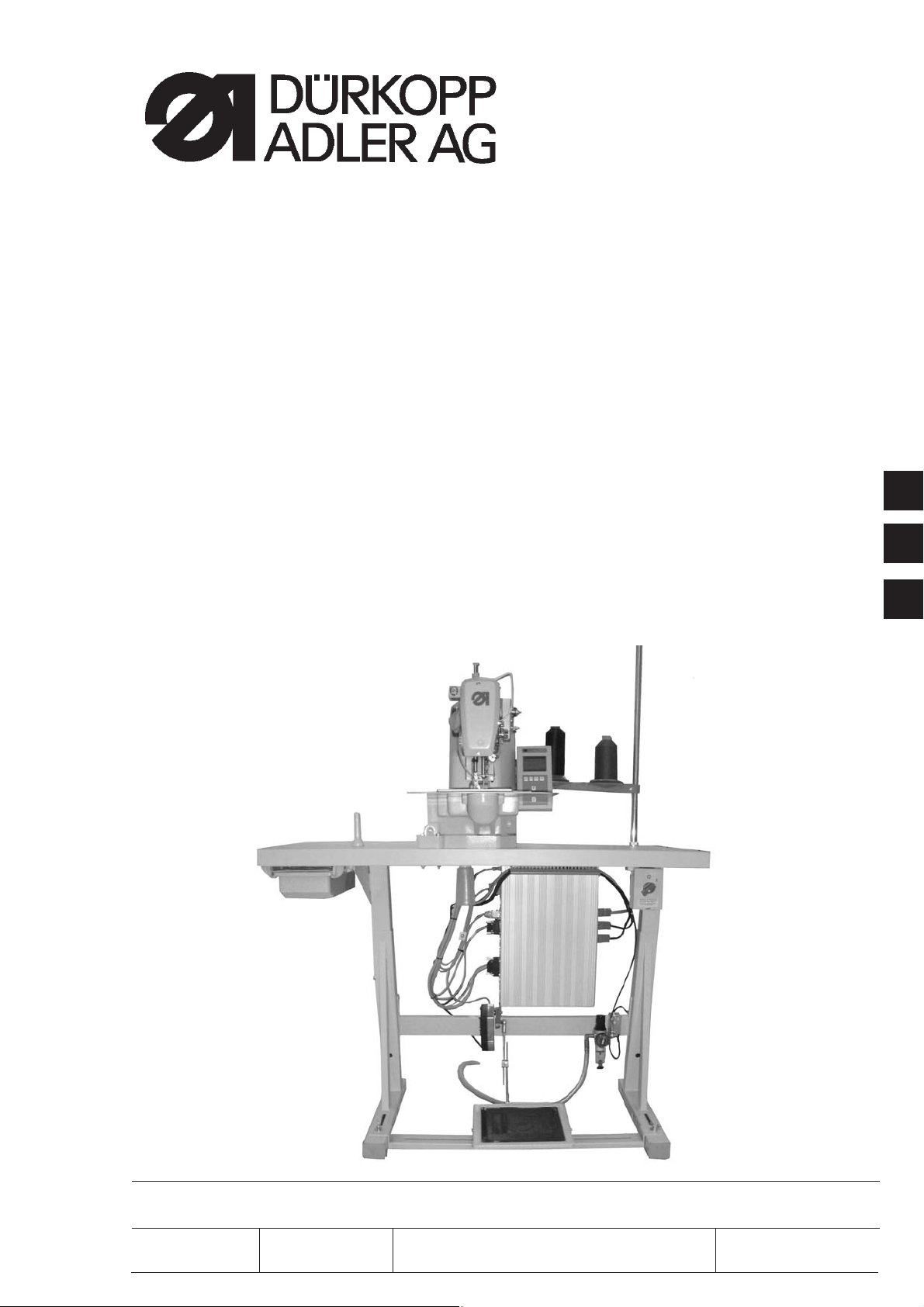

Duerkopp Adler 910 Operating Instruction

910

CNC-Nähanlage für freie Nahtkonturen

CNC sewing unit for free seam contours

Bedienanleitung / Operating Instructions

Aufstellanleitung / Installation Instructions

Serviceanleitung / Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld Potsdamer Straße 190, D-33719 Bielefeld Deutsch/Englisch

Telefon +49 (0) 5 21/ 59 25-00 Telefax+49(0)521/9252435 www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr.:/Part-No.:

04/2007 Rev. index: 01.0 Printed in Federal Republic of Germany 0791 910001

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise

Wiederverwendung dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG

verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright

ã 2007 - Dürkopp Adler AG

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Index Page:

Preface and general safety hints

Part 1: Operating instructions cl. 910

(Edition 04/2007)

1. Description of product .......................................... 5

2. Use in accordance with the requirements .............................. 6

3. Subclass................................................... 6

4. Optional equipment ............................................ 7

5. Stands .................................................... 7

6. Technical data ............................................... 8

7. Operating

7.1 Switchingon-Switchingoff-Safestop................................. 9

7.1.1 Switchingon................................................. 9

7.1.2 Switchingoff................................................. 9

7.1.3 Safestop................................................... 9

7.2 Threading in the needle thread ...................................... 10

7.3 Adjusting the thread regulator ...................................... 11

7.4 Winding up the bobbin thread....................................... 12

7.5 Changing the hook thread bobbin .................................... 13

7.6 Adjusting the bobbin thread tension ................................... 14

7.7 Changing the needle ............................................ 15

7.8 Adjustingtheliftingmovementoftheclampingplate......................... 16

7.9 Sewingfootpressure............................................ 16

7.10 Sewingfootheight ............................................. 17

8. Operating the control of cl. 910

8.1 The operator terminal ........................................... 18

8.1.1 Thekeys................................................... 19

8.2 Userinterface................................................ 20

8.2.1 Structureofmenu.............................................. 20

8.3 Alteringnumericalvalues,parametervalues,selectionofalternatives.............. 21

8.3.1 Alteringnumericalvalues......................................... 21

8.3.2 Selectionofaparameter.......................................... 22

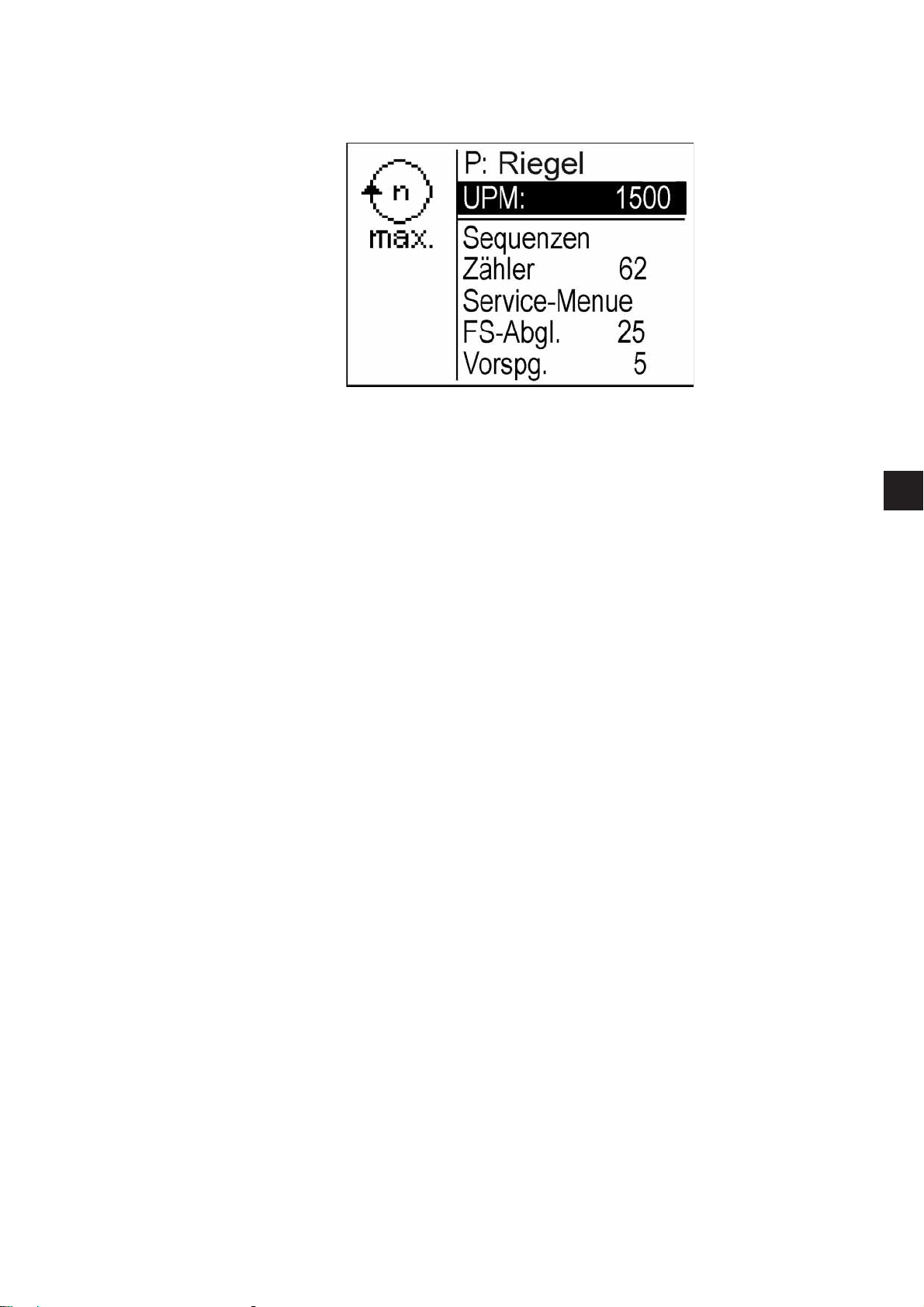

8.4 Mainmenu.................................................. 23

8.4.1 Submenu Sequences ............................................ 25

8.4.2 Submenu Counter .............................................. 26

8.4.3 SubmenuServicemenu(Teach-in) ................................... 28

8.5 CallingupMultitest............................................. 42

1

Index Page:

8.6 Technicianmode .............................................. 49

8.6.1 SubmenuThreadtension......................................... 51

8.6.2 Mechanical adjustment of thread tensions ............................... 52

8.6.3 Calibration.................................................. 53

8.6.4 SubmenuPositions............................................. 54

8.6.5 SubmenuThreadBurnerSettings.................................... 55

8.7 Loading the factory settings........................................ 57

8.8 Saving and loading of programs ..................................... 58

8.8.1 Loading programs into the control .................................... 58

8.8.2 Saving programs on the dongle ..................................... 59

8.8.3 Deletingprogram.............................................. 61

8.8.4 Formatting the dongle ........................................... 62

8.9 Machinefaults................................................ 63

9. Sewing

9.1 Threadbreakagemode .......................................... 68

10. Maintenance

10.1 Cleaning and checking ........................................... 70

10.2 Oillubrication................................................ 71

1. Description of product

The Dürkopp Adler 910 is a CNC sewing unit for free seam contours.

The seam contours c an be programmed directly at the control panel

without any further devices.

Technical features

–

–

–

–

–

–

–

DAC control with control panel.

The following functions are available:

–

4 free seam contours with a total of 2800 available stitches can

be stored.

The coordinates are entered at the control panel.

No further devices are required.

–

4 sewing sample sequence programs with up to 4 sewing

samples per sewing sample sequence program can be created

and memorized.

–

The coordinates (teach-in) are entered with a precision of

0.5 or 1 mm respectively.

–

Counter of capacity and daily number of pieces.

–

The speed can be changed from 0 rpm (manual operation with

full operability of the x-y drive) up to 2500 rpm in

steps of 100 rpm.

Fabric drive via two step motors.

Drive of the sewing unit directly at the arm shaft via brushless

direct current motor.

Maximum sewing field size 120 x 60 mm.

Thread monitor and thread pulling device.

Oil wick lubrication of arm shaft and driving shaft by means of two

oil reservoirs.

Service and maintenance work is supported by comprehensive test

programs.

1

5

2. Use in accordance with the requirements

Class 910 is a sewing unit determined for processing light to

medium-weight material, i.e. fabrics made of textile fibres or leather.

Such sewing materials are used in the clothing industry and for the

production of home and car upholstery.

Furthermore, this sewing unit can also sew so-called technical seams.

However, in this case the user has to es timate the possible risks

(preferably in c ooperation with DÜRKOPP ADLER AG) because on the

one hand such fields of application are comparatively rare and on the

other hand there is an immense variety of possibilities. According to

the result of this estimation suitable safety measures may have to be

taken.

Generally only dry fabrics must be processed on this sewing unit. The

material must not be thicker than 10 mm when compressed by the

lowered fabric clamp. It must not include any hard objects.

In general the seam is produced with sewing threads made of textile

fibres (cotton threads, synthetic threads or core threads) with the

following dimensions:

Class 910 threads of the dimension 15/3 - 120/3

If other threads are to be used, it is indispensable also in this case to

consider the possible risks and to take corresponding safety

measures, if necessary.

This sewing unit must only be installed and operated in dry and

well-kept rooms. In case it is operated in other rooms which are not dry

and well-kept further measures can become necessary which have to

be agreed upon (see EN 60204-31: 1999).

We as manufacturers of industrial sewing machines take it for granted

that at least semi-skilled operators are working with our products so

that we can assume that all usual operations and their risks are known

to them.

3. Subclass

Cl. 910 Single needle lockstitch sewing unit with thread trimmer and thread

pulling device.

Equipped with two sewing feet for general seam contours.

6

4. Optional equipment

The following optional equipment is available for the sewing unit 910:

Order number Optional equipment

0910 590044 Laser marking (pc.)

9822 510026 Sewing lamp

9822 510027 Table clamp

Needle cooling

Please contact our application centre (APC) for further optional equipment.

5. Stands

The following stand is available for the sewing unit 910:

MG55 400294 Stand package

Table top size 600 x 1060 mm

Stand height 1160 to 1305 mm

1

7

6. Technical data

Stitc h type : 301

Hook type: oscillating

large capacity hook

Needle system: DPx17 (135x17)

Needle size: 90 - 140 [Nm]

Standard needle size: 120 [Nm]

Thread size: 20/3 - 120/3

Stitch length: dependent on seam

pattern up to 12.7 mm

-1

Max. speed 2500 [min

]

Max. clamping stroke:18 [mm]

Sewing field size

max. in X-direction: 120 [mm]

max. in Y-direction: 60 [mm]

Number of sewing sample

sequence programs (sequences) 4

Number of sewing samples per

sewing sample sequence program 4

Sewing drive: DC motor

Rated voltage: 1 ~ 230V/ 50/60 Hz

Rated load: 0.45 kw

Noise: Lc = dB (A)

Emission value per work place according to DIN 45635-48-A-1-KL-2

Sewing length: __ mm

Stitches: __

Speed: _____ min

-1

Fabric: G1 DIN 23328 2 plies

Sewing cycle: 1.3 sec. On and 1.0 sec. Off

8

7. Operating

7.1 Switching on - Switching off - Safe stop

7.1.1 Switching on

7.1.2 Switching off

7.1.3 Safe stop

21

–

Switchonthemainswitch1.

–

Step the pedal back to reach the initial position of the sewing unit.

The main menu appears in the display.

–

Switch off the main switch 1.

All drives and the control are immediately separated from the

mains.

The sewing unit has to be switched off or switched to “safe stop” before

carrying out any work on it.

1

Switching on “safe stop”

–

Press key 2.

The key must snap in!

The sewing unit is in “safe stop” condition.

The lamp in the key is shining.

Switching off “safe stop”

–

Press key 2 again.

The key must be released.

–

Stepthe pedal back to reach the initial position of the sewing unit.

9

7.2 Threading in the needle thread

Caution: Risk of injury!

Switchthemainswitchoff!

Thread in the needle thread only with the sewing unit switched off.

–

Stick the thread reels on the thread reel holder and guide the

needle thread and the

bobbin thread through the unwinding arm.

The unwinding arm must be positioned vertically above the thread

reels.

–

Thread in the needle thread as shown in the illustration below.

10

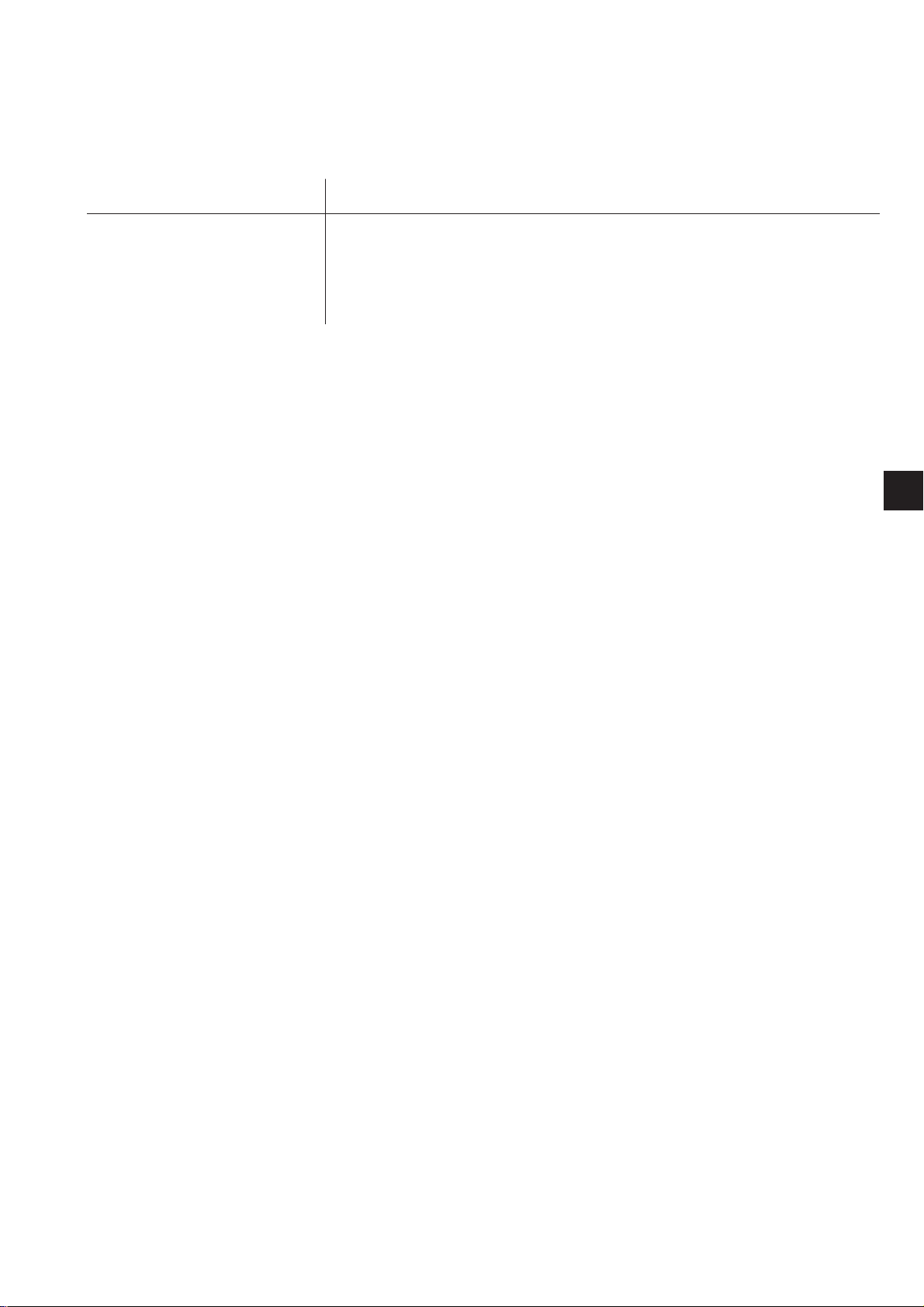

7.3 Adjusting the thread regulator

1

32 1

Caution: Risk of injury !

Switchthemainswitchoff.

Adjust the thread regulator only with the sewing unit switched off.

With the thread regulator 3 the needle thread quantity required for the

stitch formation is regulated.

Only a precisely adjusted thread regulator guarantees an optimum

sewing result.

When the thread regulator is adjusted correctly, the needle thread loop

must slide over the thickest spot of the hook with low tension.

–

Loosen screw 1.

–

Change the position of the thread regulator 3.

Thread regulator to the left = larger needle thread quantity

Thread regulator to the right = minor needle thread quantity

–

Tighten screw 1.

Adjustment hint:

If the largest thread quantity is required, the thread controller s pring 2

must be pulled up by approx. 0.5 mm from its lower end position. This

is the case when the needle thread loop passes the maximum hook

diameter.

11

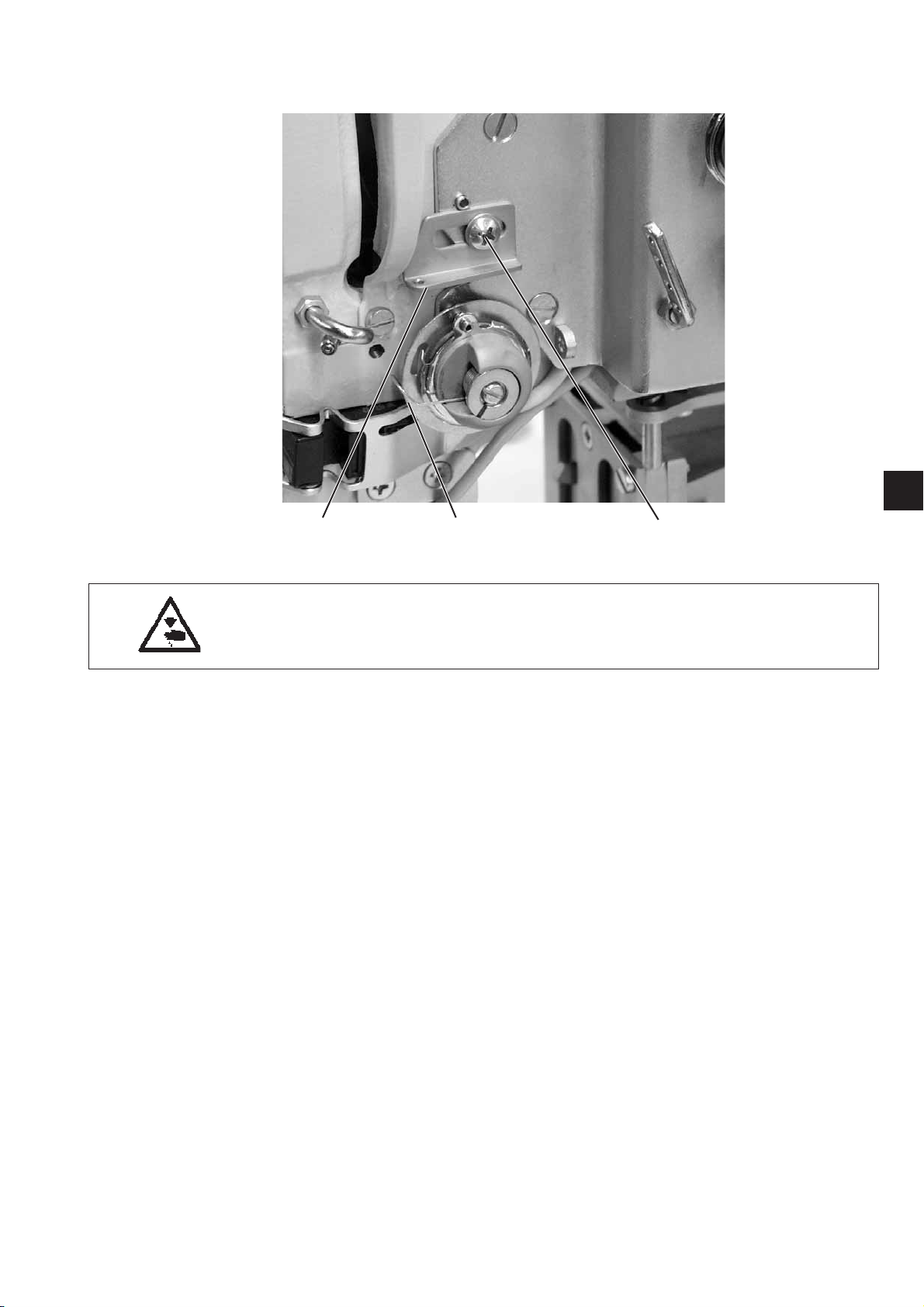

7.4 Winding up the bobbin thread

5

1

4

–

Put the bobbin on the bobbin winder 4.

–

Pull the thread through the guide 2 and around the tension 1.

–

Wind the thread counter-clockwise around the core of the bobbin

(approx. 5 times).

–

Press the winder lever 3 into the bobbin.

–

Sewing

The winder lever stops the winding process as soon as the bobbin

is full.

–

Tear off the thread at the thread clamp 5 after winding up.

3

2

12

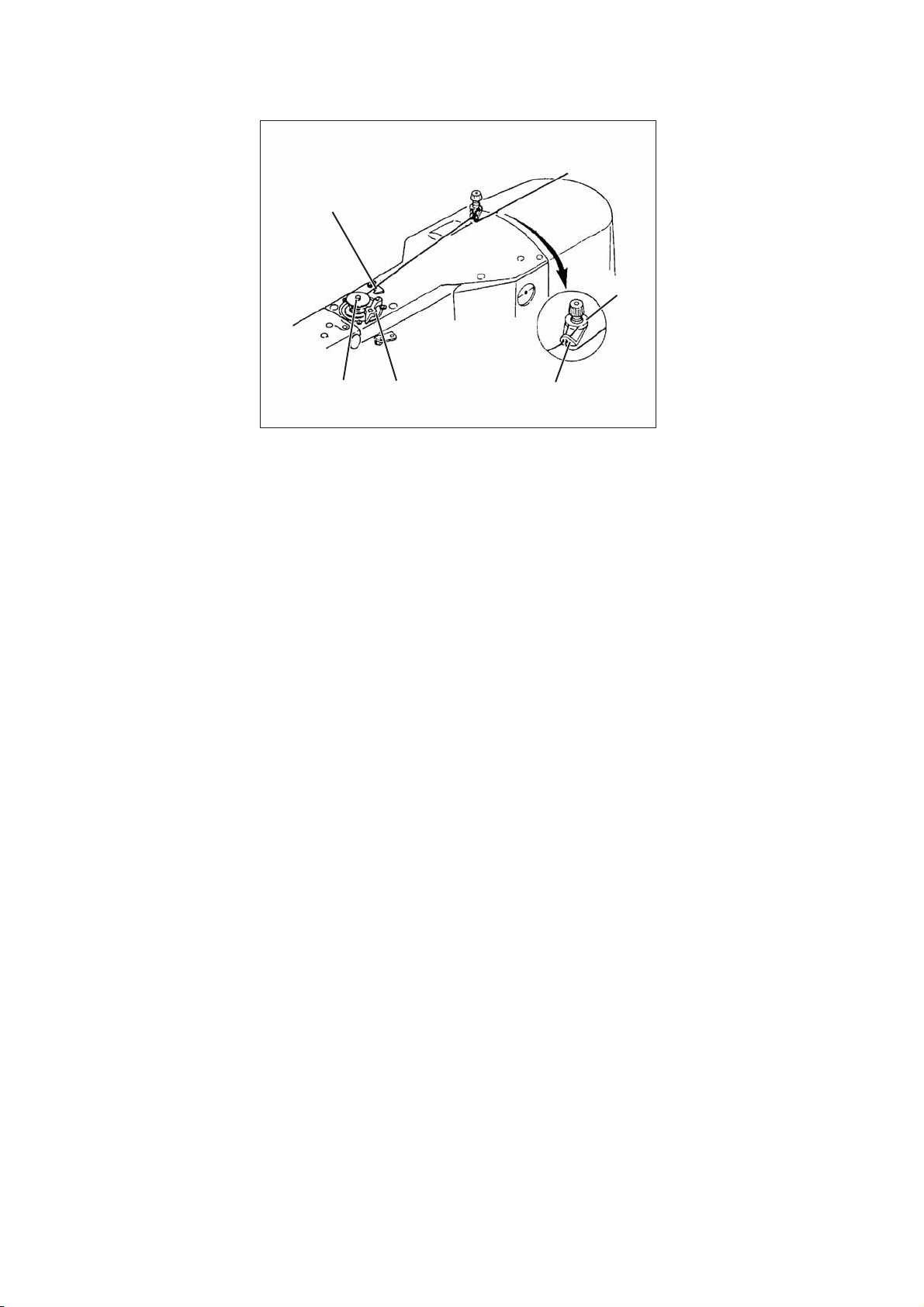

7.5 Changing the hook thread bobbin

1

7

4

2

5

6

2

3

1

Caution: Risk of injury !

Switchthemainswitchoff.

Change the hook thread bobbin only with the sewing unit switched off.

Taking the empty bobbin off

–

Pull the hook cover 3 down.

–

Lift the bobbin case cover 1.

–

Take of the top of bobbin case 2 with bobbin 6.

–

Remove the empty bobbin from the top of bobbin case 2.

Inserting the full bobbin

–

Place the full bobbin in the top of bobbin case 2.

–

Thread the bobbin thread through the slot 5 below the tension

spring 7 in the drill-hole 4.

–

Pull the bobbin thread out of the bobbin case 2 for a length of

approx. 2.5 cm.

When winding off the thread the bobbin must turn in the direction of

the arrow.

–

Reinsert the bobbin case 2.

–

Close the bobbin case cover 3.

13

7.6 Adjusting the bobbin thread tension

1

2

3

Caution: Risk of injury !

Switchthemainswitchoff.

Adjust the bobbin thread tension only with the sewing unit s witched off.

The required bobbin thread tension is to be produced by the tension

spring 1. The top of bobbin case 3 should drop slowly due to its own

weight when being held at the threaded-in bobbin thread.

Adjusting the tension spring

–

Take off the top of bobbin case 3 with the bobbin.

–

Adjust the tension spring 1 at the regulating screw 2 until the

required tension value is reached.

–

Reinsert the top of the bobbin case.

14

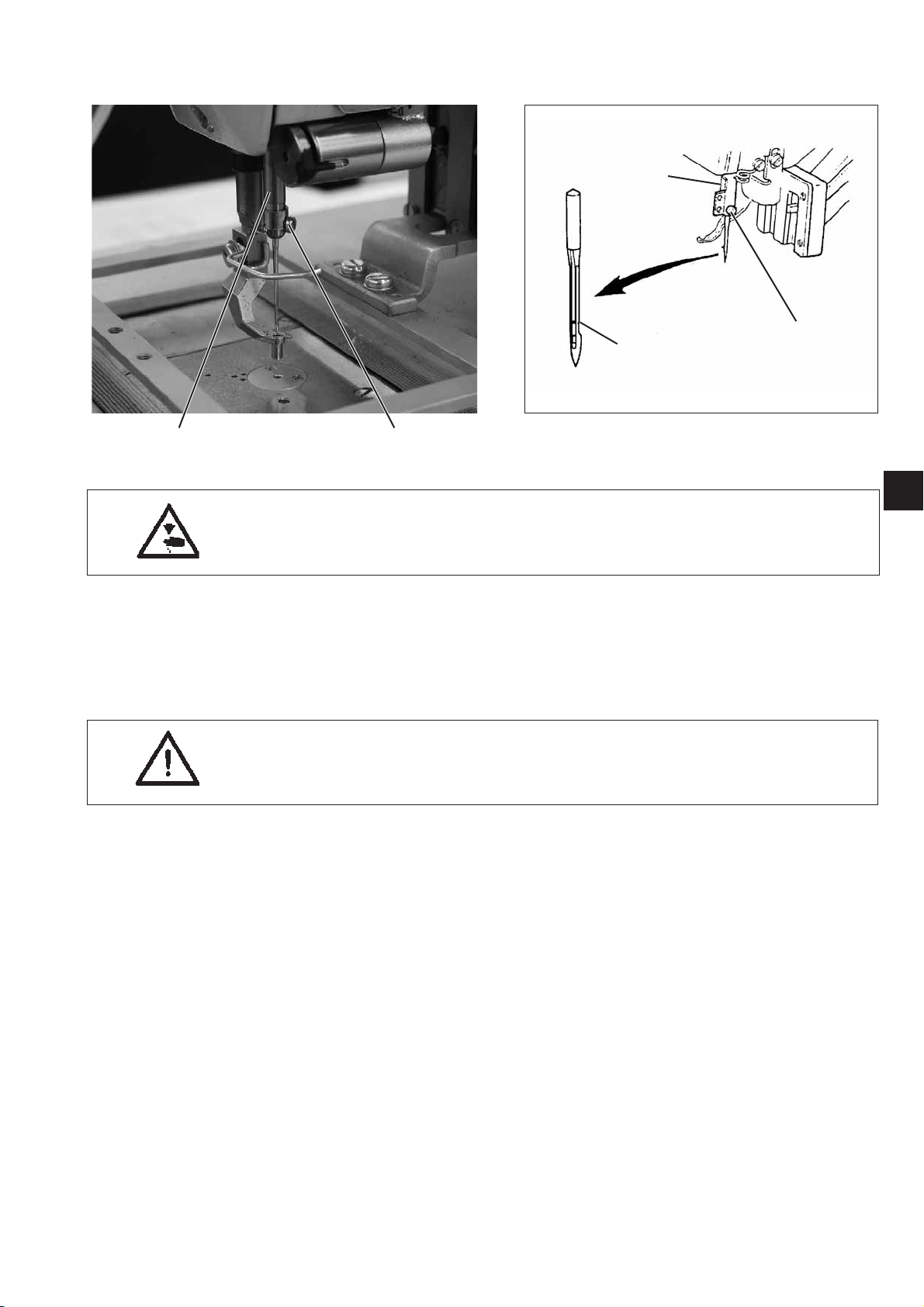

7.7 Changing the needle

2

21

Caution: Danger of injury !

Switchthemainswitchoff.

Change the needle only with the sewing unit switched off.

–

Loosen the screw 1.

–

Push the new needle into the drill-hole of needle bar 2 as far as it

will go.

ATTENTION !

The hollow groove 3 of the needle must point to the hook.

–

Tighten the screw 1.

ATTENTION !

After the changeover to another needle size the distance between

hook and needle has to be corrected (see service instructions).

3

1

1

15

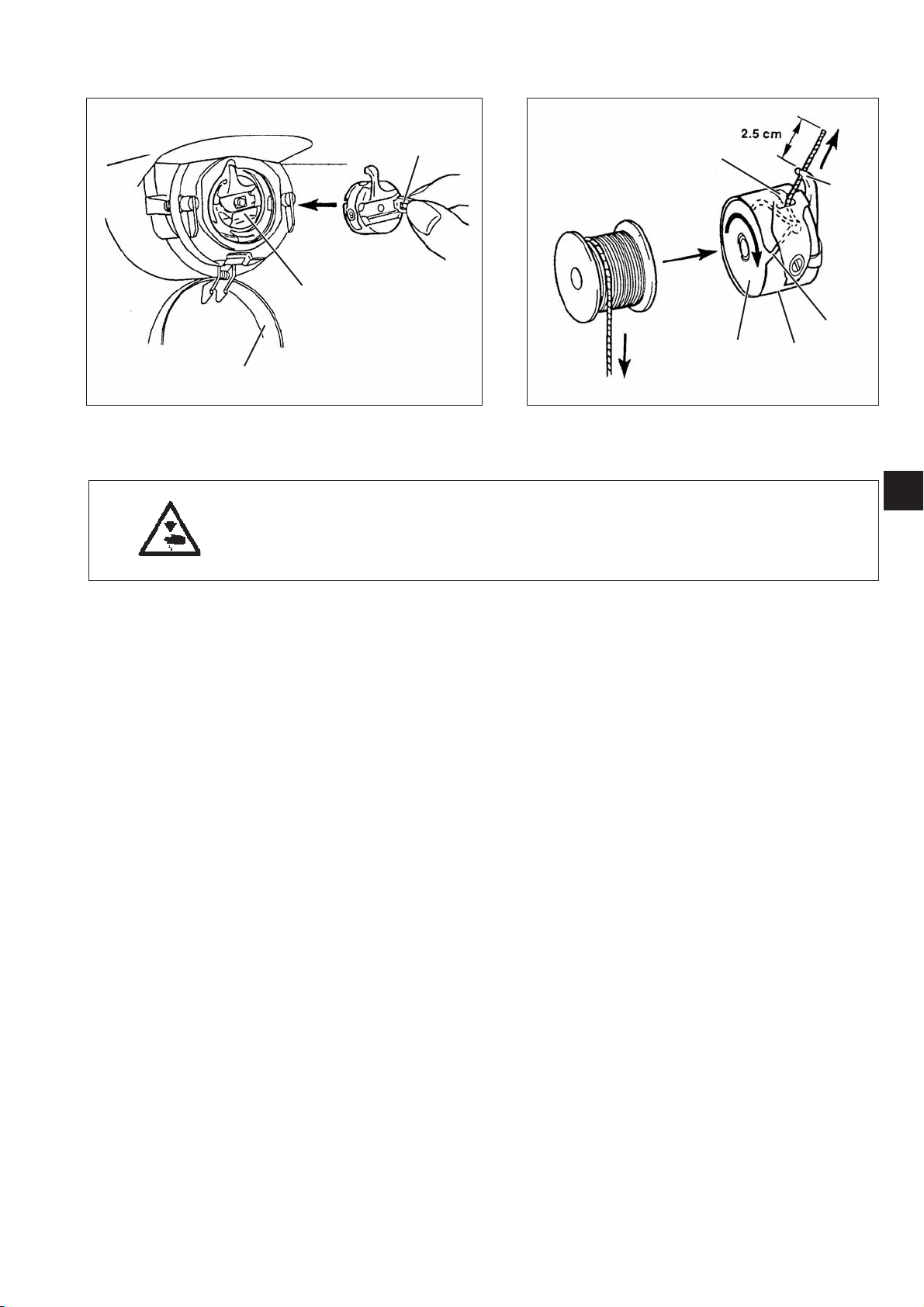

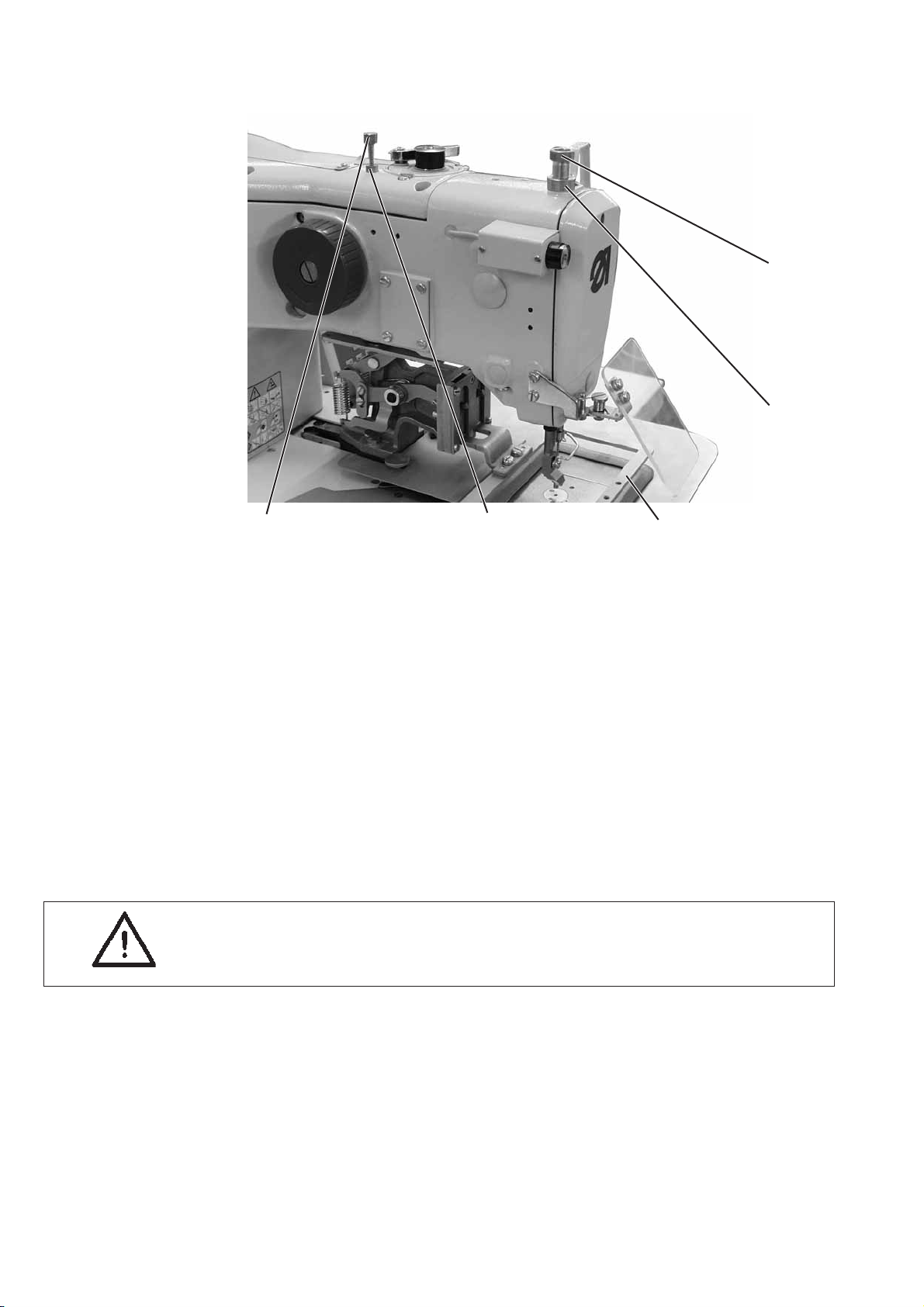

7.8 Adjusting the lifting movement of the clamping plate

4

5

321

7.9 Sewing foot pressure

The height of the opened clamping plate 1 can be adjusted via the

knurled-head screw 3.

–

Loosen the counter nut 2.

–

Turn the knurled-head screw 3.

turn to the right = c lamping plate 1 opens a little

turn to the left = clamping plate 1 opens wider.

–

Tighten the counter nut 2.

The desired sewing foot pressure is adjusted by means of the

knurled-head screw 4.

ATTENTION !

The material must not be lifted by the needle movement.

The pressure should not be set too high.

16

–

Loosen the counter nut 5.

–

Higher sewing foot pressure = turn the knurled-head screw 4 in

clockwise direction.

–

Lower sewing foot pressure = turn the knurled-head screw 4

counter-clockwise.

–

Tighten the counter nut 5.

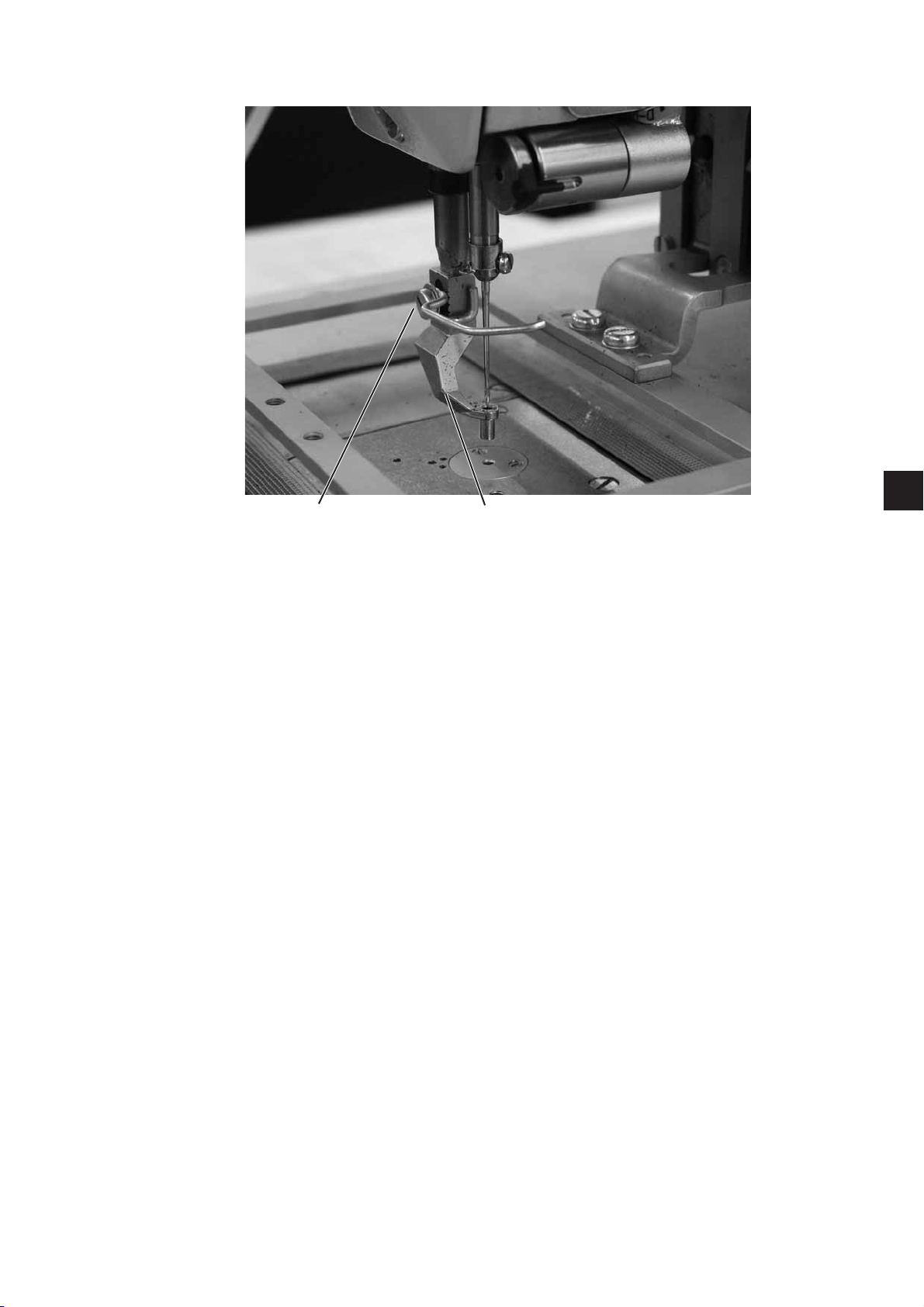

7.10 Sewing foot height

1

21

The sewing foot height is set by shifting the sewing foot 1.

–

Remove needle and thread.

–

Feed the material.

–

Switch the thread monitor on.

–

Start the sewing process and wait until the sewing unit stops

automatically.

–

Press “safe stop”.

–

Turn the handwheel until the sewing foot 1 is at its bottom position.

–

Loosen screw 2.

–

Set the height of sewing foot 1.

–

Retighten screw 2.

–

Release “safe stop”.

17

8. Operating the control of cl. 910

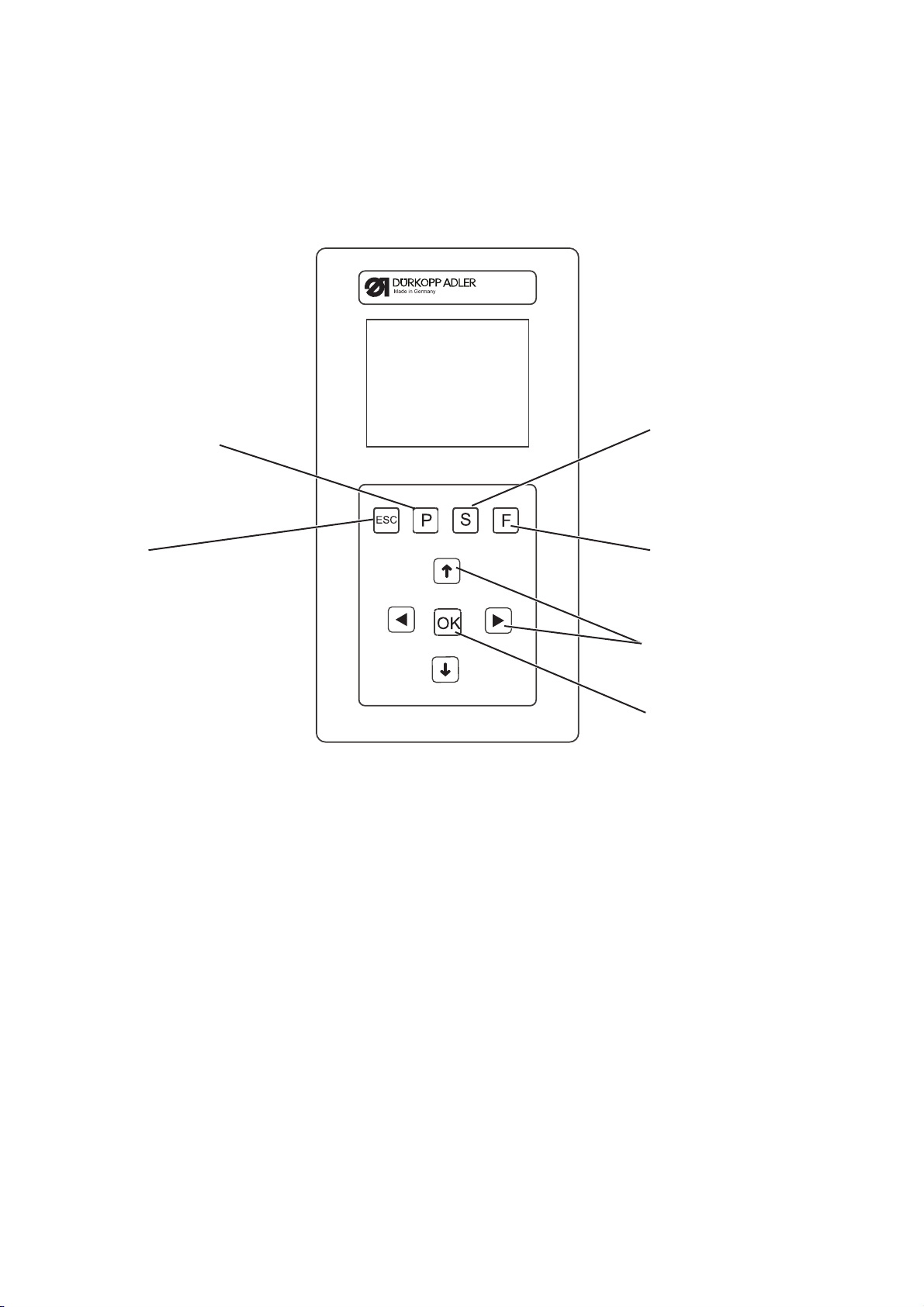

8.1 The operator terminal

For the input and output of data an operator terminal with an LCD

display and function keys is used.

P-key S-key

Loading, storing, deleting Select

of programs next program

ESC-key F-key

Select Multitest

Cursor keys

OK-key

18

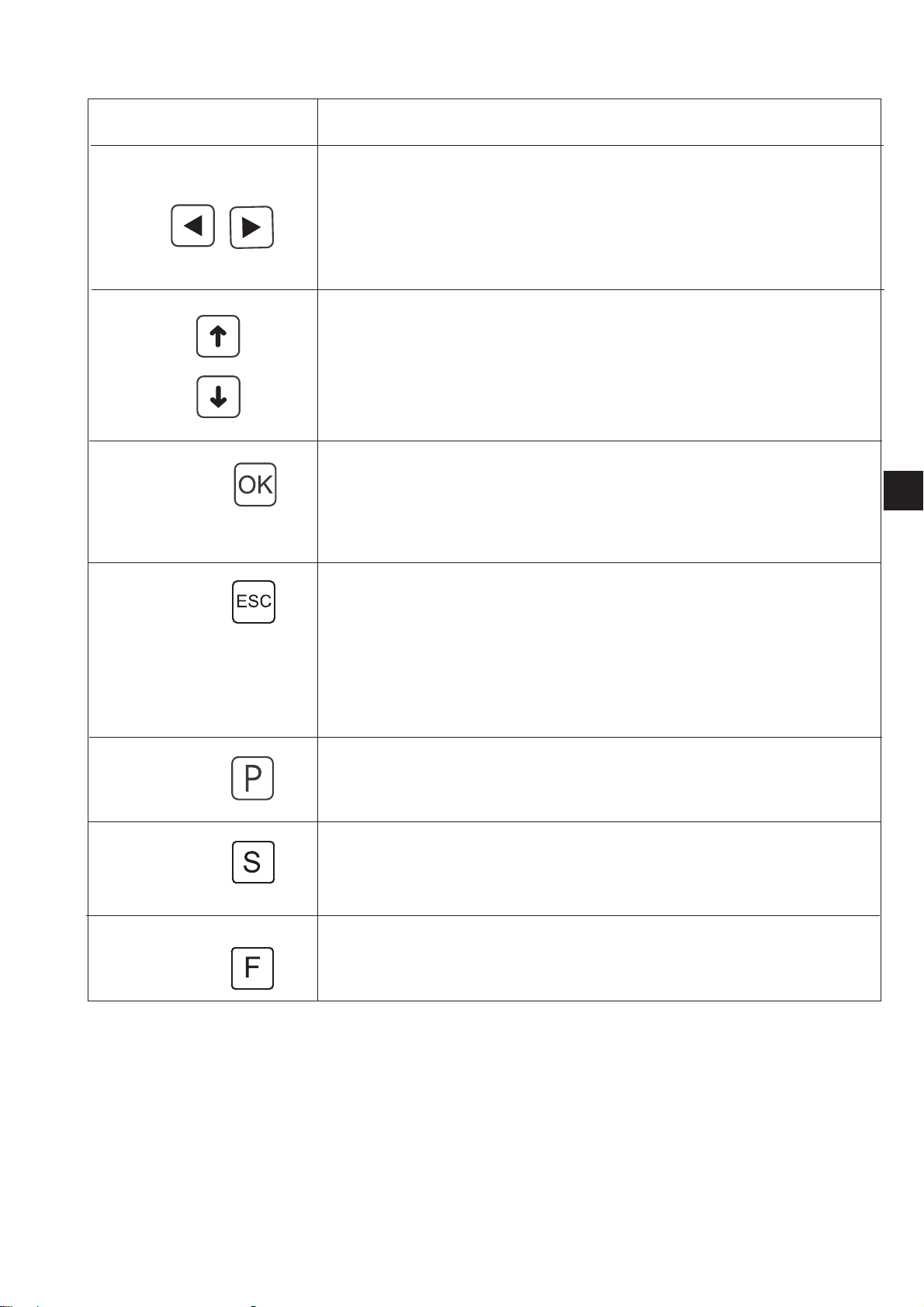

8.1.1 The keys

Function key Function

Cursor keys

In the sewing mode or sequence mode:

Shift the cursor to the left or to the right.

In the sewing mode in case of sequence operation:

Change to the next or to the preceding sewing sample.

If not input field is activated:

Change between the lines of the menus.

The selected line is displayed inversely.

If an input field is activated:

Increase or reduce the value of the respective point by one or change

between the parameters in case of functions with several choices.

OK-key If no input field is activated:

Activate the input field.

The value can be altered with the keys “ñ ” and “ò ”.

1

If an input field is activated:

The set value is taken over.

ESC-key If test functions are activated:

You return to the selection menu.

If an input field is activated:

An input is aborted.

The preceding value is maintained.

In the technician and programming level:

The control changes over to the preceding level.

P-key Loading, saving and deleting of programs.

S-key Select the next program.

In the sequence mode:

Change sequences.

F-key Call up Multitest and switch over to the technician level.

19

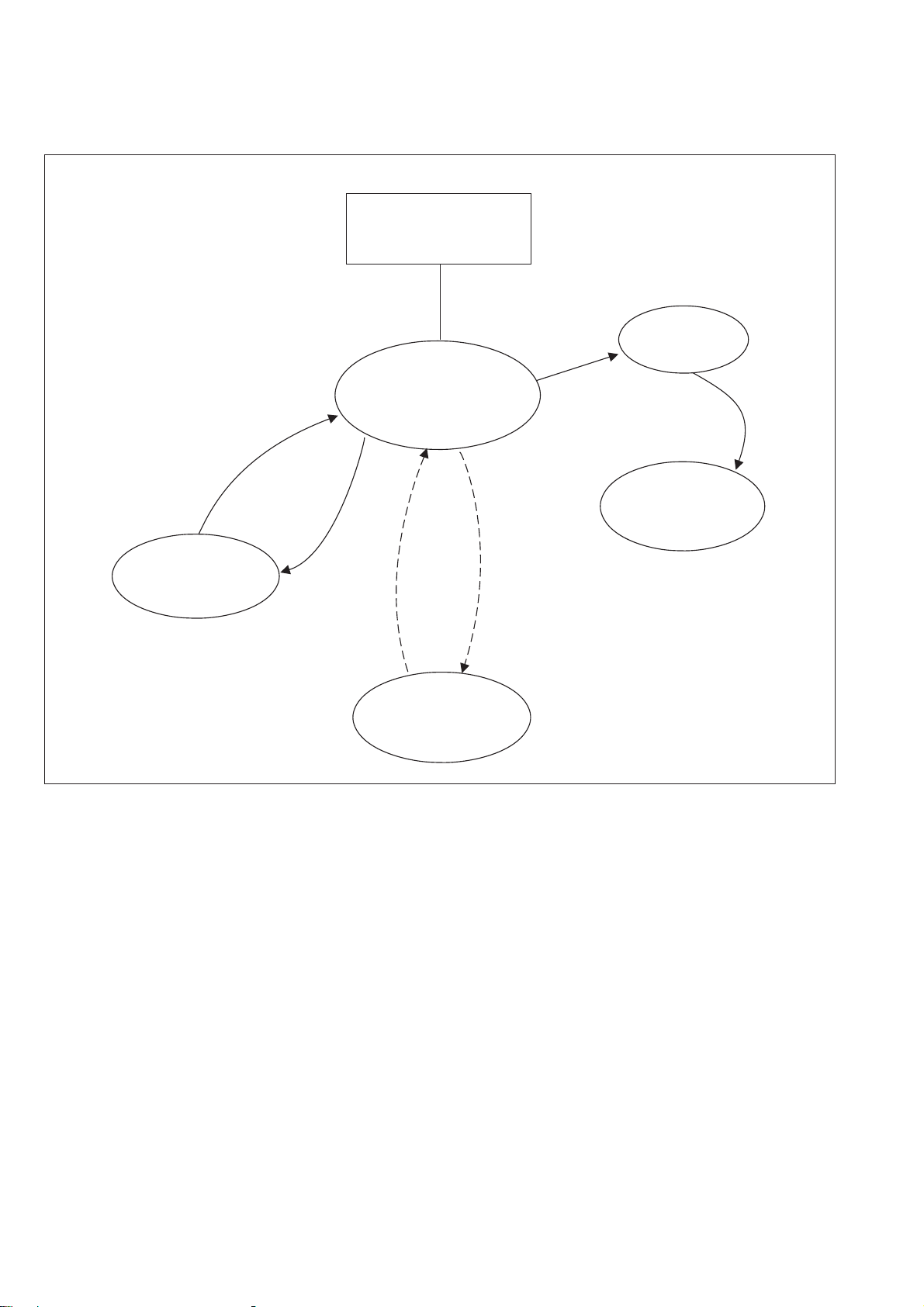

8.2 User interface

8.2.1 Structure of menu

ESC-key

Switch on

themainswitch

Multitest

Key F Menu

Sewing mode

Key F

Key P Technician mode

ESC-

Storage level key

Dongle

Calling up the service menu

–

Switchthemainswitchon.

The control is initialized.

–

Step the pedal back to reach the initial position of the sewing unit.

–

Press the function key “F”.

The display changes over to the Multitest menu.

Calling up the technician mode

–

Switchthemainswitchon.

The control is initialized.

–

Step the pedal back to reach the initial position of the sewing unit.

–

Press key “ F ”.

The display changes over to the Multitest menu.

–

Press key “ F ”.

–

EnterCode 1 (see chapter 9).

–

Press the “ OK” key.

The display changes over to the technician mode.

Key S

Program selection

or

sequence selection

20

8.3 Altering numerical values, parameter values, selection of alternatives

8.3.1 Altering numerical values

–

Select the desired line with the keys “ñ ”or“ò ”.

–

Press the “OK ”key.

The selected numerical value is marked by a flashing cursor.

–

Change between the points with the keys “ï”or“ð ”.

Increase or reduce the value of the selected point by one with the

keys “ñ ”or“ò ”.

–

Press the “OK ”key.

The currently set value is taken over.

or

–

Press the “ESC”key.

The original value is maintained.

1

Note

All values can only be altered within the minimum and maximum

values.

21

Loading...

Loading...