Dufour Yachts 360 Grand Large Owner's Manual

OWNER'S MANUAL

YACHT DESIGN CATEGORY: A

ENGLISH 29/01/2018 1/86 DUFOUR 360 Grand Large

IN ACCORDANCE WITH EUROPEAN DIRECTIVE 2013/53/UE

This page intentionally left blank.

This page intentionally left blank.

This page intentionally left blank.

ENGLISH 29/01/2018 2/86 DUFOUR 360 Grand Large

Your agent:

Name

Manual

I, the undersigned:

Name

Address

owner of DUFOUR 360 no.

confirm that I have received the DUFOUR 360 Owner's Manual and accept its being written in the

Dated:

Signature:

Detach along dotted line

…………………………………………………………………………………………………………………

11, Rue Blaise Pascal- 17187 PERIGNY CEDEX- FRANCE

I, the undersigned:

Name

Address

owner of DUFOUR 360 no.

confirm that I have received the DUFOUR 360 Owner's Manual and accept its being written in the

Dated:

Signature:

is the DUFOUR YACHTS’ representative and will give you all the help you need to solve any

difficulties you might have during the launching and masting of your boat, as well as for

commissioning and maintenance technical checks. If necessary, he will help you with the

administrative process of registering your boat.

As soon as you become the owner, familiarize yourself with the manual supplied with your boat,

sign and date the receipt acknowledgements below, and give (or send) the last one to your agent.

Acknowledgement of receipt of the Owner's Manual. Owner's copy to be kept in your

English language.

Owner's Manual receipt acknowledgment to be returned to DUFOUR YACHTS

English language.

ENGLISH 29/01/2018 3/86 DUFOUR 360 Grand Large

This page intentionally left blank.

This page intentionally left blank.

This page intentionally left blank.

ENGLISH 29/01/2018 4/86 DUFOUR 360 Grand Large

CONTENTS

Seacocks

Operation of the sea toilets

Holding tank operation (ISO 8099:2000)

INTRODUCTION

I.

GENERAL INFORMATION

YACHT DESIGN CATEGORY: ________________________________________________________________ 9

Certification _____________________________________________________________________________ 9

Identification _____________________________________________________________________________ 9

Builder's plate __________________________________________________________________________ 10

Degrees of danger _______________________________________________________________________ 10

II. PRINCIPAL SPECIFICATIONS

III. ELECTRICAL SYSTEMS

Safety and operating instructions for the electrical system _________________________________ 13

Fitting new equipment ___________________________________________________________________ 13

Batteries _______________________________________________________________________________ 14

Electric windlass_ _______________________________________________________________________ 14

Ins 220/110 volt installation (ISO 13297:2000) ___________________________________________ 15

......................................................................................................................................................... 8

............................................................................................................................. 9

................................................................................................................... 11

.................................................................................................................................... 13

IV. GAS INSTALLATION

General information _____________________________________________________________________ 16

V. DRAIN & SANITATION SYSTEM

Drainage system characteristics (ISO 15083:2003) _________________________________________ 18

Pressurized fresh-water pump ___________________________________________________________ 18

_______________________________________________________________________________ 19

VI. FLOODING

........................................................................................................................................................... 20

VII. FIRE PROTECTION

Installation _____________________________________________________________________________ 20

Safety instructions ______________________________________________________________________ 21

VIII. ENGINE

General precautions _______________________________________________________________________ 22

............................................................................................................................................................. 22

......................................................................................................................................... 16

...................................................................................................................... 18

_______________________________________________________________ 19

____________________________________________________ 19

.......................................................................................................................................... 20

Exhaust gas emission ____________________________________________________________________ 22

Safety 22

Wintering _______________________________________________________________________________ 23

IX. FUEL INSTALLATION

X. HELM SYSTEM

Tiller 23

Emergency tiller ________________________________________________________________________ 24

ENGLISH 29/01/2018 5/86 DUFOUR 360 Grand Large

.................................................................................................................................................... 23

....................................................................................................................................... 23

XI. SAILING

............................................................................................................................................................... 24

XII. FALL PREVENTION AND MEANS OF GETTING BACK ABOARD

............................................................ 25

XIII. LIGHTNING PROTECTION

Maintenance ____________________________________________________________________________ 25

Protection of people during a thunderstorm _______________________________________________ 26

XIV. ENVIRONMENTAL PROTECTION & SAFETY

XV. SAFETY FACILITIES

XVI. HANDLING, TRANSPORTING, HAULOUT

XVII. MOORING, ANCHORING, AND TOWING

Responsibility ___________________________________________________________________________ 28

XVIII. GUARANTEE, TRANSFER OF OWNERSHIP

1. Presentation plan

2. Accommodation layout

............................................................................................................................. 25

............................................................................................. 26

......................................................................................................................................... 27

.................................................................................................. 27

.................................................................................................... 28

............................................................................................ 29

........................................................................................................................................ 34

............................................................................................................................... 35

3. Deck fittings plan

4. Sail plan

......................................................................................................................................................... 39

......................................................................................................................................... 37

5. Halyard and sheet operating diagram

6. 220V circuit diagram

................................................................................................................................... 47

7. Charging and power system diagram

8. 12V electric panel

9. 12 V terminal diagram

10. 12V electrical installation diagram

11- 220V electrical installation diagram

12- Fuse location diagram

13 - Steering system diagram

14

-

Gas system diagram

........................................................................................................................................ 51

................................................................................................................................ 53

......................................................................................................... 55

.......................................................................................................... 58

................................................................................................................................ 61

........................................................................................................................ 63

................................................................................................................................. 65

.................................................................................................... 41

..................................................................................................... 49

15- Abandon ship plan

16- Fresh-water system diagram

17 - Drain system diagram

18 - Skin fitting location diagram

19 Mechanical installation diagram

20 Gas system diagram

ENGLISH 29/01/2018 6/86 DUFOUR 360 Grand Large

....................................................................................................................................... 67

................................................................................................................... 69

............................................................................................................................. 71

................................................................................................................. 73

............................................................................................................. 76

................................................................................................................................... 78

21 Holding tank installation diagram

........................................................................................................... 80

22 Lifting diagram

............................................................................................................................................. 82

ENGLISH 29/01/2018 7/86 DUFOUR 360 Grand Large

INTRODUCTION

DUFOUR YACHTS is pleased to present you with this Manual which will help you get to know your boat

better.

This Manual has been produced to help you use your boat safely and enjoyably. It contains details of the

boat, the equipment supplied or fitted, its systems and information about their use. Read it car efully and

familiarize yourself with the boat before using it.

This Owner’s Manual is not a course in sailing safety or seamanship. If this is your first boat or you are

changing to a type of boat you are unfamiliar with, for your convenience and safety, make sure you gain

experience in handling and using it before taking command. Your agent, national sailing or cruising

federation or yacht club will be happy to give you information about sailing schools or qualified instr uctors

in your area.

Ensure that forecast wind and sea conditions correspond to the design category of your boat, and that you

and your crew are capable of handling the boat in these conditions. Even when your boat is suitable f or

them, the sea and wind conditions corresponding to design categories A, B, and C vary from severe storm

for category A to severe conditions for the top end of category C, subject to dangers of abnormal gusts or

waves; these are dangerous conditions in which only an experienced, trained crew in good shape, sailing a

properly-maintained boat, can sail in a satisfactory manner.

This Owner's Manual is not a detailed maintenance or repair guide. In the event of problems, consult the

boatbuilder or their representative. If a maintenance manual is provided, be sure to use it.

Always employ the services of an experienced professional for maintenance, fitting accessories, or

modifications. Modifications that could affect the characteristics of the boat must be assessed, performed

and documented by qualified personnel. The boatbuilder cannot be held responsible for modifications

made without their approval.

In certain countries, a skipper's license or some form of authorization is required, or special rules and

regulations are applicable.

Always maintain your boat correctly and make allowances for deterioration due to age or resulting, where

applicable, from heavy or unsuitable use. Any boat, however sturdy, can be severely damaged if it is used

incorrectly. This is incompatible with safe sailing. Always adapt the speed of your boat to the surrounding

conditions.

If your boat is equipped with a life-raft, read its instruction manual carefully. The crew must have all the

safety equipment on board (life-jackets, harnesses, etc.), corresponding to the type of boat, weather

conditions, etc. I n some countries, this equipment is mandatory. The crew must be familiar with the use of

all the safety equipment and the emergency safety procedures (man overboard recovery, towing, etc.);

training sessions are regularly organized by sailing schools and clubs.

It is recommended that all persons wear appropriate buoyancy aids (life-jackets, personal flotation devices)

when on deck. It should be noted that in certain countries, it is compulsory to wear a buoyancy aid

(complying with national regulations) at all times.

KEEP THIS MANUAL IN A SAFE PLACE AND PASS IT ON TO THE NEW OWNER IF YOU

SELL THE BOAT.

WARNING: Our boats are regularly improved in light of our customers’ experiences and

research carried out by the shipyard. As a result, the specifications given in this Owner’s

Manual are not contractually binding and may be changed without notice and wi thout any

obligation to update them. This manual is intended to cover as much information a s

possible, so certain equipment or paragraphs might not apply to your boat. In case of

doubt, please refer to the inventory which should have been given to you by your agent

when you placed your order.

ENGLISH 29/01/2018 8/86 DUFOUR 360 Grand Large

I. GENERAL INFORMATION

Effective wave

into account

Up to and including

4 m

Up to and including

2 m

Up to and including

0.5 m

YACHT DESIGN CATEGORY:

Your DUFOUR 360 comes under the OCEAN-GOING design category A.

Under conditions of normal use, your boat is designed to sail in waves with a significant height

exceeding 4 m and winds of force 8 or above on the Beaufort scale, and to withstand the severest

conditions.

This sailing capability is equally dependent on the skills of the crew, their physical capacities, the

maintenance of the boat and its equipment.

So always take care before putting to sea.

DUFOUR YACHTS is not able to guarantee perfect functioning of the boat in exceptional sea

conditions (violent storms, hurricanes, cyclones, waterspouts, etc.)

SUMMARY OF DESIGN CATEGORIES

Design

categories

Wind strength

(Beaufort)

Wind

speed

height to be taken

A Higher than 8 Up to 28 m/s Higher than 4 m

B Up to 8 Up to 21 m/s

C Up to 6 Up to 17 m/s

D Up to 4 Up to 13 m/s

Check weather information before putting to sea: Take to the sea, don’t take risks!

In port: every day, the Harbor Master's Office posts weather bulletins and forecasts for the

next few days .

Météo France on 08 36 68 08 08

Navifax - direct line: +33 (0)8.36.70.18.52.

VHF: CROSS transmits several bulletins per day, preceded by an announcement on

Channel 16.

Certification

DUFOUR YACHTS has chosen the Institut pour la Certification et la Normalisation dans le Nautisme

as the notified body for verifying that your boat complies with European directive CE 2013/53, in

accordance with module B.

Identification

The hull identification number is located on the starboard side of the transom. It contains a series

of letters and numbers that begin with FR-DUF...

ENGLISH 29/01/2018 9/86 DUFOUR 360 Grand Large

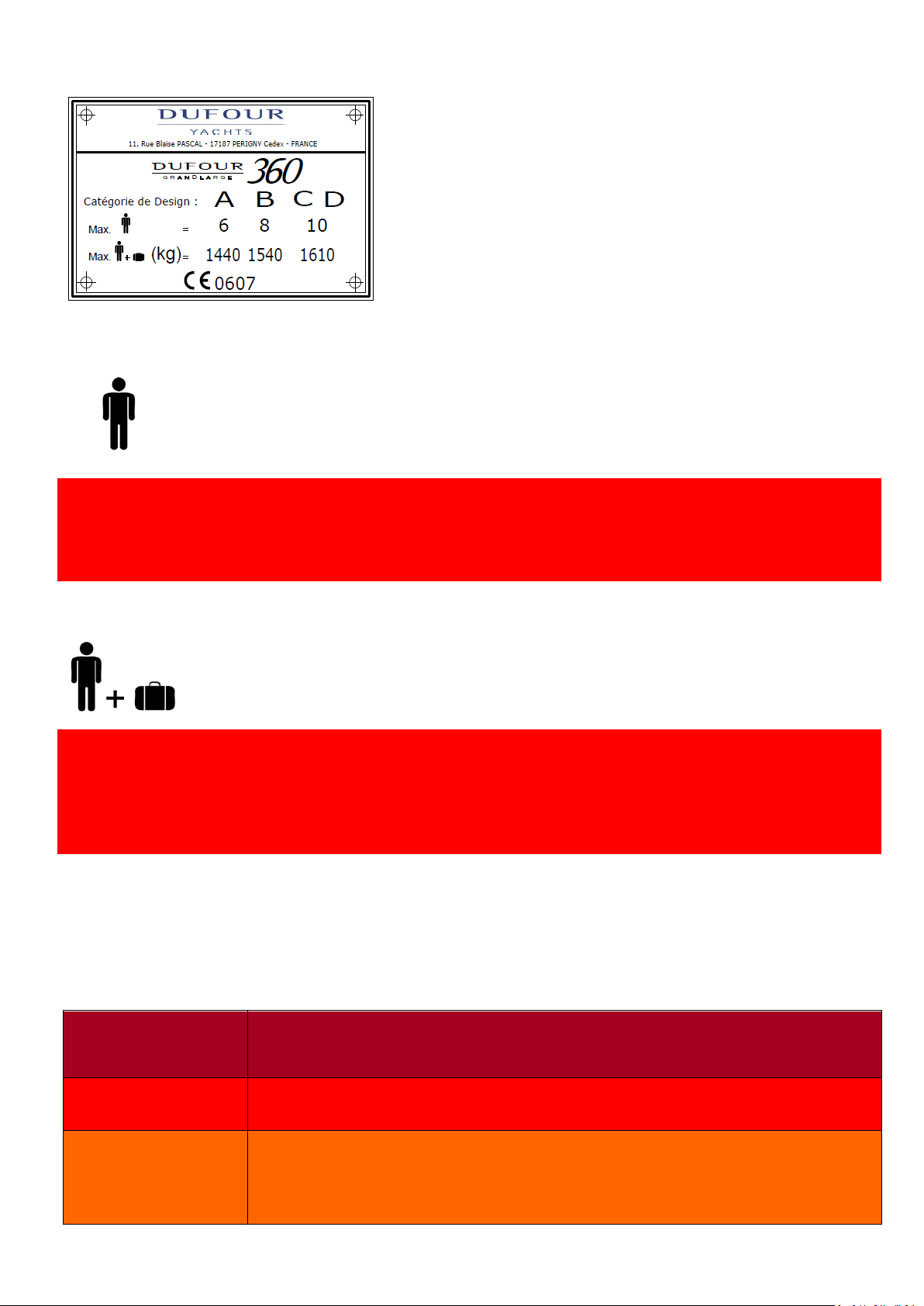

Builder's plate

Category A = 6

Category D = 10

: recommended by the builder for navigation in sea

: CE mark indicating that the boat complies with all the

: recommended by the manufacturer including the

weight of all passengers aboard, provisions and

included in the boat’s light displacement, but

excluding the contents of the tanks.

Some of this information is provided on the builder’s

plate attached to the boat. A full expl anati o n o f this

information is given below.

Design category = A : (See 1.1)

Maximum number of people:

Category B = 8

Category C = 10

WARNING

Do not exceed the maximum recommended number of people. However many people there are

aboard, the total weight of the people and equipment must never exceed the maximum

recommended load.

Recommended max. load:

Category A = 1,440 kg

Category B = 1,540 kg

Category C = 1,610 kg

Category D = 1,610 k g

WARNING

When loading the boat, never exceed the recommended maximum load. Always load the boat

carefully and distribute the weight in a suitable manner in order to maintain the theoretical trim

(approximately horizontal). Avoid placing heavy loads high up.

conditions corresponding to the category for which it

was built.

personal belongings, in addition to all equipment not

CE 0607

requirements of the Directive. The sequence of digits is

the code for the Certifying Body. In this case, it is ICNN

(Institut pour la Certification de la Normalisation dans le

Nautisme), (see also: Sa fety Compliance Declaration).

Degrees of danger

DANGER

WARNING

NOTE

ENGLISH 29/01/2018 10/86 DUFOUR 360 Grand Large

Indicates an extreme intrinsic risk that presents a high probability of

death or permanent injury if proper precautions are not taken.

Indicates a risk that presents a high probability of death or permanent

injury if proper precautions are not taken.

Indicates a reminder about safety-relate d pr actices, or points out

dangerous practices that could result in personal injury or damage to

the boat or its components, or to the environment.

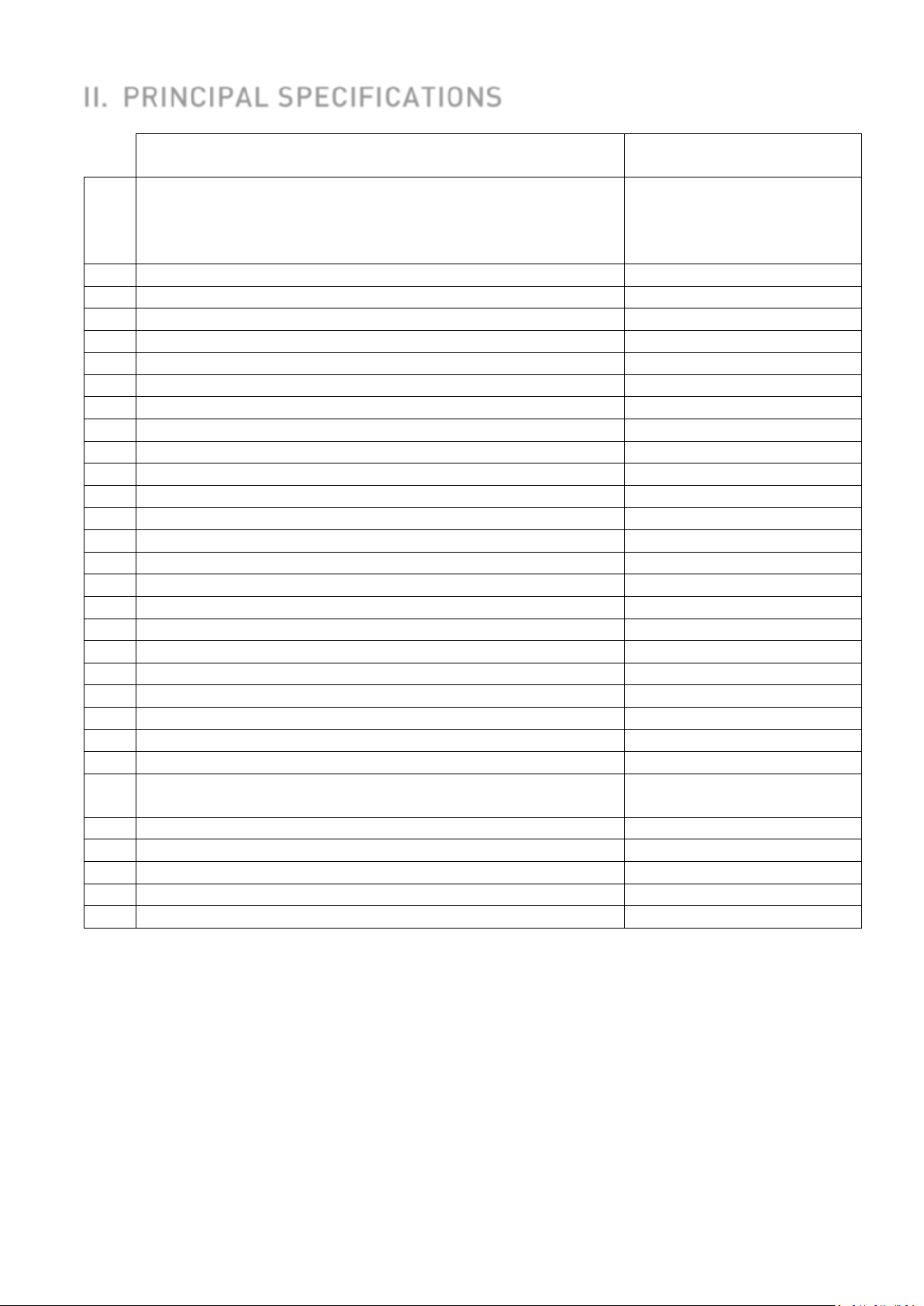

Model:

DUFOUR 360

Grand Large

Boatbuilder

Dufour Yachts

FRANCE

Architecture:

Umberto Felci

Interior design

DUFOUR Design

YACHT DESIGN CATEGORY:

A

Notified body no.

CE/0607

Engine #

FR-DUFGXXX8XXXX

Primary means of propulsion

Sail

L

max

LOA (with overhang stemhead)

10.30 m (10.73 m)

LH

Hull length*

9.98 m

B

max

Maximum beam*

3.54 m

BH

Hull beam*

3.54 m

HA

Maximum air draft*

15.00 m

T

max

Draught (deep keel)*

1.90 m

Deep keel weight

1,550 kg

Draft (shallow keel)*

1.55 m

Shallow keel ballast weight

1,650 kg

Standard mainsail area (approximate)

34 m²

Jib area (approximate)

18 m²

Genoa area (approximate)

25 m²

Maximum permissible on-board engine power

30 HP / 20.9 kW

Water capacity excl. 20L (approx.) water heater

200 L (+180 L as option)

Diesel capacity (approximate)

200 L

Holding tank

50 L

Engine battery

75 Ah

Auxiliary battery (1 standard + 1 optional)

75 Ah + (+75 Ah as an

optional extra)

MLC

Light displacement (deep keel)

5,775 kg

MMO

Minimum condition displacement (deep keel)

6,008 kg

ML

Maximum loading

1,780 kg

Total weight of liquids (all tanks full)

333 kg

M

LDC

Displacement with maximum load

7,531 kg

II. PRINCIPAL SPECIFICATIONS

11, Rue Blaise Pascal

17187 Périgny cedex

*The above dimensions comply with ISO 8866, specifically:

L

: maximum length of the vessel including normally fixed parts such as bow rollers,

max

balconies, etc.

LH: maximum length of the vessel including structural elements that are an integral part of the

vessel, and excluding removable parts.

B

: breadth of the vessel measured between the outermost portions and may include

max

detachable parts such as top rails, railings, etc.

B

: vessel width measured between the outermost fixed portions and excluding all removable

H

parts

H

vertical distance between the water plane under light displacement and the highest point of

A:

the mast structure. (this does not take into account equipment such as lights and antennas that

can be attached to the masthead)

ENGLISH 29/01/2018 11/86 DUFOUR 360 Grand Large

T

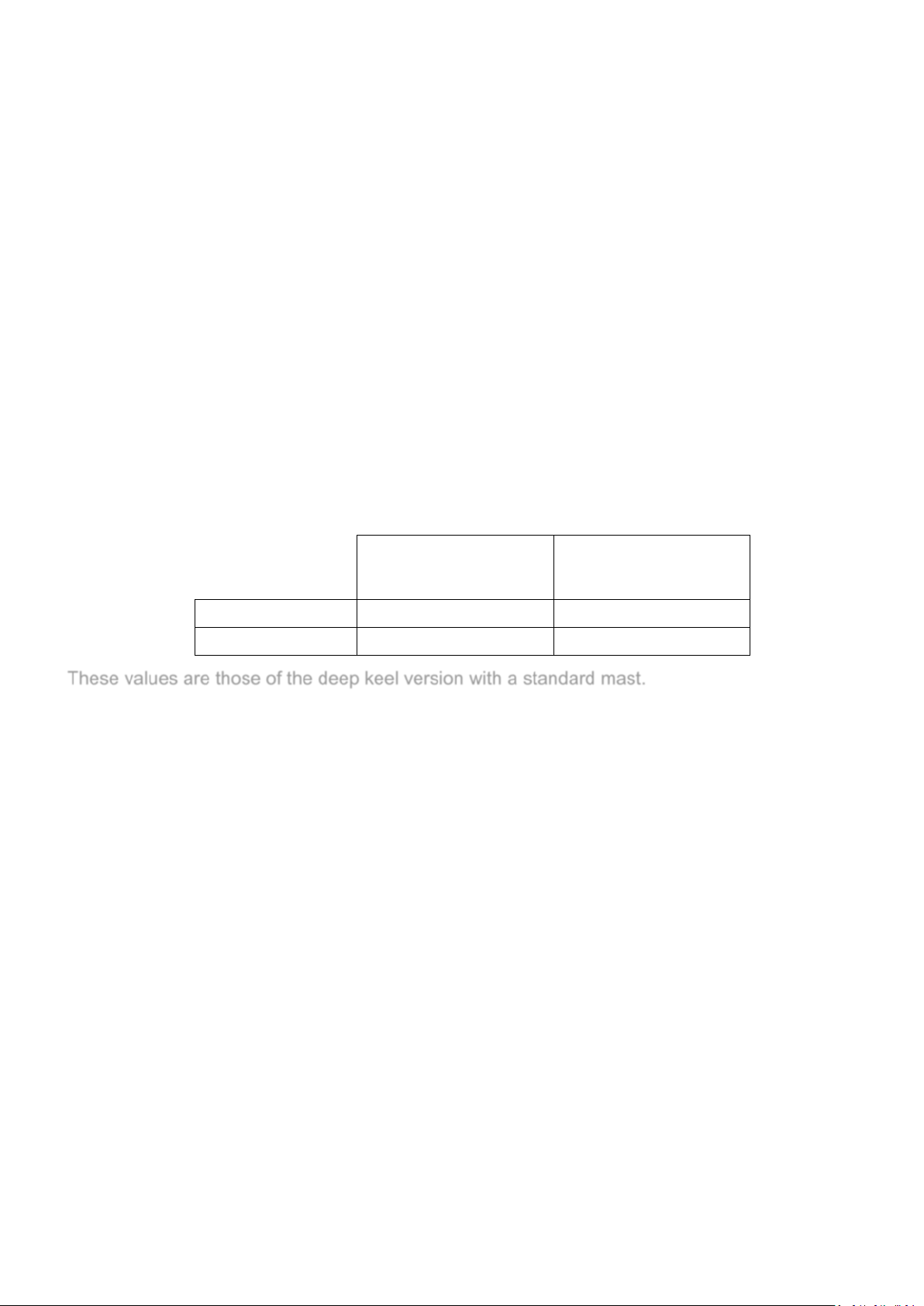

Loaded arrival

(Mla)

STIX (deep keel)

34.96

32.30

AVS(deep keel)

127.2°

122.4 °

: the maximum draft is measured at the lowest points of ballast on board the vessel

max

M

: The Maximum Load is the sum of the maximum recommended load plus the total mass of the

L

various liquids (drinkable or not)

Nota bene: due to the trim and loading of the boat, is it not usually possible to use the whole

of the various tank capacities for fresh water and diesel. It is recommended that you

maintain a diesel reserve of 20%.

Specific information

This vessel has been assessed with the help of the Stability Index (STIX), a measure of overall

safety with regard to stability, which takes into account the effects of the length of the vessel, its

displacement, hull proportions, stability characteristics and its resist anc e to fl oodi ng .

The maximum total load is the sum of the maximum recommended load and the total mass of the

various liquids (see ISO 12217-2: 2015)

The second index (AVS, angle of vanishing stability) represents the heel angle at which stability is

lost, in degrees.

Minimum operating

condition (MMO)

condition

These values are those of the deep keel version with a standard mast.

ENGLISH 29/01/2018 12/86 DUFOUR 360 Grand Large

III. ELECTRICAL SYSTEMS

Make any modification to an installation and the relevant diagrams, unless it is carried out by an

Safety and operating instructions for the electrical system

WARNING

Improper use of the DC and/or AC systems may give rise to fire or explosion hazards.

Improper use of the DC and/or AC systems may give rise to fire or explosion hazards.

Always:

● Check the condition of the batteries (charge and electrolyte level) and the charging system

before putting to sea.

● Disconnect and remove batteries for wintering.

● Do not let battery voltage drop below 10.5 V during wintering.

● Carry spare bulbs for all navigation lights and interior lighting. Respect power ratings,

particularly for navigation lights.

● Check operation of the navigational instruments.

● Check operation of the navigation lights before sailing at night.

You must never:

● Work on a live electrical installation.

●

electrician qualified in marine electrical work.

● Change or modify the breaking capacity of overload protection devices.

● Replace electrical apparatus or equipment with units exceeding the rated capacity without

uprating wiring and protection.

● Leave the boat unattended when the electrical installation is powered, with the exception of the

automatic bilge pump and the fire or theft protection circuits when applicable.

If a fuse or circuit-breaker blows repeatedly, you should consult a specialist to determine the cause

of the short-circuit.

Fitting new equipment

Since January 1st 1996, electrical equipment is subject to the European “electromagnetic

compatibility” directive (Ref 89/336/CEE). It is therefore necessary that any new equipment you

may wish to install meets the requirements of this standard and bears the CE mark. Equipment

must also be supplied with a compliance certificate and instructions for use.

In the case of 220 or 110V installations, use only double-insulated or earthed equipment. When

such equipment is being installed, respect the fitting instructions (conductor size, protection).

To avoid maintenance problems, make sure that any modifications made to the electrical circuit are

recorded in writing in the manual.

ENGLISH 29/01/2018 13/86 DUFOUR 360 Grand Large

Batteries

The battery system comprises one standard 75 Ah auxiliary batteries (plus 1 optional 75 Ah

battery) and one 75 Ah Ah battery for starting the engine.

Their capacities have been designed to handle the power requirements of the on-board

accessories. To avoid any problems, it is necessary to keep a close eye on the maintenance and

correct charging of the batteries.

ATTENTION!

● When installing new electrical appliances, take care that the total consumption of these

appliances remains within the capacity of your batteries.

● Always disconnect the negative (-) battery terminal before the positive (+) terminal.

● Never allow a conductive object (tools, etc.) to bridge across the two battery terminals.

● When handling batteries, keep them horizontal to avoid spillage of electrolyte. Wear gloves and

protective clothing that will prevent any risk of contact with electrolyte in the event of a leak.

● If any electrolyte comes in contact with skin, eyes, etc., rinse the affected part of the body

thoroughly and consult a doctor.

Electric windlass

ATTENTION!

It is essential to run the engine with the throttle slightly open when using the electric windlass.

ENGLISH 29/01/2018 14/86 DUFOUR 360 Grand Large

220/110 volt installation (ISO 13297:2000)

DANGER!

The on-board 220V installation is protected by a circuit breaker and fitted with a residual current

device. The wiring of additional 220V on-board accessories must be carried out by professionals,

and the master circuit-breaker uprat ed i f nec ess ary.

- Do not modify the vessel’s electrical installation nor the relevant diagrams. Installation, modification

and maintenance should be carried out by a qualified marine electrician. Have the system checked

every 2 years

- Disconnect the boat’s power supply when system is not in use.

- Connect the metal cases or housings of installed electrical equipment to the ship's protective

conductor (green or green / yellow wire).

- Use double-insulated or earthed electrical appliances.

- If possible, the differential circuit-breaker should be tested monthly.

ATTENTION!

When the boat is moored at the quayside, set the isolator to the 'off' position.

DANGER!

Your boat is not supplied with a shore/boat supply cable or a male plug for the shore outlet. The

cable must be suitable for outdoor use. Its cross-sectional area must be adjust ed ac cor di ng to its

length and the rating of the main circuit-breaker (see electrical diagram). The plug must be

suitable for the socket on the shore (if necessary, seek professional advice). It should be as

close as possible to the IP 67/IEC 52 9 type

WARNING: To reduce the risk of electric shock and fire.

● Switch off the shore supply at the on-board isolator before connecting or disconnecting the

shore/boat supply cable.

● Connect the shore/boat supply cable at the boat end before connecting it to the shore outlet.

● Disconnect the shore/boat supply cable at the shore outlet before disconnecting it at the boat

end.

● Close the shore outlet cover properly

You must never:

● Make any modifications to the shore supply cable: use only compatible connectors.

● Go swimming close to a boat connected to a shore supply socket: danger of electrocution!

Location of the 220 V master circuit-breaker: port aft cabin

Have the system checked every 2 years.

During haul-out maintenance, set to the ‘on’ position in order to have earth [grounding]

protection via the shore socket.

WARNING

Never let the end of a ship/shore supply cable dangle into the water. It may create an electrical

field that could injure or kill nearby swimmers.

ENGLISH 29/01/2018 15/86 DUFOUR 360 Grand Large

WARNING

IV. GAS INSTALLATION

General information

- Operating pressure: 30 mbar (see indications on the label in the gas locker and on the regulator

valve).

- Ventilation openings to be used for the evacuation of exhaust gases: hatch above the cooker and

the companionway

- Do not obstruct quick access to the elements of the gas installation (cylinder locker, shut-off valve).

- Regularly inspect the hoses (at least once a year) and change them if you observe any

deterioration, if the expiry date has been exceeded or within five years of the date printed on the

hose.

- The cylinder shut-off valves should be closed and disconnected. Protection hatches, covers and

caps should be kept in place. Reserve cylinders should be stored in the LPG cylinder housing or

lockers with a ventilation circuit leading towards the exterior, or stored at the exterior of the vessel,

protected from weathe r and mechanical damage and allowing any gas leakage to evacuate

towards the exterior .

- LPG cylinder lockers must not be used for the storage of any other material.

- Ensure that the gas cylinder and regulator are in accordance with the requirements of the cooker

(flo w rate, pressure, type of gas) and with the regulations in force in the country where it is being

used.

Operation of the LPG system

- Supply system shut-off valves and cylinder valves should be kept closed when the appliances are

not in use, before filling and immediately in case of emergency.

- Appliance shut-off valves must be closed before opening cylinder valves.

● Fuel-burning naked-flame appliances use up the oxygen in the cabin and release combustion

products inside the vessel. Proper ventilation is necessary: Open both the deck hatch or porthole

located nearby and the companionway when the appliances are in operation.

- The cooker is mounted on gimbals and can therefore be used when the vessel is under way.

Nevertheless, limit use when wide angles of roll or heel are likely.

Checking the system

- The LPG system should be checked for leakage before each use in the f oll owing way:

- Close the shut-off valve of the appliance, open the valve of the LPG cylinder, allow the pressure

indicated on the pressure gauge to stabilize, close the valve of the LPG cylinder, observe the

pressure indicated by the pressure gauge located near the cylinder for three minutes. The pressure

indicated by the pressure gauge should remain constant if there is no leakage in the system.

- Information: the pressure gauge does not indicate the quantity of liquid LPG remaining in the

cylinder, but only its vapor pressure, which is a constant at a given temperature.

- If an LPG leak of detected or suspected, take the following steps immediately:

- Cut off the supply at the main supply valve(s).

- Extinguish any naked flames and other sources of combustion (heating appliances, cooking

appliances, lights, etc .)

- Do not operate any electrical switch.

- Evacuate the area if possible

ENGLISH 29/01/2018 16/86 DUFOUR 360 Grand Large

WARNING

● Do

not use any installation with a leak before it has been inspected and repaired by a competent

WARNING

person.

DANGER!

Never use a flame to look for leaks.

- Note: the above tests do not replace periodic inspection that is recommended to be carried out by

a professional.

Safety warning

Never leave the vessel unattended when gas appliances are on

refrain from smoking or using a naked flame while LPG cylinders are being changed. Close the

valve on the empty cylinder before disconnecting it to change. Ventilate the gas cylinder

compartment well when changing the gas cylinder.

Do not use the cooker/oven as a heating appliance.

If a leak is detected, close the main LPG supply valve and do not use devices running on LPG.

After the boat has been shut up, never smoke when going below, and ensure that there is no

smell of gas.

Do not modify the LPG system of the vessel. Installation, the modifications and maintenance

must be carried out by a competent person. Have the system inspected at regular intervals or at

the intervals fixed by national requirements.

ATTENTION!

Certain precautions must be taken to avoid any contact with naked flames or other hot areas.

Do not use solutions containing ammonia during manual tests for leaks

.

ENGLISH 29/01/2018 17/86 DUFOUR 360 Grand Large

V. DRAIN & SANITATION SYSTEM

Pump type

Theoretical flow rate

Manual

38 L @ 45

strokes/minute

12V Electrical

2,000 L/h

Drainage system characteristics (ISO 15083:2003)

Read the operating and maintenance instructions for your boat’s bilge pump carefully.

WARNING

The bilge pump system is not designed to handle water entering as a result of holing of the hull.

It is intended to remove water coming from spray, leaks from seacocks or other moderate

leaks.

ATTENTION!

● The level of water in the bilge must be kept to a minimum.

● Make sure that bilge pumps are in working order before putting to sea.

● Regularly remove any debris that might obstruct the sump well and the pump intake points or

strainers.

If the watertight bulkheads that isolate the fore- and after-peaks are fitted with valves, they should

normally be kept closed and should only be opened to drain the water into the main bilge.

● Know where to find each hand pump and its handle.

● Locate the switch for the electric bilge pump on the electrical panel.

Fresh water is supplied to the sink and washbasins by an electric pump. A filter is installed

upstream of the pum p, and must be cleaned regularly.

Never allow the pump to run if the tank is empty. Refill the tank before using the water

supply again.

The tanks can be sterilized using Clonazone® tablets (available from pharmacies). Every year,

remove the inspection covers and clean them by filling with water containing a bactericidal

detergent; leave it to act for a few hours, then rinse two or three times. During wintering, completely

fill the tanks to avoid the development of algae or bacteria. If there is a risk of freezing, empty the

tanks; never use anti-freeze.

Hot water is produced by a water-heater connected to the engine cooling circuit and the shore

electric supply.

After the water-heater has been emptied, make sure that the element is covered before power is

re-applied.

ENGLISH 29/01/2018 18/86 DUFOUR 360 Grand Large

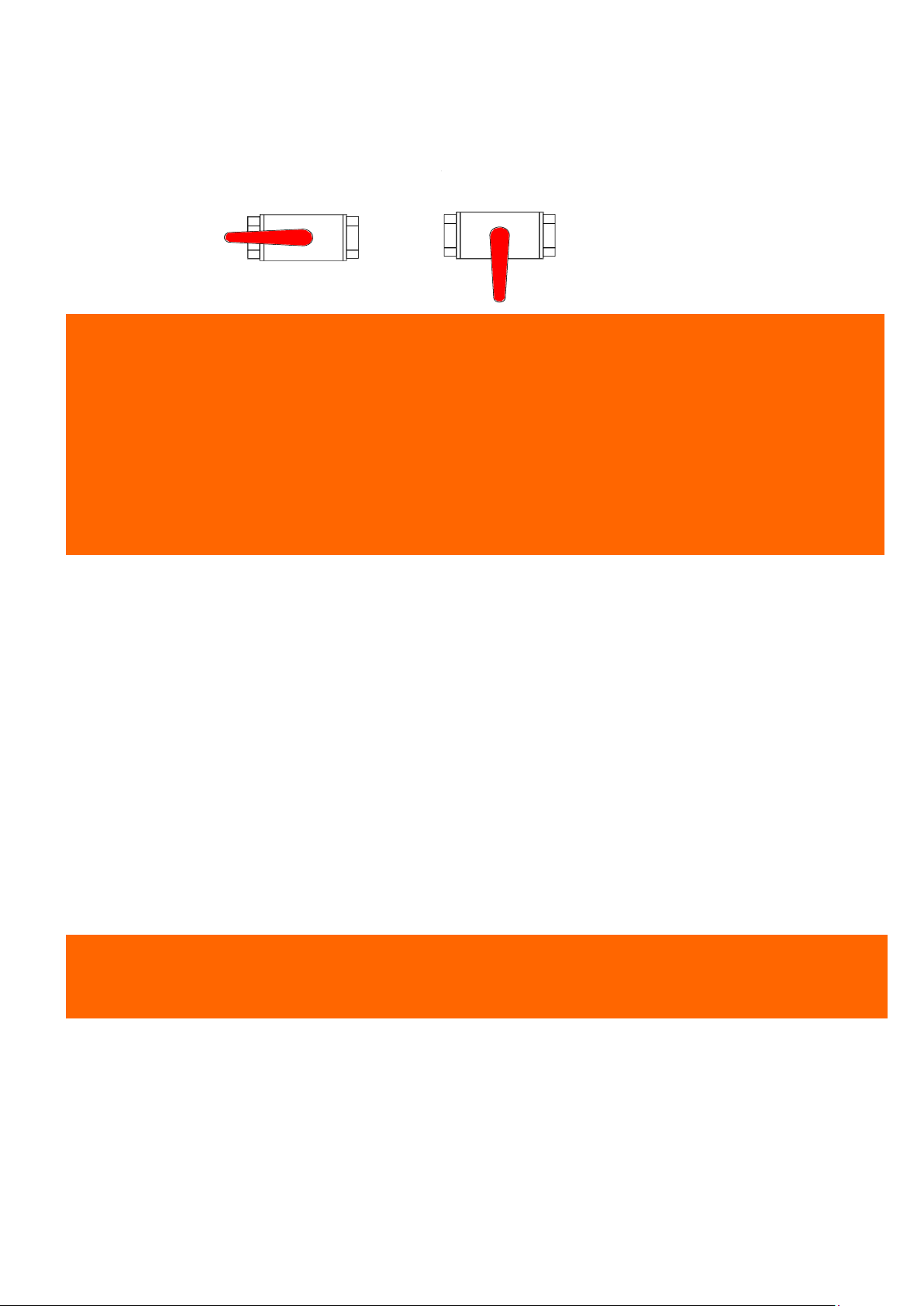

Vanne ouverte

Vanne fermée

Open seacock

Closed seacock

Seacocks are of the ¼-turn type:

- OPEN position: handle in line with seacock body,

- CLOSED position: handle perpendicular to the seacock body.

ATTENTION!

● Never interfere with the tightening of the seacocks to the hull. In the event of a leak, consult a

professional.

● In bad weather or when leaving your boat, close all the sanitation system seacocks.

● Keep seacocks closed when not in use and remember to manipulate them regularly to keep

them from seizing. A seacock that is not used for a long period can jam.

● During wintering, clean and rinse the seacocks and skin-fittings. Inspect brass fittings; slight

surface corrosion is normal.

● In the event of more serious corrosion, consult your agent.

- Open the sea water inlet cock.

- Open the bowl emptying seacock.

- Set the lever to the “FLUSH” position.

Operate the pump.

- To empty the bowl and avoid any water slopping when heeling, set the lever to the “DRY BOW L”

position.

- Operate the pump until the bowl is dry.

- Repeat these flushing/emptying operations as many times as is necessary to ensure complete

emptying of the pipes.

When toilets are not being used, set the lever to the "DRY BOWL" position, or the "CLEF" position

for certain models.

- Close seacocks after use, as the toilet is below the waterline.

- Change the toilet seals regularly.

ATTENTION!

Where a holding tank is fitted, take care to lock the discharge valve, to avoid any accidental

discharge during wintering.

- The (50L) sewage tank operates using the manual toil et pu mp.

- The contents of the toilet pan are discharged straight into the holding tank.

- Periodically check that the vent is working properly.

- A deck plate is provided for emptying the tank.

- The discharge valve can be sealed in the closed position using a padlock.

- Once a season, arrange to clean out the tank using a biodegradable disinfectant chemical.

Leave the system empty if the vessel is to be left in below-freezing temperatures

ENGLISH 29/01/2018 19/86 DUFOUR 360 Grand Large

VI. FLOODING

To avoid the risk of flooding the boat:

- Check that portholes, deck hatches, and any other openings that may cause flooding, are closed

before putting to sea.

- While under way, close all seacocks when they are not in use, except for the engine water intake.

- Do not exceed the maximum recommended loading.

- The level of water in the bilges must be kept to a minimum.

- Avoid adding weight in high places so as not to affect the stability.

Periodically check:

- Skin fittings, seacocks and pipes are watertight.

- Proper emptying of the cockpit drains.

- Stern glands or sail-drive seals for watertightness.

WARNING

Cockpit locker lids must be fastened shut before putting to sea. This is particularly important

for those lockers that represent a major flooding risk.

VII. FIRE PROTECTION

Installation

Since fire extinguishers are subject to national regulations, they are not supplied with the boat.

However, when in use, this boat must be fitted with portable extinguishers with the following

capacities, installed in the following locations (see drawing in Appendix 17):

- No. 1 – cockpit locker, within reach of the helmsman - capacity 1 kg - 5A34B

- No. 2 - saloon banquette (fore) - extinction capacity 1 kg - 5A34B

- No. 3 - port aft cabin - extinction capacity 1 kg - 5A34B

If you decide to install a carbon dioxide (CO2) extinguisher, be aware that it may only be fitted in

accommodation areas that contain powered electrical equipment (e.g. electric motors, battery

compartments, electrical panels) or flammable liquids (e.g. galley).

Only compatible replacement parts must be used in the fire protection system. They must bear the

same markings and be technically equivalent.

In addition, a fire blanket should be stored in the saloon banquette (in the 3-cabin version), close to

the galley. This can be very useful, particularly in the event of an oil-based pan fire.

Similarly, for safety on deck, a fire bucket equipped with a lanyard must be stored in an

immediately accessible locker.

If non-combustible materials are stored in the engine com partment, they must be secured to avoid

the risk of falling onto the machinery and must not obstruct access to the engine compartment or

its exit.

ENGLISH 29/01/2018 20/86 DUFOUR 360 Grand Large

WARNING

If a CO2 extinguisher is fitted, the following information must be displayed close to its location:

“This extinguisher contains CO2 - use only on electrical or cooker fires. To avoid

suffocation after discharging, leave the area immediately. Ventilate before re-entering.»

Do not open the engine compartment immediately after putting out a fire to avoid the release of

toxic smoke or spraying of burning materials (oil, water)."

Safety instructions

ATTENTION!

It is the responsibility of the owner/skipper to:

● Have fire-fighting equipment checked in accordance with the stipulations of the builder and the

regulations in your country.

● Replace fire-fighting equipment if it has expired or been discharged, with extinguishers of equal

or greater capacity.

● Show members of the crew:

- The location and operation of fire-fighting equipment.

- the location of the engine compartment discharge hole

● Ensure that fire-fighting equipment is readily accessible whenever the boat is occupied.

● Always keep the bilges clean and check that there is no fuel vapor or gas leak.

● Point out the escape routes.

You must never:

● Obstruct gangways leading to emergency exits (deck hatches).

● Obstruct safety controls (gas valves, fuel valves, electrical switches).

● Obstruct fire extinguisher stowages.

● Leave the boat unattended with a cooker or heater on.

● Use a gas lamp in the boat.

● Fill a fuel tank or change a gas cylinder while the engine is running, or the cooker or heater are

on.

● Smoke while handling fuel or gas.

● Place free-hanging curtains near the cooker or any other appliance which has an open flame.

● Store flammable substances in the engine compartment.

●Modify, or allow any non-qualified person to modify, any of the boat’s installations (especially

electrical, fuel, or gas).

ENGLISH 29/01/2018 21/86 DUFOUR 360 Grand Large

VIII. ENGINE

ATTENTION!

.

Regular maintenance must be carried out in accordance with the engine manufacturer’s

recommendations. Read the engine operating instructions that come with the boat carefully. Do not

hesitate to consult your agent or a qualified professional. In particular, follow the instructions for

wintering.

General precautions

Do not use the sail and engine if the heel angle is more than 10°.

Any engine change m ust respect the capacities of the boat and be performed by an engineer

specializing in marine mechanics.

After the first launching and tensioning of rigging, check the alignm ent of the propeller shaft or the

sail-drive flange ring.

● Make sure that the ventilation openings (vents, engine air intake grating) are completely clear.

● Make sure that the water intake seacock for the cooling system is open, and that water is

indeed coming out of the engine exhaust.

● Prevent any deterioration to the fuel supply circuits.

● Do not store any equipment containing gasoline (outboard engine, tank, gasoline generator,

etc.) in compartments that are not designed for this purpose.

Put the throttle in neutral before starting the engine to keep the boat from moving and/or the

propeller from turning .

On subsequent launches, a brief check of propeller fixing can be made. Incorrect operation of the

folding propeller will lead to vibration.

Regularly check the condition of the anodes and ensure that they are suitable for the boat's

environment (fresh water, salt water). Change the anodes every year. The anodes have an

average life of 1–2 years.

These anodes are made of zinc. You must not use magnesium ones. Impressed current cathodic

protection systems should not be used.

If the anodes are not eroded, you need to check:

- that they have not been painted over,

- that they are correctly fixed and in contact with the hull,

- and that they are indeed made of zinc.

Exhaust gas emission

DANGER!

Internal combustion engines produce carbon monoxide. Prolonged exposure to exhaust gases

can have serious consequences, and may even cause death.

Safety

DANGER!

In order to avoid all risk of serious injury from the propeller, the engine must not be started when

there are people swimming near the boat.

Whenever possible, the engine must be stopped for any engine maintenance or checking

operations. Otherwise, special attention must be paid to moving parts (propeller shafts, belts,

etc.) in order to avoid any risk of injury.

ENGLISH 29/01/2018 22/86 DUFOUR 360 Grand Large

Wintering

Read the operating and maintenance instructions for the engine that goes with your boat and the

instructions for wintering carefully.

In the absence of other instructions, proceed as follows:

- Close the engine water intake seacock,

- Disconnect the pipe from the engine water intake seacock,

- Drain the sea-water circuit,

- Place the pipe into a drum of –25° anti-freeze coolant,

- Run the engine until the fluid comes out of the exhaust,

- At the end of this operation, re-connect the pipe to the seacock,

- Attach a notice to the electrical panel and the battery isolator stating that the engine water intake

seacock is closed.

IX. FUEL INSTALLATION

In the event of deterioration, flexible fuel pipes must be replaced by pipes bearing the same

markings. Do the same for all fuel lines.

ATTENTION!

● Depending on the trim and loading of your boat, not all of the nominal fuel capacity may be

used. Always maintain a 20% reserve for safety.

● Avoid contact between flammable materials and hot parts of the engine.

● Clean up any overflow of fuel that m ay occur when filling the tanks.

You must never:

● Store flammable materials in unventilated spaces.

● Smoke while filling tanks.

● Obstruct ventilation openings (vents, engine air intake grating): Make sure they are completely

clear.

● Modify the installation, unless work is done by a qualified technician.

X. HELM SYSTEM

The steering system plays a vital role in the safety and comfort of your boat.

Tiller

The DUFOUR 360 is fitted with a dual wheel with a system of rudder cables and chains as well as

with an emergency tiller.

Checks to be carried out periodically: Check the play in the various elements (rudder

stock/bearings, tension and wear in mechanical components) and grease the sprocket and chain if

necessary.

In the event of any doubt or problem, consult your agent.

ENGLISH 29/01/2018 23/86 DUFOUR 360 Grand Large

Emergency tiller

ATTENTION!

● The Dufour 360 is fitted with an emergency tiller which must be kept readily accessible; we

advise stowing it in one of the nacelle cockpit lockers.

● It is designed only for sailing at reduced speed in the event of damage to the helm.

To use it:

- Unscrew the deck-plate to reveal the head of the rudder stock.

- Fit the tiller onto the head of the rudder stock.

XI. SAILING

WARNING

In all situations, adapt the speed of your boat to the surrounding conditions and always maintain a

safety margin. Pay particular attention to:

● Sea conditions, currents and the strength of the wind

● Movement of other boats

● Manoeuvers in port

● When passing through mooring areas

● Obey the rules of right of way as set out in the Rules of the Road as established by COLREG

● Ensure that you always have enough room for stopping or for any necessary manoeuvers to

avoid a collision.

● Respect speed limits

● Out of courtesy and for the safety of other boats, exercise care and attention to minimise your

boat's wake near other boats

● Movable items must be carefully secured when at sea

WARNING

● You must fit your boat with grab lines. Anchor-points are provided on the deck. Please refer to

the deck fittings plan for your boat.

● The stability of your boat has been designed taking into account the boat's weight specification

for light displacement, the standard equipment on board and the manufacturer's catalogue

options.

Any alteration to on-board weight distribution (for example: adding a radar, changing the engine,

etc.) can affect the stability, trim and performance of your boat.

Breaking waves represent a significa nt threa t to stabili ty .

Towing another boat produces significant extra loading, which will have an adverse effect on the

stability of your boat.

● You must never:

Lift heavy weights using the boom.

ENGLISH 29/01/2018 24/86 DUFOUR 360 Grand Large

XII. FALL PREVENTION AND MEANS OF GETTING BACK ABOARD

While underway, it is recommended to move about on deck only in areas provided for this

purpose. These areas (gangways, cockpit, roof, side seats, etc.) are provided with non-skid

coatings or teak (depending on option selected) making it safe to move about.

On the DUFOUR 360, it is possible to move safely around the entire deck area included within the

guardlines. Pathways are provided for on glazed surfaces where necessary and are indicated by

anti-slip surfaces.

Note that when open, the aft platform is not considered as a secure area. It should be k ept c los ed

when under way.

Depending on sea conditions, wind and the degree of heel, it is also recommended that you use

use the harness by attaching it to the various attachment points mentioned in the deck fittings plan.

When the vessel is under way, use the various handholds available whenever possible, such as

the grab rails on the helm console and cockpit table, lateral grab rails on the coachroof, shrouds,

etc.

The DUFOUR 360 is equipped with a swim ladder that adapts to the stern door. It can be stowed

away in the cockpit locker. In this case, lower the stern gate by releasing the retrieval cord then

insert the ladder into the sockets provided for this purpose.

A safety ladder is also provided in case of emergency. It is located on the starboard stern rail, and

can be deployed from the water. Ensure that you are familiar with the system and can operate it

under any circumstances, notably when the vessel is under way.

XIII. LIGHTNING PROTECTION

Your boat is protected against lightning. The rigging is electrically earthed (grounded).

Nonetheless, for your safety, it is necessary to respect certain precautions.

Maintenance

If the vessel has been hit by lightning:

- The protection installation must be inspected to detect physical damage and check

the integrity of the device, as well as the continuity of the earthing.

ENGLISH 29/01/2018 25/86 DUFOUR 360 Grand Large

- The compasses, electrical and electronic devices must be examined in order to

ascertain if damag e or cal ibration changes have occurred.

Protection of people during a thunderstorm

WARNING

During a thunderstorm, it is recommended that you comply with the following instructions:

● People should stay below as much as possible.

● People should stay out of the water and not let their arms or legs hang into the water.

● While maintaining satisfactory control of the vessel and its course, persons aboard should not

touch any parts connected to a lightning protection system, and especially not in such a way as

to form a link between these parts.

● People should avoid touching any metallic parts of the rigging, spars, deck fittings and lifelines.

XIV. ENVIRONMENTAL PROTECTION & SAFETY

We recommend that you find out about local regulations concerning the environment and obey

international regulations against pollution in the marine environment (MARPOL), together with the

codes of good practice.

Do not discharge the toilets or the contents of the holding tanks near coasts or in prohibited areas;

use port or marina pumping systems for emptying the holding tanks before leaving port.

ATTENTION!

● Most cleaning products, engine oils and fuels are likely to impact the environment, so they

should be discharged in authorized locations (check with the Harbor Master’s office).

● Do not run the bilge pump when oil or fuel is present in the engine compartment, as these

chemicals must be discharged in authorized locations.

● Certain products can also pose a risk to your safety and that of others, which is wh y it is

important to read and foll ow the instructions for use.

● Chemicals must be labelled and stored in an appropriate place on the boat.

ENGLISH 29/01/2018 26/86 DUFOUR 360 Grand Large

Loading...

Loading...