Duerkopp Adler 838 Service Manual

838

Spezialnähmaschine

Serviceanleitung

Service Instructions

D

GB

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

06/2008 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 838641

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise Wiederverwendung

dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner, even

in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2008

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Contents Page:

Service Instructions for the Class 838

(Edition 06/2008)

1. General

1.1 Setting gauges ................................................ 3

1.2 Adjusting the handwheel .......................................... 4

2. Bottom feed

2.1 Base setting for stitch adjustment and stitch length limit ....................... 5

2.2 Stitchuniformityforforwardsandreversestitching.......................... 6

2.3 Adjustingtheleversontherearfeedshaft................................ 7

2.4 Position of the eccentric tappet for the feed movement ........................ 8

2.5 Position of the eccentric tappet and the feed dog stroke ....................... 9

2.6 Switchingoverthefeedclutch....................................... 10

2.7 Position of the eccentric tappet for the switch over of the feed clutch ............... 11

2.8 Checkingtheswitchoverofthefeedclutch............................... 12

2.9 Feeddog.................................................... 13

3. Top feed

3.1 Positioning the needle holder for single-needle sewing machines ................. 14

3.2 The needle feed ............................................... 16

3.3 Toproller.................................................... 18

3.4 Liftingthetoproller ............................................. 19

3.5 Press pad for the double-needle sewing machine ........................... 20

4. Adjusting the needle bar and the hook

4.1 Hookheight.................................................. 21

4.2 Needle bar height, play of needle to hook tip, loop stroke ...................... 22

4.3 Protection for the hook tip and loop former ............................... 23

4.4 Bobbin housing lift .............................................. 24

4.5 Hooklubrication ............................................... 25

5. Adjusting the thread

5.1 Thread regulator, thread take-up lever, bolt for the thread lever mechanism ........... 26

5.2 Bobbin Winder ................................................ 27

6. Thread trimmer

6.1 Height of the thread trimming blade. Position of the counter-knife ................. 28

6.2 Startingpositionforthethreadtake-upknife.............................. 29

6.3 Controlcam.................................................. 30

6.4 Bobbin thread clamp............................................. 31

7. Electronic control and machine drive – positioning drive .................... 32

1. General

These service instructions describe the adjustments that can be made

to the Class 838 special sewing machine.

CAUTION!

The operations described in these service instructions may only be

carried out by qualified staff or other appropriately trained persons!

Caution: Risk of Injury!

Turn the main switch off for repair, conversion and maintenance work

and separate the machine from the pneumatic supply line.

Any adjustment work and functional testing with the machine running

should be conducted only under observance of all safety measures

and with the greatest possible caution.

These service instructions describe the adjustment of the sewing

machine in a logical order. Please observe that various setting

positions are dependent on each other. Thus it is essential that the

settings be conducted while keeping to the order described.

GB

1.1 Setting gauges

For all adjustments of parts involved in the stitch formation, a new

undamaged needle must be inserted.

This text does not specifically mention any machine covers or panels

which must be removed or re-mounted in order to conduct inspections

or adjustments.

Note

Some shafts on the special 838 machine are provided with flat

eccentric surfaces. This significantly simplifies machine adjustments.

For all adjustments on flat surfaces, the first screw screwed in the

direction of the eccentric surface.

The retention pin required for adjusting the machine in included with all

units. It is located with the machine accessories and can be attached

so that it is easily accessible below the oil tray.

3

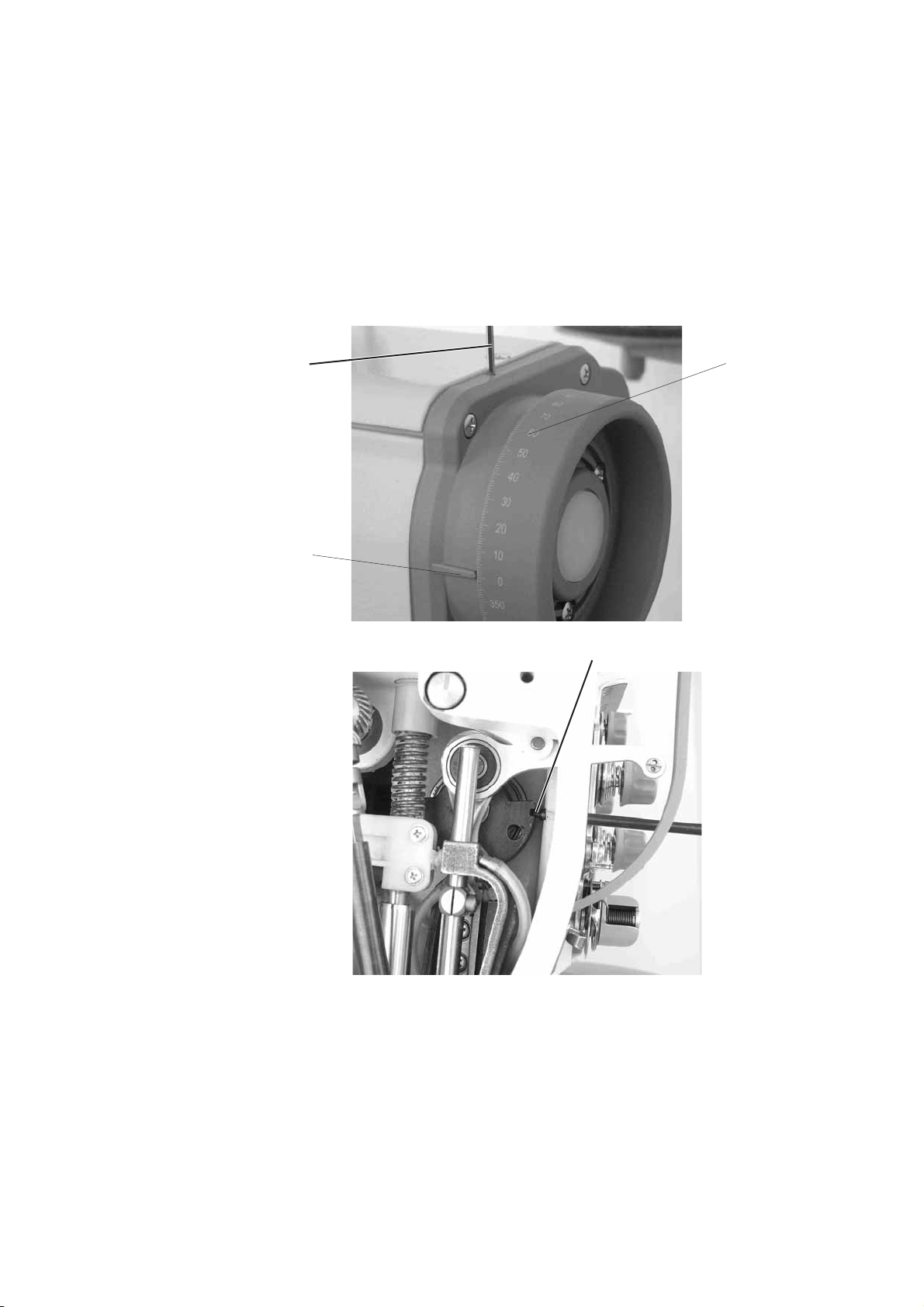

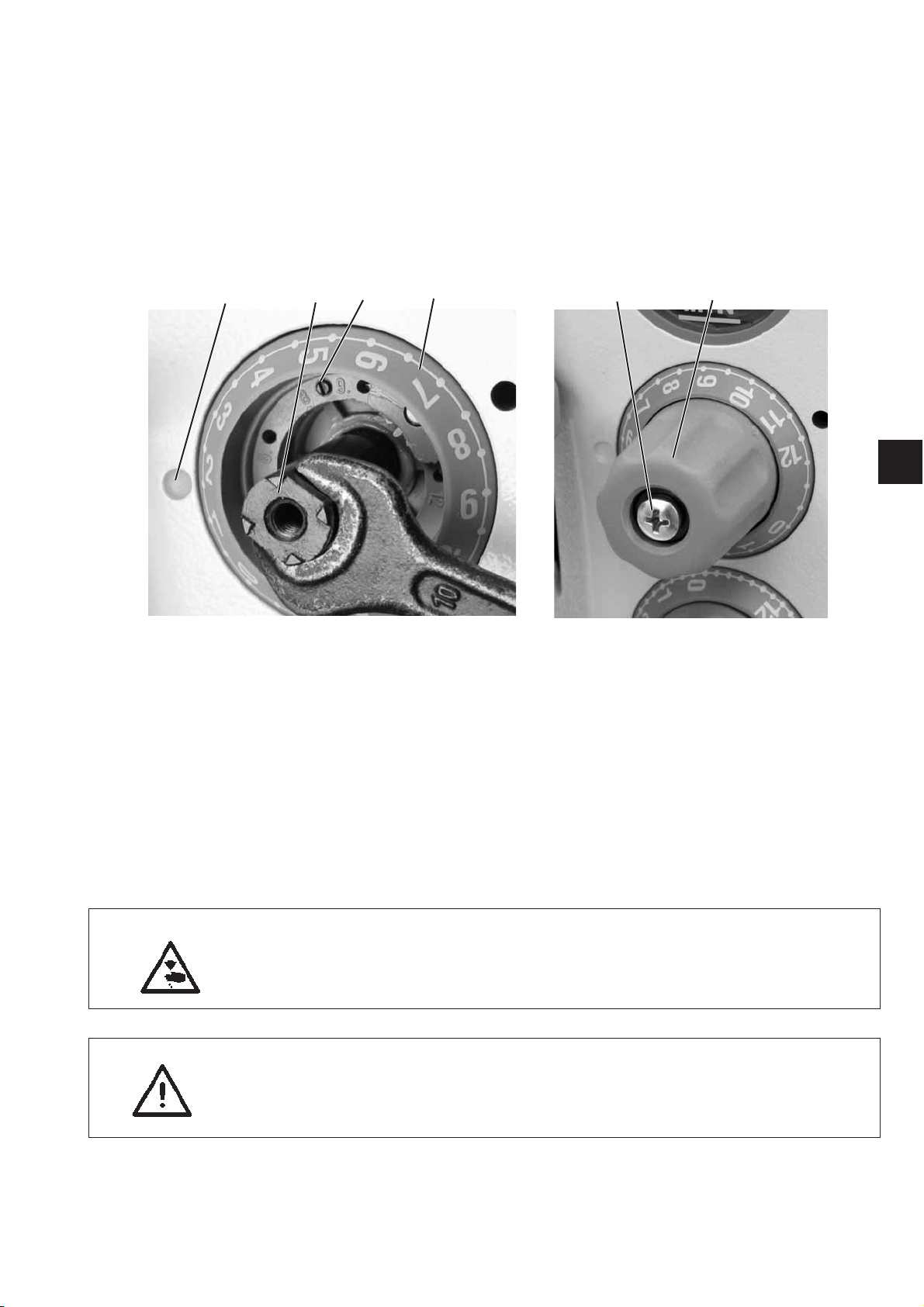

1.2 Adjusting the handwheel

Rule:

The handwheel (4) is labelled with degree numbers.

Certain adjustments are made with these marked handwheel positions.

–

Turn the handwheel until the degree value specified in the

instructions is aligned with the pointer (3).

–

Proceed with the adjustment described.

When the needle bar is at top dead centre, the pointer (3) should be

aligned with“0” degrees.

1

4

3

2

–

Loosen the handwheel screws with a 3-mm hexagon socket

wrench (1).

–

Position the needle bar in the top dead centre position. Use the

retention pin (3 mm diameter) to peg the position (2).

–

Turn the handwheel so that the pointer (3) points to 0 degrees on

the rotary scale.

–

Tighten the first screw with the wrench (1). Turn the handwheel

to 50° and tighten the second screw with the wrench (1).

4

2. Lower (bottom) feed

2.1 Base setting for stitch adjustment and stitch length limit

Rules:

1. When setting the stitch length at “0”, the stitch regulator gear should

have as little play (clearance) as possible when you press down on

the bartacking lever.

2. The maximum stitch length is limited to 8mm.

5

36

4

12

GB

–

Loosen screw (1) and take off the settings dial (2).

–

Turn the screw (3) as far as needed to the right using a 10-mm

spanner wrench. Verify that the stitch regulator gear is without

motion by pressing down on the bartacking lever. This fulfils rule 1.

–

Set the scaling ring (4) with stitch length 0 to align with the circular

mark (5).

–

Limit the stitch length according to rule 2. For this, screw the

retention pin (6) into the proper hole. The holes are marked with

numbers which indicate the maximum stitch length.

–

If a maximum stitch length of 7 mm is required, unscrew the screw

(6) for 2.5 mm. Another end stop is available for this length.

–

Put the settings dial (2) back on and tighten the screw (1).

Caution: Risk of Injury!

Turnthemainswitchoff.

Only carry out this stitch adjustment when the machine is turned off.

ATTENTION: Danger of breakage!

If the set stitch length is larger than allowed by the sewing equipment

in use, then the needle will hit against the throat plate insert.

5

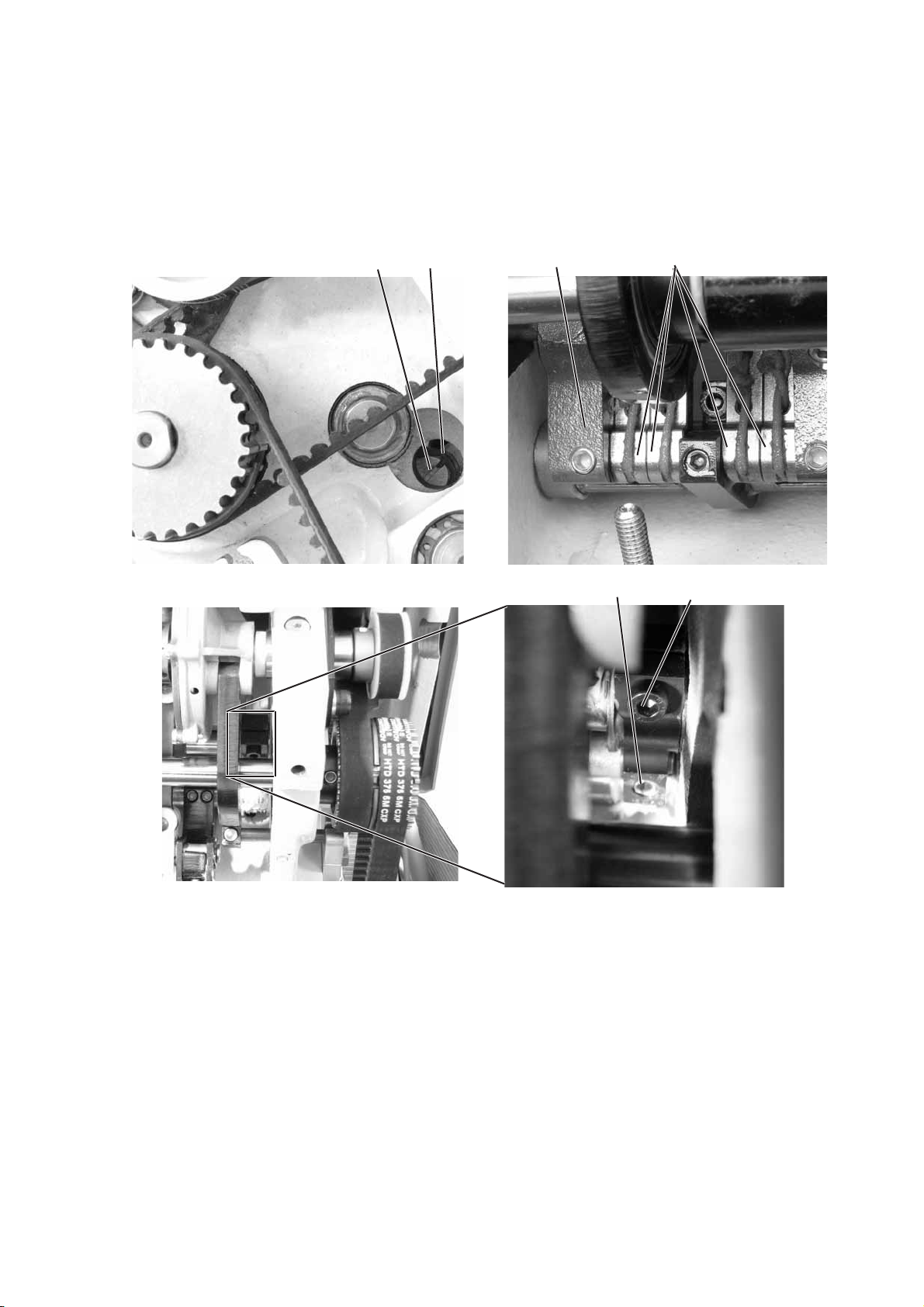

2.2 Stitch uniformity for forwards and reverse stitching

Rules:

1. When making a rough-scale adjustment to the stitch regulator gear,

the machine should not feed when the stitch length is set to 0.

2. When making a fine-scale adjustment to the stitch regulator gear,

the forwards and reverse stitch lengths should only deviate in value by

a half stitch.

32

5

6

1 4

–

Set the stitch length to “0”.

–

Loosen screw (1) and turn the grooved (3) eccentric tappet (2)

according to the illustration. Fasten with screw (1).

–

Loosen screw (4) on the clamping lever. Turn the settings frame (5)

so that the shackles (6) are parallel. Tighten screw (4). This then

fulfils rule 1.

–

The next step is to match up the forwards and reverse stitch

lengths. Sew ten stitches forwards. Press the bartacking lever and

then sew ten stitches backwards. Rotate the eccentric tappet (2) so

that rule 2 is met.

–

Clockwise = enlarge forward stitch, decrease reverse stitch.

–

Counter-clockwise = decrease forward stitch, enlarge reverse stitch.

6

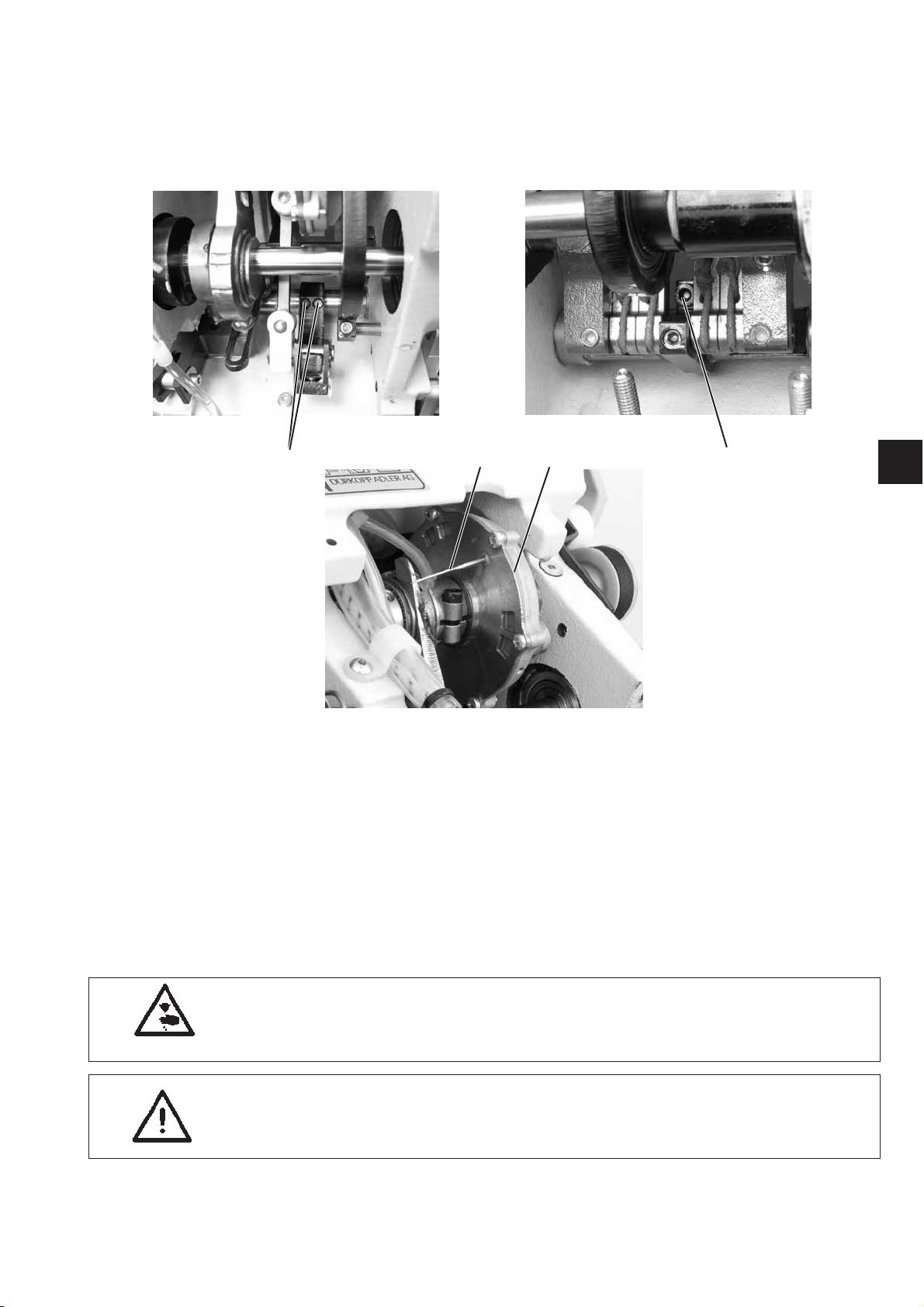

2.3 Adjusting the levers on the rear feed shaft

Rule:

When setting the stitch length" 0“, the feed clutch should be in the

middle range of the work limit settings.

2

–

Set the stitch length to “0”.

–

Loosen screw (1).

–

Set the lower feed dog in the middle between the dead centre

points of its motion in the throat plate.

–

Tighten screw (1).

–

Loosen screws (2).

–

Screw out the screw on the feed clutch (4). Push the needle (3) into

this opening. Turn the clutch (4) with your hand until the needle (3)

is 5mminto the hole. The rule is then fulfilled.

–

Tighten screw (1).

34

1

GB

Caution: Risk of Injury!

Turnthemainswitchoff.

Only carry out this lever adjustment when the machine is turned off.

ATTENTION: Danger of breakage!

With large stitch lengths, it is possible that parts within the clutch will

collide if the middle working range of the clutch is not maintained.

7

Loading...

Loading...