887

Spezialnähmaschine

Betriebsanleitung

Instruction manual

D

GB

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

06/2008 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 887740

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise Wiederverwendung

dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner, even

in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2008

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Contents Page:

Preface and general safety instructions

Part 1: Operating Instructions Class 887

(Edition 06/2008)

1. Product description ............................................ 5

2. Designated use ............................................... 5

3. Subclasses and sewing equipment

3.1 Subclasses .................................................. 6

3.2 Sewing equipment .............................................. 6

4. Optional equipment............................................. 7

5. Technical data ................................................ 8

6. Machine operation

6.1 Threading the needle thread ........................................ 9

6.2 Winding the hook thread .......................................... 9

6.3 Inserting the bobbin and threading the hook thread .......................... 10

6.4 Adjustingthethreadtension........................................ 11

6.4.1 Adjusting the hook thread tension ..................................... 11

6.4.2 Adjusting the needle thread tension .................................... 12

6.5 Switching the thread tensioner on/off ................................... 13

6.6 Adjusting the thread regulator ....................................... 14

6.7 Needle change ................................................ 15

6.8 Liftingandfoldingtherollerpresser.................................... 16

6.9 Sewing-footpressure ............................................ 17

6.10 Reversesewing(Backtacking)....................................... 18

6.11 Setting the stitch length ........................................... 19

6.12 Starting up the manually controlled machine with a clutch motor .................. 19

6.13 Controlling the machine equipped with a positioning motor ...................... 20

6.13.1 By a control pedal .............................................. 20

6.13.2 By a key panel ................................................ 21

GB

7. Positioning motor Efka DC1600/DA82GA

7.1 General ..................................................... 22

8. Positioning motor (drive) Efka VD552/6F82FA

8.1 General ..................................................... 22

9. Positioning drive Efka DC1550/DA321G

9.1 General ..................................................... 23

Contents Page:

10. Sewing w ith machine w ith positioning motor (drive)

10.1 Machineautomaticfunctions........................................ 24

10.2 Example of machine operation at sewing ................................ 25

11. Maintenance

11.1 Cleaning and checking ........................................... 26

11.2 Lubrication ................................................... 29

1. Product description

Dürkopp Adler 887 is a special sewing machine for universal use.

It is a flatbed double-lockstitch machine.

•

The machine has a double intermittent feeding. A lower wheel

•

feeder and a driven r oller presser feed in two steps, a needle feed

feeds in the first step only. The first step represents 50% of the total

stitch length.

Depending on subclass, the machine may be equipped with a large

•

or oversized hook, with automatic functions such as thread

trimming, automatic backtacking, automatic foot lifting.

Equipped with a two-piece vertical hook.

•

With a maximum of 12 mm clearance when sewing feet are lifted.

•

The residual thread length after thread trimming is about 15 mm.

•

A safety clutch prevents a changing of the hook setting or a hook

•

damage in the case of a thread deflection into the shuttle track.

The throat plate has replaceable inserts with the stitch hole

•

dimension difference, which are optional in dependence on the

needle number.

Automatic wick lubricating with an inspection glass on the arm for

•

machine and hook lubrication.

Integrated winder.

•

GB

2. Designated use

The 887 is a s ewing machine designated for shoe, leather, and

upholstery sewing. The usual material is leather (natural or artificial).

It is possible to use it for shoe fabrics too. The equipment for light,

medium or heavy sewing is mounted on the machine as an option.

This special sewing machine can also be used to produce so-called

technical seams. In this case, however, the operator must assess the

possible dangers which may arise (with which DÜRKOPP ADLER AG

would be happy to assist), since such applications are on the one hand

relatively unusual and, on the other, so varied that no single set of

criteria can cover them all. The outcome of this assessment may

require appropriate safety measures to be taken.

Generally only dry material may be sewn with this machine. The

material may be no thicker than 7 mm when compressed by the

lowered sewing feet. The material may not contain any hard objects,

since if it does the machine may not be operated without an

eye-protection device. No such device is currently available.

This special sewing machine may be set up and operated only

in dry, well-maintained premises. If the sewing machine is used in

premises which are not dry and well-maintained it may be

necessary to take further precautions (which should be agreed in

advance - see EN 60204-31:1999).

As manufacturers of industrial sewing machines we proceed on the

assumption that personnel who work on our products will have

received training at least sufficient to acquaint them with all normal

operations and with any hazards which these may involve.

5

3. Subclasses and sewing equipment

3.1 Subclasses

Class and subclass Needle Stitch Machine Hook Trimming

number length control and

backtacking

of the needle

1 needle, hook to the right

upto5mm

upto7mm

manual

automatic foot lifting

and electric backtacking

automatic foot lifting

and pneumatic backtacking

big, two part

very big, two part

without trimming,

manual backtacking

0887 160020 X X X X X

0887 160040 X X X X X

0887 160122 X X X X X

0887 160142 X X X X X

3.2 Sewing equipment

with trimming,

automatic backtacking

Needle number

Sewing equipment

887-E1

887-E2 medium 90-110 90 50-30 40 5 2500 2500 - -

887-E3 heavy

For classes and subclasses

0887 160020

0887 160122

0887 160020

0887 160040

0887 160122

0887 160142

Number of needles

Sewing category

light 70-80 70 80-60 60 4 3000 2500

1

Scope

0,01mm0,01

120-160 120

mm

Standard

thread label

number

Scope Polyester

Standard

Maximum stitch length

- - mm 1/min 1/min mm mm mm mm dB (A)

25-10 20 7 2000 1600 - -

Sewing speed

Maximum

Standard *

35

Top roller diameter

crosswise grooving

Wheel feed tooth pitch

Seam distance

--

* When sewing very thick layers, it is necessary to reduce the sewing speed significantly.

** Equivalent acoustic pressure level of a separate machine in the workplace by 20 % use of the machine.

Measured at the maximum stitch length and maximum sewing speed in compliance with

DIN 45635-48-A-1-KL2.

Trimming distance from the

needle

Machine noise **

6

4. Optional equipment

Order number Optional equipment

0888 220334 Roller presser Æ 25 mm knurled

0888 220344 Roller presser Æ 25 mm smooth

0888 220354 Roller presser Æ 25 mm rubberized

0888 220364 Roller presser Æ 35 mm knurled (basic)

0888 220374 Roller presser Æ 35 mm smooth

0888 220384 Roller presser Æ 35 mm rubberized

0888 220394 Roller presser Æ 45 mm, width 3.8 mm

0888 220404 Roller presser Æ 45 mm, width 2.0 mm

9880 888100 Diode lamp

MG55 400334 Stand set MG 55-3 for the machine driven with a V-belt (contains a frame, pedal,

drawer and a table top 1060 x 500 mm)

MG55 400324 Stand set MG 55-3 for the machine driven with a toothed belt (contains a frame, pedal,

drawer and a table top 1060 x 500 mm)

0700 088802 Stand top plate for the V-belt

0700 088804 Stand top plate for the toothed belt

N800 080030 Tiltable material guide

N800 080004 Tiltable material guide with a roller

0887 320143 Wheel feeder rubberized

N800 015412 Tiltable material guide with a roller on the slide plate

GB

7

5. Technical data

Stitch type double lockstitch 301

Needle system 134LR, 134 KKLR, 134, 134 D

Foot lifting with a hand lever 6 mm

Foot lifting with a knee lever or automatically 12 mm

Thread length after trimming max. 15 mm

Machine head clearance height 137 mm

Machine head clearance width 280 mm

Machine base plate plan dimensions 178 x 518 mm

Table top plan dimensions 1060 x 500 mm

Table top minimum height 740 mm

Table top maximum height 900 mm

Machine height max. 1630 mm

Maximum input (short-time) 0,8 kW

Weight of machine head 0887 160020, 0887 160040

Weight of machine head 0887 160122, 0887 160142

Weight of stand 30 kg

Weight of motor FIR 19 kg

Weight of motor EFKA DC 1600 18 kg

Weight of motor EFKA DC 1550 10 kg

8

6. Machine operation

6.1 Threading the needle thread

1

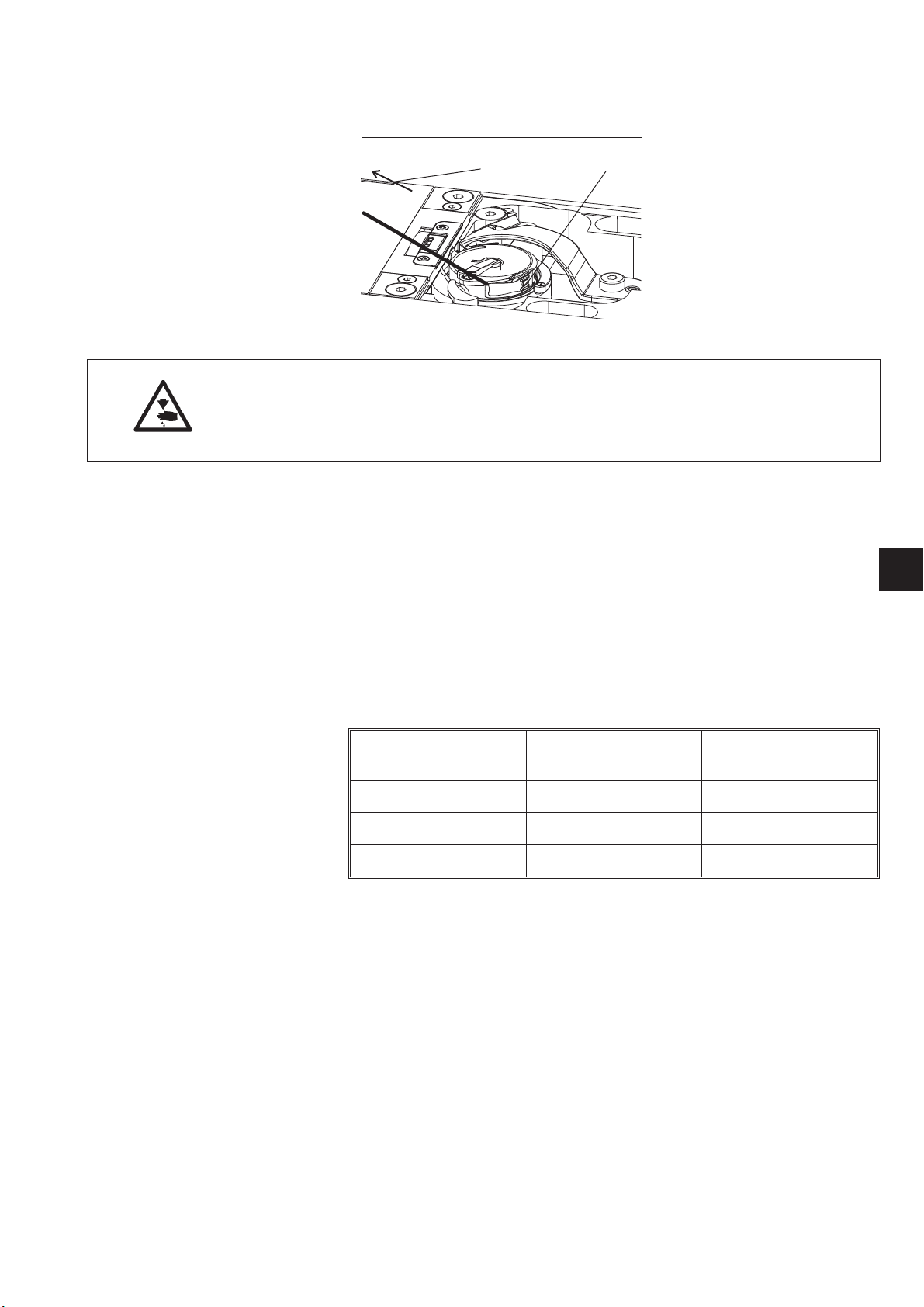

6.2 Winding the hook thread

Caution! Risk of injury!

Turn off the main switch.

The needle thread may only be threaded with the sewing machine

switched off.

–

Thread the single needle machine according to Fig. If the machine

is equipped for heavy sewing, wind the thread around the pin (1).

1234

–

Thread the thread according to the picture.

–

Insert the thread under the knife (1) and tear off by pulling in the

arrow direction (2).

–

Fix the bobbin and press the lever (3) in the direction (4).

–

Start the machine up.

–

After the thread winding, slide the thread under the knife again (1)

and tear it off.

–

Insert another bobbin immediately and press the lever (3).

GB

9

6.3 Inserting the bobbin and threading the hook thread

2

3

10

6

1

4

5

Caution! Risk of injury!

Turn off the main switch.

The hook-thread bobbin may only be changed with the machine

switched off.

–

Tilt the shutter (1) up.

–

Insert the bobbin (2) with the thread end (3) oriented according to

the picture.

–

Thread the thread through the slit (4) and space (5), hook upon the

shutter (1) and fasten it under the spring (6).

–

Trim the thread ends according to the picture.

10

6.4 Adjusting the thread tension

6.4.1 Adjusting the hook thread tension

Caution! Risk of injury!

Turn off the main switch.

The hook thread tension may only be adjusted with the machine

switched off.

–

–

13

Adjust the hook thread tension by the screw (1) with a screwdriver.

The tension is increased by tightening the screw.

Measure the thread tension with a dynamometer. Thread the

thread according to the picture and pull in the arrow direction (3).

This tension is adjusted in the factory in dependence on the

selected sewing equipment according to the below table, and it is

suitable for the usual sewing operations. For sewing thin soft

materials, it is necessary to reduce the tension. If the seam is to be

tightened strongly, it is necessary to increase the tension and

reduce the sewing speed at the same time.

GB

Hook thread tension mean value

Sewing category Needle used

thread Nadelstärke Nm

light 70-80 50

medium 90-110 65

heavy 120-160 90

Tension in

grams

11

6.4.2 Adjusting the needle thread tension

1

2

3

4

Supplementary tensioner adjustment (1)

–

Adjust the supplementary tensioner (1) so that it has the lowest

tension possible, but so high that, when taking out the sewn

material after the preceding trimming (when the tensioners (2)

and (3) are switched off), the thread is not pulled out of the

tensioner (1). (Tensioner (1) is not switched off at the foot lifting).

Tensioner (2) and (3) adjustment

The machine can be equipped with a lever (4) for the tensioner (2)

temporary switching off. In this case, two thread tension values can be

pre-selected and a good stitch tightening can be achieved when

sewing over a variable number of layers of the sewn material with one

seam.

–

Switch the tensioner off (2) with the lever (4) and sew on a smaller

number of layers.

–

Regulate the thread tension with the tensioner (3), till a good

thread loop is achieved (see opposite figure).

–

Switch the tensioner on (2) by the lever (4) shifting out and sew on

a greater number of layers.

–

Regulate the thread tension with a tensioner (2), till a good thread

loop is achieved (see opposite figure).

–

If the machine is not equipped with the lever (4), regulate the

tension by both tensioners (2) and (3) at the same time so that their

nuts are screwed approximately in the same height.

12

Correct thread interlacing in the center

of the material

Needle-thread tension too low

or

hook-thread tension too high

Needle-thread tension too high

or

hook-thread tension too low

6.5 Switching the thread tensioner on/off

1

GB

All machines

–

When pulling the hand lever (1) towards the operator, the

tensioners (3) and (4) are switched off.

–

Tensioner (2) is never switched off.

Manually controlled machines (without the thread trimming)

–

Tensioners (3) and (4) are mechanically switched off when the foot

is lifted with a hand or knee lever.

Machines with the thread trimming

–

Tensioners (3) and (4) are switched off with an electric magnet or

pneumatic cylinder at the foot automatic lifting. If the automatic foot

lifting at the machine stop is pre-selected, the tensioners are

switched off, but temporarily only, so that the switching off electric

magnet does not overheat.

–

Tensioners (3) and (4) are also switched off temporarily during the

trimming cycle.

–

Tensioners (3) and (4) are not switched off at the foot lifting with

the hand or knee lever.

2

3

4

13

6.6 Adjusting the thread regulator

2

1

The thread regulator (2) controls the quantity of needle thread required

for stitch formation.

The thread regulator must be precisely adjusted for an optimum result.

–

Loosen the screw (1), shift the thread regulator (2), and tighten the

screw (1).

–

For most of the sewing operations, the regulator optimal setting is

with its right edge corresponding to the No. 2.

–

For a thin material layer and a very short stitch only, the setting

corresponding to the No. 3 is suitable.

1234

14

6.7 Needle change

1

2

MAX. 3°

3

4

5

Caution! Risk of injury!

Turn off the main switch.

The needle may only be changed with the sewing machine switched

off.

GB

–

Draw the lever (1) in your direction to loosen the screw fixing the

needle.

–

Remove the needle and insert a new one with the needle scarf (2)

to the right according to the section (3) or (4). The needle may not

be oriented according to the section (5).

–

Turn the lever (1) back to tighten the needle fixing screw.

Caution!

A false orientation of the needle turning may cause the hook point

destruction.

When changing to another needle size, the distance between hook

and needle must be readjusted (see service instructions).

15

6.8 Lifting and folding the roller presser

Lifting the roller presser with a hand lever

–

Lift the roller presser by the lever turning (1) in the arrow direction

to the stop (the roller presser remains lifted, the lever (1) remains

tilted).

–

Lower the roller presser by putting the lever (1) to the initial

position, or by pressing the knee lever (3) and its subsequent

release.

–

After the roller presser lifting with the hand lever, the machine may

be started up (e. g. at the hook thread winding).

1

3

4

Roller presser lifting with the knee lever

–

The roller presser is lifted by pressing the lever (3); the roller

presser is lowered at the lever release.

Caution!

At the roller presser lifting higher than 6 mm over the throat plate the

machine may not operate, otherwise the needle bar with the needle

holder hits the roller presser, or the needle guides of the double needle

machines.

Roller presser lifting with a pedal - automatically

–

The roller presser lifting in the machines equipped with a

positioning motor (drive) can be controlled by the pedal (4)

treading in the position -1 (see par.6.13.1). The roller presser is

lifted to the upper dead point by means of an integrated electric

magnet or pneumatic cylinder. After the pedal is released, the roller

presser is lowered.

–

It is possible to pre-select the automatic roller presser lifting at

each machine stop without the necessity to tread the pedal in the

position to the position -1. In this case, the roller presser is lowered

at the pedal treading in the position +1. After the finishing of the

seam, the roller presser remains lifted permanently.

16

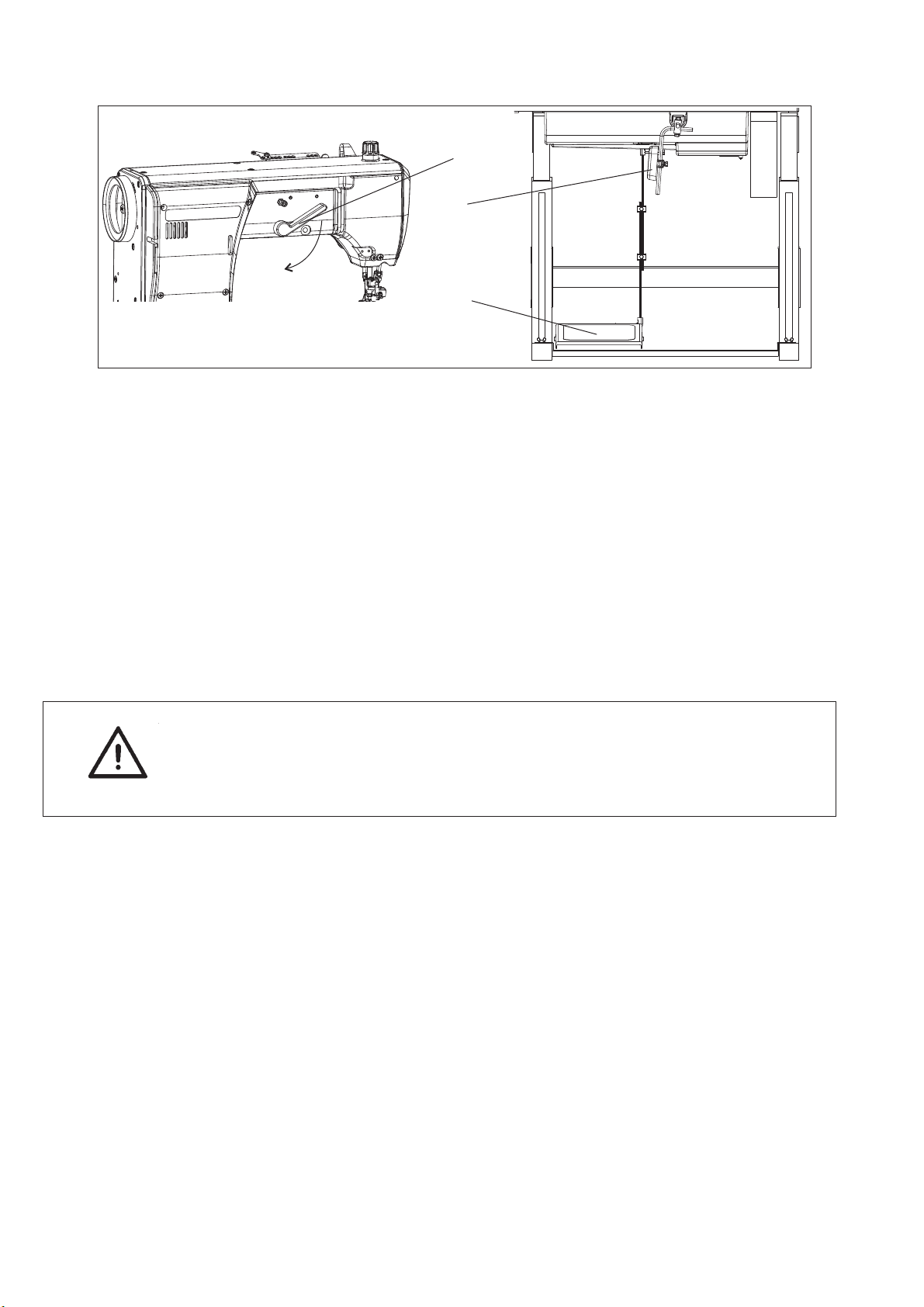

Roller presser folding

–

Lift the roller presser with the hand lever.

–

Lift the roller presser by pressing in the signed direction.

Caution! Risk of injury!

Roller presser folding to be done at main switch off and standing

motor.

6.9 Sewing-foot pressure

1

+

–

Regulate the roller presser pressure with the setting wheel (1).

–

To incre ase the roller pres se r pressu re = turn the setting wheel (1)

clockwise.

To decre ase the ro lle r pre sser pressur e = turn the setting wheel (1)

anti-clockwise.

–

The roller pressure is to be as small as possible, but strong enough

that the roller presser is not lifted by the needle friction in the

material during the upward movement and that the feeding is

reliable.

–

The maximum roller presser pressure is 100N in the machine

equipped with electric magnets, and in the machine with the

pneumatic cylinders 160N.

GB

17

6.10 Reverse sewing (Backtacking)

Backtacking with a hand lever

–

Press the lever (1) downwards. As long as the reverse feed

lever (1) is pressed down, the machine sews in reverse.

Backtacking with a key

–

Press the key (2) or lever (3). The machine sews in reverse, as

long as the key (2) or lever (3) is pressed down.

Automatic backtacking (bartacking)

In the machines equipped with the positioning motor it is possible to

pre-select the backtacking by a pre-selected backstitches number both

at the beginning and at the seam end. At the seam beginning (after the

preceding thread trimming) after the pedal treading forwards the

machine sews the pre-selected bartack entirely automatically. The

same at the seam end after the pedal treading in the position –2 the

machine sews the pre-selected end bartack and then trims the threads.

1

2

3

18

6.11 Setting the stitch length

1

2

3

–

Turn the button (1) so that the number (2) indicating the required

stitch length in mm is opposite the mark (3).

6.12 Starting up the manually controlled machine with a clutch motor

–

Switch on the motor (1) with a switch (2) – the drive motor operates

permanently.

–

Tread the pedal (3). The motor friction clutch gets switched and the

sewing machine starts running.

–

Regulate the sewing speed by the pressure on the pedal (3).

Dependent on this pressure, the clutch slip changes and

subsequently the machine speed as well.

–

Release the pedal (3). The sewing machine stops.

GB

2

1

3

19

6.13 Controlling the machine equipped with a positioning motor

6.13.1 By a control pedal

-2

-1

0

1

2

13

The pedal position is scanned by a sensor distinguishing 16 levels.

The meaning is given in the table:

Pedal position Pedal motion Meaning

-2 Over heel fully backwards Command for thread trimming

(seam finishing)

-1 Over heel slightly backwards Command for foot lifting

0 Neutral position See notes

1 Slightly forwards Command for foot lowering

2 Further forwards Sewing at minimum speed

(1. speed gear)

3 Further forwards Sewing - 2. speed gear

:: :

13 Fully forwards Sewing at maximum speed

(12. speed gear)

Note: In addition to the neutral position, it is possible to pre-select the

needle position (down/up) and the foot position (down/up) at the

stopping in the seam (by the pedal positioning in the neutral position),

the foot position (down/up) after the seam finishing (by the pedal

treading fully backwards and positioning the pedal in the neutral

position).

20

6.13.2 By a key panel

Key Function

1 Manual bactacking

2 Needle positioning to the upper or lower position

3 Calling out/cancellation of the start or end bartack

4 Half length stitch

7 810911123 4

When the key is pressed during the sewing, the sewn material is fed backwards.

By parameter F-140 (Efka DA82GA); F-242 (DA321) the following function keys can

be defined:

1 = needle up (DA82GA); needle up/down (DA321)

2 = needle up/down (DA82GA); needle up (DA321)

3 = one stitch

4 = one stitch with the second/shorter stitch length (in machines with this equipment)

5 = needle up, if it is out of position 2

(factory setting is 1 = needle up)

If the start and end bartack are switched on, the following bartack is switched

off by pressing the key.

If the start and end bartack are switched off, the following bartack is switched on

by pressing the key.

By pressing the key 1 stitch of half length is sewn.

GB

LED Function

8 and 9 Warning of an empty bobbin in the machines with rest bobbin thread

sensor (left/right bobbin).

10 LED signals the network switching on

Through the arresting of the pin 11 under the key 1 it is possible to transfer the

key 1 function to key 7:

- select the function (e. g. 1 = manual backtacking)

- turn the pin 11 under the key 1 by 90° clockwise (the groove is vertical)

The manual backtacking function can be called out by the keys 1 and 7 now.

CAUTION!

Before key (7) can be programmed with a new function, the former

setting must be deactivated.

21

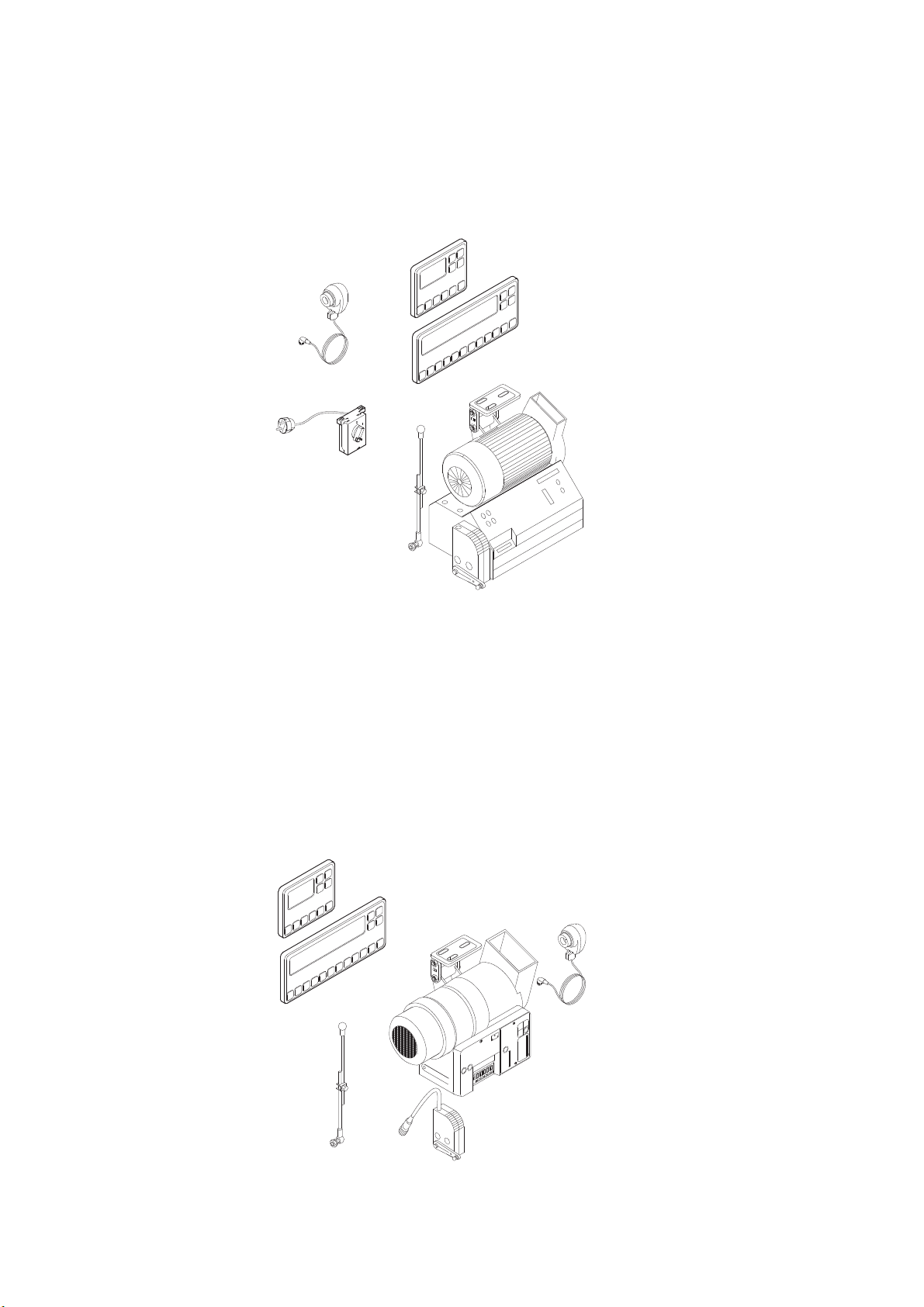

7. Positioning motor Efka DC1600/DA82GA

7.1 General

For a detailed description of the control unit, please consult the

enclosed current issue of the operating manual of the motor

manufacturer (see also www.efka.net).

8. Positioning motor (drive) Efka VD552/6F82FA

8.1 General

For a detailed description of the control unit, please consult the

enclosed current issue of the operating manual of the motor

manufacturer (see also www.efka.net).

22

9. Positioning drive Efka DC1550/DA321G

9.1 General

For a detailed description of the control unit, please consult the

enclosed current issue of the operating manual of the motor

manufacturer (see also www.efka.net).

GB

23

10. Sewing with machine with positioning motor (drive)

10.1 Machine automatic functions

The machine has the below functions which are automatically

performed during the seam sewing depending on:

–

Pre-selection

–

Pedal position (according to the machine operator´ s selection)

–

Working phase of seam sewing

Automatic function

Needle positioning

Bartacks

Initial bartack

End bartack

Pre-selection

Needle down at machine stopping in seam

•

Needle up at machine stopping in seam

•

Note: after the seam * finishing the machine stops always

with the needle up.

Standard

•

Decorative**

•

Single

•

Double

•

Standard bartack stitch number forwards

•

Decorative bartack stitch number forwards

•

Standard bartack stitch number backwards

•

Decorative bartack stitch number backwards

•

Single

•

Double

•

Standard bartack stitch number backwards

•

•

Decorative bartack stitch number backwards

•

Standard bartack stitch number forwards

•

Decorative bartack stitch number forwards

Thread trimming

Automatic foot lifting

•

ON

•

OFF

•

Foot lowered at stopping in seam

•

Foot lifted at stopping in seam

•

* The seam is finished after the pedal shifting to the position -2 (if the thread trimming is pre-selected, then after

the trimming).

** The decorative bartack is characterized by the fact that the needle sews stitch in stitch in the previous seam at

the bartacking. At the sewing direction change the machine stops for a moment.

24

10.2 Example of machine operation at sewing

Pre-selection:

Needle down at machine stopping in seam

Standard bartacks

Double initial bartack

Double end bartack

Thread trimming on

Foot lowered at stopping in seam

Foot lifted at seam finishing

Operator´ s action Machine work

Machine stopped. Needle in upper position. Foot lifted in

accordance with pre-selection.

Insertion of sewn material.

Pedal treading to position +1. Foot lowering.

Pedal release to position 0. Foot lifting.

Material position correction.

Pedal treading to position +1. Foot lowering.

Pedal treading to position +3. Sewing of standard double bartack (at speed pre-selected by

producer and subsequent sewing at speed corresponding with

third speed level +3.

Pedal release to position 0. Machine stopping with needle down.

Pedal treading to position -1. Foot lifting.

Turning of sewing material

on needle.

Pedal treading to position +5. Foot lowering and subsequent machine running to fifth speed

grade of sewing.

Pedal treading to position -2. Speed reduction. Sewing of standard double bartack.

Thread trimming under throat plate and machine stopping with

needle up. Foot lifting.

Pedal release. (Foot remains lifted).

Putting out of sewn material.

GB

25

11. Maintenance

11.1 Cleaning and checking

Caution! Risk of injury!

Maintenance may be carried out only with the machine switched off

and the motor stopped!

Maintenance work must be carried out no less frequently than at the

intervals given in the tables (see ”operating hours” column).

Maintenance intervals may need to be shorter when processing

heavy-shedding materials.

2

4

6

5

3

1

7

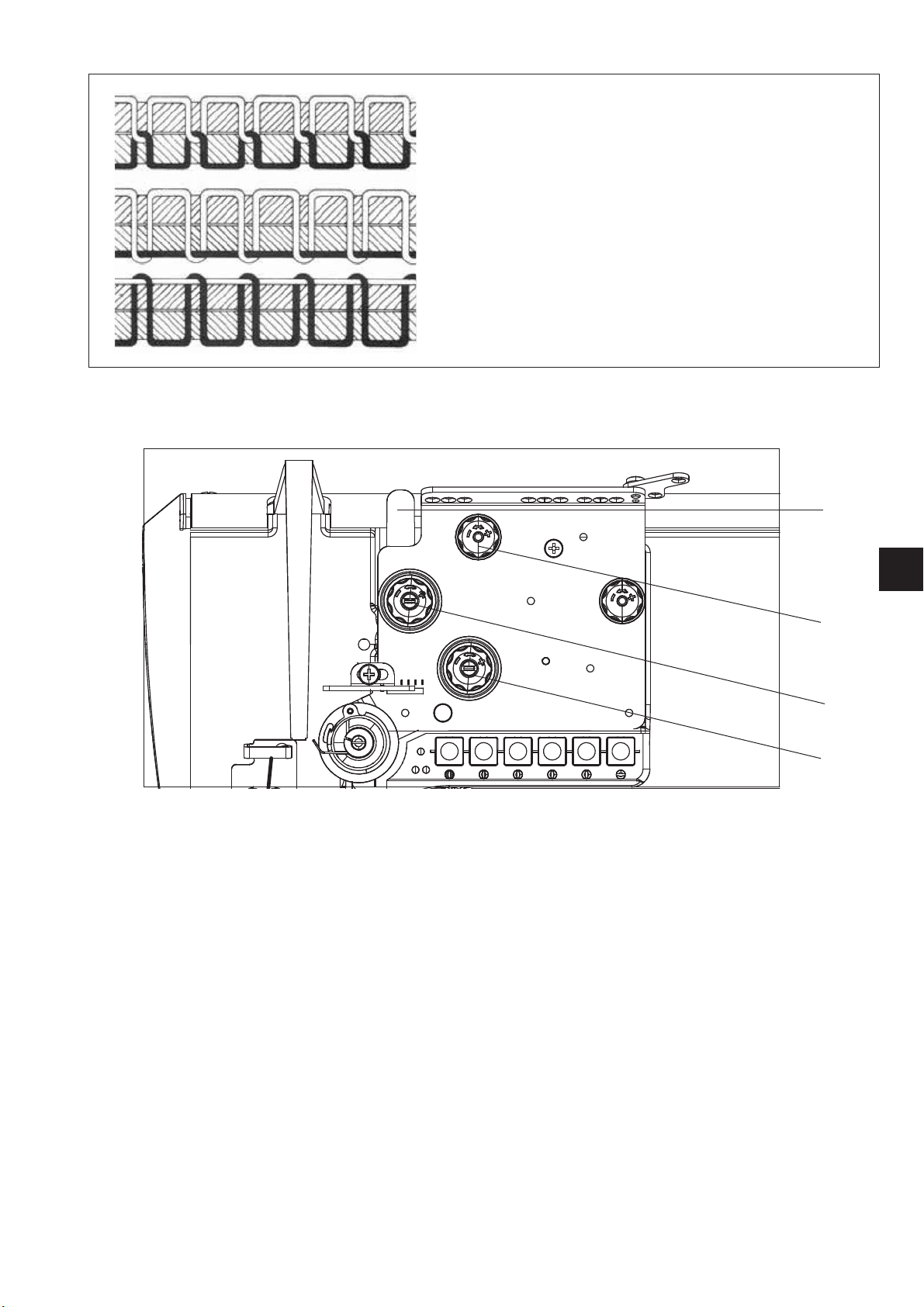

Maintenance work Explanation Operating

to be carried out hours

Machine head

- Remove lint, pieces of thread

and other debris (e.g. w ith

an air blow gun)

- Remove lint, pieces of thread

and other debris (e.g. w ith

an air blow gun)

- Check the hook Check the clearance of the bobbin housing (6)

Places in special need of cleaning:

- area under the throat plate , feed dog (2),

roller foot.

- area around the hook (1)

- bobbin housing (6)

- thread trimmer

- needle area

CAUTION !

Hold the air blow gun in a way that the lint is

not blown into the oil sump.

Dismantle the throat plate, thread pulling

knife (4), dismantle the hook plunger ring (5),

remove the bobbin housing (6) from the hook.

Clean the inner part of the hook, clean the

bobbin housing - especially the glue

remainder on the surface (7).

and the hook (1).

8

20

500

26

4

3

2

1

Maintenance work Explanation Operating

to be carried out hours

- Clean the oil sump. Cleaning the oil sump (1) for example with

a special vacuum cleaner.

- Clean fan grille. Remove lint and pieces of thread from

air-intake openings (2) and (3) (e.g. with an

air blow gun).

- Check condition and

tension of V-belt.

Check the condition of the V-belt (4).

(check the service instructions).

20

GB

20

500

27

2

4

6

8

10

1

2

3

Maintenance work Explanation Operating

to be carried out hours

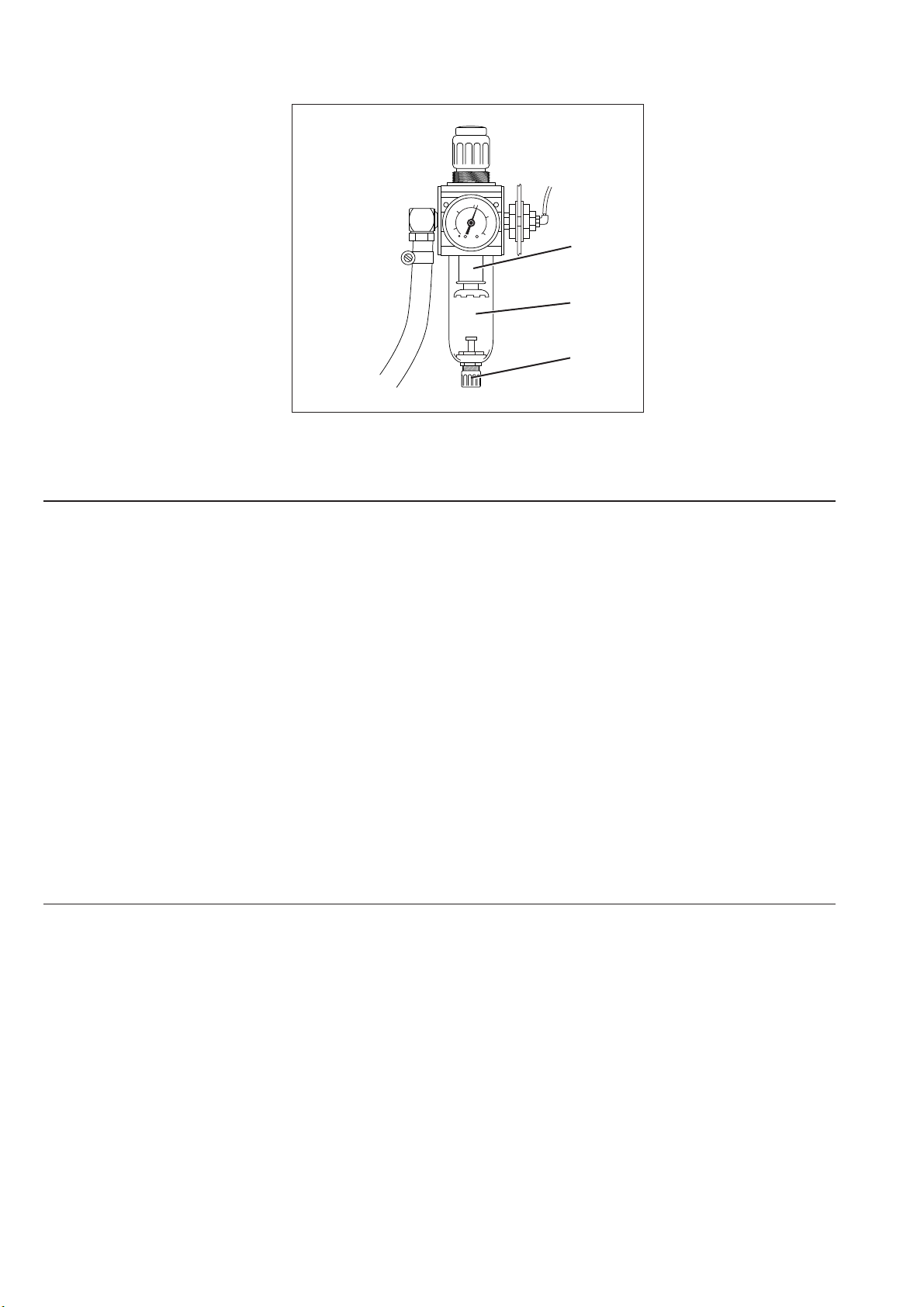

Pneumatic system

- Check water level in

pressure regulator.

- Clean filter cartridge.

- Check the system for leaks.

The water level must not rise to the level of

the filter cartridge (1).

- After unscrewing the drain screw (3), the

water under pressure will flow out of

the water separator (2).

Dirt and condensation are separated out by

the filter cartridge (1).

- Disconnect the machine from the

compressed-air supply.

- Unscrew the drain screw (3).

Theremustbenopressureinthe

machine’s pneumatic system.

- Unscrew water separator (2).

- Unscrew filter cartridge (1).

Wash the filter shell and cartridge

with cleaning fluid (no solvent) and

blast clean.

- Re-assemble the maintenance unit.

40

500

500

28

11.2 Lubrication

2

1

3

Caution: danger of injury

Oil can cause skin eruptions.

Avoid protracted contact with the skin.

In the event of contact, thoroughly wash the affected area.

CAUTION:

The handling and disposal of mineral oils is subject to legal regulation.

Deliver used oil to an authorised collection point.

Protect your environment.

Take care not to spill oil.

GB

To lubricate the special sewing machine use only DA-10 lubricating oil

or an equivalent oil of the following specification:

–

Viscosity at 40° C: 10 mm²/s

–

Flashpoint: 150° C

DA-10 is available from DÜRKOPP ADLER AG retail outlets under the

following part numbers:

250-ml container: 9047 000011

1-litre container: 9047 000012

2-litre container: 9047 000013

5-litre container: 9047 000014

If the oil volume drops to the level (3), supply the oil through the

hole (2) to the “MAX” level.

Check the oil level every day!

All points of the sewing machine head lubricated with oil are supplied

from the central tank (1).

Caution! Risk of failure!

The oil may be supplied only into the central tank or in the hook path.

The other points must not be lubricated separately, so that the oil does

not penetrate to the spots, which must not be lubricated.

29

Notes:

30

Loading...

Loading...