Page 1

868

Spezialnähmaschine

Betriebsanleitung

Instruction manual

D

GB

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

05/2008 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 868740

Page 2

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise Wiederverwendung

dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner, even

in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2008

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 5

Contents Page:

Part 2: Installation Instructions Class 868

1. Scope of Delivery ............................................ 5

2. General and transport packing .................................... 5

3. Assembling the stand

3.1 Assembling the stand components ( Standard) ............................ 7

3.2 Assemblingthetableplate........................................ 7

3.3 Settingtheworkingheight........................................ 8

4. Sewing drives

4.1 Drive category, type and use ...................................... 9

4.2 Drive-pack components ......................................... 9

4.3 Fittingthesewingdrive.......................................... 10

4.4 Fitting the pedal .............................................. 10

4.5 Fitting the sewing-drive control for machines with Efka DC 1550 / DA 321G.......... 11

4.6 Fittingthesetvalueinitiator....................................... 11

GB

5. Assembling the machine head

5.1 Fitting the hinges on the machine head ................................ 12

5.2 Fitting the direct drive (Efka DC 1550/DA321G) ........................... 13

5.3 Tensioning the toothed belt of the direct drive (Efka DC 1550/DA321G) ............ 13

5.4 Placing the sewing machine head on the stand ........................... 14

5.5 FittingandtensioningtheV-belt .................................... 15

5.6 Fittingthebeltcover ........................................... 16

5.7 Fittingtheoilsuctiontube........................................ 17

5.8 Attachingthekneelever......................................... 18

5.9 Fitting the operating panel ........................................ 19

5.10 Fitting the sewing lamp (optional equipment)............................. 20

6. Electrical connection

6.1 General ................................................... 22

6.2 Checkingthemainsvoltage....................................... 22

6.3 Connecting the sewing drive....................................... 22

6.3.1 Connecting the clutch motor ....................................... 22

6.3.2 Connecting the direct-current positioning actuator ......................... 22

6.4 Earthing................................................... 23

6.5 Connecting the sewing drive to the mains............................... 24

6.6 Connecting the machine head ..................................... 24

6.7 Connecting the sewing light transformer (optional equipment) .................. 25

6.8 Connecting the direct drive ....................................... 26

6.8.1 Connecting the Hall sensor (optional equipment) .......................... 26

6.8.2 Attaching and connecting the sewing light transformer (optional equipment).......... 28

Page 6

Contents Page:

6.8.3 Connection to the DA321G control unit ................................ 28

6.8.4 Connecting the sockets of the DA321G control unit ......................... 29

6.8.5 Connecting the DA321G control unit .................................. 29

6.8.6 Checkingthedirectionofrotationofthesewingdrive ....................... 30

6.8.7 Checkingthepositioning......................................... 30

6.8.8 Machine-specificparameters...................................... 31

6.9 Masterreset................................................. 31

7. Pneumatic connection

7.1 Pneumatic sewing foot lifting ...................................... 33

8. Lubrication ................................................ 34

9. Sewing test ................................................ 35

Page 7

GB

Page 8

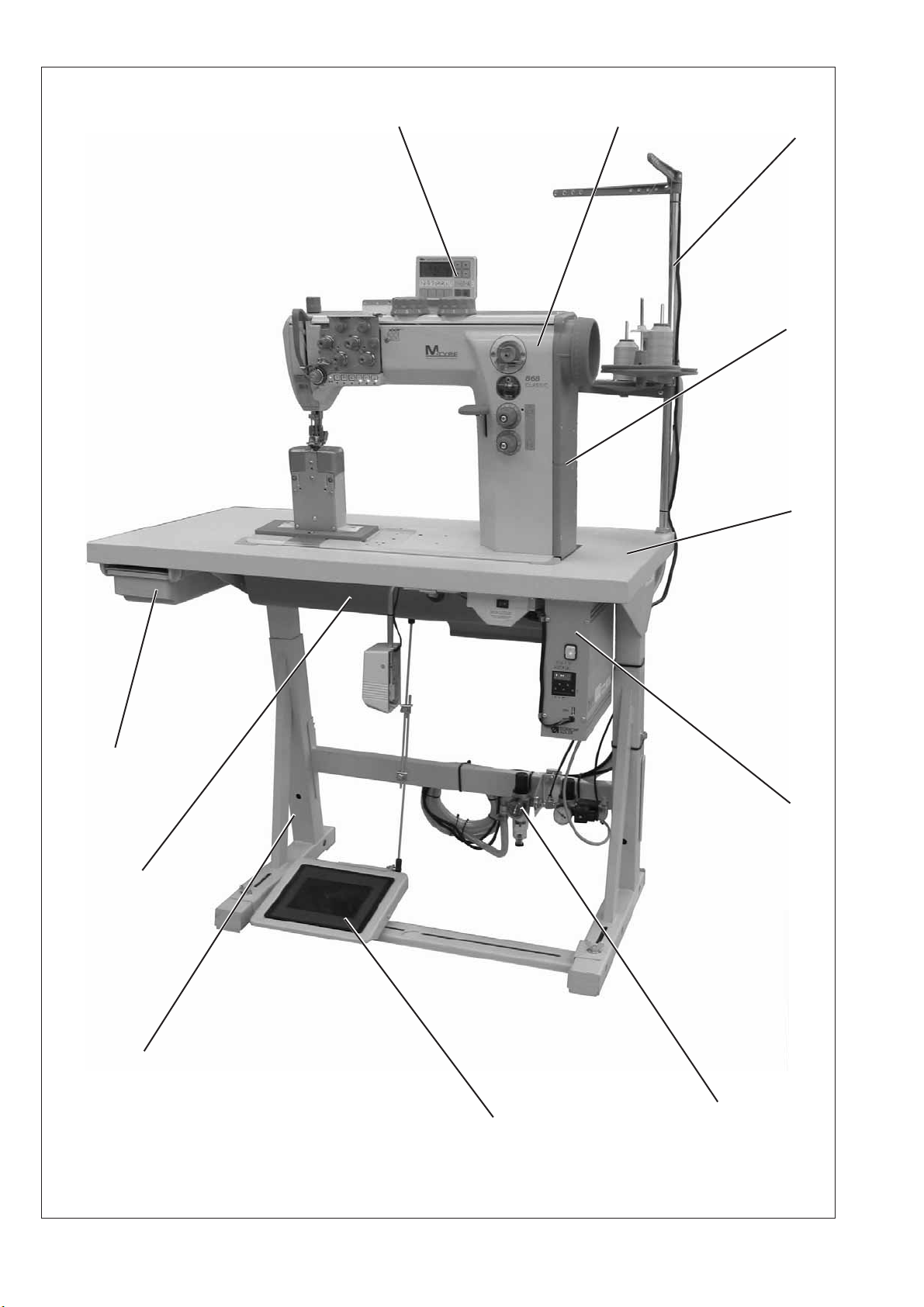

11

1

2

3

4

10

5

9

8

7

6

Page 9

1. Scope of Delivery

What items are supplied depends on your order.

Prior to setting up, please check that all the required parts are present.

This description refers to a special sewing machine, of which all individual

components can completely be delivered by Dürkopp Adler AG.

–

1 Machine head

Dürkopp Adler accessory set box with:

–

2 Reel stand

–

Protection cover (not represented)

–

9 Oil tray

Set of electronic parts, depending on the order, for:

Machines with Efka DC 1550 / DA321G actuator

–

5 Efka control unit

–

11 Operating panel

–

3 Cover

Machines with clutch motor

–

Main switch

–

Sewing-drive

–

Belt guard

Optional equipment

–

8 Stand (optional)

–

7 Pedal and linkage (optional)

–

4 Table top (optional)

–

10 Drawer (optional)

–

Knee lever

–

Pneumatic sewing foot lifting

2. General and transport packing

Caution:

The special sewing machine must be set up by trained specialist

personnel.

GB

Transportation locks

If the special sewing machine you have bought is already set up, the

following transport packing must be removed:

–

Safety straps and battens on the machine head, table and stand.

–

Safety block and straps on the sewing drive.

5

Page 10

12

Observe the punch-marks of the table plate!

1

13

15

4,5x15 (x 4)

2

14

3

11

3,5x17 (x 6)

10

9

4

5

6

3,9x15 (x 5)

3,5x17 (x 2)

7

B8x35 (x 4)

8

6

Page 11

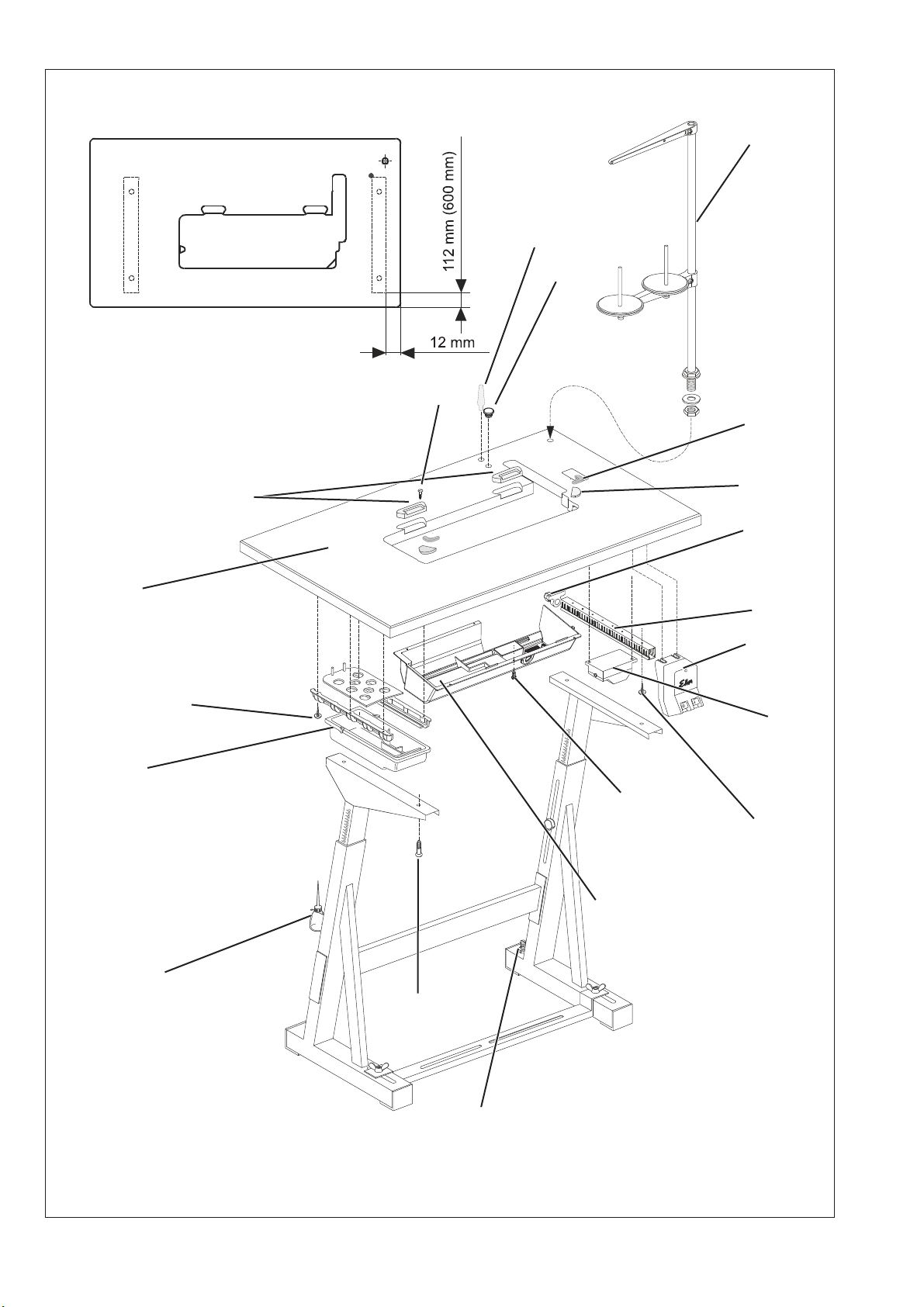

3. Assembling the stand

3.1 Assembling the stand components (Standard)

–

Assemble the individual stand components as shown in the

illustration.

–

Adjust the set screws 8 to insure the stability of the stand.

Make sure that the stand is safe by insuring that every single foot

of the stand touches the ground.

3.2 Assembling the table plate

For an optimal arrangement, please respect the corresponding table

top layout:

Stand Table top layout

MG55 400364 0791 868710

MG55 400374 0791 868710

–

Screw the drawer 10 with its holders onto the left side underneath

thetableplate.

–

Screw the oil sump 7 under the table plate.

The three stops of the oil sink should be fitted against the table

opening.

–

Screw the main switch 5* to the right side under the table plate.

–

Screw the cable duct 4* behind the main switch 5 under the table

plate.

–

Screw the holder 3 for the traction relief of the connecting cable

behind cable duct 4 under the table plate.

–

Screw the sewing-lamp transformer 6 (optional equipment) under

thetableplate.

–

Fit the machine head support 13** into the bore hole of the table

top .

–

Put the cap 15** into the bore hole of the table top.

–

Place the hinge bottoms 12 for the machine head into the cutout

of the tabl e pl ate 11 and tighten the screws.

–

Insert the inclination support 14**.

–

Insert the rubber corners 2.

–

Attach the tabl e pl ate 11 to the stand with woodscrews (B8 x 35)

(see sketch for position).

–

Insert the yarn stand 1 into the bore hole in the table plate and

secure it with the nuts and washers. Fit and align the yarn reel and

unwinding holders. The yarn reel holder and the unwinding arm

must be vertically in line.

–

Screw the holder for the oil-can 9 onto the left-hand stand brace

GB

* Not applicable with sewing machines with direct drive.

** If the machine’s position in the stand should not be inclined but

horizontally straight, exchange position 13 against 15. Do not use the

inclination support 14.

7

Page 12

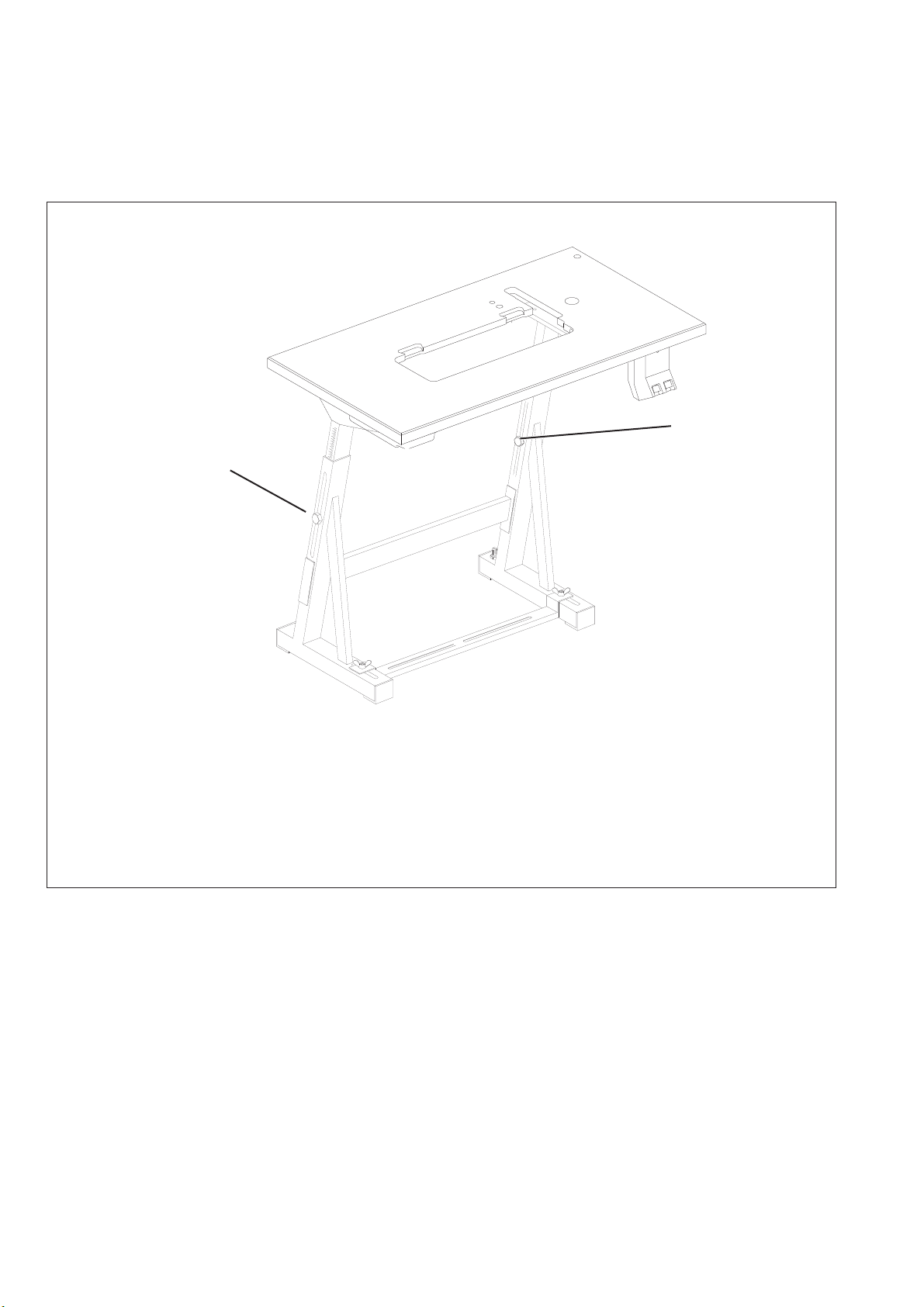

3.3 Setting the working height

1

1

–

The working height is adjustable between 750 and 900 mm

(measured to the upper edge of the table plate).

–

Undo screws 1 on the stand braces.

–

Adjust the table plate horizontally to the required working height.

To prevent tilting, pull the table plate out or push it in by the same

distance on both sides.

–

Tighten both screws 1.

8

Page 13

4. Sewing drives

4. 1 Drive category, type and use

The following sewing drives are available:

Subclass Clutch motor DC-positioning drive

868-190020

868-290020

868-190322

868-190341

868-290322

868-290341

868-390322

FIR 1147-F.752.3 *

FIR 1148-F.752.3

* This clutch motor incorporates an electromagnetic brake that rapidly

stops the rotor when it runs on after the motor has been switched off.

This prevents the sewing machine from starting up unintentionally if

the pedal is operated shortly after switching off.

** For machines with the drive positioned under the table

Efka DC1550/DA321G

Efka DC1550/DA321G**

Efka DC1550/DA321G

Efka DC1550/DA321G**

GB

4.2 Components of the drive sets

The desired drive is delivered as a “drive package” that, apart from the

drive, also includes the belt pulley, the V-belt, connection cables, the

pedal linkage, fixing material and diagrams.

9

Page 14

4.3 Fitting the sewing drive

8

1

1

2

2

1

2

7

6

6

5

6

5

5

7

3

3

4

–

Attachthesewingdrive2 with its base 1 on the bottom side of the

table plate by screwing the three hexagonal screws (M8 x 15) with

washers into the nuts 8 of the table plate bottom.

4

4.4 Fitting the pedal

–

Attach the pedal 4 to the stand brace 3.

–

For ergonomic reasons align the pedal 4 as follows:

The center of the pedal must be approximately under the needle.

There are slots in the stand brace 3 to help align the pedal.

–

Attach the ball pins to the lever 7 as required by the drive.

–

Hook in the pedal linkage 5.

–

Slightly undo screw 6.

–

Adjust the height of the pedal linkage 5 as follows:

when released the pedal 4 should be inclined about 10°.

–

Tighten screw 6.

10

Page 15

4.5 Fitting the sewing-drive control for machines with Efka DC 1550 / DA 321G

8

7

1

2

–

–

4.6 Fitting the set value initiator

–

–

GB

Fix the sewing-drive control 1 with 4 screws underneath the table

plate 2.

Fix the power supply cable of the sewing-drive control with the

traction relief clip 3 underneath the table plate.

Screw angle 7 under the table plate 8.

Screw the set value initiator 2 onto the angle 7.

11

Page 16

5. Assembling the machine head

The sewing machine heads of the class 868 can be fitted into the stand

horizontally straight as well as inclined.

Therefore the positions of the hinges on the machine head and the

fastening of the direct drive must be considered.

5.1 Fitting the hinges on the machine head

Position of the hinges for the

inclined set-up of the machine head

12

Position of the hinges for the

straight set-up of the machine head

Page 17

5.2 Fitting the direct drive

21

Position of the motor support for the

inclined set-up of the machine head

5.3 Tensioning the toothed belt of the direct drive

Loosen the screws 1 in order to tighten the toothed belt. The belt

tension can be altered by shifting the motor with its support in the

oblong hole 2. Afterwards the screws 1 must be tightened again.

The toothed belt tension is to be set so that when a load of 20N is put

on the belt center in the middle between the belt pulleys, the belt

shows a bow of 4

between the two belt pulleys.

+1

mm. The measure is be taken exactly in the middle

GB

Position of the motor support for the

straight set-up of the machine head

When setting the belt tension with a measuring device the belt tension

should be about 150 Hz.

13

Page 18

5.4 Placing the sewing machine head on the stand

1

3

2

–

If the sewing machine is equipped with motor on the table plate

bottom, place the machine head 1 vertically into the table plate’s

cutout.

–

If the machine is equipped with motor on the machine head, incline

the machine head 2 in order to place it into the table plate’s cutout.

–

After placing the machine head immediately fix the retaining plate

that prevents the machine head from falling out when being tilted.

–

The retaining plate 3 is part of the accessories that come with the

machine head.

14

Page 19

5.5 Fitting and tensioning the V-belt

Only concerns machines with motor on the table plate bottom.

6

2

9

11 10

4

3

1

5

V-belt 2, V-belt pulley 1 and belt guard are part of the drive set

–

Fix the V-belt pulley 1 on the shaft of the sewing drive.

–

Put the V-belt on the belt pulley 6 on the machine head.

–

Pass the V-belt 2 down through the cutout of the table plate.

–

Tilt the sewing machine head to the back.

–

Place the V-belt 2 on the V-belt pulley 1.

–

Tilt the machine head back to the front.

–

Loosen the screw 3 on the socket 4 of the sewing drive.

–

Tension the V-belt 2 by swivelling the sewing drive 5.

With the correct belt tension the V-belt 2 bows by about 20 mm at

its mid-point under a load force of F =10 N (~1 kg).

–

Tighten the screw 3.

–

Set the belt inlet protection 9 and the belt catch device 10 of the

belt guard 11. The V-belt 2 must remain on the belt pulleys when

the sewing machine head is tilted backwards. See the motor

manufacturers’ operating instructions!

–

Screw on the belt guard cover 11.

GB

15

Page 20

5.6 Fitting the belt cover

1

2

1

4

5

–

Remove the handwheel 1.

–

When the machine’s motor is situated underneath the table plate

mount the belt cover 2 on the machine head .

(The belt cover is part of the drive package)

–

When the machine’s motor is situated on the sewing machine head

mount the belt cover 4 and 5 .

(The belt guard is part of the drive package)

–

Mount the handwheel 1. Pay attention to the correct position:

The position of the needle in its upper dead center must

correspond to the value “0" on the handwheel’s graduated scale.

16

Page 21

5.7 Fitting the oil suction tube

521

–

Remove the cap from the end of the suction tube 3.

–

Put the end of the suction tube 3 into the fitting of the cover 1.

–

Snap the tube into the tube holder 5 in the oil sump 2.

–

Screw the cover 4 onto the base plate.

34

GB

17

Page 22

5.8 Attaching the knee lever

3

2

The knee lever 2 mechanically raises the sewing foot.

–

Attach the knee lever 2.

–

Undo the screws on the joint 1.

–

Adjust the knee lever so that it can be conveniently operated with

the right knee.

–

Tighten the screws on joint 1 again.

–

Undo screw 3.

–

Align the knee-pad.

–

Tighten screw 3 again.

1

18

Page 23

5.9 Fitting the operating panel

34 1

–

Fix the control panel fixing angle 1 together with the thread

guide 2.

–

Remove the valve c ap 4.

–

Lay the power supply cable 5 of the operating panel as follows:

Lay the power supply cable behind valve cap 4 and arm cover 3 in

the machine arm and down through the table plate cutout 6.

–

Plug in the plug of the connection cable into the socket B776 of the

drive control unit.

–

Replace the arm cover 3 and the valve cap 4.

65

GB

19

Page 24

5.10 Fitting the sewing lamp (optional equipment)

Caution !

Turning off the main switch does not turn off the current for

the sewing lamp.

Remove the mains plug before connecting.

43 1

7

65

8

20

Page 25

The sewing lamp is mounted on the arm cover. In order to do so

lift off the arm cover 3. Drill through the fastening holes with a 4,5 mm

drill and fasten the holder.

–

Stick the safety warning label on the front of the main switch 7.

–

Fix the sewing light on the holder.

–

Lift off the arm cover 3 and the valve cap 4.

–

Lay the power supply cable in the cutout of the machine arm.

–

Pass the power supply cable down through the hole in the table

plate 6.

–

Attach the s ewing lamp transformer 8 underneath the table plate

with chipboard screws.

–

Attach the power supply cable underneath the table plate with

cable ties.

–

Plug in the sewing-light transformer connection.

–

Fit the arm cover 1 and valve cap 4.

GB

21

Page 26

6. Electrical connection

6.1 General

Caution !

All work on the electrical equipment of this special sewing

machine may only be carried out by qualified electricians or

other appropriately trained persons.

While working on the electrical equipment the mains plug must be

removed!

6.2 Checking the mains voltage

Caution !

The mains voltage must coincide with the rated voltage specified

on the model-identification plate.

6.3 Connecting the sewing drive

6.3.1 Connecting the clutch motor

–

Lay the connection cable from the main switch through the cable

duct to the sewing drive and connect it to the sewing drive. See

connection diagram 9800 110002 A/ 9800 110002 D (in the

connection pack) or the circuit diagram on the clutch motor.

–

Lay the main cable from the main switch through the cable duct to

the back and attach it to the stress-relief.

6.3.2 Connecting the direct-current positioning actuator

–

Lay the connection cable from the main switch through the cable

duct to the sewing drive and connect it to the sewing drive. See

connection diagram 9800 130014 R (in the connection pack).

–

Lay the main cable from the main switch through the cable duct to

the back and attach it to the stress-relief.

Plug the cable from the set-point generator into socket b80 of the

drive control. See sketch on page 29.

22

Page 27

6.4 Earthing

1

2

The earthing cable 1 is in the machine’s accessory pack.

The earthing cable 1 takes static charges from the machine head to

earth via the motor base.

–

Connect the earthing cable 1 to the flat plug 2 (already screwed on

the machine head) and lay it through the cable duct to the motor

base.

–

Screw the earthing cable 1 onto the motor base at the point

provided.

–

Additionally attach the earthing cable 1 under the table plate with

the nail clamps.

GB

Caution!

Please make sure that the earthing cable 1 does not touch

the drive belt.

Hint

You do not need to care for the earthing with machines having the

sewing motor fit onto the machine head, since it is already established

through the fitted motor.

23

Page 28

6.5 Connecting the sewing drive to the mains

Caution:

The sewing machine must be connected to the mains w ith a plug.

Clutch motors must be connected toa3x380-415V 50/60Hz or 3 x

220 - 240V 50/60Hz three-phase AC.

The connection is done according to the connection diagrams

9800 110002 A or 9800 120009 D.

The direct-current positioning actuator is operated with a

single-phase alternating current of 190 - 240V 50/60 Hz. The

connection is done according to the connection diagrams

9800 120009 A or 9800 130014 R.

If it is connected to a three-phase supply of 3 x 380V, 3 x 400V or

3 x 415V the sewing drive is connected to one phase and the neutral

conductor.

If the mains supply is three-phase 3 x 200V, 3 x 220V, 3 x 230V or 3 x

240V the sewing drive is connected to two phases.

If a number of direct-current positioning actuators are connected to a

three-phase mains supply they should be equally distributed over all

phases to avoid overloading one of the phases.

6.6 Connecting the sewing machine head

–

The cable 9870 367004 or 9870 867000 is plugged on the

distributor 9850 867000 in the machine head and is conducted

downwards inside the machine head.

–

Plug the 37-pin plug of the cable into bush A of the sewing drive

and screw it tight.

24

Page 29

6.7 Connecting the sewing light transformer (optional equipment)

21

–

Remove the machine’s mains plug.

–

Pass the mains cable 1 of the sewing-lamp transformer through the

cable duct 2 to the main switch.

–

It is connected to the mains-connection side of the main switch (or

motor-protection switch). See connection diagram 9800 120009 A

or 9800 110002 A or 9800 130014 R.

–

Stick the adhesive label with the safety instruction on the front of

themainswitch.

–

If the sewing-lamp transformer is connected toa3x380-415V

three-phase supply it must have a neutral conductor.

GB

Caution !

The sewing-light transformer is directly connected to the mains.

It is therefore live even when the main switch is switched off.

The mains plug must be removed before carrying out any work

on the sewing-light transformer, e.g. changing the fuse.

25

Page 30

6.8 Connecting the direct drive

6.8.1 Connecting the Hall-effect sensor (Optional Equipment)

Only with DC 1550 drive:

Motor mounted under the table

·

Gear reduction motor - machine 1,55:1

·

Attention !

Turn off the main switch.

Connect the Hall-effect sensor only with the sewing machine

switched off.

–

Fit the Hall-effect sensor 1 onto the machine head.

21

–

Check whether a magnet is fitted into the belt pulley 2 of the

machine. The magnet is positioned on the inner side of the belt

pulley towards the machine.

–

If the belt pulley is fitted c orrectly, the magnet must be positioned

above the Hall-effect sensor, when the tip of the needle penetrates

the throat plate.

43

26

Page 31

–

B 7 7 6

V 8 . .

B 1 8

L S M . . .

B 2

M

B 8 0

E B . . .

B 4 1

M

A

Connect the 9-pole SuB-D plug of the Hall-effect sensor to the

bushing “B18" (IPG / HSM / LSM) of the Efka control drive DA321G.

–

Set the correct machine class with parameter F-290 according to

the corresponding parameter sheet 9800 331104 PBXX.

–

In order to position the machine correctly and to optimize all

functions the following parameters must still be set:

Parameter F-111: set to 3.000 rpm or less.

Parameter F-270: setto6(selectionaccordingtothepositionsensor)

Parameter F-272: canbecalculatedaccordingtotheformulabelow:

Motor pulley diameter (teeth)

x 1000

Machine pulley diameter (teeth)

–

Inserted needle: up to a thickness of 180.

Due to the gear reduction of 1,55:1 the maximum possible speed

is 3.000 rpm.

Due to the new transmission ratio of 1,55:1 a higher torque and a

higher penetration force of the needle of about 30% above a

transmission rate of 1:1 is achieved.

In order to achieve an even higher penetration force, the parameter

F-225 can be set from value “0" to value ”1".

It may happen, that the motor produces a snarling noise.

If this is the case, the toothed belt between motor and machine must

be tightened.

GB

27

Page 32

6.8.2 Attaching and connecting the sewing light transformer (optional equipment)

–

Remove the machine’s mains plug!

–

Connect the mains cable of the sewing light transformer to the

mains input side of the control unit.

Caution !

The sewing-light transformer is directly connected to the mains.

It is therefore live even when the main switch is switched off.

The mains plug must be removed before carrying out any work

on the sewing-light transformer, e.g. changing the fuse.

6.8.3 Connection to the DA321G control unit

26 5 1

–

Loosen the 4 screws on the front plate of the controls.

–

Remove the front plate.

–

Push the cable from the back through the c able duct 1 into the

control unit.

–

Remove the black rubber grommet 2.

–

Push through the round opening of the rubber grommet with a

screwdriver.

–

Guide the cable of the sewing light transformer through the

resulting opening in the rubber grommet.

–

Insert the rubber grommet again.

–

With a small screwdriver press on the terminal openings 4 and 3 to

open the terminals 5 and 6.

–

Connect the blue cable to terminal 6 and the brown cable to

terminal 5.

–

Fasten the front plate with the 4 screws again.

654 3

28

Page 33

6.8.4 Connecting the sockets of the DA321G control unit

B 7 7 6

V 8 . .

B 1 8

L S M . . .

B 2

M

B 8 0

E B . ..

B 4 1

M

A

21

6.8.5 Connecting the DA321G control unit

–

Plug the cable from the controller (pedal) into socket B80 of the

controls.

–

Plug the cable from the motor sensor 1 into socket B2 of the

controls.

–

Plug the cable 2 from the motor into socket B41 of the controls.

–

Plug the cable to the sewing machine into socket A of the control

unit.

–

Lay all cables through the cable duct.

–

Plug the cable from the control panel (if present) into socket B776.

GB

29

Page 34

6.8.6 Checking the direction of rotation of the sewing drive

Caution !

Before putting the special sewing machine into operation, the direction

of rotation of the sewing drive must imperatively be checked.

Operating the special sewing machine in the wrong direction of

rotation can lead to damages.

The arrow on the belt guard indicates the correct direction of

rotation of the machine.

The direction of rotation of the direct-current positioning actuator is set

by the preset value of the corresponding parameter to the

anti-clockwise rotation of the handwheel. Nevertheless the direction of

rotation must be checked first. In order to do so follow this procedure:

Preparation! Lock the sew ing foot in lifted position.

(see the operating instructions)

Control unit DA321G

–

The plugs of the set value initiator, motor, motor sensor and

operating panel (if existing) must be plugged in.

–

Do not plug in the 37-pole plug of the sewing machine head.

–

Switch on the main switch.

The operating panel displays “Inf A5" or ”A5" which means that no

valid autoselect resistance is recognized and therefore the

maximum speed is limited.

–

Push the pedal slightly to the front; the drive rotates; check the

direction of rotation.

–

If the direction of rotation is not correct, the parameter 161 in the

“technician level” must be set to 1 .

–

Turn off the main switch.

–

Plug in the 37-pole plug of the sewing machine head again

6.8.7 Checking the positioning

30

Upon delivery of the sewing machine the needle positions were set

correctly. Nevertheless the needle positions should be checked before

putting the machine into operation.

Prerequisite!

The sewing foot must be locked in lifted position. (see operating

instructions).

The machine must position during an intermediary s top in position 1

(needle downwards).

Position 1

–

Switch on the main switch.

–

Briefly push the pedal to the front and bring it back to its initial

position. The needle positions in position 1 (about 126° on the

handwheel).

–

Check the position of the needle.

Page 35

6.8.8 Machine-specific parameters

6.8.8.1 General

Position 2

–

First push the pedal forward and then completely backwards.

–

The needle positions in position 2 ( about 66° on the handwheel).

–

Check the needle position.

If one or both needle positions are not correct then carry out the

correction of the needle position. (see operating instructions)

The functions of the sewing-drive control are determined by the

program and the parameter settings.

Prior to delivery all parameter values have been correctly preset for

each particular class and subclass. For this purpose some preset

values of the control unit have also been altered (for example the

maximum speed). When exchanging the control unit the

machine-specific parameters have to b e reset correctly. (see operating

instructions)

6.8.8.2 Autoselect

6.9 Masterreset

The control unit “recognizes” by measuring the Autoselect resistance

in the machine which machine series has been connected. Autoselect

selects the control functions and the pre-set parameter values.

Caution !

If the control fails to recognize a valid Autoselect resistance (or any at

all), the drive runs only with the so-called emergency operating

functions to prevent machine damage

By effectuating a masterreset all parameter values are reset to the

pre-set values. After a masterreset all machine-specific parameters

have to be corrected again.

GB

31

Page 36

2

4

6

8

10

1

2

3

4

32

5

6

7

Page 37

7. Pneumatic connection

Caution:

The pneumatic units will only operate properly at a supply

pressure of 8 to 10 bar. The special sewing machine’s

operating pressure is 6 bar.

Pneumatic-connection pack

A pneumatic connection pack for stands with compressed-air

maintenance unit is available under order no. 0797 003031.

It contains the following components:

–

Connection hose, 5 m long (Ø = 9 mm)

–

Hose nozzles and ties

–

Plug-and-socket connector

Connecting the compressed-air maintenance unit

–

Attach the c ompressed-air maintenance unit 1 with bracket, screws

and strap to the stand-brace.

–

Connect the unit to the compressed-air supply with the connection

hose 5 (Ø = 9 mm) and connector R1/4".

Connecting the compressed-air maintenance unit to the upper

part of the sew ing machine

–

Unscrew and remove the cover 6.

–

Connect the hose 3 (in the accessory pack) to the distributor

plate 7 on the machine head.

–

Replace the cover 6.

Adjusting the operating pressure

The operating pressure is 6 bar.

It can be read off at the pressure gauge 4.

–

To adjust the operating pressure raise and turn handle 2:

Clockwise to increase the pressure.

Counter-clockwise to reduce the pressure.

–

Press down the handle 2.

7.1 Pneumatic sewing foot lifting

See Instructions 0791 867704.

GB

33

Page 38

8. Lubrication

1

2

3

Caution: danger of injury !

Oil can cause skin eruptions.

Avoid protracted contact with the skin.

In the event of contact, thoroughly wash the affected area.

CAUTION !

The handling and disposal of mineral oil is subject to legal regulation.

Deliver used oil to an authorised collection point.

Protect your environment.

Take care not to spill oil.

To lubricate the special sewing machine use only DA-10 lubricating oil

or an equivalent oil of the following specification:

–

Viscosity at 40° C : 10 mm

–

Flashpoint: 150 °C

DA-10 is available from DÜRKOPP ADLER AG retail outlets under the

following part numbers:

250 ml container: 9047 000011

1-litre container: 9047 000012

2-litre container: 9047 000013

5-litre container: 9047 000014

Lubricating the machine head (first filling)

NB:

All wicks and felts are saturated with oil prior to delivery. This oil is

returned to the oil reservoir 1, which should therefore not be overfilled.

–

Top up the oil reservoir 1 through the hole 2 to the “ max.”mark3.

2

/s

34

Page 39

9. Sewing test

A sewing test must be carried out when setting-up is complete.

–

Insert the mains plug.

Caution: danger of injury !

Turn off the main switch.

The needle and looper threads may only be threaded with the

sewing machine switched off.

–

Thread the bobbin-winder thread (see operating instructions).

–

Turn on the main switch.

–

Lock the sewing feet in lifted position (see operating instructions).

–

Fill the bobbin at low speed.

–

Turn off the main switch.

–

Thread the needle and looper threads (see operating instructions).

–

Select the material to be processed.

–

Carry out the sewing test, first at low speed and then gradually

increasing it.

–

Check that the seams are of the requisite quality.

If not, alter the thread tensions (see operating instructions).

If necessary the settings given in the servicing instructions should

also be checked and corrected.

GB

35

Page 40

36

Loading...

Loading...