17

Benchtop ...................................................................................................... 17

Rack Mounting............................................................................................. 18

Rear Panel Overview ............................................................................ 19

Ground the System............................................................................... 19

Connect the Cables .............................................................................. 20

Hand Probe System ......................................................................................20

Automated Probe System ........................................................................... 20

Multiple Probe System ................................................................................ 22

Automated Thruster System ....................................................................... 23

Dukane Press System ................................................................................... 24

Emergency Stop Switch Interface ...............................................................25

Rear Electrical Power Switch .......................................................................25

Section 4 – Controls & Displays.............................................. 27

Front Panel Layout ............................................................................... 29

AC Power .............................................................................................. 30

Generator Status Section ..................................................................... 30

Generator Control Keys...............................................................................30

System Status Display .................................................................................. 31

System Power Output Display..................................................................... 32

Process Control ..................................................................................... 33

Process Control Keys .................................................................................... 33

Menu Display ............................................................................................... 35

Dukane Manual Part No. 403-566-01 v

DPC II Plus and EZ Welder System – User’s Manual

Section 5 – Rear Connectors .................................................. 37

Rear Panel Layout ................................................................................ 39

System Input Connector....................................................................... 40

System Output Connector ................................................................... 42

Remote Amplitude Control ................................................................. 46

Power Output Module Option ............................................................ 47

Press Control Module Option .............................................................. 48

Multi–Probe Module Options.............................................................. 50

Jumper Block Options .......................................................................... 51

Card Slot and Jumper Block Locations .......................................................52

Jumper Block Details ................................................................................... 53

Section 6 – Menu Structure ................................................... 55

Process Setup ........................................................................................ 57

Process Control ..................................................................................... 58

Process Limits........................................................................................60

Utilities..................................................................................................61

Section 7 – Process Setup Menu ............................................ 63

Hand Probe...........................................................................................65

Untimed Hand Probe ...................................................................................66

Timed Hand Probe ....................................................................................... 66

Timed Hand Probe – Energy........................................................................ 67

MPC Probe ............................................................................................ 68

Auto Stop Option ........................................................................................ 68

Untimed MPC Probe – Probe Delay ............................................................68

Weld Method – Time ...................................................................................69

Weld Method – Energy................................................................................ 70

Weld Method – Ground Detect .................................................................. 70

Auto Probe ........................................................................................... 71

Auto Stop Option ........................................................................................ 72

Untimed Auto Probe – Delay ......................................................................73

Timed Auto Probe – Weld Method.............................................................73

HoldTime ......................................................................................................73

Afterburst .....................................................................................................73

Press Mode ........................................................................................... 75

Initiate Mode ............................................................................................... 76

Auto Stop ..................................................................................................... 76

Head Up On Auto Stop ............................................................................... 76

Trigger Type..................................................................................................76

Single/Dual Pressure Mode ......................................................................... 76

vi Dukane Manual Part No. 403-556-01

Table of Contents

Press Mode Example ............................................................................ 77

Hot Keys ................................................................................................ 81

Process Control Recap .......................................................................... 82

Section 8– Process Limits Menu ............................................. 87

Process Limits Menu ............................................................................. 89

Limit Definition .................................................................................... 90

Suspect and Bad Limits ........................................................................ 90

Process Limits ........................................................................................ 90

Single Pressure Mode .................................................................................. 91

Dual Pressure Mode.....................................................................................92

Section 9 – Utilities Menu ...................................................... 95

Setup Utilities ....................................................................................... 97

Select Setup ..................................................................................................98

Copy A Setup................................................................................................ 99

Erase Setups ................................................................................................. 99

Part Count........................................................................................... 100

Reset Part Count ........................................................................................100

Count Suspect/Bad Parts............................................................................100

Preset Part Count .......................................................................................101

Status Outputs .................................................................................... 101

Cycle Press Off Line ............................................................................ 101

Section 11 – Probes/Probe Stacks ........................................ 103

The Ultrasonic Probe .......................................................................... 105

Theory of Operation..................................................................................105

Probe Configuration..................................................................................105

Ultrasonic Horn .......................................................................................... 106

Booster .......................................................................................................106

Stack Assembly ................................................................................... 107

Installing Replaceable Tips ........................................................................107

Mounting Stud to Horn/Booster ...............................................................108

Horn to Booster ......................................................................................... 109

Booster to Probe ........................................................................................ 109

Horn to Probe ............................................................................................ 109

Torque Unit Conversion Chart ........................................................... 110

Stack Disassembly............................................................................... 111

Booster Notes ..................................................................................... 114

Stack Mounting .................................................................................. 115

Dukane Manual Part No. 403-566-01 vii

DPC II Plus and EZ Welder System – User’s Manual

Section 11 – DPC Checkout .................................................. 117

Startup and Self–Test ......................................................................... 119

System Test ......................................................................................... 120

Probe Operation................................................................................. 121

Stopping the Weld Cycle ................................................................... 121

Manual Systems ......................................................................................... 121

Automated System .................................................................................... 121

End of Day ..................................................................................................121

Section 12 – Troubleshooting .............................................. 123

No Ultrasonic Output......................................................................... 125

Probe ..........................................................................................................125

Cable ...........................................................................................................125

Generator ...................................................................................................126

Operate Input ............................................................................................ 126

Generator Faults................................................................................. 127

OVERLOAD Indicator .................................................................................127

OVERTEMP Indicator ................................................................................. 127

FAULT Indicator.......................................................................................... 127

Generator Errors................................................................................. 128

INPUT TEST Indicator .................................................................................128

TEST Control Key........................................................................................ 128

Troubleshooting Flowchart ............................................................... 129

Error Messages ................................................................................... 131

Section 13 – Care & Maintenance ....................................... 133

Front Panel ......................................................................................... 135

Rear Panel........................................................................................... 135

Chasis .................................................................................................. 135

Stack Surfaces ..................................................................................... 136

Stack Maintenance .................................................................................... 136

Stack Inspection .........................................................................................136

Even Contact ..............................................................................................136

Uneven Contact ......................................................................................... 136

Crowning ....................................................................................................137

Center Depression...................................................................................... 137

Corrosion ....................................................................................................137

Probe Reconditioning ........................................................................ 138

Overview ....................................................................................................138

Machining the Mating Surfaces................................................................ 138

Manual Resurfacing...................................................................................138

viii Dukane Manual Part No. 403-556-01

Table of Contents

Section 14 – Contacting Dukane ......................................... 141

Ultrasonics Division Main Office ....................................................... 143

Email Addresses.................................................................................. 144

Telephone Extensions ........................................................................ 144

Section 15 – Specifications ................................................... 145

Regulatory Compliance...................................................................... 147

Federal Communications Commission...................................................... 147

CE Marking (Conformité Europeéne) .......................................................147

Dimensions ......................................................................................... 148

Operating Enviornment..................................................................... 148

Power Requirements.......................................................................... 149

Interpreting The DPC Model Number............................................... 150

Section 16 – Warranty.......................................................... 151

Domestic warranty ............................................................................. 153

International Warranty ...................................................................... 154

Appendix A - List of Figures ................................................ 155

Appendix B - List of Tables .................................................. 159

Appendix C - User Supplied Circuitry .................................. 161

Manual Switch Circuit ........................................................................ 163

Automation Switch Circuits ............................................................... 164

Isolated Automation Controls ........................................................... 165

Current Sink ...............................................................................................166

Current Source ........................................................................................... 167

Index ..................................................................................... 169

Dukane Manual Part No. 403-566-01 ix

DPC II Plus and EZ Welder System – User’s Manual

This page intentionally left blank

x Dukane Manual Part No. 403-556-01

Section 1 – Introduction

SECTION 1

Introduction

• General Information

• Manual Organization

• DPC–II Plus Overview

• Key DPC–II Plus Features

• Key EZ Welder Features

Before Operating ............................................ 3

Read The Manual First ............................................3

Caution and Warnings ...........................................3

Drawings Labels .....................................................3

Manual Organization ...................................... 4

DPC–II Plus Overview ...................................... 6

EZ Welder™ Overview .................................... 6

Key DPC–II Plus Features ................................. 7

Key EZ Welder™ Features ............................... 8

Dukane Corporation • • Ultrasonics Division

Dukane Manual Part No. 403–566–01

1

DPC™ II Plus and EZ Welder System – User’s Manual

This page intentionally left blank

2

Dukane Manual Part No. 403–566–01

Important User Information

Read This Manual First

Before operating the DPC™ II Plus, read this

User’s Manual to become familiar with the system. This will ensure correct and safe operation.

The manual is organized to allow you to learn how

to safely operate an ultrasonic system. The examples given are chosen for their simplicity to illustrate basic setup procedures.

Notes and Tips

Throughout this manual we use NOTES to provide

information that is important for the successful application and understanding of the product. A

NOTE block is shown to the right.

NOTE

NOTE statements provide additional information or highlight procedures.

Section 1 – Introduction

Cautions and Warnings

In addition, we use special notices to make you

aware of safety considerations. These are the CAU-

TION

and WARNING blocks as shown here. They

represent increasing levels of important information. These statements help you to identify and

avoid hazards and recognize the consequences. One

of three different symbols also accompany the

CAUTION and WARNING blocks to indicate whether

the notice pertains to a condition or practice, an

electrical safety issue or a hand protection issue.

Drawings and Tables

The figures and tables are identified by the section number followed by a sequence number. The

sequence number begins with one in each section. The figures and tables are numbered separately. The figures use arabic sequence numbers

(e.g. –1, –2, –3) while the tables use roman sequence numerals (e.g. –I, –II, –III). As an example, Figure 3–2 would be the second illustration in section three while Table 3—II would be

the second table in section three.

CAUTION

CAUTION statements

identify conditions or

practices that could result

in damage to the equipment or other property.

WARNING

WARNING statements

point out conditions or

practices that could result in personal injury or

loss of life.

Ꮨ

Condition

or Practice

Electrical

Hazard

Hand

Hazard

Dukane Manual Part No. 403–566–01

3

DPC™ II Plus and EZ Welder System – User’s Manual

Manual Organization

Section 1 – Introduction describes the manual organization

and the key features of the Dukane DPC

namic Process Controller

Section 2 – Safety discusses OSHA regulations and safety

considerations.

Section 3 – Unpacking and Installation explains the DPC II

Plus placement and setup. It also shows the cable

connections for quick–start operation.

Section 4 – Controls describes the function of the front

panel controls, menu keys and status display.

Section 5 – Connectors gives the function, pinout and sig-

nal description of the rear panel connectors

on the DPC II Plus. Operation of the optional

modules is described in detail. The internal

jumper blocks to control process automation

are also identified.

) II Plus Generator.

TM

(Dy-

Section 6 – Process Setup describes the overall menu or-

ganization of the DPC–II Plus, the setup and

operate modes and gives a brief summary of the

three main menus.

Section 7 – Process Control Menu describes the Hand

Probe, Timed Auto, MPC and Press mode

menus and the Weld Methods. It also covers

the user interface configuration and parameter values.

Section 8 – Limit Definition Menu describes the Suspect

Limit and Bad Limit menus in detail.

Section 9 – Utilities Menu describes the Setup File Utilities,

Part Count and Status Output menus in detail.

Section 10 –Hand Probe and Stack Assembly describes the

assembly and mounting of both hand probes and

probe stack assemblies.

Section 11 –System Checkout describes basic system

tests to ensure that the DPC II Plus is functioning properly.

4

Dukane Manual Part No. 403–566–01

Section 12 –Troubleshooting provides helpful tips on solv-

ing the most common problems.

Section 13 –Maintenance lists a schedule of suggested pre-

ventive maintenance items.

Section 14 –Contacting Dukane provides information on

contacting or obtaining support from your Dukane Ultrasonics team.

Section 15 –Specifications lists the DPC–II Plus dimen-

sions, power and space requirements. It also

interprets the model number coding.

Section 16 –Warranty contains a copy of our equipment

warranty and tooling warranty.

Section 1 – Introduction

Appendices

A – List of Figures.

B – List of Tables.

C – Sample Circuitry for user supplied automation.

Index

Dukane Manual Part No. 403–566–01

5

DPC™ II Plus and EZ Welder System – User’s Manual

DPC II Plus Overview

The DPC™ II Plus is the newest model in Dukane’s Dy-

namic Process Controller product family. This system will

accept a wide variety of optional modules and is designed

for use with ultrasonic presses or applications that require the use of hand probes or thruster systems.

The DPC II Plus provides basic system control inputs

and system monitor and status outputs. This makes the

DPC II Plus ideal for automated control systems. Signal

conditioning and electrical isolation are also provided.

Like other DPC models, the II Plus includes the same

internal ultrasonic generator circuitry and features. Optional modules are available to enhance the DPC’s ability to meet a wide variety of process requirements. The

most common combination includes the Timer board

and a Press control board. Other options include an

Remote Amplitude control, a Power Signal module for

Weld–by–Energy requirements and up to two Multi–

Probe controller modules (DPC II Plus only) for driving multiple probe systems. In most cases, DPC II Plus

systems in the field can be upgraded on-site if they already have the standard Timer board.

All DPC II Plus generators (except the highest power

models) and the EZ/EZ–X Model 1000 feature a universal power supply with dual line–voltage

tion, the equipment is designed and tested to comply with

FCC and CE regulations that apply to this product.

1

input. In addi-

EZ Welder™ Overview

The EZ Welder™ system combines the best features of

the DPC II Plus ultrasonic generator with a quality press

in a matched, low–cost welding system. The generator

and press are sold as a package and are not upgradable or

interchangeable with other Dukane generators.

The EZ and EZX Welders are both single–pressure systems. The EZX model adds an energy mode and features additional limit switches for pretrigger and end–

of–weld indication. The EZ Welder press has a

maximumstroke of 5–inches.

1

See Tables 15—I and 15—II

6

Dukane Manual Part No. 403–566–01

DPC II Plus™ Key Features

• Timer Board option provides weld and hold

time control and stores up to eight setup files.

• Press Board option provides control for a

Dukane ultrasonic press and thruster.

• Multi–Point Control Module option permits

one DPC to handle up to eight probes in an

automation environment (DPC II Plus or DPC II).

• Plug and Weld system recognizes when modules

are added or removed from the system

• Process Control Menu automatically

reconfigures the user interface to conform to the

modules or hand probes currently installed.

• 4–Line LCD Display gives the complete

parameter setting to speedup the setup process.

Section 1 – Introduction

• System Connections are provided for

automation equipment to monitor and control

the ultrasonic welding process.

• Modular Design simplifies upgrades and

increases flexibility as your application

requirements change.

• Flow Through Cooling Tunnel is

thermostatically controlled to reduce thermal

gradients and increase component life. Fan runs

only when required to minimize dust buildup.

• Pulse Width Modulation is Dukane’s patented

circuitry that allows the DPC power supply to

efficiently control the voltage sent to the

transducer in the acoustic stack.

• Linear Ramp Softstart circuitry is provided

allowing the acoustic stack to be brought to

operating amplitude smoothly, minimizing the

startup shock stress.

• Auto-Trac Tuning automatically tracks the

resonant frequency of the acoustic stack (horn,

booster, transducer), and adjusts the generator

output frequency to match it.

(continued on next page)

Dukane Manual Part No. 403–566–01

2

2

Within specified ranges

7

DPC™ II Plus and EZ Welder System – User’s Manual

• Dual Line–Voltage 1 Universal Power Supply

means that the DPC will operate worldwide.

Auto-Ranging means that adjustments by the

operator related to power input are unnecessary.

• Line Voltage Regulation automatically

maintains a constant output regardless of line

voltage deviation.

• Load Regulation provides constant amplitude

automatically up to the rated overload power level.

• Electronic Overload protection prevent

component failure.

• CE Certification means that the DPC II Plus and

DPC EZ meets the required European standards

to be sold and used in Europe.

• ISO 9001 Certification means that the DPC II

Plus and EZ are manufactured to very high quality

standards and assures you of Dukane’s

commitment to being a quality vendor and its goal

of continuous improvement.

2

1

See Tables 15—I and 15—II

2

Within specified ranges

EZ Welder™ Key Features

• DPC Based generator means a rugged, quality

system for reliable operation.

• Narrow–Profile Press (4.5 inches) for close

spacing in multihead and automation

installations.

• Top–of–Stroke limit switch output for

automation applications.

• Chrome plated press column and aluminum

alloy–booster are standard.

• Cast Aluminum heavy–duty base for stability.

• Calibrated dynamic trigger system with LED

indicator initiates the weld cycle at user

selectable force.

• Pneumatic stroke speed adjustment on press

controls horn travel velocity to workpiece.

• Hinged press transducer door for quick

tooling changeover.

8

Dukane Manual Part No. 403–566–01

Section 1 – Introduction

SECTION 2

Safety Tips

• Health & Safety

• RFI Considerations

Health & Safety Tips...................................... 11

Plastics Health Notice ...........................................12

Electrical Grounding Safety .................................. 12

RFI Considerations ........................................ 13

Dukane Corporation •• Ultrasonics Division

Dukane Manual Part No. 403–566–01

9

DPC™ II Plus and EZ Welder System – User’s Manual

This page intentionally left blank

10

Dukane Manual Part No. 403–566–01

Health and Safety Tips

Please observe these health and safety recommendations for safe, efficient, and injury-free operation of your equipment. In this manual, the term

system refers to a complete group of components

associated with the welding of plastic or metal

parts, also known as an ultrasonic assembly sys-

tem. A typical system consists of a generator and/

or ultrasonic process controller, start and stop

switches, power controls, connecting cables, and

the probe assembly which includes the transducer,

booster, horn and replaceable horn tip.

Proper Installation – Operate system components

only after they are properly installed and checked.

No Unauthorized Modifications – Do not modify

your system in any way unless authorized to do so

by Dukane Corporation. Unauthorized modifications may cause injury to the operator and/or equipment damage. In addition, unauthorized modifications will void the equipment warranty.

Keep the Cover On – Do not remove the equip-

ment cover unless specifically directed to do so by

Dukane Corporation. The generator produces hazardous electrical voltages which could cause injury.

Grounded Electrical Power – Operate this equipment only with a properly grounded electrical connection. (See Electrical Safety Grounding Instructions on the next page.)

Comply with Regulations – You may be required

to add accessories to bring the system into compliance with applicable OSHA regulations.

Ꮨ

Section 2 – Safety Tips

IMPORTANT

Never operate the DPC II

Plus with the cover off.

This is an unsafe practice

and may cause injury.

CAUTION

Parts being joined ultrasonically sometimes

vibrate at audible frequencies. Wear ear

protection to reduce annoying or uncomfortable

sounds. In addition,

sound absorbing materials, enclosures or sound

deflectors may be installed to reduce the

noise level.

Dukane Manual Part No. 403–566–01

11

DPC™ II Plus and EZ Welder System – User’s Manual

Plastics Health Notice

Before using any Dukane ultrasonic welding system, be sure you are familiar with OSHA regulations from the U.S. Department of Labor about the

particular type of plastic(s) you are using.

When plastic materials are being processed, they

may emit fumes and/or gases that could be hazardous.

Make sure there is proper ventilation whenever

these plastics are processed.

Electrical Safety Grounding

Instructions

For safety, the power cords used on all Dukane

products have a three-prong, grounding-type plug.

Ꮨ

CAUTION

If you must have a twoprong electrical receptacle, we strongly

recommend that you replace it with a properly

grounded three-prong

type. Have a qualified

electrician replace it following the National Electric Code and any local

codes and ordinances

that apply.

See Figures 2-1 and 2-2.

Approved 2 pole, 3 wire grounding

receptacle BRYANT No. 5621 or

equivalent to NEMA 5–15R or 5–20R

Figure 2-1 Example of 120 Volt, Grounded,

3-Prong Receptacle

Approved 2 pole, 3 wire grounding

receptacle HUBBELL No. 5652 or

equivalent to NEMA 6–15R or 6–20R

Figure 2-2 Example of 220 Volt, Grounded,

3-Prong Receptacle

Ꮨ

CAUTION

If there is any question

about the grounding of

your receptacle, have it

checked by a qualified

electrician. Do not cut

off the power cord

grounding prong, or alter the plug in any way.

If an extension cord is

needed, use a threewire cord that is in good

condition. The cord

should have an adequate power rating to

do the job safely. It must

be plugged into a

grounded receptacle.

Do not use a two-wire

extension cord with this

product.

12

Dukane Manual Part No. 403–566–01

The power cable normally provided for international use is compatible with many power outlets

(refer to Figure 2-3.) However, if your application requires another type of cable, check with

the local Dukane products representative, and follow local regulations concerning proper wiring

and grounding.

Section 2 – Safety Tips

Grounding Contacts

Typical Outlet

AC Power Cable (Provided)

RFI Considerations

In addition to the safety considerations, proper

grounding at the generator power cord is essential for the effective suppression of RFI (Radio

Frequency Interference). Every DPC contains a

RFI filter which blocks noise on the AC power

line from entering the DPC control circuitry. This

filter also prevents ultrasonic RFI from being fed

back into the AC power line. In order for the RFI

filter to operate properly, it is necessary to adequately ground the DPC. Run an additional

grounding wire from the rear grounding connection (see Figure 2-4) to the nearest grounded metal

pipe or equivalent earth ground by means of a

ground clamp. Use at least an 14 AWG** wire

for the connection to the DPC chassis. Stranded

is more flexible and easier to work with than solid

wire. However if you use stranded wire, crimp

spade lugs on the end to ensure a good connection.

If you have a color choice, green is the commonly

accepted color for an electrical ground connection.

Figure 2-3 International 220/240V Grounding

10 – 24 x 1/2" threaded stud

I

O

14 AWG to Earth Ground

Figure 2-4 DPCGrounding Arrangement

If you have connected the DPC to a Press and/or

Thruster, use a star † connection from the earth

ground to the DPC and Press as illustrated in

Figure 2–5.

** 14 AWG wire has a diameter of 1.63mm or 0.064"

†

Run seperate ground wires from each piece of

equipment to the earth ground. See the appropriate schematic diagram in Figures 3–4 thru 3–8.

Dukane Manual Part No. 403–566–01

To

Ground

14 AWG Wire

Figure 2-5 Press Grounding Arrangement

13

DPC™ II Plus and EZ Welder System – User’s Manual

This page intentionally left blank

14

Dukane Manual Part No. 403–566–01

Section 3 – Unpacking and Installation

SECTION 3

Unpacking & Installation

• Unpacking the DPC

• Placement of the DPC

• Rear Panel Overview

• Grounding the System

• Connecting the Cables

Shipping Carton Contents ............................ 17

DPC Placement ............................................. 17

Benchtop .............................................................17

Rack Mounting .................................................... 18

Rear Panel Overview ..................................... 19

Ground the System ....................................... 19

Connect the Cables ...................................... 20

Hand Probe System ..............................................20

Automated Probe System .....................................20

Multiple Probe System..........................................22

Automated Thruster System .................................23

Dukane Press System............................................24

Rear Electrical Power Switch .................................25

Dukane Corporation •• Ultrasonics Division

Dukane Manual Part No. 403–566–01

15

DPC™ II Plus and EZ Welder System – User’s Manual

This page intentionally left blank

16

Dukane Manual Part No. 403–566–01

Shipping Contents

2200

PERCENTAGE OF AVAILABLE POWER

D

y

n

amic Proc

es

s

Con

t

r

oll

e

r

DPC

I

I

P

LUS

Quantity Item Part Number

Section 3 – Unpacking and Installation

DPC II Plus or EZ Generator1

1

DPC II Plus/EZ User's Manual 403–566–00

**

** DPC Part Number depends upon Frequency and Power Rating

AC power cord and cables as specified. See your Packing List.

Compare with Table

3—II

on page 21.

Table 3—I Contents of DPC II Plus Shipping Container

Carefully open the shipping container, and make

sure it contains the items shown in Table 3–I. Inspect the DPC for damage. Report any damage

immediately to Dukane Ultrasonics Support/Service.

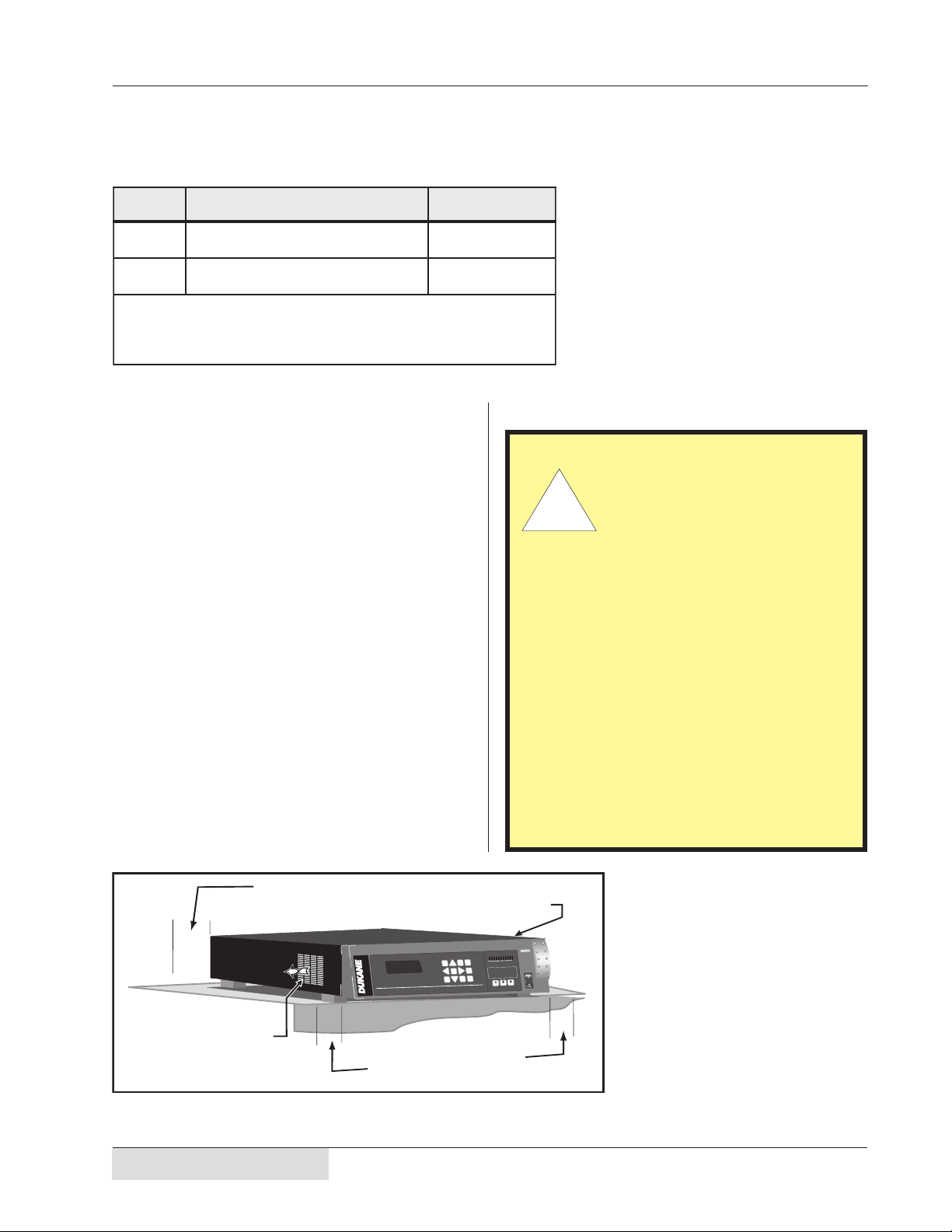

DPC Placement

Placement of the DPC depends on whether it is a

benchtop or rack-mounted configuration

Benchtop

Place the DPC on a flat surface with its front panel

easily accessible. Make certain the placement and

cabling do not interfere with the assembly operation.

Allow 5 inches (13 cm) at the rear of the DPC for

cable clearance. Allow 2 inches (5 cm) of space

on either side of the DPC for air circulation. Refer to the illustration in Figure 3-1.

CAUTION

Allow space for air

ventilation around the DPC II

Plus chassis, the air intake

and exhaust. The fan draws

in fresh air to cool the internal components,

reduce

thermal gradients and

increase component life.

When viewed from the

front, the fresh air intake is

on the right and the hot air

exhaust is on the left side.

If excessive dust accumulates

in the slots, wipe or vacuum

them clean. Do not use compressed air as this may force

the dust inside the chassis.

Allow 5 inches (13 cm) space for cables behind the DPC

Intake Vent for Thermostatically Controlled Fan

Exhaust Air from

Flow–Thru Cooling Tunnel

Figure 3-1 Installing a Benchtop DPC

Dukane Manual Part No. 403–566–01

N

E

G

.

O

F

N

I

.

P

M

A

T

S

U

J

D

A

ontroller

ic Process C

ynam

D

2200

Allow space for ventilation,

2 inches (5 cm) on each side.

E

+

E

D

O

M

R

E

T

–

N

E

DPC II

R

E

W

O

P

E

L

1

B

P

A

L

I

A

V

A

F

O

E

G

A

T

N

E

C

R

E

P

D

A

O

L

R

E

V

T

O

S

E

T

T

U

P

IN

T

L

U

A

F

D

L

E

W

2

P

E

IN

L

F

F

O

P

M

E

T

R

E

V

O

E

N

I

L

N

O

S

U

T

A

T

S

L

E

C

N

A

C

F

F

O

N

O

T

S

E

E

T

N

I

L

E

N

I

L

S

U

L

P

T

U

P

T

U

O

R

E

W

O

P

M

E

T

S

Y

S

0

0

1

D

0

L

8

E

W

0

6

0

4

0

2

R

E

0

T

N

17

DPC™ II Plus and EZ Welder System – User’s Manual

2200

PERCENTA

GE OF AVAI

LABLE POW

ER

Dyna mic

P

roc

ess

C

o

nt

ro

ller

D

PC

I

I

P

lus

Rack Mounting

Figure 3-2 shows the use of a bracket kit in

mounting a DPC to a 19-inch equipment rack.

(Contact Ultrasonic Sales at Dukane, and request

Part Number US-1155.) The DPC illustrated

has the standard, angled front panel of impactresistant ABS plastic.

Allow 5 inches (13 cm) of space behind the DPC for cables

S

Y

S

T

E

M

P

O

W

E

R

W

E

L

D

P

1

W

E

L

D

P

1

N

C

E

L

O

U

T

P

U

T

0

20

40

60

80 100

P

E

R

C

E

N

T

A

G

E

O

F

A

V

A

I

L

A

B

L

E

P

O

W

E

R

F

A

U

L

T

I

N

P

U

T

T

E

S

T

O

V

E

R

L

O

A

D

O

N

L

I

N

E

O

V

E

R

T

E

M

P

O

F

F

L

I

N

E

STATUS

O

N

O

F

F

T

E

S

T

L

I

N

E

L

I

N

E

Dynamic Process Controller

2200

G

E

N

.

W

E

L

+

D

O

I

N

F

O

.

P

1

M

O

D

E

A

M

P

.

–

E

N

T

E

C

R

A

A

D

J

U

S

T

D

PC II Plus

Approximate

17.35 inches (44 cm)

19 inches (48 cm)

Figure 3-2 Rack-mounted DPC Using Bracket Kit

Approximate

22.25 in

(57 cm)

CAUTION

Allow space for air

ventilation around the DPC II

Plus chassis, air intake and

exhaust. The fan draws in

fresh air to cool the internal components,

reduce

thermal gradients and

increase component life.

When viewed from the

front, the fresh air intake is

on the right and the hot air

exhaust is on the left side.

If excessive dust accumulates

in the slots, wipe or vacuum

them clean. Do not use compressed air as this may force

the dust inside the chassis.

18

Dukane Manual Part No. 403–566–01

Section 3 – Unpacking and Installation

Rear Panel Overview

Familiarize yourself with the connection points for

power, ground, ultrasound output, system I/O and

the optional modules on the rear of the DPC II

Plus shown below in Figure 3–3. The standard

modules and connectors are labeled with the black

boxes. The optional modules are labeled with italics. The EEPROM Serial Programming Port is

used to upgrade the DPC™ firmware. The grounding lugs, serial number tags, etc. are located in the

same position on all DPC II, EZ Welder, DPC II

Plus, DPC III and DPC IV generators.

Slave Multi–Probe

Controller Module

Grounding

Lug

Rear AC

Power Switch

NOTE

Not all of the modules illustrated below can be

installed simultaneously. They are shown to represent the various configurations that can be

assembled to meet specific requirements.

(DPC II Plus only)

Master Multi–Probe

Controller Module

(DPC II Plus only)

Press Control

Module

EEPROM Serial

Programming Port

Power Signal

Output Module

Remote Amplitude

Control Module

IEC

AC Power

Input

Figure 3-3 DPC II Plus and EZ Welder Rear Panel and Optional Modules

Model No. Tag

Connector

Ground the System

The DPC II Plus includes an internal RFI filter.

The standard building AC ground connection is

normally not sufficient to completely suppress

the RFI. Attach a ground cable from the DPC

grounding lug (located next to the rear AC power

switch) to an earth ground. If you are using a

press or automated probe system, each piece of

equipment must also be solidly grounded. Refer

to Figure 2–5 and Figures 3–4 through 3–8 for

the proper grounding arrangement.

Dukane Manual Part No. 403–566–01

Ꮨ

System

Output

System

Input

Connector

J1 Ultrasound

Output (BNC)

CAUTION

Before attaching the

cables, make sure the

DPC II Plus is properly

grounded. Refer to Figure

2–5 and the appropriate

diagram (Figures 3–4 thru

3–8) for the correct

grounding connections.

Serial

No.

Ta g

19

DPC™ II Plus and EZ Welder System – User’s Manual

Connect the Cables

The instructions here and the diagrams in Figures

3–4 through 3–7 are meant to serve as a quick–

start guide. The connectors and their pinouts are

discussed in greater detail in Section 5.

Manual Probe System

Step 1. Ground the DPC II Plus chassis.

Step 2. Attach the System In adapter cable (see

Figure 3–4) to the 14-pin AMP

connector at the end of the probe cable.

Step 3. Connect the other end of the adapter

to the System In HD-15 connector on

the rear of the DPC II Plus.

Step 4. Attach the high voltage ultrasound

coaxial cable to the rear-panel J1

connector.

CAUTION

Make sure electrical power

is OFF before connecting/

Ꮨ

sure BOTH the front and rear panel AC

power breaker switches are in the OFF

position.

Failure to turn off the power may result in damage to the DPC and/or the

modules.

disconnecting cables or installing/removing modules

from the DPC II Plus. Make

Step 5. Optional – If your system has a Press

Control Module, you will also need a

jumper block (Part No. 200-1293) to

replace the normally closed contact

from the Emergency Stop safety switch.

Step 6. Attach the power cord to the DPC II

Plus and plug the other end into an

approved AC outlet.

Automated Probe System

Step 1. Ground the DPC II Plus chassis and

the probe support.

Step 2. Attach the high voltage coax cable

from the probe mount to the rear-panel

DPC connector J1 (see Figure 3–5).

Step 3. Connect the automation control cable

from the user–supplied automation

equipment to the System Input rear

panel HD-15 connector (Figure 3–5).

CAUTION

The power cord is

equipped with a three-

Ꮨ

ceptacle is encountered, we strongly

recommend that it be replaced with

a properly grounded three-lead receptacle. Have a qualified electrician

perform the installation in accordance with the National Electrical

Code and local codes and ordinances.

DO NOT cut off the AC power cord

grounding prong or alter the plug in

any way.

prong, grounded-type

plug for your safety.

Whenever a two-slot re-

20

Dukane Manual Part No. 403–566–01

Loading...

Loading...