Page 1

KIA SKT210SY

TRAINING MANUAL

PROGRAMMING MANUAL -1-

Manual Iss 1

This document is based on information available at the time of its publication.

While efforts have been made to render accuracy to its content, the

information contained herein does not purport to cover all details or variations

in hardware and software, nor to provide every possible contingency in

connection with installation, operation, programming, and maintenance.

Features maybe described herein which are not present in all hardware and

software systems.

Dugard Ltd assumes no obligation of notice to holders of this document with

respect to changes subsequently made.

Dugard Ltd makes no representation or warranty, expressed, implied or

statutory with respect to, and assumes no responsibility for the accuracy,

completeness, sufficiency or usefulness of the information in the manual.

Page 2

PROGRAMMING MANUAL -2-

Cutting speed formula: ............................................................................................................................. 9

Vc= Cutting speed .................................................................................................................................... 9

D= Part standard diameter ....................................................................................................................... 9

n= Rpm limit. ............................................................................................................................................ 9

Machines must be at the X home position for turret indexing. .................................................................. 9

We advise you to enter workpiece zero at the beginning of the program. .............................................. 10

G10 P0 Z-80. .......................................................................................................................................... 10

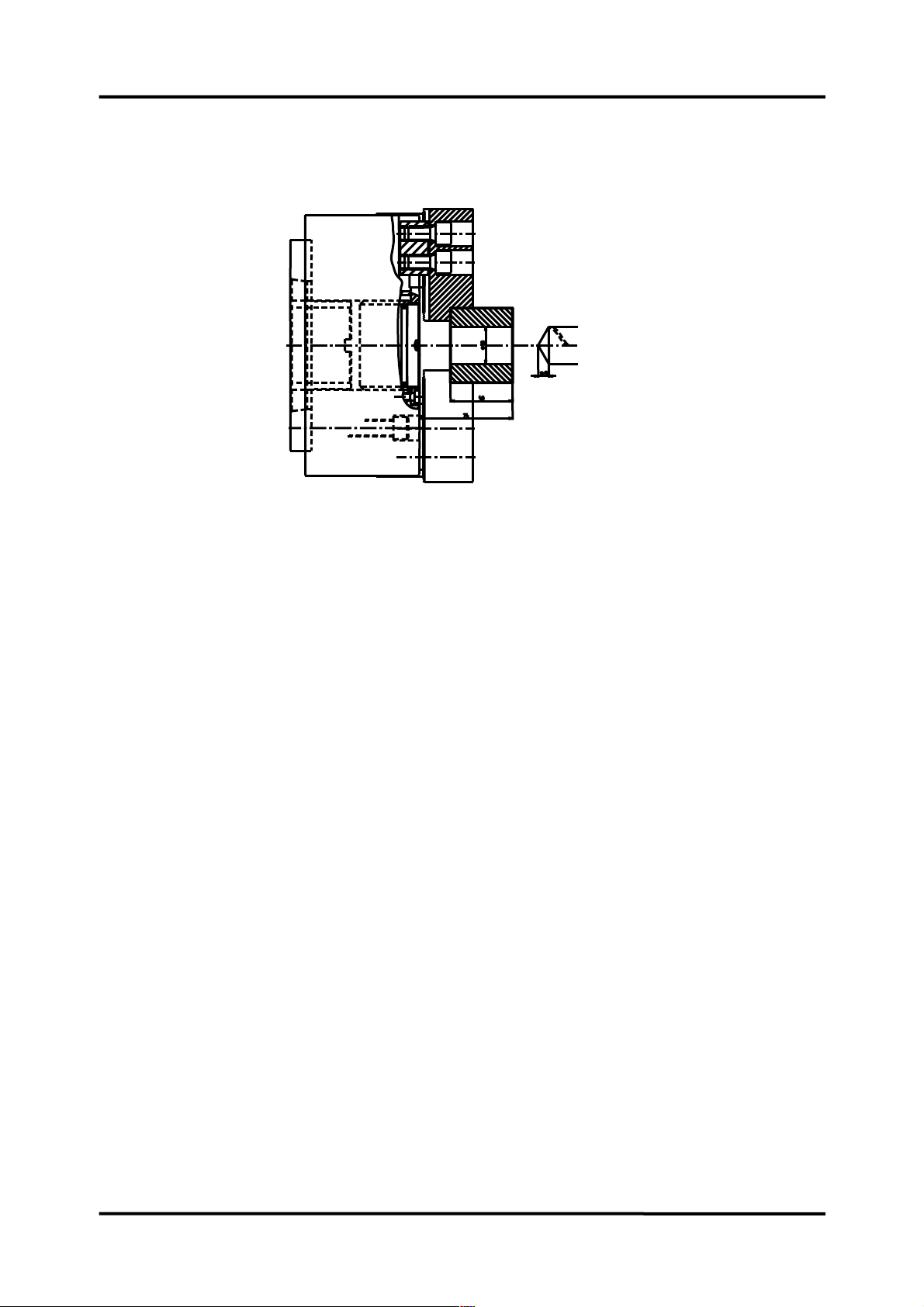

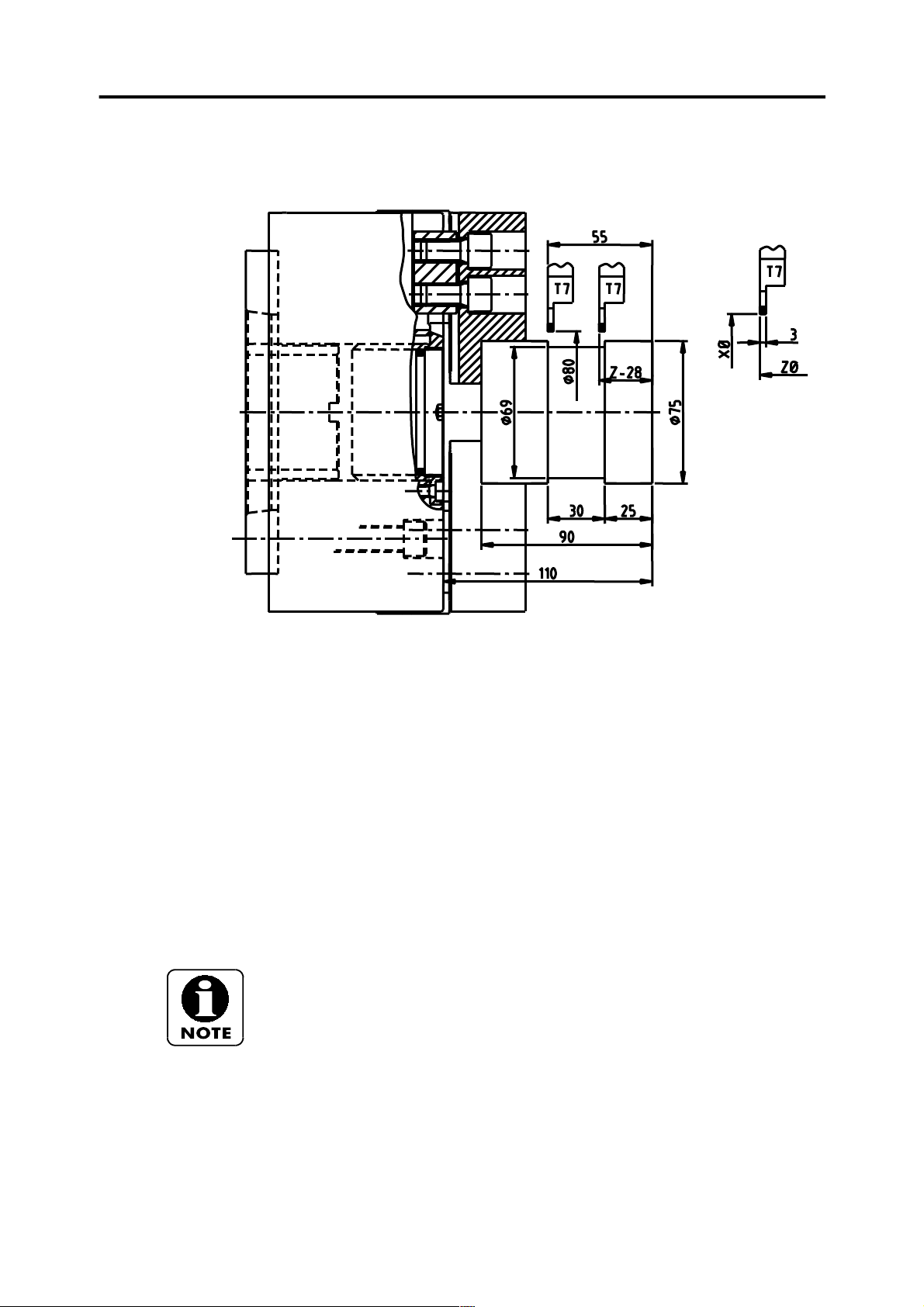

How to prepare the machine for machining operations with transfer: ..................................................... 11

1st Determine workpiece zero and carry out the 1st machining stage .................................................... 11

G54 is programmed. ............................................................................................................................... 11

2nd Stop the machine and verify the dimension before doing the transfer. ............................................ 11

3nd Do the transfer and place the sub-spindle in working position. ........................................................ 11

4nd Stop the machine and determine workpiece zero before performing the 2nd machining stage G55 is

programmed. ........................................................................................................................................... 11

In this manual we will always refer to G codes type A. .......................................................................... 12

Comment:: .............................................................................................................................................. 12

These are notes included in the program. .............................................................................................. 12

These notes are totally optional, and it is up to the programmer to enter them or not. ........................... 12

These notes will be always placed in round brackets () in order to prevent the program reading them. . 12

T101 12

Here is shown that the tool to be used is in position 1 and a offset value of 01 is applied. ..................... 12

T0101 could be also entered, as the four mandatory characters are present, however, the first zero is

optional. ................................................................................................................................................... 12

Head rotation direction: .......................................................................................................................... 12

M3 head rotation direction forward ......................................................................................................... 12

M4 head rotation direction reverse ......................................................................................................... 12

M5 spindle stop ...................................................................................................................................... 12

If instructing the reverse from the forward direction or vice versa, the spindle must be stopped first. ... . 12

This is also valid for the sub spindle and live tools. ................................................................................ 12

G0 X150 Z100 ........................................................................................................................................ 12

Page 3

PROGRAMMING MANUAL -3-

Note that tool retraction in this example is to 150 mm on X+ and 100 mm on Z+ from work piece zero, and

not from chuck face, as no order for changing the position is given to work piece zero, which in this example

is maintained in the previous position. ..................................................................................................... 12

Line number (N10, N20...) ...................................................................................................................... 12

Line numbers are optional, and can be either entered or not. ................................................................. 13

G0 G40 G99 X45. Z0. M8 ....................................................................................................................... 13

As you can see, G codes are first placed and then X, Z and M codes. Codes can be also entered in the

following manner: G0 X45. Z0.G99 G40 M8 ............................................................................................ 13

Entering codes such as G96 and G50 in the same line is not permitted. ................................................ 13

In this example we assume that the part is rough machined. ................................................................. 16

As seen in this example, G2 is used to machine radii in clockwise direction and G3 in counterclockwise

direction. .................................................................................................................................................. 16

You can also see that G2 or G3 is first entered, then the end point, and finally the radius, .................... 16

Circular interpolation ............................................................................................................................... 17

As you can see, for the interpolation, you must know the point from which this interpolation will take place in

order to change radius direction (in this example on point X69.282 Z-60). .............................................. 17

Time delays are entered each time a slot is machined in order to improve the ..................................... 18

surface finish. ......................................................................................................................................... 18

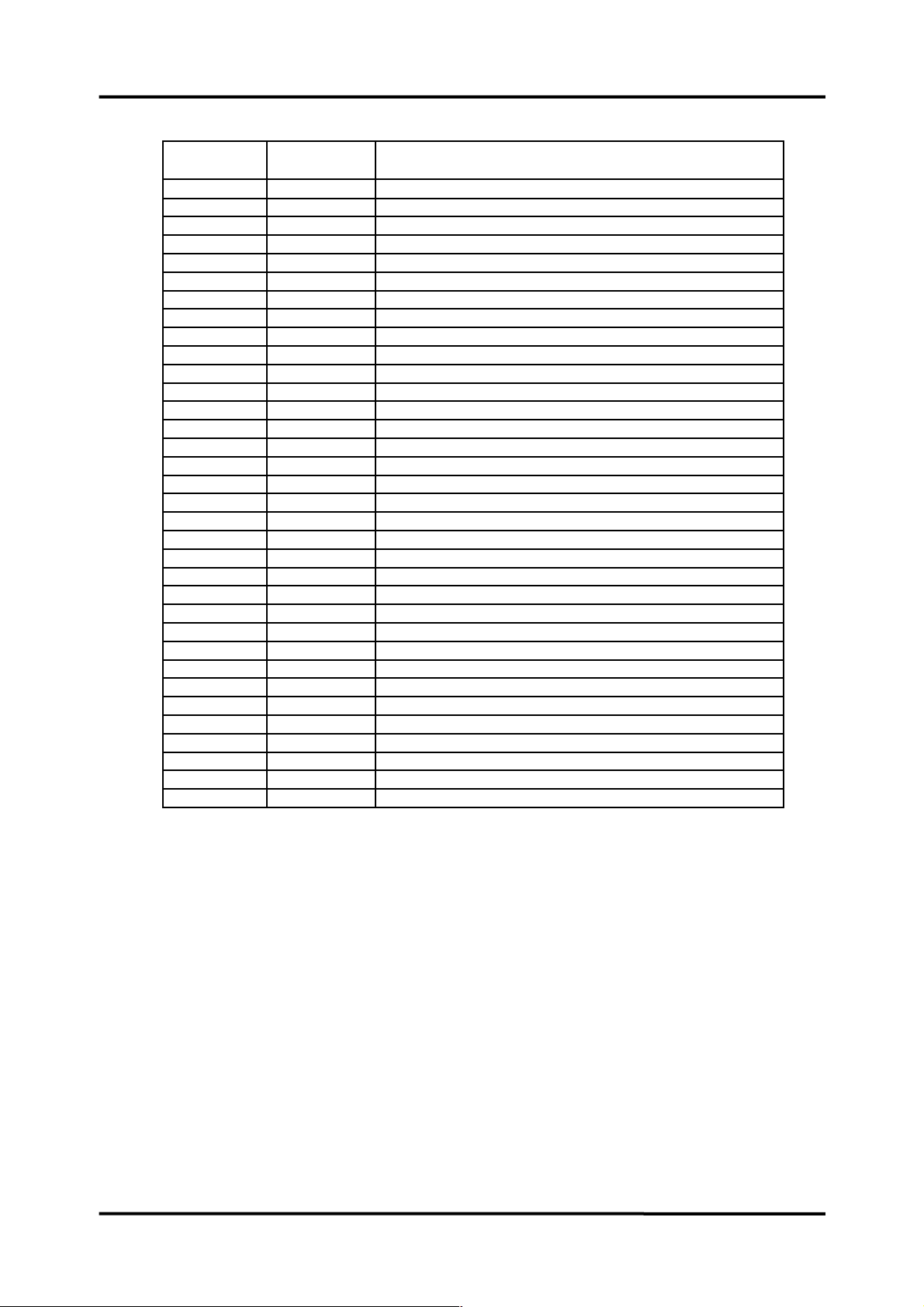

G Code List ............................................................................................................................................ 21

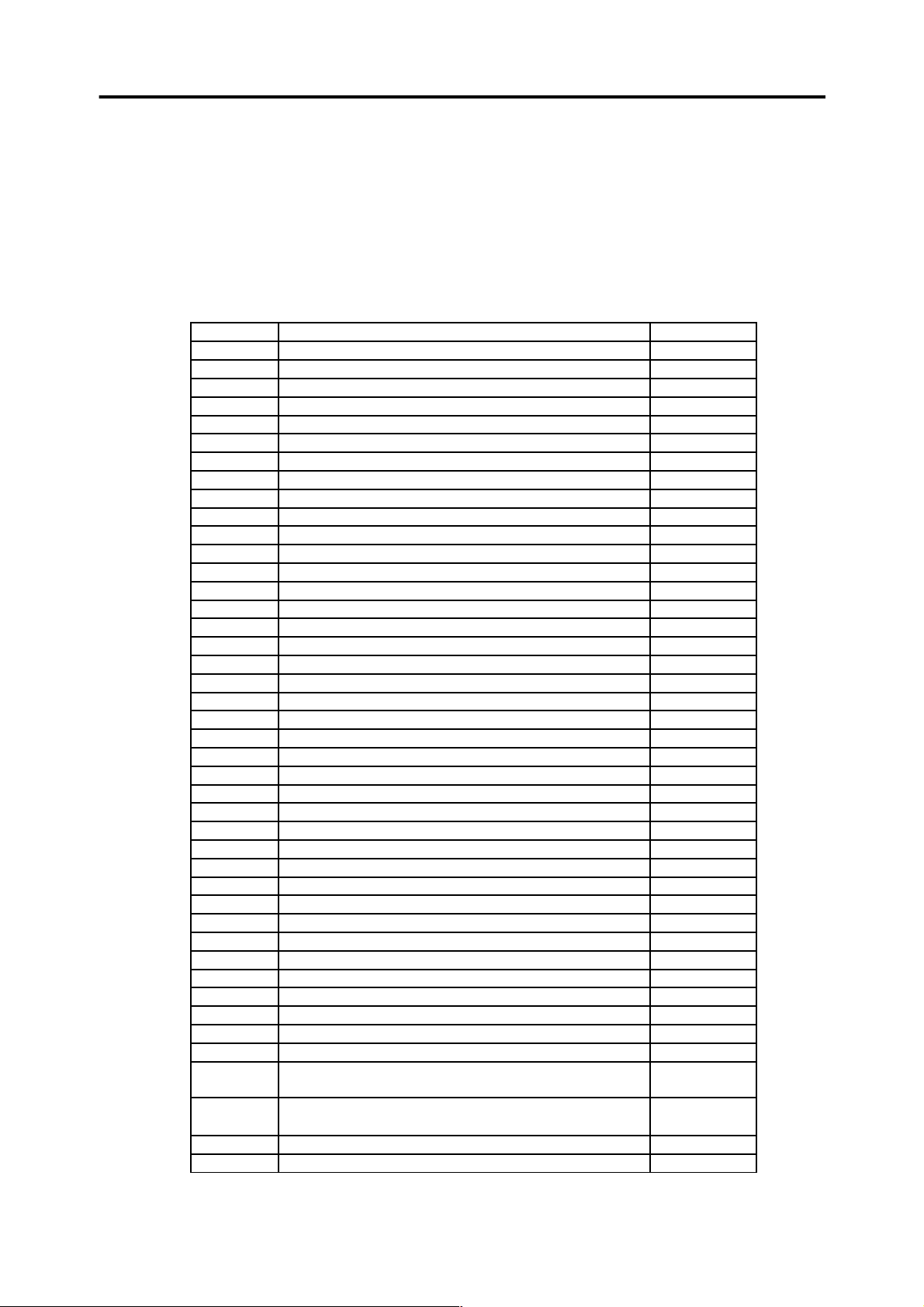

M FUNCTIONS ...................................................................................................................................... 23

THREADING .......................................................................................................................................... 25

G32 for threading operations, always operate at fixed rpm (G97). ......................................................... 26

When retapping threads, do not release the work piece, do not change the speed and do not change the

start point. ................................................................................................................................................ 26

CANNED CYCLES ................................................................................................................................. 27

At the end of each cycle sequence the machine is always positioned in the position at which this cycle

sequence was started. The tool will be commonly located in the position used for rough machining. ..... 27

The profile allows changing X and Z direction. ....................................................................................... 27

At the end of each cycle sequence the machine is always positioned in the position at which this cycle

sequence was started. ............................................................................................................................. 27

The positioning allows changing X- and Z-axis direction. ....................................................................... 27

Page 4

PROGRAMMING MANUAL -4-

Same as the above one, excepting for the profile. .................................................................................. 28

IMPORTANT: Roughing cycles are without tool radius compensation. Because of this, higher allowances will

be specified for X and Z depending on tool radius. .................................................................................. 30

1. EXAMPLES OF CANNED CYCLES .................................................................................................... 31

Groove width or groove end point can be defined with a W code in this example (W27, that is, 30 – 3 of tool),

if tool is positioned on the right-hand would be (W-27). For either Z or W, tool width must be subtracted. 35

N5 G28 U0. V0. ...................................................................................................................................... 38

T505; 38

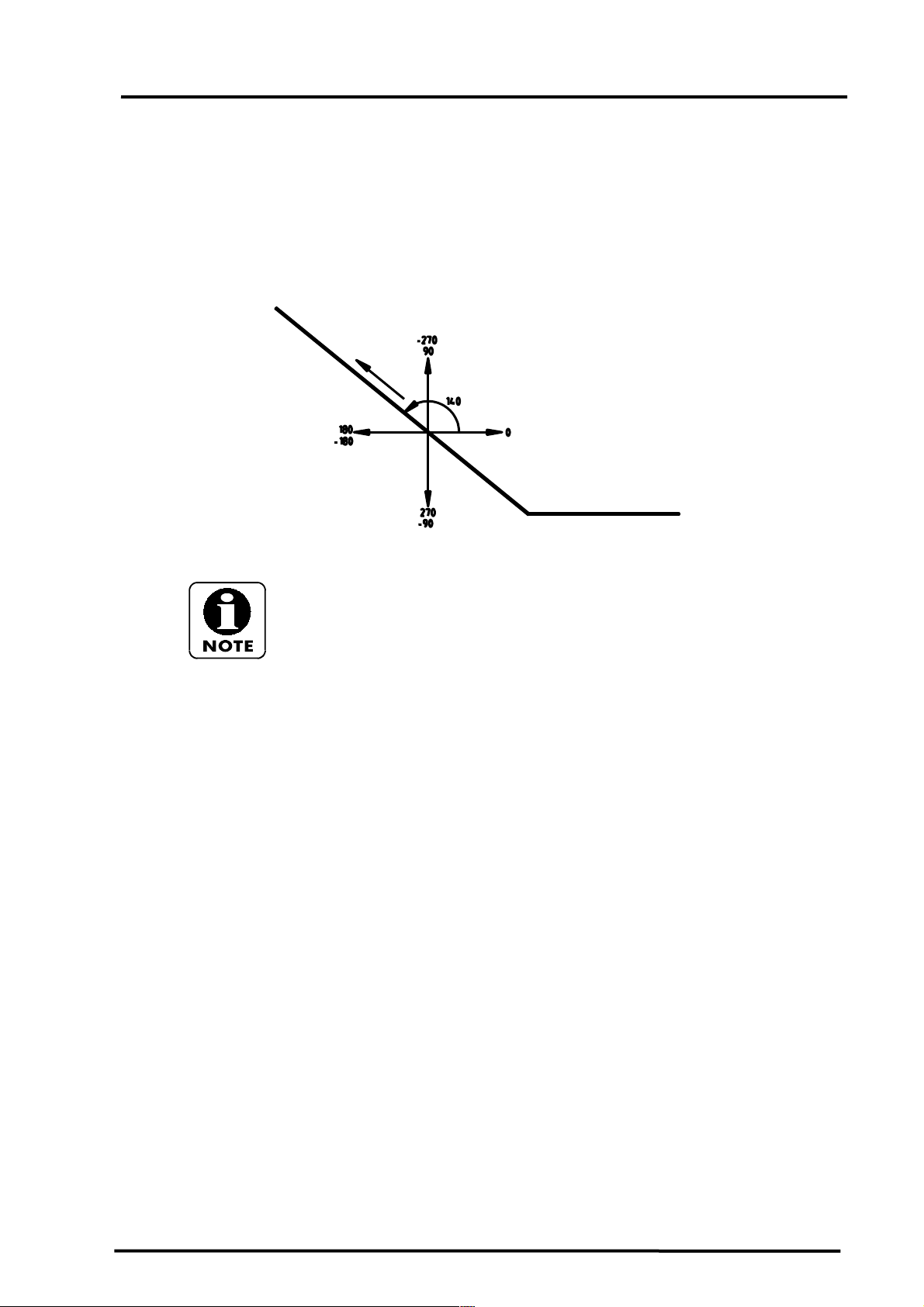

PROGRAMMING SIMPLIFICATION FUNCTIONS ................................................................................ 39

In theses cases, considering tool direction is most important. ................................................................ 39

The easier procedure is drawing a quadrant on the drawing and locate the degrees as shown on the above

diagram. .................................................................................................................................................. 39

All cycles end where they are started and, because of this, finishing positioning is done above the workpiece.

47

For control units with capability for machining profiles with X-axis direction reversal, the first block for defining

the profile must state the movement of the two axes. .............................................................................. 49

M98 Repetitions of a subprogram .......................................................................................................... 53

1- Stop the spindle (S1 and/or S2) by entering the command M5 (S1) or M115 (S2) before entering M43 or

M143 command. ..................................................................................................................................... 59

2- After activating M43 C-axis on G28 C0. must be entered . .................................................................. 59

3- After activating M143 A-axis on G28 A0. must be entered. ................................................................. 59

4- Before entering command M40 and M140, the powered tool must be stopped by entering command M15.

59

59

M160, M161 and M162 commands are only used on machines equipped with a sub-spindle (S). ......... 90

M160; ............ Speed synchronisation mode on. .................................................................................... 90

M161; ............ Phase and synchronisation mode off. ............................................................................. 91

M162; ............ Phase synchronisation mode on. .................................................................................... 91

1- For transferring a workpiece from main spindle to sub-spindle, main and sub-spindle speed must be

synchronised by means of M160 command. If the workpiece is transferred without activating the

synchronisation mode, damage of the workpiece could result. ................................................................ 91

Page 5

PROGRAMMING MANUAL -5-

2- For transferring an hexagonal bar, main and sub-spindle phase and speed must be synchronised by

means of M160 and M162 command, as otherwise the transfer operation will not be possible, although it is

recommended that if the part has been turned that you locate on the turned diameter so to achive any

squareness or concentricity tolerences. .................................................................................................. 91

3- M162 function can be also used for round parts, but considering that phase (and speed) synchronisation

time is longer and speed synchronisation time, using only M160 function is recommended when machining

round parts. ............................................................................................................................................. 91

Machining program. ................................................................................................................................ 92

G97 S50 M3; Main spindle rotates at 50 rpm ......................................................................................... 92

S50 M113;……………………..Sub spindle rotates at 50 rpm ................................................................. 92

M160; Synchronise spindles. .................................................................................................................. 92

M162; Synchronise spindle phase (if required). ...................................................................................... 92

Main and sub-spindle speed is synchronised to 50rpm .......................................................................... 92

M119; Sub-spindle chuck open. ............................................................................................................. 92

M151;……………………………Air blow on sub-spindle ......................................................................... 92

B-???; Sub-spindle is moved clear fo component (machine co-ordinates) ............................................. 92

G1 G98 B-??? F1500; Sub-spindle is moved over the workpiece at 1500 mm/min ................................ 92

M152; Air blow off sub-spindle. ............................................................................................................... 92

G28 B0; Sub-spindle is returned to reference point on B-axis ................................................................ 92

M161; Synchronisation mode is disabled ............................................................................................... 92

Machining program. ................................................................................................................................ 93

G97 S50 M3; Main spindle rotates at 50 rpm ......................................................................................... 93

S50 M113;………………………Sub spindle rotates at 50 rpm ............................................................... 93

M160; Synchronise spindles. .................................................................................................................. 93

M162; Synchronise spindle phase (if required). ...................................................................................... 93

Main and sub-spindle speed is synchronised to 50rpm .......................................................................... 93

M119; Sub-spindle chuck open. ............................................................................................................. 93

M151;……………………………Air blow on sub-spindle ......................................................................... 93

B-???; Sub-spindle is moved clear fo component (machine co-ordinates) ............................................. 93

G1 G98 B-??? F1500; Sub-spindle is moved over the workpiece at 1500 mm/min ................................ 93

Page 6

PROGRAMMING MANUAL -6-

G28 B0; Sub-spindle is returned to reference point on B-axis ................................................................ 93

G0 X50…………………………..Move off component. ............................................................................ 93

G28 U0………………………….Move turret home in X-axis. ................................................................... 93

G28 W0…………………………Move turret home in Z-axis. ................................................................... 93

M161; Synchronisation mode is disabled ............................................................................................... 93

G28 U0.: Turret home position in X ........................................................................................................ 94

M115: Sub-spindle is stopped ................................................................................................................ 94

G4 X0.5: Dwell for half a second ............................................................................................................ 94

M73; Parts catcher forward. ................................................................................................................... 94

Workpiece collector operates independently from turret position. .......................................................... 94

The B-axis co-ordinate value will be the G30 position, at which the workpiece is released from the sub-

spindle, without causing any interference with workpiece collector, turret, etc. ........................................ 94

G4 X0.5; Dwell for half a second ............................................................................................................ 94

M119; Open jaws on sub-spindle. .......................................................................................................... 94

G4 X3.; Dwell for three seconds to allow the part to be ejected fully. ..................................................... 94

M74; Parts catcher back. ........................................................................................................................ 94

G28 B0.; Sub spindle home. ................................................................................................................... 94

G4 X1.; Dwell for one second. ................................................................................................................ 94

G83 Example of face front drilling cycle (powered tool main spindle)…………………………………59

G83 Example of face front drilling (powered tool sub spindle)…………………………………………………..60

G87 Example of side drilling cycle (powered tool main spindle)………………………………………………..61

G87 Example of side drilling cycle (using main spindle and Y-axis)…………………………………………..62

G87 Example of side drilling cycle (powered tool sub spindle )………………………………………………...63

G184 Example of front face drilling cycle (powered tool main spindle)………………………………………...64

G185 Example of back face tapping cycle (powered tool sub spindle)………………………………………..65

G188 Example of side tapping cycle (powered tool main spindle)…………………………………………… ..66

G188 Example of side tapping cycle (powered tool main spindle using Y-axis)…………………………… ..67

Cylindrical interpolation………………………………………………………………………………………………68

Tool nose radius copensation and circular interpolation used with G112 polar coordinate interpolation….70

Example of machining a square using polar milling………………………………………………………………71

Example of machining a hexagon using polar milling…………………………………………………………….72

Page 7

PROGRAMMING MANUAL -7-

Milling using the Y-axis and C-axis…………………………………………………………………………………73

Milling usng the Y-axis and A-axis………………………………………………………………………………….76

Helical Interpolation using the Z-axis and Y-axis………………………………………………………………….79

Cylindrical Interpolation G107………………………………………………………………………………………..80

Tool nose radius compensation and circular interpolation used with G107 cylindrical interpolation…………82

Rectangle engrave example (cylindrical interpolation)…………………………………………………………….83

Rectangle with corner radii example (cylindrical interpolation)…………………………………………………..84

Part transfer (Billet)…………………………………………………………………………………………….........87

Part transfer (with part off).…………………………………………………………………………………….........87

Sub Spindle example…………………………..……………………………………………………………………..89

Part eject…………………………..……………………………………………………………………………........90

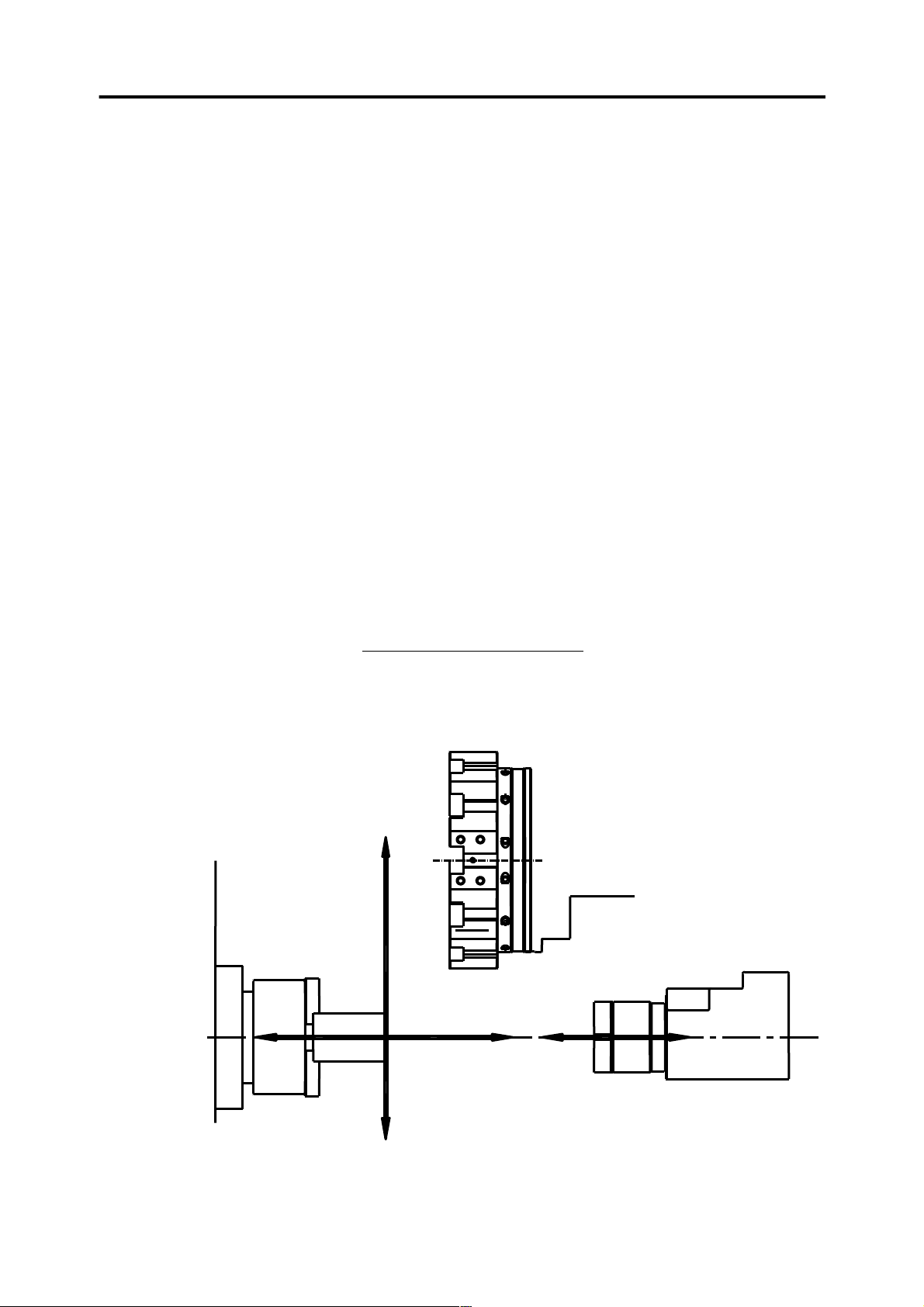

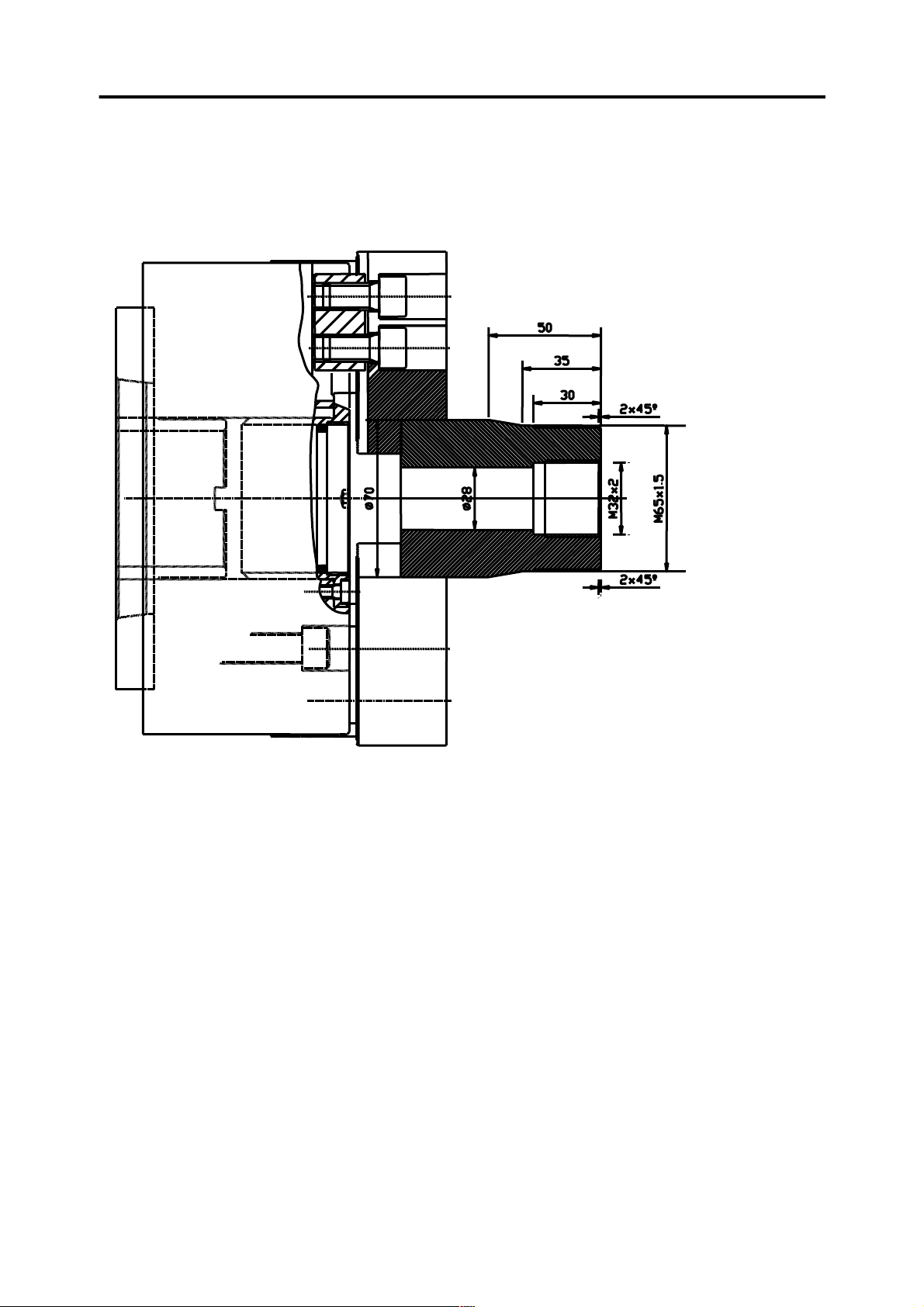

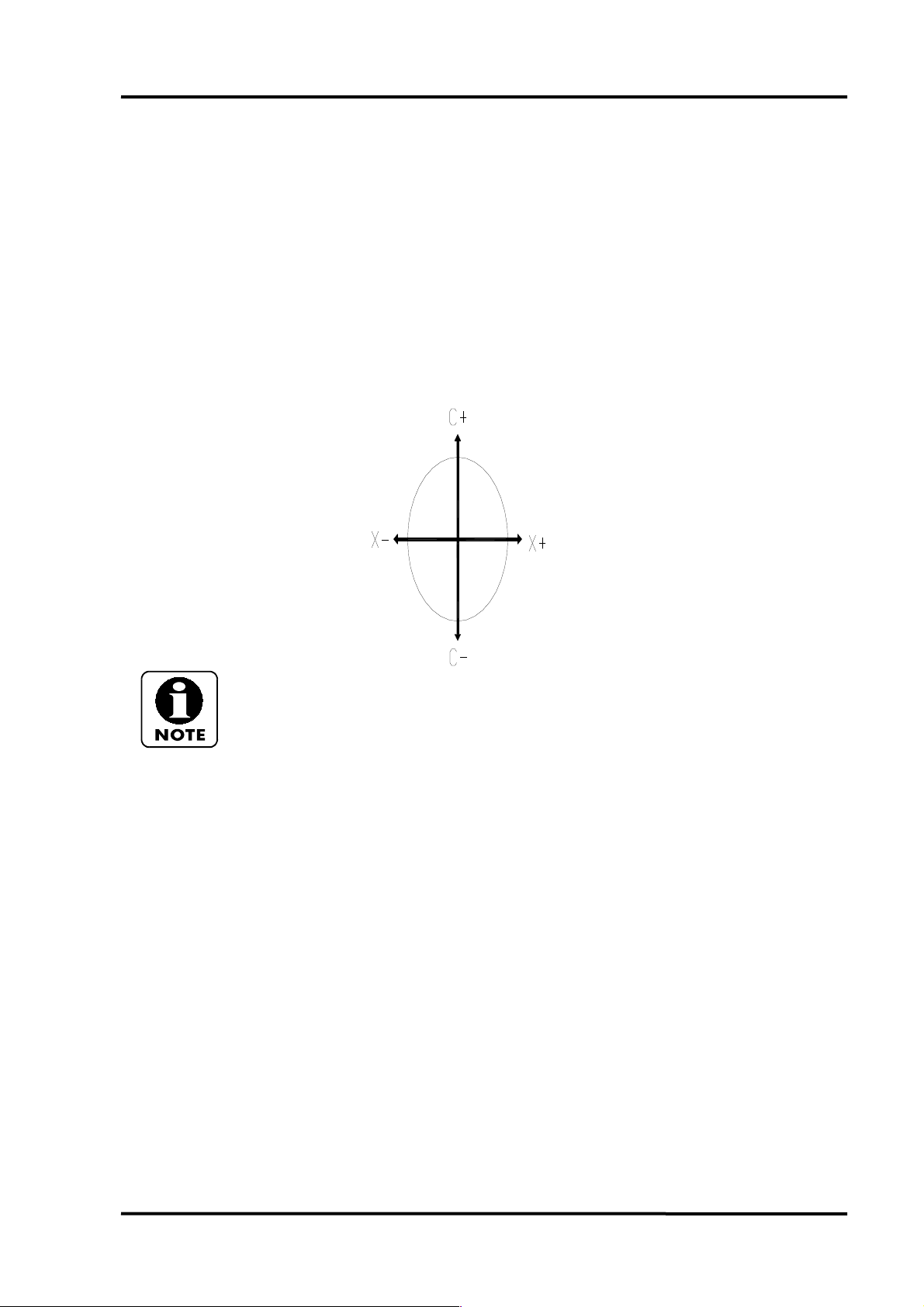

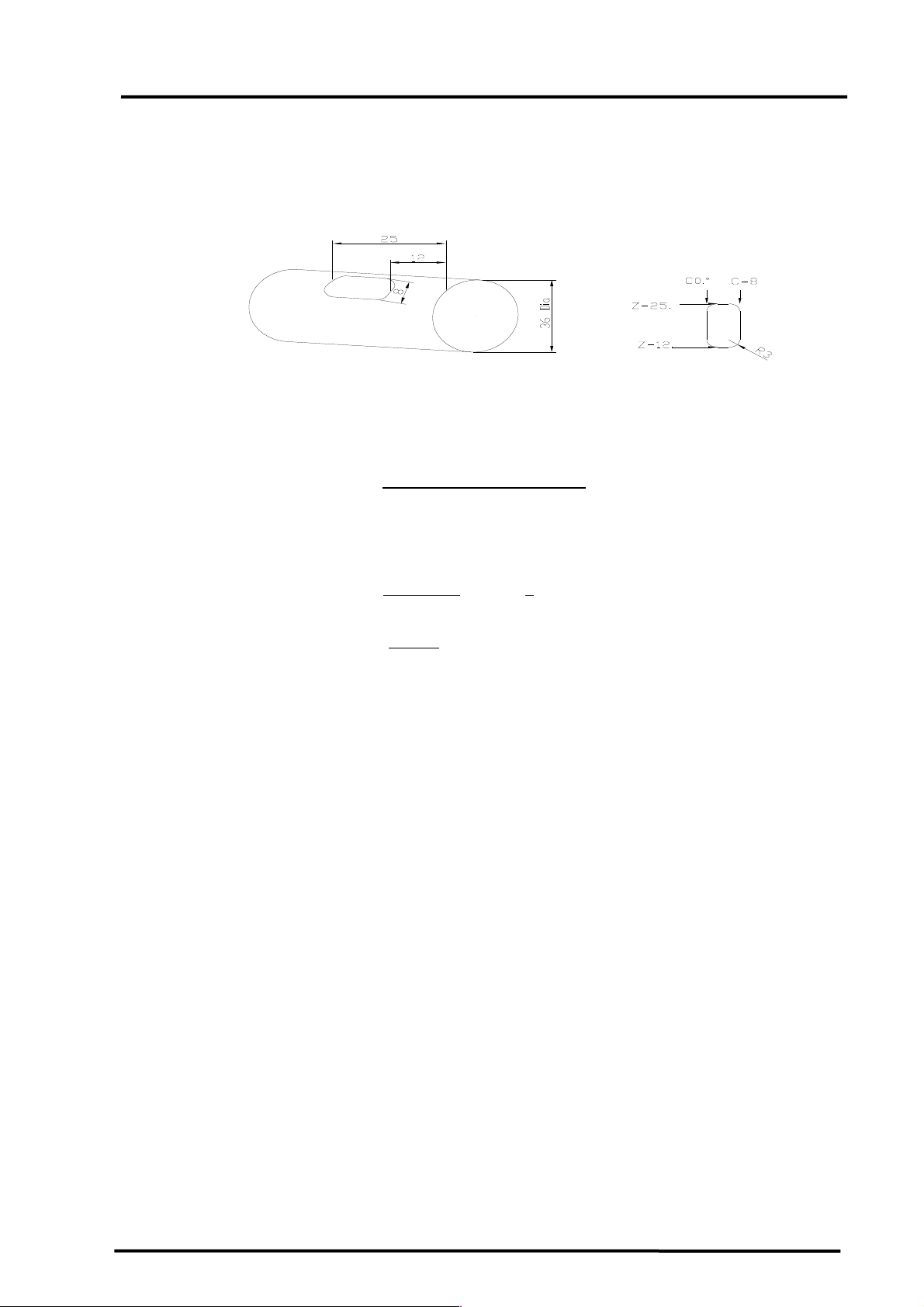

Machine axes

BASIC CONCEPTS

X+

Z- B- B+

Z+

X-

Page 8

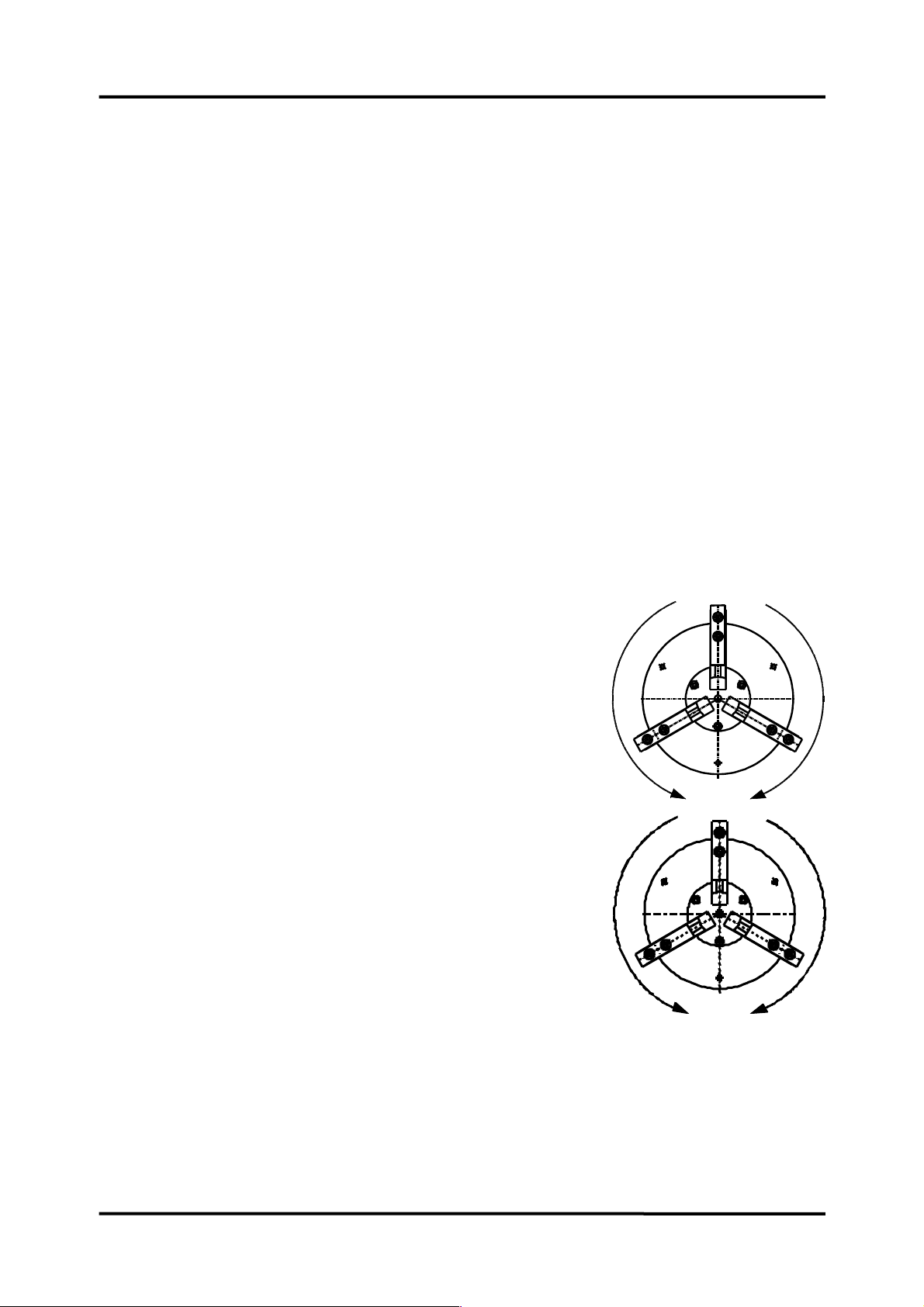

C+

C-

A+

A-

PROGRAMMING MANUAL -8-

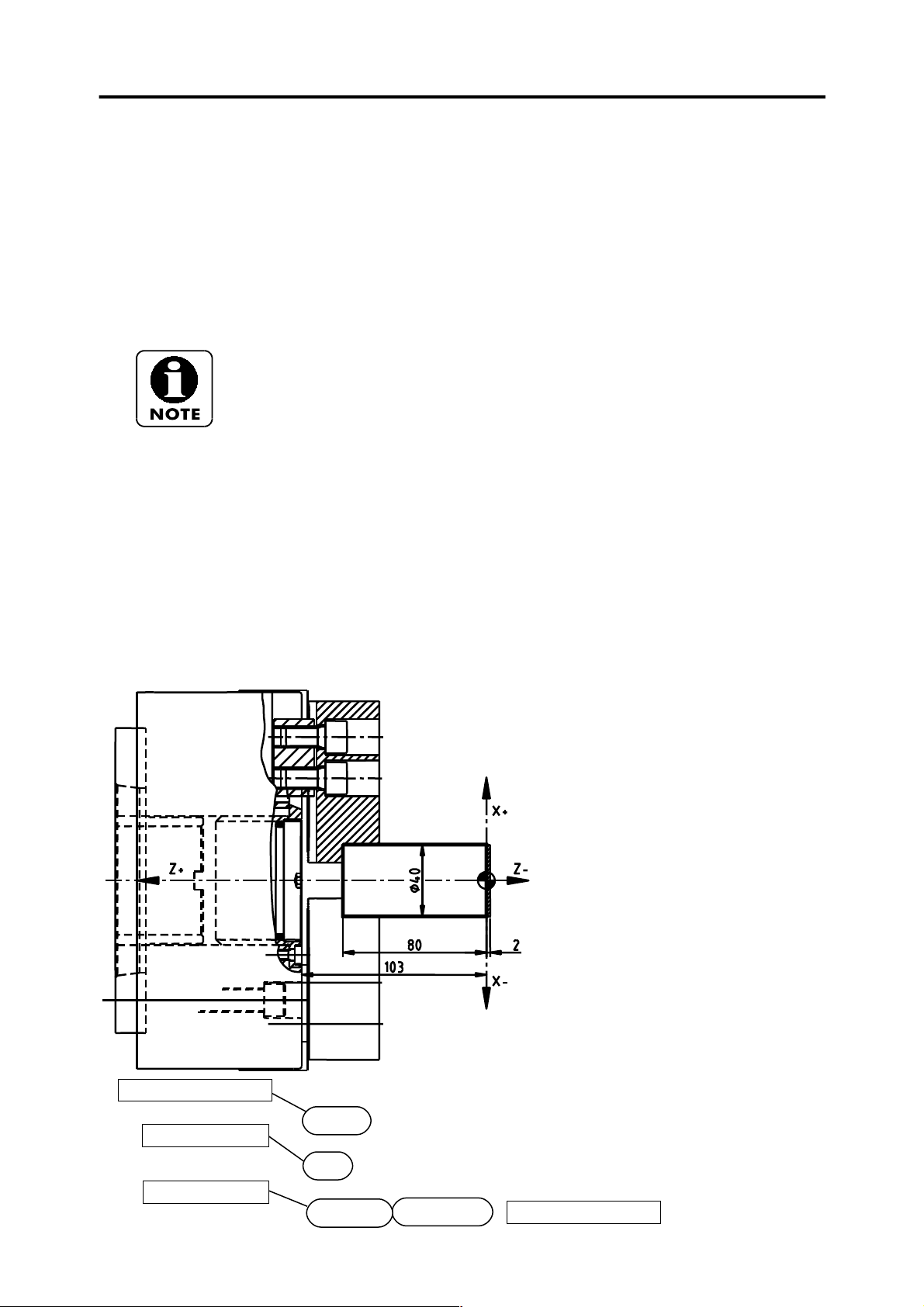

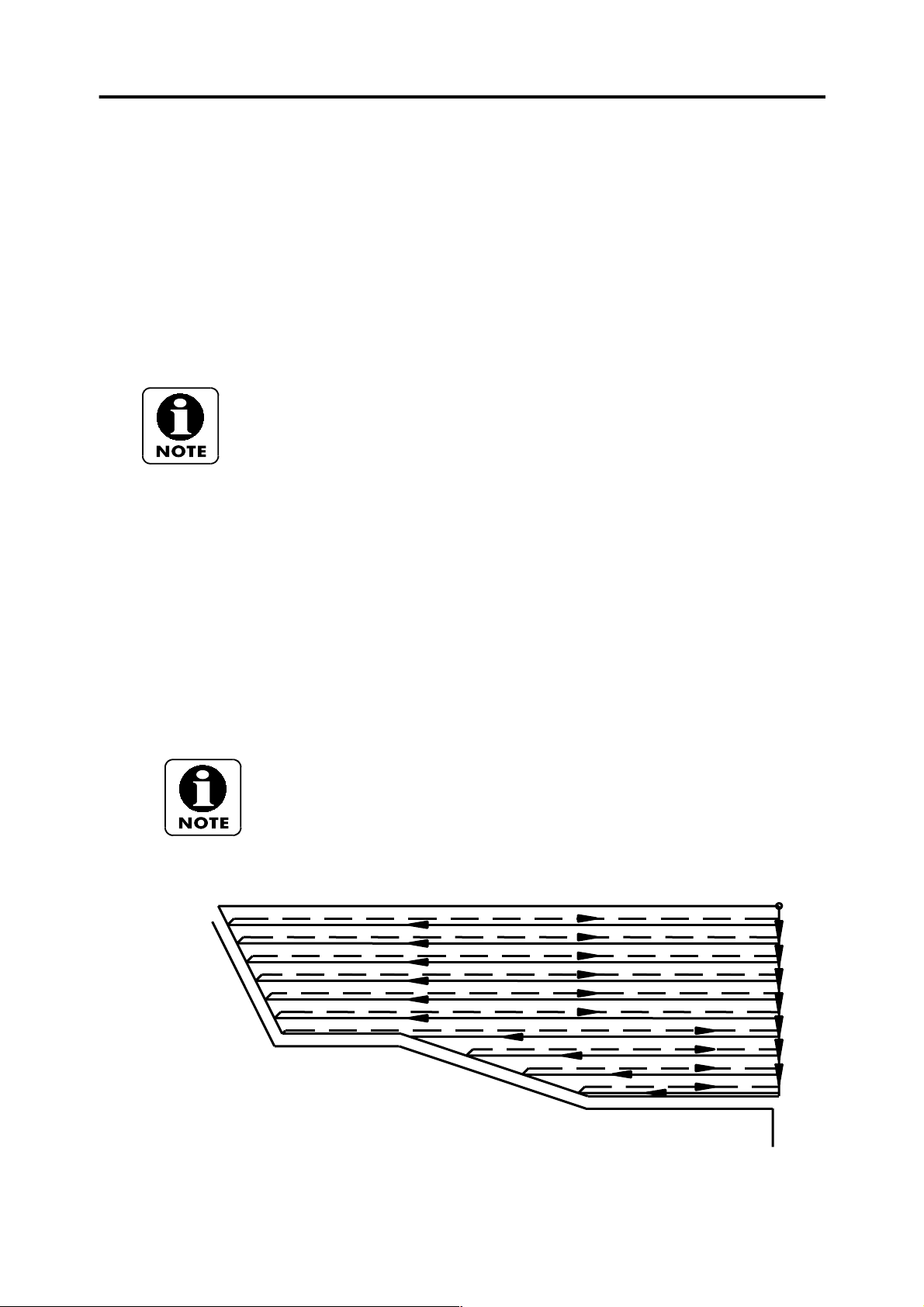

X-, Z- and B-axis and their respective positive and negative displacement directions are shown on

the above schematic diagram.

Y+ and Y- axis are not shown Y- is towards machine bed and Y+ away from the machine bed,

40mm+,40mm– to give stroke of 80mm. (machine needs to be on Y zero for turning operations).

As you can see, when workpiece zero reference point is located on workpiece end (most common

case), the positive direction is outside the workpiece, while the negative direction is on the

workpiece area to be machined (inside the workpiece).

Commonly, you will operate in the quadrant defined by X+ and Z-.

The machine will enter only in X- area for facing operations.

You may also operate X+ Z+ quadrant when the workpiece is clamped on the subhead.

C-axis would be used to swivel the main spindle head in

order to position the work piece for drilling operations using a powered tool.

C+ is in clockwise direction and C- is counter clockwise direction.

A-axis would be used to swivel the sub-spindle head in

order to position the work piece for drilling operations using a powered

tool.

A+ is in clockwise direction and A- is counter clockwise direction.

Page 9

PROGRAMMING MANUAL -9-

Other axes that could be encountered when programming the machine are

F: feed axis (related to slides) to be programmed when in operation.

In millimetres x per revolution when the head is rotating (turning)

For example:

G99 F0.3 this means “03 millimetres per revolution”.

In millimetres per minute when the head is stopped (MC).

For example:

G98 F80 this means “80 millimetres per minute”

T: is turret rotation.

R: is radius programming.

S: are head revolutions (cutting speed) This letter is always related to heads.

G50 S1000 Rpm limit.

G97 S1000 fixed rpm (for tapping and drilling).

G96 S200 cutting speed (m/min) for all turning operations.

,C: Chamfer programming.

,A: Angle programming.

Tool offset

Cutting speed formula:

Dn

Vc=

1000

Vc1000

n=

D

Machines must be at the X home position for turret indexing.

Vc= Cutting speed

D= Part standard diameter

n= Rpm limit.

The required offset values must be entered each time tool position is changed with respect to the

aforementioned position; if tool position is not changed, entering a offset value will not be necessary

as these values are stored in the memory.

Entering tool offset values

There are two ways for entering tool correction values.

1st.) Supplied with presetter.

Page 10

PROGRAMMING MANUAL -10-

For machines with presetter, place the presetter in position and preset the tool.

2nd.) supplied without presetter.

For machines without presetter, turn the work piece and retract the tool without moving it out the

axis. Then measure the work piece and enter the readings in the geometry table.

To enter a value, go to the geometry table (offset value), enter the required value and press the

intermediate key; by this way the control unit will calculate the offset value.

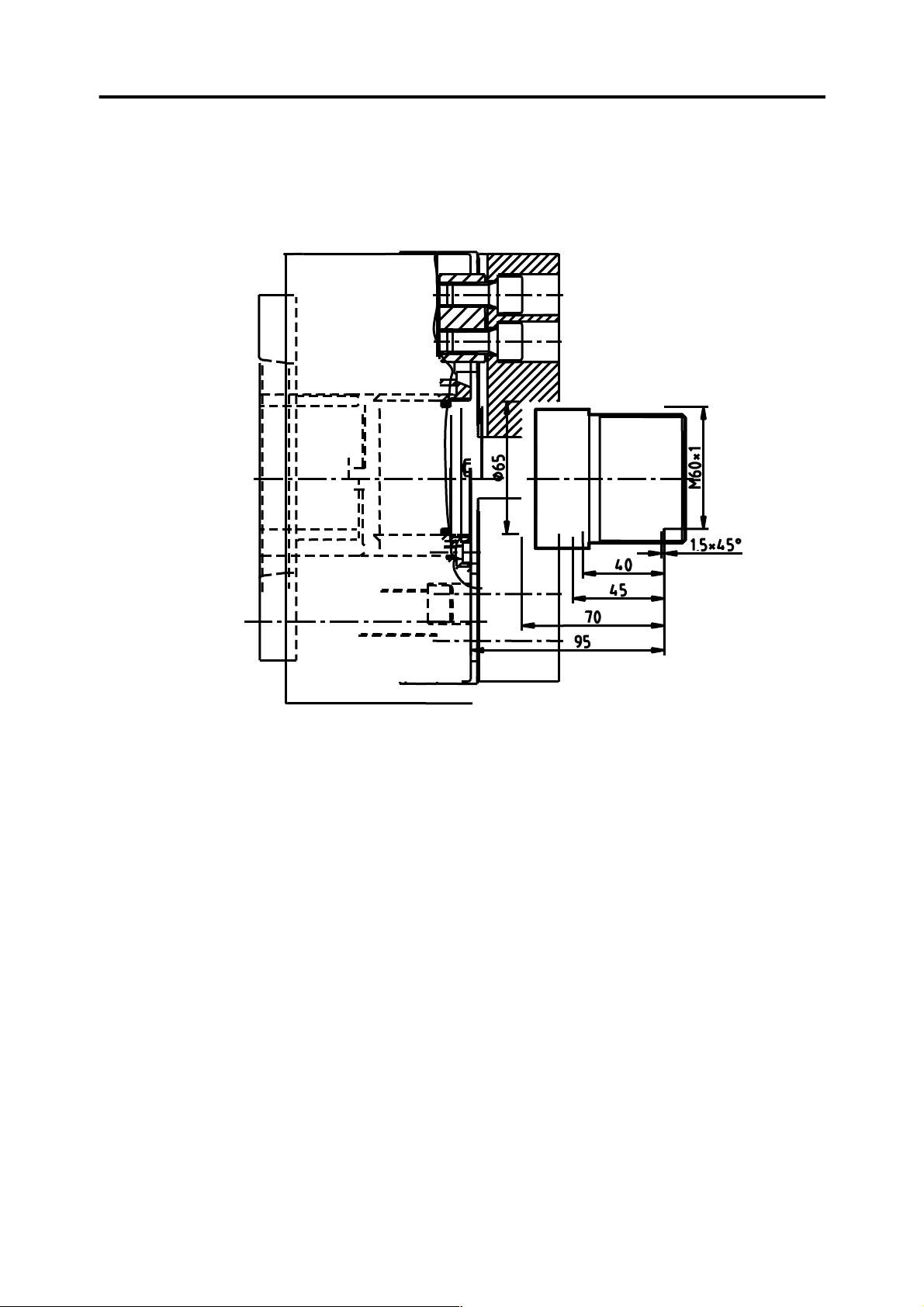

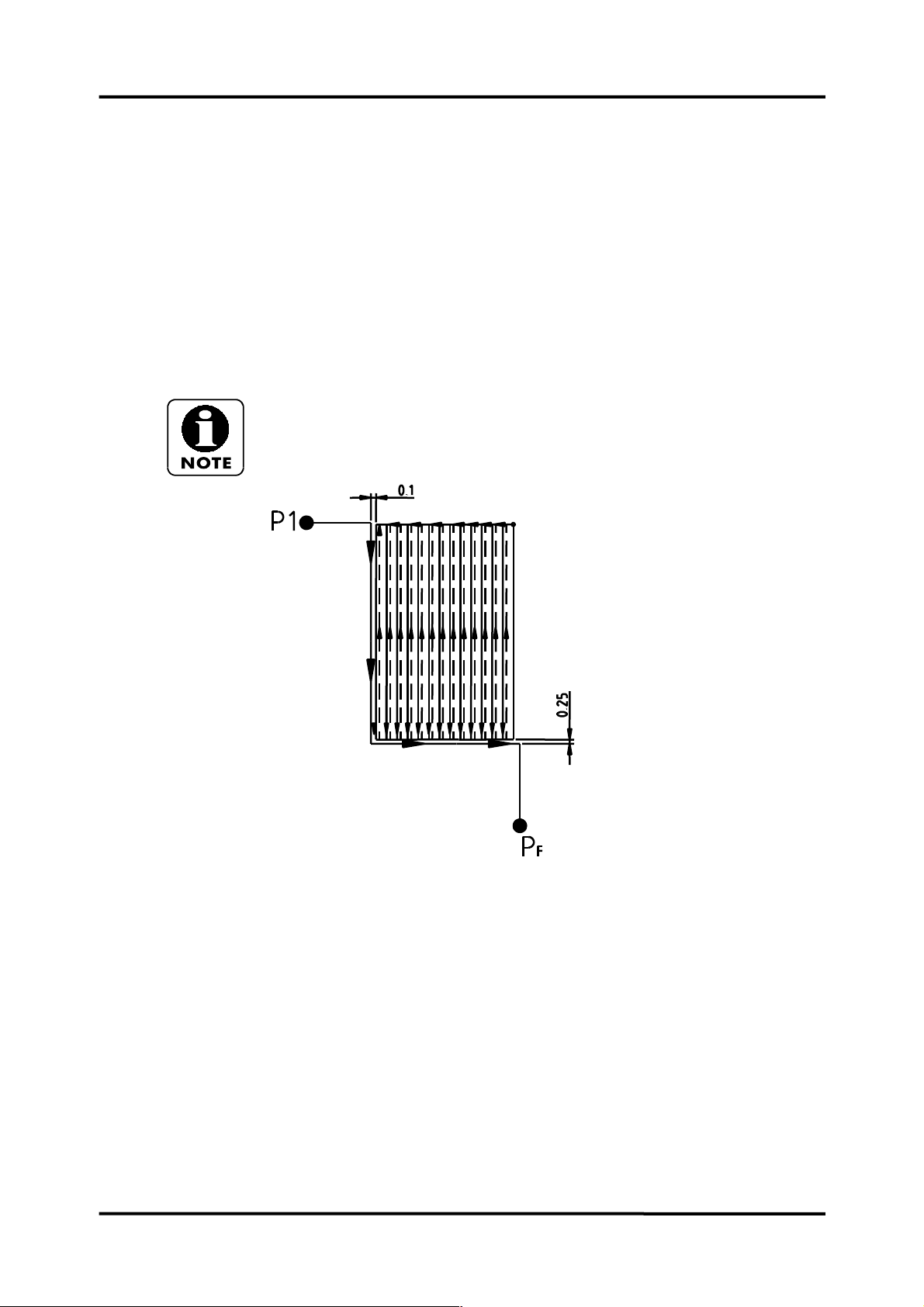

Workpiece zero reference point

Workpiece zero is the workpiece protruding length from main chuck face.

We advise you to enter workpiece zero at the beginning of the program.

Single spindle machine format

G10 P0 Z-80.

Sub spindle machine format

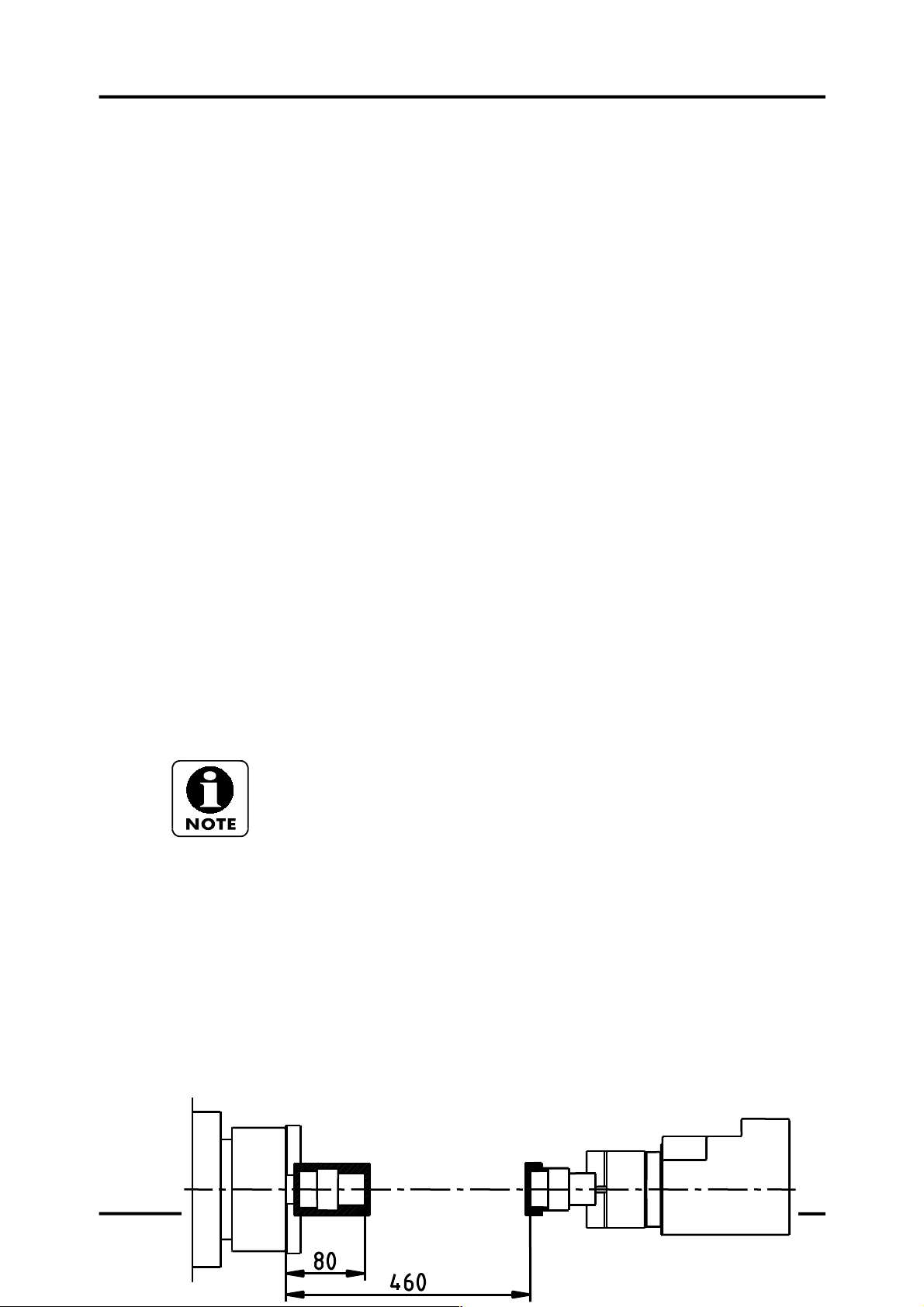

In the following example we explain how a value of 80 is entered for the first stage G54 (machining

the workpiece on the main spindle), while a value of 460 is entered for the second stage G55

(machining the workpiece on the sub-spindle).

G10 L2 P1 X0. Z-80. ;

G10 L2 P2 X0. Z-460. ;

Zero 1st phase

G10 L2 P1 Z-80

Zero 2nd phase

G10 L2 P2 Z-460

Page 11

PROGRAMMING MANUAL -11-

How to prepare the machine for machining operations with transfer:

1st Determine workpiece zero and carry out the 1st machining stage

G54 is programmed.

2nd Stop the machine and verify the dimension before doing the transfer.

3nd Do the transfer and place the sub-spindle in working position.

4nd Stop the machine and determine workpiece zero before performing the 2

machining stage G55 is programmed.

nd

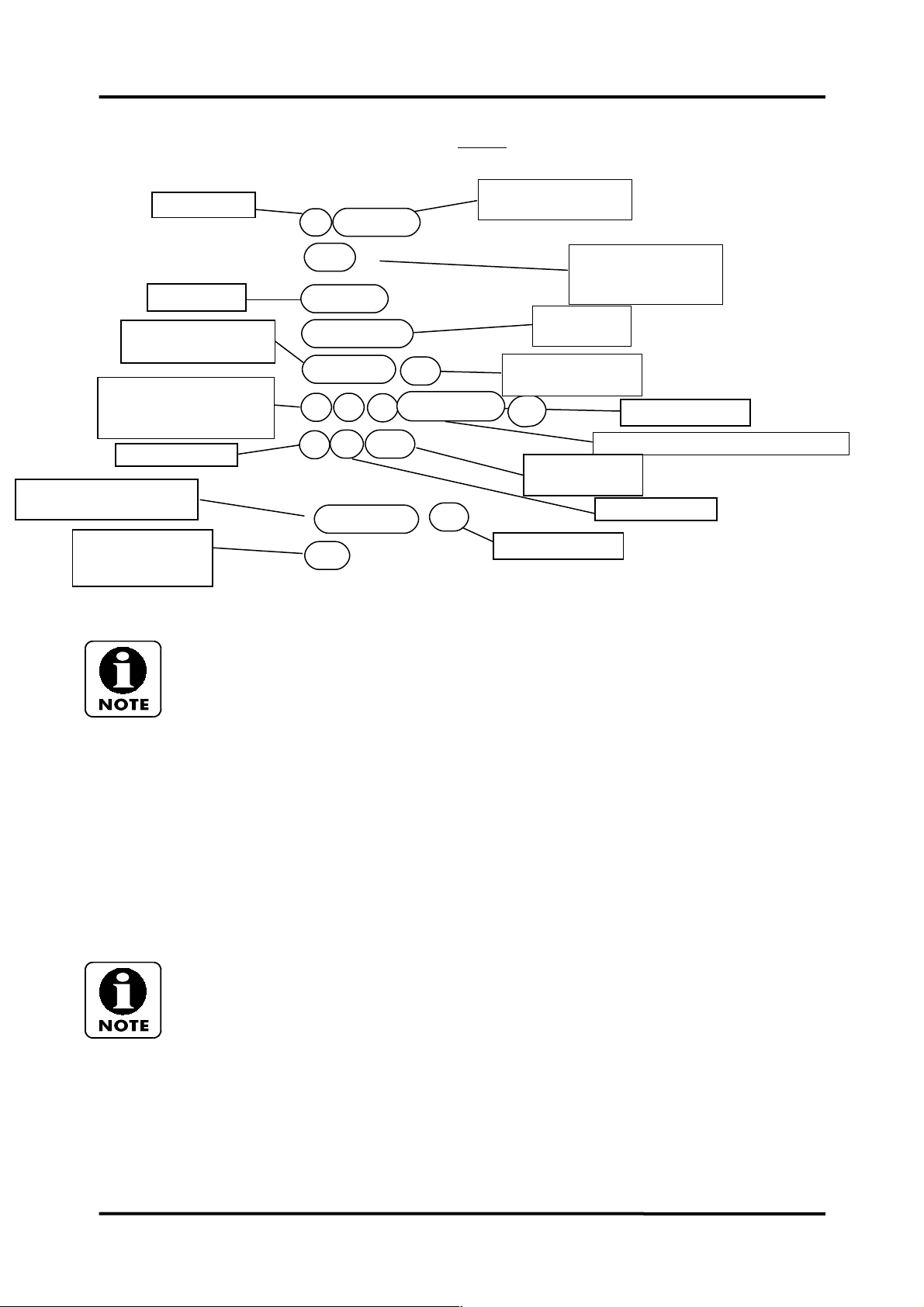

Facing

Program number

O0001;

G21 ;

G10 L2 P1 X0. Z103 ;

M1;

N1 G28 U0. ;

T101

(FACING);

G50 S2000 (LIMIT R.P.M.);

G96 S200 M3;

G0 G40 G54 G99 X45 Y0. Z0 M8;

G1 X-2 F0.25;

G0 X150 Z100 M9;

M30;

Metric input

Data input

O0001;

G21;

Workpiece zero 103

Page 12

PROGRAMMING MANUAL -12-

G10 L2 P1 X0. Z103;

Line number

Comment

Spindle speed in

Rapid, Cancel tool

compensation and Feed

(mm/revolution)

Feed move

Rapid move to a safe

position

Program end rewind

to start of program

m/min

Move to X and Y

home position

N1 G28 U0.V0.

T101;

(FACING);

G50 S2000

G96 S200 M3;

Spindle rotation in

forward direction

G0 G40 G99 G54 X45. Z0. M8;

G1 X-2. F0.25;

G0 Z2. ;

X150. Z100. M9

M30;

Coolant off

Position the turret on

tool 1 with offset

number 01

Limit to

2000 r.p.m.

Coolant on

Selected work offset & Position tool

Feed rate per

revolution

End Point

In this manual we will always refer to G codes type A.

Comment::

These are notes included in the program.

These notes are totally optional, and it is up to the programmer to enter them or not.

These notes will be always placed in round brackets () in order to prevent the program reading

them.

T101

Here is shown that the tool to be used is in position 1 and a offset value of 01 is applied.

T0101 could be also entered, as the four mandatory characters are present, however, the first zero

is optional.

Head rotation direction:

M3 head rotation direction forward

M4 head rotation direction reverse

M5 spindle stop

If instructing the reverse from the forward direction or vice versa, the spindle must

be stopped first.

This is also valid for the sub spindle and live tools.

G0 X150 Z100

Note that tool retraction in this example is to 150 mm on X+ and 100 mm on Z+ from work piece

zero, and not from chuck face, as no order for changing the position is given to work piece zero,

which in this example is maintained in the previous position.

Line number (N10, N20...)

Page 13

PROGRAMMING MANUAL -13-

Line numbers are optional, and can be either entered or not.

G0 G40 G99 X45. Z0. M8

As you can see, G codes are first placed and then X, Z and M codes. Codes can be also entered in

the following manner: G0 X45. Z0.G99 G40 M8

Entering codes such as G96 and G50 in the same line is not permitted.

Page 14

PROGRAMMING MANUAL -14-

Taper turning

O0002; Name of the program

G21; Metric program

G10 L2 P1 X0. Z78; Part-zero at 78

N1 G28 U0.V0. Line number and move to X and Y home position

T101; Tool call (pos. 01 and offset 01)

(TURN); Description

G50 S1500; Spindle turning limit: 1500 rpm

G96 S200 M3; Cutting speed (m/min), Spindle fwd direction.

G0 G40 G54 G99 X52.5 Z2 M8; Rapid feed to point X52.5 Z2, Cancel tool nose radius

compensation, Feed per rev, Coolant on.

G1 Z-19.9 F0.25; Feed move Z-19.9 (First pass), Feed rate.

G0 X55 Z2; Rapid feed to X55 Z2

X45; Rapid feed to start point of cone in X45 Z2

G1 Z0; Feed move to X45 Z0

X52 Z-20 F.2; Machine the cone to X52 Z-20 (Second pass)

X61; Machine to X61 Z-20

G0 X150 Z100 M9; Rapid to safe position to 100mm in both axes and coolant

off

M30; End of program and back to he beginning

Page 15

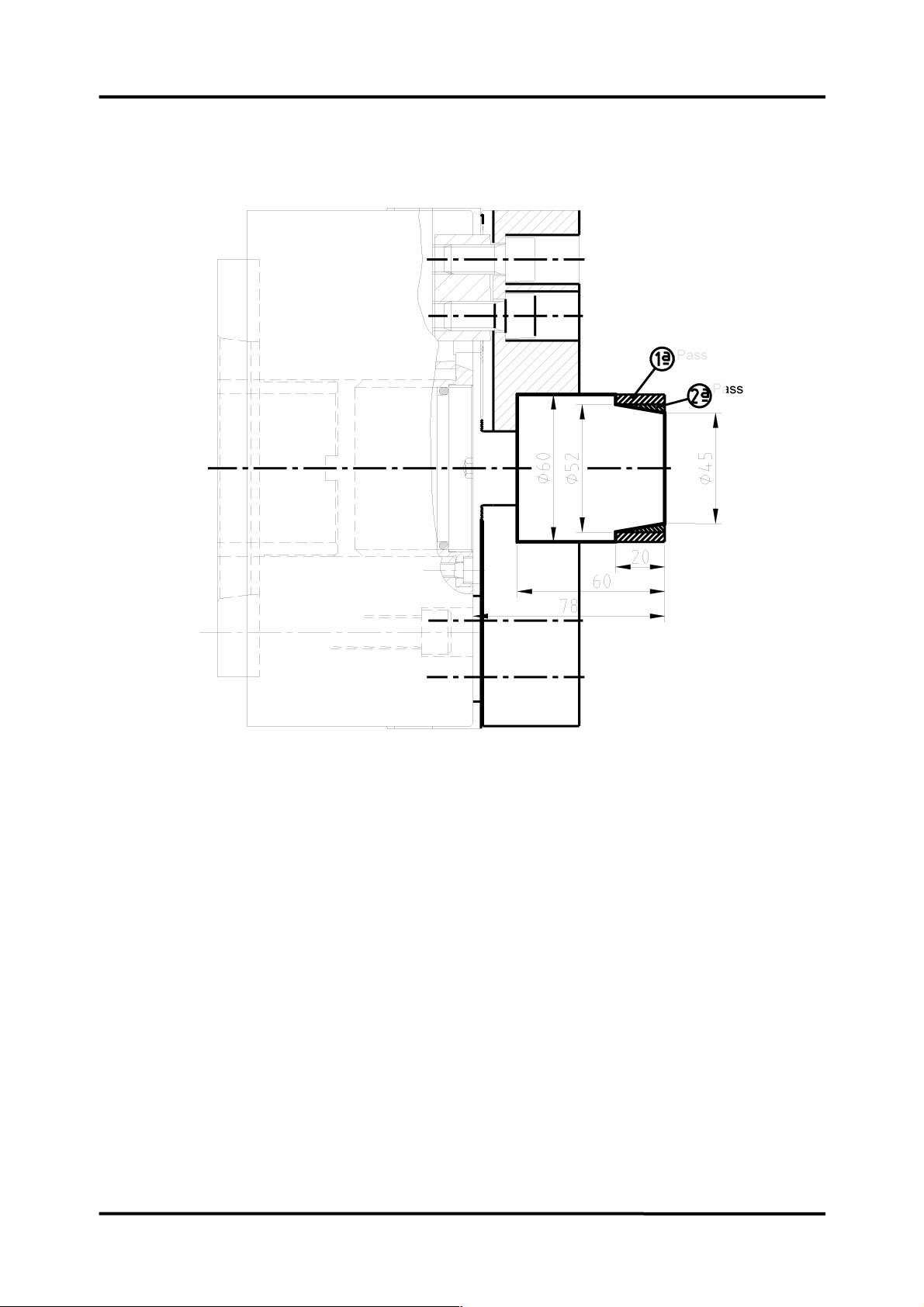

Inside turning:

PROGRAMMING MANUAL -15-

O0003;

G21; Metric input

G10 L2 P1 X0. Z85; Part zero at 85

N6 G28 U0.V0. Line number and move to X and Y home position

T606; Tool call (pos. 06 and offset 06)

(BORE); Description

G50 S2000; Turning speed limit: 2000 r.p.m.

G96 180 M3; Cutting speed =180 mm/rev, Spindle fwd direction.

G0 G40 G54 G99 X44 Z2 M8; Rapid move Z2 axis to the height of the chamfer 2x45º ,

Cancel tool nose radius compensation, Feed per rev,

Coolant on.

G1 Z0 F0.2; Feed move to Z0, feedrate 0.2 mm/rev

X40 Z-2 F.15; Machine chamfer with feedrate 0.15 mm/rev

Z-40 F.2; Machine the bore at ø40 with federate 0.2 mm/rev

X35; Face the inside until ø35

G0 Z5; Rapid feed to Z5

X150 Z100 M9; Rapid to safe position to X150 Z100 and coolant off

M30; End of program and back to he beginning

Page 16

PROGRAMMING MANUAL -16-

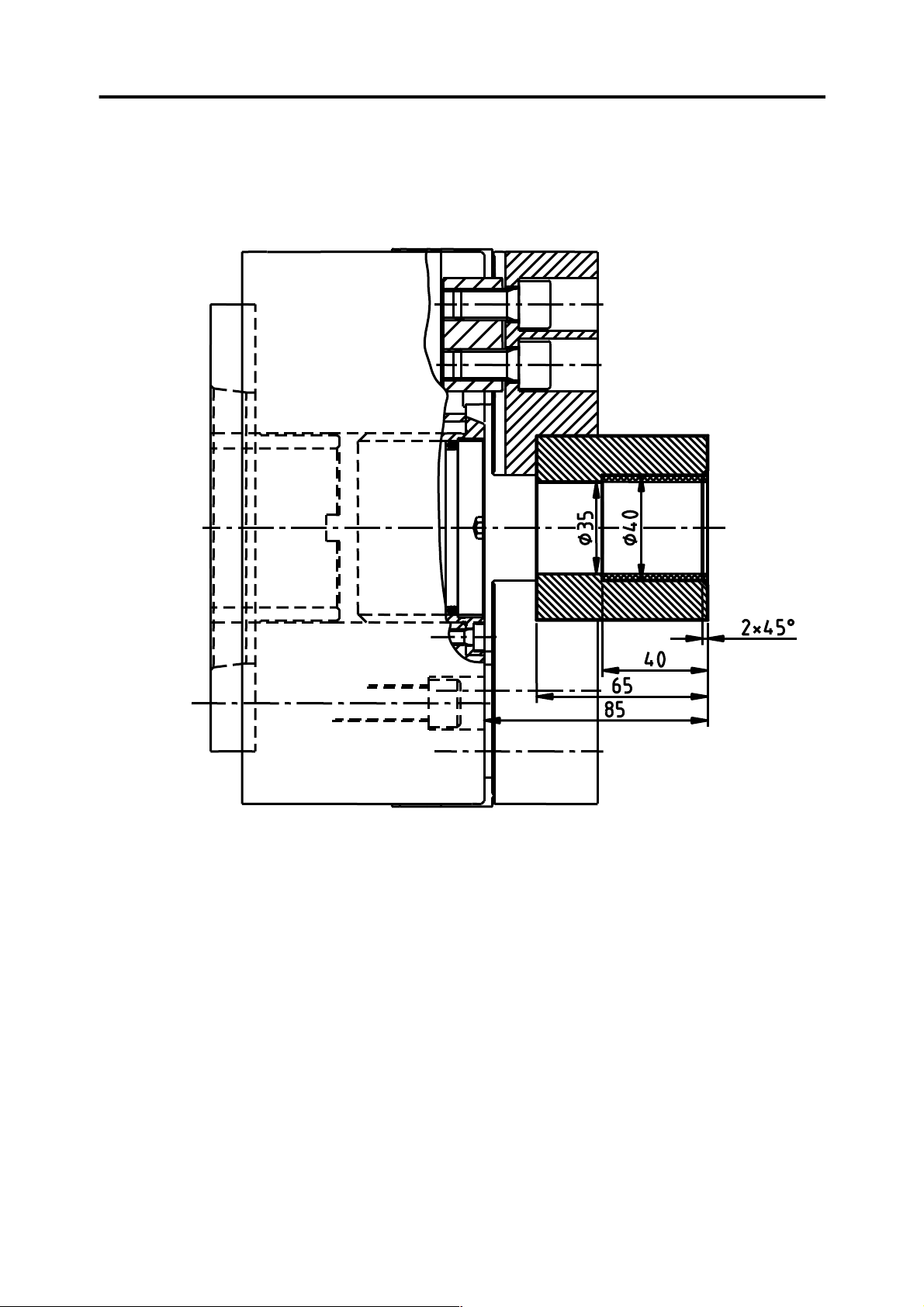

Circular Interpolation

G3G2

O0004;

G21; Metric input

G10 L2 P1 X0. Z110; Part zero at 110

N3 G28 U0.V0. Line number and move to X and Y home position

T303; Tool call (pos. 03 and offset 03)

(TURN); Description

G50 S2500;

G96 S220 M3;

G0 G40 G54 G99 X30 Z2 M8;

G1 Z-22 F0.2; Machine to ø30 and Z-22

G2 X40 Z-27 R5 (CLOCKWISE); 5mm radius clockwise to X40 Z-27

G1 X55; Face to X55

G3 X80 Z-57 R80 (COUNTERCLOCKWISE); 80mm radius counter clockwise to X80 Z-57

G1 Z-62; Machine to Z-60

X86; Face to X86

G0 X100 Z100 M9;

M30;

In this example we assume that the part is rough machined.

As seen in this example, G2 is used to machine radii in clockwise direction and G3 in

counterclockwise direction.

You can also see that G2 or G3 is first entered, then the end point, and finally the

radius,

Page 17

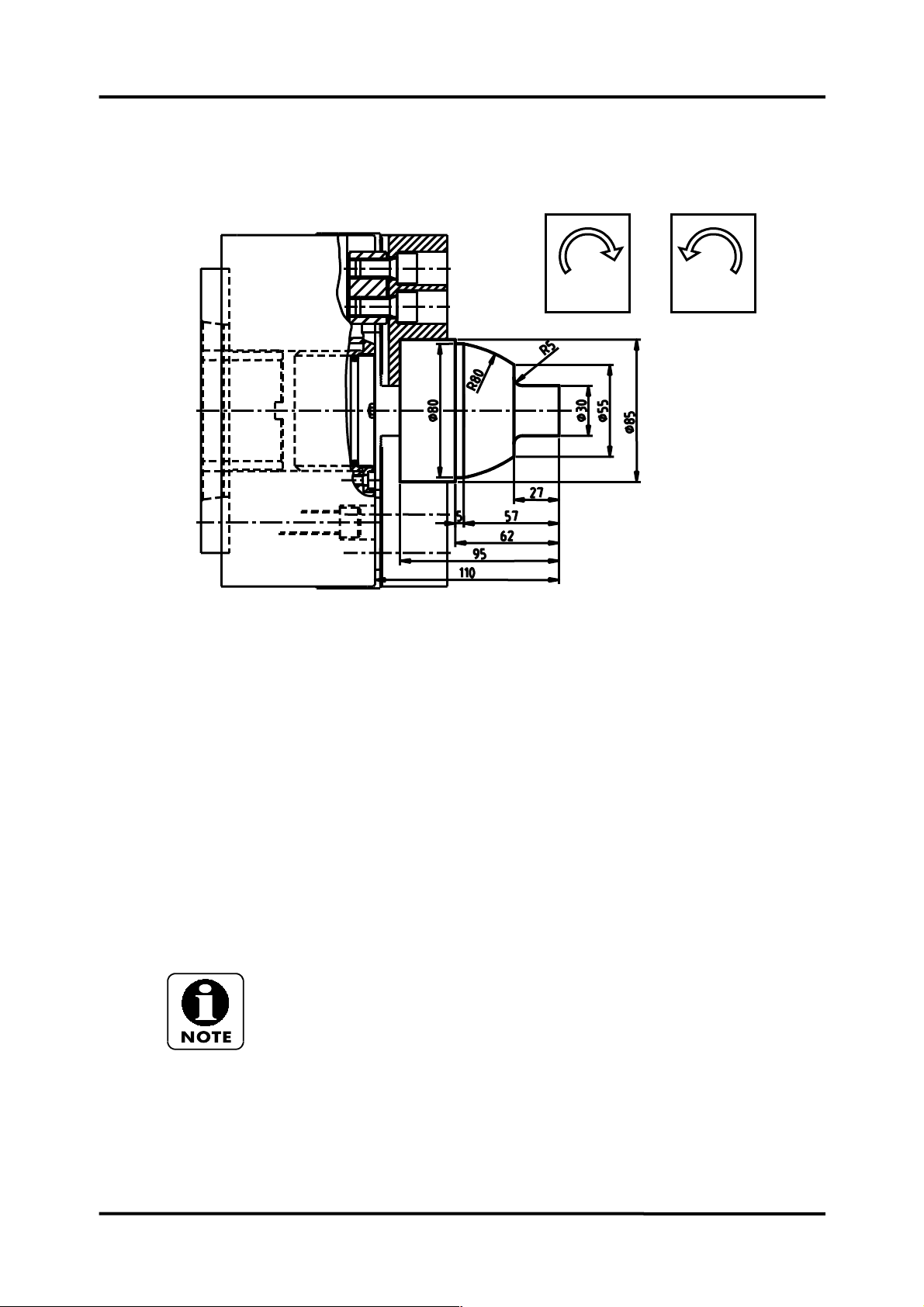

Circular interpolation

PROGRAMMING MANUAL -17-

O0005;

G21;

G10 L2 P1 X0. Z165;

N4 G28 U0.V0.

T404;

(TURN);

G50 S2000;

G96 S200 M3;

G0 G40 G54 G99 X69.282 Z2 M8; Rapid feed to X69.292 Z2

G1 Z-20 F0.2; Machining to Z-20

G3 X69.282 Z-60 R40; Machine a 40mm radius until point X69.282 Z-

60 counter clockwise direction

G2 X69.282 Z-100 R40; Machine a 40mm radius until point X69.282 Z-

100 clockwise direction

G1 Z-105; Machining to Z-105

G0 X150. Z100. M9;

M30;

As you can see, for the interpolation, you must know the point from which this

interpolation will take place in order to change radius direction (in this example on

point X69.282 Z-60).

Page 18

PROGRAMMING MANUAL -18-

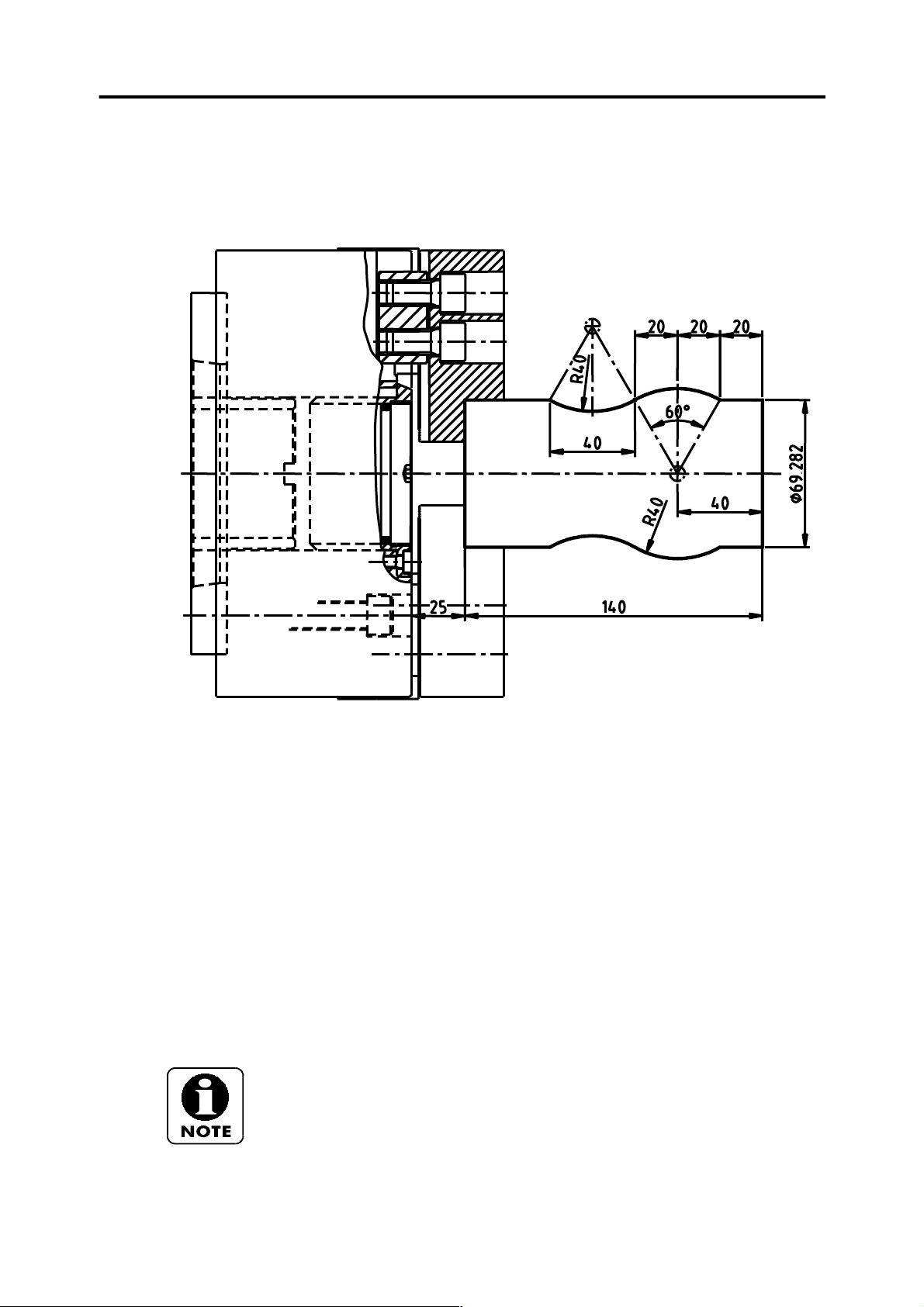

Incremental commands (U and W)

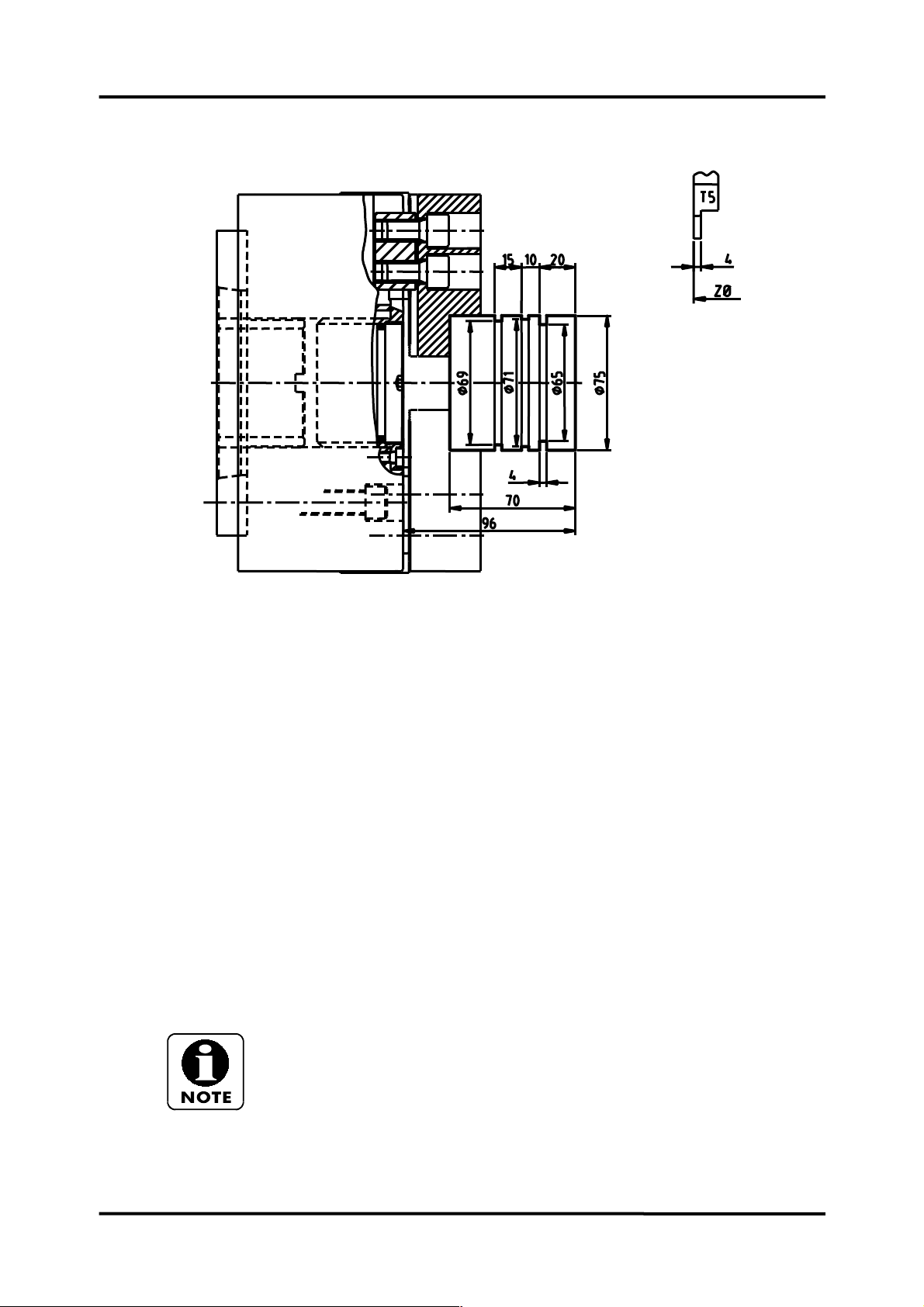

O0006;

G21;

G10 L2 P1 X0. Z96:

N5 G28 U0.V0.

T505;

(GROOVE);

G97 S1250 M3;

G0 G40 G54 G99 X78 Z-20 M8; Rapid feed to X78 Z-20

G1 X65 F0.1; Grooving to ø65

G4 X1; Dwell (X1=1 second dwell )

G0 X78; Rapid feed to X78

W-10.; Incremental move –10mm in Z axis (W=Z)

G1 U-7.; Incremental move –7mm in X axis (U=X)

G4 X1; Dwell

G0 U7; Rapid feed 7mm in X axis (U=X)

W-15; Incremental move –15mm in Z axis (W=Z)

G1 U-9; Groove incrementally –9mm in X axis (ø69)

G4 X1; Dwell

G0 U9; Rapid feed incrementally 9mm in X axis (ø78)

X150 Z100 M9;

M30;

Time delays are entered each time a slot is machined in order to improve the

surface finish.

Page 19

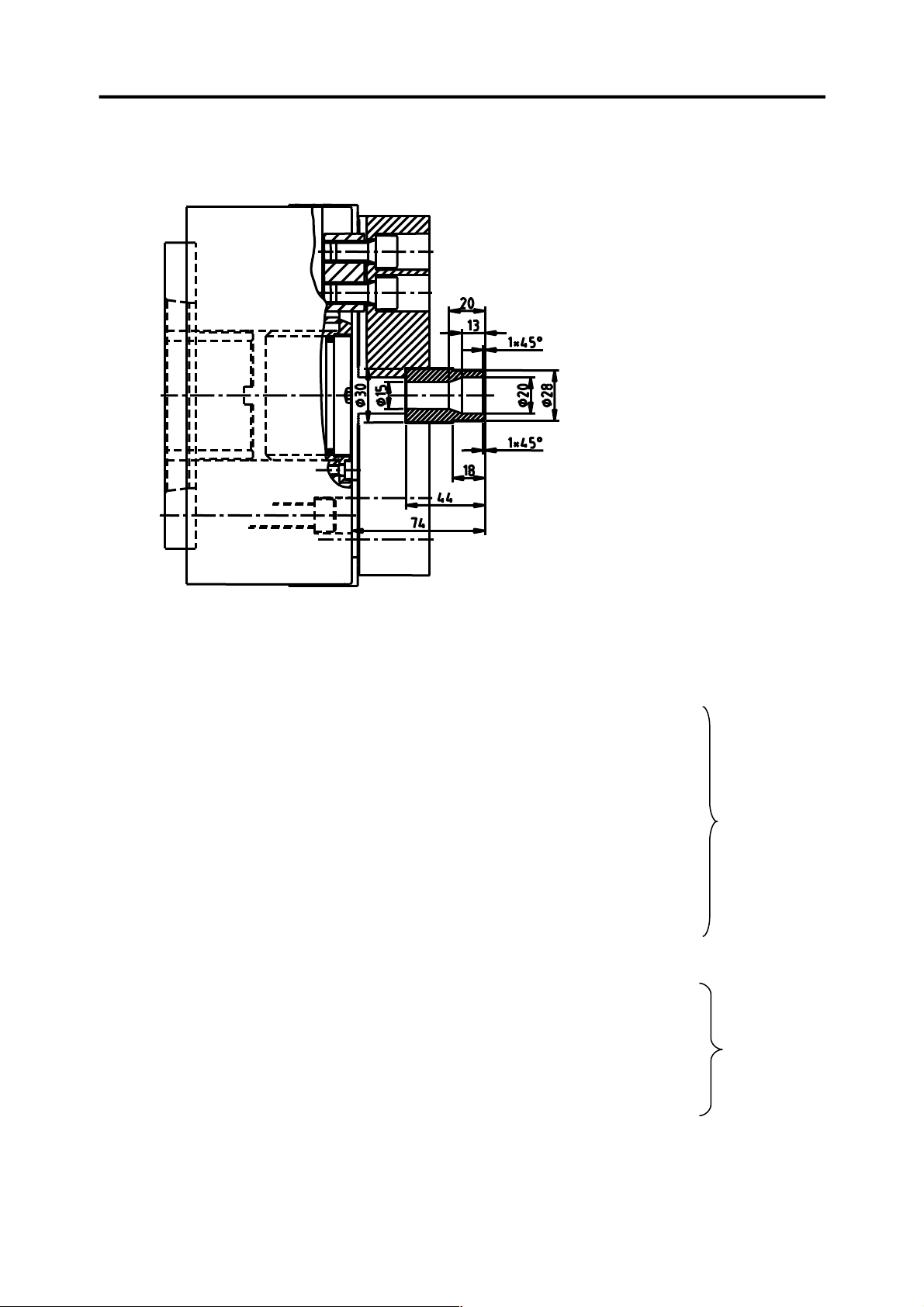

Example for operation

PROGRAMMING MANUAL -19-

Tools:

T1= Outside and facing.

T2= ø15 twist drill.

T4= Bore.

O0007;

G21;

G10 L2 P1 X0 Z74;

N1 G28 U0.V0.

T101;

(TURN);

G50 S2500;

G96 S220 M3;

G0 G40 G54 G99 X35 Z0 M8;

G1 X-2 F0.15;

G0 X26 Z2;

G1 Z0;

X28 Z-1 F0.2;

Z-18 F0.25;

X32;

G0 X150 Z100 M9;

M1;

N2 G28 U0.V0.

T202 ;

(15MM DIA DRILL);

G97 S600 M3;

G0 G40 G54 G99 X0 Z3 M8;

G1 Z-47 F0.1;

G0 Z10 M9;

X150. Z100.;

M1;

External machining

Drill

Page 20

PROGRAMMING MANUAL -20-

N4 G28 U0.V0.

T404;

(BORE);

G50S2250

G96 S150 M3;

G0 G40 G54 G99 X22 Z3 M8;

G1 Z0 F0.25;

X20 Z-1 F0.15;

Z-13 F0.2;

X15 Z-20 F0.15;

G0 Z5 M9;

X150 Z150;

M30;

Bore

Page 21

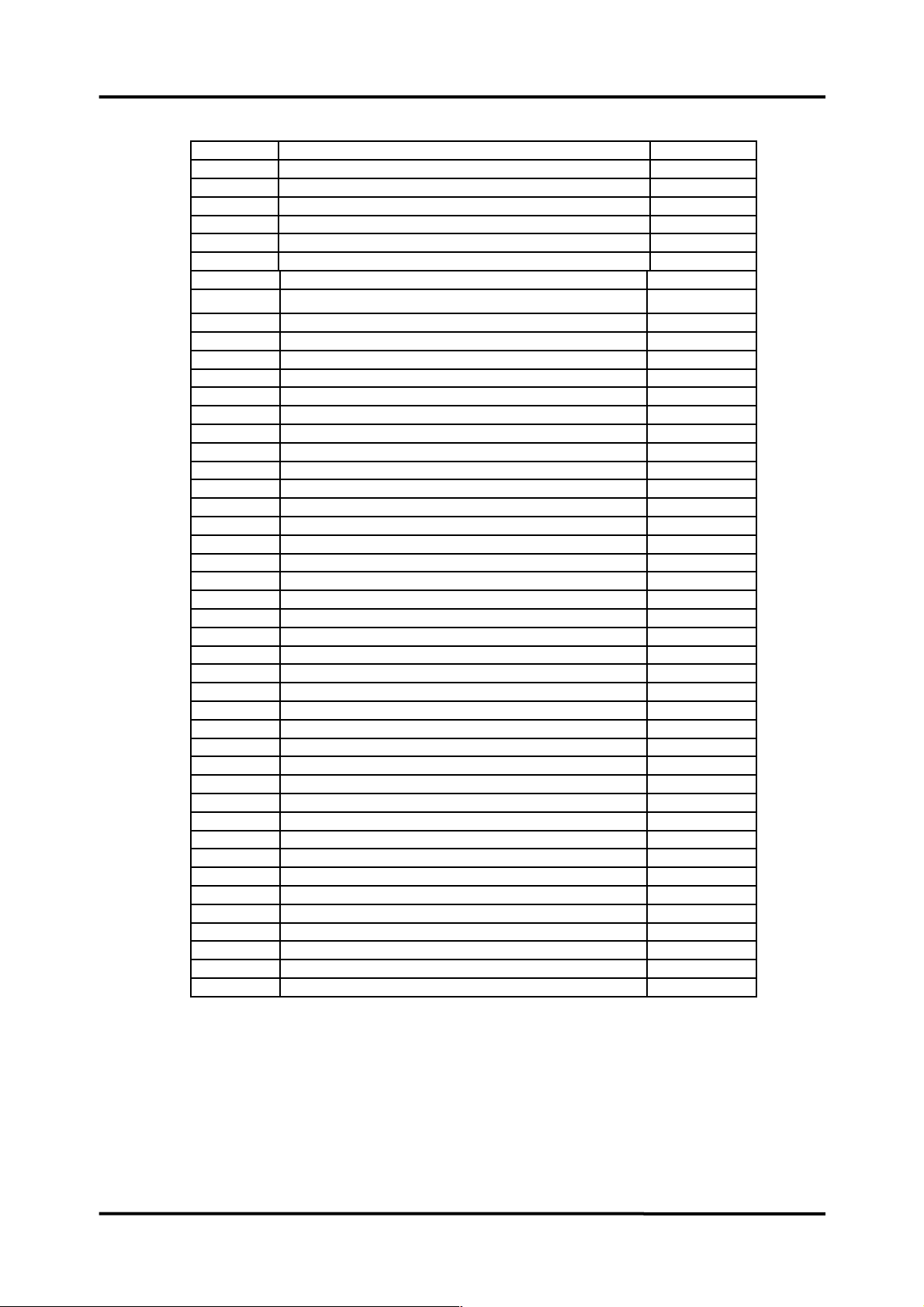

G Code List

For full explanation of the following G codes, refer to the examples in this manual or in the Fanuc

programming manual.

PROGRAMMING MANUAL -21-

STANDARD

G CODE

G00 01 RAPID TRAVERSE

G01 01 LINEAR INTERPOLATION

G02 01 CIRCULAR INTERPOLATION CLOCK WISE

G03 01 CIRCULAR INTERPOLATION COUNTERCLOCK WISE

G04 00 DWELL

G05 00 HIGH SPEED REMOTE BUFFER

G07.1 00 CYLINDRICAL INTERPOLATION

G10 00 PROGRAMMABLE DATA INPUT

G11 00 PROGRAMMABLE DATA INPUT CANCEL

G12.1 21 POLAR COORD INTERPOLATION MODE

G13.1 21 POLAR COORD INTERPOLATION MODE CANCEL

G17 16 XY PLANE SELECTION

G18 16 XZ PLANE SELECTION

G19 16 YZ PLANE SELECTION

G20 06 INCH INPUT

G21 06 MM INPUT

G22 09 STORED STROKE CHECK FUNCTION ON

G23 09 STORED STROKE CHECK FUNCTION OFF

G25 08 SPINDLE SPEED FLUCTUATION DETECTION OFF

G26 08 SPINDLE SPEED FLUCTUATION DETECTION ON

G27 00 REFERENCE POSITION RETURN CHECK

G28 00 REFERENCE POSITION RETURN

G30 00 2ND REFERENCE POSITION RETURN

G31 00 SKIP FUNCTION

G32 01 THREAD CUTTING

G34 01 VARIABLE LEAD THREAD CUTTING

G36 00 AUTOMATIC TOOL COMPENSATION X

G37 00 AUTOMATIC TOOL COMPENSATION Z

G40 00 TOOL NOSE RADIUS COMPENSATION CANCEL

G41 07 TOOL NOSE RADIUS COMPENSATION LEFT

G42 07 TOOL NOSE RADIUS COMPENSATION RIGHT

G50 07 MAXIMUM SPINDLE SPEED CLAMP

GROUP FUNCTION

Page 22

PROGRAMMING MANUAL -22-

STANDARD

G CODE

G52 00 LOCAL COORDINATE SYSTEM SETTING

G53 00 MACHINE COORDINATE SYSTEM SETTING

G54 14 WORKPIECE COORDINATE SYSTEM 1 SELECTION

G55 14 WORKPIECE COORDINATE SYSTEM 2 SELECTION

G56 14 WORKPIECE COORDINATE SYSTEM 3 SELECTION

G57 14 WORKPIECE COORDINATE SYSTEM 4 SELECTION

G58 14 WORKPIECE COORDINATE SYSTEM 5 SELECTION

G59 14 WORKPIECE COORDINATE SYSTEM 6 SELECTION

G65 06 MACRO CALL

G66 12 MACRO CALL MODAL

G67 12 MACRO CALL MODAL CANCEL

G70 00 FINISHING CYCLE

G71 00 STOCK REMOVAL IN TURNING

G72 00 STOCK REMOVAL IN FACING

G73 00 PATTERN REPEATING

G74 00 END FACE PECK DRILLING

G75 00 OUTER DIA DRILLING CYCLE/ GROOVING CYCLE

G76 00 MULTIPLE THREADING CYCLE

G80 10 CANNED CYCLE CANCEL

G83 10 CANNED CYCLE FOR FACE DRILLING

G84 10 CANNED CYCLE FOR FACE TAPPING

G85 10 CANNED CYCLE FOR FACE BORING

G87 10 CANNED CYCLE FOR SIDE DRILLING

G88 10 CANNED CYCLE FOR SIDE TAPPING

G89 10 CANNED CYCLE FOR SIDE BORING

G90 01 OUTER DIA/ INTERNAL DIA CUTTING CYCLE

G92 01 THREAD CUTTING CYCLE

G94 01 END FACE TURNING CYCLE

G96 02 CONSTANT SURFACE SPEED

G97 02 CONSTANT SURFACE SPEED CANCEL

G98 05 FEED PER MINUTE

G99 05 FEED PER REVOLUTION

GROUP FUNCTION

Page 23

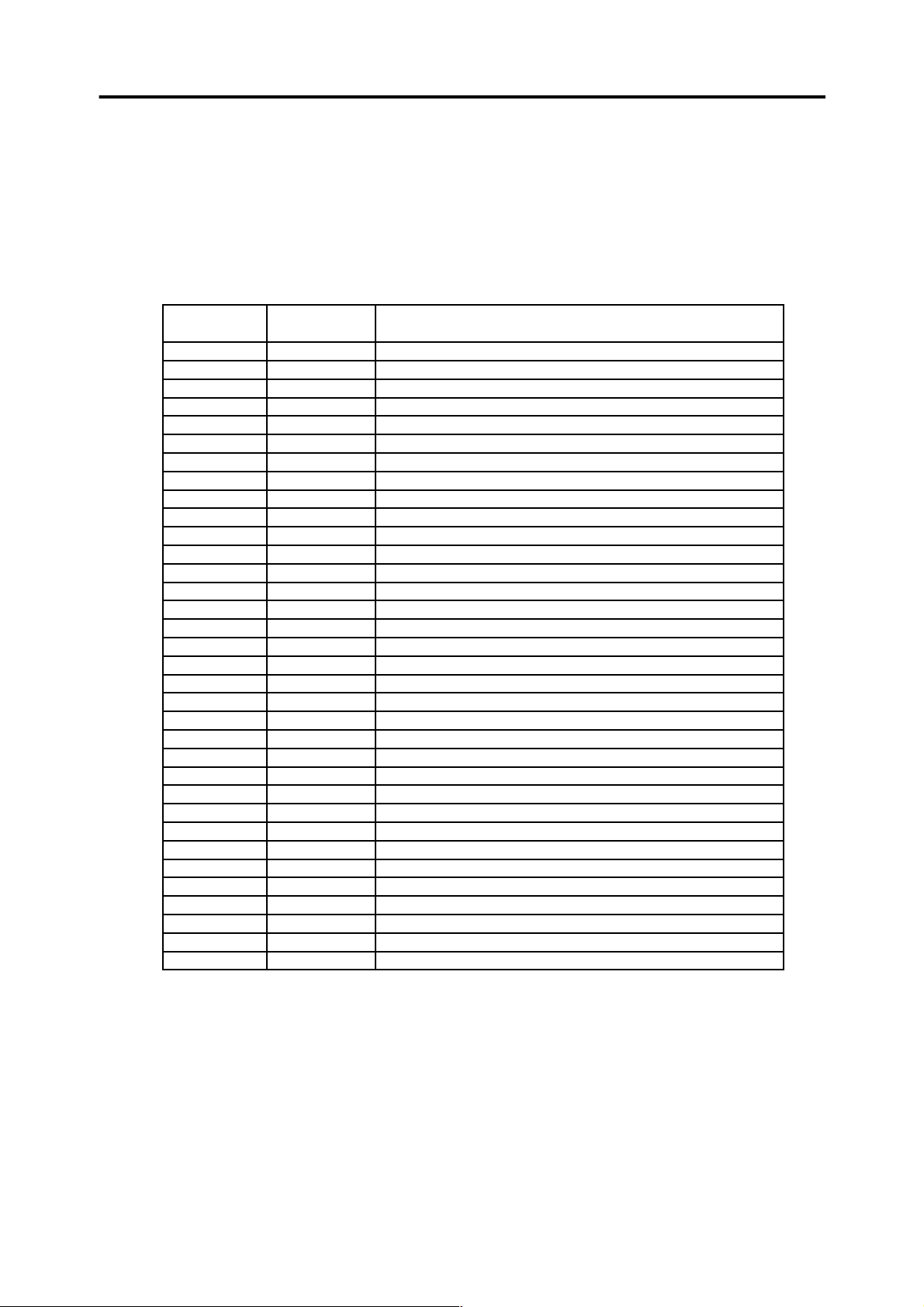

PROGRAMMING MANUAL -23-

M FUNCTIONS

M functions used in machining programs are described in this section, this is a general list for the Kia range,

and some codes may not be active due to the machine specification.

Please refer to the individual manual supplied with the machine.

These codes control functions complementary to those controlled by G codes. For instance, coolant supply,

head rotation direction, etc.

M CODE FUNCTION NOTE

M00 PROGRAM STOP

M01 OPTIONAL STOP

M02 PROGRAM END

M03 SPINDLE FORWARD

M04 SPINDLE REVERSE

M05 SPINDLE STOP

M08 COOLANT ON

M09 COOLANT OFF

M10 BAR FEEDING ON OPTION

M11 BAR FEEDING OFF OPTION

M12 COUNTER OPTION

M13 MILL SPINDLE FORWARD

M14 MILL SPINDLE REVERSE

M15 MILL SPINDLE STOP

M18 SPINDLE ORIENTATION OFF OPTION

M19 SPINDLE ORIENTATION ON OPTION

M21 ERROR DETECT ON

M22 ERROR DETECT OFF

M23 CHAMFERING ON

M24 CHAMFERING OFF

M30 RESET AND REWIND OPTION

M31 COUNT UP CHECK OPTION

M36 AUTO POWER OFF ENABLE OPTION

M37 AUTO POWER OFF DISABLE OPTION

M38 CENTRE AIR BLOW ON OPTION

M39 CENTRE AIR BLOW OFF OPTION

M40 C-AXIS OFF OR LOW GEAR OPTION

M41 AUTO Q-SETTER ARM DOWN OPTION

M42 AUTO Q-SETTER ARM UP OPTION

M40 C-AXIS OFF OR LOW GEAR OPTION

M43 C-AXIS ON OR HIGH GEAR OPTION

M46 SPINDLE OVERRIDE ENABLE

M47 SPINDLE OVERRIDE DISABLE

M48 FEED OVERRIDE ENABLE

M49 FEED OVERRIDE DISABLE

M51 MAIN SPINDLE AIR BLOW ON OPTION

M52 MAIN SPINDLE AIR BLOW OFF OPTION

M54

M55

M61 AUTO DOOR OPEN OPTION

M62 AUTO DOOR CLOSE OPTION

CONSTANT SPINDLE SPEED CONTROL (MAIN

SPINDLE)

CONSTANT SPINDLE SPEED CONTROL (SUB

SPINDLE)

Page 24

PROGRAMMING MANUAL -24-

M63 PARTS CATCHER UP OPTION

M64 PARTS CATCHER DOWN OPTION

M66 LOW CHUCK PRESSURE OPTION

M67 HIGH CHUCK PRESSURE OPTION

M68 CHUCK CLOSE

M69 CHUCK OPEN

M70 CALL LIGHT ON

M73 SUB SPINDLE PARTS CATCHER UP

M74 SUB SPINDLE PARTS CATCHER DOWN

M75 CHIP CONVEYOR ON

M76 CHIP CONVEYOR OFF

M81 ROBOT SERVICE REQUEST 1 OPTION

M82 ROBOT SERVICE REQUEST 2 OPTION

M85 NEW BAR FEEDER LOADING OPTION

M90 C-AXIS BRAKE ON (HIGH)

M91 C-AXIS BRAKE OFF (LOW)

M98 SUB PROGRAM CALL

M99 END OF SUB PROGRAM

M108 SUB SPINDLE COOLANT ON

M109 SUB SPINDLE COOLANT OFF

M113 SUB SPINDLE FORWARD

M114 SUB SPINDLE REVERSE

M115 SUB SPINDLE STOP

M116 SUB SPINDLE ORIENTATION ON

M117 SUB SPINDLE ORIENTATION OFF

M118 SUB SPINDLE CHUCK CLAMP

M119 SUB SPINDLE CHUCK UNCLAMP

M114 SUB SPINDLE REVERSE

M115 SUB SPINDLE STOP

M116 SUB SPINDLE ORIENTATION ON

M117 SUB SPINDLE ORIENTATION OFF

M118 SUB SPINDLE CHUCK CLAMP

M119 SUB SPINDLE CHUCK UNCLAMP

M140 A-AXIS OFF

M141 EXTERNAL M CODE 1 OFF

M142 EXTERNAL M CODE 2 ON

M143 A-AXIS ON

M144 EXTERNAL M CODE 3 ON

M145 EXTERNAL M CODE 3 OFF

M146 EXTERNAL M CODE 4 ON

M147 EXTERNAL M CODE 4 OFF

M151 SUB SPINDLE AIR BLOW ON

M152 SUB SPINDLE AIR BLOW OFF

M160 S1, S2 SYNCHRONISATION ON

M161 S1, S2 SYNCHRONISATION OFF

M162 S1, S2 PHASE SYNCHRONISATION ON

Page 25

THREADING

PROGRAMMING MANUAL -25-

O0008;

G21;

G10 L2 P1 Z95;

N1 G28 U0.V0.

T101;

(TURN);

G50 S2500;

G96 S200 M3;

G0 G40 G54 G99 X70 Z0 M8;

G1 X-2 F0.25;

G0 X57 Z1;

G1 Z0;

X59.9 Z-1.5;

Z-45;

X66;

G0 X150 Z100 M9;

M1;

Page 26

PROGRAMMING MANUAL -26-

N2 G28 U0.V0.

T202;

(SCREWCUT);

G97 S700 M3;

G0 G40 G54 G99 X60 Z6 M8;

X59.4 (First pass);

G32 Z-40 F1 (F=THREAD PITCH);

G0 X62;

Z6;

X58.8 (Second pass);

G32 Z-40 F1;

G0 X62;

Z6;

X58.7 (Last pass);

G32 Z-40 F1;

G0 X62;

X150 Z100M9;

M30;

G32 for threading operations, always operate at fixed rpm (G97).

When retapping threads, do not release the work piece, do not change the speed

and do not change the start point.

Page 27

CANNED CYCLES

G70 Finishing cycle

G70 P100 Q200

P Block number from which the profile operation begins.

Q Block number from which the profile operation ends.

At the end of each cycle sequence the machine is always positioned in the position at

which this cycle sequence was started. The tool will be commonly located in the

position used for rough machining.

The profile allows changing X and Z direction.

G71 Longitudinal roughing cycle parallel to Z-axis

PROGRAMMING MANUAL -27-

G71 U3 R1

G71 P100 Q200 U0.3 W0.1 F0.25

U Cut depth on radius (mm).

R Retraction in radial direction from diameter to prevent touching the machined diameter (mm).

P Block number from which the profile operation begins.

Q Number of end block of profile.

U Finishing allowance for radius on X-axis (mm).

W Finishing allowance on Z-axis (mm).

F Instantaneous feed (mm/revolution).

At the end of each cycle sequence the machine is always positioned in the position at

which this cycle sequence was started.

The positioning allows changing X- and Z-axis direction.

Page 28

PROGRAMMING MANUAL -28-

G72 Cross roughing cycle transversal parallel to X-axis

G72 W3 R1

G72 P100 Q200 U0.25 W0.1 F0.3

W Depth of cut on Z-axis (mm).

R Retraction amount.

P Block number from which the profile operation begins.

Q Number of end block of profile.

U Finishing allowance for radius on X-axis (mm).

W Finishing allowance on Z-axis (mm).

F Instantaneous feed (mm/revolution).

Same as the above one, excepting for the profile.

G73 Roughing cycle with passes parallel to profile

G73 U9 W9 R3

G73 P100 Q200 U0.4 W0.1 F0.3

U Stock allowance (for radius) unmachined on X-axis (mm).

W Stock allowance on Z-axis (mm).

R Number of roughing passes.

P Block number from which the profile operation begins.

Q Number of end block of profile.

U Finishing allowance for radius on X-axis (mm).

W Finishing allowance on Z-axis (mm).

F Instantaneous feed (mm/revolution).

Page 29

G74 Drilling cycle (chip break)

G74 R0.5

G74 Z-100 Q2500 F0.25

R Retract distance (chip break).

Z Final drilling depth (absolute dimensions in mm).

Q Cut depth per pass (Microns).

F Feed rate (mm/revolution).

G83 Peck drilling cycle

G0 G80 G99 X0 Z3

G83 Z-60 Q2000 F0.2

G80

Z Final drilling depth (absolute dimensions in mm).

R Distance from the initial position to the start point (incremental value, not required if

already in position)

Q Depth of cut (Microns).

P Dwell time (s) at the bottom of the hole.

F Feed rate (mm/revolution).

PROGRAMMING MANUAL -29-

G84 Tapping cycle

Please note that if not using a LM or MS machine, then M122 and M123 can be omitted

G97 S500 M3

G0 G80 G99 X0 Z6

M122 (MAIN SPINDLE RIGID TAP ON)

M129S500 (RIGID TAP ON)

G84 Z-10 F1

G80

M128 (RIGID TAP OFF)

M123 (MAIN SPINDLE RIGID TAP OFF)

Z Final tapping depth (absolute dimensions in mm).

P Dwell time (s) at the bottom of the hole.

F Feed rate (mm/revolution).

G74 Front counter boring cycle

G74 R0.5

G74 X50 Z-4 P3000 Q4000 F0.15

R Retraction (mm) to break chips.

X (U) End position on X-axis (mm).

Z (W) End position in slot direction (mm).

P Step over on X-axis for next pass (Microns)

Q Cutting depth (Microns)

F Feed rate (mm/revolution).

Page 30

PROGRAMMING MANUAL -30-

G75 Longitudinal grooving cycle

G75 R0.2

G75 X43 W-7.5 P4000 Q2500 F0.15

R Retraction (mm) to break chips

X Groove bottom diameter (mm).

W Groove end point on Z-axis (mm) if Z is specified in absolute dimensions and W is the

displacement in incremental mode; from left-hand to right-hand (W+) and from right-hand to

left-hand (W-), always subtracting tool width.

P Cutting depth on X-axis (Microns).

Q Step over on Z-axis for next pass (Microns).

F Feed rate (mm/revolution).

IMPORTANT: Roughing cycles are without tool radius compensation. Because of

this, higher allowances will be specified for X and Z depending on tool radius.

G76 Threading cycle

G76 P030060 Q200 R0.05

G76 X98.773 Z-40 R0 P1227 Q400 F2

P03 Number of finishing passes.

P00 Thread run out ; distance at which thread outlet is started, in tenths of turn Example: If thread

pitch is 2 and 20 is entered: 2mm x 2 turns = 4 mm (thread runs out 4mm before the end point).

This is normally set to 00

P60 Thread angle in degrees

Q Minimum depth of cut (Microns).

R Finishing allowance (mm).

X Core diameter (mm).

Z Thread end point on Z-axis (absolute dimensions in mm).

R Height difference on radius (mm) for taper threads (Microns).

P Thread depth (Microns).

Q Cut depth for first pass (Microns).

F Thread pitch (mm).

Page 31

1. EXAMPLES OF CANNED CYCLES

G71 Canned roughing cycle

PROGRAMMING MANUAL -31-

O0071;

G21;

G10 L2 P1 X0. Z130;

N1 G28 U0.V0.

T101;

(ROUGH TURN);

G50 S2500;

G96 S200 M3;

G0 G40 G54 G99 X105 Z0 M8;

G1 X-2 F0.25;

G0 X105 Z1;

G71 U3 R1;

G71 P100 Q200 U2 W2 F0.3;

N100 G0 X40;

G1 Z-30;

X60 Z-60;

Z-80;

N200 X105 Z-90;

G70 P100 Q200 (FINISHING CYCLE)

G0 G40 X150 Z100 M9;

M30;

Page 32

PROGRAMMING MANUAL -32-

G74 and G83 fixed drilling cycles (with chip breakage)

G74 Drilling cycle with a short retraction for chip breakage

O0009;

G21;

G10 L2 P1 X0 Z75.;

N8 G28 U0.V0.

T808;

(DRILL);

G97 S265 M3;

G0 G40 G54 G99 X0 Z3. M8;

G74 R0.5;

G74 Z-60 Q20000 F0.2;

G0 X150 Z100 M9;

M30;

G83 Fixed drilling cycle with retraction at the start for chip breakage and removal

O0010;

G21;

G10 L2 P1 X0 Z75.;

N8 G28 U0.V0.

T808;

(DRILL);

G97 S500 M3;

G0 G40 G54 G99 X0 Z3 M8;

G83 Z-60 Q20000 F0.2;

G80

G0 X150 Z100 M9;

M30;

Page 33

G84 Rigid Tapping Cycle (Main spindle)

O0011;

G21;

G10 L2 P1 X0 Z-75.;

N8 G28 U0.V0.

T808;

(DRILL);

G97 S500 M3;

G0 G80 G54 G99 X0 Z3 M8;

M122

M129

G83 Z-60 Q20000 F0.2;

G80

M128

M123

G0 X150 Z100 M9;

M30;

PROGRAMMING MANUAL -33-

Page 34

PROGRAMMING MANUAL -34-

Page 35

Fixed longitudinal grooving cycle

PROGRAMMING MANUAL -35-

O0011;

G21;

G10 L2 P1 X0 Z110.;

N7 G28 U0.V0.

T707;

(GROOVE);

G50 S1000;

G96 S110 M3;

G0 G40 G54 G99 X80 Z-55 M8;

G75 R.5; Grooving with chip breaking

G75 X69 Z-28 P3000 Q2500 F.1; Grooving, penetrate until ø69 and until Z(W)-28,

penetration in X(P) 3mm, movement in Z(Q) 2.5mm.

G0 X150 Z100 M9;

M30;

Groove width or groove end point can be defined with a W code in this example

(W27, that is, 30 – 3 of tool), if tool is positioned on the right-hand would be (W-27).

For either Z or W, tool width must be subtracted.

Threading fixed cycle

Page 36

PROGRAMMING MANUAL -36-

O0012;

G10 L2 P1 X0 Z88;

N1 G28 U0.V0.

T101;

(TURN);

G50 S2000;

G96 S200 M3;

G0 G40 G54 G99 X68 Z0. M8;

G1 X-2 F0.25;

G0 Z2;

G42 X54. Z1;

G1 X60 Z-2 F0.15;

Z-35 F0.25;

X66;

G0 G40 X150 Z100 M9;

M1;

N9 G28 U0.V0.

T909;

(SCREWCUT);

G97 S800 M3;

G4X1.

G0 G40 G54 G99 X62 Z6 M8;

G76 P030060 Q200 R0.03;

G76 X57.4 Z-30 P1227 Q400 F2;

G0 X150 Z100 M9;

M30;

Page 37

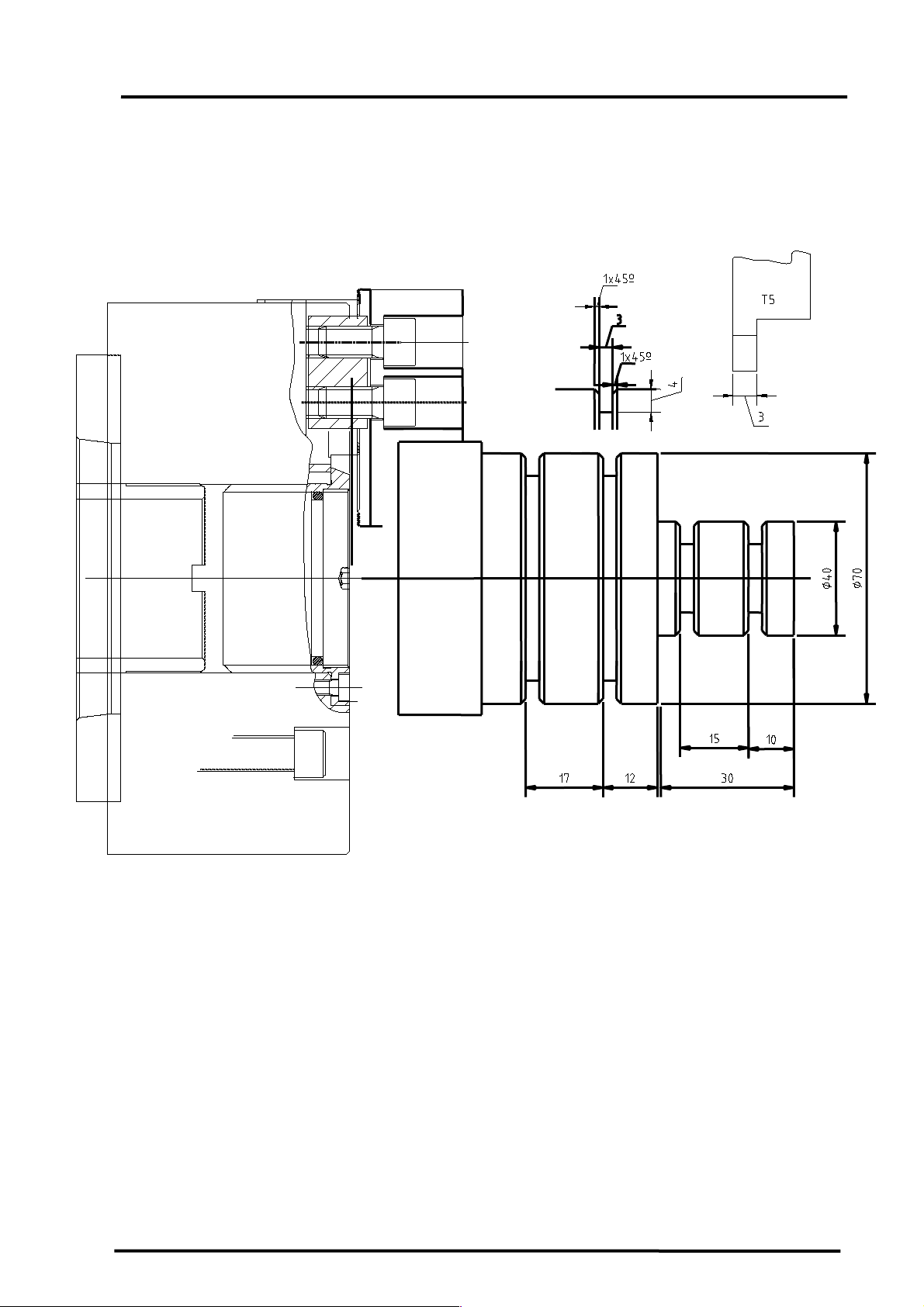

Application exercise for threading operations

PROGRAMMING MANUAL -37-

T1= OUTSIDE AND FACING.

T8= TWIST DRILL ø28

T10= BORING

T12= INTERNAL THREADING CUTTING

T5= EXTERNAL THREADING CUTTING

O0013;

G21;

G10 L2 P1 X0 Z100;

N1 G28 U0. V0.

T101;

(TURN)

G97 S200 M3

G0 G40 G54 G99 X73 Z0. M8;

G1 X-2 F0.2;

G0 X61 Z2;

G1 Z0;

X64.9 Z-2 F0.15 (THREAD DIAMETER);

Page 38

PROGRAMMING MANUAL -38-

Z-35 F0.2;

X70 Z-50 F0.15;

X71;

G0 X150 Z100 M9;

M1;

N8 G28 U0. V0.

T808

(DRILL)

G97 S300 M3

G0 G54 G99 X0 Z3 M8;

G74 R1;

G74 Z-84 Q3000 F0.15;

G0 X150 Z100 M9;

M1

N10 G28 U0. V0.

T1010

(BORE)

G97 S150 M3;

G0 G40 G54 G99 X34 Z2 M8;

G1 Z0 F0.25;

X29.6 Z-2 F0.15;

Z-30 F0.2;

X27;

G0 X150 Z100 M9;

M1;

N12 G28 U0. V0.

T1212

(INTERNAL SCREWCUT)

G97 S1275 M3;

G4X2.;

G0 G54 G99 X28 Z6;

G76 P030060 Q300 R0.05;

G76 X32 Z-25 P1230 Q450 F2;

G0 X150 Z100 M9;

M1;

N5 G28 U0. V0.

T505;

(EXTERNAL SCREWCUT)

G97 S650 M3;

G4 X2.;

G0 G54 G99 X67 Z6.;

G76 P030060 Q300 R0.05;

G76 X63.05 Z-30 P920 Q400 F1.5;

G0 X130 Z25 M9;

M30;

Page 39

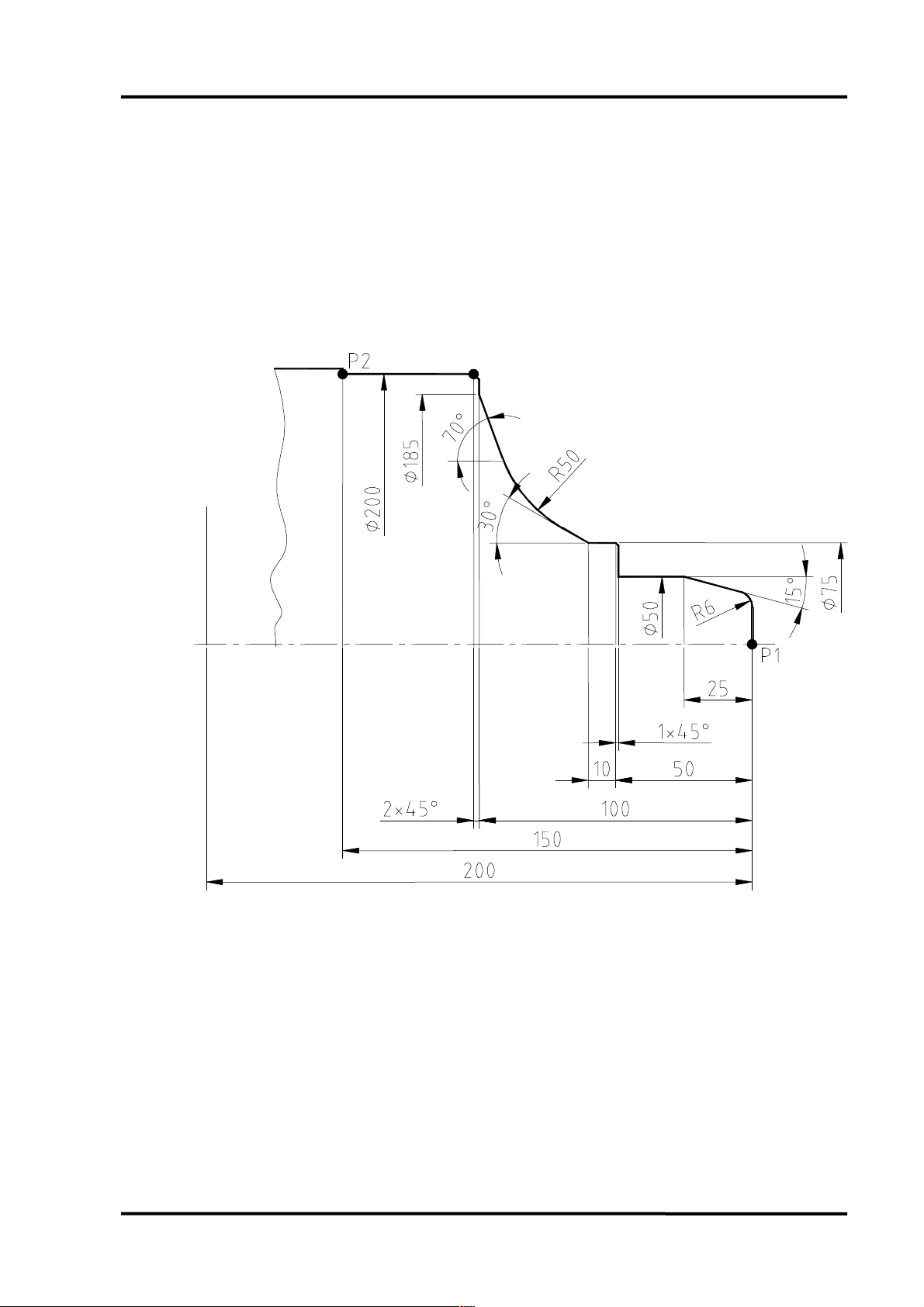

PROGRAMMING SIMPLIFICATION FUNCTIONS

PROGRAMMING MANUAL -39-

In theses cases, considering tool direction is most important.

The easier procedure is drawing a quadrant on the drawing and locate the

degrees as shown on the above diagram.

Page 40

PROGRAMMING MANUAL -40-

Direct programming of profile (angles and round edges)

Page 41

PROGRAMMING MANUAL -41-

O0014;

G21;

G10 L2 P1 X0 Z120;

N3 G28 U0.V0.

T303;

G50 S2200;

G96 S230 M3;

G0 G54 G40 G99 X0 Z3. M8;

G1 Z0 F0.15 (P1);

,A90 ,R6 (FIRST ANGLE);

,A165 X50 Z-25 (SECOND ANGLE); A165 comes from 180°-15°=165°

,A180 Z-49.;

,A90 X75. ,C1;

Z-60;

,A150 ,R50; A150 comes from 180°-30°=150°

,A110 X185 Z-100; A110 comes from 180°-70°=110°

,A90 X200 ,C2;

,A180 Z-150. (P2);

G0 X250 Z100 M9;

M30;

Page 42

PROGRAMMING MANUAL -42-

Tool radius compensation

1st) Type of tool (Control) T (Offsets table).

2st) Radius inserts of tool (Control) R (Offsets table).

3st) Workpiece position with respect to tool (Part program) G41 or G42.

<EXTERNAL>

<INTERNAL>

Page 43

Tool types

PROGRAMMING MANUAL -43-

Milling cutters are assigned with type “0” or “9” for interpolations.

Page 44

PROGRAMMING MANUAL -44-

G40 G41 and G42 tool radius compensation

Tools

T1 = EXTERNAL

T8= TWIST DRILL ø38

T10 = INTERNAL

Page 45

O0015 (TOOL RADIUS COMPENSATION G40, G41, G42);

G21;

G10 L2 P1 X0 Z-95.;

N1 G28 U0.V0.

T101;

(TURN);

G50 S2200;

G96 S200 M3;

G0 G40 G54 G99 X110 Z0 M8;

G1 X-2 F0.25;

G0 X100 Z2;

G1 Z-17;

G0 X102 Z3;

G42 X95 Z1 (ACTIVES COMPENSATION RIGHT);

G1 Z0 F0.1;

X97 Z-1 F0.15;

Z-15 F0.2;

,A150 X102.;

,A180 Z-45;

X106.;

G0 G40 X150 Z100 M9 (CANCEL TOOL COMPENSATION);

M1 ;

PROGRAMMING MANUAL -45-

N8 G28 U0.V0.

T808 ;

(DRILL 38MM DIA);

G97 S165 M3;

G0 G54 G99 X0 Z3 M8;

G74 R1;

G74 Z-80 Q25000 F0.25;

G0 X150 Z100 M9;

M1;

N10 G28 U0.V0.

T1010

(BORE);

G50 S2000

G96 S150 M3;

G0 G40 G54 G99 X45 Z2 M8;

G1 Z-6 F0.2;

X41 Z-35;

Z-38.9;

G0 X37 Z2;

G41 X50 Z1 (ACTIVES COMPENSATION LEFT);

G1 X46 Z-1 F0.15;

Z-6;

X42 Z-35;

Z-39;

X37;

G40 X35(CANCEL TOOL COMPENSATION);

G0 Z10. M9 ;

X150 Z100 ;

M30;

Page 46

PROGRAMMING MANUAL -46-

G71 Type I - Example of roughing and finishing cycle with direct definition of profile and tool radius compensation

Page 47

O0016 (Example of roughing cycle G71 Type I);

G21;

G10 L2 P1 X0 Z115.;

N1 G28 U0.V0.

T101

(ROUGH TURN);

G50 S2500;

G96 S200 M3;

G0 G40 G54 G99 X115 Z2 M8;

G1 X-2 F0.25;

G0 Z2. ;(POSITIONING, STARTOF CYCLE);

X111;(POSITIONING, STARTOF CYCLE);

G71 U3 R1 (ROUGHING CYCLE);

G71 P100 Q200 U0.3 W0.1 F0.25;

N100 G0 X52 (START OF PROFILE);

G42 X54. Z1.

G1 X60. Z-2 F0.15;

Z-22;

,A170. ,R20;

,A140. X95 Z-50. ,R5.;

,A180.;

,A135. X110 Z-64;

N200 G40 X111 (END POINT OF PROFILE);

G0 X150 Z100 M9;

M1;

PROGRAMMING MANUAL -47-

N3 G28 U0.V0.

T303

(FINISH TURN);

G50 S2500;

G96 S230 M3;

G0 G40 G54 G99 X62 Z0 M8;

G1 X-1 F0.15;

G0 Z2;

X111. (POSITIONING START OF CYCLE);

G70 P100 Q200 (FINISHING CYCLE);

G0 X150 Z100 M9;

M1;

N5 G28 U0.V0.

T505;

(SCREWCUT);

G97 S750 M3;

G4X1.;

G0 G54 G99 X62 Z6 M8;

G76 P030055 Q050 R0.05;

G76 X57.641 Z-19. P1179 Q450 F1.814;

G0 X150 Z100 M9;

M30;

All cycles end where they are started and, because of this, finishing positioning is

done above the workpiece.

Page 48

PROGRAMMING MANUAL -48-

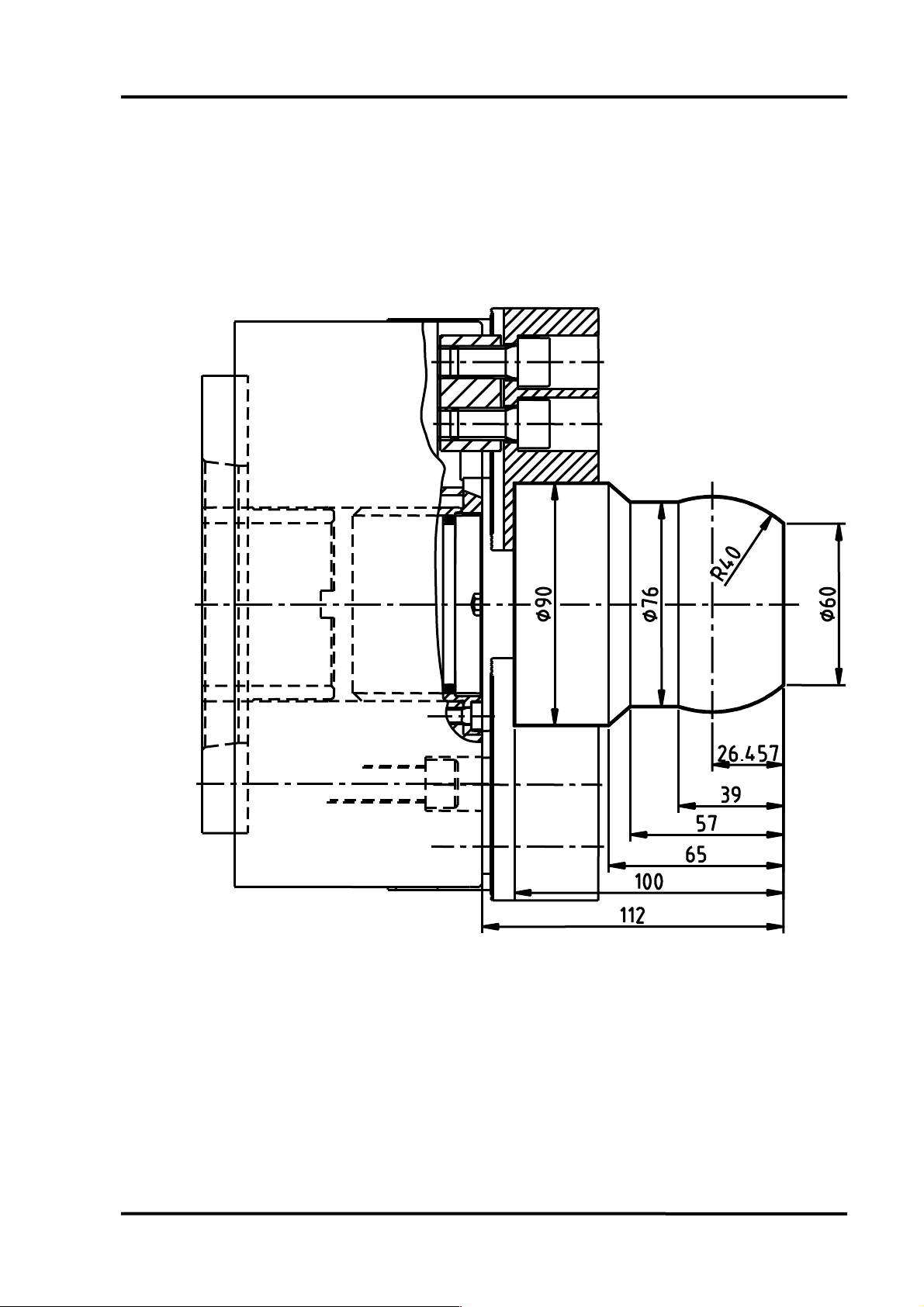

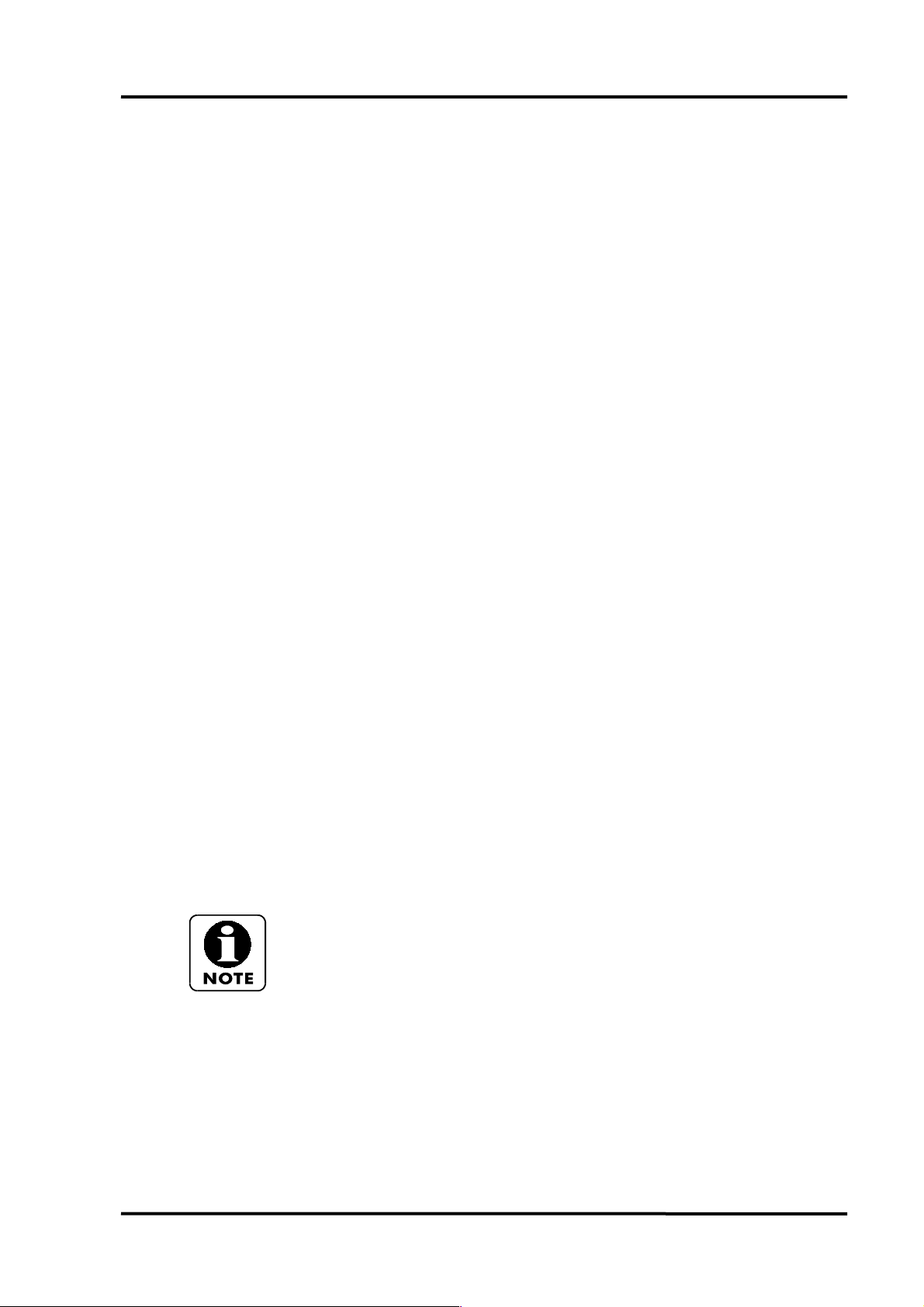

G71 Type II - Roughing cycle with displacement direction reversal on X-axis

Page 49

O0017 (Example of roughing cycle G71 Type II)

G21;

G10 L2 P1 X0 Z115;

N1 G28 U0.V0.

TI01;

(ROUGH TURN);

G50 S2250;

G96 S200 M3;

G0 G40 G54 G99 X95 Z0.1 M8;

G1 X-2 F0.2;

G0 Z2.;

X92;

G71 U2.5 R1;

G71 P100 Q200 U1.2 W0.1 F0.2;

N100 G0 X60 Z1.;

G1 G42 Z0 F0.15;

G3 X76 Z-39 R40;

G1 Z-57;

X90 Z-65;

N200 G0 G40 X92;

X150 Z100 M9;

M1;

PROGRAMMING MANUAL -49-

N3 G28 U0.V0.

T303;

(FINISH TURN);

G50 S2750;

G96 S220 M3;

G0 G40 G54 G99 X65 Z0 M8;

G1 X-2 F0.15;

G0 Z2.;

X92;

G70 P100 Q200;

X150 Z100 M9;

M30;

For control units with capability for machining profiles with X-axis direction

reversal, the first block for defining the profile must state the movement of the two

axes.

Page 50

PROGRAMMING MANUAL -50-

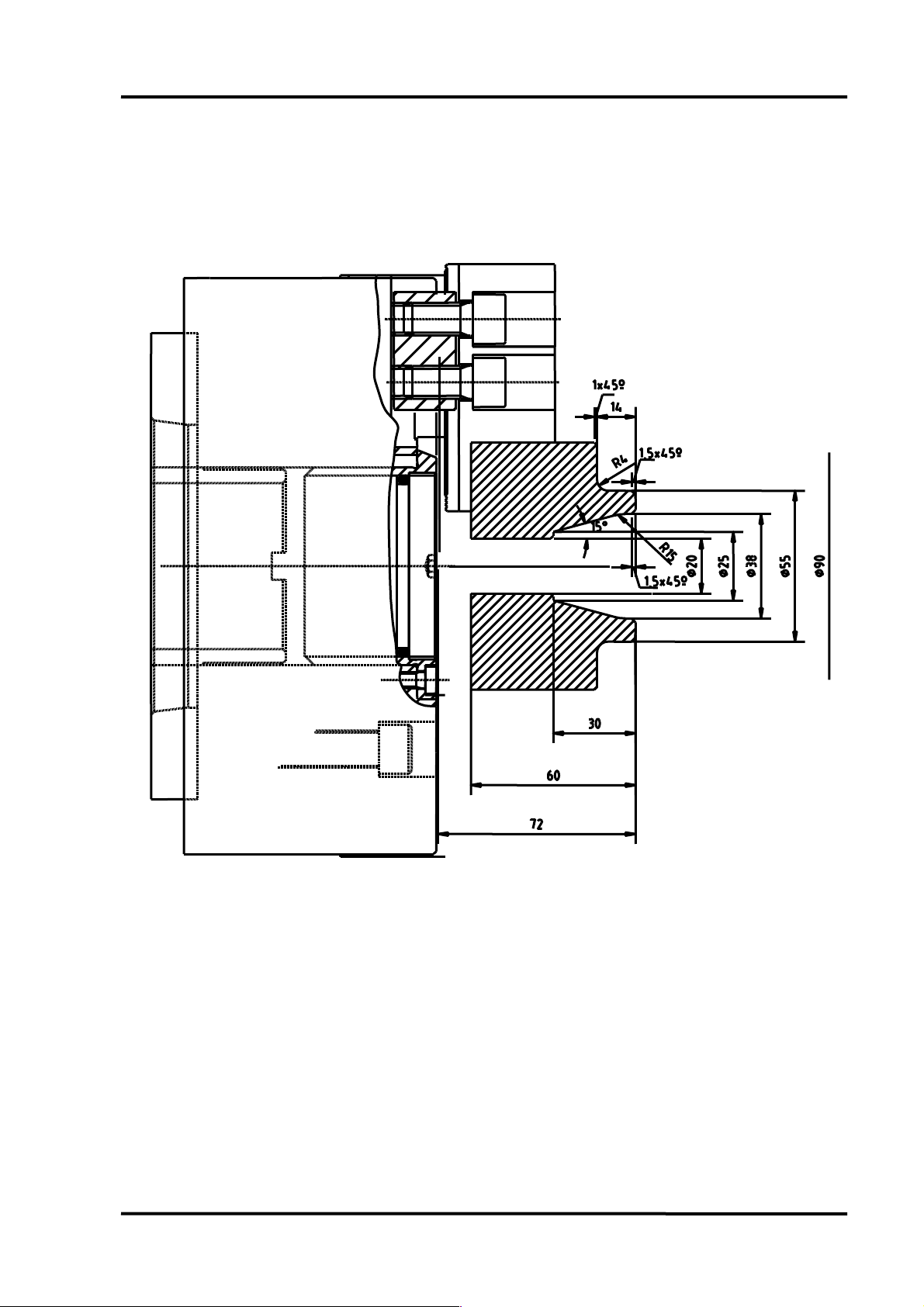

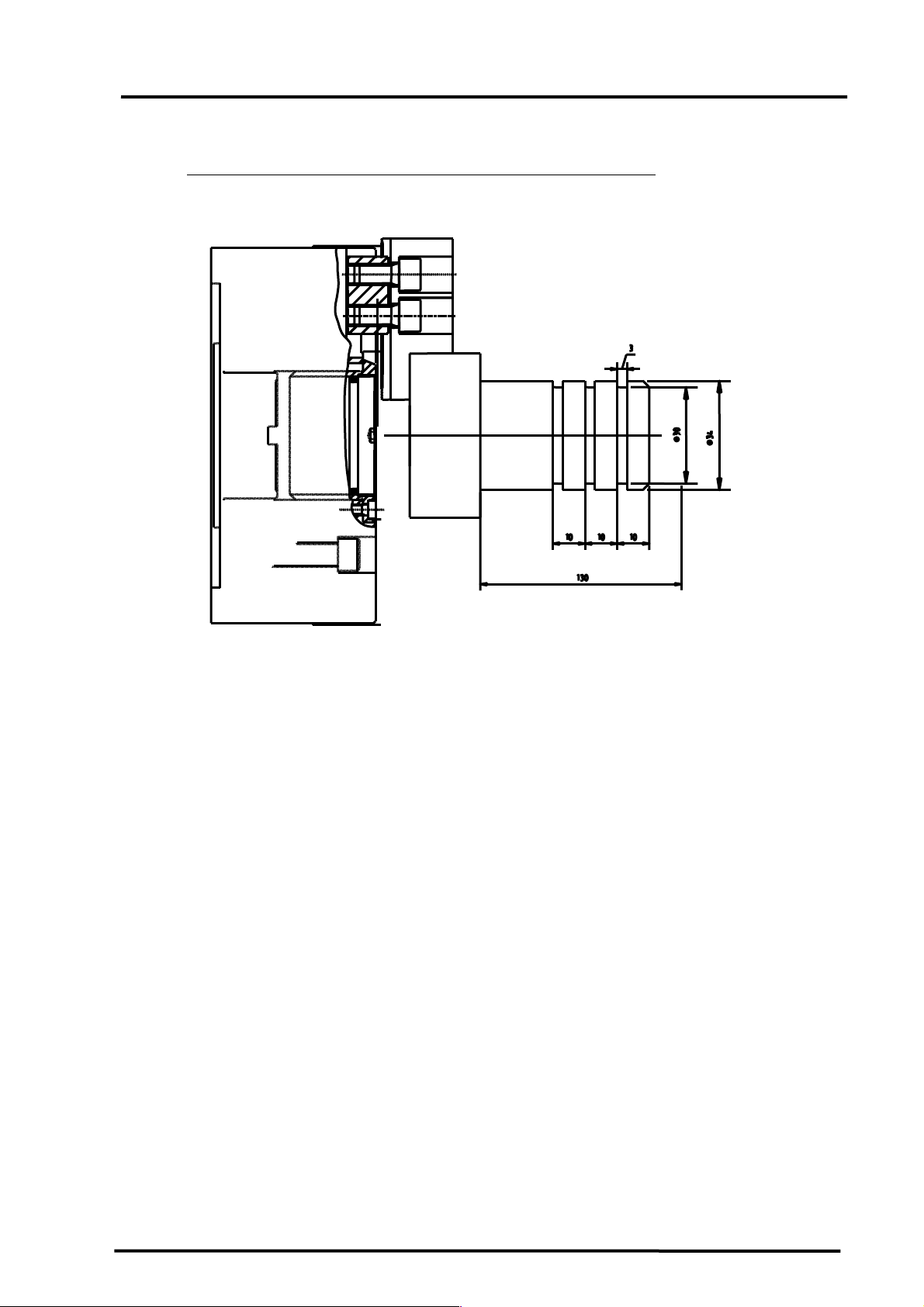

G72 Example of cross roughing cycle parallel to X-axis

TOOLS:

T1 = EXTERNAL ROUGHING

T2 = EXTERNAL FINISHING

T6 = INTERNAL ROUGHING

T10 = INTERNAL FINISHING

Page 51

ROUGHING CYCLE APPLICATION

00018 (Example of roughing cycle G72);

G21;

G10 L2 P1 X0 Z115.;

N1 G28 U0.V0.

T101;

(ROUGH TURN);

G50 S2200;

G96 S200 M3;

G0 G40 G54 G99 X95 Z0.1 M8;

G1 X18 F0.25;

G0 X92 Z2;

G72 W2.5 R1;

G72 P100 Q200 U0.3 W0.15 F0.25;

N100 G0 G41 Z-15;

G1 X90;

X88 Z-1;4;

X55 ,R4;

Z-1.5;

N200 X50. Z1;

G0 X150 Z100 M9;

M1;

PROGRAMMING MANUAL -51-

N6 G28 U0.V0.

T606;

(ROUGH BORE);

G50 S2250;

G96 S150 M3;

G0 G40 G54 G99 X18 Z2 M8;

G71 U2.5 R1;

G71 P300 Q400 U-0.3 W0.1 F0.2;

N300 G0 X45;

G41 X43. Z1;

G1 X38 Z-1.5 F0.1;

,A180 ,R15;

,A195. X25 Z-30;

X22;

X20 Z-31;

N400 G40 X18.

G0 X150 Z100 M9;

M1;

N10 G28 U0.V0.

T1010;

(FINISH BORE);

G50 S1750;

G96 S180 M3;

G0 G40 G54 G99 X18 Z2 M8;

G70 P300 Q400;

G0 X150 Z100 M9;

M1;

Page 52

PROGRAMMING MANUAL -52-

N3 G28 U0.V0.

T303;

(FINISH TURN);

G50 S2250;

G96 S230 M3;

G0 G40 G54 G99 X57 Z0 M8;

G1 X35. F0.1;

G0 X92 Z2;

G70 P100 Q200

G0 G40 X150 Z100 M9;

M30;

Page 53

M98 Repetitions of a subprogram

PROGRAMMING MANUAL -53-

SUBPROGRAM REPETITION APPLICATION

00019 (Repeating of subprogram M98);

G21;

G10 L2 P1 Z150.;

N5 G28 U0.V0.

T505;

(GROOVING);

G50 S1750;

G96 S100 M3;

G0 G40 G54 G99 X74 Z-59 M8;

M98 P1000 (CALLING TO SUBPROGRAM 01000);

G0 Z-42;

Page 54

PROGRAMMING MANUAL -54-

SUBPROGRAM FOR A SLOT:

M98 P1000;

G0 Z-25;

X44;

M98 P1000;

G0 Z-10;

M98 P1000;

G0 X200 Z200 M9;

M30;

01000 (SUBPROGRAM FOR THE SLOT);

G1 U-12 F0.1;

G4 X1;

G0 U12;

W-1;

G1 U-4;

U-2 W1;

G0 U6;

W1;

G1 U-4;

U-2 W-1;

G0 U6;

M99 (END OF SUBPROGRAM);

The subprogram is called by means of command P followed by a number. This

number consists of four or more characters.

If the number consists of four characters, it indicates the identification number of

subprogram to be called.

If the number consists of more than four characters, the first four characters, from

right to left, indicate the identification number of subprogram to be called. Next

characters indicate the number of repetitions of subprogram to be called.

Page 55

M98 Repetition of parts of a program

PROGRAMMING MANUAL -55-

Page 56

PROGRAMMING MANUAL -56-

PARTS OF A PROGRAM REPETITION APPLICATION:

00020 (REPEATING OF PARTS OF A PROGRAM);

G21;

G10 L2 P1 Z150.;

N4 G28 U0.V0.

T404;

(GROOVING);

G50S1750;

G96 S90 M3;

G0 G40 G54 G99 X46 Z0 M8;

M98 P21001 (REPEATS TWO TIMES 1001);

G0 X200 Z200 M9;

M30;

SUBPROGRAM FOR A SLOT:

O1001 (SUBPROGRAM FOR GROOVING);

W-10;

G1 X30 F0.1;

G4 X1;

G0 X36;

M99;

As described above, a subprogram or part of a subprogram is repeatedly called by means of a

command P followed by several numerical characters. In this example, the subprogram is

repeatedly called by means of “P21001”.

This command consists of three parts:

“P” calling a subprogram.

“2” number of subprogram repetitions.

“1001” number consisting of four characters and directly referring to the subprogram.

The maximum number of repetitions for a subprogram in a single call is

9999.

Page 57

PROGRAMMING MANUAL -57-

OTHER EXAMPLE OF SUBPROGRAM EXECUTION REPETITION

PROGRAM:

O0021 (EXAMPLE OF M98);

G21

G10 L2 P1 Z130;

M98 P30002 (REPEATS 3 TIMES THE SUBPROGRAM 0002);

G0 X150 Z150 M9;

M30;

SUBPROGRAM

00002 (SUBPROGRAM);

N1 G28 U0.V0.

T101;

G50 S1500;

G96 S150 M3;

G0 G40 G54 G99 X30 Z-10;

G1 X-2 F0.08;

G0 X30;

G10 P0 W10;

M99

Page 58

PROGRAMMING MANUAL -58-

Bar feed examples (Hydrafeed)

O5000 (BAR FEED DEMO)

G21

G10 L2 P1 X0. Z165.

N12 G28 U0.V0.

T1212

(STOP)

#110=50(COMPONENT LENGTH)

M98 P8888

M1

O8888(BAR FEED)

(#110=COMPONENT LENGTH AS POSITIVE)

G28U0.V0.

M5

G0G40G98M9M10(PUSH)

Z50.

X0.

/2 M98 P8889

G1Z-#110F2500.

M69 (CHUCK OPEN)

G4X2.

Z0.5 F3500.

M68 (CHUCK CLOSE)

M11 (STOP PUSH)

G04 X2.

G0 Z50.

G28U0.V0.

M99

O8889 (LOAD NEW BAR)

G0 Z50.

G28 U0. V0.

M63 (PARTS CATCHER UP)

M69 (CHUCK OPEN)

M85 (EJECT)

G4 X1.

M64 (PARTS CATCHER DOWN)

G4 X1.

G0 X0.

G1G98Z-#110F2500.

M85 (NEWBAR)

M68 (CHUCK CLOSE)

G99

M99

Page 59

A+

A-

C+

C-

C-Axis, A axis and powered tooling

This section describes the procedures used to program SY type machines controlled by the Cand A-axis.

1- Stop the spindle (S1 and/or S2) by entering the command M5 (S1) or M115

(S2) before entering M43 or M143 command.

2- After activating M43 C-axis on G28 C0. must be entered .

3- After activating M143 A-axis on G28 A0. must be entered.

4- Before entering command M40 and M140, the powered tool must be stopped

by entering command M15.

PROGRAMMING MANUAL -59-

C or A -axis would be used to swivel the head in order to

position the work piece for drilling operations using a

powered tool.

C or A + is in clockwise direction and C or A- is counter

clockwise direction.

Page 60

PROGRAMMING MANUAL -60-

M codes related to C and A-axis functions

M13 Mill spindle forward direction

M14 Mill spindle reverse direction

M15 Mill spindle stop

M40 C-Axis disconnect

M43 C-Axis connect

M90 C-axis brake on (high pressure set to 24 bar)

M91 C-axis brake off (low pressure set to 6 bar)

M140 A-Axis disconnect

M143 A-Axis connect

G83 Front drilling cycle (powered tool)

(chip breakage with retraction to the start point)

G0 G80 G98 X30 Z3

G83 Z-30 H90 K4 Q2000 M90 F100

G80

X hole position

C hole position (not required if already in position)

Z Final drilling depth (absolute dimensions in mm)

R Distance from the initial position to the start point (incremental value, not required if

already in position)

H distance between two holes in degrees.

K number of holes.

Q Depth of cut (microns).

P Dwell time (s) at the bottom of the hole.

F Feed rate (mm/min).

M90 brake on (the brake will automatically unclamp before indexing within the cycle).

Page 61

PROGRAMMING MANUAL -61-

G184 Front rigid tapping cycle (Z-axis direction powered tool)

G0 G80 G98 X30 Z6

G184 C30 R-2 D.5 W20 Q1 F500

G184 C150 R-2 D.5 W20 Q1 F500

G184 C270 R-2 D.5 W20 Q1 F500

C C-axis angle.

R Return point.

D Dwell at bottom of hole.

WDistance from R point to the bottom of the hole.

Q Pitch of tap.

F Cutting feed.(Rpm x Pitch).

(Must use decimal point)

(M90 and M91 are automatically commanded in the macro).

G87 Side drilling cycle (powered tool)

(chip breakage with retraction to the start point)

G0 G80 G98 X50 Z-20

G83 X30 H90 K4 Q2000 M90 F100

G80

X Final drilling depth (absolute dimensions in mm)

C hole position (not required if already in position)

Z hole position

R Distance from the initial position to the start point (incremental value, not

required if already in position)

H distance between two holes in degrees.

K number of holes.

Q Depth of cut (microns).

P Dwell time (s) at the bottom of the hole.

F Feed rate (mm/min).

M90 brake on (the brake will automatically unclamp before indexing within the

cycle).

Page 62

PROGRAMMING MANUAL -62-

G188 Side rigid tapping cycle (X-axis direction powered tool)

G0 G80 G98 X50 Z6

G188 C30 R-2 D.5 U20 Q1 F500

G188 C150 R-2 D.5 U20 Q1 F500

G188 C270 R-2 D.5 U20 Q1 F500

(M90 and M91 are automatically commanded in the macro).

C C-axis angle.

R Return point.

D Dwell at bottom of hole.

UDistance from R point to the bottom of the hole.

Q Pitch of tap.

F Cutting feed.(Rpm x Pitch).

(Must use decimal point)

G185 Back rigid tapping cycle (Z-Axis Direction powered tool Sub Spindle)

G0 G80 G98 X50 Z-6

G185 A30 R2 D.5 U20 Q1 F500

G185 A150 R2 D.5 U20 Q1 F500

G185 A270 R2 D.5 U20 Q1 F500

A A-axis angle.

R Return point.

D Dwell at bottom of hole.

UDistance from R point to the bottom of the hole.

Q Pitch of tap.

F Cutting feed.(Rpm x Pitch).

(Must use decimal point)

(M90 and M91 are automatically commanded in the macro).

Page 63

PROGRAMMING MANUAL -63-

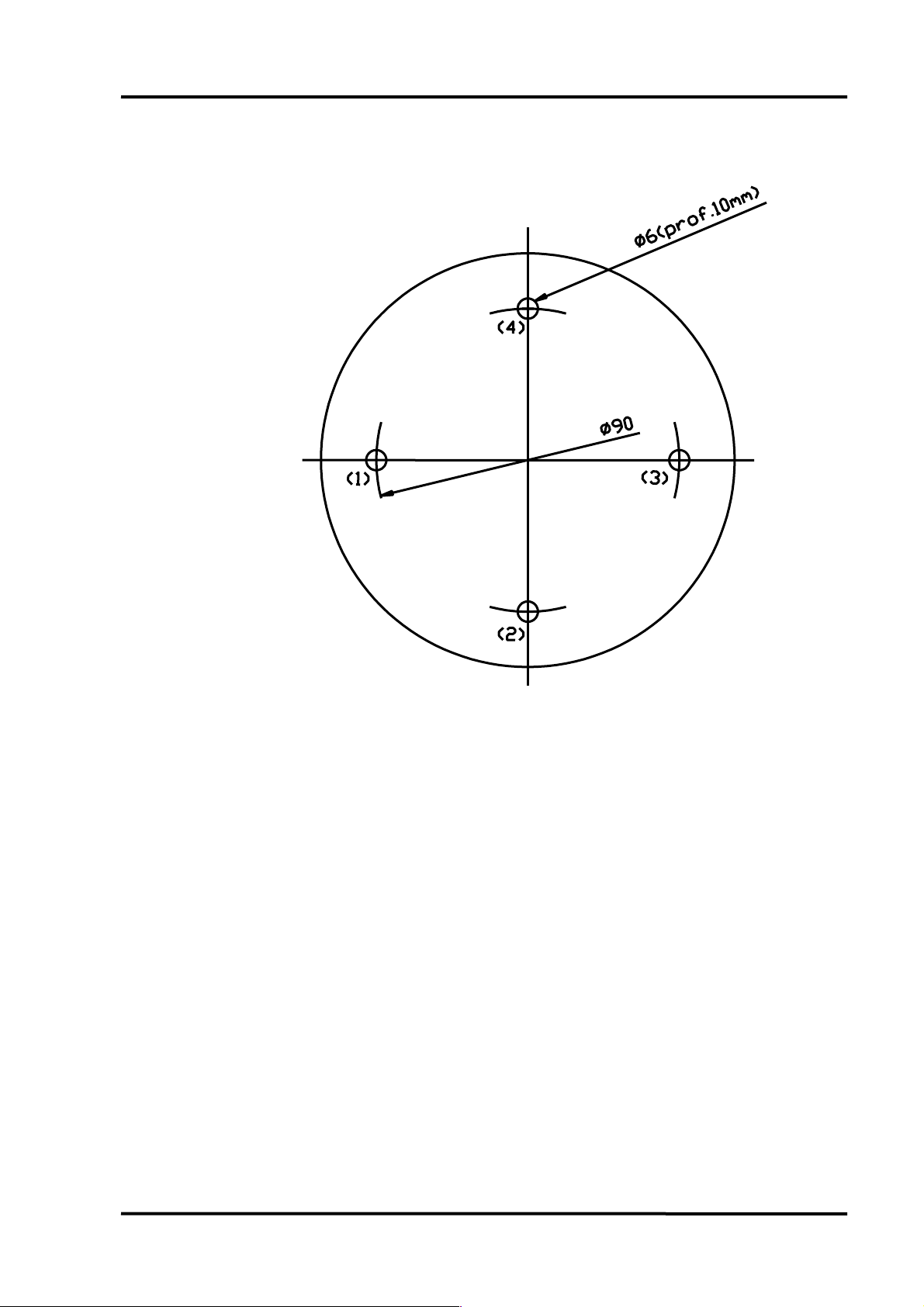

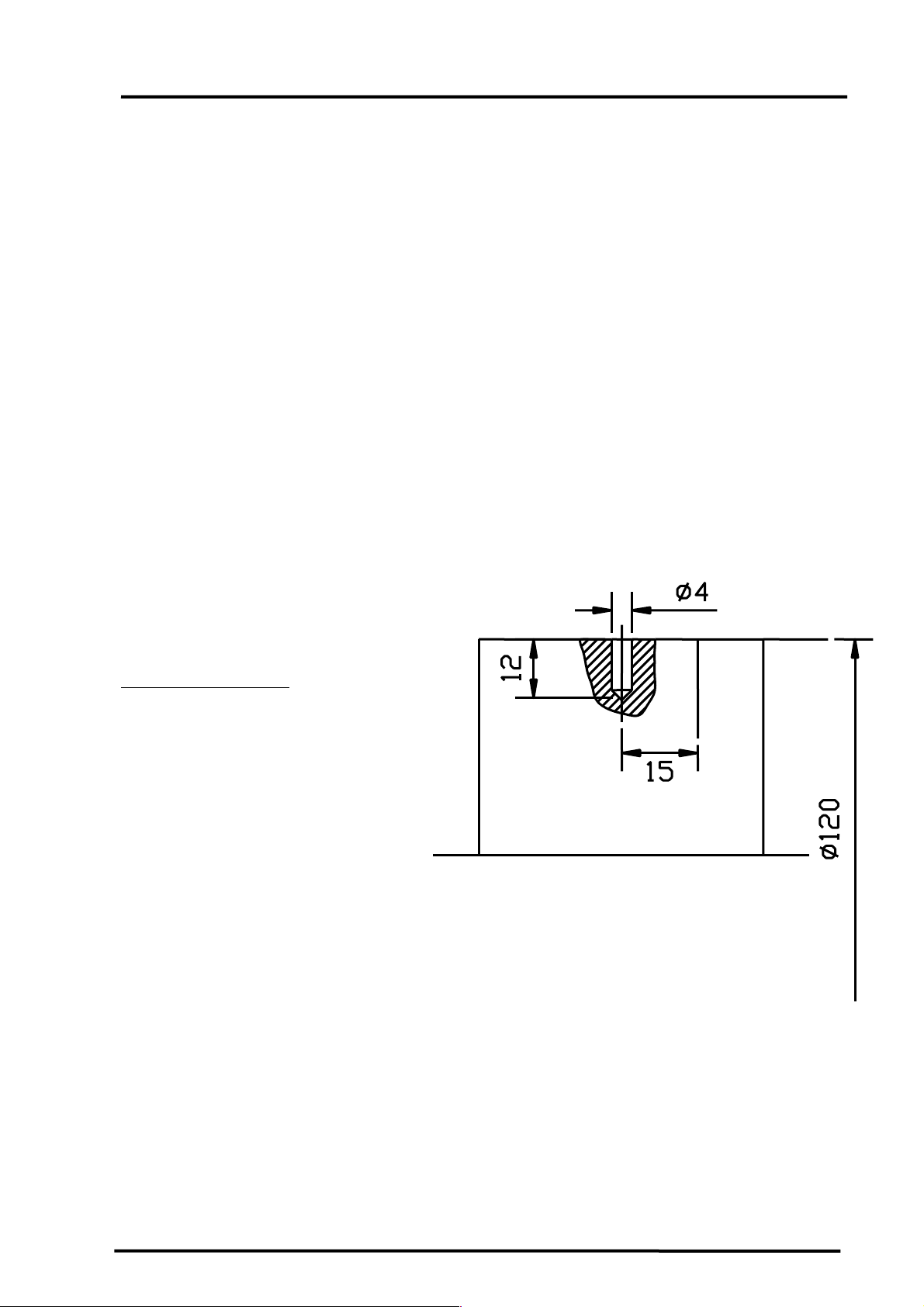

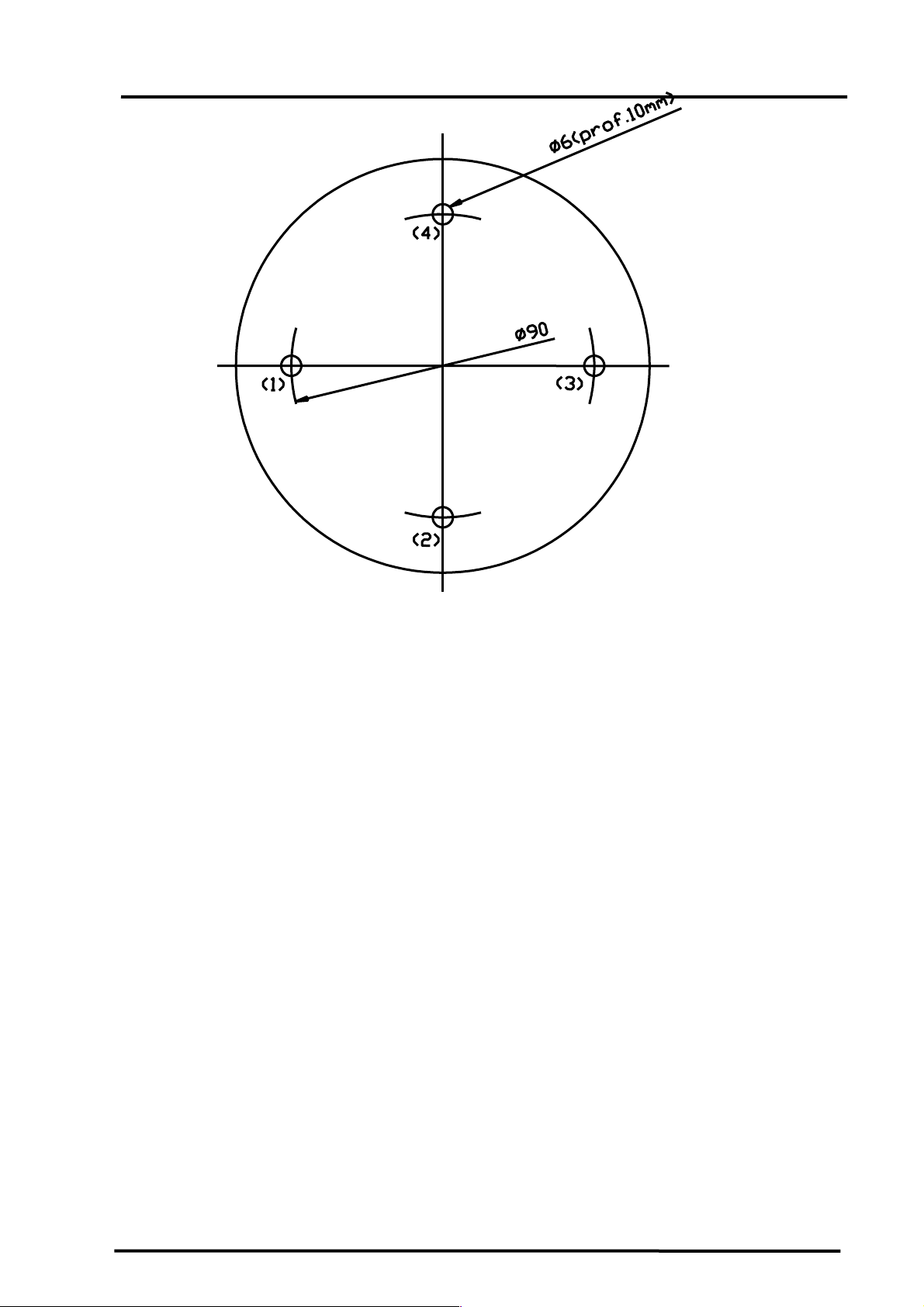

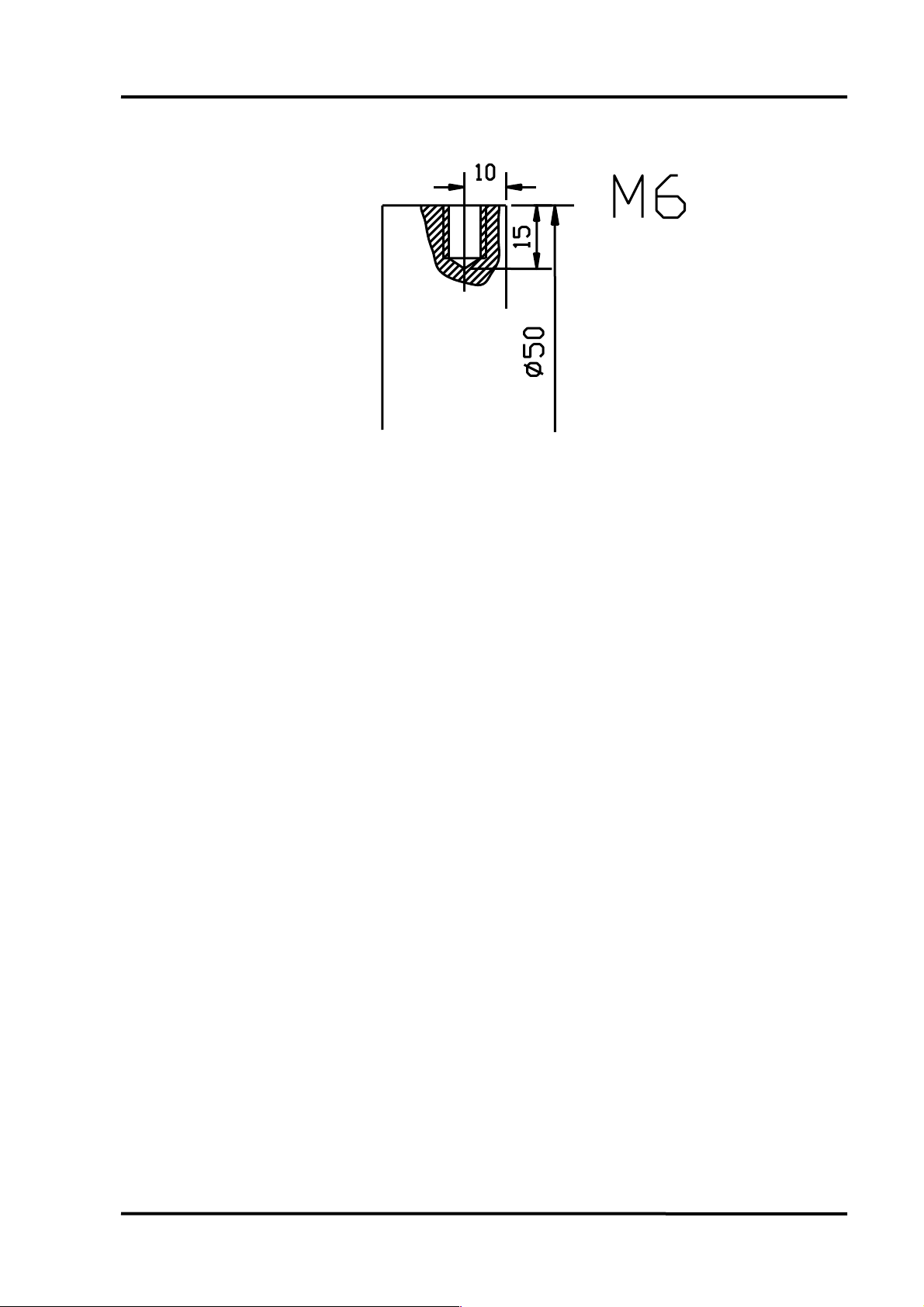

G83 Example of face front drilling cycle with powered tool (Main Spindle)

O0019

G21;

G10 L2 P1 X0 Z100;

N6 G28 U0. V0.

T606

(AXIAL 6MM DIA DRILL)

M5

M43

G28 H0

G97 S2500 M13

G0 G54 G80 G98 X90.Z2M8

G83 Z-10.K4 H90.M90 F100.

G80

M15

M40

G0 X150 Z150 M9

M1

ALTERNATIVE PROGRAM

This fixed drilling cycle can be programmed in the apparently more logic and simple sequence, ie,

0º - 90º - 180º - 270º. This cycle would be as follows:

O0020

G21;

G10 L2 P1 X0 Z100;

N6 G28 U0. V0.

T606

(AXIAL 6MM DIA DRILL)

M5

M43

G28 H0

G97 S2500 M13

G0 G54 G80 G98 X90.Z2M8

G83 Z-10. Q2000 M90 F100.

C90. Q2000 M90

C180. Q2000 M90

C270. Q2000 M90

G80

M15

M40

G0 X150 Z150 M9

M1

Page 64

PROGRAMMING MANUAL -64-

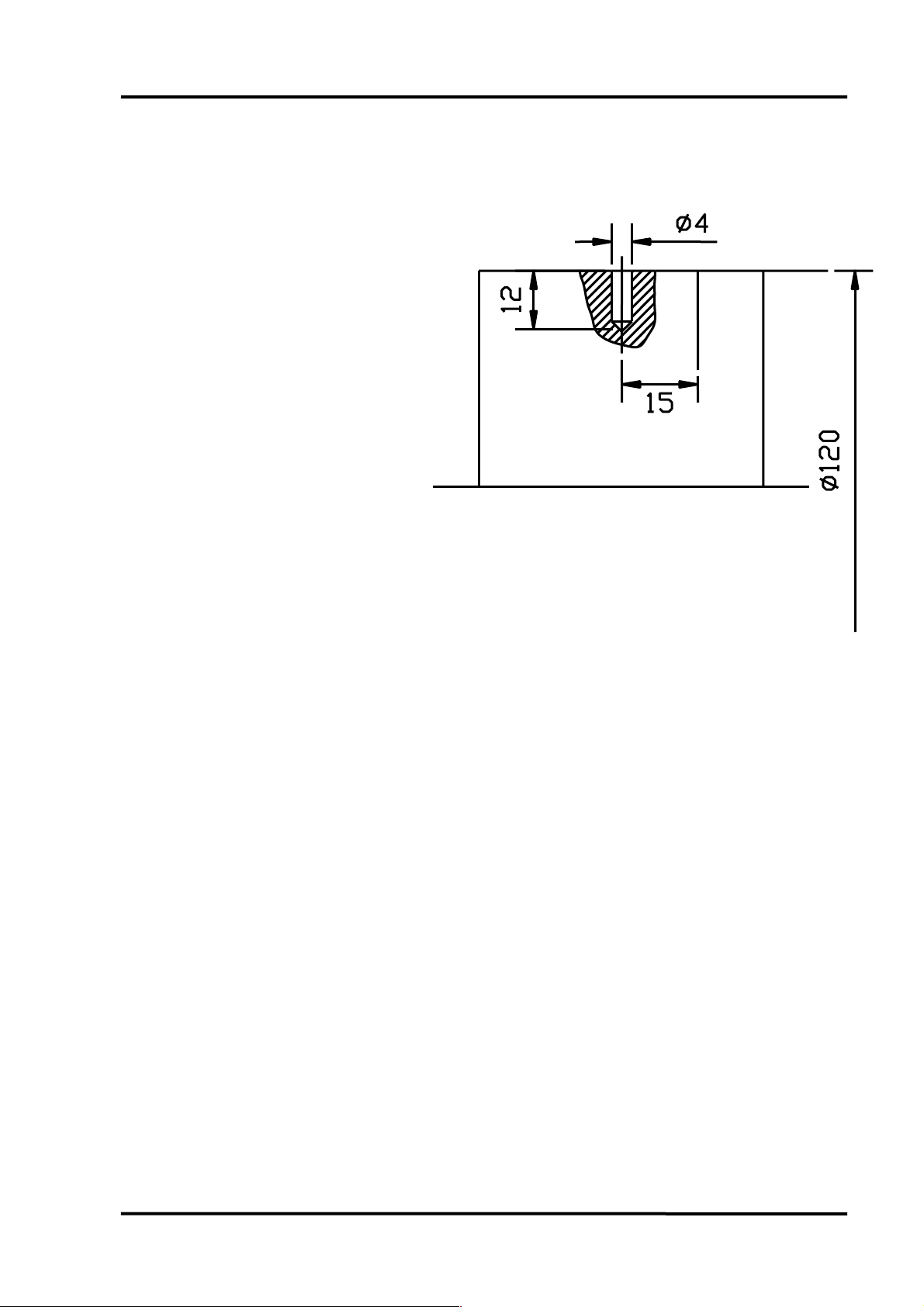

G83 Example of face front drilling cycle with powered tool (Sub Spindle)

O0019

G21;

G10 L2 P2 X0 Z100;

N6 G28 U0. V0.

T606

(AXIAL 6MM DIA DRILL)

M5

M143

G28 A0.

G97 S2500 M13

G0 G55 G80 G98 X90.Z-2.M8

G83 A0. Z10. Q2000 M90 F100.

A90. Q2000 M90

A180. Q2000 M90

A270. Q2000 M90

G80

M15

M140

G0 X150 Z150 M9

M1

Page 65

PROGRAMMING MANUAL -65-

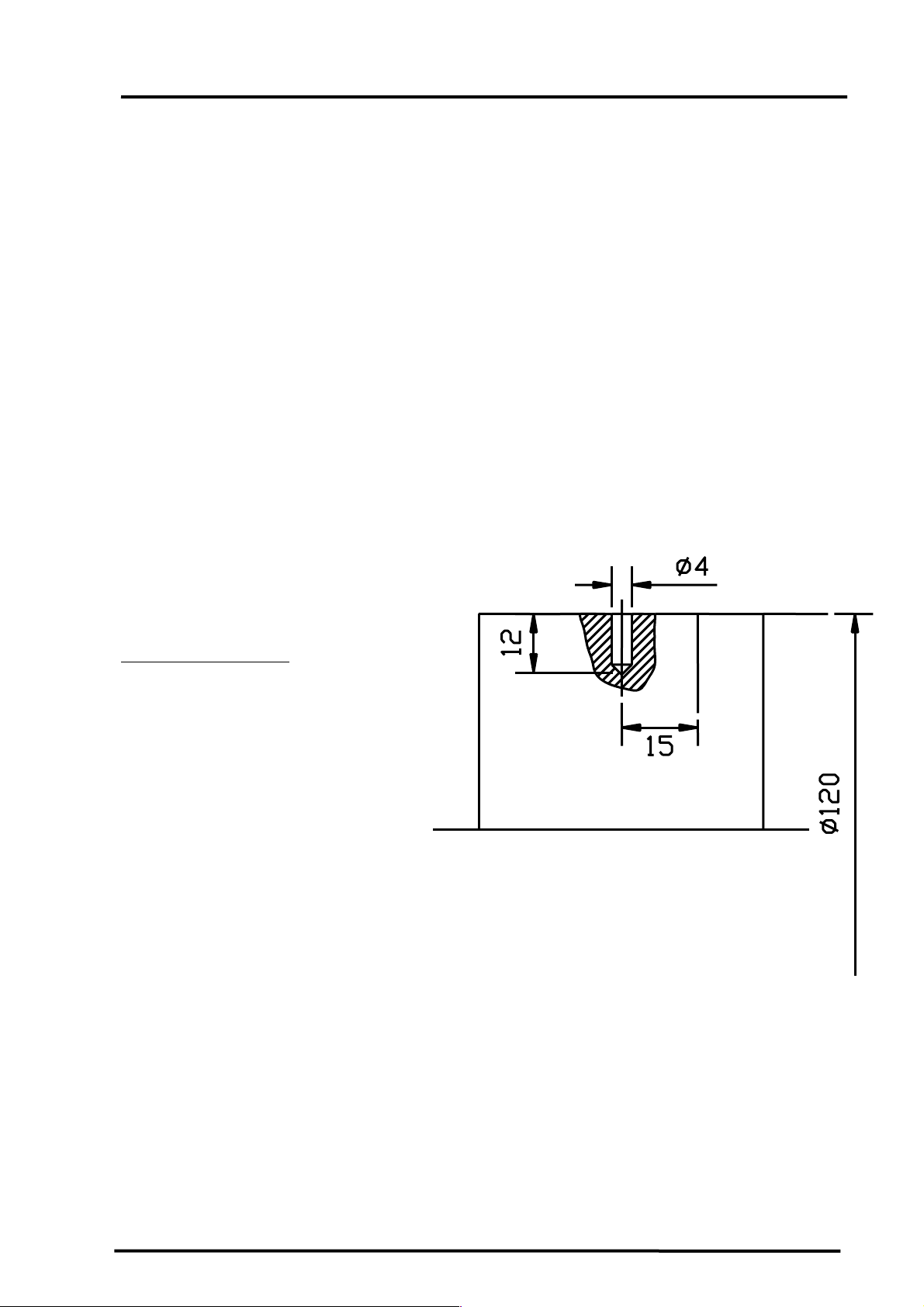

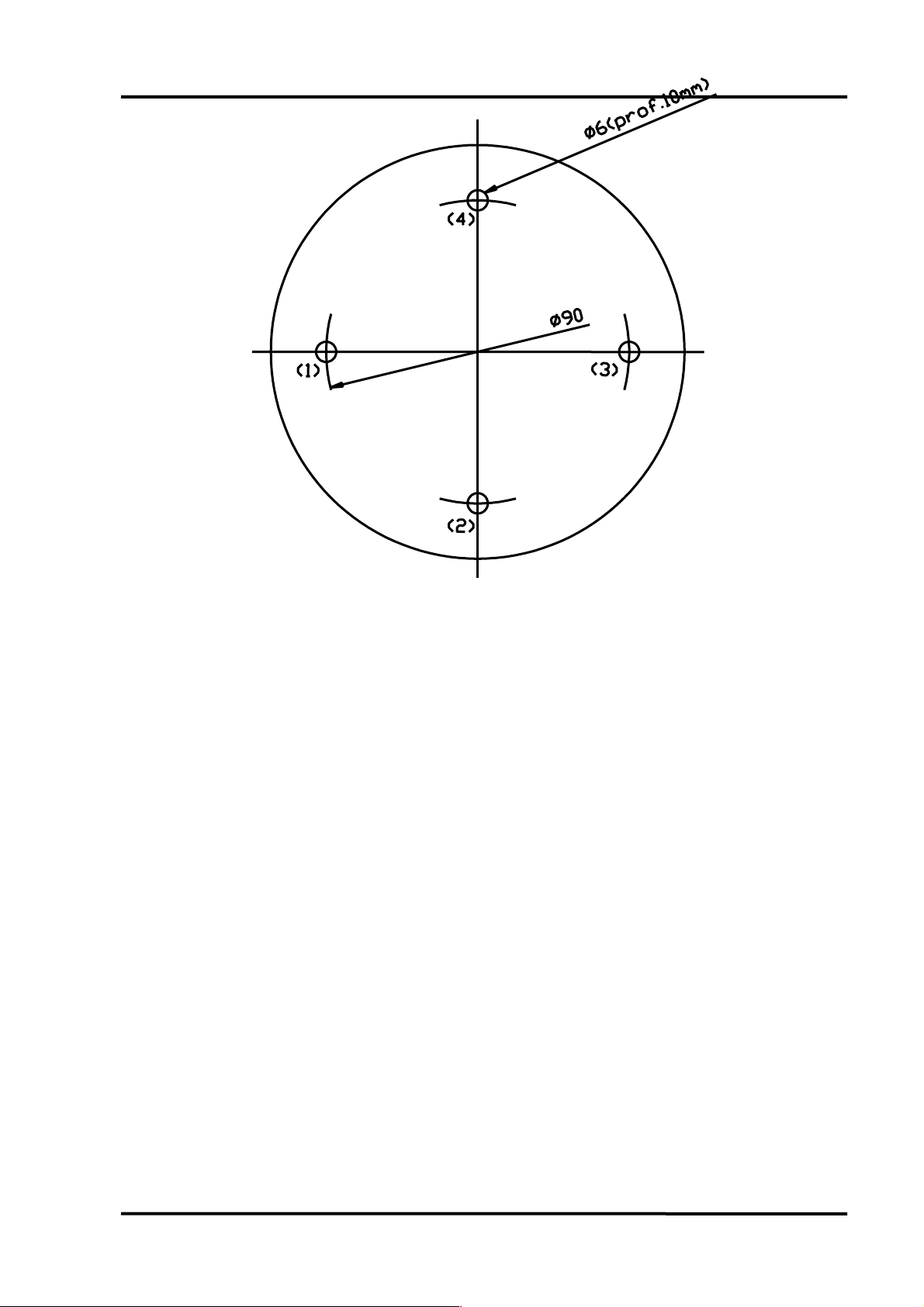

G87 Example program of a side radial drilling cycle with powered tool(Main Spindle).

3 HOLES SPACED 120º

O0021

G21;

G10 L2 P1 X0 Z100;

N8 G28 U0.

T808

(RADIAL 4MM DIA DRILL)

M5

M43

G28 H0

G97 S3500 M13

G0 G54 G80 G98 X122.Z-15.

G87 X96.Q3000 M90 F350.

C120.Q1000 M90

C240.Q1000 M90

G80

M15

M40

G0 X150.Z150.M9

M1

Page 66

PROGRAMMING MANUAL -66-

G87 Example program of a side radial drilling cycle with powered tool(Main Spindle using Y-axis).

O0221

G21;

G10 L2 P1 X0 Z100;

N8 G28 U0.

T808

(RADIAL 4MM DIA DRILL)

M5

M43

G28 H0

G97 S3500 M13

G0 G54 G80 G98 X122.Z-10.

G87 X96. Y-10. C0. Q3000 M90 F350.

Z-20. Y-10. Q1000 M90

Z-20. Y10. Q1000 M90

Z-10. Y10. Q1000 M90

G80

M15

M40

G0 X150.Z150.M9

M1

Page 67

PROGRAMMING MANUAL -67-

G87 Example program of a side radial drilling cycle with powered tool(Sub Spindle).

3 HOLES SPACED 120º

O0021

G21;

G10 L2 P1 X0 Z100;

N8 G28 U0.

T808

(RADIAL 4MM DIA DRILL)

M5

M143

G28 A0.

G97 S3500 M13

G0 G55 G80 G98 X122.Z15.

G87 X96.Q3000 M90 F350.

A120.Q1000 M90

A240.Q1000 M90

G80

M15

M140

G0 X150.Z150.M9

M1

Page 68

PROGRAMMING MANUAL -68-

G184 Example program of a front face tapping cycle with powered tool (Main spindle )

O0184 (FRONT TAP)

G28 U0 V0

T1010

M5

M43

G28 H0

G0 G54 G80 G98 X90 Z6

G184 C0 R2 W14 Q1 F800

G184 C90 R2 W14 Q1 F800

G184 C180 R2 W14 Q1 F800

G184 C270 R2 W14 Q1 F800

M15

M40

G0 Z100

G28 U0 V0

M30

Page 69

PROGRAMMING MANUAL -69-

G185 Example program of a back face tapping cycle with powered tool (Sub spindle)

O0185(SUB TAP)

G28 U0 V0

T0404

M5

M143

G28 A0

G30 B0

G0 G55 G80 G98 X90 Z-6

G185 A0 R2 W14 Q1 F800

G185 A90 R2 W14 Q1 F800

G185 A180 R2 W14 Q1 F800

G185 A270 R2 W14 Q1 F800

M15

M140

G0 Z-100

G28 U0 V0

M30

Page 70

PROGRAMMING MANUAL -70-

G188 Example program of side tapping cycle with powered tool (Main spindle)

O0188 (SIDE TAP)

G28 U0 V0

T1212

M5

M43

G28 H0

G0 G54 G80 G98 X90 Z-10

G188 C0 R2 U14 Q1 F800

G188 C90 R2 U14 Q1 F800

G188 C180 R2 U14 Q1 F800

G188 C270 R2 U14 Q1 F800

M15

M40

G0 Z100

G28 U0 V0

M30

Page 71

PROGRAMMING MANUAL -71-

G188 Example program of side tapping cycle with powered tool (Main spindle using Y Axis).

O0189 (SIDE TAP Y MAIN)

G28 U0 V0

T1212

M5

M43

G28 H0

G0 G54 G80 G98 X90 Y10 Z-5

G188 C0 R2 U14 Q1 F800

Y-10.

G188 C90 R2 U14 Q1 F800

Y10

G188C180R2U14Q1F800

Y-10

G188C270R2U14Q1F800

M15

M40

G0Z100

G28U0V0

M30

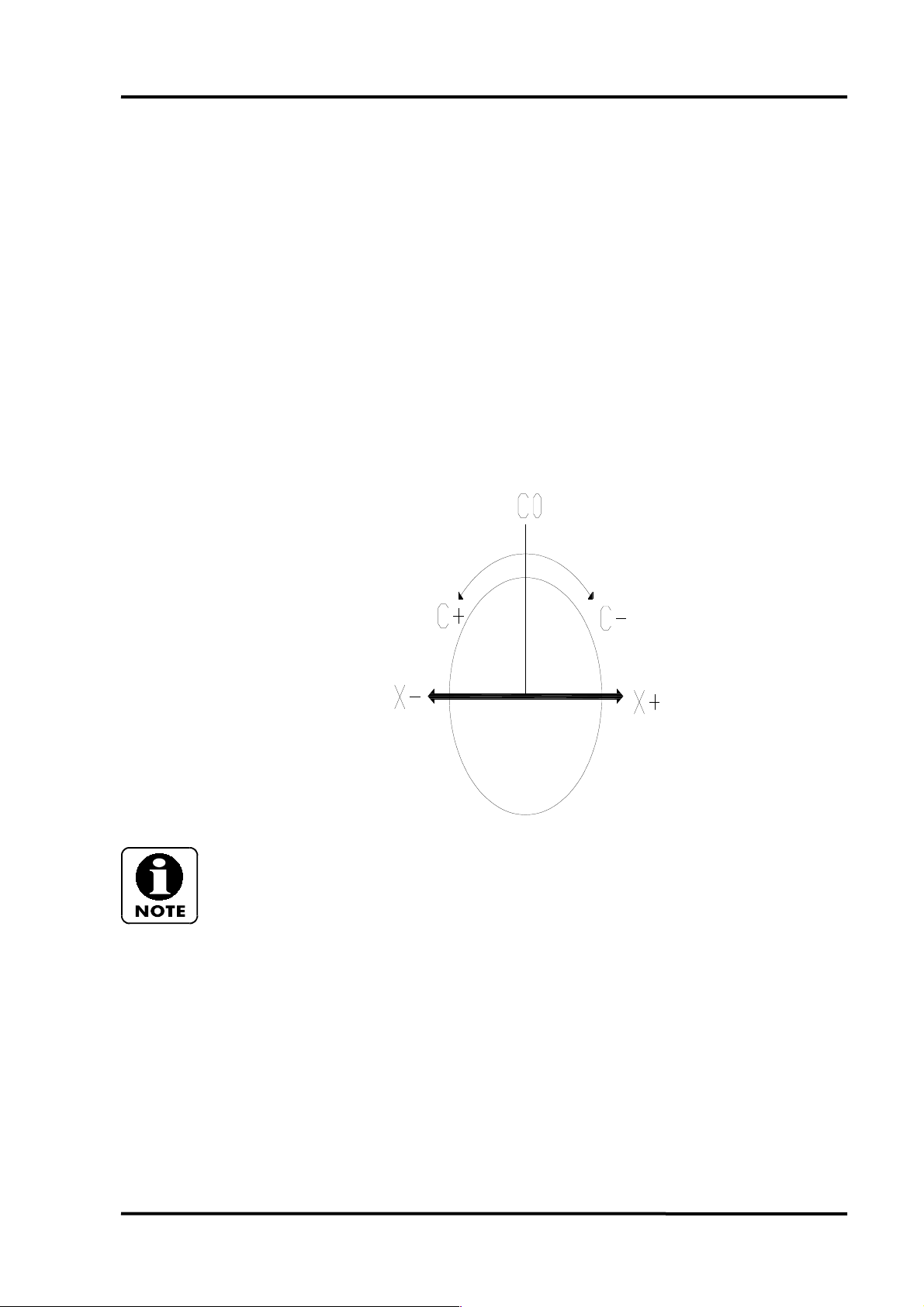

Polar coordinate interpolation

Page 72

PROGRAMMING MANUAL -72-

Polar coordinate interpolation is used when it is desired to perform milling operations on the face

of the work piece, which require synchronous movement of the spindle and live tooling mounted

on the turret.

When polar coordinate interpolation is commanded by the G112, the control interprets several

pieces of data to determine the direction and speed at which the axes must be moved to reach

the commanded end point.

The drawing below shows the coordinate system used with polar coordinate interpolation.

The programmed end points are laid out as coordinates on this plane.

Note the signs for X and C. The following program examples illustrate the use of this system.

1. The following G codes may be used when G112 is active: G1, G2, G3, G40,

G41, G42, G65, and G98.

2. G0 positioning is not allowed when G112 is active.

3. When using G2 or G3, the arc radius is specified using the R word.

4. M40 C axis mode must be active before commanding polar coordinate

interpolation.

5. The spindle should be oriented to C0 degrees before commanding polar

coordinate interpolation.

6. If machining in the X axis only, do not activate polar coordinate interpolation.

7. The unit of command for the C axis, when polar coordinate interpolation is

used, is MM or inches, not degrees.

8. When using cutter compensation during polar coordinate interpolation,

the same basic TNRC rules apply as with normal lathe programming. However,

the following rules must also be observed:The tool radius and the quadrant must be loaded into the geometry offset file.

For polar coordinate interpolation, the X tool offset represents the centre of the

cutter and the tool tip location (Quadrant) will be set to 9.

Page 73

PROGRAMMING MANUAL -73-

9. The TNRC start up block (G41 or G42 line) must be programmed after

the polar coordinate interpolation command (G112 line) has been activated. For

polar coordinate interpolation, the X axis move must be equal to at least two

times the tool radius entered in the tool offset file. Program the G40 (TNRC

cancel) command before the block containing the G113 (cancel polar coordinate

interpolation).

10. Program restart and block restart are not allowed when G112 is active.

11. Specify the feedrate as millimetres per minute.

12. X values are diameters and C values are radii

Page 74

PROGRAMMING MANUAL -74-

Tool nose radius compensation and circular interpolation used with

G112 polar coordinate interpolation

The drawings below show the combination of tool nose radius and circular interpolation codes

used with polar coordinate interpolation.

The shaded area in each drawing represents the finished part contour.

G41 Part right (cutter left) G42 Part left (cutter right)

G2 Clockwise arc G3 Counter-clockwise arc

Page 75

PROGRAMMING MANUAL -75-

G42 Part left (cutter right) G41 Part right (cutter left)

G2 Clockwise arc G3 Counter-clockwise arc

Example of machining a square

N6 G28 U0. V0.

T606

(AXIAL MILL)

M5

Page 76

PROGRAMMING MANUAL -76-

M43

M111

G28 H0

G97 S1500 M13

G0 G40 G98 G54 X80.Z2.

G1 Z-5. F2500.

G112

G42 X50.F500.

C20.

X-50.

C-20.

X50.

C0.

G1 G40 X80.F1500.

G113

G0 Z10.M9

M15

M110

M40

G0 X150 Z150 M9

M1

Example of machining a Hexagon

Use the following formula to calculate the following hexagon.

Data known: Across flats and angle

A= 50/2 = 28.867

Cos30

B= 30Tan*50/2 =14.433

N6 G28 U0. V0.

T606

(AXIAL MILL)

Page 77

M5

M43

M111

G28 H0

G97 S1500 M13

G0 G40 G98 G54 X80.Z2.

G1 Z-0.25 F2500.

G112

G42 X50.F500.

C14.433

X0. C28.867

X-50. C14.433

C-14.433

X0. C-28.867

X50. C-14.433

C0.

G40 X80.F1500.

G113

G0 Z10.M9

M15

M110

M40

G0 X150 Z150 M9

M30

PROGRAMMING MANUAL -77-

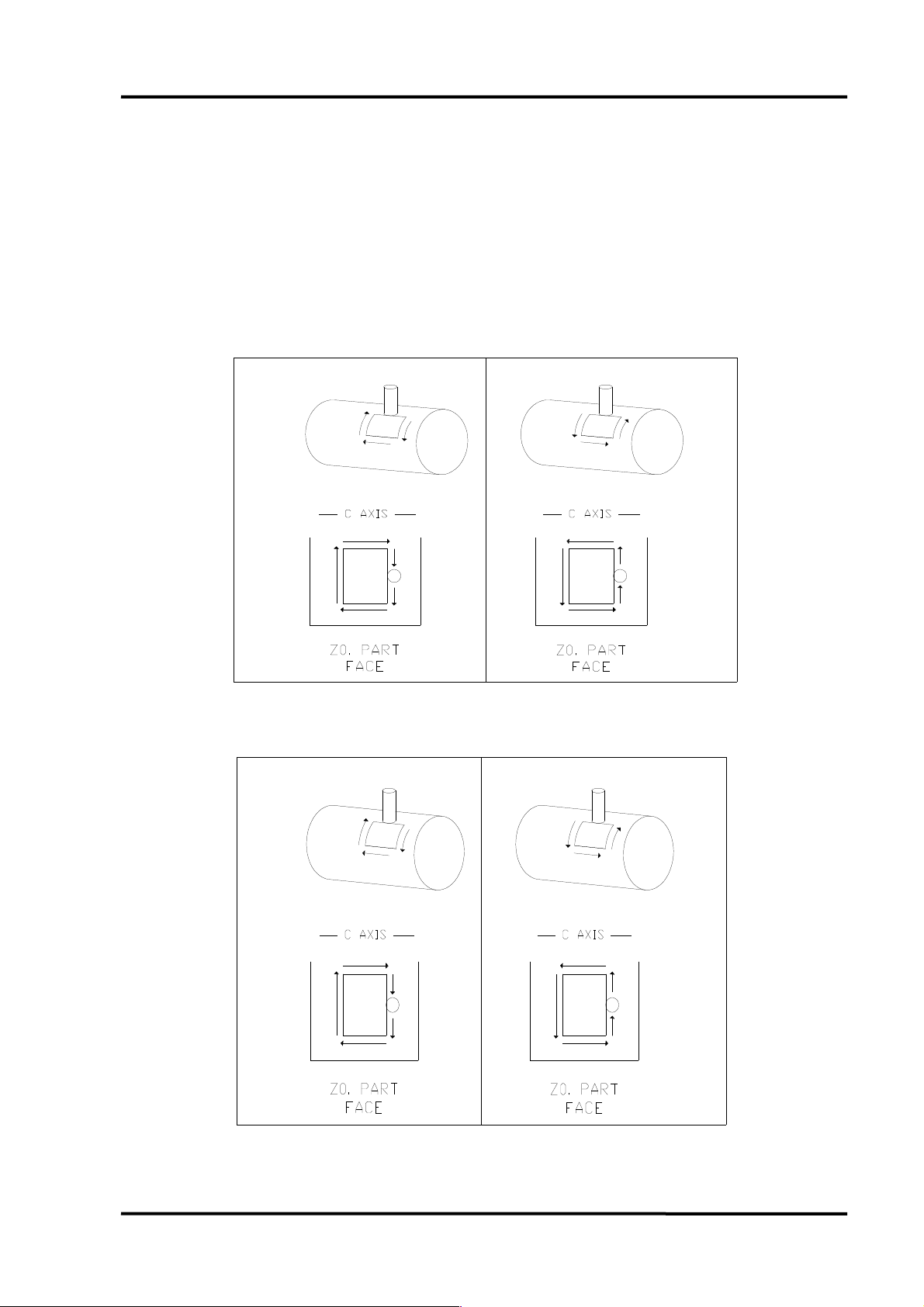

Milling using the Y-axis and C-axis.

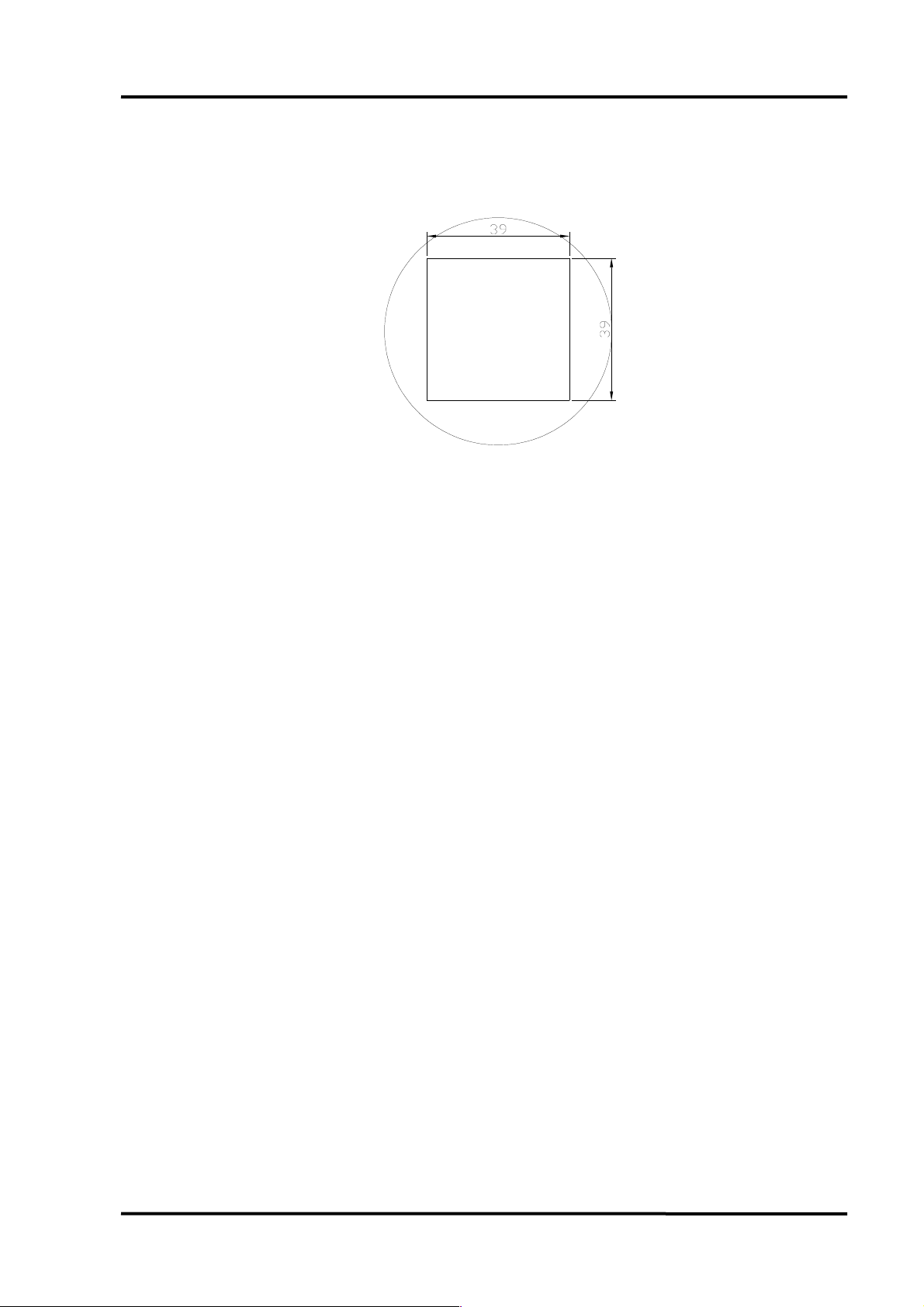

Mill square 39mm across flats 20mm deep (20mm end mill set on center line).

O2000

M5

M54

Page 78

PROGRAMMING MANUAL -78-

G28 U0. V0.

M40 (C-AXIS DE-SELECT)

M91 (C-AXIS LOW BREAK PRESSURE)

T0505 (MILL FLATS)

G98 (FEED PER MINUTE)

G55 (WORK OFFSET FOR SUB SPINDLE)

G00 Z150.

M5 (MAIN SPINDLE STOP)

M43 (SELECT C-AXIS)

G28 C0. (FIRST FLAT)

M90 (C-AXIS HIGH BREAK PRESSURE)

G97 S4000 M14 (START MILL SPINDE)

G00 X52. Y30. Z0. M8

G00 X40.

G01 G98 Y-30. F400

G00 Z-5.

G01 Y30.

G00 Z-10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 X52. Y30 .Z0. M8

G00 X39.

G01 G98 Y-30. F400

G00 Z-5.

G01 Y30.

G00 Z-10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 Y39. Z0.

M91

G00 C90. (SECOND FLAT)

M90

G00 X52. Y30. Z0. M8

G00 X40.

G01 G98 Y-30. F400

G00 Z-5.

G01 Y30.

G00 Z-10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 X52. Y30. Z0. M8

G00 X39.

G01 G98 Y-30. F400

G00 Z-5.

G01 Y30.

G00 Z-10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 Y39. Z0

M91

G00 C180. (THIRD FLAT)

M90

Page 79

G00 X52. Y30. Z0 M8

G00 X40.

G01 G98 Y-30. F400

G00 Z-5

G01 Y30.

G00 Z-10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 X52. Y30. Z0. M8

G00 X39.

G01 G98 Y-30. F400

G00 Z-5.

G01 Y30.

G00 Z-10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 Y39. Z0.

M91

G00 C270. (FOURTH FLAT)

M90

G00 X52. Y30. Z0. M8

G00 X40.

G01 G98 Y-30. F400

G00 Z-5.

G01 Y30.

G00 Z-10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 X52. Y30. Z0. M8

G00 X39.

G01 G98 Y-30. F400

G00 Z-5

G01 Y30.

G00 Z-10.

G01 Y-30.

G00 X52.

G00 Y0.

G28 U.0 V0.

M15

M9

M90

M40

M30

PROGRAMMING MANUAL -79-

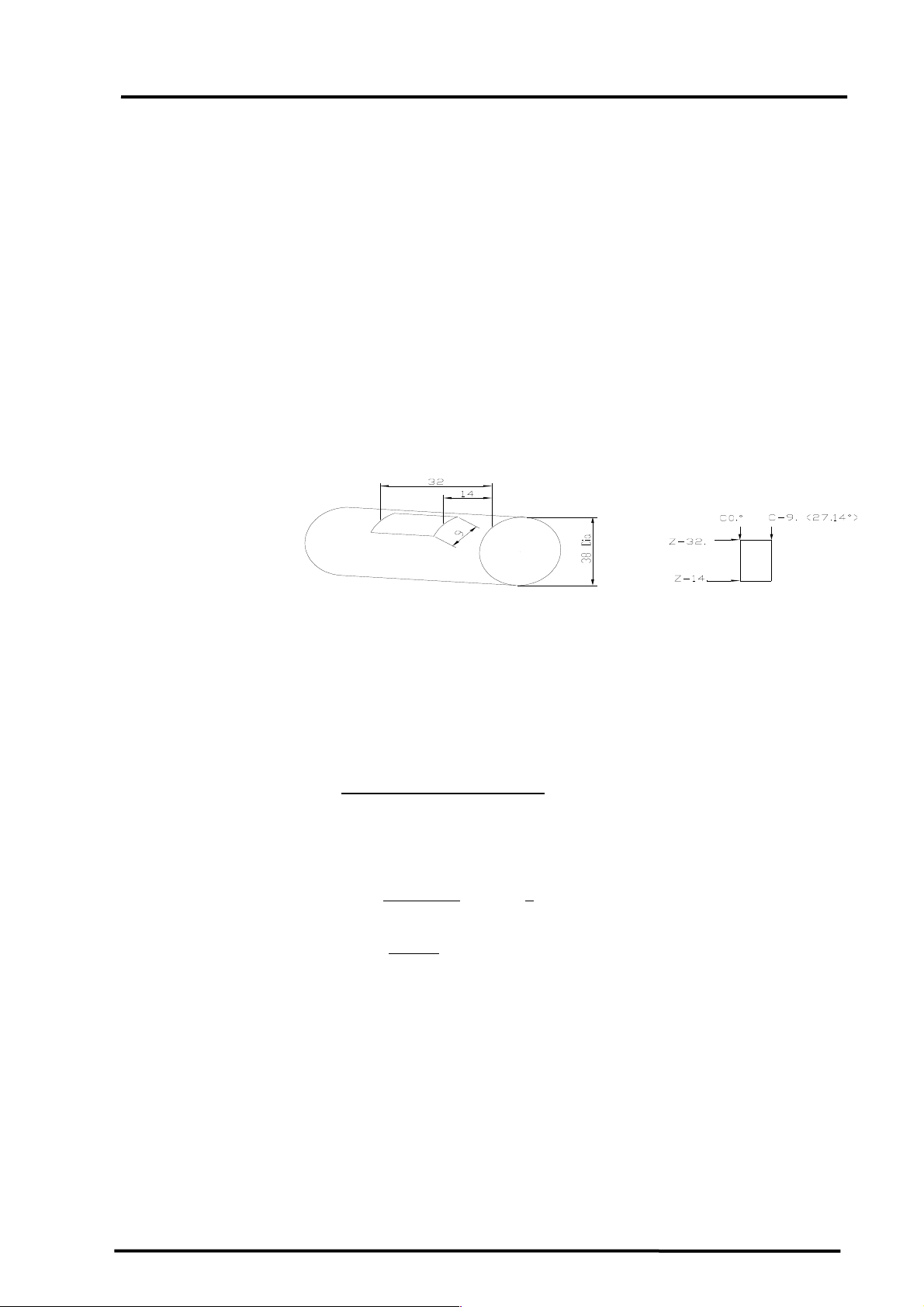

Milling using the Y-axis and A-axis.

Page 80

PROGRAMMING MANUAL -80-

Mill square 39mm across flats 20mm deep (20mm end mill set on center line).

O2000

M5

M55

G28 U0. V0.

M140 (A-AXIS DE-SELECT)

M91 (A-AXIS LOW BREAK PRESSURE)

T0505 (MILL FLATS)

G98 (FEED PER MINUTE)

G55 (WORK OFFSET FOR SUB SPINDLE)

G00 Z-150.

G30 B0. (SUB SPINDLE TO MACHINING POSSITION)

M115 (SUB SPINDLE STOP)

M143 (SELECT A-AXIS)

G28 A0. (FIRST FLAT)

M90 (A-AXIS HIGH BREAK PRESSURE)

G97 S4000 M14 (START MILL SPINDLE)

G00 X52. Y30. Z0. M8

G00 X40.

G01 G98 Y-30. F400

G00 Z5.

G01 Y30.

G00 Z10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 X52. Y30 .Z0. M8

G00 X39.

G01 G98 Y-30. F400

G00 Z5.

G01 Y30.

G00 Z10.

Page 81

G01 Y-30.

G00 X52.

G00 Y0.

G00 Y39. Z0.

M91

G00 A90. (SECOND FLAT)

M90

G00 X52. Y30. Z0. M8

G00 X40.

G01 G98 Y-30. F400

G00 Z5.

G01 Y30.

G00 Z10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 X52. Y30. Z0. M8

G00 X39.

G01 G98 Y-30. F400

G00 Z5.

G01 Y30.

G00 Z10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 Y39. Z0

M91

G00 A180. (THIRD FLAT)

M90

G00 X52. Y30. Z0 M8

G00 X40.

G01 G98 Y-30. F400

G00 Z5

G01 Y30.

G00 Z10.

G01 Y-30.

G00 X52.

G00 Y0.

G00 X52. Y30. Z0. M8

G00 X39.

G01 G98 Y-30. F400

G00 Z5.

G01 Y30.

G00 Z10.