Duerkopp Adler N291 Service Manual

Contents: Page:

General safety instructions

Service manual N291

1. Set of gauges and handwheel positions

1.1 Parts of the set of gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Adjustments in the different handwheel positions . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Sewing machine

2.1 Adjustment disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Stitch regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Feed dog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Needle bar frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Hook, needle bar, hook guard and thread sluice . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 Dials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.7 Sewing feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.8 Sewing foot lift and thread tension release . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.9 Thread regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.10 Check spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.11 Oil lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.12 Speed limitation with greater sewing foot strokes and stitch lengths . . . . . . . . . . . . . 33

3. Thread trimmer

3.1 Function sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.2 Activation timing of the bobbin brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.3 Braking effect of the bobbin brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4 Position of the cam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5 Position of the cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.6 Height of the thread catcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.7 Thread catcher range of motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.8 Pressure of the counter knife on the thread catcher . . . . . . . . . . . . . . . . . . . . . . 36

3.9 Position of the bobbin thread clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.10 Position of the released thread tension assembly . . . . . . . . . . . . . . . . . . . . . . . 36

3.11 Pressure of the thread pre-tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4. Synchronizer

4.1 Reference position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.2 1st and 2nd position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.3 Stop position after "needle re-positioning" from the 2nd position . . . . . . . . . . . . . . . 39

5. Changing the elements

5.1 Changing the hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2 Changing the PC-board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1. Set of gauges and handwheel positions

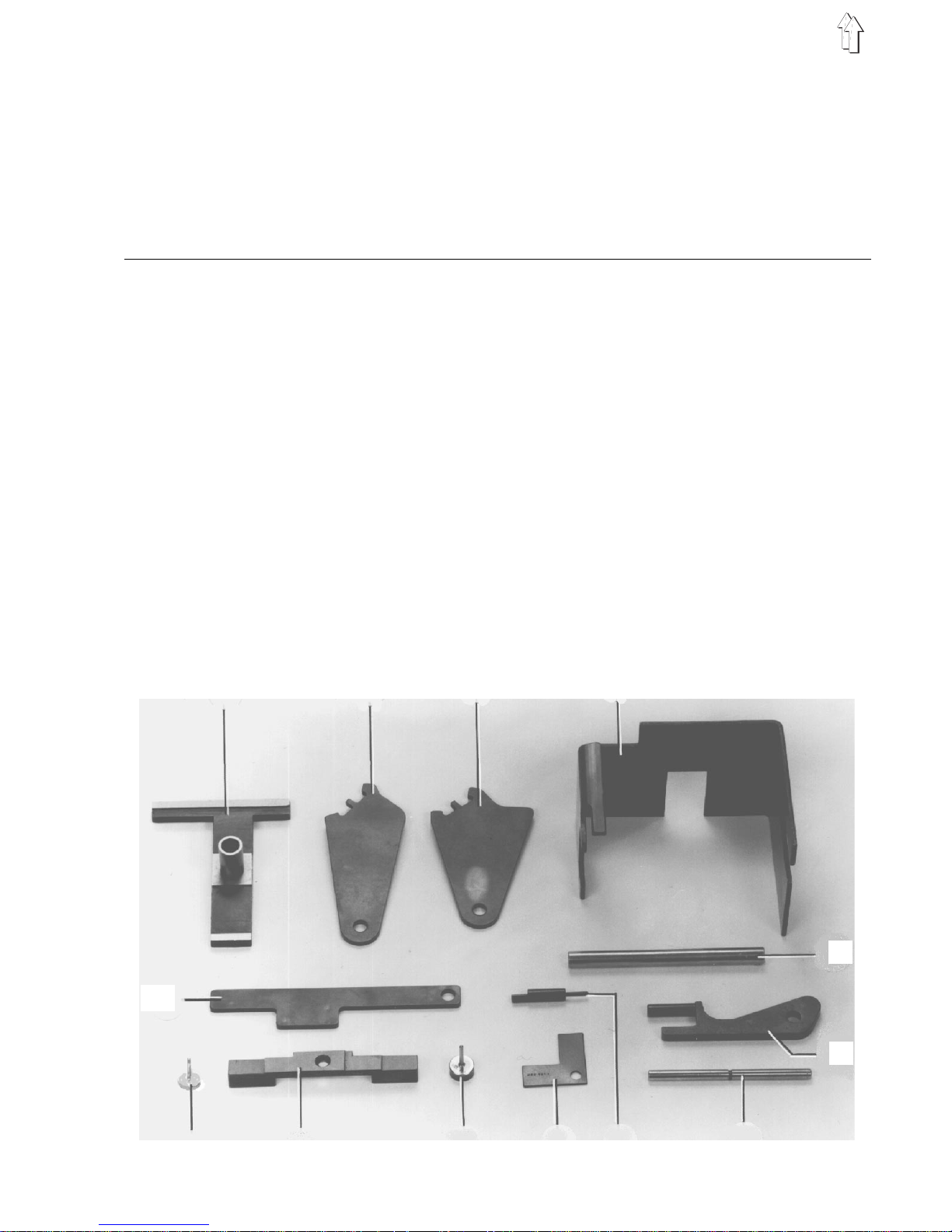

1.1 Parts of the set of gauges

The pin 7 of the 13-part set of gauges (parts no. 491 79991) is also incorporated in the accessories of

every machine. It is thus possible to lock the handwheel in the positions A, B, C, D, E and F, even without

the set of gauges.

Gauge Parts no. Adjustment

Gauge 1 244 1001 – Height of the hook shaft

Gauge 2 491 79995 – Timing of the sewing foot stroke motion

Gauge 3 491 79994 – Timing of the sewing foot feed travel

Gauge 4 with 491 80001

Pin 5 742 52082

– 0-position of the "bottom" stitch regulator

Gauge 6 491 79997

– 0-position of the "top" stitch regulator

Pin 7 791 8110

– Locking the ha nd wh ee l in t he de s i red po s iti o ns

– Equalizing the foot strokes

– Position of the adjustment disk and further

elements

Gauge 8 244 1014 – Distance between the hook and needle

Gauge 9 241 1011 – Distance between the thread catcher and

thread trimmer

Pin 10 244 1009

– Needle bar height for needle system 2134-35

DU KK

Measuring

bridge 11 212 4942

– Needle bar he i gh t

– Feed dog height

Pin 12 244 1008

– Needle bar height for needle system 134 KK

Gauge 13 491 79996

– Foot stroke adjustment range

1 2 3 4

5

6

12 11 10 9 8 7

13

5

1.2 Adjustments in the different handwheel positions

For some adjustments the needle bar or take-up lever must be in a defined position.

This position is marked by letters on the handwheel 3 and can be locked as follows:

– Turn the handwheel i nt o t he position def i ne d f or the adjustment .

– Slide the ti m i ng pi n 1 into the hole 2 of the housing.

– Turn the handwheel s l i gh tl y forward and back ward until the timing pin can be sl i d a l l th e w ay i n to th e

respective slot of the adjustment disk 4.

Only with po si ti o n F t he pi n mu s t re s t a ga i ns t th e r e spective side of th e c u to ut .

Slot Position Adjustment

A Needle bar 2 mm behind the

lower dead poi nt

– Position of th e a dj u s tm en t d i s k on th e arm shaft

– Loop stroke

– Needle bar h ei g ht ( wi t ho ut ga ug e)

– Distance between the hook and needle

B Needle bar ne ar ing its upper

dead point

– Timing of the feed ing foot feed travel (w i th

gauge)

C Take-up lever nearing its upper

dead point

– Position of th e t hr e ad tri m me r c am

D Take-up lever nearing its lower

dead point

– Timing of the feeding foot stroke motion

– Setting the reference position of the

synchronizer

E Needle bar at th e l o we r de ad

point

– Distance between the feeding foot bar and

sewing foot bar

– Checking the timing of the feeding foot feed

travel

– Needle bar height (with gauge)

– Timing of the feed do g f ee d t r ave l

F Shortly behind the loop stroke

– Synchronizer (1st position)

6

1 2 3

1

4

D

F

A

E

B

C

G

7

2. Sewing machine

Turn off main switch!

Otherwise there is danger of injury!

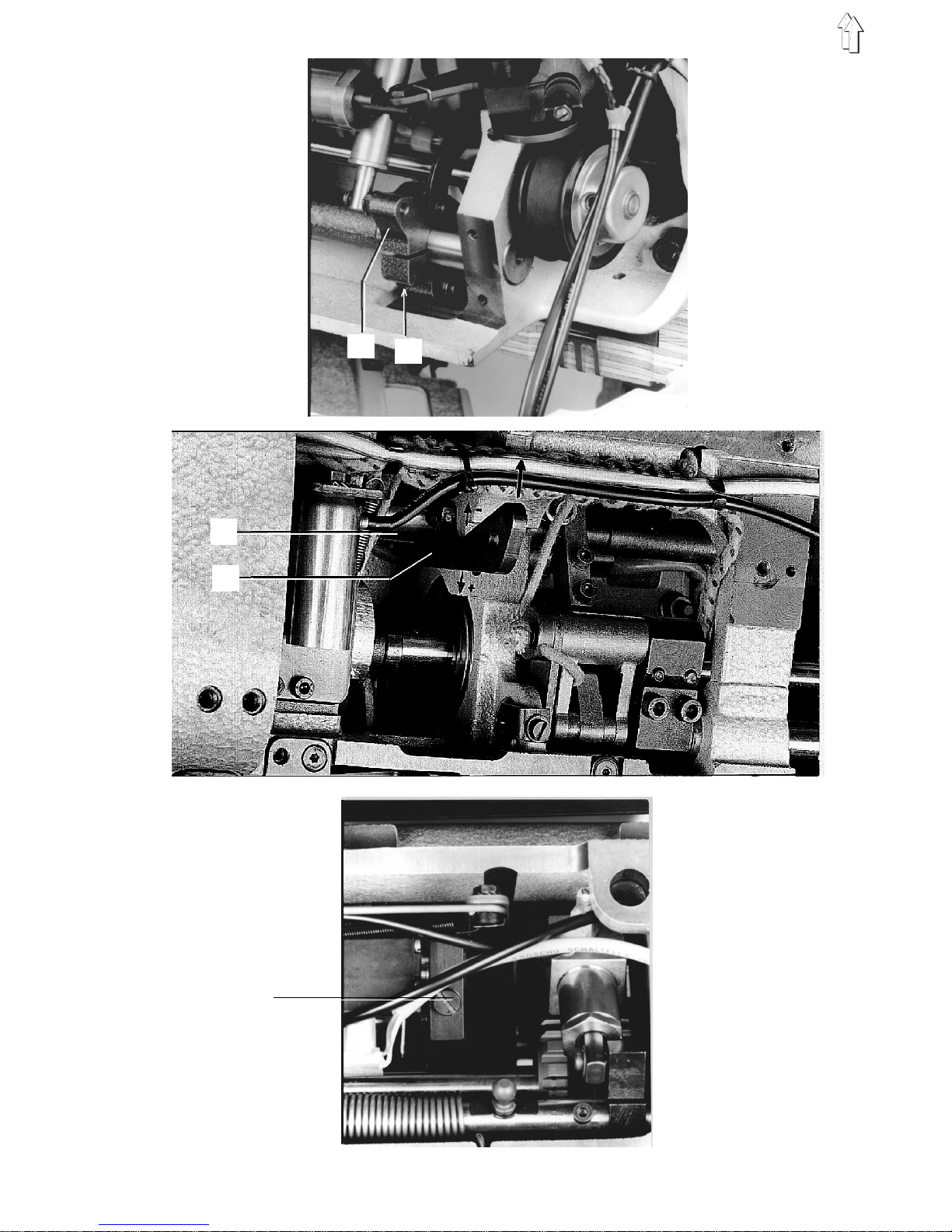

2.1 Adjustment disk

Explanati on:

The positions locked with the timing pin 1 are

only correct, when the adjustment disk 4 has

been adjusted ac c o rdi n g t o t he rule.

Rule:

The groove in the arm shaft crank 3 and the

lowest slot i n t he ad j us t me nt di s k 4 mu s t b e

aligned.

Check:

– Slide the pi n 2 (5 mm Ø) of the set of gauges

through the hole of the housing all the way into

the groove of the arm shaft crank 3.

– Push the ti m i ng pi n 1 t hrough the hole of the

housing right ag ai n s t t he ad j us t me nt di s k .

When the pin is located in the deepest slot of

the adjustment disk, the adjustment disk is

positioned correctly. In this case, the ring

groove in the timing pin is no longer visible.

Correction:

– Move the ti mi n g b el t 5 o n t he up per timing

pulley 6 to the left until its 2 screws are

accessible.

To do this, use a round pin and turn the

handwheel.

– Loosen the t wo s c rews at the timin g p ul le y 6.

– Slide the pi n 2 (5 mm Ø ) th r ou gh th e h ole al l

the way into th e g r oo ve o f the arm shaft c ran k 3.

– Slide the ti m ing pi n 1 t hr o ug h t he ho l e in th e

housing.

– Turn the timing pulley until the timing pin 1 can

be slid into the deepest slot of the adjustment

disk 4.

– Tighten both scr ew s at th e t i mi n g p ul l e y.

At the same time shift the timing pulley to the

right against th e timing pin 1.

– Remove both pi n s .

– Turn the handwheel un ti l t he ti m i ng be l t i s

again centred on the timing pulley.

2

1

8

1

4

D

F

A

E

B

C

G

2

3

6 5

9

2.2 Stitch regulator

Turn off main switch!

Otherwise there is danger of injury!

2.2.1 Stitch regula tor 0-position for the bottom

feed

Rule:

The feed dog sh ou l d p erf or m th e m i ni m um

possible feed tra v el , wh en th e re s pe cti v e dia l

has been set at th e s t i tc h l en gt h " 0 " .

Check:

– Set the stitch length "0".

– Lock the sewing feet in their lifted position.

– Turn the handwheel.

Pre-adjustment with gauge:

– Slide the ga ug e 1 on to th e c o ul i s se s ha ft 2 and

axle 4.

– Insert the pin of the gauge 3 (8 mm) into the

hole of the coulisse shaft 2.

– Loosen the screw 5 at the block 6.

– Turn the coulisse shaft until the pin of the

gauge rests against the edge o f t he gauge.

– Tighten the scre w 5 .

– Check the adjustment, and if necessary correct.

Correction:

– Loosen the screw 5.

– Insert a pin into the hole of the coulisse shaft 2.

– Turn the coulisse shaft accordingly using the

pin.

2.2.2 Stitch regula tor 0-position of the top feed

Rule:

The needle and the feeding foot should perform

the minimum pos s ibl e fe ed tr a vel , wh en th e

respective dial has been set at the stitch length

"0".

Check:

– Set the stitch length "0".

– Turn the handwheel.

Pre-adjustment with gauge:

– Loosen the screw 9.

– Insert the gauge 8 into the hole of the coulisse

shaft 7 and push it against the flat at the arm.

– Tighten the scre w 9 .

Correction:

– Loosen the screw 9.

– Insert the pin into the hole of the coulisse

shaft 7.

– To increase the feed travel:

turn the coulisse shaft 7 towards (+).

– To decrease the fe ed travel:

turn the coulisse shaft 7 towards (–).

– Tighten the scre w.

4 3 2 1

10

6

5

7

8

9

11

2.3 Feed dog

Turn off main switch!

Otherwise there is danger of injury!

2.3.1 Feed dog position in the throat plate

cutout

Prerequisi te:

Correct distance between the feeding foot bar

and cloth presser bar. (See 2.4.2).

Rule:

– In line of feed motion:

The feed dog sh ou l d b e a l igned such that i n

line of feed motion the needle enters at the

centre of the needle hole.

–

Across the line of feed motion:

The feed dog sh ou l d b e centred in the th r oa t

plate cutout.

Correction i n l i ne of fe ed motion:

Loosen the sc rew at the feed lev er 4 an d

change the position of the feed dog holder 2

accordingly.

Correction across the li ne of fe ed mo ti o n:

– In the case of small deviations:

Change the posit i on of th e f ee d d og on i ts

holder 2 accordingly.

– In the case of greater deviations:

Loosen the sc rews at the stroke l ev e r 1 and

feed lever 4.

Change the posi t i on of th e feed dog holder 2

accordingly.

2.3.2 Feed dog height

Rule:

At its highest point of travel the feed dog

should extend above the throat plate by 0.5 mm.

In this positi o n t he feed dog shoul d a l s o b e

parallel to th e throat plate.

Check:

– Lock the sewing feet in their lifted position.

– Turn the handwheel un ti l t he fe ed dog has

reached its highest point of travel.

– Check whet he r th e h ei g ht is c orr e ct u s i ng th e

gauge 5 or a feel e r gauge.

Correction:

– Loosen the screw at the stroke lever 1 and

change the height of the feed dog holder 2

accordingly.

– Slightl y l oo s en th e s c re w s a t the feed dog and

turn the supporting screw 3 accordingly.

1

2

3

4

5

12

Turn off main switch!

Otherwise there is danger of injury!

2.3.3 Timing of the feed dog feed travel

Rule:

When the stitch regulator lever is actuated, the

needle bar must not move under the following

conditions:

–

Maximum stitch length has been set.

–

Handwheel lock e d in po s i tio n E ( n ee dle at th e

bottom of its stroke)

Adjustment w i th ga uge:

– Loosen the screws at the eccentric 2.

– Slide the gauge 1 onto the coulisse shaft and

axle.

– Lock the handwheel in position E.

– Turn the eccentric until the gauge can

submerge in i ts g r oo v e.

– Slide the eccentric to the right against the

bearing.

– Tighten the screws at the eccentric.

Correction:

– Loosen the screws at the eccentric 2 and turn

the eccentric accordingly.

The eccentric is positioned correctly, when not

only the rule is fulfilled, but also the slot of the

eccentric points downward. If this is not the

case, turn the eccentric by 180°.

– Move the ecc e nt ri c to th e r ight against the

bearing.

– Tighten the screws at the eccentric.

2.3.4 Timing of the feed dog stroke motion

Rule:

When the needle is at the bottom of its stroke

the feed dog sh ou l d h av e r ea c he d its highest

point of travel.

Check:

– Lock the sewin g f ee t i n th ei r l i f te d p osi t i on .

– Set the stitch length "0".

– Turn the handwheel.

Pre-adjustment:

When the feed eccentric 2 is adjusted correctly,

proceed as fol l o ws f or t he pre-adjustment :

– Loosen the screws at the stroke eccentric 3

and turn it on the shaft until the 1st screw (seen

in direction of rotation) of the stroke eccentric

is aligned with the 2nd screw of the feed

eccentric.

– Move the stroke eccentric to the right until it

touches the oil leather strip 4.

– Tighten the screws.

Correction:

Loosen the screws and turn the stroke

eccentric 3 on the shaft accordingly.

1 2

3

4

13

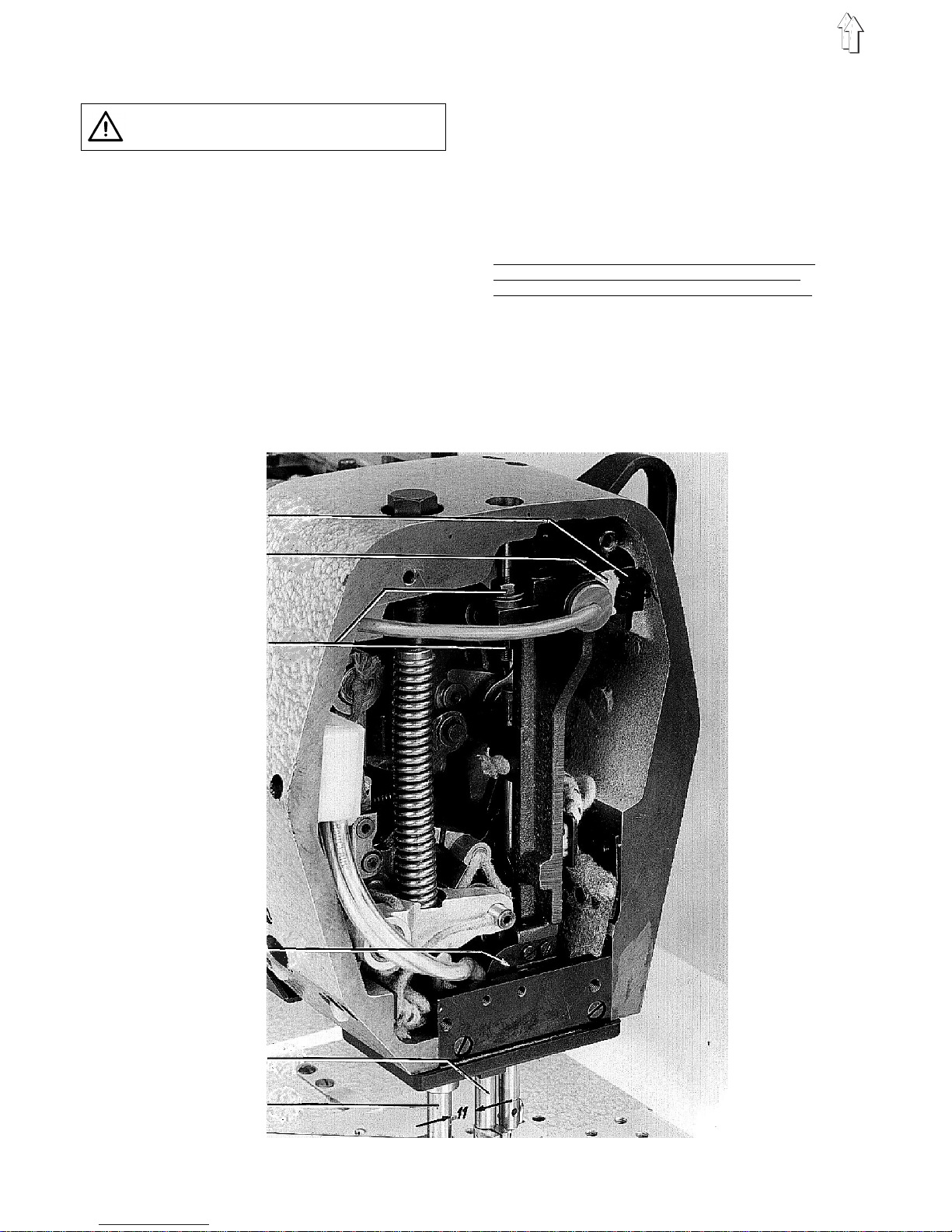

2.4 Needle bar frame

Turn off main switch!

Otherwise there is danger of injury!

2.4.1 General information

– The stop screw 5 that is sealed with yellow

paint and is secured with glue to prevent i t f rom

turning must rest against the inside of the arm

casting.

– The left gu i de bo l t 3 (w ithin the frame) and the

right guide bolt 7 (within the arm) were adjusted

at the factory su c h t ha t t he ne ed l e b ar frame

moves smooth ly an d without cleara nc e .

Therefore, the position of the two guide bolts

must not be changed.

– Using the nuts 4 the frame holder 6 must be

adjusted such that it is parallel with the bottom

edge of the arm h ea d.

2.4.2 Distance between the feeding foot bar

and cloth presser bar

Rule:

The distance between the bars 1 and 2 should

be 11 mm, when the handwheel is loc ke d i n

position E (n ee dl e at th e b ottom of its str o ke) .

Correction:

– Lock the hand wh ee l i n p osi t i on E.

– Remove the p l ug 9 a nd loosen the scr e ws

behind.

– Turn the eccentric 8 accordingly.

6

5

4

3

2

1

14

Loading...

Loading...