838

Spezialnähmaschine

Betriebsanleitung

Instruction manual

D

GB

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

10/2008 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 838740

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise

Wiederverwendung dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG

verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2008

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Contents Page

Part 2: Installation instructions – Class 838

1. Items delivered ............................................... 3

2. General and transport packaging ................................... 4

3. Assembling the stand

3.1 Assembling the stand components .................................... 4

3.2 Completing the table plate and mounting to the stand ........................ 5

3.3 Adjustingtheworkingheight........................................ 6

4. Assembling the sewing machine head

4.1 Integrating the sewing machine head into the stand.......................... 7

4.2 Assembling the protective belt cover on the sewing machine head ................. 7

4.3 Pedal adjustment .............................................. 8

4.4 Assemblingthekneeleverandoilpumphose............................. 9

4.5 Assembling the connection cable, control panel, and diode illumination on the machine head . . 10

5. The special sewing machine’s electrical connections

5.1 C onnecting the special sewing machine to the low voltage supply ................. 11

5.1.1 Connecting the sewing light transformer to the supply voltage ................... 12

5.2. Establishing equipotential bonding .................................... 13

5.3 C onnecting the sewing machine head to the sewing drive ...................... 14

6. Adjusting the Efka positioning drive

6.1 Adjustingthepositioningdriveparameters............................... 15

6.1.1 Adjustingtheparameterswiththe“Auto-select”function ...................... 15

6.1.2 Class-838specificadjustmentstotheparametersoftheEfkadrive................ 15

6.1.3 SpecificparametervaluesfortheClass838.............................. 16

6.2 Adjustingthemachinepositioning .................................... 16

6.2.1 Definingthepositions ........................................... 16

6.2.2 Adjusting the machine positioning for the DC1550/DA321G drive ................. 16

6.2.2.1 General .................................................... 16

6.2.3 Checkingthesetpositions ........................................ 17

6.3 Masterreset ................................................. 17

7. Pneumatic connections .......................................... 18

GB

8. Lubrication ................................................. 18

9. Sewing test ................................................. 19

For your notes:

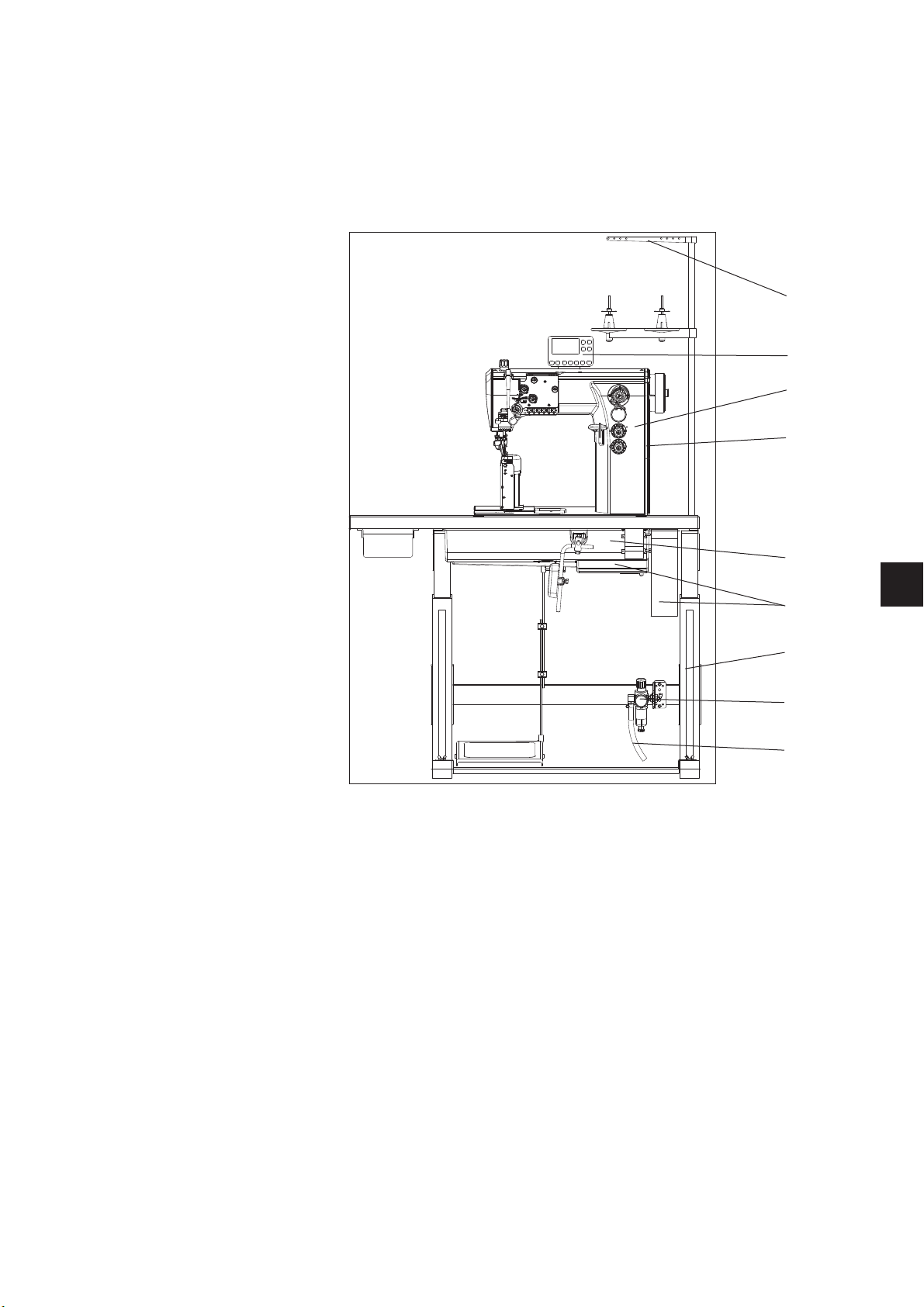

1. Items delivered

It is possible to order either a complete sewing unit or only individual

components. Before setup, please check that all the required

components are present.

This description is valid for the special sewing machine whose

individual components are delivered directly and completely from

Dürkopp Adler A G. These directions describe the assembly and

installation of the special sewing machine.

3

7

1

5

2

4

6

8

9

Required components:

–

Upper section (machine head) (1)

–

Accessory pack (contains oil collector (2), reel stand (3), tools and

additional items)

–

Parts set (contains direct drive (4), protective belt cover (5), and

additional parts)

Optional components:

–

Stand (6)

–

Operating panel (7)

–

Compressed air maintenance unit (8)

–

Pneumatic connection kit (9)

GB

3

2. General and transport packaging

Caution!

The special sewing machine may only be set up by trained personnel.

Transport packaging

If you have purchased a mounted sewing machine, you must remove

the following packaging:

–

Safety straps and battens from the upper machine head, table and

stand,

–

Safety blocks and straps from the sewing drive.

3. Assembling the stand

3.1 Assembling the stand components

3

1

2

–

Assemble the stand components according to the illustration.

Fasten the pedal (1) to the stand brace (3). Align the pedal after

you have assembled the complete machine.

–

Turn the adjusting screw (2) to ensure a secure mount on the

stand. The stand must be resting with all four feet on the floor.

4

3.2 Completing the table plate and mounting to the stand

10 2 69 58 13 10

15

328

4

180

80

460

30

30

50

72

185

770

7

260

368

80

15

15

11

15

14

12

13

16

17

–

Turn over the tabl e p lat e (1).

–

Screw on the cable channel (2).

–

Screw on the setpoint director device (3).

–

Screw on the cable clamp (4).

–

Position the oil collector (5) in direction of arrow (6) so that the

edge of the oil collector is aligned with the table plate edge. Screw

on the oil collector.

–

Screw on the drawer (7) together with its fixtures.

–

Screw on the control unit (8) (the drill holes for the wood screws

are pre-drilled).

–

Screw on the sewing light transformer (9) (optional equipment).

–

Mount the electrical cable according to the instructions in

Chapter 5.

–

Mount the tabl e p lat e (1) to the stand using the wood screws

(B8x35). Drill the holes (10) for the wood screws. Turn the stand so

that it is positioned in its normal position.

–

Put the reel stand (11) into the drilled hole in the table plate.

Fasten with nut and washer.

Mount and align the reel holder and unwinder holder.

These two holders must be positioned on top of each other.

–

Put the support (12) in the drilled hole.

–

Insert the lower hinge section (13) for the machine head into the

space on the table plate (1). Then screw it in.

–

Insert the wedges (14) into the clearance space in the table plate

(for the rubber corners).

–

Insert the rubber corners (15).

–

Remove the plug (16) on the oil collector for the knee lever (17).

–

Remove the knee lever (17) and guide through the opening, as

shown in the illustration.

GB

5

3.3 Adjusting the working height

–

The stand height can be adjusted between 750 and 900 mm.

–

Loosen the screws (1).

–

Set the horizontal height of the table plate as needed. Check the

scale on the stand spar. The height of the stand should be

appropriate to the height and operating position of the operator.

–

Tighten the screws (1).

1

Caution Danger of Injury!

Ergonomic-related, operator injuries can result if the stand height is

not adjusted to fit the operator.

6

4. Assembling the sewing machine head

4.1 Integrating the sewing machine head into the stand

1

2

–

If the special sewing machine is equipped with a drive (direct drive)

on the machine head, then you should insert the head section (1)

diagonally into the space on the table plate.

–

Be sure to screw in the installation plate (2) immediately after

inserting the head section. This will prevent the head section from

falling out if tilted or turned over.

The installation plate is included in the machine head’s accessory

pack.

GB

4.2 Assembling the protective belt cover on the sewing machine head

1

3

4

–

Take off the handwheel (1).

–

Mount the Hall sensor (2) to the machine head. This part is

included in the “motor part set”.

–

Mount the protective belt covers (3) and (4). (These are included in

the “motor part set”.)

–

Mount the handwheel (1). Be sure to maintain the proper angled

position: when the needle position is “high”, the handwheel

pointer “0" should be aligned with the mark on the machine head.

2

7

4.3 Pedal adjustment

2

90

3

2

1

–

For proper ergonomic function, set the pedal (1) as follows:

The middle of the pedal should be position approximately under the

needle.

The stand brace (3) is fitted with slotted holes to help in aligning

the pedal properly.

–

Adjust the tie rod (2) so that the foot axis is perpendicular to the

pedal surface.

Caution Danger of Injury!

Ergonomic-related, operator injuries can result if the proper pedal

position is not maintained.

8

4.4 Assembling the knee lever and oil pump hose

1

4

6

5

3

7

9

8

–

Use the hand lever to lift the sewing foot.

–

Tilt the machine head (1) to the rear.

–

Insert the shaft (3) into the lever (4).

–

Screw the screw (5) with the washer (6) into the shaft (3).

–

Press the hose (7) into the clamps (8) and pull on to the

strainer (9).

–

Reposition the machine head vertically and adjust the knee

lever (10) as shown in the illustration.

–

Align the knee cushion.

10

GB

10°± 5°

9

4.5 Assembling the connection cable, control panel, and diode illumination on the

machine head

41

2

3

5

6

7

8

9

–

A connection cable (1) is included in the delivery of all machines

that come with a positioning drive.

–

The operating panel (2) must be ordered separately (optional

equipment). When the operating panel is ordered, the thread

guide (3) is also included in the delivery.

The diode illumination (5) must also be ordered separately

(optional equipment). With it are delivered two types of holder

brackets. This allows you to choose between two different

mounting positions for the light. Position (5) is the home (starting)

position. Position (7) is used when a material guide is mounted

onto the sewing machine.

–

Take off the arm cover (9) and the valve cover from the machine

head.

–

Install the connection cable with the connector (1) as shown in the

illustration.

–

Mount the operating panel (2) with the thread guide (3). Install

cable (4) as shown in illustration.

–

Install lighting (5) and cable (6) as shown in illustration.

–

Lead the connection cables through the opening in the table plate

and fasten with the s elf-adhesive clamp (8).

10

5. The special sewing machine’s electrical connection

The sewing machine drive is supplied from the low voltage power

supply.

Caution!

Work on the electrical equipment of the sewing machine may only be

carried out by qualified electricians or other appropriately trained

persons.

It is strictly required to carefully read the drive instructions provided by

the manufacturer!

The power cord must always be disconnected while working on the

electrical equipment!

5.1 Connecting the special sewing machine to the low voltage supply

Caution!

The voltage of the mains must comply with the voltage specified on the

ratings plate!

The following items are part of the low voltage system:

–

Connection cable

–

Sewing drive

–

Sewing light transformer (optional equipment)

–

Cable

When the sewing machine is delivered, some of these items are

included in the “drive set” while other items are included in the “motor

part set”.

The connection to the low voltage supply should be carried out

according to the circuit diagram included in the “motor part set”.

Caution Danger of Injury!

The drive may only be operated with a protective earth conductor.

It must be connected to protect personnel from fire or electric shock, in

compliance with accident prevention regulations.

It is unsafe to operate the sewing machine while the protective earth is

disconnected. This protection may not be cancelled out in any way (for

example, by the use of an extension cable without grounding/earth).

GB

11

5.1.1 Connecting the sewing light transformer to the supply voltage

Caution Danger of Injury!

The sewing light cannot be turned off with the main switch

(EN 60 204-31)! The mains power supply must be disconnected before

mounting the illumination, repairing the transformer or changing fuses.

26 5 1

–

Pull the plug out of the socket.

–

Loosen the four screws on the front plate of the control cabinet.

–

Take off the front plate.

–

Guide the sewing light transformer cable through the cable duct (1)

into the control cabinet.

–

Take off the black rubber guide track (2).

–

Make a hole in the guide track (2) with a screw driver.

–

Guide the cable for the sewing light transformer through this new

opening.

–

Re-mount the rubber guide track (2).

–

Use a thin screwdriver to press on the terminal openings (3) and

(4). This opens up the terminals (5) and (6).

–

Connect the blue cable to terminal (6) and the brown cable to

terminal (5).

–

Screw the front plate back on.

–

Install a strain relief mechanism (e.g., a cable tie) for the

transformer cable.

65 4 3

12

5.2 Establishing equipotential bonding

The earth (grounding) cable (1) is included in the machine’s accessory

pack.

The earth cable (1) conducts static charges from the machine head via

the motor foot to the earth.

–

Attach the earth cable (1) to the tab connector (2) (which is already

screwed on to the machine head). Guide the other end of the cable

under the table plate.

–

Screw the end of the earth cable to the earth (grounding) point on

the drive ( ).

–

The earth cable (1) should also be fastened under the table plate

with nail clips.

1

2

Caution: For sewing machines with a sewing drive (direct drive)

integrated into the machine head, there is no need to establish

equipotential bonding since this is implemented with the attached

sewing drive.

GB

13

5.3 Connecting the sewing machine head to the sewing drive

B 7 7 6

V 8 . .

B 1 8

L S M .. .

B 2

M

B 8 0

E B . ..

B 4 1

M

A

The electrical connection to the machine head is described in

section 4.5.

741 2 935 6 8

–

Plug the connection cable from the machine head into the plug

connector (1).

–

Plug the cable from the operating panel into the plug connector (2).

–

Plug the connector (3) from the motor sensor (6) into the plug

connector (4).

–

Plug the connector (5) from the motor (6) into the plug

connector (7).

–

Plug the cable from the setpoint (pedal) device (8) into the plug

connector (9).

–

Plug the cable from the handwheel proximity switch into the B18

socket.

14

6. Adjusting the Efka positioning drive

The programming and setting of parameters is used to specify the

function of the sewing drive controller.

All parameter values for the corresponding sub-classes are already

assigned when the complete sewing machine is delivered. Some

pre-set values for the controller (e.g., maximum rotational speed) may

also be changed. When replacing the controller, these

machine-specific parameters must be re-specified on the new

controller.

6.1 Adjusting the positioning drive parameters

Drive parameters are set in two steps. In the first step, the function

“Auto-select” is used to set the machine class parameters. In the

second step, some pre-set parameters are changed in order to set the

machine-specific parameters in the sub-class.

6.1.1 Adjusting the parameters with the “Auto-select” function

The sewing drive controller detects which sewing machine class is

connected by measuring the auto-select resistance from the machine.

Auto-select is used to select control function and the pre-set values of

the parameters.

Caution! If the controller detects an invalid or absent auto-select

resistance, then the sewing drive will only operated with

emergency-run functions. This serves to protect the machine from

damage.

GB

6.1.2 Class-838 specific adjustments to the parameters of the Efka drive

Caution!

Be very careful when adjusting the parameter values. The machine can

be damaged when settings are made improperly.

Note:

All parameter values can be reset to their default (pre-set) values by

using the Master Reset function (refer to section 6.3).

A description of parameter settings can be found at www.efka.net or in

the Efka operating instruction booklet provided by the drive

manufacturer.

15

6.1.3 Specific parameter values for the Class 838

Changing machine parameters for machines with 18/28 tooth drive

ratios

Parameter Original value New value Description of parameter

290* 0 4 Sewing machine class

111 1700 - Max. sewing speed

170 - - Reference position

171-2E 315 325 Position 2

180 20 30 Angle of turn back after cutting

250 16 4 1 stitch with the second stitch length

* This parameter must be selected first.

Note: In order to changing tooling-level parameters, the code 3312

must be entered with program access rights.

6.2 Adjusting the machine positioning

6.2.1 Defining the position

Position 1

At stop position, the needle is down in the seam. The number 225 on

the handwheel scale is aligned with the mark on the arm.

Position 2

After the thread cut, the needle is in the up position. The number 35 on

the handwheel scale is aligned with the mark on the arm.

6.2.2 Adjusting the machine positioning for the DC1550/DA321G drive

6.2.2.1 General

An incremental proximity switch is attached to the handwheel for

helping to position the needle. It delivers 512 pulses (value is shown

on the display) and an additional pulse per rotation. In general, the

specific position is specified by the angle between this position and the

reference position. The angle is specified by the value of the

corresponding parameter. (But it is not identical with the parameter

value.) The parameter values and positions are already set (refer to

section 6.1.3). The reference position is not set and must be specified.

The reference position is the starting position used for all other

positions. This position is defined when the handwheel number 105 is

aligned with the mark o n the arm.

After disassembly, assembly, or replacement of the motor, the

reference position must be specified again.

16

The description of changing the reference position is found in the

booklet entitled “Instructions for Efka Operation”.

6.2.3 Checking the set positions

6.3 Master reset

1. Position

Turnthemainswitchon.

Step forwards slightly on the pedal and then release. The machine will

stop in the first position (refer to 6.2.1).

The number 225° (± 5°) on the handwheel scale is aligned with the

mark on the arm.

2. Position

First step slightly forwards on the pedal. Then press backwards with

your heel until the machine stops.

The machine will stop in the second position (refer to 6.2.1).

The number 35° (± 5°) on the handwheel scale is aligned with the mark

on the arm.

All changed values will be reset to their pre-set default values after a

master reset is executed.

After a master reset, all machine-specific parameters must once again

be properly set.

This is described in the booklet entitled “Instructions for Efka

Operation”.

GB

17

7. Pneumatic connection

Caution!

A working air pressure for the sewing machine should be 6 bar.

3

5

2

6

1

4

7. Lubrication

–

Screw the compressed-air maintenance unit (1) to the stand brace

as shown in the illustration.

–

Screw on the elbow fitting (2) (contained in the accessory pack).

Connect the hose (3) from the machine head to the elbow

fitting (2).

–

Screw on the connection hose (4) according to the illustration.

Connect the other end fitted with the quick-coupling to the

compressed air system.

–

Raise up the settings dial (5) and turn the dial until the

manometer (6) indicates 6 bar. Lower the dial (5).

All wicks and felts should be saturated with oil before the machine is

started up. Check the oil level on the reservoir and fill is necessary.

Refer to Chapter 9 in the operation instructions.

18

8. Sewing test

You should perform a sewing test after you have completed all work on

the installation and settings.

–

Thread in the winder thread (refer to operating instructions).

–

Turnthemainswitchon.

–

Lock the sewing foot in the lifted position (refer to operating

instructions).

–

Fill up the bobbin at a low speed.

–

Turnthemainswitchoff.

–

Thread in needle thread and bobbin thread (refer to operating

instructions).

–

Select the material to be processed.

–

Start the test with a low sewing speed and then work with a

continually increasing s peed.

–

Check that the seams satisfy your requirements.

Change the thread tensions if your requirements are not satisfied

(refer to operating instructions).

GB

19

For your notes:

20

Loading...

Loading...