Page 1

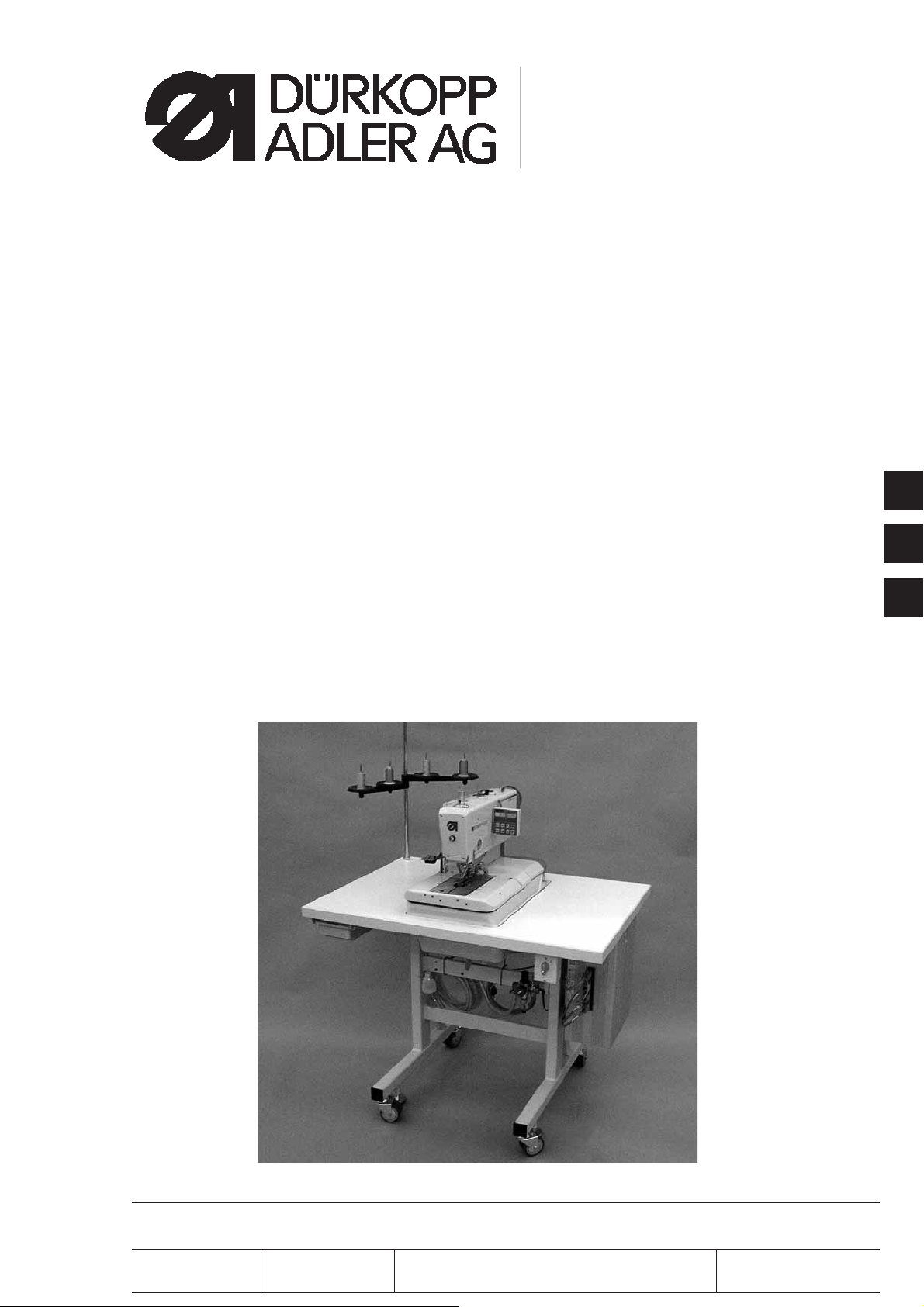

559

Doppelkettenstich Knopflochautomat

Einfachkettenstich Schnürlochautomat

Automatic double-chainstitch buttonholer

Automatic single-chainstitch eyelet machine

Bedienanleitung / Operating Instructions

Aufstellanleitung / Installation Instructions

Serviceanleitung / Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 5 21/ 9 25-00 Telefax+49(0)521/9252435 www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

07/2007 Rev. index: 01.0 Printed in Federal Republic of Germany 0791 559001

Page 2

Anleitung, komplett / Manual, complete

Übersicht Summary

559

Bedienanleitung

Aufstellanleitung

Serviceanleitung

Bauschaltplan

9890 580001 B

Pneumatikgeräteplan

9770 559001

Operating Instructions

Installation Instructions

Service Instructions

Interconnection-diagram

9890 580001 B

Pneumatic circuit plan

9770 559001

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise

Wiederverwendung dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG

verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2007

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 5

Index Page:

Preface and general safety hints

Part 1: Operating Instructions cl. 559

(Edition: 07/2007)

1. Description of product

1.1 Use in accordance with the requirements ...................................5

1.2 Briefdescription..................................................5

1.3 Subclasses.....................................................6

1.4 Structure of product ................................................7

2. Technical data ...................................................8

1

3. Operation

3.1 Needles, threads and gimps ...........................................9

3.2 Removingandinsertingtheclampingplates ................................10

3.3 Needle change ..................................................11

3.4 Threading the needle thread ..........................................12

3.5 Threading the looper thread ..........................................13

3.6 Threading the gimp thread ...........................................14

4. Swivelling the automat up and down ...................................14

5. Thread tension

5.1 Needle and looper thread tension .......................................15

6. Changing of cutting blocks and knives ..................................17

7. Push button ...................................................18

8. Setting the cloth stops ............................................18

9. Switching o n - Switching off - Threading mode

9.1 Switchingon....................................................19

9.2 Switchingoff....................................................19

9.3 Threading mode .................................................19

10. Control

10.1 General notes ...................................................20

10.2 Index of the control panel keys.........................................20

Page 6

Index Page:

10.3 Mainlevelofthemenusystem.........................................21

10.3.1Directeditingofthevaluesinthemainlevel ................................21

10.3.2 Selecting the buttonhole program .......................................21

10.3.3Adjustingthethreadtensioninthemainlevel ...............................22

10.3.4 Adjusting the cutting length in the main level ................................22

10.3.5 The counter ....................................................22

10.4 Operatingthemenu...............................................23

10.4.1Selectionofamenuitem............................................23

10.4.2Editingofavalue.................................................23

10.4.3Listofmenuandsubmenuitems .......................................24

10.4.4 Programming a buttonhole ...........................................25

10.5 Sewing operation .................................................28

10.5.1Switchingon....................................................28

10.5.2 Selection of a buttonhole program ......................................28

10.6 Sewing.......................................................29

11. Information messages

11.1 Needle not in basic position ..........................................30

11.2 Pressuremonitor.................................................30

11.3 Threadbreakage.................................................30

11.4 Threading mode .................................................31

12. Error messages .................................................31

13. Maintenance

13.1 Cleaning ......................................................32

13.2 Oiling ........................................................33

13.3 Control.......................................................34

Page 7

1. Description of product

1.1 Use in accordance with the requirements

The DÜRKOPP ADLER 559 is a sewing automat determined for

sewing buttonholes in light to medium-weight material, i.e. fabrics

made of textile or synthetic fibers.

Such sewing materials are used in the clothing industry. Furthermore,

this sewing automat can possibly also sew so-called technical seams.

However, in this case the user has to estimate the possible risks

(preferably in c ooperation with DÜRKOPP ADLER) because on the one

hand such fields of application are comparatively r are and on the other

hand there is an immense variety of possibilities. According to the

result of this estimation suitable safety measures are to be taken.

Generally only dry fabrics must be processed w ith this machine. The

material must not be thicker than 8mmwhen compressed by the

lowered upper fabric clamps.

It must not include any hard objects. When working with the sewing

automat the operator must wear a finger and eye protection.The

sewing automat must be installed and operated in dry and well-kept

room s only. If it is operated in other rooms, which are not dry and

well-kept, further measures can become necessary which have to be

agreed upon (see EN 60204-31:1999). We as manufacturers of

industrial sewing machines take it for granted that at least semi-skilled

operators are working with our products so that we can assume that all

usual operations and their risks are known to them.

1

1.2 Brief description

The DÜRKOPP ADLER 559 is an automatic double-chainstitch

buttonholer or a s ingle-chainstitch automat for stitched eyelets with

CNC step motor technology for the material feed and the rotation of the

sewing mechanism. The automatic buttonholer works with two

chainstitch loopers the left of which is thread-guiding. For sewing of

buttonholes with or without eyelet, with taper tack, round tack, cross

tack or without bartacks. The automat is equipped with a needle thread

trimmer and an electronically regulated needle thread tension.

Technical features

The automat is driven by a positioning drive integrated in the machine

arm.

The drive for the motion of the axes X, Y and Z is effected via one step

motor each. These drives are controlled via an electronic control in

conjunction with various pneumatic machine functions.

The control panel is fitted on the machine arm in such a way that the

operator has a good view on it and that it is easily accessible. This

drive and control system offers the following advantages:

–

Variable sewing speed according to the sewing parameters

(e.g. needle thread, looper thread, material, seam width)

up to 2200 stitches/min. max.

–

Quiet running (no mechanical switching on and off).

Additional noise reduction by optimized needle bar and looper

drive.

–

The use of step motors allows a very variable field of application.

Control cams are not used.

–

The control panel with 8-digit LED display and membrane keyboard

is fitted on the right of the sewing head within easy reach of the

operator.

–

The following functions are operated via push button:

- Closing and opening the clamp

- Activating the sewing operation

- Quick stop with needle position “up”

5

Page 8

–

Pneumatic cutting open of the buttonhole.

–

Automatic adaptation of the cutting power of the buttonhole knife

dependent on the programmed buttonhole length.

–

Due to the vertically working cutting block support no follow-up

work required in case of different cutting block heights.

–

Central oil wick lubrication from two oil reservoirs.

–

Switch at the head cover for moving to the ideal position for

threading in.

–

Electronically controlled needle thread tension.

–

In case of needle thread breakage the needle thread monitor

interrupts the sewing cycle, the fabric clamps remain closed and

hold the workpiece which can be removed at the touch of a button.

–

Covered, smooth design. The swivelling up of the automat is

supported by a gas-pressurized spring which also helps that the

machine head is swivelled back slowly.

Control

–

A counter of the number of buttonholes sewn is shown in the

display.

–

5 programmable buttonholes can be memorized.

–

Integrated test and monitoring system ”Multitest”. Apart from the

monitoring of the sewing process this allows a rapid test of the

input and output elements as well as of the motor functions without

additional measuring instruments.

–

Electronic alteration of the throw width in lip and eyelet.

–

By means of a setting provision in the display it is made possible

that the fabric support plate moves to the initial position of the next

buttonhole after releasing the workpiece. This means a better view

when loading the workpiece.

–

According to the buttonhole type the following parameters can be

set at the control panel:

- with or without eyelet

- max. speed 2200 min

-1

- buttonhole length

- cutting before or after sewing

- without cutting open

- number of stitches in the eyelet

- stitch distance

- taper tack length

1.3 Subclasses

6

559-151000 With trimmer for the needle thread cut short.

For cutting lengths up to 42 mm. Universal machine for

buttonholes in fabrics of different quality and size;

according to the sewing equipment with or without

lower gimp alternatively.

Page 9

1.4 Structure of product

Subclasses

Equipment Material number

Sewing automat 0559 990001 X

Accessories 0791 580501 X

Optional equipment:

Pneumatic connection package 0797 0030031 O

Integral sewing lamp (LED) 0580 100344 O

Foot switch 9880 580002 O

Upper gimp guide 0580 590804 O

Fabric deflector for back trousers 0580 590574 O

Support table for operating while standing 0580 590504 O

Positioning aids

Spacer for the distance from buttonhole to buttonhole 0580 590394 O

(R+L)

Spacer (R+L) for the distance between buttonhole 0580 590404 X

and fabric edge

Laser marking lamp 0580 590564 O

Slide-on table for vertical positioning 0580 590604 O

Kit for vertical positioning 0580 590554 O

(left and right clamping plate)

559-151000

1

Stands

MG58-13 (normal installation) MG58 400104 O

Stand with fastening parts and table top 1060x750

incl. maintenance unit and rollers

MG58-13 (normal installation, narrow stand) MG58 400124 O

Stand with fastening parts and table top 620x750

incl. maintenance unit and rollers

MG58-13 (vertical positioning, narrow stand) MG58 400114 O

Stand with fastening parts and table top 1060 x 600

incl. maintenance unit and rollers

X = Standard equipment

O = Equipment as per request

7

Page 10

2. Technical data

Machine head: Class 559

Type of sewing stitch: Double-chainstitch

Number of needles: 1

Needle system: 558 / 579

Attention!

When changing over from one needle system to the other the distance

between looper and needle and the adjustment of the needle

protection have to be checked in any case (see service instructions).

Max. needle size: Nm 80-120 (558) / Nm 90-125 (579)

Needle thread size: max. Nm 50

Looper thread size: max. Nm 30

Max. Speed: 2200 min

-1

Stitch distance: 0,5-2mm

Max. sewing length: 50 mm

(depending on the sewing equipment)

Max. cutting length: 50 mm

(depending on the sewing equipment)

Operating pressure: 6 bar ± 0,5 bar

Air consumption: approx. 3 NL per working cycle

Rated load: 320 VA

Rated voltage: 1 x 190-240 V, 50/60 Hz

Dimensions: Machine head:

550 x 370 x 580 (L x B x H)

Table top (standard installation):

1060 x 750 x 1150 mm (L x W x H)

Table top (narrow stand):

620 x 850 x 1150 mm (L x W x H)

Working height: 730-900 mm (upper edge of the table top)

upper edge of the machine table:

830-1000 mm

Weight with stand: approx. 160 kg

Weight of head: approx. 100 kg

Weight of control: approx. 12 kg

Rated noise value: Lc = 77 dB (A)

Workplace-related emission value in accordance with DIN 45635-48-B-1

(sewing cycle 4,2 s ON and 1,0 s OFF)

Stitch distance: 1,2 mm

Speed: 2200 rpm

Buttonhole length: 24 mm

Material: double denim 509g/m

2

8

Page 11

3. Operation

3.1 Needles, threads and gimps

Needles

Needle system: 558 / 579

Needle sizes: Nm 80-120 (558) / Nm 90-125 (579)

Attention!

When changing over from one needle system to the other the distance

between looper and needle and the adjustment of the needle

protection have to be checked in any case (see service instructions).

Threads

The look of the buttonhole is essentially influenced by the used sewing

thread.

Threads of synthetic fibre or even silk threads can be used as needle

and looper threads.

The look of the buttonhole is essentially influenced by

–

–

according to the type of sewing thread,

fabric and sewing equipment (E-No.).

1

the used thread.

the use of different needle and looper thread sizes.

Gimps

The gimp is meant to stabilize the buttonhole and to give it a relief-type

appearance at the same time.

It should have the following features:

–

not too thick, but supple and tight

–

even thickness

The threads mentioned in the following table are recommendations

only. Depending on the sewing equipment (E-No.) and the material

also other threads and thread sizes may be required.

Subclass Type and size of needle Type and size of bottom Type and size of low er

thread thread gimp

559-151000 Poly-Poly 80/2 Poly-Poly 80/2 Poly-Schappe 15/3

9

Page 12

3.2 Removing and inserting the clamping plates

21 3

Caution: Danger of injury !

The removing and inserting of the clamping plates 1 has to be done

with the sewing automat switched off or in the position “Threading

mode” (see chapter “Threading mode”).

Remove the clamping plates

–

Slightly lift the right clamping plate 1 at the back and pull it

backwards.

Then remove the clamping plate sideways to the right.

–

Slightly lift the left clamping plate 1 at the back and pull it

backwards.

Then remove the clamping plate sideways to the left.

Insert the clamping plates

–

Push the clamping plate to the front into the recess.

–

Snap in the clamping plate in the pin 3.

Hint!

Wrongly inserted clamping plates can lead to damage or injuries.

10

Page 13

3.3 Needle change

1

2

3

Caution: Danger of injury !

The needle has to be changed with the sewing automat switched off or

in the position “Threading mode” (see chapter “Threading mode”).

–

Loosen screw 1 (Allen key in the accessories).

–

Pull needle 2 out of the needle bar.

–

Push the new needle into the hole of the needle bar as far as it will

go.

–

Align needle 2 in such a way that the hollow groove points to the

front and the flat 3 at the needle butt to the left (towards the

fastening screw 1). Only needle system 579 has got this flat 3 !

When using needle system 558 align the needle 2 in such a way

that the hollow groove points to the front.

–

Tighten screw 1.

1

11

Page 14

3.4 Threading the needle thread

1

2

Caution: Danger of injury !

The needle thread must only be threaded in when the machine is

switched off or in the “Threading mode” (see chapter “Threading

mode”).

–

Thread in the needle thread as shown in the illustrations.

–

For threading in the needle thread push the threading in wire (in

the accessories) through the hollow needle bar 1 from the bottom

to the top.

–

Lead the needle thread behind the looper.

–

Pull the wire with the needle thread down.

–

Lead the needle thread to the left behind the tension disc 2 and

thread it in the needle from behind to the front.

12

Page 15

3.5 Threading the looper thread

Looper thread Gimp thread

1

Caution: Danger of injury !

The looper thread must only be threaded in when the machine is switched

off or in the “Threading mode” (see chapter “Threading mode”).

The automat must be in its final position, i.e. the looper turret with the

loopers has to point to the front.

–

Remove the clamping plates (see chapter 3.2).

–

Swivel the automat upwards.

–

Thread in the looper thread according to the illustrations with the

help of the long threading in wire included in the accessories.

–

Leave an approx. 25 mm long looper thread end hanging out of the

needle hole of the throat plate.

–

Insert the clamping plates (see chapter 3.2).

13

Page 16

3.6 Threading the gimp thread

Bottom thread Gimp thread The looper turret has been turned 90° counter clockwise in

order to show clearly the thread guide of the gimp thread.

Caution: Danger of injury !

The gimp thread must only be threaded in when the sewing machine is

switched off or in the “Threading mode” (see chapter “Threading mode”).

–

Thread in the gimp thread as shown in the illustrations.

–

Leave an approx. 25 mm long gimp end hanging out of the gimp

hole of the throat plate.

4. Swivelling the automat up and down

Caution: Danger of injury !

The automat must only be swivelled up when the machine is switched

off or in the “Threading mode” (see chapter “Threading mode”).

For various operations (e.g. for threading the looper thread or the gimp

thread) the automat has to be swivelled up.

Swivelling up:

–

Pull the locking bolt 1 and lift the automat at the front.

–

Let the locking bolt 1 go again and snap it in a drill-hole (maybe

you have to swivel the automat up and down a little).

–

You should not let the automat go before the locking bolt 1 has

snapped in.

Swivelling down:

–

Keep hold of the automat and pull the locking bolt 1.

–

Swivel the automat down slowly.

1

14

Hint!

If the automat is swivelled up very high, the effect of the

gas-pressurized spring braking the swivelling down is low at first.

Therefore keep hold of the automat when you s wivel it down.

Operating the automat when it is swivelled up c an lead to injuries and

damage.

Page 17

5. Thread tension

5.1 Needle thread and looper thread tension

1

The thread tensions are dependent on the type and quality of the

threads and fabrics. The buttonhole looks best if it is sewn with the

lowest possible thread tension.

Too tight thread tensions can lead to undesired ruffling and thread

breakage, particularly when processing thin materials.

Upper thread tension

In general the upper thread tension has to be tighter than the looper

thread tension. The upper thread tension is designed as an electronic

tension. It consists of the main tension for the sewing process and a

remaining tension (cutting tension) for tightening the upper thread

during the cutting operation under the throat plate.

Depending on the elasticity of the upper thread used, the remaining

tension (cutting tension) has to be adjusted in such a way that the

upper thread end hanging out of the needle is long enough to ensure a

safe sewing start.

–

Adjust the main tension for the sewing operation via the control

panel (see chapter 10.3.3 Adjusting the thread tension in the main

level).

–

Adjust the remaining tension (cutting tension) via the control panel

(menu item 130).

1

15

Page 18

1

Looper thread tension

–

Swivel the machine head up.

–

Adjust the looper thread tension by means of tension 1.

Turn the tension in clockwise direction in order to increase the

looper thread tension.

Turn the tension counter-clockwise in order to reduce the looper

thread tension.

–

Swivel the machine head down.

Caution: Danger of injury !

The looper thread tension must only be adjusted when the machine is

switched off or in the “Threading mode” (see chapter “Threading

mode”).

Hint

The length of the starting thread can be adjusted by changing the

thread tension at the start.

16

Page 19

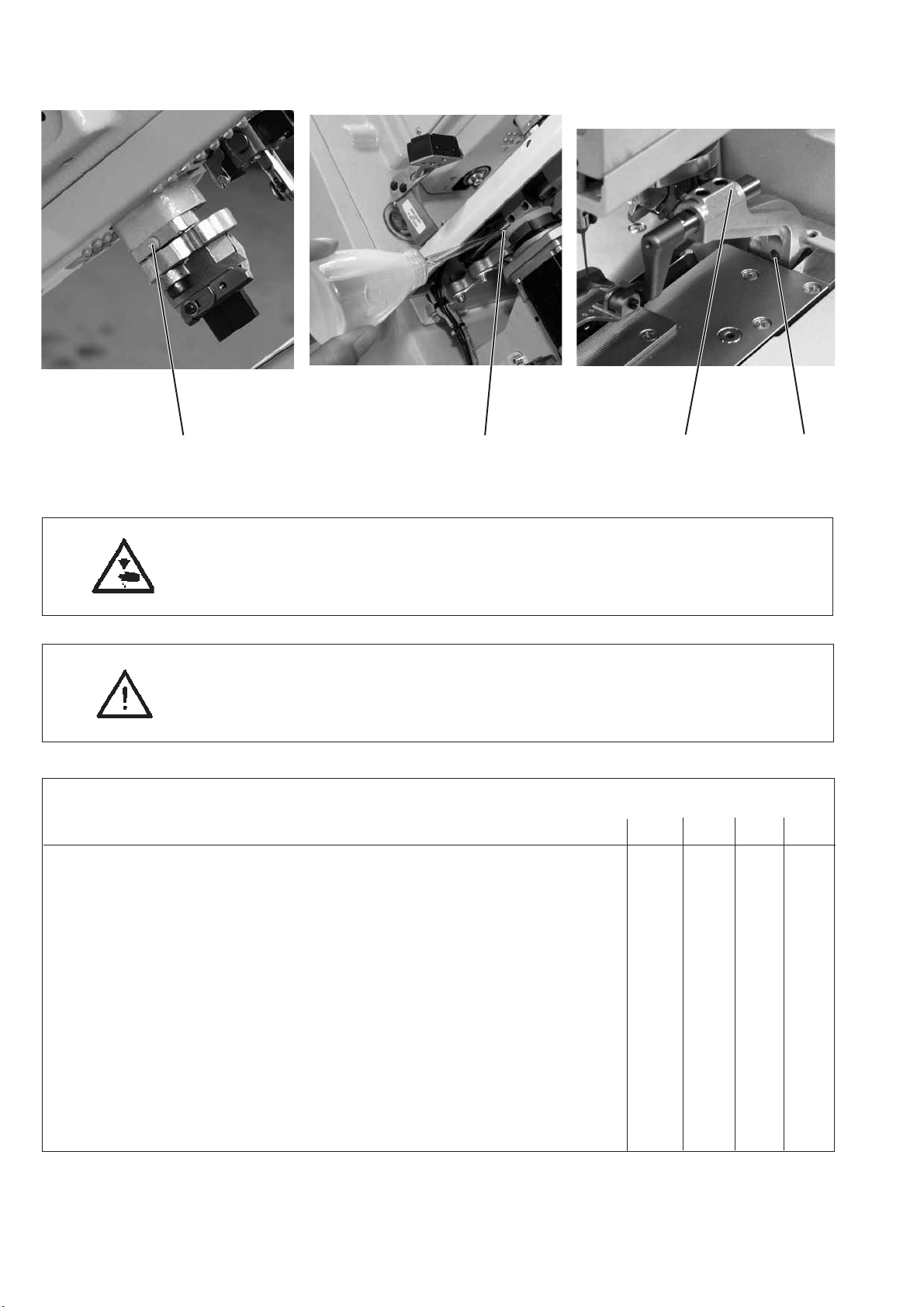

6. Changing of cutting blocks and knives

1

2

4

3

The cutting length can be altered by changing the cutting blocks.

Caution: Danger of injury !

Change the cutting block or the knife only when the automatic

buttonholer is switched off!

Change the cutting block

–

Loosen the Allen screw 1 (Allen key in the accessories).

–

Pull the cutting block 2 to the front and remove it.

–

Insert new cutting block and push it as far as it will go.

–

Tighten the Allen screw 1 again.

Change the knife

–

Loosen the Allen screw 3 (Allen key in the accessories).

–

Pull the knife 4 to the front and remove it.

–

Insert new knife and push it as far as it will go.

–

Tighten the Allen screw 3 again.

1

17

Page 20

7. Push button

By means of the push button it is possible to control the clamps and to

start the sewing operation. According to the adjustment in the service

menu (see service instructions) the function is different.

1. Adjustment

–

–

2. Adjustment

–

–

8. Setting the cloth stops

Caution: Danger of injury !

Adjust the cloth stops only when the automatic buttonholer is

switched off!

Key 1: The clamps are opened or closed respectively.

Key 2: The sewing operation starts when the clamps are closed.

Key 1: The clamps are opened or closed respectively.

Key 2: If the clamps are not lowered, they will be lowered now. The

sewing operation starts.

1

2

1

–

Place the sewing material until it touches the cloth stops 2 on both

sides (right and left).

–

Loosen the screws 1 on the right and left.

–

Adjust the sewing position by moving the cloth s tops 2.

–

Tighten the screws 1 again.

18

Page 21

9. Switching on - Switching off - Threading mode

1

9.1 Switching on

9.2 Switching off

9.3 Threading mode

–

Switchthemainswitch1on.

The machine moves to the loading position and is ready for sewing.

–

Switchthemainswitch1off.

All drives and the control are immediately separated from the

electric supply lines.

Attention!

The main switch is also the emergency stop button! When the main

switch is turned off, the machine is separated from the power supply!

Attention!

The “threading mode” must only be used for the operations necessary

for threading the needle thread, the looper thread and the gimp thread!

For all further operations (e.g. change of knife or cutting block) the

machine has to be switched off with the main switch!

1

Switching on the “Threading mode”

–

Press key 2 in the front plate. The key must snap in!

The sewing automat is in the ”Threading mode".

The key is shining in the “Threading mode”.

The fabric support plate moves to the best position for threading.

The fabric clamps remain in the same position as they were when

switching on the “Threading mode”.

Thesewingdriveisseparatedfromthemains.

The knife for cutting open is switched off.

Switching off the “Threading mode”

–

Press key 2 again. The key must be released.

After a short stop the sewing automat is ready for sewing again. The

sewing operation is continued where the ”Threading mode" had been

activated.

2

19

Page 22

10. Control

LED display

Keyboard

10.1 General notes

The automatic buttonholer class 559 is equipped with a programmable

control. Up to 5 different buttonholes can be defined. It is possible to

change between the programmed buttonholes when sewing.

There are two buttonhole types to choose from:

–

Buttonholes without bartack

–

Buttonholes with taper tack

–

Buttonholes with cross tack

–

Buttonholes with round tack

–

Eyelets (depending on the sewing equipment)

For all buttonhole types the respective characteristics, as e.g.

buttonhole length and shape of the eyelet, can be adjusted (see

chapter “Altering the buttonhole program”).

10.2 Index of the control panel keys

On the control panel Designation of the keys in this instruction manual

“ESC”-key

“P”-key

“F”-key

“OK”-key

Key ï

Key ð

Key ñ

Key ò

20

Page 23

10.3 Main level of the menu system

After the automat has been switched on and while sewing the display

of the automat indicates the main level of the menu system. In the main

level three values are indicated:

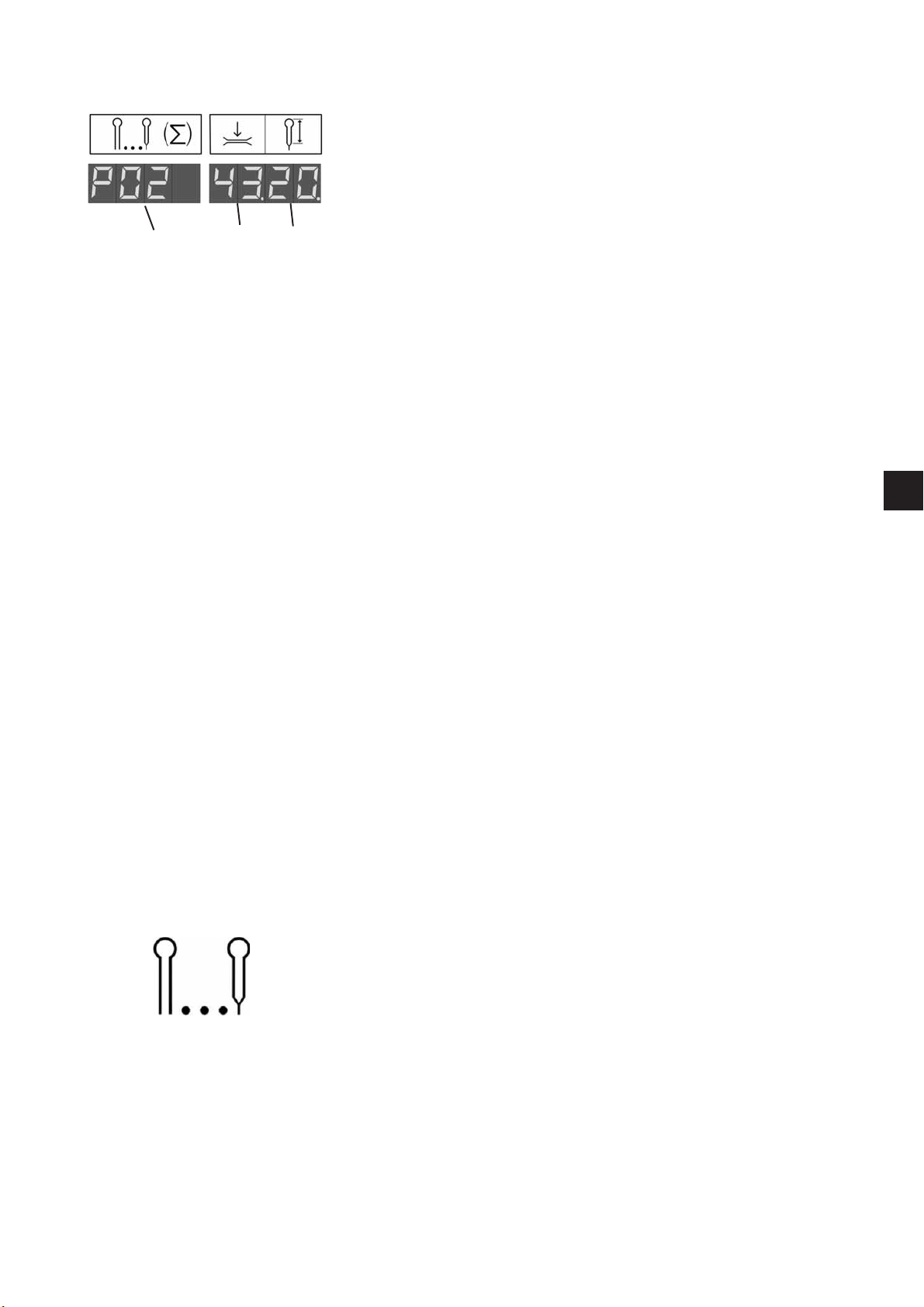

- The buttonhole program 1 (in the example P02)

- The needle thread tension 2 (in the example 43)

- The cutting length 3 (in the example 20)

123

In the main level there are the following options:

- Direct editing of the values in the main level (”F”-key)

- Buttonhole programming (”P”-key)

- Sewing start (control panel, push button, pedal)

10.3.1 Direct editing of the values in the main level

The values of the main level can directly be altered as follows:

“F”-key Press the “F”-key in order to edit the values of the

main level. A value of the main level is blinking.

Keys ïð Change over to the value you w ant to alter with

the keys ïð. The selected value is blinking.

Keys ñò Change the selected value with the keys ñò.

With the key ñ you increase the value, with the

key ò you reduce it. If you have altered a value,

you can no longer change over to another value

with the keys ïð.

“OK”-key Take over the s et value with the “OK”-key.

You quit the editing mode. The values of the main

level are indicated.

“ESC”-key Cancel the alteration with the “ESC”-key.

The altered value is not taken over.

You quit the editing mode. The values of

the main level are indicated.

1

10.3.2 Selecting the buttonhole program

In the main level you can directly select a buttonhole programmed

before:

“F”-key Press the “F”-key. A value is blinking

Keys ïð Select the left field with the keys ïð.

Keys ñò Select the desired buttonhole program with the

“ESC”-key Press the “ESC”-key in order to cancel

“OK”-key Press the “OK”-key for confirmation.

in the display.

The buttonhole program (P01 to P05) is blinking.

keys ñò.

alterations.

21

Page 24

10.3.3 Adjusting the thread tension in the main level

In the right field of the display the first two digits indicate the needle

thread tension when sewing. This can be adjusted directly from the

main level.

“F”-key Press the “F”-key. A value is blinking in the display.

Keys ïð Select the first two digits of the right field of the display

with the keys ïð . The value of the needle thread

tension is blinking.

Keys ñò Adjust the desired value with the keys òñ .

“ESC”-key Press the “ ESC”-key for cancelling alterations.

“OK”-key Press the “OK”-key for confirmation.

10.3.4 Adjusting the cutting length in the main level

In the right field of the display the last two digits indicate the cutting

length. This can be adjusted directly from the main level.

“F”-key Press the “F”-key. A value is blinking in the display.

Keys ïð Select the last two digits of the right field with the

keys ïð . The value of the cutting length is blinking.

Keys ñò Adjust the desired value with the keys òñ .

“ESC”-key Press the “ ESC”-key for cancelling alterations.

“OK”-key Press the “OK”-key for confirmation.

10.3.5 The counter

You can have the daily count number of pieces indicated or set it back

to 0 manually. If the daily number of pieces exceeds the maximum

value of 9999, it is set back automatically and starts counting with 0

again.

2x“F”-key Press the “F”-key in order to edit the values of the main

level. Press the “F”-key anew and the display changes

over from the buttonhole program to the counter of the

daily number of pieces.

“ESC”-key Press the “ESC”-key for quitting the counter of the daily

number of pieces. The main level is indicated again.

Setting the counter of the daily number of pieces back:

“OK”-key When the daily number of pieces is indicated, hold the

“OK”-key pressed for several seconds.

The counter is set to 0 and the display changes over to

the main level again.

22

Page 25

10.4 Operating the menu

10.4.1 Selection of a menu item

Menu item without submenu

Menu item with submenus

Submenu item

The menu system of the 559-151000 is subdivided in 3 levels. The

main level indicates the used buttonhole program, the needle thread

tension and the cutting length while sewing. You can change over from

the main level to the menu for programming buttonholes. A menu item

can include further submenu items.

“P”-key Press the “P”-key for changing over from the main level

to the menu system. A menu item is indicated.

If the menu item has no submenus you see a value,

which you can alter, in the right field of the display.

If the menu item has submenus, you see three items in

the right field of the display. The values of this menu

item are adjusted in the submenus.

Keys ñò Select the desired menu item with the keys ñò.

“OK”-key Press the “OK”-key to confirm the value of the selected

menu item.

If the selected menu item includes submenus a menu

item of the selected submenu is indicated when

pressing the “OK”-key. Select the desired submenu item

also with the keys ñò and confirm with the “OK”-key.

Now you can alter the value.

Key ï With the key ï you return to the next menu level above,

from the submenu level to the menu level, from the

menu level to the main level.

“ESC”-key With the “ESC”-key you always return directly to the

main level.

1

10.4.2 Editing of a value

Keys ïð With the keys ïð you select the digit of the value you

want to alter.

The values can only be altered in certain steps. The

sewing speed for example can only be altered in steps

of 1000 or 100, i.e. the digits 10 and 1 cannot be selected.

Keys ñò With the key ñ the value of the selected digit is

increased.

With the key ò the value of the selected digit is

reduced.

All values have got minimum and maximum values

which cannot be exceeded or fallen below.

“OK”-key With the “OK”-key you take over the altered values.

You return to the menu selection.

“ESC”-key With the “ESC”-key you abort the value alteration.

The previous value is reproduced again. You r eturn to

the menu selection.

23

Page 26

10.4.3 List of menu and submenu items

Menu item Description

100 Buttonhole number: up to 5 different buttonholes can be programmed.

110 Taper tack selection: buttonholes with taper tack (1), cross tack (2), round tack (3),

and without taper tack (0) can be programmed.

120 Length adjustments

121 Sewing length: the sewing length can be set from 6 to 50 mm, depending

on the equipment.

121 Eyelet diameter: the internal diameter of the eyelet, depending on the

equipment adjustable between 1-7.5 mm.

122 Stitch length in the lip: distancefromstitchtostitchwithinthelip(from0.5to2mm).

122 Number of stitches in the eyelet*: number of the uniformly divided stitches in the

entire eyelet.

123 Thread trimming length: it is possible to alter the length of the needle thread on

the underside of the buttonhole.

Condensed stitches increase the sewing security at the seam beginning and seam end.

124 Length of the condensed stitches at the seam beginning: distance between the

stitches within the stitch condensation at the seam beginning.

125 Length of the condensed stitches at the seam end: distance between the

stitches within the stitch condensation at the seam beginning.

126 Number of condensed stitches at the seam beginning: stitch number inside the

stitch condensation at the seam beginning.

127 Number of condensed stitches at the seam end: stitch number inside the

stitch condensation at the seam end.

128 Eyelet overlap*: overlapping of the seam beginning and the seam end.

130 Needle thread tension

131 Sewing tension: sewing tension electronically regulated within the sewing cycle.

132 Trimming tension: lowered needle thread tension for the needle thread trimmer

133 Tension at the sewing start: the length of the starting thread can be adjusted by

changing the thread tension at the seam beginning.

140 Eyelet adjustments

141 Eyelet type: up to 6 different eyelet types can be programmed.

Knife Shape

No.

(X x Y)

0 0,0x0,0 0,0x0,0 0,0x0,0

1 1,3x3,0 1,6x3,5 1,1x2,6

2 2,1x3,2 2,4x3,9 1,7x2,8

3 2,8x4,3 3,3x4,6 2,4x3,9

4 3,0x4,6 3,6x4,8 2,6x4,1

5 3,2x5,4 3,6x6,1 2,8x4,7

Buttonhole shape for

cut after sewing/

no cut

(X x Y)

Buttonhole shape for

cut before sewing

(X x Y)

142 Number of stitches in the eyelet: from4to25stitchescanbesetinthecircle

of the buttonhole eye.

24

Page 27

Menu item Description

143 Eyelet inclination: the buttonhole eye can be slightly inclined to the left or to the right.

150 Throw width: the mechanically regulated throw width (stitch width) can

be enlarged up to 1 mm and reduced up to 0.5mm.

160 Cutting adjustments

161 Cutting mode: depending on the sewing equipment, the buttonhole cut can be

set either after sewing (1), before (2), or not at all (0).

0 = no cutting

1 = cutting after sewing ( CA)

2 = cutting before sewing (CB)

162 Cutting area: the internal distance between the two lips of the buttonhole

is meant by cutting area.

163 Cutting correction in x-direction: the knife position can be displaced to the right/left

within the buttonhole.

164 Cutting correction in y-direction: the knife position can be displaced to the rear/front

within the buttonhole.

165 Correction of cutting pressure: automatic adjustment (4 steps) of the cutting force

of the buttonhole knife depending on the buttonhole length.

-buttonhole length (eyelets) up to 14 mm 2 steps

-buttonhole length from 15 mm to 30 mm 3 steps

-buttonhole length from 31 mm 4 steps

The preset cutting force can be increased/decreased in the above menu item,

depending on the buttonhole length.

1

170 Taper tack adjustments

171 Taper tack length: the taper tack length c an be set from 2 mm to 36 mm, depending

on the equipment and the buttonhole length.

172 Throw width in the taper tack: the throw width (stitch width) for the whole buttonhole

(see menu item 150) can be reduced in the taper tack.

173 Overlapping in the taper tack: overlapping of the buttonhole seams.

174 Height of the tack slant: the taper length in the tack is adjustable.

180 Cross tack adjustments

181 Cross tack length: the overall length of the cross tack.

182 Stitch length in the cross tack: distance from stitch to stitch within the cross

tack (from 0,5 mm to 2 mm).

183 Throw width in the cross tack: the mechanically regulated throw width

(stitch width) can be enlarged/reduced.

184 x-position of the cross tack: the whole cross tack can be s hifted to the right/left.

185 Seam extension in the cross tack: the overlapping of the buttonhole seams

with the cross tack is meant by seam extension in the cross tack.

25

Page 28

Menu item Description

190 Round tack adjustments

191 Number of stitches in the round tack: from 6 to 12 stitches can be set in the round

tack.

192 Throw width in the round tack: the throw width (stitch width) for the whole buttonhole

(see menu item 150) can be reduced in the taper tack.

193 Seam end position (1=inthetack,2=withinthelip)

194 Overlapping in the round tack: overlapping of the seam beginning and the s eam end.

195 Seam beginning within the lip (0% = eye)

200 Speed: sewing speed (stitches per minute)

26

Page 29

Hint!

In order to give you a better overview of all the submenus and to

facilitate the programming, a quick-reference is accompanying the

manual. You can store it above the drawer.

1

10.4.4 Programming a buttonhole

taper tack without bartack

cross tack round tack

–

Press the “P”-key to get from the main level to the buttonhole

programming mode.

–

Select menu item 100 with the keys ñò.Pressthe“OK”-key for

activating the menu item. Select the buttonhole (P01 to P05)you

want to alter and confirm with the “OK”-key.

–

Select menu item 110 with the keys ñò.Pressthe“OK”-key for

activating the menu item. Select the bartack type of the chosen

buttonhole.

- Select “0”forabuttonhole without bartack.

- Select “1”forabuttonhole with taper tack.

- Select “2”forabuttonhole with cross tack.

- Select “3”forabuttonhole with round tack.

- Select “4” for an eyelet.

Confirm with the “OK”-key.

Hint!

When you alter the bartack type of a buttonhole program,

all values of this buttonhole are set back to the standard value!

Therefore always choose the bartack type before adjusting the other

values of the buttonhole!

–

Now adapt the other parameters (120 to 200)accordingtoyour

requirements (operation of the menu see chapter 10.4.1 to 10.4.3)

27

Page 30

10.5 Sewing operation

10.5.1 Sw itching on

Field 1

Field 2

–

Switch on main switch.

The machine moves to the loading position. The main level is

indicated in the display.

–

Field 1: used buttonhole program

–

Field 2: The first two digits indicate the thread tension.

10.5.2 Selection of a buttonhole program

–

Press the “F”-key.

–

Gotofield1withthekeysïð. The buttonhole program is blinking

(e.g. P02).

–

Select the desired buttonhole program (P01 to P05)withthe

keys ñò.

–

Confirm by pressing the “OK”-key.

You can also select the buttonhole program via menu item 100

alternatively.

The last two digits indicate the cutting length of the

buttonhole or the internal diameter of the eyelet in mm.

28

Page 31

10.6 Sewing

The sewing operation can be controlled either by push button or w ith

the keys “OK” and “ESC” at the control panel.

Sewing w ith the push button

With the push button the clamps can be controlled and the sewing

operation started. According to the adjustment in the service menu

(see service instructions) the function is different.

1. Adjustment (Standard)

–

Key 1: The clamps are opened or closed respectively.

–

Key 2: The sewing operation starts when the clamps are closed.

2. Adjustment

–

Key 1: The clamps are opened or closed respectively.

–

Key 2: If the clamps are not lowered, they will be lowered now. The

sewing operations starts.

Quick stop while sewing

- Press key 1 or 2. The sewing operation stops.

- Press key 1 for aborting the sewing operation.

- Press key 2 for continuing the sewing operation.

Sewing w ith the keys at the control panel

–

Load the fabric.

–

Press key “OK” once. The clamps close.

–

If you wish to open the clamps again, press key “ESC”.

–

When the sewing operation is to be started, actuate key “OK”

anew. The buttonhole is sewn.

After the sewing operation the automat moves to the loading

position again.

Quick stop while sewing

-Pressthe“OK”-key or the “ESC”-key. The sewing operation stops.

-Pressthe”ESC”-key for aborting the sewing operation.

-Pressthe“OK”-key for continuing the sewing operation.

Sewing w ith pedal (optional equipment)

The pedal is a two-step pedal without backpedal function.

–

When pedaling the first step the clamps are closed. The clamps

open again when the first step is released.

–

When pedaling the second step the sewing operation starts. The

pedal can be released as soon as the sewing operation has

started.

Quick stop while sewing

- Step on the pedal. The sewing operation stops.

- Step on the pedal once again for aborting the sewing operation.

- The sewing cannot be continued with the pedal! For continuing the

sewing operation you have to use the control panel or the push button.

1

12

Taking off the finished w orkpiece

–

In order to take off the finished workpiece, draw the bottom thread

and the gimp under the thread clamp 2. Pull both threads along the

knife 1 from the right to the left.

The threads are cut.

29

Page 32

Replacing the knife

–

–

–

–

–

Hint!

The knife may not exceed

the fabric holder.

1

4

11. Information messages

Loosen screw 1 and remove the fabric holder 4.

Take out the old knife 2.

Stick the new knife 3 in the groove and snap it off in the arrow

direction.

Tighten the screw 1.

Fix the fabric holder using the screw 4.

1

2

3

11.1 Needle not in basic position

If the needle is not in its basic position at the sewing start, the

information code in the margin appears.

Correction

Turn the handwheel until the info disappears. (See chapter 8.3)

11.2 Pressure monitor

The pressure monitor supervises the pressure of the air inlet. If no

compressed air is available or the pressure is too low, the information

code in the margin appears in the display.

Correction

–

–

–

11.3 Thread breakage

Switch the sewing automat off.

Provide sufficient compressed air.

Switch the sewing automat on.

30

Should the thread breaks during the sewing operation, the information

code in the margin appears in the display.

Correction

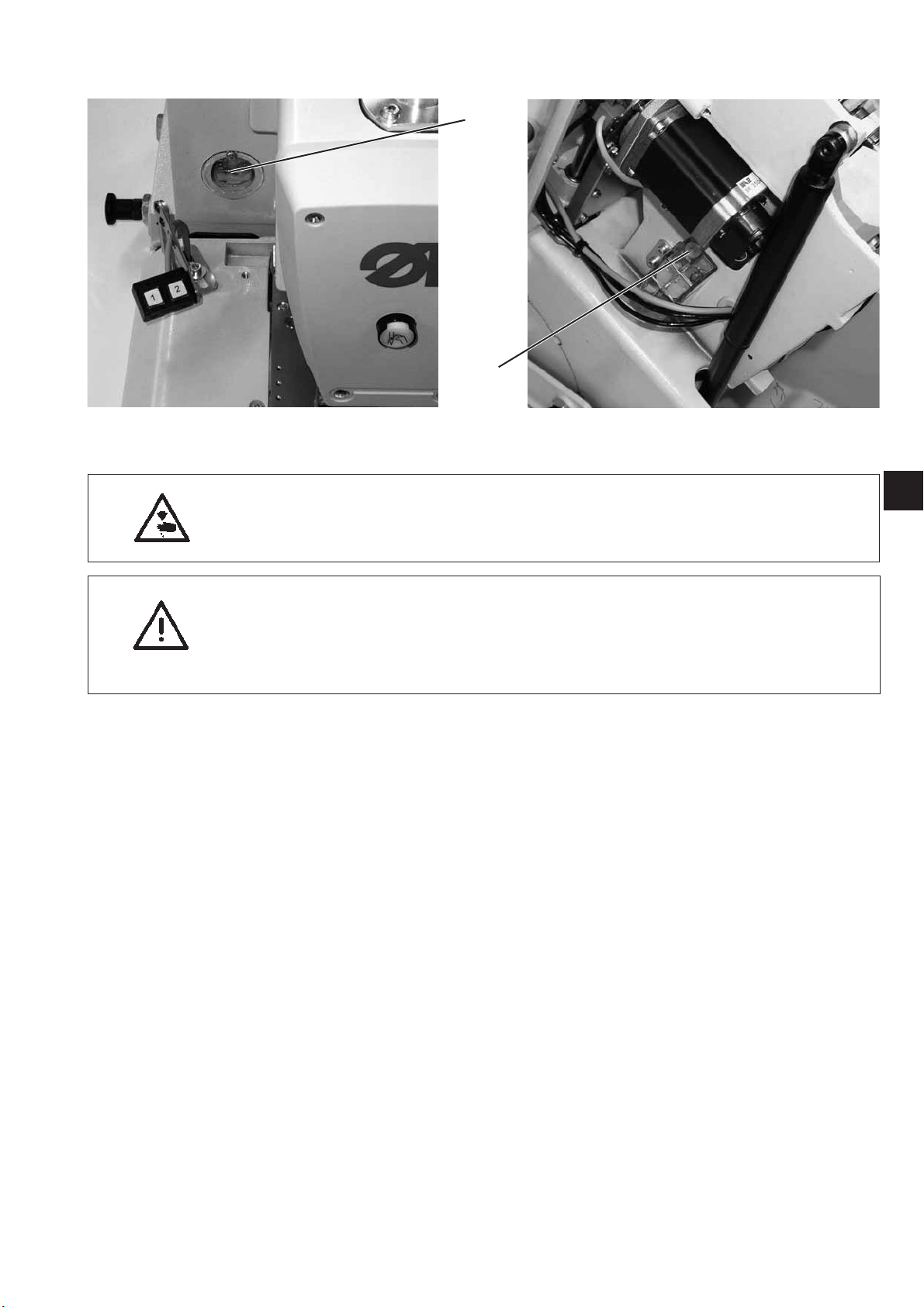

–

Press the button at the head cover to get into the “threading mode”.

–

Thread in the thread new.

Page 33

11.4 Threading mode

As long as the sewing automate is in the “Threading mode”, the

information code in the margin appears.

The sewing automat is in the “Threading mode”, the needle is not in its

upper position.

Correction

–

Switch off the “Threading mode” by pressing the button at the head

cover. The needle moves to its upper position.

–

Switch on the “Threading mode” again.

If the key for the “Threading mode” at the head plate of the automat is

pushed in before switching on, the information code below is indicated.

The same info appears when the key “Threading mode” is pressed

while sewing.

1

12. Error messages

Correction

–

Switch the automat off.

–

Release the “Threading mode” key.

–

Switch the automat on again.

see Error messages in the Service Instructions

31

Page 34

13. Maintenance

13.1 Cleaning

Caution: Danger of injury !

Carry out maintenance work only when the machine is switched off.

In case maintenance work has to be done when the machine is

running, practice utmost caution.

A clean sewing automat avoids disturbances !

Daily cleaning:

–

Clean the zone around looper, thread trimmer and throat plate as

well as the sewing head daily from sewing dust, thread tails and

cutting waste.

If a vacuum cleaner is available, vacuum up the waste.

–

Empty the waste container, if required.

32

1

2

3

–

Check the water level in the pressure regulator daily.

The water level must not rise up to the filter insert 2.

Let the water run out of the water separator 1 under pressure after

screwing in the drain screw 3.

Page 35

13.2 Oiling

4

5

Check the oil level in the oil reservoirs 4 and 5 weekly !

Caution: Danger of injury !

Oil can cause skin eruption!

Avoid a longer contact with the skin!

Wash yourself thoroughly after a contact!

ATTENTION !

The handling and disposal of mineral oils is subject to legal

regulations.

Deliver used oil to an authorized collecting station!

Protect your environment. Take c are not to spill oil!

Fill up the oil reservoirs exclusively with lubricating oil DA-10 or an

equivalent oil w ith the following specification:

–

Viscosity at 40°C: 10 mm²/s

–

Ignition point: 150°C

The oil can be bought at the sales points of DÜRKOPP ADLER AG

under the following parts numbers:

250 ml Container: 9047 000011

1 l Container: 9047 000012

2 l Container: 9047 000013

5 l Container: 9047 000014

1

General notes

All the machine’s moving parts are lubricated by two oil reservoirs via

an oil-wick system.

Check and fill up the oil reservoirs, from time to time it is necessary to

oil the felts 2 and the clamp arms 3 of the punch 1.

33

Page 36

13.3 Control

1 326

Caution: Danger of Injury !

Turnthemainswitchoff.

The maintenance of the automatic buttonholer must only be

carried out with the machine switched off!

ATTENTION !

If the automatic buttonholer has not been used for a long time or after

assembling the machine, oil the wicks, felts, looper and needle bar

components (see Installation Instructions chapter 10).

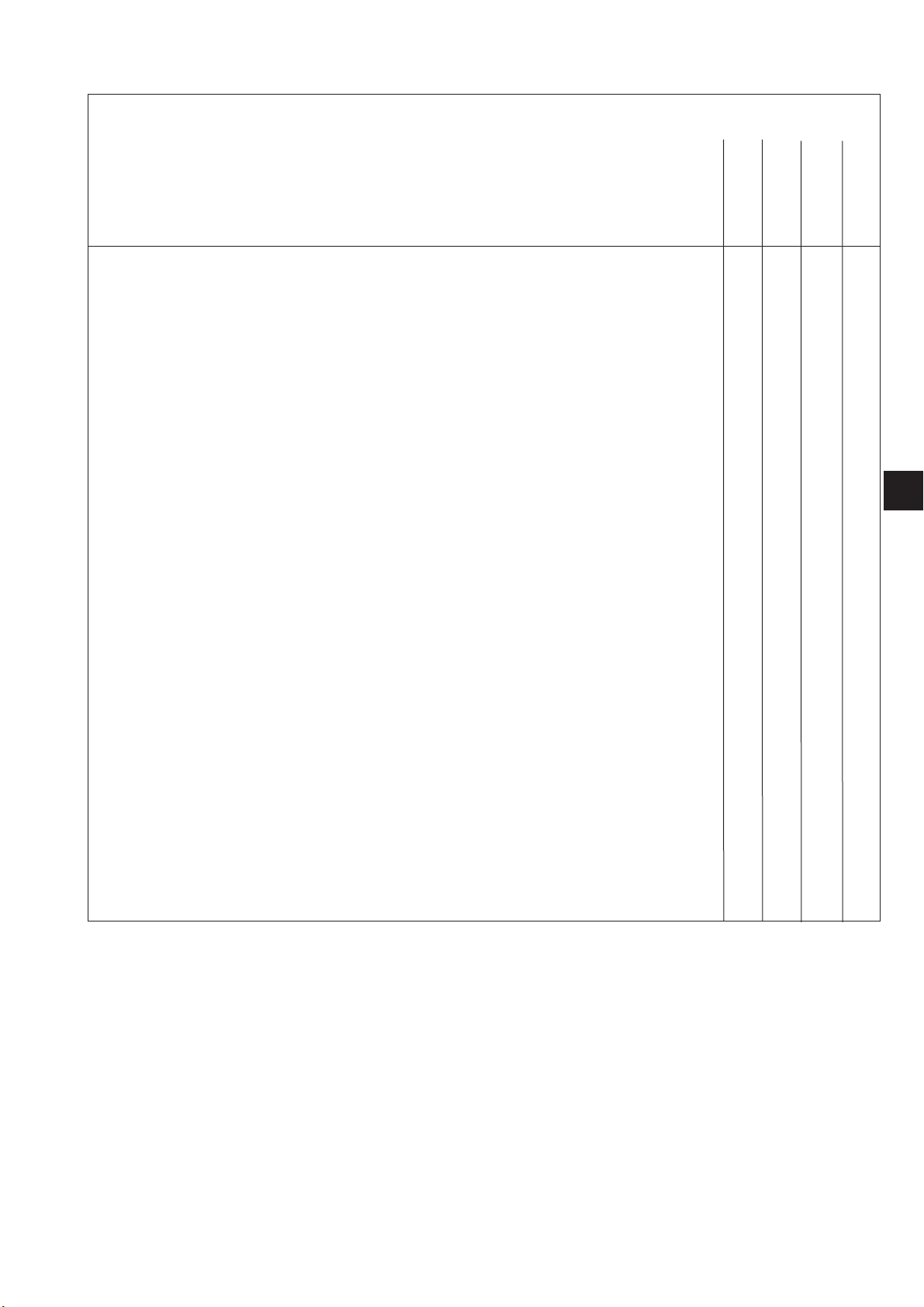

Maintenance work to be done Operating hours

8 40 160 500

Automatic buttonholer

Clean the area under the needle plate of sewing dust X

Check the oil level X

Check and clean the toothed belts X

Oil the punch 1 X

Oil the clamp arms 3 and the felts 2 X

Oilthefelt6onthecamdisc X

Pneumatic system

Check the water level in the pressure regulator X

Clean the filter insert in the maintenance unit X

Check the system for leaks X

34

Loading...

Loading...