Page 1

DACeco M-TYPE

operating manual

0791 100632 EN

Dürkopp Adler AG, PO Box 17 03 51, D-33703 Bielefeld, Potsdamerstr. 190, D-33719 Bielefeld

Phone +49 (0) 521 9 25 00, Fax +49 (0) 521 9 25 24 35, www.duerkopp-adler.com

Ausgabe/ Edition : August 2013 Rev. Index : V 1.0.0

Page 2

DACeco M-TYPE

© 2013 Dürkopp Adler AG

All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic, electronic, or

mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without the

written permission of the publisher.

Products that are referred to in this document may be either trademarks and/or registered trademarks of the

respective owners. The publisher and the author make no claim to these trademarks.

While every precaution has been taken in the preparation of this document, the publisher and the author assume no

responsibility for errors or omissions, or for damages resulting from the use of information contained in this

document or from the use of programs and source code that may accompany it. In no event shall the publisher and

the author be liable for any loss of profit or any other commercial damage caused or alleged to have been caused

directly or indirectly by this document.

Printed: August 2013 in Bielefeld, Germany

Doc Version: 1.0.0

Page 3

Inhaltsverzeichnis

Table of contents

3.1

3.2

3.3

4.1

4.2

5.1

5.2

5.3

5.4

7.1

7.2

7.2.1

7.2.2

7.3

7.4

7.5

Important safety instructions

Scope of Delivery

User settings

Technical information

Assembly instructions

Commissioning

Setting the basic functions

Set soft start speed

Setting the maximum speed

Error, warning and information messages

41

62

73

7Soft start

8Stop position of the needle

8Reducing the speed

94

9Technical specifications

10Intended use

115

11Fitting the reference value transmitter

11Power supply (m ains connection)

13Electromagnetic compatibility (EMC)

14Wiring diagram

166

177

18Number of stitches during soft start

18Speed

18

18

19Holding force when idle

19Setting the positions

21Machine selection

228

appendix

© 2013 Dürkopp Adler AG

3

Page 4

DACeco M-TYPE

1 Important safety instructions

Important safety instructions

This DAC

eco M-TY PE

sewing machine drive is manufactured and tested in accordance with the applicable

conditions and safety regulations and left the factory in a perfectly safe condition.

The user must observe all instructions and warning notices contained in these operating instructions in order to

maintain this condition and guarantee safe operation.

Any other use or use exceeding that specified, e.g. in the open air, in a wet or hazardous explosive environment,

is not regarded as intended use.. Use for the intended purpose includes observing the manufacturer's prescribed

conditions for operation, maintenance and repair.

The DAC

eco M-TY PE

will only work safely and reliably if the control unit is used in accordance with these operating

instructions and its intended use.

Read these operating instructions carefully before unpacking and commissioning the DAC

eco M-TY PE

yourself with the safety, assembly, operating and maintenance instructions before using the DAC

. Familiarize

eco M-TY PE

, its

accessories and its additional attachments for the first time.

All operations on and with the DAC

eco M-TY PE

must only be carried out in compliance with the following general

and particular safety instructions in the following sections of the operating instructions.

All persons affected by this must be made aware of these safety instructions and must comply with them. Noncompliance with the safety instructions may lead to personal injury, damage to equipment or malfunctions of and

damage to the drive itself.

The applicable accident prevention regulations in the respective user's country and the rules for safe and

professional working must be observed. The drive must only be assembled and commissioned by trained and

instructed persons.

Installation and commissioning of the DAC

eco M-TY PE

must be carried out carefully by skilled workers so that the

effects of interference that may cause a risk to the health of personnel and dangerous conditions are reduced to

a minimum. Working on live parts and equipment is not permitted. Exceptions are governed by EN 50110.

Before removing covers, fitting additional attachments or accessories, e.g. reference value transmitters, photo

sensors etc., the control unit must be switched off, disconnected from the mains and you must wait until the

machine has come to a standstill [DIN VDE 0113 Teil 301; EN 60204-31; IEC 60204-31].

To reduce the risk of burns, fire, electric shock or injuries, alterations or modifications to the DAC

eco M-TY PE

are

strictly forbidden.

No covers or protective devices may be removed during operation. Before leaving the work place, the machine's

on/off switch must be switched to the off position. If it is to be idle for long periods, the power plug must be

removed so that the drive cannot be switched on accidentally.

If additional attachments or equipment are connected to the DAC

eco M-TY PE

control unit, these may only be

operated at low voltage that is produced by a safety transformer.

Do not put your hands near moving parts.

Do not operate the DAC

eco M-TY PE

if aerosols (sprays) or oxygen are being used.

0791 100632 EN

4

© 2013 Dürkopp Adler AG

Page 5

Important safety instructions

This symbol is a warning notice on the DAC

eco M-TY PE

. It indicates life threatening voltages.

Caution - In the event of a malfunction, there may be life threatening voltages in this area

even after the electricity has been switched off (undischarged condensers).

The DAC

eco M-TY PE

must only be operated with a protective earthing conductor in a working

protective earthing conductor system that complies with all local regulations and decrees.

These operating instructions are a component part of the DAC

eco M-TY PE

and must be passed on to any

subsequent owners.

The instructions in the following sections are for your safety.

The DAC

eco M-TY PE

control unit is not an independently operating unit and is intended for installation in other

machines. Commissioning is not allowed until it has been ascertained that the machine in which the control unit

is to be installed complies with the provisions of the EU Directive.

© 2013 Dürkopp Adler AG

5

0791 100632 EN

Page 6

DACeco M-TYPE

2 Scope of Delivery

1x control unit with power switch

1x reference value transmitter

1x foot pedal connecting rod

1x operating instructions

Scope of Delivery

0791 100632 EN

6

© 2013 Dürkopp Adler AG

Page 7

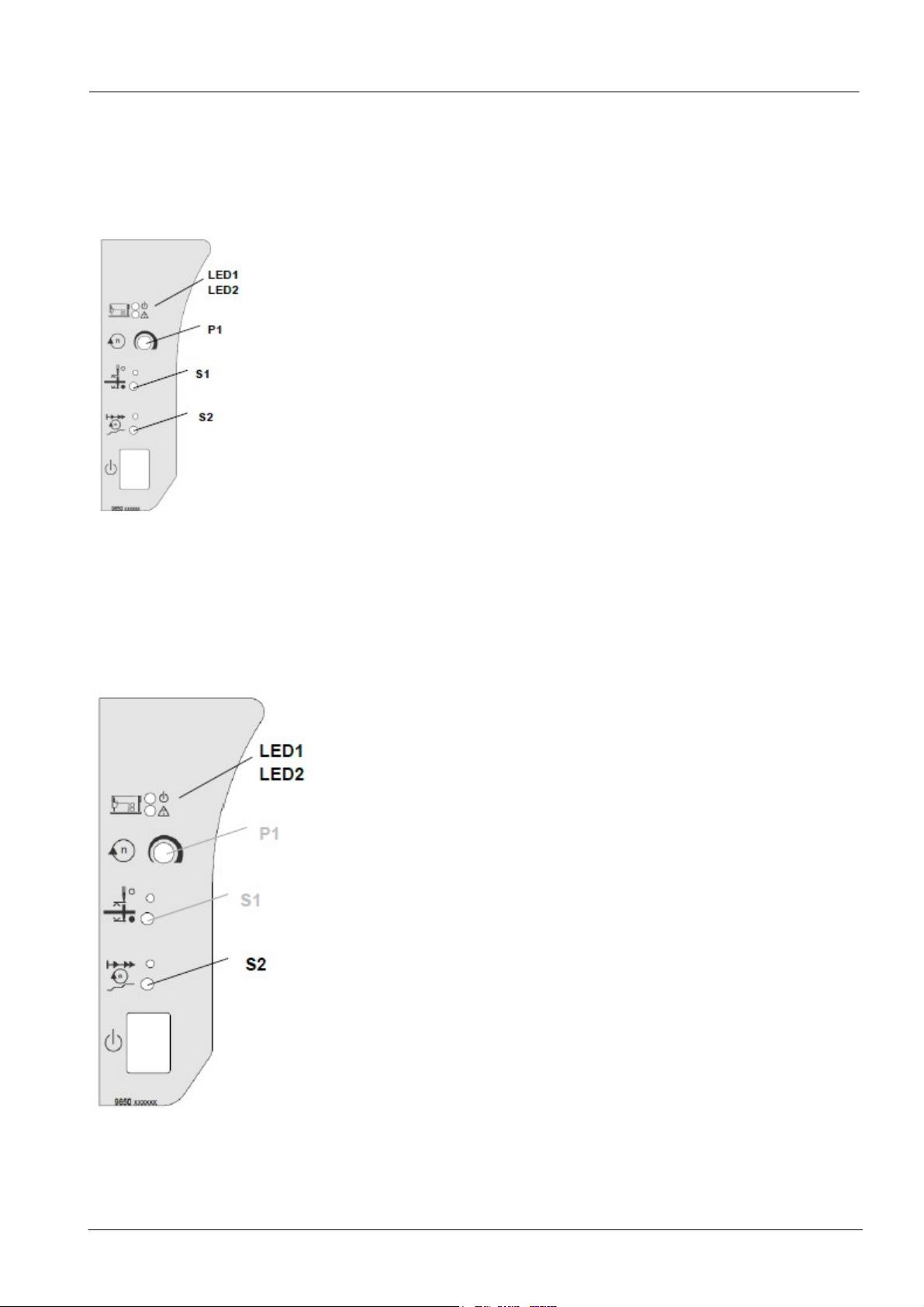

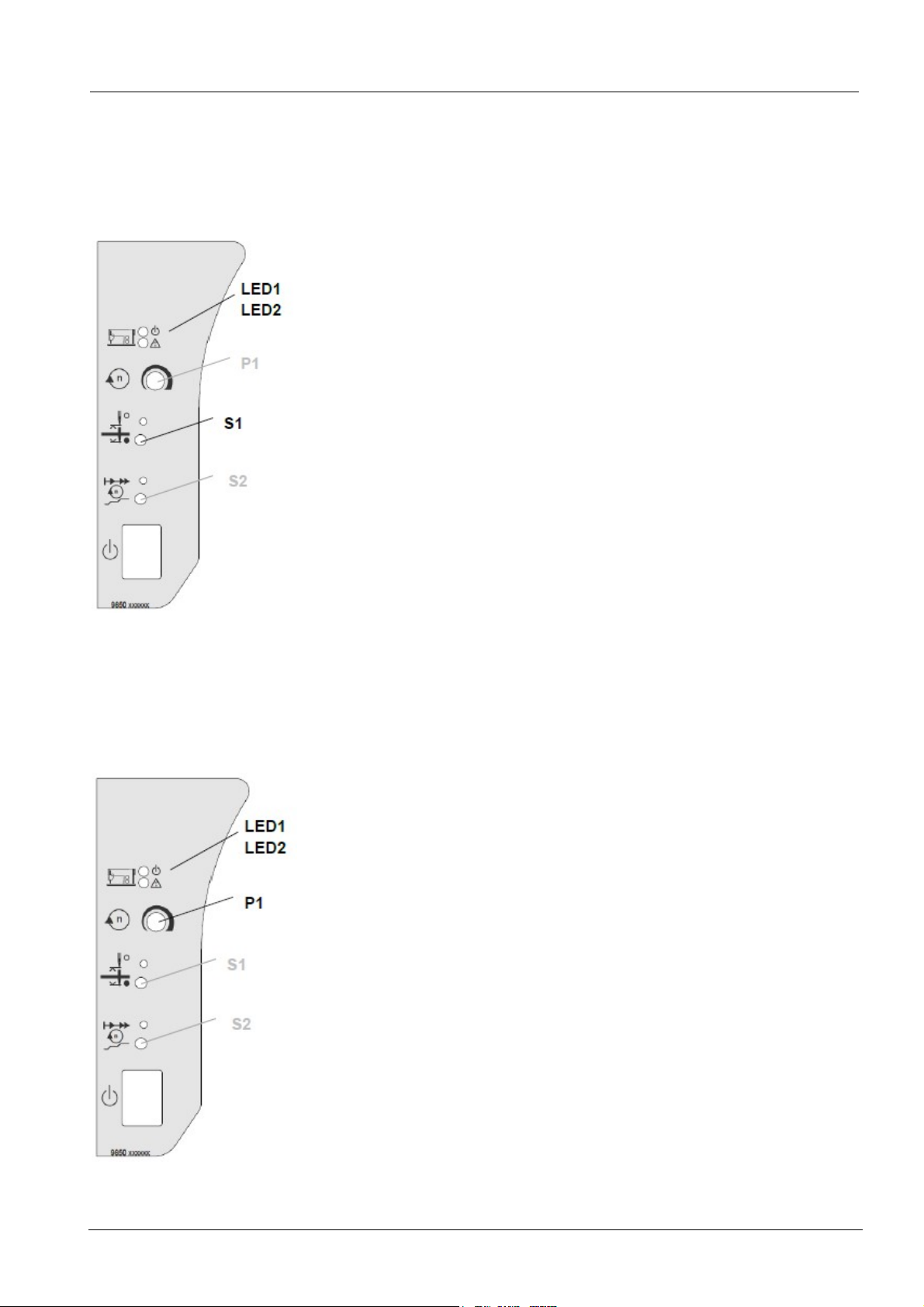

3 User settings

User settings

User settings of the DAC

potentiometer available for this.

3.1 Soft start

eco M-TY PE

can be set directly on the control unit. There are two buttons and a

The soft start function can be turned on and off with S2. If the function is turned on, the corresponding LED is lit.

The last setting is saved when switching of the control unit and is available at the next start.

© 2013 Dürkopp Adler AG

7

0791 100632 EN

Page 8

DACeco M-TYPE

User settings

3.2 Stop position of the needle

Select the function Stop position of the needle with S1. If the stop position is set to "Needle up", the

corresponding LED is lit.

Pressing the button changes the stop position of the needle.

The last setting is saved when switching of the control unit and is available at the next start.

3.3 Reducing the speed

The speed can be adjusted to the current sewing process with the potentiometer. The basis is the maximum

speed listed for the machine class; reduce the speed starting at that point.

The set value remains until the operator adjusts the potentiometer.

The last setting is saved when switching of the control unit and is available at the next start.

0791 100632 EN

8

© 2013 Dürkopp Adler AG

Page 9

4 Technical information

4.1 Technical specifications

Rated values:

Voltage (UN) [V] 230, mono-phase

Frequency (fN) [Hz] 50/60

Current (control unit) [A] 3

Power (output) (P2) [W] 550

Speed (nn) [1/min] 3400

Torque (Mn) [Nm] 12

Type of protection IP40

Insulation class E

Limits:

Rated voltage range [V] 180-260

mono-phase

Speed (n

Torque (M

Power (P2

) [1/min] 3400

max

, short-term) [Nm] 13

max

, short-term) [W] 1500

max

Technical information

© 2013 Dürkopp Adler AG

9

0791 100632 EN

Page 10

DACeco M-TYPE

4.2 Intended use

Technical information

The DAC

eco M-TY PE

is not a motor drive (control unit) that can be used on its own. The control unit is intended to

be fitted into other machines, i.e. sewing units and sewing equipment in the sewing thread processing industry

and trade.

Dry and clean areas must be provided to use the DAC

eco M-TY PE

.

Use in wet, dusty or hazardous explosive environments is an infringement of the specified use.

Use for the intended purpose includes observing the manufacturer's prescribed conditions for operation,

maintenance and repair.

0791 100632 EN

10

© 2013 Dürkopp Adler AG

Page 11

Assembly instructions

The reference value transmitter is fastened under the machine table with an assembly bracket.

The reference value transmitter's pull and push rod are connected to the machine pedal by a connecting rod.

Screw the assembly bracket for the reference value transmitter under the machine table so that the reference

value transmitter's push and pull rod and the pedal connecting rod form as straight a line as possible in order

to ensure the best transfer of power between the reference value transmitter and the pedal.

The connecting rod and the pedal should form an angle as close to 90° as possible.

Make sure that the pedal moves freely.

TN mains with a directly earthed point, with a protective earth (PE) that is connected to this point.

TT mains with a directly earthed point where the protective earth (PE) is not connected to this mains earthing

point

IT mains that is not directly earthed.

5 Assembly instructions

5.1 Fitting the reference value transmitter

5.2 Power supply (mains connection)

Working on the electrical equipment (connection, maintenance, repairs) must only be done by or under the

supervision of a qualified electrician.

The DAC

rated voltage in the range of 180V - 260 V 50/60 Hz.

Before connecting the mains lead, make sure that the rated voltage is within the rated voltage range

specified on the DAC

It must only be connected using a multi-pin plug with an earthing contact.

A fixed connection is not permitted. The following potentials must be connected:

Phase (L1 or L2 or L3)

Neutral cable (N)

Protective earth (PE)

The DAC basic control unit is suitable for connection to the following mains:

eco M-TY PE

control unit is intended to be connected to an earthed alternating current network with a

rating plate.

eco

.

© 2013 Dürkopp Adler AG

11

0791 100632 EN

Page 12

DACeco M-TYPE

PE N L3 L2 L1

DAC

DAC

DAC

DAC

L1

L2

PE

DAC

L3

PE N L3 L2 L1

DAC

DAC

TN - Netz

Assembly instructions

The following applies to TT mains and IT mains:

All units protected jointly by one protective device must be connected to the same earthing device by a

protective earth.

Simultaneously exposed units must be connected to a joint earth.

The following applies additionally to IT mains:

No active conductor of the unit must be earthed directly. The units must be connected individually, in groups or

in their entirety to a protective earth.

Mono-phase plug connection

0791 100632 EN

12

© 2013 Dürkopp Adler AG

Page 13

5.3 Electromagnetic compatibility (EMC)

-

Via suitable filters, delay units, suitable cables and cable runs.

-

Run cables of different electrical circuits (mains voltage, low voltage) physically separate from each other

in order to keep interference low.

-

Reference potential wires for the electrical circuits or joint connection point: star-shaped wiring with one

or more reference points that are earthed with large cross-section insulated wires

-

Electrically conductive parts of the sewing unit or sewing equipment must be connected to the protective

earth on the DAC

eco M-TY PE

housing via voltage equalising cables. (Cables suitable for high frequency:

extra-fine stranded wires with a cross section of at least 2.5 mm

2

or wide copper bands.) When

connecting the potential equaliser, make sure of secure contact, i.e. on painted parts. the connection

must be made using toothed washers.

-

Sewing machine

-

Sewing machine support frame

-

Pedal

-

Magnet or magnetic valve housings

-

Holder for buttons

-

Support frames for stackers, tape feed etc.

-

Earth connections

Earth connections must be run from each part of the equipment to a common point. Braided, large crosssection wires must be used between moving parts and the housing and the earth connection must be kept as

short as possible.

-

Signal transfer

Make sure that no interference voltage is transferred from the control and main current cables to signal cables

by using electrostatic and magnetic shielding, twisted wires and the cable run. (A cable crossover at right

angles is better than one with a smaller angle. Parallel runs must definitely be avoided.)

-

Separating equipment parts

Equipment parts susceptible to interference (components with pulse processing and/or with low levels) should

be separated and/or shielded from switch equipment such as electromagnetic relays, thyristors etc.

-

In spite of the fact that it is not susceptible to interference, the DAC

eco M-TY PE

must not be operated in the

immediate vicinity of HF welding machines or similar equipment in order to avoid malfunctions. Should

problems occur, please contact the manufacturer.

Assembly instructions

The DAC

eco M-TY PE

is prepared for installing in or attaching to sewing units and sewing equipment and meets the

relevant EMC regulations required for this (EN 60204-31, IEC 60204-31) with a cable length of up to 500 mm on

each input or output socket. From experience, this is sufficient for sewing units. With sewing equipment, further

measures may be necessary because of longer cables, bad cabling, strong adjacent interference fields etc. The

effect of interference can be reduced or eliminated by doing the following:

The following parts must be included in the potential equalisation:

© 2013 Dürkopp Adler AG

13

0791 100632 EN

Page 14

DACeco M-TYPE

5.4 Wiring diagram

Assembly instructions

Top side

Bottom side

0791 100632 EN

14

© 2013 Dürkopp Adler AG

Page 15

Assembly instructions

© 2013 Dürkopp Adler AG

15

0791 100632 EN

Page 16

DACeco M-TYPE

6 Commissioning

Before commissioning the control unit, the following must be ensured, checked or set:

The correct assembly of the drive, position sensor and any accessories used

If necessary, the correct setting of the motor rotation direction

The correct maximum speed that is compatible with the sewing machine

The position settings

The settings of the remaining relevant parameters

Saving the set values

Commissioning

0791 100632 EN

16

© 2013 Dürkopp Adler AG

Page 17

7 Setting the basic functions

Parameter

Min

Max

Unit1Soft start stitches

120Stitches

2

Soft start speed

100

1000

rpm3Maximum speed

100

3400*

rpm4Holding force

06A5Needle positions and reference position

---6Machine selection

17-

Confirmation - Keep S1 (OK) pressed (> one second)

Cancellation - Keep S2 ( ESC) pressed (> one second)

Plus - Briefly press S1 (+) (< one second)

Minus - Briefly press S2 (-) (< one second)

Setting the basic functions

With S1 and S2, the DAC

eco M-TY PE

can be programmed to a lesser degree.

There are six parameters listed in the table that can be changed.

*Depence of the selected machine class.

To access the programming mode, keep S1 pressed when turning on the control unit.

Once the programming mode is active and the corresponding parameter can be selected, LED2 flashes.

Buttons S1 and S2 have the following functions in programming mode:

Select the corresponding parameter by briefly pressing S1.

The LED allocated to S1 indicates the currently selected parameter.

Confirm by keeping S1 pressed > one second.

Example: Briefly press S1 twice = programming the soft start speed. The corresponding LED repeatedly briefly

flashes twice.

© 2013 Dürkopp Adler AG

17

0791 100632 EN

Page 18

DACeco M-TYPE

Confirmation - Keep S1 (OK) pressed (> one second)

Cancellation - Keep S2 ( ESC) pressed (> one second)

Plus - Briefly press S1 (+) (< one second)

Minus - Briefly press S2 (-) (< one second)

Confirmation - Keep S1 (OK) pressed (> one second)

Cancellation - Keep S2 ( ESC) pressed (> one second)

Plus - Briefly press S1 (+) (< one second)

Minus - Briefly press S2 (-) (< one second)

Confirmation - Keep S1 (OK) pressed (> one second)

Cancellation - Keep S2 ( ESC) pressed (> one second)

Plus - Briefly press S1 (+) (< one second)

Minus - Briefly press S2 (-) (< one second)

Confirm the selected parameter by keeping S1 pressed.

Setting the basic functions

7.1 Number of stitches during soft start

If the programming level of a parameter is selected, buttons S1 and S2 have the following functions:

Briefly pressing S1 increases the number of soft start stitches by one stitch; briefly pressing S2 reduces the

number by one stitch.

The set value is then indicated by the flashing LEDs.

S1 LED : 10s digit

S2 LED : 1s digit

The LEDs flash every 0.5 seconds. After a pause of 1.5 seconds, the sequence is repeated until it is confirmed

or cancelled.

Confirm the programmed result by pressing S1. Leave the programming level by pressing S2.

7.2 Speed

7.2.1 Set soft start speed

If the programming level of a parameter is selected, buttons S1 and S2 have the following functions:

Briefly pressing S1 increases the soft start speed by 100rpm; briefly pressing S2 reduces it by 100rpm.

The set value is then indicated by the flashing LEDs.

S1 LED : 1000s digit

S2 LED : 100s digit

The LEDs flash every 0.5 seconds. After a pause of 1.5 seconds, the sequence is repeated until it is confirmed

or cancelled.

Confirm the programmed result by pressing S1. Leave the programming level by pressing S2.

7.2.2 Setting the maximum speed

If the programming level of a parameter is selected, buttons S1 and S2 have the following functions:

0791 100632 EN

18

© 2013 Dürkopp Adler AG

Page 19

Setting the basic functions

Confirmation - Keep S1 (OK) pressed (> one second)

Cancellation - Keep S2 ( ESC) pressed (> one second)

Plus - Briefly press S1 (+) (< one second)

Minus - Briefly press S2 (-) (< one second)

Holding force takes effect when idle

The effect can be adjusted

The higher the set value, the stronger the holding force

on first commissioning

after replacing the control unit

after replacing the motor or the incremental sensor.

Briefly pressing S1 increases the maximum speed by 100rpm; briefly pressing S2 reduces it by 100rpm.

The set value is then indicated by the flashing LEDs.

S1 LED : 1000s digit

S2 LED : 100s digit

The LEDs flash every 0.5 seconds. After a pause of 1.5 seconds, the sequence is repeated until it is confirmed

or cancelled.

Confirm the programmed result by pressing S1. Leave the programming level by pressing S2.

7.3 Holding force when idle

If the programming level of a parameter is selected, buttons S1 and S2 have the following functions:

Briefly pressing S1 increases the holding force by 0.5 A; briefly pressing S2 reduces it by 0.5 A.

The set value is then indicated by the flashing LEDs.

S1 LED : Pre-decimal position

S2 LED : Decimal place

The LEDs flash every 0.5 seconds. After a pause of 1.5 seconds, the sequence is repeated until it is confirmed

or cancelled.

Confirm the programmed result by pressing S1. Leave the programming level by pressing S2.

This function prevents unwanted "wandering" of the needle when the machine has come to a standstill.

The effect can be checked by turning the hand wheel.

- for a stop in the seam

- after the end of the seam

7.4 Setting the positions

The angle settings required on the machine, e.g. "Needle down" or "Thread lever up" are saved in the control

unit. A reference position is required to establish a relationship between the position sensor information and the

actual mechanical position. The reference position may be different depending on the parameter settings,

normally "Point at which the needle penetrates the stitch plate (EP)"

The reference position must be set:

© 2013 Dürkopp Adler AG

19

0791 100632 EN

Page 20

DACeco M-TYPE

Installation

Keep S1 pressed when

turning on the control unit

Select parameter 5

Push foot pedal forward

until LED S1 and S2 start

flashing

Adjust ref. Position by

handwheel

Keep S1 pressed to confirm

ref.position

Adjust lower position of

needle by handwheel. The

LED2 are flashing. Keep S1

pressed to confirm

Adjust upper position of

needle by handwheel. The

LED1 are flashing. Keep S1

pressed to confirm.

Setting the basic functions

0791 100632 EN

20

© 2013 Dürkopp Adler AG

Page 21

Setting the basic functions

Acception - Keep S1 (OK) pressed (> one second)

Cancellation - Keep S2 ( ESC) pressed (> one second)

Plus - Briefly press S1 (+) (< one second)

Minus - Briefly press S2 (-) (< one second)

machine class

delivery speed

maximum speed

1.

669-180010-M

2800

3000

2.

867-1900x0-M

3000

3400

3.

867-2900x0-M

3000

3000

4.

868-x900x0-M

2500

2500

5.

869-x800x0-M

2800

2800

6.

887-160040-M

2000

2000

7.

888-160020-M

1700

3000

7.5 Machine selection

If the programming level of a parameter is selected, buttons S1 and S2 have the following functions:

Select the next parameter set by briefly pressing S1. Select the previous parameter set by briefly pressing S2.

The set value is then indicated by the flashing LEDs.

LED1 : 10s digit

LED1 : 1s digit

The LEDs flash every 0.5 seconds. After a pause of 1.5 seconds, the sequence is repeated until it is confirmed or

cancelled.

Confirm the programmed result by pressing S1. Leave the programming level by pressing S2.

The following machine classes can selected:

You can change the selection with the upper and lower buttons.

The actual selected class will be shown by flashing of the LEDs.

Example select class 867– 1900x0-M:

Push 2 times the upper button.

The lower LED will flash 2 times and after this it has got a longer break. The cycle will be repeated.

Example select class 887-160140-M:

Push 7 times the upper button.

The lower LED will flash 7 times and after this it has got a longer break. The cycle will be repeated.

To accept the selection push and hold the upper button for approx. 2 sec.

Now the parameters will be loaded and you can see it by flashing of the Message LED and you can hear a signal.

If the Message LED is flashing in a constant cycle and you can’t hear any signal you can switch off the control.

© 2013 Dürkopp Adler AG

21

0791 100632 EN

Page 22

DACeco M-TYPE

Degree

Description

Error

Serious error

Turn off the control unit and correct the error.

Warning

Eliminate the condition that caused the warning and the control unit will continue to work normally.

Information

Press OK

You can continue to work; only emergency running properties may be available.

Degree

Code

Error or information description

Remedial measures

Warning

1

Travel stop

- Check the tilt sensor on the machine

Information

2

Low voltage warning (1st threshold)

(mains voltage < 180V AC)

- Check mains voltage

- Stabilise mains voltage

- Use generator

Warning

3

Pedal position is not in position 0

- When switching on the control unit, take foot off

pedal

Error

4

Pedal not connected

- Connect analogue pedal

Error

5

Sewing motor encoder plug (Sub-D,

9-pin) not connected.

- Insert the encoder lead into the control unit. Use the

correct interface.

Error

6

Motor stalls

- Eliminate sluggish movement in the sewing machine

Error

7

Sewing motor overload

- Eliminate sluggish movement in the sewing machine

Error

8

Sewing motor error

Sewing motor plug (AMP) is not

connected.

- Check the connection and if necessary plug in.

- Test sewing motor phases (R= 2.8 Ohm, highresistance compared with PE)

- Replace sewing motor

- Replace control unit

Error

9

Sewing motor insulation error

- Check motor phase and PE for low-resistance

connection

- Replace sewing motor

Error

10

High voltage error, mains voltage

>290V for some time

- Check mains voltage, if rated voltage exceeded

permanently - stabilise or use generator

Error

11

EEprom communication error

- Check the connection of the Mach ID

- Turn off the control unit, wait until LEDs are off,

restart

Information

12

No valid data on external EEprom

- Check the connection of the Mach ID

- Turn off the control unit, wait until LEDs are off,

restart

- Update software

Error

13

Low voltage failure (2nd threshold)

(mains voltage < 150V AC)

- Check mains voltage

- Stabilise mains voltage

- Use generator

Error

14

Sewing motor turning in the wrong

direction

- Replace encoder

- Check that the motor plug is in the correct place and

change if necessary

Error, warning and information messages

8 Error, warning and information messages

The DAC

eco M-TY PE

control unit contains three groups of messages that are divided as follows:

The messages are visualised via LED2. The coding is displayed via LED2

flashing every 0.5 seconds. The flashing sequence is then interrupted for two seconds and

repeated.

0791 100632 EN

22

© 2013 Dürkopp Adler AG

Page 23

Error, warning and information messages

Degree

Code

Error or information description

Remedial measures

- Check wiring in the machine distributor and change if

necessary

- Test motor phases and check for value

Error

15

Excess sewing motor current,

internal current increase >25A

- Replace control unit

Error

16

Maximum speed exceeded

- Replace encoder

Error

17

AC RDY time-out , intermediate

circuit voltage has not reached the

defined threshold in the given time.

- Check mains voltage

- If mains voltage OK, replace control unit

Information

18

No valid data on internal EEprom

- Check the connection of the Mach ID

- Turn off the control unit, wait until LEDs are off,

restart

- Update software

Information

19

No valid data on internal EEprom

- Check the connection of the Mach ID

- Turn off the control unit, wait until LEDs are off,

restart

- Update software

© 2013 Dürkopp Adler AG

23

0791 100632 EN

Page 24

Loading...

Loading...