669

Spezialnähmaschine

Betriebsanleitung

Instruction manual

D

GB

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

12/2008 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 669741

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise

Wiederverwendung dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG

verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2008

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Contents Page:

Part 2: Installation Instructions for Class 669

1. Scope of Delivery.............................................. 3

2. General and Transport Packaging ................................... 5

3. Assembling the Stand

3.1 MG55-3standassembly.......................................... 6

3.2 MG56-3standassembly.......................................... 7

3.3 CompletingthetableplatefortheMG55-3standwithFIRclutchmotor ............. 8

3.4 CompletingthetableplatefortheMG55-3standwithdirectdrive................. 9

3.5 CompletingthetableplatefortheMG56-3standwithFIRclutchmotor ............. 10

3.6 CompletingthetableplatefortheMG56-3standwithdirectdrive................. 11

3.7 Fasteningthetableplatetothestand.................................. 12

3.7.1 MG55-3stand................................................ 12

3.7.2 MG56-3stand................................................ 13

3.8 Assembling the supports on the table plate with cut-out (MG 55-3) ................ 14

GB

4. Adjusting the Working Height of the MG 55-3 stand ........................ 15

5. Sewing Drive

5.1 Drivetypeandapplication......................................... 16

5.2 Components in the drive packages .................................... 16

6. Mounting the set-value initiator for the direct drive

6.1 MG55-3stand................................................ 17

6.1.1 Aligning the pedal .............................................. 17

6.2 MG56-3stand................................................ 18

6.2.1 Aligning the pedal .............................................. 18

7. Putting on the Machine Head ...................................... 19

8. Putting on the V-belt and Tightening for the FIR Clutch Motor ................. 21

9. Mounting the Knee Lever......................................... 22

10. Mounting the Direct Drive

10.1 Mounting the motor and putting on the V-belt.............................. 23

10.2 Connecting the Hall sensor ........................................ 23

10.3 Mounting the operating panel ....................................... 25

10.4 Mounting the sewing light (optional equipment) ............................ 26

Contents Page:

11. Electrical Connections

11.1 General .................................................... 27

11.2 Earthing.................................................... 27

11.2.1 Machine head ................................................ 27

11.2.2 Kneeswitch.................................................. 28

11.3 Checking the mains supply voltage.................................... 29

11.4 Connecting the clutch motor (FIR) to the mains voltage ....................... 29

11.4.1 Rotational direction of the clutch motor ................................. 30

11.4.2 Checking the rotational direction ..................................... 30

11.4.3 Changing the rotational direction ..................................... 30

11.4.4 Connecting the sewing light transformer (optional equipment) ................... 31

11.5 Connecting the DC positioning drive to the mains voltage ...................... 32

11.5.1 Connecting the sewing machine head .................................. 32

11.5.2 Connecting the DA321G control unit ................................... 33

11.5.3 Checking the rotational direction of the DC positioning drive .................... 34

11.5.4 Checkingthepositioning.......................................... 35

11.5.5 Machine-specificparameters....................................... 35

11.5.6 Masterreset ................................................. 36

11.5.7 Connecting the sewing light on the DA321G control unit ....................... 37

12. Pneumatic Connections ......................................... 38

13. Lubrication.................................................. 40

14. Sewing Test ................................................. 41

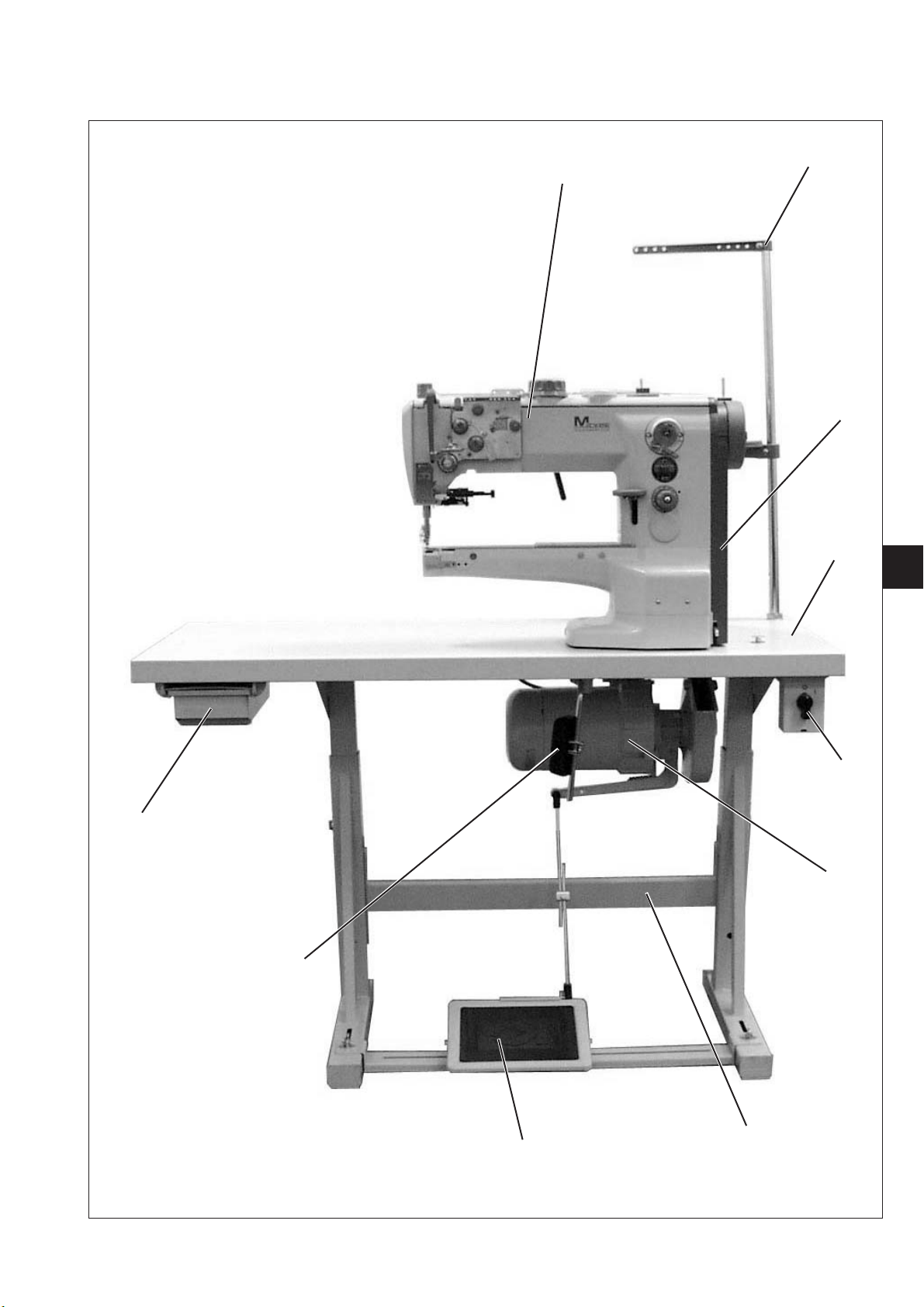

1. Scope of Delivery

Sewing machine with MG 55-3 stand

1

2

3

4

GB

10

5

6

9

7

8

3

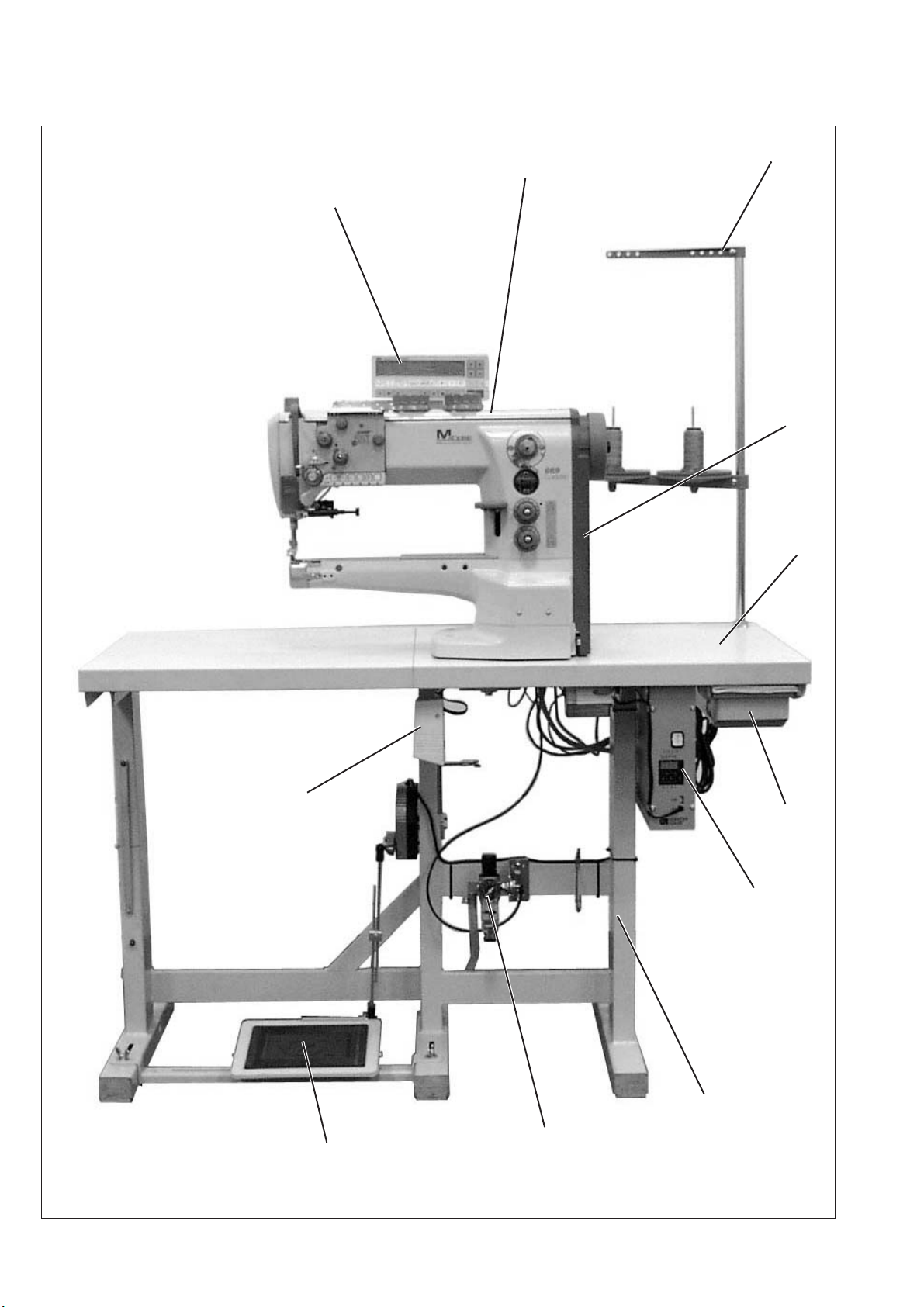

Sewing machine with MG 56-3 stand

12

1

2

3

4

13

10

11

7

8

14

4

The items that are supplied depend on your order.

Before setup, please check that all the required components are

present.

The description is valid for the special sewing machine whose

individual components are delivered directly and completely from

Dürkopp Adler A G.

–

1 Machine head

Dürkopp Adler accessory with:

–

2 Reel stand

Protective cover (not shown)

Electric parts set, depending on your order, for:

Machines with direct drive

–

3 Protective belt cover

–

11 DA control unit

–

12 Operating panel

–

13 Knee switch

Machines with clutch motor (FIR)

–

3 Protective belt cover

–

5 Main switch

–

6 Sewing drive

–

9 Knee lever

Optional equipment

–

4 Table plate (optional)

–

7 Stand (optional)

–

8 Pedal and rods (optional)

–

10 Drawer (optional)

–

14 Maintenance unit ( optional)

2. General and Transport Packaging

CAUTION !

The special sewing machine may only be set up by trained personnel.

GB

Transport packing

After purchasing a mounted sewing machine, you must remove the

following packaging:

–

Safety straps and battens from the upper machine head, table and

stand.

–

Safety blocks and straps from the sewing drive.

5

3. Assembling the Stand

There are two stand sets with different table plates available for the

669 class:

Stand set Version

MG 55-3 not separated, with or without cut-out

MG 56-3 separated, hinged

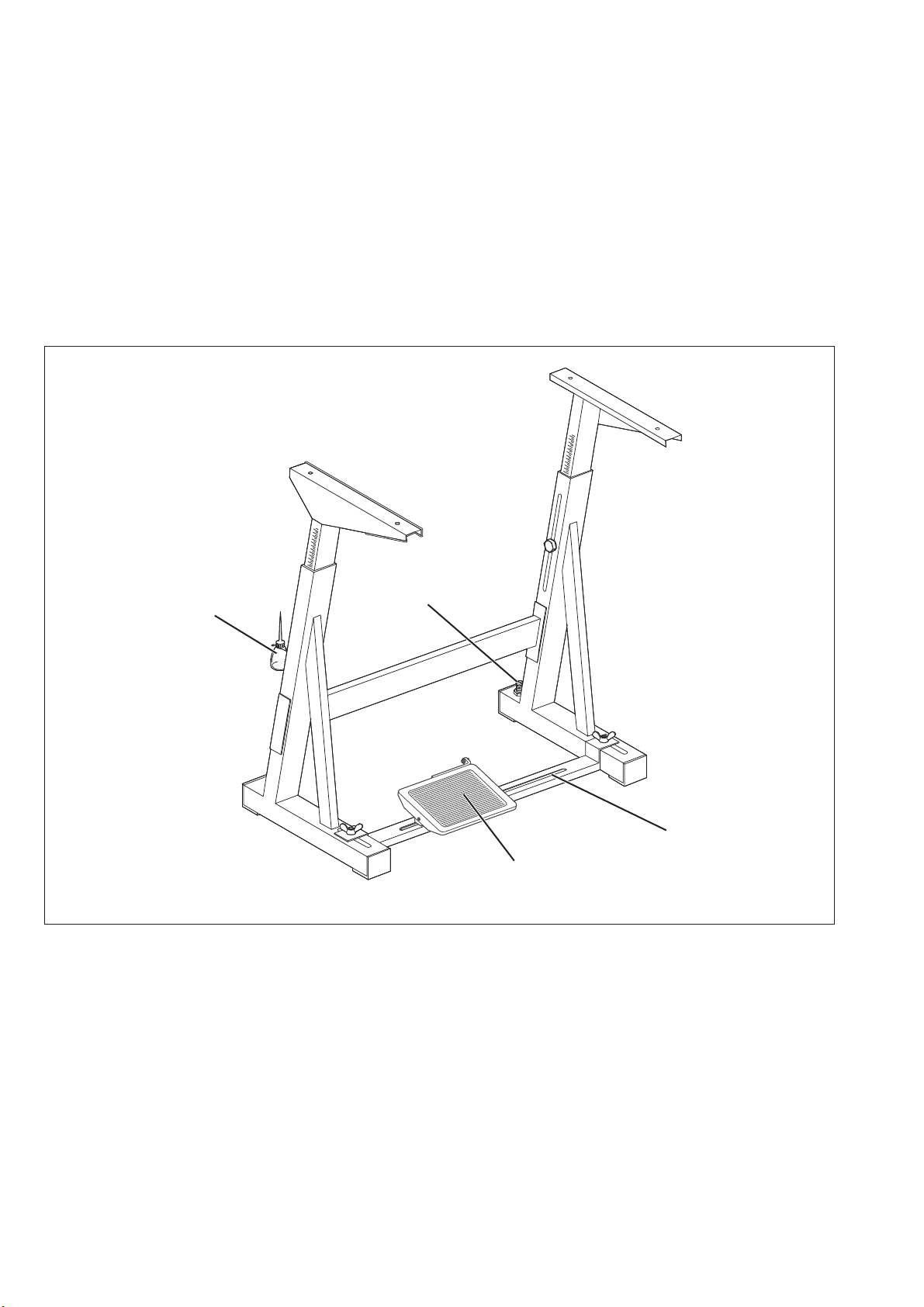

3.1 MG 55-3 stand assembly

3

4

1

2

–

Assemble the stand according to the illustration.

–

Fasten the pedal 2 to the stand brace 1.

–

Mount the s tand brace 1 to the stand.

–

Align the pedal after you have assembled the complete machine.

–

Screw on the holder for the oil can 3.

–

Turn the adjusting screw 4 to ensure a secure mount on the stand.

–

The stand must be resting with all four feet on the floor.

6

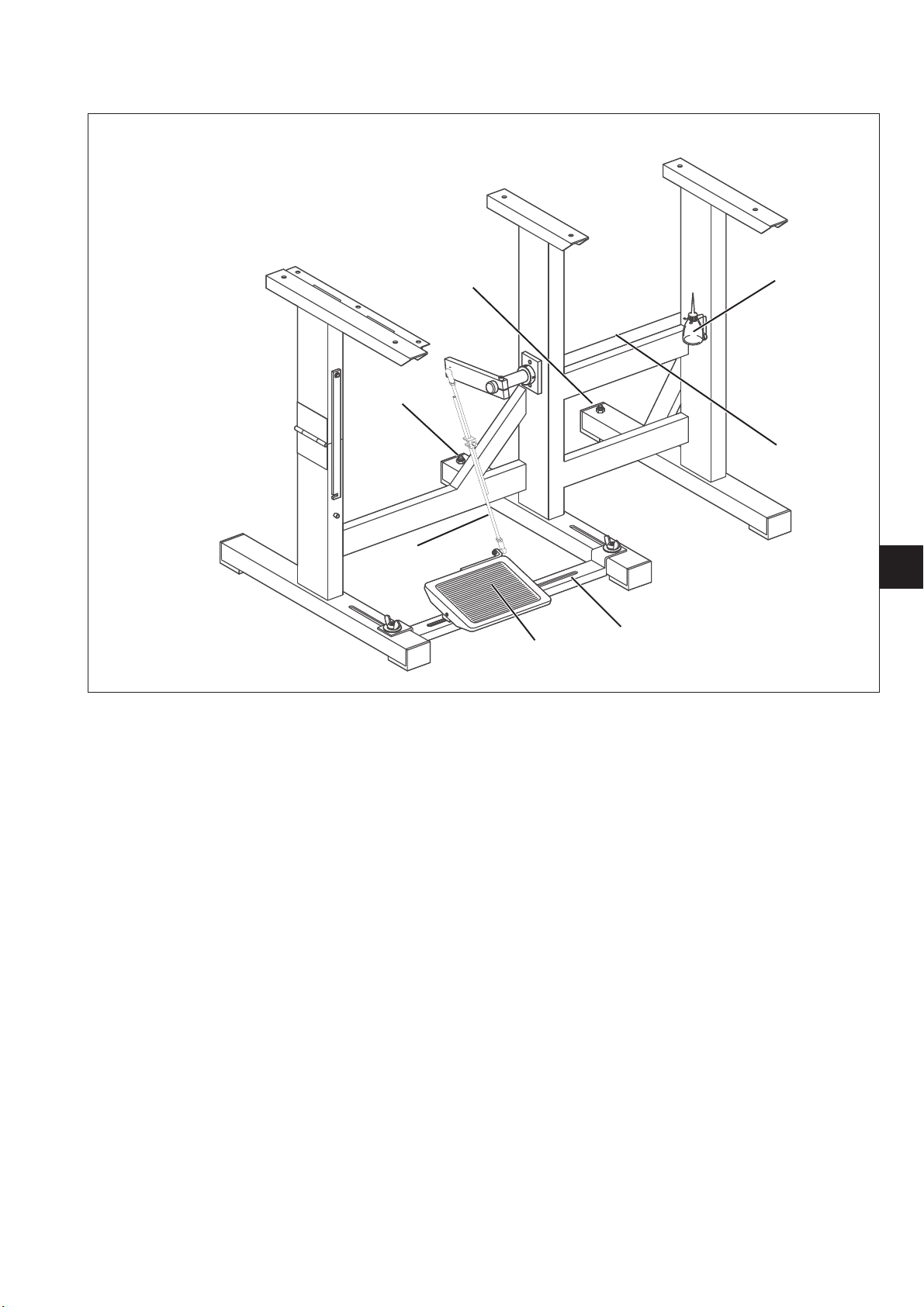

3.2 MG 56-3 stand assembly

4

5

4

6

3

GB

1

2

–

Assemble the stand according to the illustration.

–

Fasten the pedal 2 to the stand brace 1.

–

Mount the s tand brace 1 to the stand.

–

Turn the adjusting screws 4 to ensure a secure mount on the stand.

The stand must be resting with all six feet on the floor.

–

Align the pedal after you have assembled the complete machine.

–

Screw on the holder for the oil can 5.

–

Assemble the rod 6 ( only for FIR clutch motor).

7

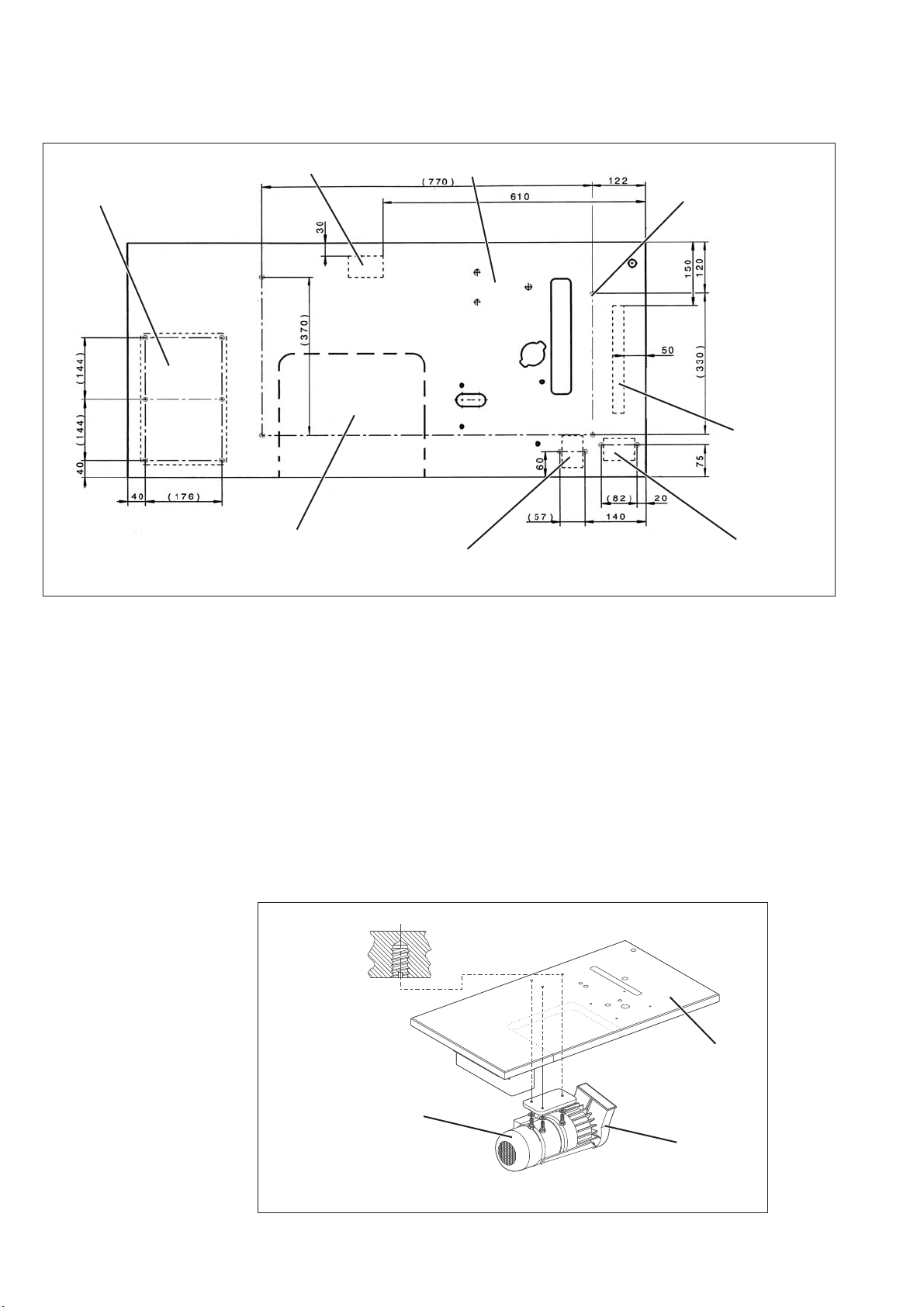

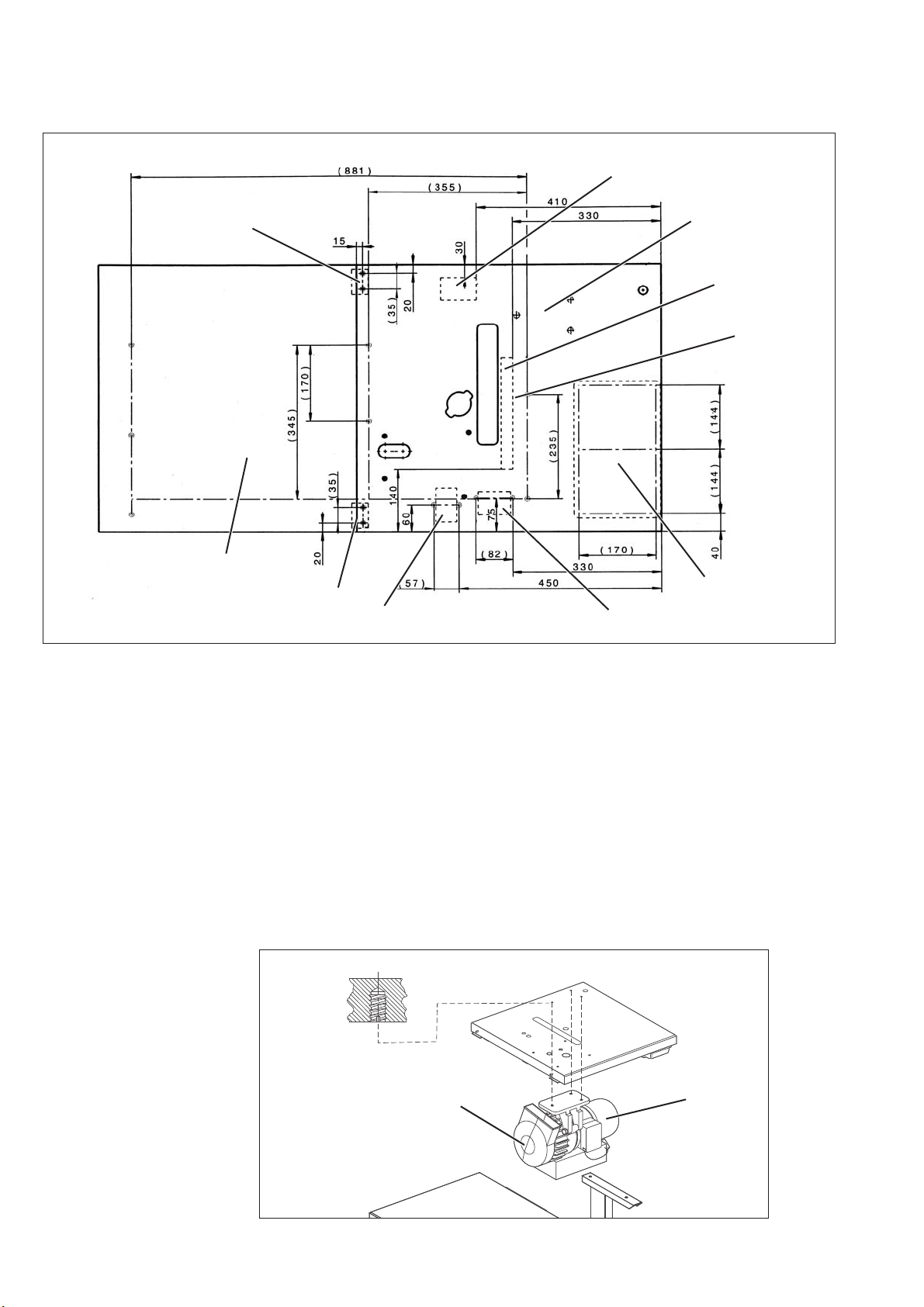

3.3 Completing the table plate for the MG 55-3 stand with FIR clutch motor

Top view of table plate

(3,5x17) x2

5

6 (4x20) x2

Marking for stand

4

7

3 (4x20) x2

1 (3,5x17) x2

2 (5x25) x2

–

Turn over the table plate 4.

–

Screw on the cable channel 1.

–

Screwonmainswitch2.

–

Screw on the power supply (optional equipment).

–

Screw on the drawer 5 together with its fixtures.

–

Screw on the sewing light transformer (optional equipment).

–

Mount the clutch motor 7.

For this, screw the three hexagon bolts (M8 x 40) with washers into

the anchor nuts on the table plate.

The belt pulley 8 must point to the right when the table plate is

mounted.

–

Mount the electrical cable according to the instructions in

Chapter 12.

4

7

8

8

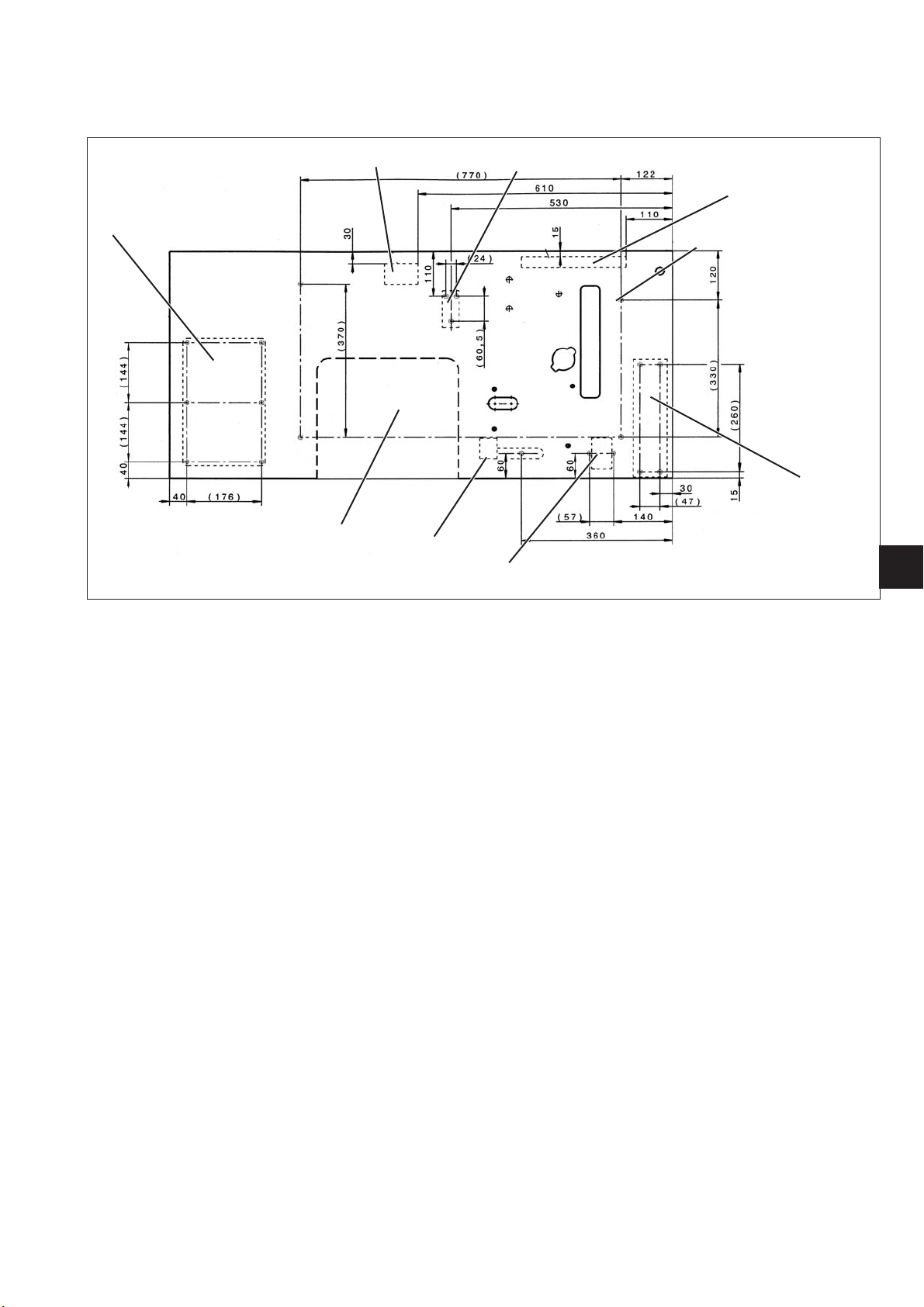

3.4 Completing the table plate for the MG 55-3 stand with direct drive

Top view of table plate

6 (3,5x17) 6x

7 (4x20) 2x

Marking for stand

5

8

1 (3,5x17) 2x

2

4

3 (4x20) 2x

GB

–

Turn over the table plate 5.

–

Screw on the cable channel 1.

–

Screw on the motor c ontrol 2.

–

Screw on the power supply 3.

–

Screw on the knee switch for the sewing-foot stroke.

(Only for sub-classes 669-180312)

–

Screw on the set value initiator 8 (refer to Chapter 6.1).

–

Screw on the drawer 6 together with its fixtures.

–

Screw on the sewing light transformer 7 (optional equipment).

–

Mount the electrical cable according to the instructions in

Chapter 12.

9

3.5 Completing the table plate for the MG 56-3 stand with FIR clutch motor

Top view of table plate

1 (4x20) 2x

7 (5x25) 2x

8

7 (5x25) 2x

Marking for

6 (4x20) 2x

,5x25) 2x

5

2

3 (3,5x17) 2x

stand

4 (3,5x17) 6x

–

Turn over the table plate 8.

–

Screw on the sewing light transformer 1 (optional equipment).

–

Screw on the cable channel 3.

–

Screw on the drawer 4 together with its fixtures.

–

Screw on the main switch 5.

–

Screw on the power supply 6 (optional equipment).

–

Screw on flap trays 7 using two wood screws per tray.

–

Mount the clutch motor 2.

For this, screw the three hexagon bolts (M8 x 40) with washers into

the anchor nuts on the table plate.

The belt pulley 9 must point to the left when the table plate is

mounted.

–

Mount the electrical cable according to the instructions in

Chapter 12.

9

2

10

Loading...

Loading...