Page 1

669

Spezialnähmaschine

Betriebsanleitung

Instruction manual

D

GB

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

12/2008 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 669741

Page 2

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise

Wiederverwendung dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG

verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2008

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 5

Contents Page:

Preface and General Safety Instructions

Part 1: Operating instructions Class 669

(Edition 12/2008)

1. Product Description ............................................ 3

2. Designated Use ............................................... 3

3. Subclasses .................................................. 4

4. Optional Equipment ............................................ 5

5. Technical Data

5.1 Technicaldatasubclasses ......................................... 7

6. Operation

6.1 Threading the needle thread ........................................ 8

6.2 Adjusting the needle thread tension.................................... 9

6.2.1 Function of the main thread tension and the supplementary thread tension

in relation to the sewing-foot lift for subclass 669-180312 ...................... 10

6.2.2 Function of the supplementary thread tension in relation to the stroke adjustment

and the Speedomat for subclass 669-180312 .............................. 11

6.3 Adjusting the needle thread tension.................................... 12

6.4 Turning the supplementary thread tension on and off for subclasses 669-180010

and 669-180112................................................ 12

6.5 Adjusting the thread regulator ....................................... 13

6.6 Winding the bobbin thread ......................................... 14

6.7 Replacing the shuttle bobbin ........................................ 15

6.8 Pre-settingtheshuttlethreadtension................................... 16

6.9 Inserting and replacing the needle .................................... 17

6.10 Raisingthesewingfeet........................................... 18

6.11 Settingthesewingfeetinthehighposition............................... 19

6.12 Sewingfootpressure ............................................ 19

6.13 Sewingfootstroke.............................................. 20

6.14 Adjusting the stitch length.......................................... 22

6.15 Keypadonthemachinearm........................................ 23

GB

Page 6

Contents Page:

7. Sewing

7.1 SewingwithmachinesusingtheFIRclutchpositioningdrive .................... 24

7.2 Sewing with machines using the Efka DC1550/DA321G positioning drive ............. 25

8. Tilting Back the Machine Head...................................... 28

9. Folding Down the MG 56-2 Stand .................................... 29

10. Maintenance

10.1 Cleaning and checking ........................................... 30

10.2 Oillubrication................................................. 32

Page 7

1. Product Description

The DÜRKOPP ADLER 669 is a single-needle double lockstitch

free-arm sewing machine featuring a lower feed, a needle feed and an

alternating foot-upper feed.

Depending on the subclass, it can also come with a thread trimmer,

second stitch length and automatic bartacking.

The maximum stitch length is either 6 mm or 9 mm, depending on the

sewing equipment.

The needle thickness is between 100 – 150 Nm.

It is equipped with a large horizontal looper hook.

·

The hook cover has a diameter o f 48 mm.

·

There is a maximum clearance of 20 mm under the sewing feet

·

when the feet are raised.

The remaining thread has a length of about 10 mm, depending on

·

the thread cutting process.

The lower feed can be easily deactivated or converted for other

·

purposes such as edge work.

A safety clutch prevents the hook from being displaced or damaged

·

if the thread gets jammed in the shuttle track.

2. Designated Use

The machine features automatic wick lubrication and a viewing

·

window in the arm for watching the machine and hook lubrication.

All subclasses, excluding those classes without a thread trimmer,

·

are equipped with a s ix-way button

An additional pull-down button, within reach of the operator, can

optionally be assigned one of the six different functions.

There is also an integrated bobbin winder.

·

The class 669 machine is a sewing machine head designed for sewing

light to medium-heavy material. Such material is generally made of

textile fibres, but it may also be leather. It is used in the clothing

industry and for domestic and motor-vehicle upholstery.

This sewing machine can also be used to produce technical seams. In

such a case, the operator must assess the possible dangers which

may arise (preferably in conjunction with DÜRKOPP ADLER AG).

Such applications are relatively unusual and varied so that no single

set of criteria can cover them all. The outcome of this assessment may

require appropriate safety measures to be taken.

Generally, only dry material may be sewn with this sewing machine

head. The material may be no thicker than 10 mm when compressed

by the lowered sewing feet. The material should not contain any hard

objects. If hard objects are present, the machine must be operated with

protective eye wear. We currently do not have such protective eye

wear available for delivery.

The seam is produced with textile-fibre sewing thread, with size

gauges up to 15/3 NeB (cotton), 15/3 Nm (synthetic) or 15/4 Nm

(covered yarn).

Before using any other thread, you must assess the dangers

associated with their use and take appropriate safety measures when

necessary.

GB

3

Page 8

3. Subclasses

This sewing machine may be set up and operated only in dry,

well-maintained premises. If the sewing machine is used in other

premises which are not dry and well-maintained it may be necessary to

take further precautions which should be agreed in advance (see

EN 60204-31: 1999).

As manufacturers of industrial sewing machines, we proceed on the

assumption that personnel who work on our products will have

received training at least sufficient to acquaint them with all normal

operations and with any hazards which these may involve.

669-180010 Single-needle double lockstitch free-arm sewing

machine with lower feed, needle feed and alternating

foot-upper feed.

669-180112 Single-needle double lockstitch free-arm sewing

machine with lower feed, needle feed and alternating

foot-upper feed. Also featuring electro-pneumatic

thread trimmer, electro-pneumatic seam bartacking,

and sewing-foot lift.

669-180312 Single-needle double lockstitch free-arm sewing

machine with lower feed, needle feed and alternating

foot-upper feed. Also featuring electro-pneumatic

thread trimmer, electro-pneumatic seam bartacking,

and sewing-foot lift.

Also includes a second stitch length

(electro-pneumatic switchable), two lifting heights

(electro-pneumatic switchable with knee lever) and

an integrated sewing light.

4

Page 9

4. Optional Equipment

The following additional equipment is available for the 669.

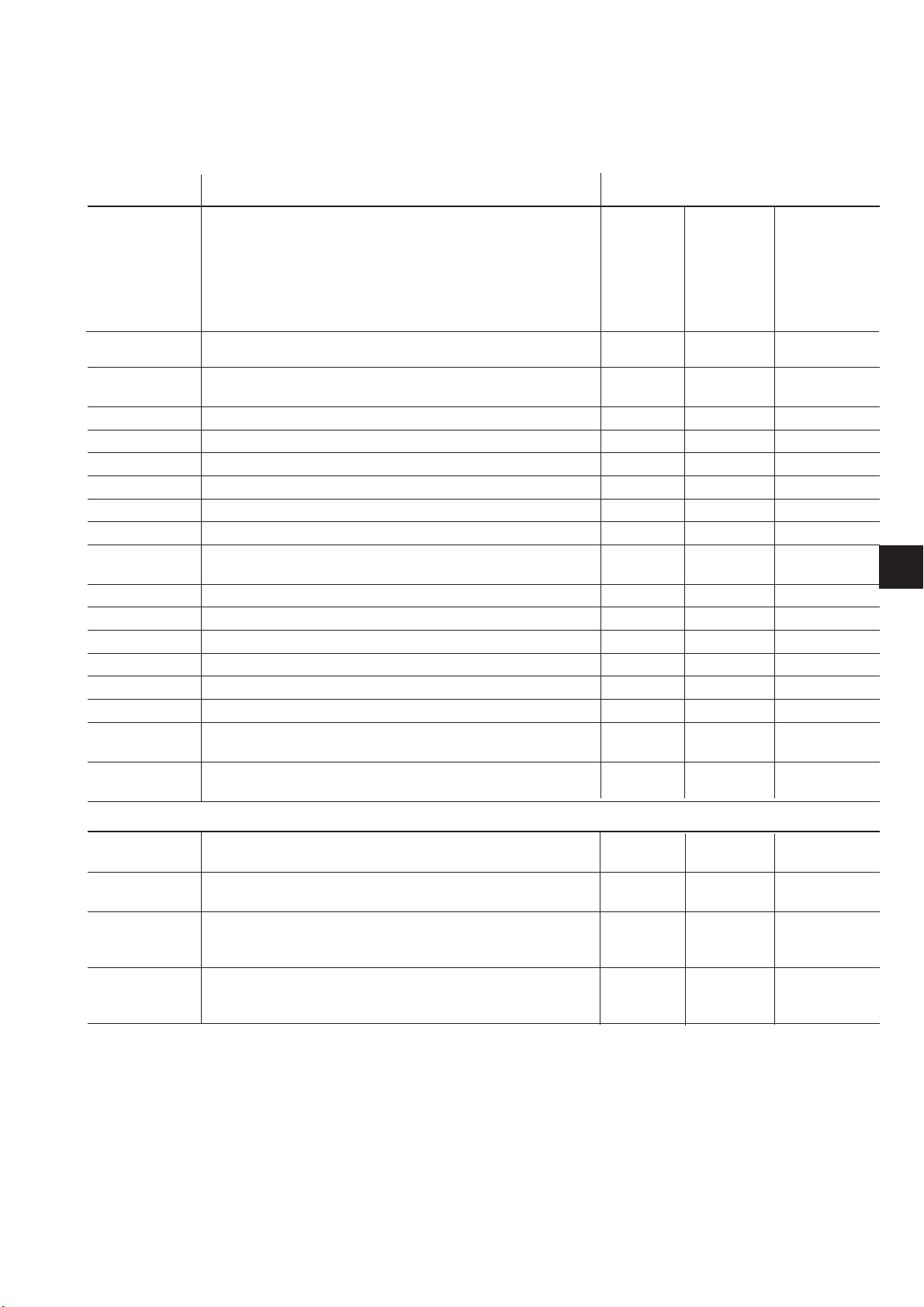

Order no. Optional equipment Subclasses

9780 000108 WE-8 maintenance unit for additional pneumatic

equipment

0797 003031 Pneumatic connection package. For connection of

stand with maintenance unit.

0867 490010 Operating panel angle bracket

9822 510001 Halogen sewing light for the sewing machine head

9880 867100 Mounting kit for the sewing light

0798 500088 Sewing light transformer

9880 867103 Diode sewing light (one diode)

9880 867102 Integrated sewing light

9850 001089 Power supply for the integrated and diode sewing

light

9850 867001 PCB for oil monitoring

0867 590014 Electro-pneumatic needle cooler, from above

0367 595124 Mechanical sewing-foot lift, with pedal

0867 590354 Pneumatic sewing-foot lift

0867 590464 Manual seam tacking

N800 080004 Edge guide, swivelling

9805 791113 USB memory key (flash drive) for data transfer

with Efka DA321G control unit

0659 510030 Distance spacer, for mounting additional

equipment

Stand

669-180010

XXX

XXX

Xoo

XXX

XXX

XXX

XXX

XXo

XXo

Xo

XX

X

X

oXo

XXX

XXX

XXX

669-180112

669-180312

GB

MG55 400384 Stand set MG 53-3.

Table plate: 1200 x 550 mm without cut-out

MG55 400394 Stand set MG 55-3.

Table plate: 1200 x 550 mm with cut-out

MG56 400064 Stand set MG 56-2.

Table plate: 1250 x 600, divided, foldable, for

clutch motors

MG56 400074 Stand set MG 56-2.

Table plate: 1250 x 600, divided, foldable, for

DC1550

XXX

XXX

X

XXX

o = Standard equipment

X = Optional equipment

5

Page 10

Further available documents concerning the class 669:

0791 669801 Parts List

0791 669641 Service Instructions

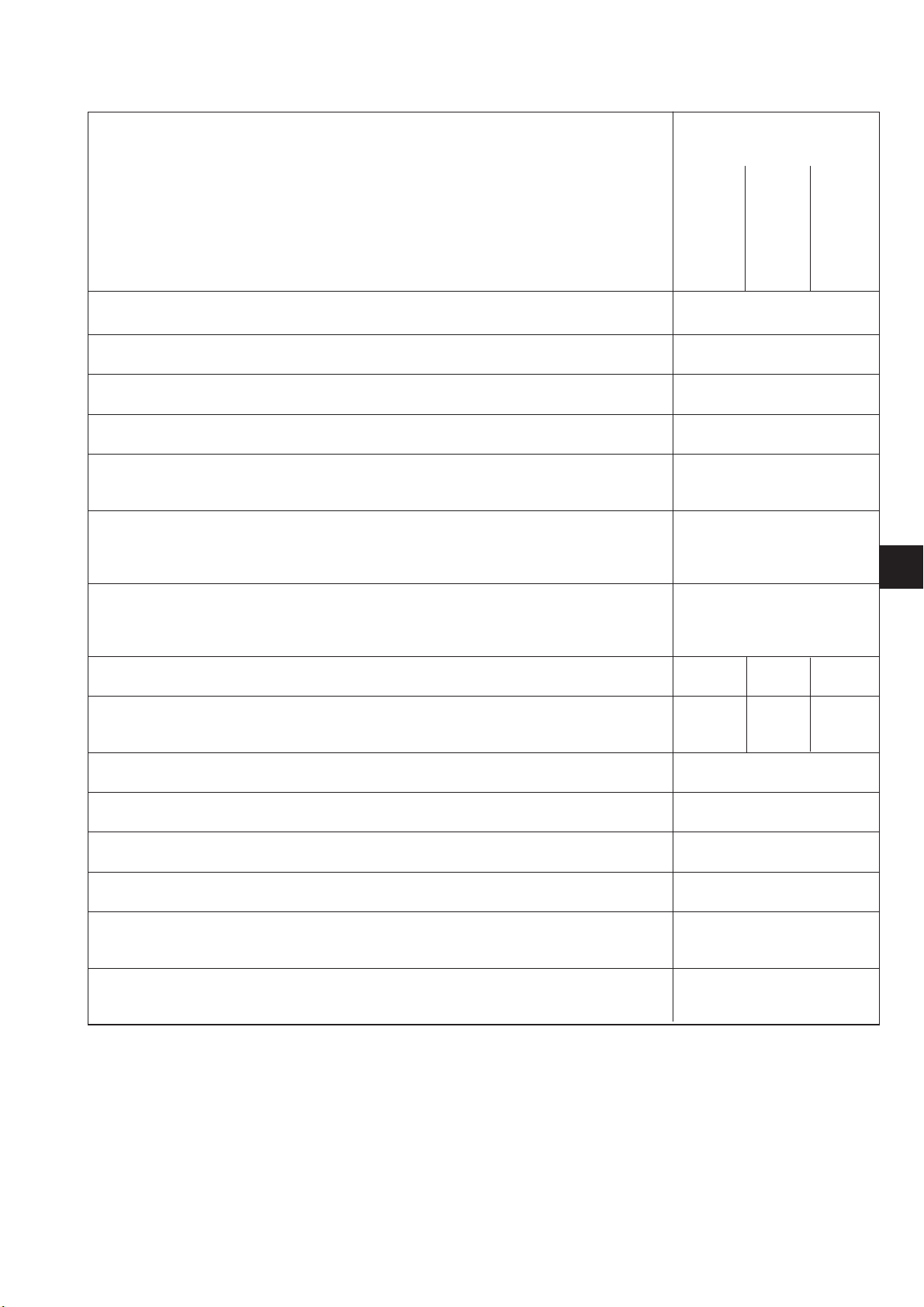

5. Technical Data

Noise level: Workplace-related emission value according to DIN 45635-48-A-1-KL-2:

669-180010 LC = —dB (A)

Stitch length: _ mm Sewing foot stroke: ___ mm Number of stitches: ____ min

Sewing material:

669-180112 LC = —dB (A)

Stitch length: _ mm Sewing foot stroke: ___ mm Number of stitches: ____ min

Sewing material:

669-180312 LC = —dB (A)

Stitch length: _ mm Sewing foot stroke: ___ mm Number of stitches: ____ min

Sewing material:

-1

-1

-1

6

Page 11

5.1 Technical data subclasses

Subclasses

669-180010

Type of stitch Lockstitch 301

Hook type horizontal, large

Number of needles 1

Needle system 134-35

Needle thickness, max. 150

(according to E no.) [Nm]

Max. sewing thread thickness:

Needle thread [Nm] 80/3 - 15/3

Bobbin thread [Nm] 80/3 - 20/3

Stitch length [mm]

Forwards 9

Reverse 9

Max. stitch count [min-1] 3000 3000 3000

669-180112

669-180312

GB

Stitch count whendelivered 2800 3000 3000

Max. sewing-foot lift [mm] 9

Max. height of lifted sewing feet [mm] 20

Operating pressure [bar] 6

Air consumption per work cycle [NL] 0.7

Dimensions (L x W x H) [mm] 600/ 230/ 470

(with attached Efka DC 1550) (600/ 300/ 470)

Weight [kg] 50

(with attached Efka DC 1550) [kg] (54)

[min

-1

]

7

Page 12

6. Operation

6.1 Threading the needle thread

11

1

10

2

3

9

4

8

5

7

6

Caution: danger of injury !

Turnthemainswitchoff!

The needle should be threaded only when the machine is turned off.

Threading the needle thread

–

Put the reel on the reel stand. Guide the needle thread through the

unwind holder.

The unwind holder must be perpendicular to the reel.

–

Insert the thread through guide 1 and guide 2.

–

Pass the thread clockwise around the pre-tensioner 3.

–

Pass the thread counter-clockwise around the supplementary

tensioner 4.

–

Pass the thread clockwise around main tensioner 5.

–

Pull the thread under the thread take-up lever 8. Thread through

the thread regulator 10 to the thread lever 11.

–

Pass the thread through thread lever 11 and through guides 9, 7

and 6 on the needle bar.

–

Pass the thread through the eye of the needle.

8

Page 13

6.2 Adjusting the needle thread tension

321

Pre-tensioner

When the main thread tensioner 2 and the supplementary tensioner 3

are open, there must still be a slight tension remaining on the needle

thread. This residual tension is created by the pre-tensioner 1.

The pre-tensioner 1 influences both the length of the cut needle thread

and the starter thread for the next seam.

–

Basic adjustment:

Turn dial 4 until its front side is flush with the bolts 5.

–

For a shorter starter thread:

Turn the dial 4 clockwise.

–

For a longer starter thread:

Turn the dial 4 counter-clockwise.

Main tensioner

The main tensioner 2 should be adjusted as little as possible. The

threads’ cross-over point should be in the centre of the material.

If the thread tension is too strong, crimping and thread tearing

canoccur when working with a thin material.

–

Adjust the main tensioner 2 so that you attain a consistent stitch

pattern.

To increase the tension,turn the dial clockwise.

To decrease the tension, turn the dial counter-clockwise.

54

GB

Supplementary tensioner

The switchable supplementary tensioner 3 is used for quick changes to

the thread tension (for example, when working with thicker seams).

–

The supplementary tension 3 should be set lower than the main

tension 2.

9

Page 14

Fig. A: Correct thread interlacing in the center of the

material

Fig. B: Needle-thread tension too weak

or

Hook-thread tension too strong

Fig. C: Needle-thread tension too strong

or

Hook-thread tension too weak

6.2.1 The influence of the sewing-foot lift on the main thread tensioner and supplementary thread

tensioner, for subclass 669-180312

Button 1 (see Chapter 6.15) on the machine’s row of buttons can be

used to activate or deactivate the supplementary thread tension at any

time. The parameter F-299 must be set to "1" for this to work.

Sewing-foot lift Sewing-foot

in the seam lift after the

thread has been cut

Par a meter Main thread Supplementary Main thread Supplementary

setting tension thread tension thread

tension tension

F-196=0 0 0 0 0

F-196=1 1 1 0 0

F-196=2 0 0 1 1

F-196=3 1 1 1 1

1 = Thread tension opened mechanically

0 = Thread tension c losed mechanically

If the supplementary thread tensioner is open, the state of the

·

sewing-foot lift does not change.

If the machine is turned off, the supplementary thread tension

·

remains at its previously set state.

10

Page 15

6.2.2 The influence of the stroke adjustment on the supplementary thread tensioner and the Speedomat,

for subclass 669-180312

Button 1 (see Chapter 6.14) on the machine’s row of buttons can be

used to activate or deactivate the supplementary thread tension at any

time. The parameter F-255 must be set to “7" for this to work.

Parameter Max. stroke Stroke adjustment

setting. adjustment via knee button

viadialwhentheHP

speed from parameter

F-117 is reached

(Speedomat)

F-197 = 0 1 1

F-197 = 1 0 1

F-197 = 2 1 (*) 0

F-197 = 3 0 0

(*) If the stroke adjustment (max.) is activated via the knee switch and

the HP speed (from parameter F-117) has been reached by the

“Speedomat”, then the supplementary thread tensioner is automatically

activated.

0 = Supplementary thread tension closed mechanically

1 = Supplementary thread tension opened mechanically

GB

If the supplementary thread tensioner is closed, the state of the

·

stroke adjustment does not change.

If the machine is turned off, the supplementary thread tension

·

remains at its previously set state.

Initial control-box settings for the automatic stepped reduction of the

stitch count (Speedomat), using the dial for the height of the alternating

feed stroke:

Parameter 188

Step 01-21 Entire Speedomat range

Step 01-10 Maximum allowed stitch count, parameter

F-111 = 3000 min

Step 11-18 Linear step-wise reduction of the maximum

stitch count (Speedomat)

Step 19-21 Maximum allowed stitch count, parameter

F-117 = 1.800 min

1

1

11

Page 16

6.3 Opening the needle thread tension

Subclasses

669-180010

When raising the sewing feet by means of the knee lever, the main and

supplementary tensioners are automatically opened.

Subclasses

669-180112, 669-180312

The needle-thread tensioner is automatically opened when the thread

is cut.

6.4 Turning the supplementary thread tension on and off for subclasses 669-180010

and 669-180112

12

21

The supplementary thread tension is turned on and off using the

lever 1.

Turning on

–

Pushtheknob2onthelever1totheleft.

Turning off

–

Pushtheknob2onthelever1totheright.

Page 17

6.5 Adjusting the thread regulator

32 1

Caution: danger of injury !

Turnthemainswitchoff.

Set the thread regulator only with the sewing machine turned off.

The thread regulator 1 is used to control the quantity of the needle

thread required by the stitch formation.

The best s ewing results can only be ensured when using a precisely

adjusted thread regulator.

At the properly adjusted setting, the needle thread loop must be able to

slide over the thickest section of the hook.

–

Loosen screw 2.

–

Change the position of the thread regulator 1.

Thread regulator to the left = more thread.

Thread regulator to the r ight = less thread.

–

Tighten screw 2.

Settings note:

At the point where the most thread is required, the thread take-up

lever 3 must be pulled up about 0.5 mm from its lower end position.

This occurs when the needle thread loop passes the section of the

hook with the widest diameter.

GB

13

Page 18

6.6 Winding the bobbin thread

543 21

–

Put the reel on the reel stand. Guide the bobbin thread through the

unwind holder.

–

Pull the thread through guide 5, the tensioner 4, and the guide 3.

–

Clamp the thread behind the blade 6 and tear off.

–

Put the bobbin 1 on the bobbin winder.

The thread does not need to be hand wound around the bobbin.

–

Press the bobbin-winder lever 2 in the bobbin.

–

Sewing

The bobbin-winder lever ends the operation as soon as the bobbin

is full.

The bobbin winder remains in position so that the blade 6 is

properly positioned (refer to the illustration on the right).

–

Take off the full bobbin 1. Clamp the thread behind the blade 6 and

tear off.

–

Put an empty bobbin on the bobbin winder for the next winding

process and press the bobbin lever 2 into the bobbin.

Caution: danger of breakage!

If the thread is not being wound during the sewing operation, the

sewing foot must be set to the raised position and the sewing-foot

stroke must be set to the smallest value.

26

14

Page 19

6.7 Replacing the shuttle bobbin

1

Caution: danger of injury !

Turnthemainswitchoff.

Change the shuttle bobbin only when the sewing machine is switched

off.

5

2

Taking off the empty bobbin

–

Raise the needle bar into its high position.

–

Pull out the hook cover 1 and fold down.

–

Lift up the bobbin enclosure hood 2.

–

Take out the upper part of the bobbin enclosure 3 with the bobbin 4.

–

Remove the empty bobbin from the upper part of the bobbin

enclosure 3.

32

GB

4

7

6

3

Inserting a full bobbin

–

Put a full bobbin in the upper part of the bobbin enclosure 3.

Please note the rotational direction of the bobbin.

The rotation is correct when the bobbin turns in the opposite

direction of the pulling direction of the thread.

–

Pull the hook thread through the slot 7 under the tension spring 6

and then through the hole 5.

–

Pull out the tension spring from the bobbin enclosure about 5 cm.

When the thread is being pulled out, the bobbin must rotate in the

direction shown by the arrow.

–

Replace bobbin housing 3.

–

Close bobbin enclosure hood 2.

–

Close the hook cover 1.

Danger of breakage !

Press down firmly on the bobbin housing and make sure that it is

correctly locked in.

15

Page 20

6.8 Pre-setting the hook thread tension

1

Caution: danger of injury !

Turnthemainswitchoff.

Only adjust the hook thread tension when the machine is turned off.

2

4

3

Brake spring

The brake spring 1 is responsible for preventing a bobbin overrun

during a machine stop and when the hook thread is being cut. It cannot

be adjusted!

Setting the tension spring

–

Adjust the tension spring 4 with the adjustment screw 3. Turn until

the required tension force is present.

Raising the hook thread tension

–

Turn the screw 3 clockwise.

Decreasing the hook thread tension

–

Turn the screw 3 counter-clockwise.

16

Page 21

6.9 Inserting and replacing the needle

21

Caution: danger of injury !

Turnthemainswitchoff.

Change the needle only when the sewing machine is switched off.

1

2

3

GB

–

Turn the handwheel until the needle bar 1 has reached its highest

position.

–

Loosen screw 2.

–

Pull the needle out from under the needle bar 1.

–

Push in the new needle until it reaches the limit stop in the hole for

the needle bar 1.

Caution!

The needle scarf 3 must be pointing towards the hook.

–

Tighten screw 2.

CAUTION !

When changing to a needle with a different thickness (gauge), you

must adjust the clearance gap between the hook and the needle (refer

to the service instructions).

The following errors can result if you do not do this:

When using a thinner needle:

–

Missing stitches and thread damage

When using a thicker needle:

–

Damage to the hook tip and damage to the needle

17

Page 22

6.10 Raising the sewing feet

1

Subclass

669-180010

The sewing feet can be lifted mechanically by pressing the knee

lever 1.

Subclasses

669-180112, 669-180312

The sewing feet can be lifted electro-pneumatically by pressing the

pedal 2 or the knee lever 1.

Raising the sewing feet mechanically (w ith t he knee lever)

–

Push the knee lever 1 to the right in order to move the sewing

material (for example, when making corrections).

The sewing feet remain in the raised position as long as the knee

lever 1 is pressed.

Raising the sewing feet electro-pneumatically (w ith t he pedal)

–

Press the pedal 2 half way back.

The sewing feet are raised when the machine is stopped.

–

Press the pedal 2 all the way back.

The thread trimmer will then be activated and the sewing feet will

be raised.

2

18

Page 23

6.11 Setting the sewing feet in the high position

1

6.12 Sewing-foot pressure

12

–

Swivel lever 1 downwards.

Set the sewing feet in the high position.

–

Swivel lever 1 upwards.

The sewing feet are released.

or

–

The sewing feet are raised pneumatically or with the knee lever.

The lever 1 swivels back to its starting position.

The knob 2 is used to set the required sewing-foot pressure.

CAUTION !

The sewing material should not “swim”.

Do not set more pressure than necessary.

–

Raising the sewing-foot pressure = Turn the dial 2 clockwise.

–

Lowering the sewing-foot pressure = Turn the dial 2

counter-clockwise.

GB

19

Page 24

6.13 Sewing-foot stroke

21

The class 669 sewing machine comes (depending on the subclass)

standard equipped with two dials for adjusting the sewing-foot stroke.

Use the dial 2 on the left to select the standard sewing-foot stroke

from1to9.

Use the dial 1 on the right to set a higher sewing-foot stroke from 1 to

9.

–

Turndial1and2(1to9):

1 = minimal sewing-foot stroke

9 = maximum sewing-foot stroke

Automatic stitch rate limit

Machines without a thread trimmer

The speed is not verified on these machines.

Please observe the notices and the information found in the tables on

the next page.

Machines with a thread trimmer

The sewing-foot stroke and stitch count are interdependent. A

potentiometer is connected mechanically with the dial. The control unit

detects what foot-stroke has been set by means of this potentiometer

and restricts the speed of rotation accordingly.

3

20

Machines with electro-pneumatic rapid stroke adjustment

When processing thick sections of material or when sewing over

transversal seams, the higher sewing-foot stroke (dial 1) can be

activated while sewing by means of the knee switch 3 (under the table

plate).

A potentiometer is used here just as in the machines with thread

trimmers.

CAUTION: Danger of breakage !

The standard sewing-foot stroke as set by the dial 2 must not be larger

than the stroke set by the dial 1.

Page 25

Operating mode for the rapid stroke adjustment

The activation time for the maximum sewing-foot stroke depends on

which operating mode is set. You can select between three different

operating modes.

The particular modes are specified on the operating panel by setting

the parameters F-138 and F-184 (refer to the instructions from the

motor manufacturer).

Operating mode

Momentary contact

F-138 = 0

F-184 = 0

Maintained contact

F-138 = 1

Momentary contact

with minimum

stitch count

F-138 = 0

F-184 = 0 < 100

3

Note!

The switch 4 on the rear of the knee switch 3 can also be used to

switch between the “maintained contact” and “momentary contact”

modes.

Operation / Explanation

The maximum sewing-foot stroke remains activated as

long as the knee switch 3 is being pressed.

The maximum sewing-foot stroke is activated when

the knee switch 3 is pressed.

Pressing the knee switch again will then deactivate

the maximum sewing-foot stroke.

The maximum sewing-foot stroke remains activated as

long as the knee switch 3 is being pressed.

After releasing the knee switch, the machine

continues to sew with the maximum sewing-foot stroke

until the specified minimum stitch count (parameter

F-184) is reached. Afterwards, sewing continues with

the standard sewing-foot stroke.

GB

4

NOTE!

Do not exceed the max. stitch count limits specified in the table.

Observing these limits will ensure safe operations and a long lifespan

for the machine.

Subclass Stitch length range Sewing-foot stroke Max. stitch count

Dial position [mm] [min

669-180010 0-6 1-3 3000

669-180112 4 2500

669-180312 5 2100

6-9 1800

1-4 2500

6-9 5 2100

6-9 1800

-1

]

21

Page 26

6.14 Adjusting the stitch length

4

The class 669 sewing machine is equipped with two dials, depending

on the subclass. This allows two different stitches to be used when

sewing. They can be selected using button 4 (see Chapter 6.15).

The stitch lengths are set using the two dials 1 and 2 found on the

machine arm.

–

Set the longer stitch length with the upper dial 1.

Position 1 = min. stitch length

Position 9 = max. stitch length

–

Set the shorter stitch length with the lower dial 2.

Position 1 = min. stitch length

Position 9 = max. stitch length

Stitch lengths are equal for both forward and reverse sewing.

–

Push the stitch regulator lever 3 down in order to manually sew

bartacks.

The machine will sew backwards as long as the stitch regulator

lever 3 is pressed down.

Note

In order to facilitate the process of adjusting the stitch lengths, the

button 2 (see Chapter 6.15) should be used to fix the stitch lengths so

that they do not shift.

321

22

CAUTION: Danger of breakage !

Make sure that the stitch length set with the lower dial 2 is not larger

than the stitch length set by the upper dial 1.

Page 27

6.15 Key pad on the machine arm

8

7

654321

Key Function

1

2

3

4

5

Supplementary tread tension

Button is back-lit: the supplementary thread tension is

activated.

Button is not back-lit: the supplementary thread

tension is not activated.

2. Stitch length

Button is back-lit: long stitch length (upper dial) is

activated

Button is not back-lit: small stitch length (lower dial) is

activated

Invoke or suppress the start/final bartacks.

If the start and final bartacks are activated, then the

next bartack is deactivated w hen the button is

pressed.

If the start and final bartacks are not activated, then

the next bartack is activated when the button is

pressed.

Move the needle to the upper or lower position.

The function of the button can be set with the

parameter F-242.

1 = needle up/down

2 = needle up

3=singlestitch

4 = full stitch

5 = needle to position 2

The factory default setting is 1 (needle up/down).

Sew backwards manually.

The machine sews backwards for as long as the

button is held down.

GB

23

Page 28

Key Function

7. Sewing

8

The key 7 can be assigned a function using the screw 6 found under

the switch.

–

Select a function.

For example: 6 = sew backwards manually

–

Then press in the screw under key 5 and turn 90° to the r ight (the

slot is then vertical).

This function can now be activated using either key 5 or 7.

CAUTION !

You must deactivate any previous assignment before assigning key 9

another function.

LED display “Power On”

7.1 Sewing with machines using the FIR clutch positioning drive

You can find a comprehensive description of the control unit in the

current operating instructions from the motor manufacturer (included).

0

1

2

3

With the pedal

0Atrest

1 Sewing forwards with minimum speed

2 Sewing forwards with higher speed

:::

3 Sewing forwards with maximum speed

24

Page 29

7.2 Sewing with machines using the Efka DC1550/DA321G positioning drive

The DA321G control unit contains all required operational interfaces

for switching functions and setting parameters.

It is possible to operate without an operating panel, but the seam

programming can no longer be carried out.

The V810 and V820 operating panels can also be connected to the

control unit. They are deliverable as accessories.

Seam programming can be performed with the V820 operating panel.

The “EFKA DC1550 – DA321G” Operating Manual contains a more

detailed description of the control unit (also refer to www.efka.net).

With the pedal

The pedal position is detected using a sampling detector with 16

different levels.

Their meanings are listed in the table below:

Pedal position Pedal movement Meaning

-2 Completely backwards Command for cutting the thread (end of seam)

-1 Half backwards Command for raising the sewing foot

0 Neutral rest position Refer to comment below

1 Slightly forwards Command for lowering the sewing foot

2 More forwards Sew with miminal speed (first level)

3 More forwards Sew with more speed (second level)

:::

13 Entirely forwards Sew with maximal speed (twelfth level)

GB

Comment:

The following functions can be programmed to correspond with the rest

position:

–

Needle position (down/up) and sewing-foot position (down/up)

when stop in seam.

–

Sewing-foot position (up/down) after end of seam. (Pedal fully

backwards, then in rest position)

25

Page 30

321

Sewing process Operation / Explanation

4

Before start of sewing

Starting position

Position material at seam start

Sewing

In the middle of seam

Interrupt sewing operation

Continue sewing operation

(after releasing the pedal)

Sewing an intermediate

lockstitch

- Pedal is in the resting position.

The sewing machine is at rest.

The needle is up.

The sewing feet are down.

- Move pedal back halfway.

Raise the sewing feet.

- Push the material to the needle.

- Step the pedal forward and hold.

The machine then continues to sew with the speed

determined by the pedal.

- Release pedal (return to rest position).

The machine stops in the first position

(needle down).

The sewing feet are down.

- Step forward on the pedal.

The machine then continues to sew with the speed

determined by the pedal.

- Press the stitch regulator lever 4 downwards.

The machine sews in reverse as long as the

stitch regulator lever is pressed.

The speed is determined by the pedal.

26

or

- Press the button 3.

Page 31

Sewing over transverse seams

(maximum sewing-foot stroke)

nd

2

set stitch length

during sewing

(max. stitch length)

The maximum sewing-foot stroke is activated.

The speed is limited to 1600 min-1.

Operating modes for maximum sewing-foot stroke:

- Briefly press the knee switch for activating the maximum

sewing-foot stroke.

- Briefly press the knee switch again for deactivating the

maximum sewing-foot stroke.

- Press the button 2.

Raise the thread tension

during sewing

At seam end

Remove sewing material

- Press the button 1.

- Step the pedal completely backwards and hold.

The final bartack is sewn (when activated).

The thread is cut.

The machine stops in the second position.

The needles are up (reverse rotation).

The sewing feet are down.

- Take out the material.

GB

27

Page 32

8. Tilting Back the Machine Head

1

Caution – Risk of injury from crushing !

Do not reach between the base and the machine arm while you are

tilting back the machine head.

Tilting back the machine head

–

Press lever 1 upwards.

The locking mechanism is then released.

–

Tilt the machine head 3 to the rear.

The machine head 3 will be supported by the strap 2.

Re-closing the machine head

–

Tilt the machine head 3 forwards.

The head tilts back to the position shown in the illustration below.

–

Pull lever 1 back up and carefully tilt the head downwards.

32

28

1

Caution!

Only tilt the head up briefly (i.e., for maintenance work).

If the head is tilted back for a longer period (for a night or weekend), oil

can leak out in the hook area.

Page 33

9. Folding down the MG 56-2 stand

21

Caution: danger of injury !

Always hold the table plate with both hands when pulling out.

–

Loosen the table plate latch 1 located under the table plate.

–

Pull out the table plate 2 to the left and fold out.

–

Hook in the diagonal brace 4 to the bolts 3.

–

Fold down the table plate.

–

Follow these steps in the opposite order to raise the table plate.

1

GB

43

29

Page 34

10. Maintenance

10.1 Cleaning and checking

Caution: danger of injury !

Turnthemainswitchoff.

Maintenance work on the sewing machine must only be carried out

when the machine is switched off.

All maintenance work must be carried out before or at the maintenance

intervals defined in the table (refer to the “operational hours” column).

When working with materials that are thick and fibrous, shorter

maintenance intervals may be required.

A clean sewing machine helps to prevent malfunctions.

3

21

Maintenance required Explanation Operational

interval, hours

Machine head

- Remove sewing dust and

residual thread

(you can use compressed

air)

Direct drive

Clean the motor ventilation

sieve (you can use

compressed air)

Points to be particularly cleaned:

- The area under the throat plate 2

- The area around the hook 1

- The bobbin enclosure

- The thread trimmer

- The area around the needle

Clean dust and residual thread from the

air-entry points.

8

8

30

Page 35

3

1

4

2

Maintenance required Explanation Operational

Sewing drive

Clean the motor ventilation

sieve 2 (you can use

compressed air)

Check condition and tension

on the V-belt 1

Pneumatic System

Check the water level in the

pressure regulator.

Clean dust and residual thread from the

air-entry points

You should be able to press down with your

finger on the V-belt so that the belt moves

about 10 mm down

The water level must not rise as far as filter

insert 3.

- After screwing in drain screw 5 blow out

the water from the water separator 4

under pressure.

5

interval, hours

8

160

40

GB

Clean the filter insert.

Check the system for leaks.

Thefilterinsert3isusedtofilteroutdirt

and condensation.

- Separate the machine from the

compressed air supply.

- Unscrew blow-out screw 5.

There must be no pressure on the

machine’s pneumatic system.

- Unscrew the water separator 4.

- Unscrew the filter insert 3.

Wash out the dirty filter bowl and filter

insert with benzene (do not use a

cleaning solvent).

Then blow dry.

- Re-assemble the maintenance unit

500

500

31

Page 36

10.2 Oil lubrication

1

Caution: danger of injury !

Oil can cause skin rashes.

Avoid prolonged skin contact.

If oil or grease contacts your skin, wash yourself thoroughly.

CAUTION !

The handling and disposal of mineral oils is subject to legal

constraints.

Deliver used oil to an authorized reception point.

Protect your environment.

Take care not to spill any oil.

Oil the sewing machine exclusively with the lubricating oil DA-10 or an

equivalent oil w ith the following specification:

Viscosity at 40° C : 10 mm²/s

Flash point: 150° C

DA-10 can be purchased at sales branches of

DÜRKOPP ADLER AG, under the following part numbers:

250-ml container: 9047 000011

1 litre container: 9047 000012

2 litre container: 9047 000013

5 litre container: 9047 000014

Maintenance required Explanation Operational

interval, hours

Lubrication of the machine

head

The head is equipped with centralized oil wick

lubrication. The bearings are supplied by the

oil reservoir 1.

- The oil level must not drop below the

mark 3 on the oil reservoir.

The oil reservoir illuminates when the oil

level falls below the mark 3.

(Only for subclass 669-180312)

- Refill oil through the hole 2 until it reaches

the “Max” mark.

8

32

Loading...

Loading...