CR 43 NDT / HD-CR 43 NDT

Installation and Operating Instructions

EN

9000-608-21/30

2

Inhalt

Important information

1. General . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Note on conformity . . . . . . . . . . . . . . 4

1.2 General Notes . . . . . . . . . . . . . . . . . 4

1.3 Disposal of appliance . . . . . . . . . . . 5

1.4 Correct Usage . . . . . . . . . . . . . . . . . 5

1.5 Incorrect Usage . . . . . . . . . . . . . . . . 6

1.6 Using Peripheral Devices . . . . . . . . . 6

1.7 Use of cassettes . . . . . . . . . . . . . . . . 6

1.8 Use of software . . . . . . . . . . . . . . . . 6

1.9 Guarantee . . . . . . . . . . . . . . . . . . . . 7

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 General notes on safety . . . . . . . . . . 7

2.2 Electrical safety instructions . . . . . . . 8

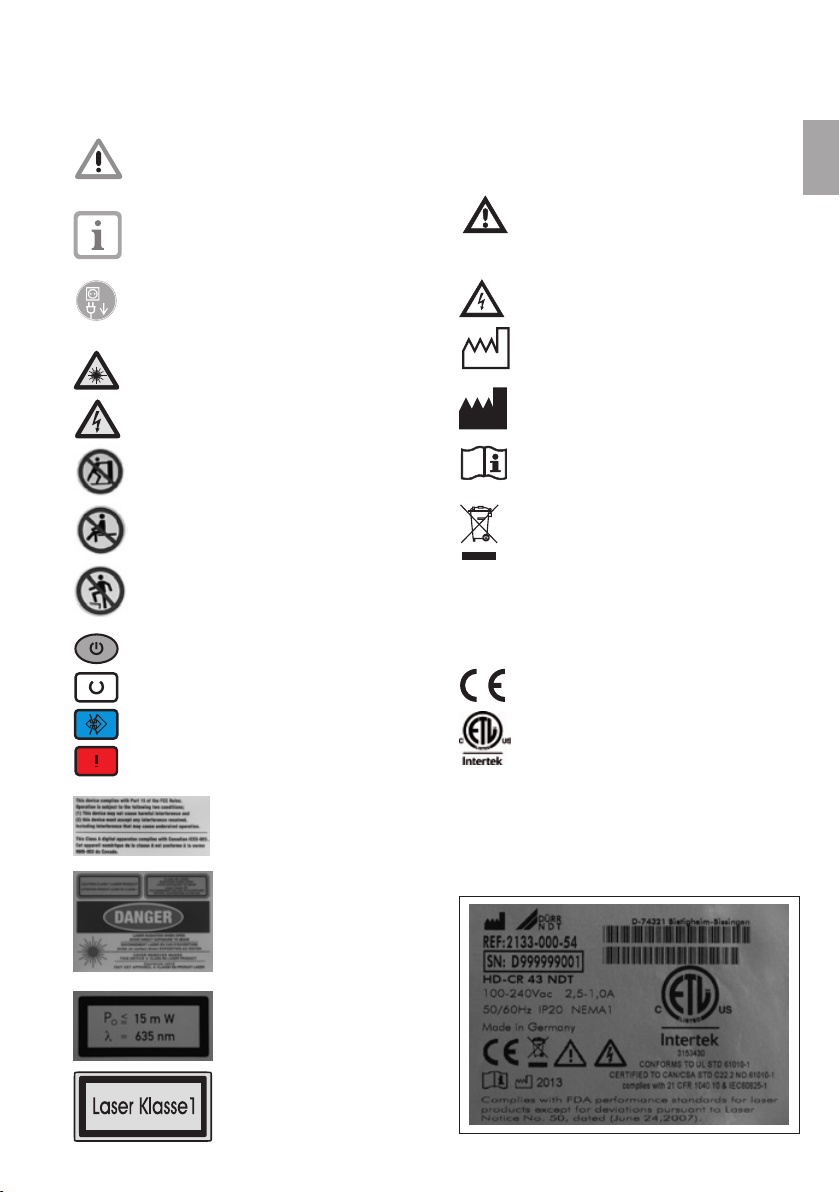

3. Warnings and Symbols . . . . . . . . . . . . 9

3.1 Model identification plate . . . . . . . . . 9

4. Delivery contents . . . . . . . . . . . . . . . . 10

4.1 Consumables . . . . . . . . . . . . . . . . . 10

4.2 Special accessories . . . . . . . . . . . . 11

5. System requirements . . . . . . . . . . . . . . 12

5.1 Monitor . . . . . . . . . . . . . . . . . . . . . 12

5.2. Minimum system requirements . . . . 12

6. Technical data . . . . . . . . . . . . . . . . . . 12

6.1 CR 43 NDT / HD-CR 43 NDT . . . . . 12

6.2 Cassettes with integrated

image plates . . . . . . . . . . . . . . . . . . 13

7. Functional layout . . . . . . . . . . . . . . . . 14

7.1 Function of individual components . 15

8. Functional description . . . . . . . . . . . 16

Use

14. Cassettes . . . . . . . . . . . . . . . . . . . . . . . 21

14.1 Identification of the cassettes . . . . 21

14.2 Handling of cassettes . . . . . . . . . . 21

15. X-ray . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

15.1 Preparation for X-raying . . . . . . . . . 22

15.2 X-ray exposure . . . . . . . . . . . . . . . 22

15.3 Preparation for reading out the

image data . . . . . . . . . . . . . . . . . . 22

14.3 Storage of cassettes . . . . . . . . . . . 22

15.4 Reading out the image data . . . . . 23

15.5 Erasing the image data . . . . . . . . . 25

16. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . 26

16.1 CR 43 NDT / HD-CR 43 NDT . . . . 26

16.2. Cassettes . . . . . . . . . . . . . . . . . . . 26

17. Maintenance . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting

18. Tips for Operators and Technicians . . 28

18.1 Unit fault . . . . . . . . . . . . . . . . . . . . 28

18.2 Error messages . . . . . . . . . . . . . . . 31

EN

Mounting

9. Transport and packaging . . . . . . . . . 17

10. Carrying the CR 43 NDT . . . . . . . . . . . 17

11. Set-up . . . . . . . . . . . . . . . . . . . . . . . . . 18

11.1 Installation room . . . . . . . . . . . . . . 18

11.2 Set-up alternatives . . . . . . . . . . . . 18

12. Electrical Connection . . . . . . . . . . . . . 19

13. Initial use and start-up . . . . . . . . . . . . 20

13.1 Remove the transport aids . . . . . . 20

13.2 Setting up the appliance . . . . . . . . 20

13.3 Installation and configuration . . . . . 20

2013/10/21 9000-608-21/30

3

Important information

EN

1. General

1.1 Note on conformity

This equipment has undergone a test of conformity as prescribed under the relevant European Union directive. This equipment conforms

to all requirements.

ETL approval

This Class A digital apparatus complies with

Canadian ICES-003. This equipment has been

tested and found to comply with the limits for a

class A digital device, pursuant to Part 15 of the

FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequence energy

and, if not installed and used in accordance

with the instruction manual, may cause harmfull

interference to radio communications. Operation

of these equipment in a residential area is likely

to cause harmful interference in which case the

user will be required to correct the interference

at his own expense.

FDA-Registration

Complies with FDA performance standards for

laser products except for deviations pursuant to

Laser Notice No. 50, date (June, 2007).

Classification:

Appliance class I, no application parts, transportable continuous operation. This appliance is

not designed for use in areas where flammable

anesthetic materials are present.

1.2 General Notes

• The Installation and Operating Instructions

constitute part of the appliance. They must

be made available to the operator. Correct

observance of the Installation and Operating

Instructions is a basic requirement for using

the appliance properly and safely, and new

personnel must be instructed accordingly.

These Installation and Operating Instructions

must be handed over to any subsequent

owner or operator of this appliance.

• The safety of the operator and trouble-free

operation of the appliance can only be

ensured where original engineering manufactured parts are used. Furthermore, only the

accessories described in the installation and

operating instructions or approved by Dürr

NDT for use with this appliance may be used.

If accessories are used manufactured by third

parties, then Dürr NDT can no longer provide

any guarantee for safe operation or correction functioning. No liability on the part of the

manufacture will be accepted in the case

that damage arises through the use of nonapproved accessories.

• Dürr NDT cannot be held responsible for the

appliance with regard to safety, reliability and

function where installation, reset, alterations,

extension or repairs were not carried out

either by or for Dürr NDT or by a third party

specifically approved by Dürr NDT, or if the

appliance is not used and operated according

to the instructions laid down in the Installation

and Operating Instructions.

• These Installation and Operating Instructions

accord with the features of the appliance

and the level of engineering at the time of

first introduction of the model. All circuits,

processes, names, software and appliances

quoted are protected under industrial property

rights.

• This translation of the Installation and Operating Instructions has been carried out in good

faith. Liability for incorrect translation will not

be accepted. The accompanying German

version of these Installation and Operating

Instructions are to be used as reference; if you

have any doubt as to the correct interpretation

of the instructions, please consult your dealer.

4

9000-608-21/30 2013/10/21

• Any reproduction of these Installation and

Operating Instructions, or parts thereof, in any

medium whatsoever including electronic is

only permitted with the prior written approval

of Dürr NDT.

• Keep original packing for possible return of

the appliance to the supplier. Ensure that the

packaging is stored away from children.

Only the original packing ensures optimum

protection for the appliance during transport.

If a return is required during the warranty

period, Dürr NDT cannot be held liable for

damages during transport that have been

caused by inadequate packaging!

1.3 Disposal of appliance

Device

EU Directive(s) 2002/96/EG - WEEE (Waste

Electric and Electronic Equipment) of 27th January 2003 and their current application in national

law states that products covered by the above

directive within the European Union must be

disposed of as special waste.

For further questions about the proper disposal

of the products, please contact Dürr NDT or the

specialised trade.

Cassettes and image plates

The image plate contains barium compounds.

• Dispose of the image plate properly in accordance with the locally applicable regulations.

• In Europe, dispose of the image plate in accordance with waste code 090199 "wastes

not otherwise specified". Disposal as domestic waste is not possible.

1.4 Correct Usage

• The appliance is intended exclusively for visual

scanning and processing of image data on an

image plate under industrial conditions.

• The device is only to be used in enclosed, dry

rooms.

• Correct usage of the appliance also involves

observing the Installation and Operating

Instructions and adhering to the instructions

concerning set-up, operating and maintenance.

• Any usage which is not in accordance with

the correct usage above will lead to the

guarantees and warranties becoming null and

void.

• The operator is liable for any damage arising

through incorrect usage.

• Correct usage includes compliance with all

legal provisions applicable at the place of use

with regard work and radiation protection.

• The scanner may only be operated in combination with cassettes from Dürr NDT.

EN

2013/10/21 9000-608-21/30

5

1.5 Incorrect Usage

The appliance is not intended for optical scanning of image plates in human and veterinary

medicine.

Any use of the appliance above and beyond

EN

that laid down here s considered to be improper

use of the equipment. Any resulting damage

thus caused is the sole liability of the user. The

manufacturer cannot be held responsible for

damage caused by improper use.

Cassettes from third-party manufacturers are

not compatible with the system and could damage the appliance.

This appliance must not be used in

operating theatres or similar types

of room, where there is a risk of

inflammable materials catching fire.

1.6 Using Peripheral Devices

Only peripheral devices (computers,

monitors, printers) conforming to standard IEC 60950-1 (EN 60950-1) may be

connected to the appliance.

• Appliances may only be connected together

or connected to other system parts where the

safety of patients, operators and also the environment is ensured.

Where there is any element of doubt concerning the safety of connected equipment,

the user must contact the manufacturers

concerned or ask an expert to determine that

the level of safety required for the operator

and the environment is not impaired by the

intended coupling.

1.8 Use of software

An X-ray software approved by DÜRR NDT

must be used, such as e.g. D-Tect. The use

of third party software requires the express

approval of DÜRR NDT. For further information

refer to our internet site at www.duerr-ndt.de.

See "System requirements for

compu ter systems in combination with

Dürr NDT - CR Systems", Order No.

9000-608-02/01 or on the Internet.

1.7 Use of cassettes

Other cassettes are not compatible with the

system and could damage the appliance.

6

9000-608-21/30 2013/10/21

1.9 Guarantee

Content

The guarantee granted herein applies only to

image plates mounted included in image plate

cassettes for scanner family„HD-CR 43 NDT

/ CR 43 NDT“. The guarantee is granted with

regard to damage-free transport of the image

plate in the scanner and the respective image

plate cassette. This means that we guarantee

that the image plate will not show any scratches

or other mechanical damage on the optical side

of the image plate within the Duration as specified below.

Duration

The guarantee is granted for a period of two

years as of the date of purchase or for 25,000

scan cycles, whatever comes first. Proof needs

to be submitted in the form of a copy of the purchase invoice or other appropriate documents

or through the RFID chip included in the image

plate cassette.

Exclusions

Excluded from guarantee are image plate

cassettes of third-party manufacturers, image

plate cassettes which have had their RFID chip

manipulated and image plate cassettes which

have been subjected to temperatures that could

affect the functionality outside the intended

usage or mechanical damage that could affect

functionality or that have their safe functionality

affected in any way. This guarantee also does

not cover cases of scanner defects caused by

inufficient maintenance or other external factors

of any kind. In addition, the guarantee does not

apply in cases of wear and ear or malfunctioning

caused by increased X-ray or gamma radiation.

2. Safety

2.1 General notes on safety

The appliance has been developed and designed in such a way that dangers are effectively

ruled out if operated in accordance with the

intended use. However, we feel it is important to

describe the following safety measures in order

to remove any likelihood of danger.

• When operating this appliance, all local and

national rules and regulations must be observed!

This appliance must not be converted or

altered in any way. Dürr NDT accepts no

liability claims where an appliance has been

converted or altered in any way. In the

interests of safe usage of the appliance, both

operator and owner are responsible for seeing

that all relevant regulations and provisions are

observed.

• Opening an appliance connected to the main

supply results in danger from Class 3B laser

radiation.

• Installation must be carried out by a specialist

authorised by the manufacturer.

• The operator must carefully check the appliance for safety of function and proper working

condition before every use.

• The operator must be trained in the correct

operation of the appliance.

EN

Rights

In case of breach of the above-defined guarantee, the client has the right to demand delivery

of a new image plate cassette. All other rights

are excluded, in particular the right to request

damages.

Applicable law

This guarantee is governed by German law.

2013/10/21 9000-608-21/30

7

2.2 Electrical safety instructions

• The appliance may only be connected to a

correctly installed electrical socket.

• Connection to a multi-socket power strip is

not permitted.

EN

• Before connecting to the electricity supply, the

appliance must be inspected and checked to

ensure that the supply voltage and the supply

frequency correspond to that of the local

electrical supply.

• Before initial use and start-up, the appliance

and all supply lines must be checked for any

signs of damage. Damaged supply lines and

connections must be replaced immediately.

• Never touch persons and open connectors of

the appliance simultaneously.

• When using the appliance, observe all the

relevant electrical safety procedures.

Before opening the device, unplug at the mains and remove all

power mains plug!

8

9000-608-21/30 2013/10/21

3. Warnings and Symbols

In the operating instructions, the following warnings and symbols have been used:

Information including preventa-

tive measures to protect injury to

persons or damage.

3.1 Model identification plate

The model identification plate is located on the

rear side of the scanner. The following designations or signs exist on the model identification

plate:

EN

Special information regarding the eco-

nomical use of the equipment and other

information

Unplug at the mains and remove all

power

Warning Laser

Warning: Dangerous

voltage

Do not push the appliance.

Do not sit on the appliance

Do not enter the appliance.

ON/OFF button

Ready for operation

Data transmission

Fault

FCC-Approval

Caution, observe accompanying docu-

mentation

Warning: Dangerous

voltage

Date of manufacture

Manufacturer

Observe accompanying documentation

Dispose of properly in accordance with

EU Directive (2002/96/EU - WEEE)

IP20 Type of protection

NEMA 1 Type of protection

REF Order number

SN Serial number

CE label without notified body number

ETL-Certification

CONFORMS TO UL STD 61010-1

CERTIFIED TO CAN/CSA STD C22:2

NO 61010-1

Complies with 21 CFR 1040.10 &

IEC 60825-1

Warning: Laser

Notes on laser source

Laser class1

2013/10/21 9000-608-21/30

9

4. Delivery contents

Please compare the completeness of the delivery with the purchase order.

CR 43 NDT 2133-31

EN

CR 43 NDT . . . . . . . . . . . . . . . . . 2133-000-53

Network cable RJ45 (3 m) . . . . . 9000-119-065

Installation and

Operating Instructions . . . . . . . . 9000-608-21/..

Country-specific:

Mains cable (EUR) . . . . . . . . . . . . 9000-118-17

Mains cable (CH) . . . . . . . . . . . . 9000-119-002

Mains cable (DK) . . . . . . . . . . . . 9000-119-041

Mains cable (GB) . . . . . . . . . . . . . 9000-118-59

Mains cable (AUS) . . . . . . . . . . . 9000-119-037

Mains cable (I) . . . . . . . . . . . . . . 9000-119-036

Mains cable (USA / J) . . . . . . . . 9000-119-039

or

HD-CR 43 NDT 2133-41

HD-CR 43 NDT . . . . . . . . . . . . . . 2133-000-54

Network cable RJ45 (3 m) . . . . . 9000-119-065

Installation and

Operating Instructions . . . . . . . . 9000-608-21/..

4.1 Consumables

Protective sleeves for cassettes

18x24 . . . . . . . . . . . . . . . . . . . . PRSH1824108

24x30 . . . . . . . . . . . . . . . . . . . . PRSH2430108

35x43 . . . . . . . . . . . . . . . . . . . . PRSH3543108

IP-Cleaning Wipes (100 pcs.) . . CCB351A0101

Other cleaning and disinfectants can be

obtained from the company Orochemie

(www.orochemie.de) under the following

names:

Disinfectant wipes B 60

Country-specific:

Mains cable (EUR) . . . . . . . . . . . . 9000-118-17

Mains cable (CH) . . . . . . . . . . . . 9000-119-002

Mains cable (DK) . . . . . . . . . . . . 9000-119-041

Mains cable (GB) . . . . . . . . . . . . . 9000-118-59

Mains cable (AUS) . . . . . . . . . . . 9000-119-037

Mains cable (I) . . . . . . . . . . . . . . 9000-119-036

Mains cable (USA / J) . . . . . . . . 9000-119-039

10

9000-608-21/30 2013/10/21

4.2 Special accessories

The parts listed in the following are not included in the scope of delivery.

Please order as required.

Cassette 18x24

Highly sensitive (G CR), normal solvent (H CR) or highly solvent (X HD)

Order number Name Copper thickness

(mm)

2133-010-70 Dürr NDT G CR Cassette 18x24 cm 0,1

2133-010-71 Dürr NDT H CR Cassette 18x24 cm 0,1

2133-010-72 Dürr NDT X CR Cassette 18x24 cm 0,1

Cassettes 24x30

Highly sensitive (G CR), normal solvent (H CR) or highly solvent (X HD)

Order number Name Copper thickness

(mm)

2133-020-70 Dürr NDT G CR Cassette 24x30 cm 0,1

2133-020-71 Dürr NDT H CR Cassette 24x30 cm 0,1

2133-020-72 Dürr NDT X CR Cassette 24x30 cm 0,1

Cassettes 35x43

Highly sensitive (G CR), normal solvent (H CR) or highly solvent (X HD)

Order number Name Copper thickness

(mm)

2133-040-70 Dürr NDT G CR Cassette 35x43 cm 0,1

2133-040-71 Dürr NDT H CR Cassette 35x43 cm 0,1

2133-040-72 Dürr NDT X CR Cassette 35x43 cm 0,1

EN

2013/10/21 9000-608-21/30

11

5. System requirements

For the operation of the scanner, the following

components and requirements are necessary.

EN

5.1 Monitor

The monitor does not form part of the

scope of supply of the scanner.

Only monitors designed for digital x-ray with

superior light intensity and broader contrast

which conform to standard EN 25580 should be

used. Bright room lighting, direct sunlight and

even reflected light will reduce the diagnostic

usefulness of the x-rays.

5.2. Minimum system requirements

See enclosed information sheet,

order number 9000-608-02

6. Technical data

6.1 CR 43 NDT / HD-CR 43 NDT

Electrical Rated connection data

Voltage (Vac) . . . . . . . . . . . . . . . . . . . 100 - 240

Frequency (Hz) . . . . . . . . . . . . . . . . . . . 50 - 60

Current consumption (A) . . . . . . . . . . . 2.5 - 1.0

Output (VA) . . . . . . . . . . . . . . . . . . . . . . . . . 250

Type of protection . . . . . . . . . . . . . . . . . . . IP20

Type of protection . . . . . . . . . . . . . . . . NEMA 1

Protection class . . . . . . . . . . . . . . . . . . . . . . .1

Transient surge voltage category . . . . . . . . . . . II

Data connections

Network . . . . . . . . . . . . . . . . . LAN 100 Base T

Weight

CR 43 NDT /

HD-CR 43 NDT (kg / lbs) . . . ca. 55 / ca. 121.25

Dimensions

(H/D/W in mm) . . . . . . . . . . . 1130 x 440 x 400

(H/D/W in ) . . . . . . . . . . .44.49 x 17.32 x 15.15

Ambient conditions during storage and

transport

Temperature (°C) . . . . . . . . . . . . . . . -20 to +60

Temperature (°F) . . . . . . . . . . . . . . . -4 to +140

Relative humidity (%) . . . . . . . . . . . . . . . 10 - 80

12

Ambient temperature during operation

Temperature (°C) . . . . . . . . . . . . . . . +10 to +35

Temperature (°F) . . . . . . . . . . . . . . . +50 to +95

Relative humidity (%) . . . . . . . . . . . . . . . 20 - 80

Atmospheric pressure for operation and

storage

Appliance in operation (hPa) . . . . . . 750 - 1060

Sea level (m) . . . . . . . . . . . . . . . . . . . . . .<2000

Sea level (m) . . . . . . . . . . . . . . . . . . . <6 561,67

Storage and transport (hPa) . . . . . . 750 - 1060

Sea level (m) . . . . . . . . . . . . . . . . . . . . . . 16000

Sea level (foot) . . . . . . . . . . . . . . . . . 52 493.43

9000-608-21/30 2013/10/21

General values

Laser protection class

external . . . . . . . . . . . . . . . . . . 1 (EN60825-1)

Laser protection class

internal . . . . . . . . . . . . . . . . . . 3b (EN60825-1)

Wavelength λ 635 nm 15mW

EN 60825-1:2006-04 +

A1:2002-07+A2:2001-03

Heat output (W) . . . . . . . . . . . . . . . . . . . . . 250

Sound level

Stand-by (db(A)) . . . . . . . . . . . . . . . approx. 42

During readout (db(A)) . . . . . . . . . . . approx. 45

Conformity Acceptance Procedure

06/95/EC (Low Voltage Directive)

04/108/EC (EMC Directive)

6.2 Cassettes with integrated image plates

Storage and transport

Temperature (°C) . . . . . . . . . . . . . . . . . . . . .<33

Temperature (°F) . . . . . . . . . . . . . . . . . . . <93.2

Relative humidity (%) . . . . . . . . . . . . . . . . . .<80

Use

Temperature (°C) . . . . . . . . . . . . . . . . . . 18 - 45

Temperature (°F) . . . . . . . . . . . . . . . . .59 - 93.2

Relative humidity (%) . . . . . . . . . . . . . . . . . .<80

EN

Pixel size

HD-CR 43 NDT

can be selected in a range from 12.5 μm to 250

μm

Resolution based on the image plate, theoretically up to max. approx. 40 line pairs/mm (LP/

mm)

CR 43 NDT

can be selected in a range from 30 μm to 250

μm

Resolution based on the image plate, theoretically up to max. approx. 15 line pairs/mm (LP/

mm)

No. of cycles

Cycles/cassette . . . . . . . . . . . . . . . . . . 25,000

A warning message is displayed after

the 25,000 cycles. The cassette can

continue to be used.

After 27,500 cycles, the cassette must

be replaced in order to avoid incorrect

diagnoses or defects.

2013/10/21 9000-608-21/30

13

7. Functional layout

EN

7

5

6

8

1 2 3

4

14

10

9

11

9000-608-21/30 2013/10/21

7.1 Function of individual components

1 LED white

The appliance is ready for operation.

2 LED blue

LED out: Communication to PC established

LED lit: Communication to PC interrupted.

3 LED red

LED lit: Error

Device fault: Urgent need for action by the

operator

• Switch off the CR 43 for approx. 10 seconds.

• Restart the CR 43.

• If the CR 43 does not start, inform the service

technician.

For further information refer to the sec-

tion Troubleshooting.

4 ON/OFF button

Press the button to switch ON and OFF.

5 LED yellow

Lights up during processing of a cassette.

6 LED green

Lights up when the cassette slide is ready.

Flashes when the process has been completed.

7 Cassette slide

The cassette is inserted into the appliance via

the cassette slide.

8 Cassette

The cassette contains the image plate and prevents the deletion of image data by foreign light

and protects the image plate from mechanical

damages.

9 Cassette lock

The cassette is locked via the recesses during

removal of the image plate.

10 Transponder

Information such as cassette size and serial number of the cassette is stored on the

transponder and is read out when the cassette

is inserted.

11 Opening:

The integrated image plate is taken out of the

cassette via the cassette opening for scanning.

EN

2013/10/21 9000-608-21/30

15

8. Functional description

CR 43 NDT / HD-CR 43 NDT converts the image data on the image plate into a digital image.

X-rays

EN

The cassette with the integral image plate is

placed into the X-ray appliance and exposed.

Scanning the image data

The CR 43 NDT is switched on by pressing the

ON/OFF button. The scan mode is then activated (via the interfaced PC and the software).

The cassette with the exposed image plate is

then pushed into the cassette slide as far as

possible. The cassette is automatically drawn in

and locked. In the cassette is a transponder that

transmits the identification data of the cassette

to the scanner when the cassette is pushed

in. This ensures that the scanned image is assigned with the correct evaluation. The image

plate is drawn automatically onto the scanner

slide by the transport mechanism. The scanner slide with the image plate moves past the

scanner unit where the image data are scanned.

The status of the image scanning is displayed

in a window on the monitor of the interfaced

PC. After scanning, the image plate passes

through the erasure unit. There the image plate

is erased. The image plate is then pushed back

automatically into the cassette by the transport

mechanism.

Rotating disc

Pentaprism

Reflection

layer

Laser source

Photomultiplier

Parabolic mirror

Image plate

16

9000-608-21/30 2013/10/21

Mounting

Only qualified specialists or persons

trained by Dürr NDT may install,

connect and commission the

appliance.

9. Transport and packaging

• Transport the appliance only in the original

packaging.

• Check that the delivery contents are complete

and check for any signs of transport damage.

• Carefully remove the packaging. Do not use a

knife in order to avoid damaging the surface

and other delicate parts of the appliance.

• Do not expose the CR 43 NDT to severe

vibrations during transport as delicate components in the appliance could be damaged.

10. Carrying the CR 43 NDT

Carry the appliance only at the

transport aids (13) installed at the

13

factory.

If the appliance is carried in any

other way (e.g. on the base, cover,

cassette slide), there is a risk of

injury or delicate parts could be

damaged.

EN

10

1

2013/10/21 9000-608-21/30

17

11. Set-up

11.1 Installation room

• Install the CR 43 NDT only in a closed, dry

and well ventilated room.

EN

• The room temperature must not drop below +

10 °C / 50 °F in winter or exceed + 35 °C / 95

°F in summer.

Danger of short circuit due to build

up of condensation.

The system can only be put into

operation once the appliance has

warmed up to room temperature

and it is dry.

• Installation in a purpose-built room, e.g. in a

boiler room or in a wet room is not permitted.

• Do not expose the appliance to direct sunlight, e.g. near windows. The ambient light

must be reduced if necessary. The maximum

light intensity is 1500 lux.

• The device is designed for use in laboratory,

test and measurement areas. There must be

no source of interference in the room for setup (e.g. strong magnetic field). Interference

fields may cause malfunctions in the appliance.

• This appliance is not equipped with its own

main power switch. Therefore, the appliance

must be set up in such a way that the socket

outlet is easily accessible in case of a possible

fault and that this is situated within the maximum cable length of 3 m / 118.11 inch.

• Install the appliance is such a way that it does

not cause interference in other appliances

during the scanning process of the and the

RFID system of the CR 43.

• Set up the appliance so that it is not in the

path of the X-rays.

11.2 Set-up alternatives

In order to avoid errors during scanning

of the image data, always install the

appliance horizontally and on a solid

surface where it is not exposed to vibrations.

Table set-up

CR 43 can be set up as a tabletop appliance.

Observe the maximum load-bearing

strength of the table. The table must

have an adequate load-bearing

strength.

The table and appliance must be

set up so that there is no danger of

tipping over.

Mobile use

The appliance can also be installed in a motor

vehicle for mobile use.

The appliance must thereby be

• transported with low vibration level (damped decoupled from the vehicle).

• safely installed in the vehicle (withsuitable

mounting kit)

Level adjustment

The front foot (14) with knurled surface is

adjustable.

See point 13.2 Aligning the appliance.

18

2

9000-608-21/30 2013/10/21

14

12. Electrical Connection

Before start-up, check the mains voltage

against the voltage indicated on the model

identification plate.

The connection ports are located in the recess

on the rear of the appliance.

• Insert the mains cable supplied into the mains

jack on the appliance.

• Plug the mains cable into the mains supply

socket.

EN

2013/10/21 9000-608-21/30

19

EN

20

18

3

4

5

14

This appliance is not equipped with its

own main power switch. Therefore, the

appliance must be set up in such a way

that the socket outlet is easily accessible in case of a possible fault and that

this is situated within the maximum

cable length of 3 m / 118.11 inch.

13. Initial use and start-up

13.1 Remove the transport aids

• When the appliance has been moved to its

intended location, remove the transport aids

by tilting the appliance slightly.

The transport aids should fall out on

their own when the appliance is tilted. If

this is not the case, pull briefly downwards on the cord.

13.2 Setting up the appliance

The front foot (14) of the appliance is adjustable.

5

The adjustment range is ±3mm / 0.12 inch.

• Set up the appliance at its intended location.

4

• Carefully tilt the appliance slightly to the rear.

3

Adjust the foot, if necessary, until the appliance is standing firmly on all four feet.

2

13.3 Installation and configuration

1

Perform the installation and configura-

tion according to the provided operating

instructions "Installation and Configuration CR 43" Order No. 9000-608-61/.. .

Connections and displays

1 Mains connection:

For connection of the appliance to the mains

power supply.

2 Reset button:

By pressing and holding the Reset button for

15 - 20 seconds while switching on, all network settings for the appliance are set back to

factory settings.

3 Status LEDs:

Display of the device status during the service

4 AUX port:

Programming and test interface. For service

purposes only.

5 Network port:

For connection of the appliance to the network.

9000-608-21/30 2013/10/21

Use

14. Cassettes

EN

The scanner may only be operated

in combination with cassettes from

Dürr NDT. Other cassettes are not

compatible with the appliance and

could damage the appliance.

Cassettes

• protect the image plate from light, soiling and

mechanical damage.

6

7

• prevent the erasure of image data on the image plate.

• are positioned at the cassette slide of the appliance.

• Are designed for approx. 25,000 cycles. After

this time the cassettes should be replaced in

order to avoid incorrect diagnoses or defects.

• can be briefly exposed to higher surface

temperatures as the surface is made of aluminium.

14.1 Identification of the cassettes

General identification: The size, order number

and identification number are shown on a label

on the narrow side.

Active side: The active side is not labelled.

Passive side: The passive side is marked

"BACK SIDE".

2013/10/21 9000-608-21/30

14.2 Handling of cassettes

Inspect cassettes for visible damage. Damaged cassettes (e.g. visible scratches that could

impair the diagnosis) must be replaced.

• Do not bend or expose to extreme pressure.

• Do not scratch or soil.

• Do not immerse cassettes in liquids and do

not spray with liquids. We recommend the use

of protective sleeves, Order No. see point 4.1

21

14.3 Storage of cassettes

• Do not store in hot or moist conditions.

• If the cassette is stored for longer than 24

hours, it must be erased again before the next

X-ray exposure.

EN

• If stored in the X-ray room, the cassettes must

be protected against exposure to X-ray radiation.

15. X-ray

15.1 Preparation for X-raying

Image plates are pre-exposed by natu-

ral X-ray radiation and scattered X-ray

radiation.

When the cassette is used for the first time or

after storage for more than 24 hours, the image

plate must be erased again before use. See also

point 16.5 Erasing the image data.

15.2 X-ray exposure

• Position the cassette in the normal way. The

inactive side (marked with "BACK SIDE") must

face away from the X-rays.

Liquids can destroy the image plate

on the inside of the cassette and the

cassette can become contaminated.

Protect cassettes against fluids.

We recommend using protective

glasses (see special accessories).

• Taking the X-ray exposure.

The image data must be read within

30 minutes after the creation.

15.3 Preparation for reading out the

image data

Soiling of the CR 43 NDT:

The cassette must be clean before

reading out the image data. Otherwise there can be a loss of the image data, soiling of the image plate

and the inside of the scanner.

22

• Remove any large debris with a damp cloth.

• Oil or grease should be removed with

a non-aggressive disinfection wipe

(e.g. Orochemie B60).

9000-608-21/30 2013/10/21

10

11

15.4 Reading out the image data

Description of the main control panel

ON/OFF button

EN

Ready for operation

Data transmission

Fault

• Switch on the CR 43 at the ON/OFF button.

• Start the computer.

• Start the software.

The sequence of the read-out pro-

cedure can differ, depending on the

software used. See also the manual of

the software used.

• Select the object type and recording mode.

• Activate the CR 43 in the software.

Observe the LEDs at the cassette slide

of the scanner.

Green LED on the cassette slide is lit:

• Place the cassette into the cassette slide and

push into the appliance straight.

The cassette is automatically locked and the

image plate drawn in for the scanning process. The cassette then moves back slightly,

but remains locked.

This movement closes the light protec-

tion flaps.

2013/10/21 9000-608-21/30

Yellow LED on the cassette slide is lit:

Cassette drawn in and locked. Read-out procedure running.

The appliance must not be exposed

to vibrations during the read-out

procedure.

Green LED on the cassette slide flashes:

• Remove cassette from the cassette slide.

23

Description of the LED on the cassette slide

Cassette slide

Appliance not ready to receive the cassette

EN

Cassette slide enabled, cassette can be pushed in.

Cassette drawn in and locked.

Remove cassette.

Cassette was inserted incorrectly (RFID was not recognised)

Cassette was ejected again or slide refuses to accept the cassette

(no matching order)

or ON Off Flashing

24

9000-608-21/30 2013/10/21

15.5 Erasing the image data

After scanning, the image plate automatically

runs through the erasure unit. There, the image data on the image plate are automatically

erased. The image plate is then transported

back into the cassette.

To erase again:

The image plate in the cassette has to be

erased again if:

• The cassette is stored for longer than 24

hours.

• The image data on the image plate was not

deleted by a fault in the CR 43 NDT.

Proceed as follows:

• Select a mode with low resolution in the software used.

• Click "Scan".

Observe the LEDs on the cassette slide.

Green LED lit:

• Place the cassette into the cassette slide and

push into the appliance straight.

The cassette is automatically locked and the

image plate drawn in for the scanning process.

EN

Yellow LED on the cassette slide is lit:

Cassette drawn in and locked. Erasure process

running.

The appliance must not be exposed

to vibrations during the erasure procedure.

Green LED on the cassette slide flashes:

• Remove cassette from the cassette slide.

2013/10/21 9000-608-21/30

25

EN

12

16. Cleaning

Only cleaning agents authorised by

Dürr NDT must be used. Other cleaning

preparations can damage the device

and accessories.

16.1 CR 43 NDT / HD-CR 43 NDT

Damage to the CR 43 NDT:

Do not spray the appliance with

cleaning preparation!

No liquid must get inside the appliance. This might damage the

appliance.

• Remove any large debris with a damp cloth.

• Oil or grease should be removed with

a non-aggressive disinfection wipe

(e.g. Orochemie B60).

See instructions for use of the

disinfectant and cleaning agent.

16.2. Cassettes

Damage to the cassettes:

Do not spray the cassettes with

a cleaning preparation! The image plate in the cassette will be

destroyed by liquids. Clean only by

wiping.

Visible soiling must be removed

before further use of the cassettes.

26

13

• Remove coarse soiling of the surface with a

damp cloth.

• Oil or grease should be removed with

a non-aggressive disinfection wipe

(e.g. Orochemie B60).

• Before using again, the cassette must be

completely dried.

9000-608-21/30 2013/10/21

17. Maintenance

• Maintenance must be carried out by a

specialist approved by the manufacturer.

Maintenance interval

The appliance must be serviced at regular intervals, but at least once a year.

The scope of the maintenance depends on the

number of operating hours and the degree of

soiling.

EN

2013/10/21 9000-608-21/30

27

Troubleshooting

EN

18. Tips for Operators and Technicians

Any repairs above and beyond routine maintenance must be carried out by suitably qualified

personnel or one of our service technicians.

Before starting repairs or opening the appliance unplug at the mains and remove all

power, remove the mains plug from the plug socket.

18.1 Unit fault

Problem Possible cause Solution

1. CR 43 does not

switch on

2. CR 43 switches

off after a short

period

3. Status or operating LED does not

light up

4. Loud noises during

operation after

switching on

5. Software does not

recognise the CR

43

6. Appliance does

not react

• No supply voltage • Check the mains cable and all

• Switch-on button defective • Inform your service technician

• Mains cable not properly plugged in• Check the mains cable and all

• Hardware defective • Inform your service technician

• Mains supply voltage too low • Check the supply voltage

• LED defective • Inform your service technician

• If the noises persist longer

than 30 seconds, then the

radiation deflector is defective

• CR 43 is not switched on • Switch on CR 43

• Connecting cable between CR43

and network loose

• PC does not recognise connection to CR 43

• Hardware fault • Inform your service technician

• CR 43 has not yet completed

boot procedure

• CR 43 is blocked by the firewall. • Enable the ports for the appliance

connections

• Check the main fuse box to building

connections

• Inform your service technician

• Check the network cable

• Driver not installed or inactive

• Check the network cable

• Check IP addresses

• The appliance takes approx. 2030 seconds to boot after switching on.

Repeat the procedure again after

this time.

in the firewall.

28

9000-608-21/30 2013/10/21

Problem Possible cause Solution

7. Cassette is not

drawn into the

cassette slide

8. X-ray exposure

does not appear

on the screen after

the scanning

9. X-ray too dark/

light

10. X-ray unclear • X-ray dose too low • Check the X-ray parameters

11. Ghosts and shad-

ows on the X-ray

exposure

12. CR 43 does not

appear in the

selection list in

CRConfig

13. Image appears

shadowy on the

scan window

Software cannot

combine data to

make a complete

image

14. When starting

the X-ray module

in D-Tect, a fault

message appears

• Cassette not properly engaged • Position the cassette correctly

• Cassette not pushed in correctly • Position the cassette correctly

• CR 43 is not ready • Activate CR 43

• Image data on the image plate of

the cassette were erased, e.g. by

natural or scattered X-ray radiation

• Problem with the hardware • Inform your service technician

• X-ray device is faulty • Inform your service technician

• No image information on the image plate of the cassette

• Wrong brightness/contrast setting

in the software

• Image data on the image plate in

the cassette were not sufficiently

erased

• Appliance is connected behind a

network router.

• The X-ray dosis on the image

plate was insufficient

• The amplification is set too low

(HV value)

• The selected scan mode is not

suitable

• The setting for the threshold value

is too high

• CR 43 is conflicting with another

device

• Image data on the image plate

must be read out as quickly as

possible after removal

• Expose the image plate

• Set the brightness of the X-ray

image with the software

• Erase the image plate of the cassette again

• Configure the IP address at the

CR 43 without an intermediate

network router.

• Connect the network router again.

• Enter the IP address manually in

CRConfig and register the appliance.

• Increase the X-ray dose

• Increase amplification (HV value)

• Select suitable scan mode

• Reduce setting

• In "CRConfig", set the CR 43 or

the like to "Demo without Scanner".

EN

2013/10/21 9000-608-21/30

29

Problem Possible cause Solution

15. X-ray exposure

has stripes on

image

EN

16. Warning message: "Too much

ambient light"

17. Pale stripes in

scanning window

18. Narrow images

with light and

dark streaks appear in addition

to the correct

image

19. Blue LED out • No connection between CR 43

20. Red LED lit • Device fault:

• Image plate in the cassette was

exposed by natural or scattered

X-ray radiation

• Image plate in the cassette soiled

or scratched

• CR 43 exposed to too much light • Darken the room

• Too much stray light entered during scanning

• Ambient light entered during

scanning

and PC

Urgent need for action by the

operator

• Only use the image plate within

24 hours of data erasure.

• Inform your service technician

• Turn the CR 43 so that the light

does not fall directly onto the

input unit

• Darken the room

• Turn the CR 43 so that the light

does not fall directly onto the

input unit

• Darken the room

• Turn the CR 43 so that the light

does not fall directly onto the

input unit

• Activate the CR 43 via the software

• Switch off the CR 43 for approx.

10 seconds.

• Restart the CR 43.

• If the CR 43 does not start, inform

the service technician.

30

9000-608-21/30 2013/10/21

18.2 Error messages

Problem Possible cause Solution

Fault code -11 Unit is in illegal condition - in

combination with an initialisation

problem

Fault code -1006 RFID Fault

EN

Fault code -1008 Internal communication fault to

sub-assembly

Fault code -1010 Temperature of unit too high • Allow unit to cool down.

Fault code -1020 Non-permissible action • Switch the appliance off and on.

Fault code -1022 Subassembly not initialised • Fault in software, if necessary

Fault code -1026 Scan mode is faulty • Choose alternative scan mode

Fault code -1100 Scanning process has exceeded

allotted time allowance

Fault code -1104 Erasure unit fault • Inform the service technician.

Fault code -1108 Motor blocks on ejecting cassette

Fault code -1117 Position error on insertion or

transport, internal faulty setting

of unit

Fault code -1120 As a result of -1160, motor

blocks on image plate ejection

Fault code -1122 Unit cannot carry out self-adjust • Check self-adjust.

Fault code -1150 Temperature of unit too high • Allow unit to cool down.

Fault code -1153 Subassembly fault • Switch the appliance off and on.

Fault code -1154 Internal data communication fault • Switch the appliance off and on.

Fault code -1160 Final radiation deflector rotation

speed not achieved

• Switch the appliance off and on.

• Check all sub-assemblies.

• Inform the service technician.

up-date the software.

• Inform the service technician.

• Correct scan mode settings

• Inform the service technician.

• Check belt drive.

• Check for blockage, remove

image plate from unit.

• Replace erasure unit.

• Switch the appliance off and on.

• Check insertion mechanism.

• Check image plate detector.

• Inform the service technician.

• Replace the deflector subassembly if problem regularly

occurs.

2013/10/21 9000-608-21/30

31

Problem Possible cause Solution

Fault code -1170 SOL-Sensor Timeout

Fault code -1171 Fault at laser • Send appliance for repair.

EN

Fault code -1172 Deflector assembly or the SOL-

Fault code -2002 Occurs when there are problems

Fault code -2395 Occurs when there are problems

Fault code -2490 Network problem /

Fault code -3000 Internal faulty setting of unit • Move transport slide to upper

Fault code -3001 Motor fault

Fault code -3002 Sensor fault

Fault code -3003 Cassette flap does not open fully • Switch the appliance off and on.

Fault code -3004 Shaft subassembly does not

Fault code -3005 Arm subassembly does not func-

Fault code -3008 Invalid cassette identification • Switch the appliance off and on.

Fault code -3009 No cassette detected, • Switch the appliance off and on.

Fault code -78 Memory card full. • Transmit image data to com-

Fault code -10000 Unit exposed to too much light • Darken room.

Fault code -10017 Unit switches off • Wait until unit has shut down

Firmware not running Firmware update not carried out • Switch the appliance off and on.

Fault at laser or SOL-sensor

sensor defect

with network

with network

faulty connection

Motor has automatically switched

itself off

Arm sensor has not switched on

(potentiometer must be set)

function correctly

Fault with cassette insertion - oc-

curs in combination with network

problems, image not correctly

scanned etc.

tion correctly

Fault in internal communication • Switch the appliance off and on.

• Switch the appliance off and on.

• Inform the service technician.

• Switch the appliance off and on.

• Inform the service technician.

• Replace the deflector assembly.

• See fault code -2490

• See fault code -2490

• Check the network.

position manually.

• Switch the appliance off and on.

• Switch the appliance off and on.

• Switch the appliance off and on.

• Switch the appliance off and on.

puter.

• Insert empty memory card.

• Turn the unit so that no direct

light falls on the entry slot.

completely

32

9000-608-21/30 2013/10/21

EN

34

9000-608-21/30 2013/10/21

EN

2013/10/21 9000-608-21/30

35

DÜRR NDT GmbH & Co. KG

Höpfigheimer Straße 22 · 74321 Bietigheim-Bissingen, Germany

Phone: +49 7142 99381-0 · Fax: +49 7142 99381-299

info@duerr-ndt.de · www.duerr-ndt.de

Loading...

Loading...