Duevi Photon System Installation Manuals

PHOTON SYSTEM – Installation Guide v8.0 - pag.1

PHOTON SYSTEM

Installation Guide

(rel. 8.0)

Fig. 1

General description of the system

The Photon system by Deitech, in its basic configuration, is

made of two bars absolutely identical (Fig. 1), placed at the two

ends of the area to be controlled thus creating an “infrared

barrier”; the bars are connected with just one cable to a hub

(Fig. 2), that, placed in the Control Unit, controls the whole

system. The bars are used for both transmission and reception

of the beams, work in couple and exists in different versions:

from 50 to 200 cm height, with or without heather, with maximum

range 25, 50 and 80 meters. They have all the same design; are

made of an aluminium body with a black polycarbonate cover

and two caps of the same colour.

On the “ROTAX” cap (Fig. 3) you can

find the connection terminals and the

ROTAX system for the orientation of

the beams. On the “NUMBER” cap

(Fig. 4) there is the selector for the ID

number to assign to the bar and, in the

models with heater, the terminal blocks

for heater power supply. Through a four

wires cable plus shield, the barriers

(from ROTAX cap) will be connected to

the hub; the connection could be a star

or in series so that it can easily adjust

to the different installation

requirements.

The hub controls the correct operation of the barriers, allows the configuration of the system

and concentrate the connexion with the control panel. The hub will manage up to a maximum

of four couples, that can be installed even in the same area and the beams will not interfere

between themselves. The four couples can be of different heights and different range but the

bars of each couple must be the same. For each couple the hub will allow to set different

operation parameters (see HUB-TC Manual for details) and manage single stand-by inputs.

The alarm output toward the control panel are different for each couple, while the technical

outputs (tamper, disqualification, failure) are common for all the couples managed by the hub.

If the installation will require more than four couples, then more hub are needed.

THE BARS

It’s absolutely fundamental to install the couple of bars properly, each couple must be placed in order

to protect the passage through which an intruder could pass. In order to determine the correct mounting

height of the bar, it must be taken into consideration that the first beam (and the last) is placed at about

20 cm from the end of the bar and that between the other beams there are 25 cm. The barrier can be

placed upside down to connect the hub either from above or from below, but it is mandatory that each

couple is installed in the same position. All the Photon barriers have a patented system that allows a

correct horizontal alignment of the beams (ROTAX). This system will enable the installer to install them

Fig. 2 – hub-tc

Fig. 3 – rotax cap

Fig.4 – number cap

PHOTON SYSTEM – Installation Guide v8.0 - pag.2

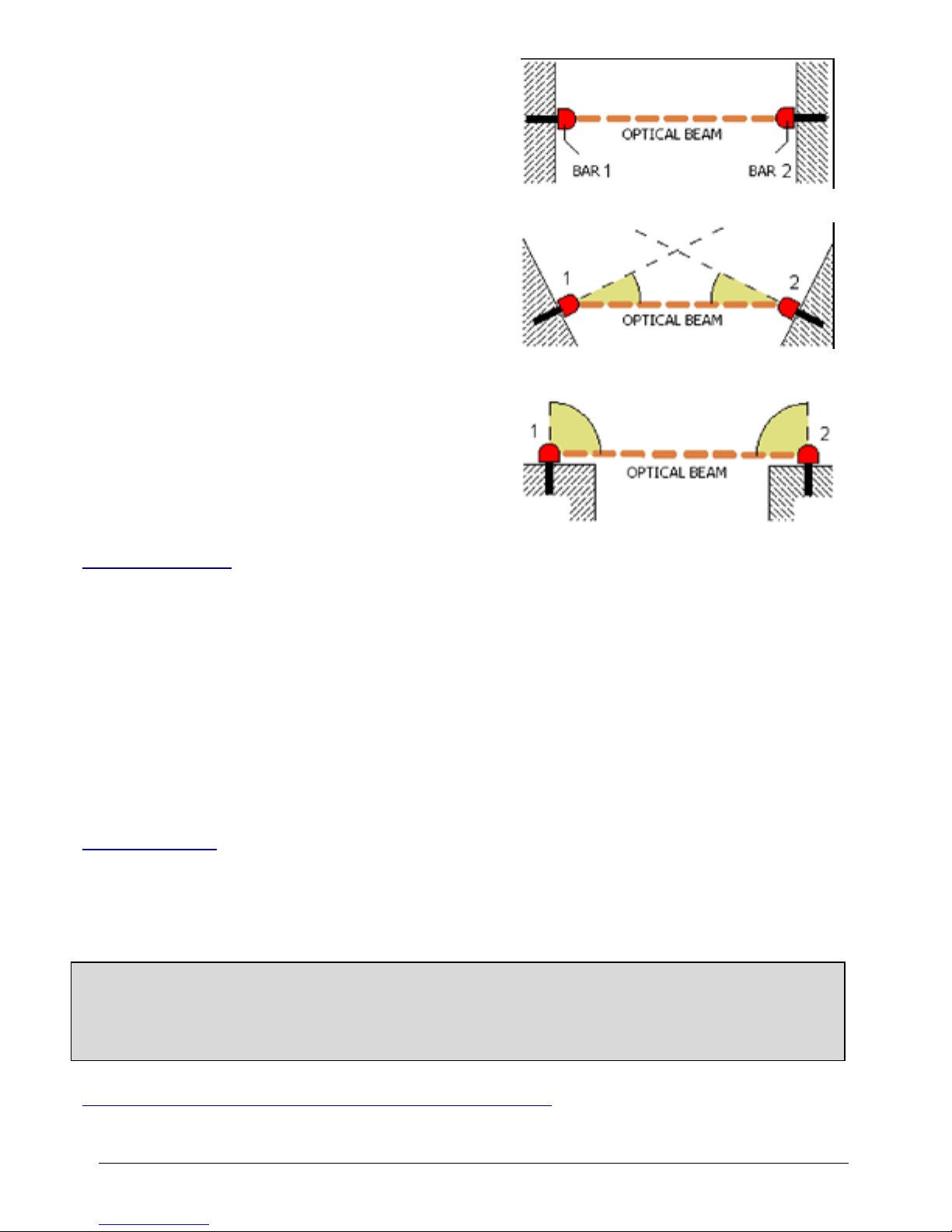

on surfaces that not necessarily are placed in front (Fig. 5).

Oblique installations can than be easily made (Fig. 6) with a

maximum angle of 90° between the walls i.e. the barriers

can be installed on the same wall (Fig. 7). The ROTAX (Fig.

17) is the rotating element that has to be used in order to

direct all the beams in the range +/- 90°.

The bars are equipped with two tamper systems. The first

one (that cannot be deactivated) is located on the cap’s

opening and goes in alarm every time the cap is open. The

second will reveal the removal of the bar from the surface

on which it is installed and can be deactivated if not used.

Inside the bar there are two red led that can flash if the

hub have the led option enabled: one will signal a tamper

alarm i.e. that at least one of the four tampers is open, the

other one light on when the barrier is in “alarm” condition.

The ice can divert the direction of the beams; it is possible

to order a version of barrier with integrated heating system

(the not “heated” ones cannot be modified later). These bars

are suggested for external installations and anyway in cold

and humid environments. The heating system, managed by

a thermostat, will guarantee the functioning up to -20° C..

Fig. 5

Fig. 6

Fig. 7

Cabling the bars

After having set where the bars have to be placed, it will be necessary to position the connecting wires

between the hub and the barriers. In a standard installation (bars positioned at a maximum of 200-300

mts from the hub) a standard 4 wire cable (two for power supply 0,75 mm2, 2 for the serial communication

0,22 mm2) and shield.

The number of possible connection typologies is quite wide and for each one of that the maximum

length of the cable may vary; Fig. 23 represents some examples with the maximum cable length.

Warning the maximum length of a cable connected to a single barrier is 1000 mts.

For the connection of the wirings, there are available waterproof interconnection boxes (Fig. 18), that

contain a terminal blocks that allows to derive from the bus two wires for the couple.

Fig. 24 represents an example of a connection of a complete system.

If the bars are the heated version, for the installation of the heating power cables you have to refer to

adding section of this manual.

Fixing the bars

The bars must be fixed on walls or supports that should be as much as possible flat and plumb; in case

it is advisable to use plies to correct and to fill the surface making it flat. If there is no intention to use the

anti-removal tamper it is sufficient to lean the bar on the support and, after having plumbed it, mark the

holes for the screws trough the holes of the two caps (see drawings attached at the end of this guide).

WARNING: TIGHTEN ONLY ONE OF TWO FIXING SCREWS AND LEAVE MOVING POSSIBILITY

TO THE SECOND SCREW, TO ENSURE THE PROFILE OF BARRIER FREE TO EXPAND /

CONTRACT FOR THERMAL EXPANSION.

BAR MUST NOT BEND UNDER ANY CONDITION, OTHERWISE IT WILL AFFECT ITS PROPER

OPERATION.

Anti-removal tamper activation on the bars (optional)

The anti-removal tampers are two waterproof buttons which are integrated in the rear of each cap and

are encased in order to avoid tampering attemps from outside..

PHOTON SYSTEM – Installation Guide v8.0 - pag.3

In order to keep each tamper pressed it is sufficient a head of a screw that stands out for from the wall

about 3/4 mm. The anti-removal system requires a certain precision of installation. For this purpose a

mask is supplied that shows the exact point where the screw has to be inserted. The head of this screw

will stand out for minimum 3 mm and not more 4 mm. If plies have been used, then the distance of the

screw’s head must be adjusted according to the needs. Once the bars have been fixed, remove the

jumper J1 on the ROTAX cap and J2 from the NUMBER cap and verify with a tester positioned on the

two pins of the J1 or J2 jumpers that the contact is closed; if it appear as open than that mean that the

screw does not stand out enough. Warning do not protrude the screw more than 4 mm in order not to

damage the micro-switch button.

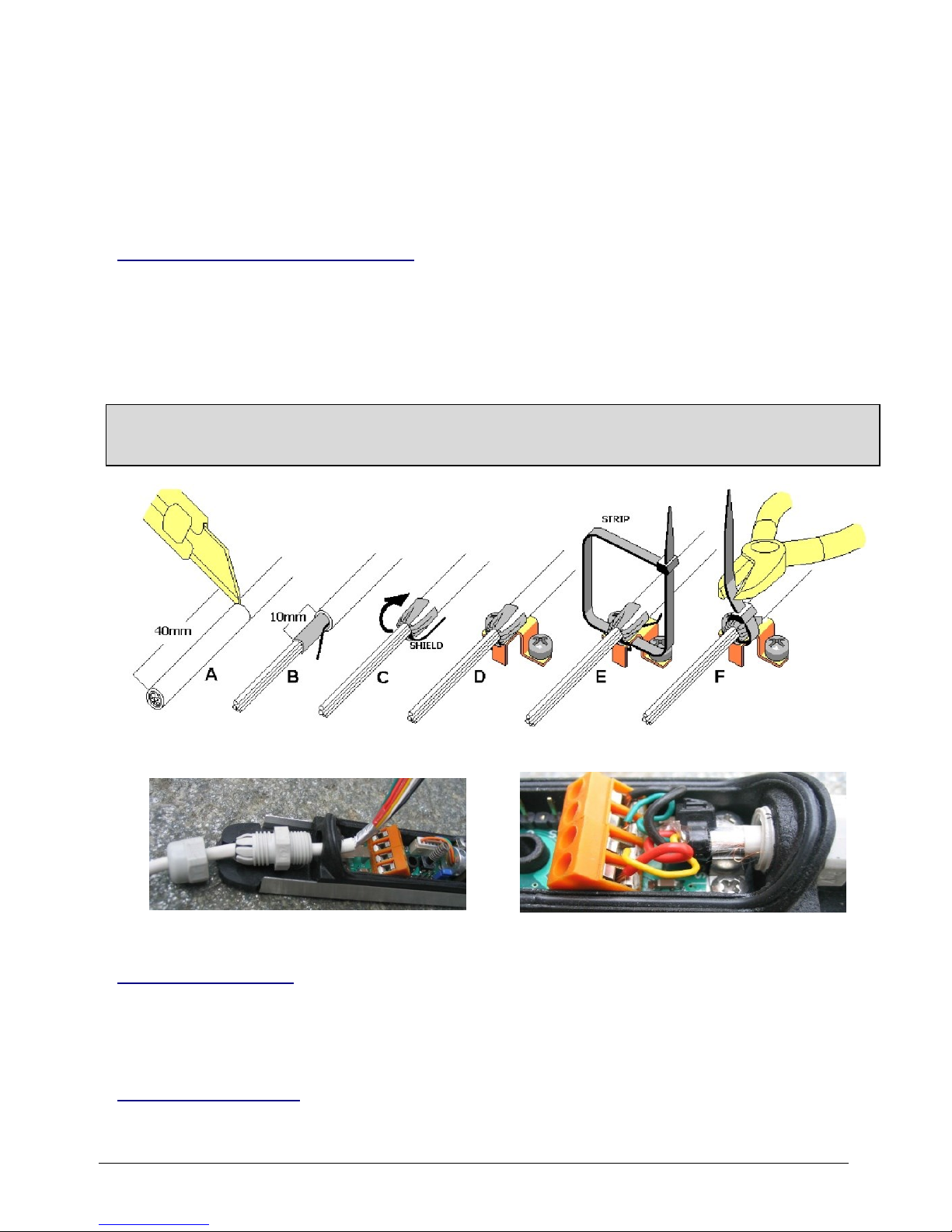

Cable connection inside the bars

The cable connection is made in the following steps:

1) Prepare the cable (Fig. 8 A / B).

2) Insert the cable in the cable gland (Fig 9).

3) Fold the cable shield backwards and lean it on the metallic holder (Fig 8 C / D).

4) Block with a strip the cable to the holder (Fig 8 E / F).

5) Cut, shear and fix the 4 wires into the terminal blocks and tighten the cable gland (Fig 10).

WARNING: USE EXTRA CARE IN THE TIGHTENING OF THE CABLE GLAND. WRONG CLOSING

AFFECTS HEAVILY THE WEATHERPROOF IP65 LEVEL OF THE BARRIER AND WILL VOID THE

PRODUCT WARRANTY.

Fig 8

Fig 9

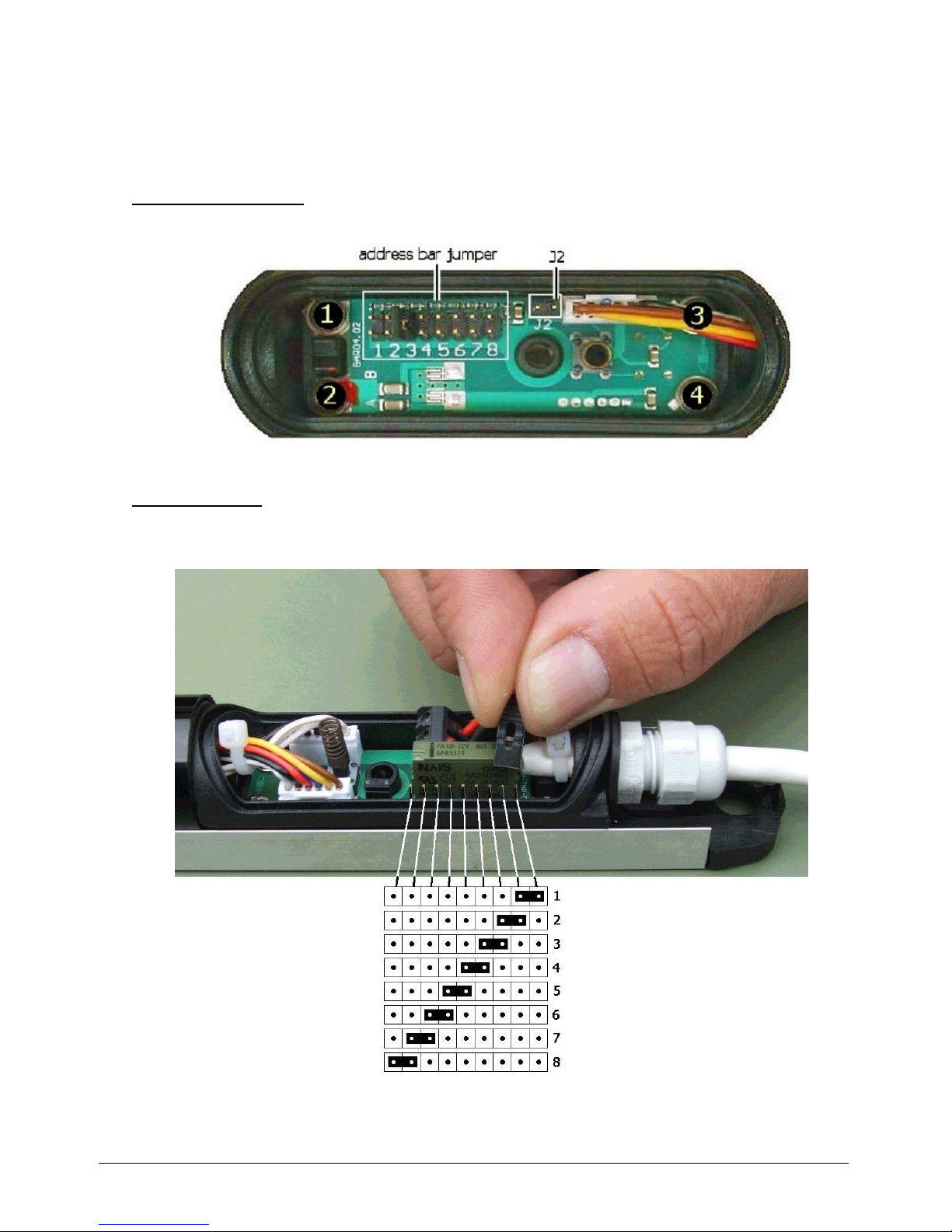

Settings of the bars

In the bars there are two settings to do. The first one will enable the anti-removal tamper. Whenever

you want to activate it you will have to remove the two jumpers that are placed in the NUMBER and in

the ROTAX caps. The other relates to the ID number of each bar (address).

Addressing the bars

Each Hub can manage up to four couples (i.e. 8 bars) and each bar must be precisely identified with

a univocal number on the bus. This will be set by jumper that can be found in the cap “NUMBER”.

Fig 10

PHOTON SYSTEM – Installation Guide v8.0 - pag.4

The ID number of the bar (address) must be set as follows:

1 and 2 for the first couple (zone ‘A’),

3 and 4 for the second couple (zone ‘B’)

5 and 6 for the third couple (zone ‘C’)

7 and 8 for the fourth couple (zone ‘D’).

NOT HEATED version has a double row of contacts on which a jumper is inserted in the position

corresponding to the address to assign to the bar (Fig 11).

Fig 11 – Addressing of the NOT HEATED version

HEATED version, due to the presence of the heater, has a single row of contacts on which a jumper

is inserted in the position corresponding to the address to assign to the bar (Fig 12). Pay great attention

to this, because due to the small space available, it is easy to fall into error.

Fig 12 – Addressing of the HEATED version

PHOTON SYSTEM – Installation Guide v8.0 - pag.5

The HUB-TC

Connection between HUB-TC and barriers

The connection with the bars can be made only through the 5 terminals of the hub (Fig. 25). Do not

connect the bars to different supplies than the one foreseen and be very careful not to invert the serial

poles S2 and S3. Fig. 24 represent an example of the connection of a complete system.

Terminals description:

S1 = Negative power supply (0V) minimum section 0,75mm2

S2 = RS485 pole A minimum section 0,22mm2

S3 = RS485 pole B minimum section 0,22mm2

S4 = Positive power supply (+12Vdc) minimum section 0,75mm2

GROUND = Shield of the cable

WARINING: THE CABLE SHIELD MUST BE CONNECTED BOTH ON THE BARS AND ON THE HUB SIDE.

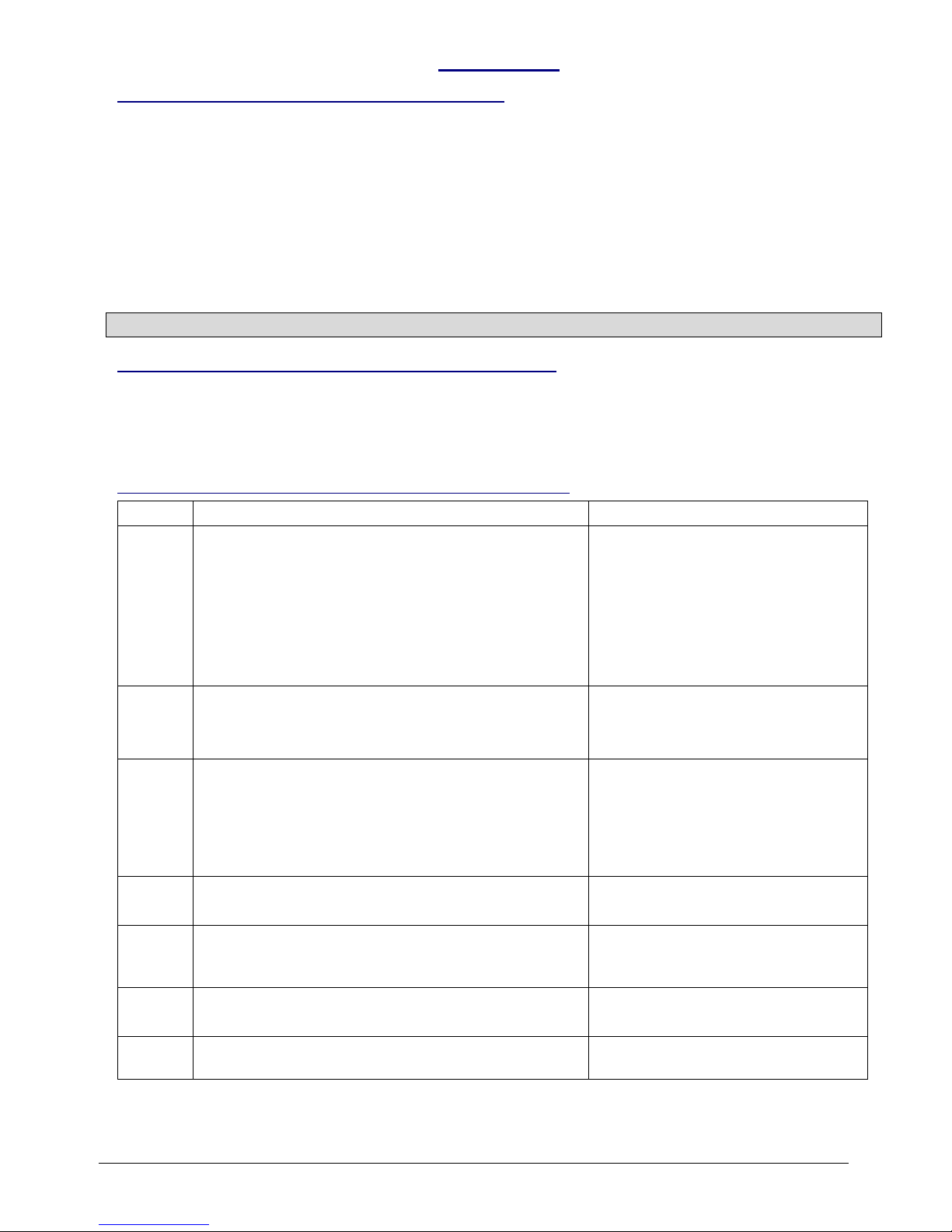

Connection between HUB-TC and Control Panel

The hub is made in such a way that it can be installed inside the Control Panel Case or in any other

protected case. Use the holes foreseen in the Hub for its fixing. The connection will be made by the cabling

of the wires between the terminal blocks of the Hub (Fig 25) and the Control Panel.

It is recommended to use for the power supply at least two wires of minimum section 0,75 mm2.

Terminals of the HUB-TC toward the Control Panel

Terminal

Description

Contact type

sA

sB

sC

sD

Stand-by command inputs.

To be connected to the Control Panel if you intend to

manage the stand-by separately. They can also be

connected all together in order to have not separate

stand-by for the different couples. When the barriers

are in stand-by, the beams are not active (this means

energy saving and less component consumption) but

the tampers and the failure are active.

Zone enabled = free or GND

Zone disabled = +12Vdc

FL

Failure Output. Normally open, it is closed at ground

when malfunctioning is detected (fault, wire

interruption, etc.)

OPEN COLLECTOR

Normal = free (max 200VDC)

Failure = to GND (max 100mA)

DQ

Disqualification output. Active only if the option is

enabled on the HUB. Normally open, it is closed at

ground when, due to limited visibility conditions (fog,

very heavy rain), the barriers cannot operate properly.

It will return open as soon as the environmental

conditions go back to optimal.

OPEN COLLECTOR

Normal = free (max 200VDC)

Disqualification = to GND (max

100mA)

TAMP

Tamper Output. Normally closed. It is open when

one of the tamper is activated.

Closed=20 Ohm (max 100 mA)

Open= infinite (max 200 V

AC-DC

)

ALRM

General Alarm Output. Normally closed. It is open

when the system detects an alarm on one of the

connected barriers.

Closed=20 Ohm (max 100 mA)

Open= infinite (max 200 V

AC-DC

)

A-B-C-D

Zone Alarm Outputs. Normally closed. It is open

when the single barrier detects an alarm.

Closed=20 Ohm (max 100 mA)

Open= infinite (max 200 V

AC-DC

)

- +

Power supply Input. It power the hub which in turn

distributes the power to all the connected bars.

Form 9 to 16 VDC

Max 0,9 A (Hub + 8 bars)

PHOTON SYSTEM – Installation Guide v8.0 - pag.6

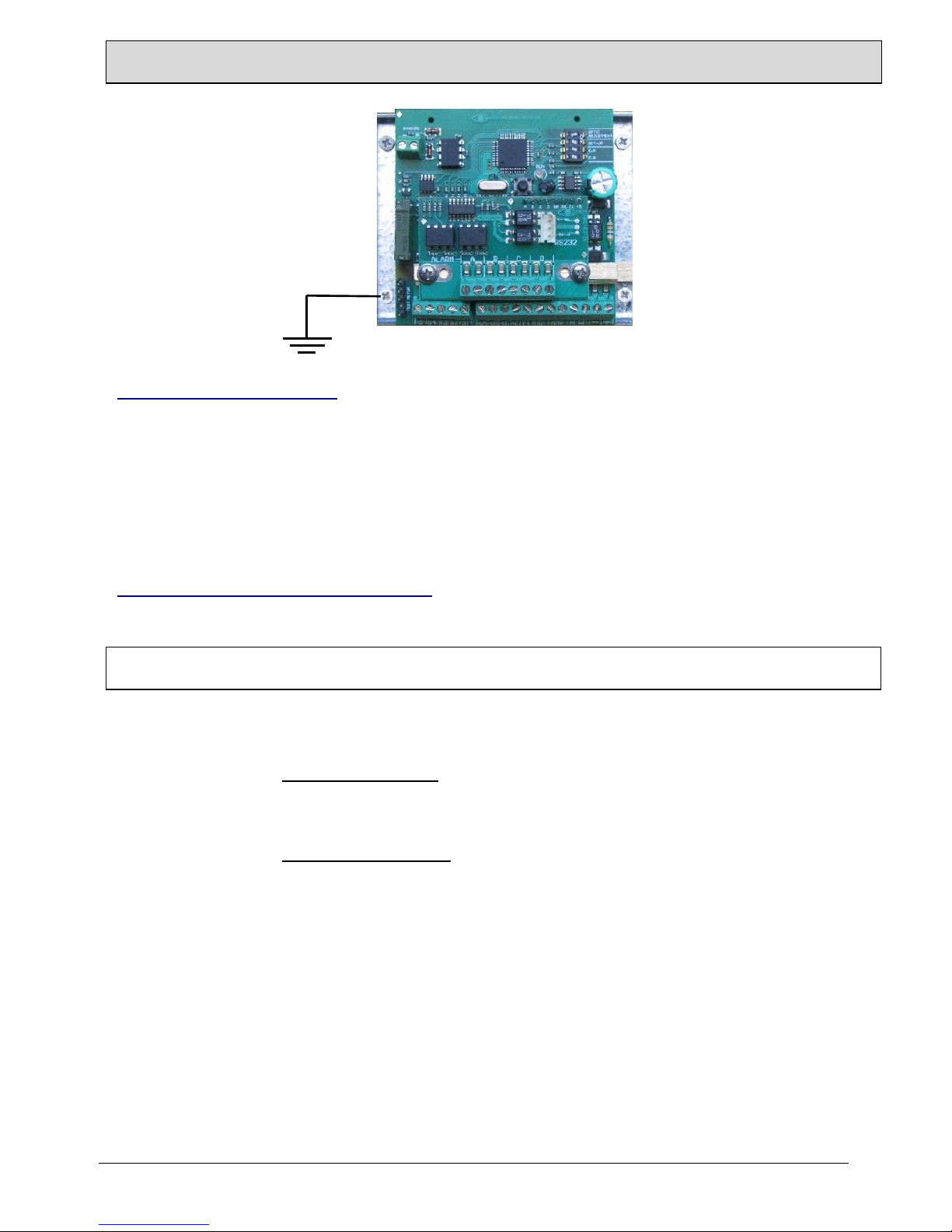

WARNING:

CONNECT THE METALLIC BASE OF THE HUB TO THE ELECTRIC PLANT GROUND.

Settings on the HUB-TC

The HUB-TC allows you to centralize the monitoring and configuration of installed barriers couples,

through the use of 3 free software:

PHOTON TEST HUB (barrier and cabling verification)

PHOTON SETUP HUB (setting of the barrier parameters)

PHOTON MONITOR HUB (real-time monitoring and activity log of the barriers)

For the use of the software you need to connect to the RS232 port of the Hub (Fig 25)

Switch on and check of the system

Once all the cabling have been done, it is necessary to verify the connection and correct setting of

the HUB.

WARNING. This is just a summary of what to do. Please see the HUB-TC manual for the step by

step procedure of system verification and programming of the system.

1) Set DIP1=ON, DIP2=ON and power the system. After few seconds the led is solid on. If the led is

off, check the power cables of the HUB.

2) Use the software PHOTON TEST HUB to verify that all the address of the connected bars are

detected by the software (1-2-3-4-5-6-7-8). If some bar is not detected, check that the addresses

on the bars and the connections are correct, then make again the test. Do not go to the next step

until any connected barrier is detected.

3) Use the software PHOTON SETUP HUB to program the working parameters of each couple.

WARNING: Enable only the barrier couples that are really connected to the system (A-B-CD), otherwise the HUB will not start correctly and will signal continuously a FAILURE.

4) Set DIP2=OFF and press reset button on the HUB to restart.

5) After few seconds, check the proper operation of the Hub with the continuous quick flashing of led

(Fig 25). If the led is solid on or flashing in a different way, it means that the HUB is in FAILURE

mode, so you have to check again the previous steps (check the cables to the bars, the enabled

couples A-B-C-D, the correct addressing of the bars – Fig 11).

6) If the HUB gives tamper alarm and all the caps are already closed, please check the proper

closing of the caps. If some cap is open, then it is a correct alarm condition.

7) At this step you have to start the beam adjusting procedure and it is normal that, as it is not

performed yet, the HUB can give alarm or disqualification condition.

Loading...

Loading...