Manual, complete

540 - 100

CNC double lockstitch buttonholer

Operating Instructions

Installation Instructions

Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Phone + 49 (0) 5 21 / 9 25-00 • Fax + 49 (0) 5 21 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: 04/2006 Printed in Federal Republic of Germany Teile-Nr./Part.-No.: 0791 540001

540 - 100

Manual, complete

Contents

Operating Instructions

Installation Instructions

Service Instructions

Interconnection-diagram

9890 540001 B

Software version

A04.1

B04.1

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruc ti o n m an ual contains i m po rt a nt i nf orm ation on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruc ti o n m an ual must alway s be available at the

machine/sewing unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, i ncl u di n g e qu i pp i ng , t r ou bl e s ho ot i ng du r ing the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair and/or

– Transport.

The user also has to assure that only authorized personnel work on

the machine.

The user is o bl i g ed to c he ck th e m ac h i ne at l ea s t o nc e pe r shi f t f or

apparent da ma ge s and to immedia tl y r e po r t a ny c h an ge s ( inc l u di n g

the performanc e i n se r vi c e), wh i c h im pa i r th e sa fe ty.

The user comp an y mu s t e ns u re that the machi n e i s o nl y o pe r at ed i n

perfect working order.

Never remove or disable any safety devices.

If safety dev i c e s ne ed to be removed for equi pp i ng , r e pa i ri ng or

maintaining, the safety devices must be

remounted directly after completion of the maintenance and repair

work.

Unauthorized modification of the machine rules out liability of the

manufacture r fo r da ma ge res u l ti n g f r om th i s .

Observe all safety and danger recommendations on the machine/unit!

The yellow -and-black str i pe d surfaces desig na t e pe rma ne nd danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate

training.

2. Before putting into service also read the safety rules and

instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot,

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time

as the entire sewing unit is found to comply with EC directives.

It is absolutely necessary to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Contents Page:

Foreword and general safety instructions

Part 1: Operating Instructions Class 540-100

1. Product description

1.1 Designated use ................................................ 5

1.2 Subclasses .................................................. 6

2. Technical data ................................................ 6

3. Operating the machine head

3.1 Needle threading ............................................... 7

3.2 Winding the hook thread .......................................... 8

3.3 Changing the bobbin ............................................. 8

3.4 Changing the needle ............................................ 10

3.5 Changing the knife .............................................. 11

3.6 Checkingtheknifeheight.......................................... 12

3.7 Threadtension................................................ 13

3.8 Regulating the sewing basket lifting height ............................... 14

3.9 Regulating the sewing basket pressure ................................. 14

1

4. Control panel and control

4.1 Control panel ................................................. 15

4.1.1 Control panel elements ........................................... 16

4.2 Changing parameter values ........................................ 17

4.2.1 Numericalvalues............................................... 17

4.2.2 Parameterselection............................................. 17

4.3 Mainmenu................................................... 18

4.4 Hookthreadmonitoring........................................... 19

4.4.1 Hook thread counter adjustment ...................................... 19

4.5 Softstarton/off ............................................... 20

4.6 Sequences ................................................... 20

4.6.1 General ..................................................... 20

4.6.2 Switching the sequence mode on / off .................................. 21

4.6.3 Select a sequence in the sequence mode (Main menu) ........................ 21

4.6.4 Automatic or manual mode ......................................... 21

4.7 Programming of sequences ......................................... 22

4.7.1 Programming of a single sequence .................................... 22

4.7.2 Adding a buttonhole at the end of a sequence ............................. 23

4.7.3 Deleting a buttonhole within the buttonhole sequence......................... 23

4.7.4 Inserting a buttonhole within the buttonhole sequence ........................ 23

Contents Page:

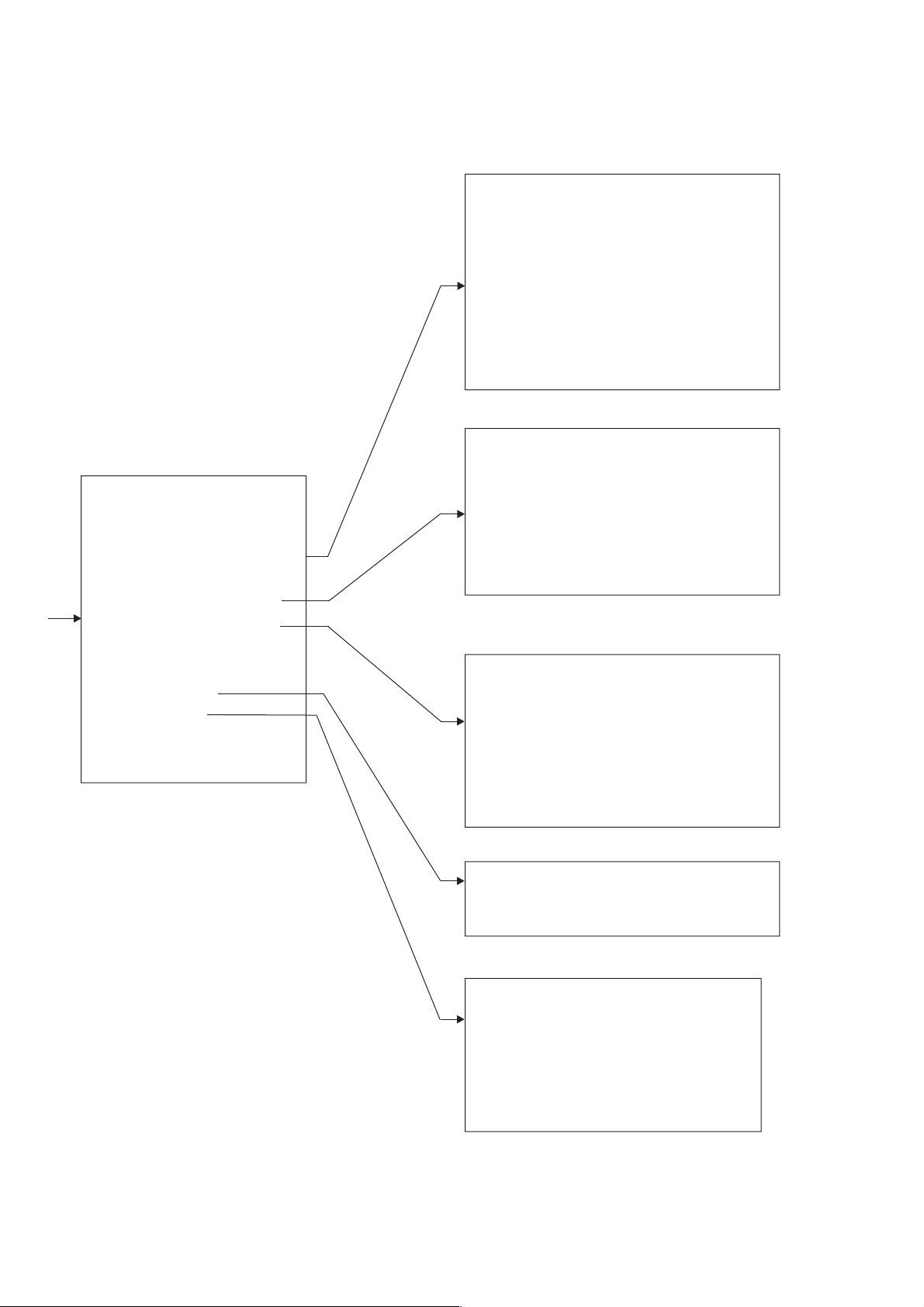

5. Buttonhole programming

5.1 Composition of a buttonhole ........................................ 24

5.2 Submenu programming (general view) .................................. 26

5.3 Parameterprogrammingmode....................................... 27

5.4 Adjusting the cut length ........................................... 28

5.5 Selectingastartvariant........................................... 28

5.6 Setting buttonhole seam .......................................... 29

5.7 Settingbartack ................................................ 30

5.7.1 Selectablebartacktypes .......................................... 30

5.7.2 Programmingmenu“bartack” ....................................... 31

6. Knitwear mode

6.1 Selectingorswitchingoffknitwearmode................................. 35

6.2 Submenubastingstitch........................................... 36

6.3 Submenuzigzag............................................... 36

7. Sewing procedure

7.1 Normal sewing procedure.......................................... 37

7.2 Interruption of sewing procedure ..................................... 37

7.2.1 Interruption by the operator......................................... 37

7.2.2 Clearingthreadbreakage.......................................... 37

8. Error messages ............................................... 39

9. Maintenance

9.1 Cleaning and inspection........................................... 42

9.2 Oillubrication................................................. 43

1. Product description

The Dürkopp Adler 540-100 is a CNC double lockstitch buttonhole

machine with stepping motor technology for the sewing of flat form

linen button holes in light to medium weight material. Maximum

buttonhole length is 65 mm and maximum buttonhole width is 6 mm

(equipment dependent).

Including a knife for all cutting lengths, longitudinal or transversal

setting possible, fine adjustment of the buttonhole with the push of a

button, integrated direct DC drive.

Additional functions:

–

Selectable bartack forms :

Cross tack (vertical), Cross tack (horizontal), Cross tack ( divided),

Round tack (to the middle point), Round tack (horizontal), Taper

tack, Eye tack, Simple tack, Snaffle-shaped tack

–

50 variable seam makers

–

20 Buttonhole – each sequence can be programmed with a

maximum of 20 buttonholes

–

Programmable sewing revolution to a max. of 4000 stitches/min

–

Soft start

–

Bobbin capacity meter

–

Daily quantity meter

–

Multi test functions

–

Voltage rating: 1 x 190 - 240V 50/60Hz

1

1.1 Designated use

The DÜRKOPP ADLER 540-100 is an automatic sewing machine

designed for sewing buttonholes in light to medium-heavy material.

Such material, which is generally made of textile or synthetic fibres, is

used in the clothing industry. This sewing machine can also be used to

produce so-called technical seams. In this case, however, the operator

must assess the possible dangers which may arise (with which

DÜRKOPP ADLER would be happy to assist), since such applications

are on the one hand relatively unusual and, on the other, they are so

varied that no single set of criteria can cover them all. The outcome of

this assessment may require appropriate safety measures to be taken.

Generally only dry material may be sewn with this machine. The

material may b e no thicker than 4 mm when compressed by the

lowered upper material sewing basket.

The material may not contain any hard objects. The machine may only

be operated with finger and eye protection. The seam is generally

produced with sewing threads of gauge up to 65/2 Nm (synthetic

threads with or without cotton covering). Before using any other thread

the possible dangers arising must be assessed and appropriate safety

measures taken if necessary. This machine may be set up and

operated only in dry, well-maintained premises. If it is used in other

premises which are not dry and well-maintained it may be necessary

to take further precautions (which should be agreed in advance - see

EN 60204-31: 1999). As manufacturers of industrial sewing machines

we proceed on the assumption that personnel who work on our

products will have received training at least sufficient to acquaint them

with all normal operations and with any hazards which these may

involve.

5

1.2 Sub classes

540-100

For the sewing of raised-form or flat-form linen buttonholes in light to

middle weight material, with pneumatically steered thread tensioner for

flat form sewing and a second pneumatically switchable /

programmable thread tensioner for raised form sewing. Buttonhole

length max. 70 mm, buttonhole width max. 6 mm. A knife for all cut

lengths.

2. Technical data

Machine head: Class 540-100

Needle system:

Needle thickness:

Threads:

Stitch type:

Stitch number:

Double stitch distance:

Sewing foot stroke:

Buttonhole length :

Buttonhole width:

Cut length:

Power rating:

Operating pressure:

Air consumption:

Rated voltage:

System 265 with slightly rounded head

70 – 100 (dependent on equipment )

Synthetic thread and synthetic thread with cotton covering

up to 65/2 Nm

Double lockstitch ( 304 )

Max. 4000 RPM (adjustable)

0,2-3mm

12 mm

6 - 70 mm (dependent on equipment)

3 - 6 mm (dependent on equipment)

6-65mm

1,3 kW

6 bar

apprx.4 NL per working cycle

1 ~ 230 V, 50/60 Hz

1~ 190 - 240 V, 50/60 Hz

Frame:

Work height:

Weight:

Rated noise level :

6

1060 x 620 x 1250 mm (L x B x H)

780 - 880 mm (Top edge of table top)

ca. 100 kg (with frame)

ca. 70 Kg (without frame)

Lc = 79 dB (A) Emission value per workplace according to

DIN 45635-48-B-1 (sewing cycle 3.6 s ON and 1.0 s OFF).

Buttonhole width: 4 mm

Cutting length: 17 mm

Speed: 4.000 min

Stitch length: 0.6 mm

Fabric: G1 DIN 23328 two-ply

-1

3. Operating the machine head

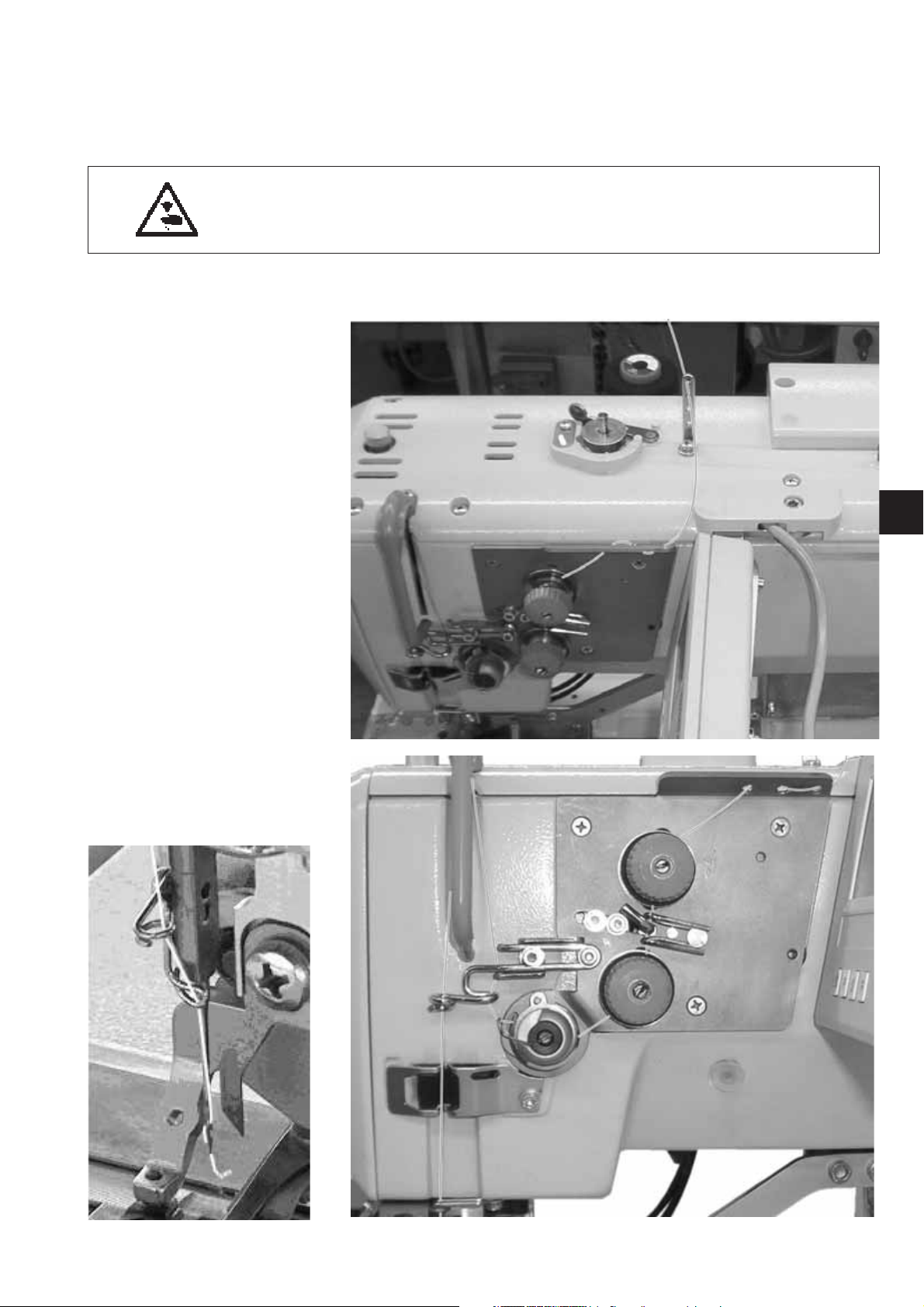

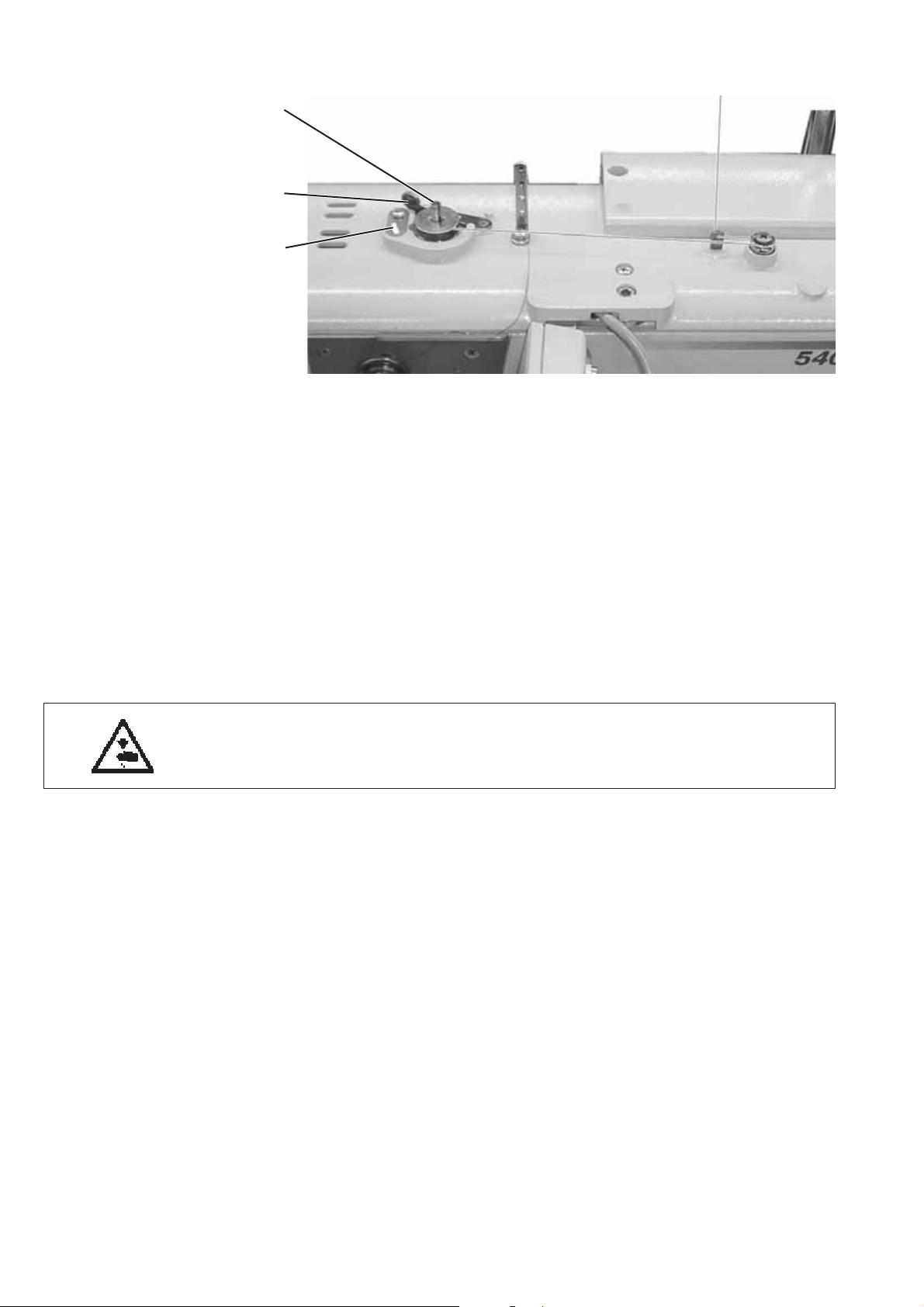

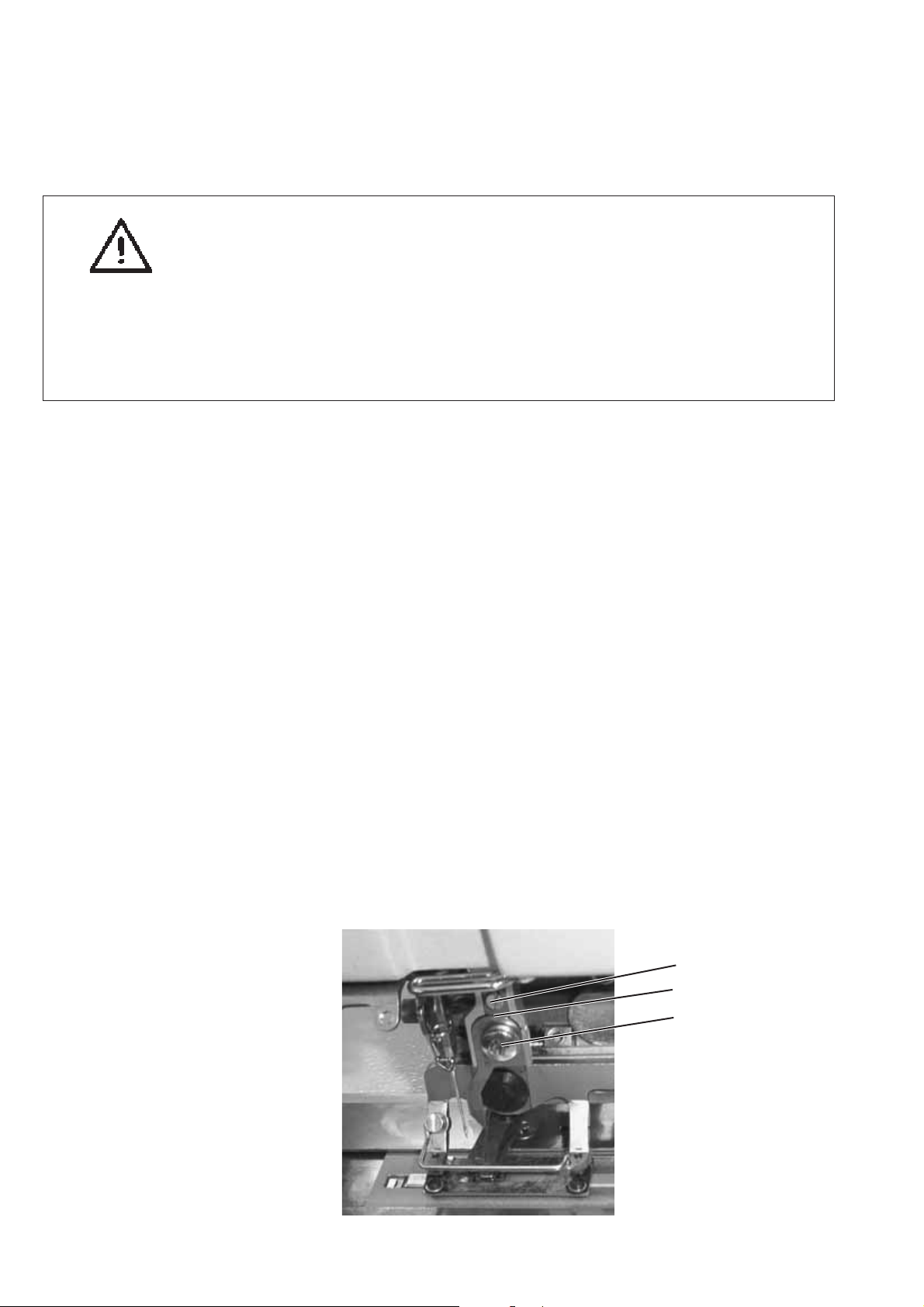

3.1 Needle threading

Caution: Danger of injury !

The needle should only be threaded when the sewing automat is

switched off.

- Thread needle according to diagram

1

Picture threading the needle

7

3.2 Winding the hook thread

1

2

3

Threading the hook thread is independent of sewing operation.

–

Put the thread on the thread stand.

–

Thread the hook as shown in the picture.

–

Put the empty bobbin onto the bobbin winder 1.

–

Wind the hook thread clockwise about 5 times around the bobbin

core.

–

Swing winder lever 2 towards spool and click in.

The thread will be wound on.

–

Winder lever 2 ends the spooling event when the bobbin is full.

–

After spooling snap out the bobbin thread from thread clamp 3.

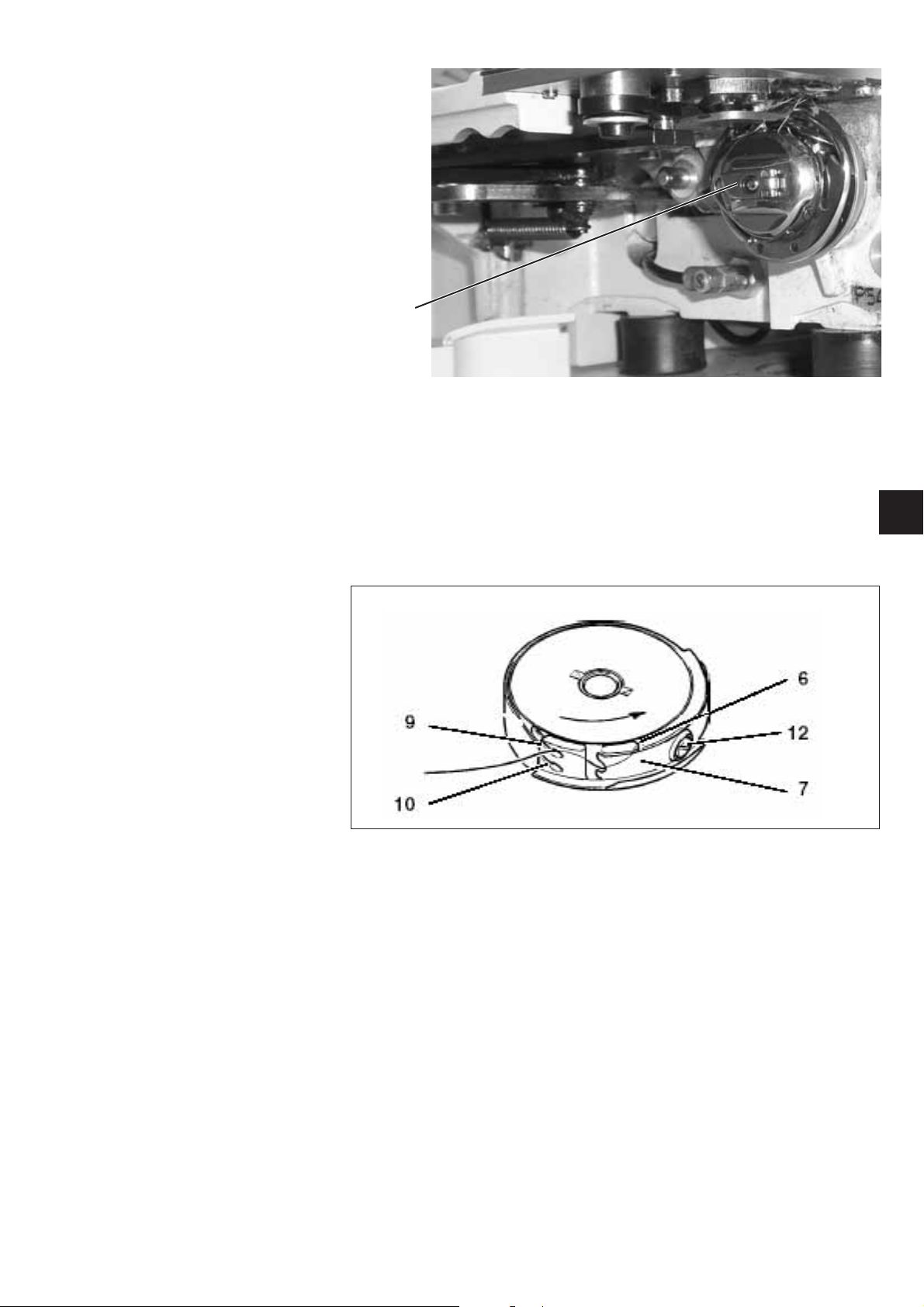

3.3 Changing the bobbin

Caution: Danger of injury !

The bobbin should only be changed when the sewing automat is

switched off.

Remove empty bobbin.

–

Open bobbin case lid.

–

Flip up the clip 5 and remove the top of the bobbin housing with

bobbin.

–

Remove the bobbin from the top of the bobbin housing.

8

5

Threading the bobbin

–

Place the full bobbin in the bobbin housing top, whereby the bobbin

has to turn in anti-clockwise direction when the hook threader is

pulled.

–

Pass the hook thread through the slit 6 and under the spring.

–

Dependent on chosen buttonhole the hook thread has to go

through slit 9 for raised-form buttonholes and slit 10 for flat-form

buttonholes.

1

Setting the hook thread tension

–

Set the hook thread tension by turning screw 12 so that the bobbin

housing slowly sinks with its own weight when the hook thread is

held tight.

–

Flat-form buttonholes will require a higher tension.

Fitting of bobbin housing

–

Put the bobbin housing top along with the bobbin on the bobbin

housing bottom, make sure that the clip 5 audibly snaps into place.

–

Close bobbin case lid.

9

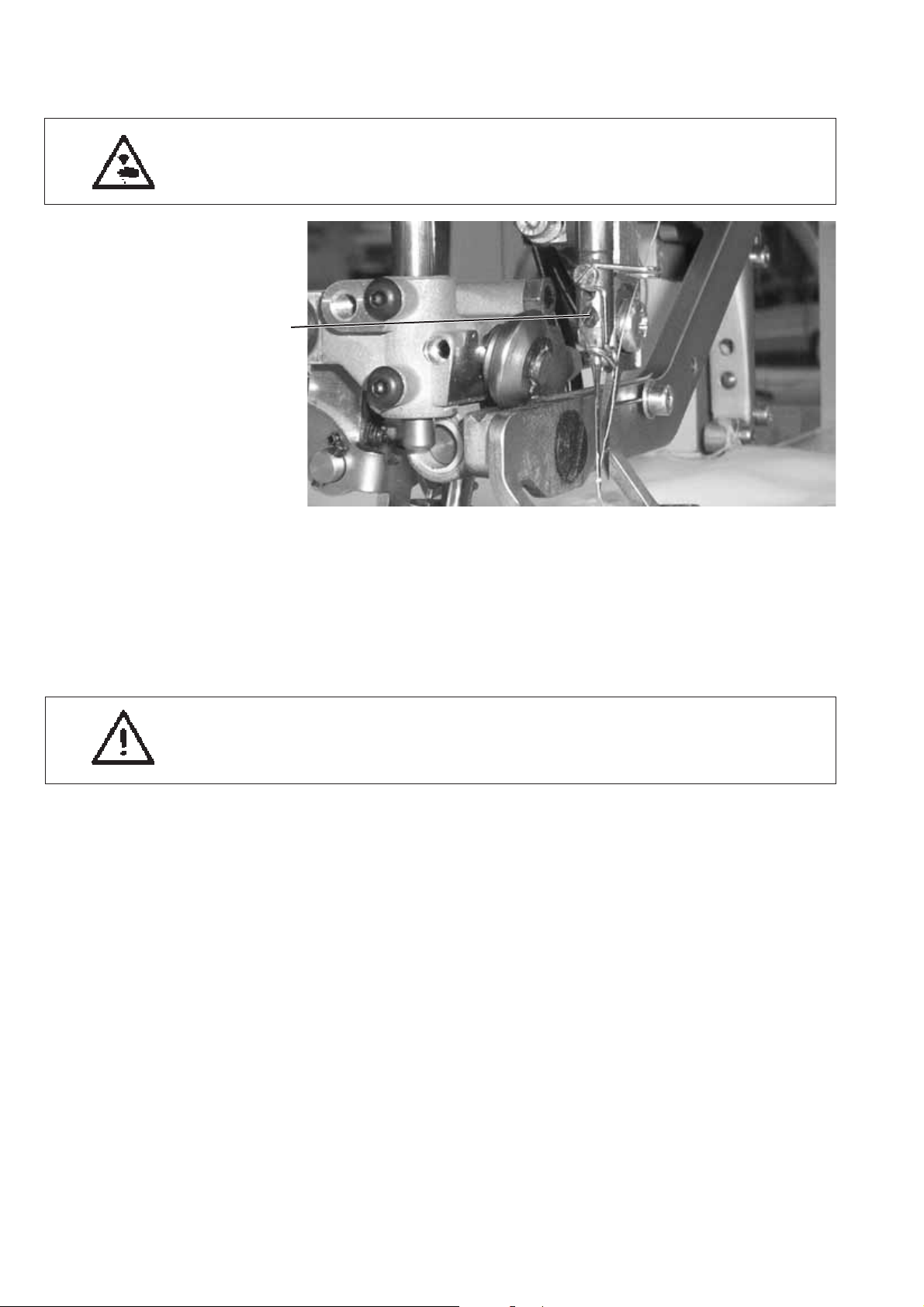

3.4 Changing the needle

Caution: Danger of injury !

Switch off at main power switch ! Only change the needle when the

sewing automat is switched off !

1

–

Loosen screw 1.

–

Pull needle form the needle bar.

–

Insert the new needle to the stop in the bore of the needle bar.

–

Set the needle so that the needle scarf lies on the backward facing

side of the knife.

–

Tighten screw 1.

CAUTION !

If the needle thickness is changed, the distance between the hook

and the needle may need to be changed.

10

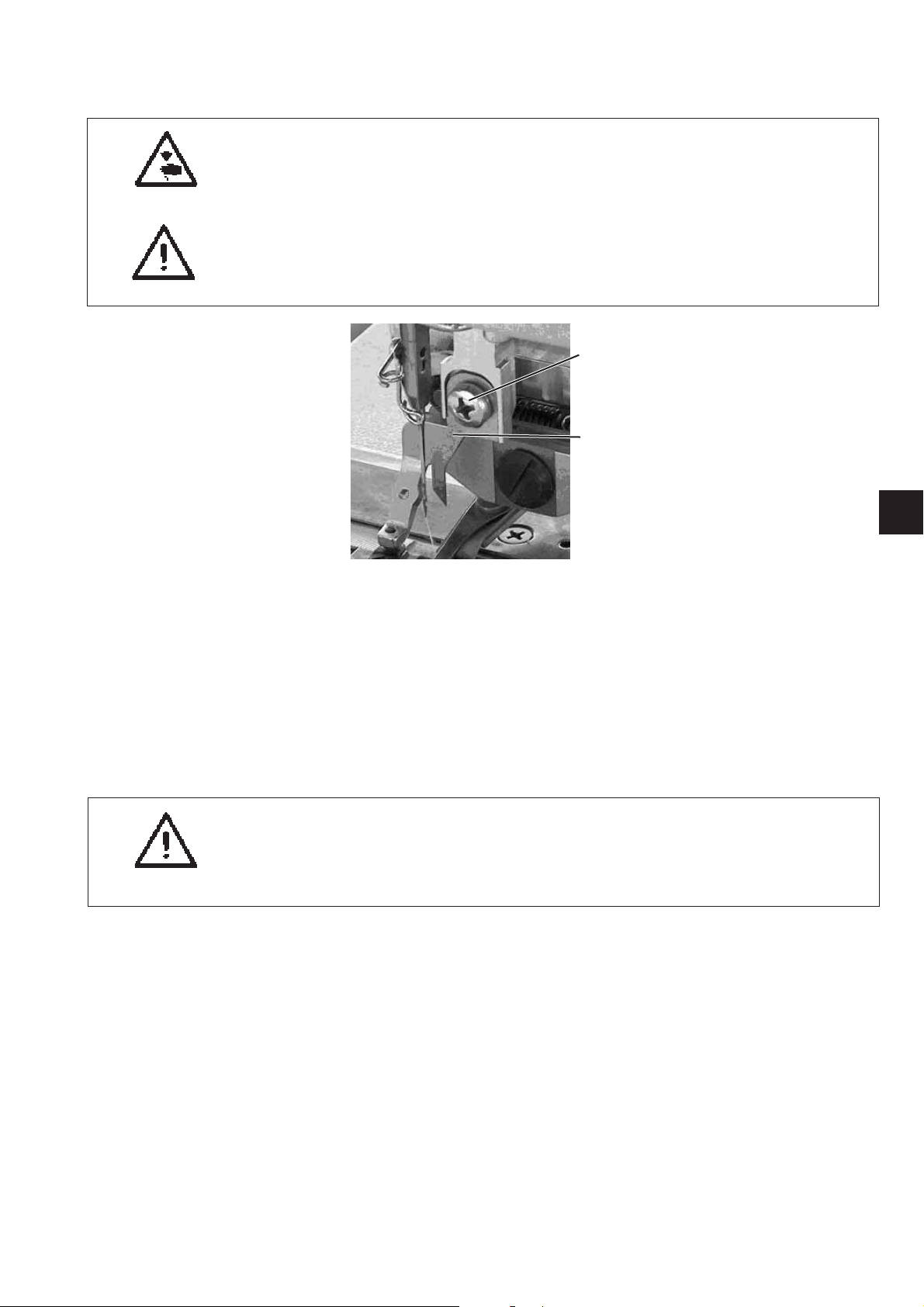

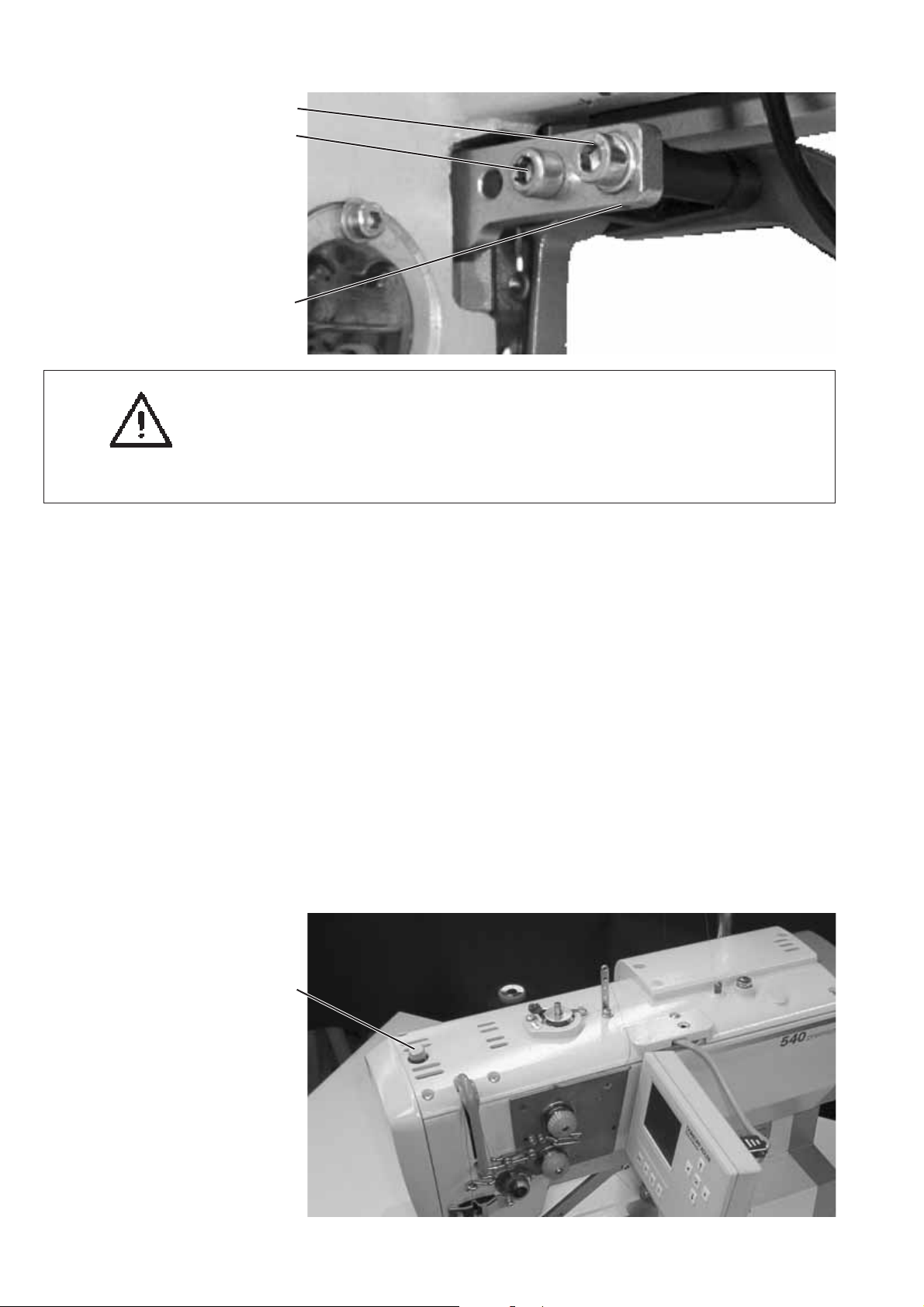

3.5 Changing the knife

Caution: Danger of injury !

Switch off at main power switch ! Only change the knife when the

sewing automat is switched off !

CAUTION !

Ensure that the lifted basket has a minimum distance of 1mm between

the upper thread scissors and the bottom knife edge.

2

3

1

Knife removal

–

Loosen screw 2.

–

Remove knife 3.

Knife insertion

–

Insert new knife and set it right at the top.

–

Tighten screw 1.

Note!

If the cut does not occur in the middle of the buttonhole or not parallel

to the buttonhole seam, the knife needs to be readjusted.

Instructions for service 540-100, Chapter: Knife adjustment.

11

3.6 Checking the knife height

Rule:

The knife point is needed only when diving into the material. The knife

point should not leave the throat plate during the cutting procedure.

CAUTION !

Ensure that the lifted basket has a minimum distance of 1mm

between the upper thread scissors and the bottom knife edge.

Note !

When a knife is sharpened, its length will be shorter.

With the insertion of the sharpened knife the knife height may

need to be corrected.

Adjusting:

–

Position the material under the clamp and start the sewing process.

–

Stop the sewing process during the cutting process on the reverse

buttonhole seam stitch by pushing the pedal backwards.

–

Make the slit on the throat plate visible by pulling the material a

little away from the clamp.

–

Turn the hand wheel in the direction of rotation until the knife has

reached its highest position to the throat plate.

–

In this position 0.2mm of the knife point should remain dipped in

the throat plate slit.

–

Knife height adjustment: Loosen screw 1.

Push the knife as far as needed until the c orrect knife position has

been reached.

Re-tighten screw 1.

–

Loosen screw 3.

–

Push stop 2 right up to the knife

–

Re-tighten screw 3.

–

End the sewing process by pushing the pedal backwards.

12

3

2

1

3.7 Thread tension

1

2

Thread tension 1

The tension s erves the purpose of sewing flat-form tacks and

buttonhole seams.

The tension is always effective and opens only with thread cutting.

1

Thread tension 2

The thread tension can be switched on and off. The complete tension

of thread tension 1 and thread tension 2 generate raised-form tacks

and buttonhole seams. The selection can be freely programmed for

each buttonhole section of a buttonhole.

The tension is only effective if programmed and opens during thread

cutting.

Check:

–

Thread the needle and hook thread with different colored yarn.

–

Make a trial seam.

–

For the flat parts of the buttonhole the cross-over point of the

thread should be in the middle of the material.

Setting: Change the thread tension 1

–

For the raised parts of the buttonhole the cross-over point of the

thread should be on the top side of the material.

Setting: Change the thread tension 2 until the seam pattern is

regular.

With the correct setting, in the flat buttonhole parts the upper thread

and in the raised buttonhole parts only the looper thread will be visible

on the material top side.

Increase tension Turn knurled nut clockwise.

Reduce tension Turn knurled nut anti-clockwise.

13

3.8 Regulating the sewing basket lifting height

1

2

3

CAUTION !

Ensure that,

–

a distance of at least 1mm lies between top thread cutter and the

knife bottom edge of the lifted basket

–

the knife point does not protrude out of the basket bottom.

Factory setting for the basket lifting height is 12mm. Adjust the basket

lifting height in the following way:

–

Switch of the machine.

–

Loosen screws 1 and 2.

–

Increase the basket lifting height: Turn set screw 3 clockwise.

Reduce basket lifting height: Turn set screw 3 anti-clockwise.

–

Tighten screws 1 and 2.

–

Switch on the machine and check settings.

3.9 Regulating the sewing basket pressure

–

The sewing basket pressure is adjusted using screw 4.

Increase pressure: Turn screw 4 clockwise.

Reduce pressure: Turn screw 4 anti-clockwise.

4

14

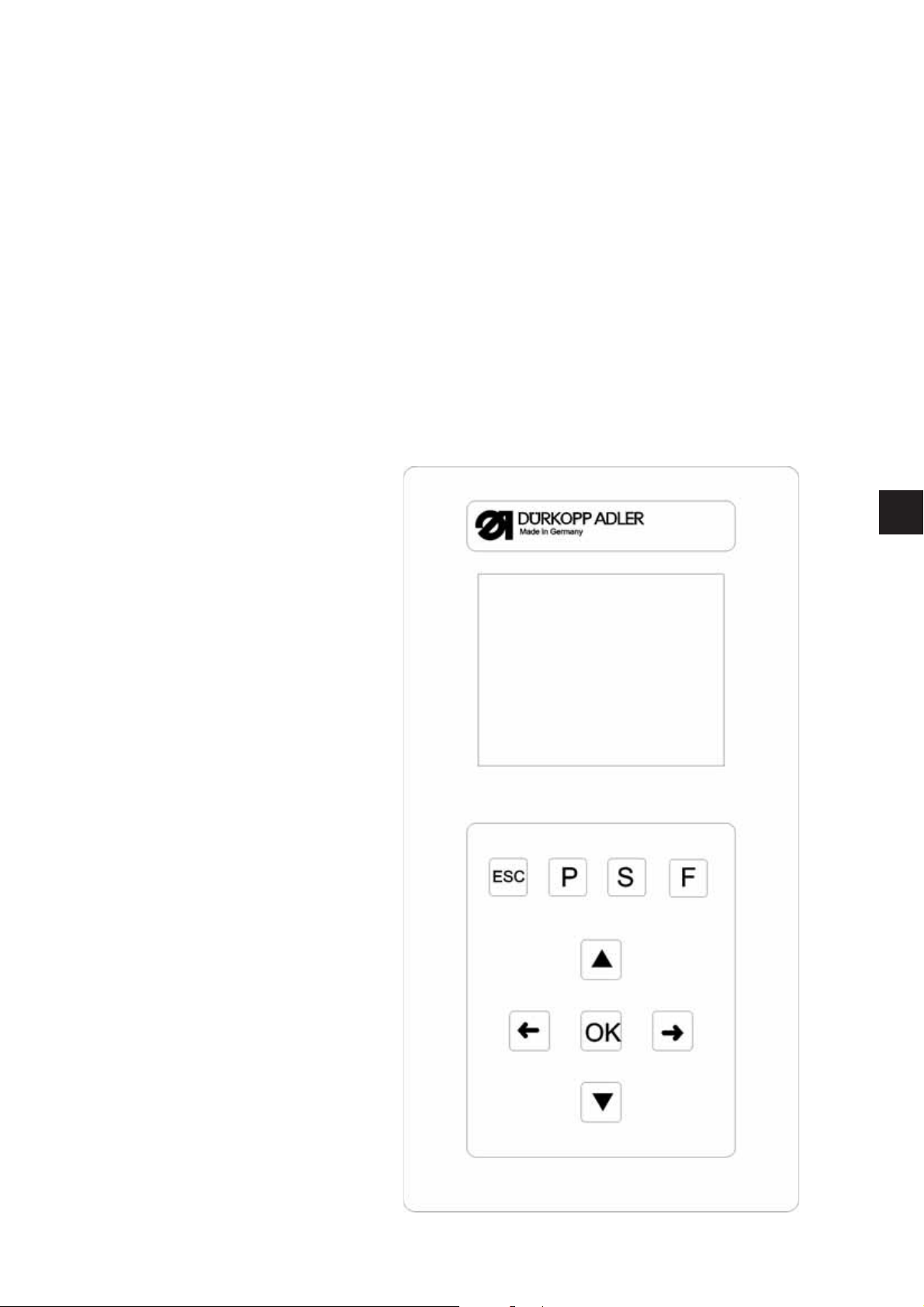

4. Control panel and control

In this operating manual only the functions of the keys and the

parameter changes that the operator can make are listed.

4.1 Control panel

Through the operating panel the control is programmed and the

functions for the respective seams are set. This occurs partly through

direct pressing of the corresponding key or through parameter

adjustment. The input of parameters occurs in programming mode “P”.

The parameter and the corresponding values are shown on the display.

In order to avoid inadvertent changes of parameters, the operation of

the control panel is sub-divided into several levels (operator,

technician, equipper)

The operator (seamstress) can directly access his/her level.

Access to other levels is only possible after the input of a code number.

1

15

4.1.1 Control panel elements

Key Function

When no input panel is activated:

–

–

When an input panel is activated:

–

–

When an input panel is activated:

–

–

When an input panel is activated:

–

Change to the higher level menu.

In the main menu, change between the buttonhole programs within

a sequence.

Change between the digits tenths, units and tens.

Change lines within the menu. The active line appears white on

black.

Increase or decrease the value of the corresponding digit by 1 or

with functions having several options change between the options,

e.g. “Buttonhole seam tension on” and “Buttonhole seam tension

off”.

Activate the input panel. The value can be changed by using “ñ”

and “ò”keys.

The set value will be accepted

–

Change from a submenu back to sewing mode.

–

Resolve a thread breakage – repair mode, the basket drives to the

end position, raises and releases the material

–

After stopping the sewing procedure the basket drives to the end

position, raises and releases the material

When an input panel is activated:

–

An input is discontinued. The previous value remains valid.

–

The control changes from sewing mode to programming mode. The

buttonhole parameters can be changed in this mode.

–

The control changes from either the sewing mode or programming

mode to the sequence programming mode.

–

The control changes from the sewing mode to the technician mode.

This mode can only be activated by entering a code. In this

operating condition basic machine parameters can be set,

diagnosis and calibration programs can be started

16

4.2 Changing parameter values

4.2.1 Numerical values

Numerical values can be altered in the following w ays:

–

–

–

–

–

–

4.2.1 Parameter selection

With the arrow keys ñ and ò choose the line in which the value

needs to be changed.

Press the OK key.

The curser blinks under the position of the value to be changed.

With the arrow keys ï and ð change between the values.

With the arrow keys ñ and ò increase or decrease the chosen

value.

With parameters that can not be arbitrarily changed, by pressing of

the arrow keys ñ and ò another possible parameter is shown on

the display.

Press the OK key.

The set value will be accepted.

If the set value is not to be accepted, press the ESC-key.

The original value or setting will be reestablished.

With some parameters several choices are available.

The parameter can be changed in the following way:

–

With the arrow keys ñ and ò choose the line with the parameter to

is be changed.

–

Press the OK key.

–

With the arrow keys ñ and ò change between the possibilities. The

respective parameter is shown.

–

Press the OK key. The set value or parameter will be accepted.

–

If the set value or parameter is not to be accepted, press the

ESC-key.

The original value or parameter setting will be reestablished.

1

17

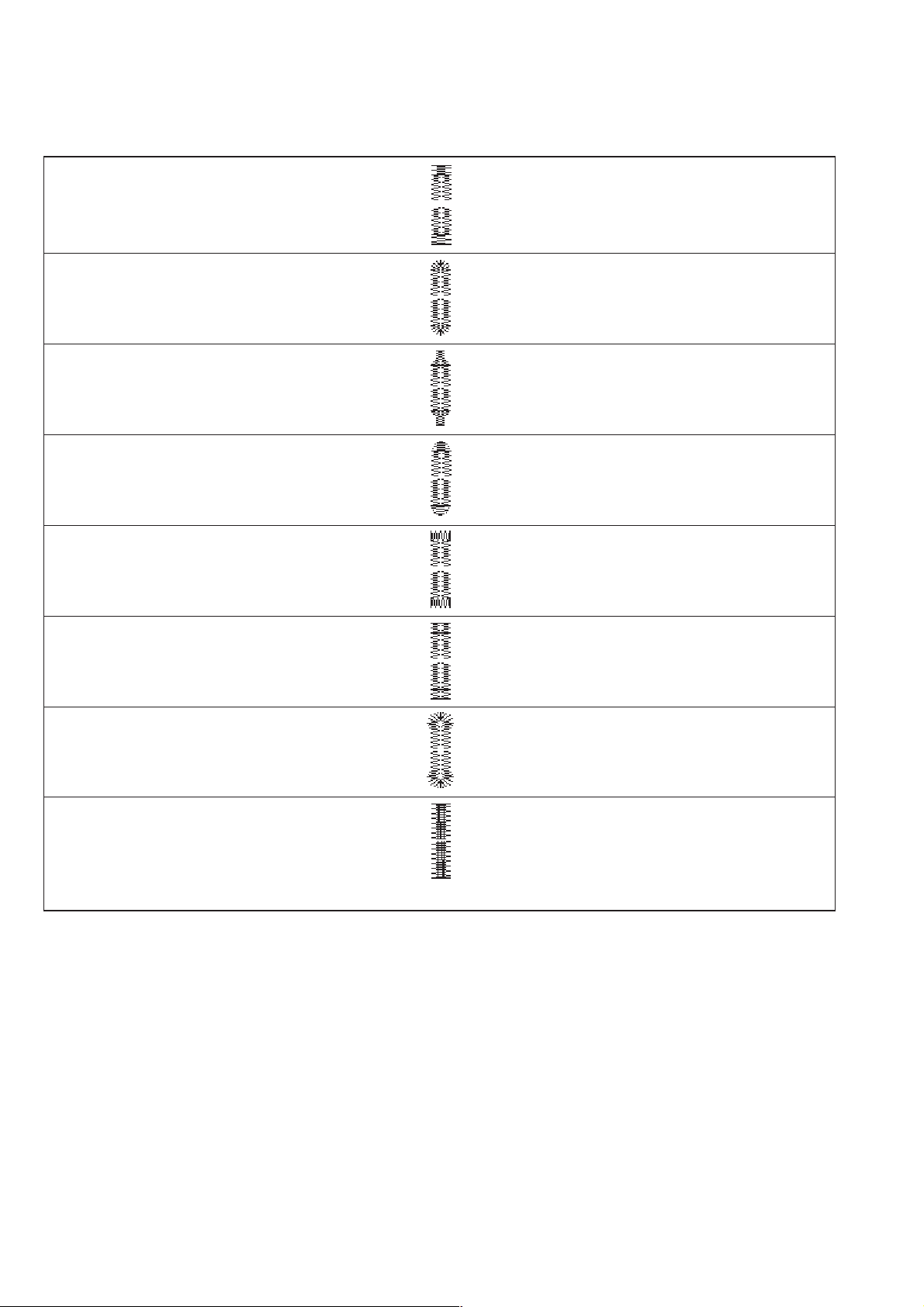

4.3 Main menu

Symbol Parameter Meaning

Buttonhole number

N1

Thread tension

N2

Cut length

N3

Speed

N4

Selection of the buttonhole to be sewn

- Program number 1 to 50 contains

buttonhole programs. Program number 51

and 52 contain free contour sewing

programs.

- The preprogrammed form of the chosen

buttonhole is shown in the left half of the

display.

- Additionally an info window is shown with

some buttonhole specific values:

- Cut length

- Intermediate fabric

- Buttonhole seam stitch length

- Buttonhole width

Selection of the submenu for changing the

thread tension values. Only visible when

the electric thread tension control is

activated

- Selection of buttonhole cut length

from 6 – 65mm

- The setting is dependent of the buttonhole

number.

- Selection of sewing speed for the buttonhole

to be sewn from von 200 - 4000 RPM.

The setting is dependent of the buttonhole

number.

- If the set sewing speed is less than the soft

start speed a cautionary warning is

displayed and the soft start is switched off.

- The high speed that is here selectable can

be set in the technician level.

Soft start

N5

Daily quantity c ounter

N6

Hook thread counter

N7

Repair mode

N8

Soft start switch on and off

- Number of soft start stitches and their

sewing speed can be preset in the

technician level.

The daily quantity counter counts the number

of sewn buttonholes.

- By pressing the “OK”- key twice, the daily

quantity counter will be reset to zero.

Display of the current hook thread counter

state (when active) and selection of the

submenu for the changing of the initial value

and for the switching on and off of the hook

thread counter.

Repair mode.

18

4.4 Hook thread monitoring

Hook thread monitoring mode of operation:

Hook thread monitoring is carried out by counting the buttonholes.

With the insertion of a full bobbin the hook thread counter is set to a

predetermined value. This value is subtracted by one with each

complete cycle. When the value 0 is reached the operator receives an

information message.

There should be some remaining thread on the bobbin.

Note

This principle only functions when the same amount of bobbin

thread is used per buttonhole or sequence. Changing frequently the

cut length, buttonhole form or buttonhole parameter changes the

amount of bobbin thread used per buttonhole.

4.4.1 Hook thread counter adjustment

Select the submenu “Hook thread counter”

–

–

With the ñ and ò keys choose in the main menu the line “Hook

thread counter”.

Press OK-key.

The submenu “Hook thread counter“ is displayed.

1

Submenu “Hook thread counter” displayed parameters:

Current hook thread counter value

N7.1

Sets the display in the main menu to the initial value indicated in N7.2

below.

–

With the ñ and ò keys select the relevant line.

–

By pressing the OK-key the indicated value in the main menu will

be set to the initial value.

–

The display changes automatically back to the main menu.

Initial value

N7.2

Total number of possible buttonholes with the remaining thread on the

bobbin.

–

Select the relevant line with the ñ and ò keys.

–

Press the OK-key.

The curser blinks under the position of a numerical value.

–

Move between the digits with the keys ï and ð.

–

Increase or decrease the digit value with the keys ñ and ò.

–

Confirm with the OK-key.

–

Choose line N7.1 with the arrow keys ñ and ò

–

By pressing the OK-key the indicated value in the main menu will

be set to the initial value.

–

The display changes automatically back to the main menu.

19

4.5 Soft start on /off

Hook thread counter on and off

N7.3

The function of the hook thread counter is either switched on or off.

–

Select the relevant line with the ñ and ò keys.

–

Press the OK-key.

–

Select the parameter On or Off by using the the arrow keys ñ and ò.

The main menu will indicate no parameter with the hook thread

counter switched off.

–

Select the “Soft start” in the main menu with the arrow keys ñ and ò.

–

Press the OK-key.

–

Select the parameter On or Off by using the the arrow keys ñ and ò.

–

Press the OK-key.

Note !

The number and sewing speed of the soft start stitch can be

preset in the technician level.

If a main sewing speed is less than the soft start sewing speed,

the soft start will be automatically switched off.

4.6 Sequences

4.6.1 General

Single buttonhole mode

One buttonhole can be selected from a total of 50 preprogrammed

buttonhole programs. Memory locations 51 and 52 can be used for free

sewing contours.

This buttonhole will be sewn until another buttonhole is s elected.

Sequence mode

The seamstress will be in a position to sew a sequence of different

buttonholes without having to push a key on the control panel.

20 different sequences can be created and saved in the memory.

·

Each sequence can contain up to 20 buttonholes.

·

In principle all buttonholes can be selected in one sequence.

·

Note

A plausibility check of the individual buttonhole parameters is first

made when the sequence is selected in the sewing mode!

20

4.6.2 Switching the sequence mode on / off

Switching t he sequence mode on or off

–

Press the S-key.

The control panel changes to the menu for the programming of

buttonholes sequences.

–

With the arrow keys ñ and ò select the relevant line

–

Press the OK-key.

–

With the arrow keys ñ and ò choose between on(sequence mode)

or off (single buttonhole mode)

–

Confirm by pressing the OK-key.

–

To return to the main menu press the ESC-key.

4.6.3 Select a sequence in the sequence mode (Main menu)

After switching on, the top line of the display will appear white on

black. The last used sewing sequence will be displayed.

Select another sequence

–

Press the OK-key.

–

Moving between the sequences can be achieved by using the

arrow keys ñ and ò.

–

Confirm by pressing the OK-key.

1

4.6.4 Automatic or manual mode

02 ð 05 ð 12 ð 09 Automatic operation

In the sequence that is shown on the display, arrows will be displayed

between the buttonhole forms.

–

After sewing a buttonhole, the control will change automatically to

the next buttonhole form.

–

After sewing the last buttonhole, the control will change again to

the first buttonhole within the sequence.

–

The current buttonhole will be indicated with a bar.

–

The form of each chosen buttonhole will be shown in the left half of

the display.

02–05–12–09 Manualoperation

In the sequence that is shown on the display, no arrows will be

displayed between the buttonhole forms.

–

The control does not change automatically between the buttonhole

forms.

–

The current buttonhole will be indicated with a bar.

–

The form of each chosen buttonhole will be shown in the left half of

the display.

Change between automatic and manual operation

–

Choose the relevant line in which the current sequence is

displayed using the arrow keys ñ and ò

–

Press the OK-key.

–

Change between the two operational modes using the arrow keys

ñ and ò.

–

Confirm by pressing the OK-key.

21

Select another buttonhole to be sew n within the sequence

Selection between the different programmed buttonholes is always

possible when the sewing menu is displayed

–

The next or previous buttonhole is selected within the displayed

sequence.

4.7 Programming of sequences

Up to 20 buttonhole sequences can be programmed.

Each sequence can contain up to 20 buttonholes.

4.7.1 Programming a single sequence

Select program menu sequence

–

–

Press the arrow keys ï or ð.

Press the key “S” on the control panel.

The control panel changes to the buttonhole programming

sequence menu.

Press the ESC-key to leave this menu.

Selection of the sequence number

–

Select the line for choosing the sequence number with the arrow

keys ñ and ò.

–

Press the OK-key.

–

Select the sequence number to be programmed with the keys ñ

and ò.

–

Press the OK-key to confirm.

Default example: Buttonhole 1: 1

Buttonhole 2: 0

Programming example: Buttonhole 1: 19

Buttonhole 2: 2

Buttonhole 3: 0

Buttonhole sequence programming

–

Select line “Buttonhole 1:” with the arrow keys ñ and ò

–

Press the OK-key.

–

Select the desired buttonhole program

(1 to 50) with the arrow keys ñ and ò.

–

Press the OK-key to confirm the selection.

With the confirmation of the buttonhole program a new menu line

appears containing the buttonhole to be programmed next

–

The last line of a buttonhole sequence program always shows the

buttonhole number “Buttonhole X: 0", unless all 20 programs are

occupied.

–

Press the ESC-key to return to the main menu.

22

4.7.2 Adding a buttonhole at the end of a sequence

–

Select the last line “Buttonhole X: 0" in the programmed buttonhole

sequence with the arrow keys ñ and ò.

–

Press the OK-key.

–

Select the desired buttonhole program (1 to 50) with the arrow

keys ñ and ò.

–

Press the OK-key to confirm the selection.

With the confirmation of the buttonhole program a new menu line

appears containing the buttonhole to be programmed.

–

Press the ESC-key to return to main menu.

4.7.3 Deleting a buttonhole within the buttonhole sequence

–

Select the buttonhole program line that is to be deleted with the

arrow keys ñ and ò.

–

Press the OK-key.

–

Select buttonhole program “0" with the arrow keys ñ and ò

–

Press the OK-key to confirm.

With the confirmation the selected buttonhole will be deleted. Following

buttonholes (if any) will move up.

–

Press the ESC-key to return to the main menu.

1

4.7.4 Inserting a buttonhole within the buttonhole sequence

Note

The insertion of a single buttonhole program within a buttonhole

sequence is not possible.

–

Make a note of the programmed buttonholes following.

–

Select the desired line of the programmed buttonhole sequence

with the arrow keys ñ and ò.

–

Press the OK-key.

–

Select the desired buttonhole program (1 to 50) with the arrow

keys ñ and ò.PresstheOK-key to confirm the setting.

–

Then alter the following buttonholes according to your notes.

–

Press the ESC-key to return to main menu.

23

5. Buttonhole programming

5.1 Composition of a buttonhole

Buttonhole width = Bartack width

Bartack length

Length in front of the cut

Cut length

Length behind the cut

First Bartack

m

a

e

s

e

l

o

h

n

o

t

t

u

b

g

n

i

d

a

e

L

Final Bartack

Cut

Trailing buttonhole seam

24

Buttonhole seam width L

Intermediale material width

Buttonhole seam width R

Stitch distance

Throw width

First bartack First bartack to be sewn in connection to the

leading buttonhole seam

Final bartack

Leading buttonhole

seam

Trailing buttonhole

seam

Buttonhole width

Cut length

Cut length

Intermediate material

width

Throw width

Final bartack in connection to the trailing

buttonhole seam

Buttonhole seam from sewing start to the first

bartack

Buttonhole seam between first bartack and

final bartack

Distance between the outer stitches of a

buttonhole

Length of the knife’s cutting edge in mm

Length of the buttonhole to be cut in mm

(=Buttonhole seam length)

1

Distance between the inner stitches of the

leading buttonhole seam and the trailing

buttonhole seam

= Buttonhole seam width

Characteristics

Stitch distance

Length in front of the

cut

Length behind the cut

Leading and trailing

buttonhole seam

Buttonhole width

=Bartackwidth

Bartack

Buttonhole length

Distance between double stitches in the y-axis

Distance between the first bartack and the cut

Distance between the final bartack and the cut

Leading buttonhole seam is symmetrical to the

trailing buttonhole seam with the cut length as

symmetrical axis.

The setting “buttonhole width” automatically

gives the bartack width. The bartack width can

be altered with the corresponding parameters

“offset l” and “offset r” in the bartack menu.

The final bartack length is the same as the first

bartack length if both bartacks are identical.

The bartack length for both is set in the menu

“First bartack”.

The complete buttonhole length is determined

by the cut length + length in front of the cut +

length behind the cut + first bartack length +

final bartack length.

25

5.2 Submenu program (general view)

Intermediate material width: Input

Stitch distance buttonhole seam: Input

Buttonhole width: Input

Buttonhole seam tension: Selection

Cutting: Selection

Length in front of the cut: Input

Length behind the cut: Input

Cut correction x: Input

Correction right side: Input

First bartack type: Selection

Bartack stitch distance: Input

Buttonhole number: Selection Bartack length: Input

Cut length: Input Width offset right side: Input

Speed: Input Width offset left side: Input

Buttonhole seam parameters Number of bartack stitches: Input

Starting variants: Selection Bartack tension: Selection

First bartack parameters

P

Final bartack parameters

2x seams: Selection

Knitwear: Selection Final bartack: Selection

Basting stitches Bartack stitch distance: Input

Zigzag seams Bartack length: Input

Cutting: Selection Width offset right side: Input

Copying: Input Width offset left side: Input

Number of bartack stitches: Input

Bartack tension: Selection

26

Number of seams: Selection

Stitch length: Input

Thread tension: Input

Number of seams: Selection

Stitch length: Input

Buttonhole width: Input

Speed: Input

Thread tension leading seam: Input

Thread tension trailing seam: Input

5.3 Parameter programming mode

Buttonhole number

P1 1 … 50

Cut length

P2 6.0 … 65.0 mm

Speed

P3 200 … 4000 RPM

Buttonhole seam

paramet er

P4

Starting variants

P5 A,B,C,D

Upper bartack

paramet er

P6

Lower bartack

paramet er

P7

2x seams

P8 ON / OFF

Selection of the buttonhole number

Dependent on buttonhole

Select the submenu for the selection of

buttonhole seam parameters

Selection of the sewing start variants

Select the submenu to adjust the upper

bartack

Select the submenu to adjust the lower

bartack

1

Switching on/off of the double-stitching of the

whole buttonhole (the buttonhole is sewn

twice).

Knitwear sewing

mode

P9

Basting stitches

P10*

Zigzag seams

P11*

Cutting

P12*

úú

Copying from

P13

*) Those programs are only visible, if the P9 (Knitwear sewing mode) is switched on.

ú

M

ê

M

ON / OFF

0…50

Switching the knitwear sewing mode on or off

Selection of the submenu for the setting of the

number of the basting stitches and the display

of the characteristics

Selection of the submenu for the setting of a

second zigzag seam and the display of the

characteristics

Cutting during the last cycle

Cutting during the cycle before the last one

Cutting during both cycles

The buttonhole data of the chosen buttonhole

number is copied into the currently active

buttonhole.

27

5.4 Adjusting the cut length

Correcting the buttonhole length (Cut length). The adjustment is

possible in both, the main menu and programming mode.

–

–

–

–

–

5.5 Selecting a starting variant

Select a starting variant

The starting variant of the starting stitch serves to ensure the correct

sewing start for different materials and threads. The starting variant is

individually set for each individual buttonhole.

Starting variant A (Standard)

–

Select the line “cut length” in the main menu with the arrow keys ñ

and ò

Press the OK-key.

The curser blinks under a digit value.

Change between the digits with the arrow keys ï and ð.

Increase or decrease the value of the selected digit with the arrow

keys ñ and ò.

Press the OK-key to confirm the value.

The starting stitches are flat form s titches.

Starting variant B (Thin material, lining)

–

The starting stitches are flat form stitches. With the use of a cross

stitch the upper thread holds better to the material.

Starting variant C (very thin material)

–

The starting stitches are flat form s titches.

With the use of forward and backward bartack stitches the upper

thread holds better to the material.

Starting variant D (very thin material)

–

Alternative to starting variant C.

Select starting variant:

–

Press P-key.

–

Select the line “Starting variant” with the arrow keys ñ and ò.

–

Press the OK-key.

–

Select the relevant Starting variant A, B, C or D with the arrow

keys ñ and ò

–

Press the OK-key

–

Press the ESC-key.

28

5.6 Setting buttonhole seam

In the program menu “Buttonhole seam”

Select program menu Buttonhole seam

–

Press the P-key.

–

Select the line “Buttonhole seam” with the arrow keys ñ and ò.

–

Press the OK-key.

–

Select the relevant line with the arrow keys ñ and ò.

–

Press the OK-key. The curser blinks under one of the digit values.

–

Change between the digits with the arrow keysï and ð.

–

Increase or decrease the value of the chosen digit with the arrow

keys ñ and ò.

–

Press the OK-key to confirm. Press the ESC-key.

The following parameters can be changed for the buttonhole seam section:

Intermediate material

width P4.1

Stitch distance within

the buttonhole seam

P4.2

Buttonhole width

P4.3

Buttonhole seam

tension P4.4

Cutting

P4.5

Length in front of the

cut P4.6

Length behind the cut

P4.7

- 1,0...+1,0 mm

0,3...1,5 mm

1,6...6,0 mm

on;off

on;off

-P6.3...5,9 mm

(1.8 mm - P7.3)5,9 mm

Distance between the inner stitches of the

buttonhole seam.

Distance in the y-axis of a double stitch.

1

Overall width of a buttonhole (outer stitches).

on: additional thread tension on (raised-form)

off: additional thread tension off (flat-form)

on: cutting during the sewing cycle

off: no cutting

1. Correction of the position of the first tack in

relation to the end of the cut

2. Additional buttonhole length in front of the

cut with asymmetrical cutting within the

buttonhole.

1. Correction of the position of the first tack in

relation to the end of the cut

2. Additional buttonhole seam length behind

the cut with asymmetrical cutting within the

buttonhole.

Cut correction x

P4.8

Correction right side

P4.9

-0,5...+0,5 mm

Position of the cut within the buttonhole on the

x-axis.

Correction of the rightsided buttonhole seam

width, only visible with bartack type A (Cross

bartack).

29

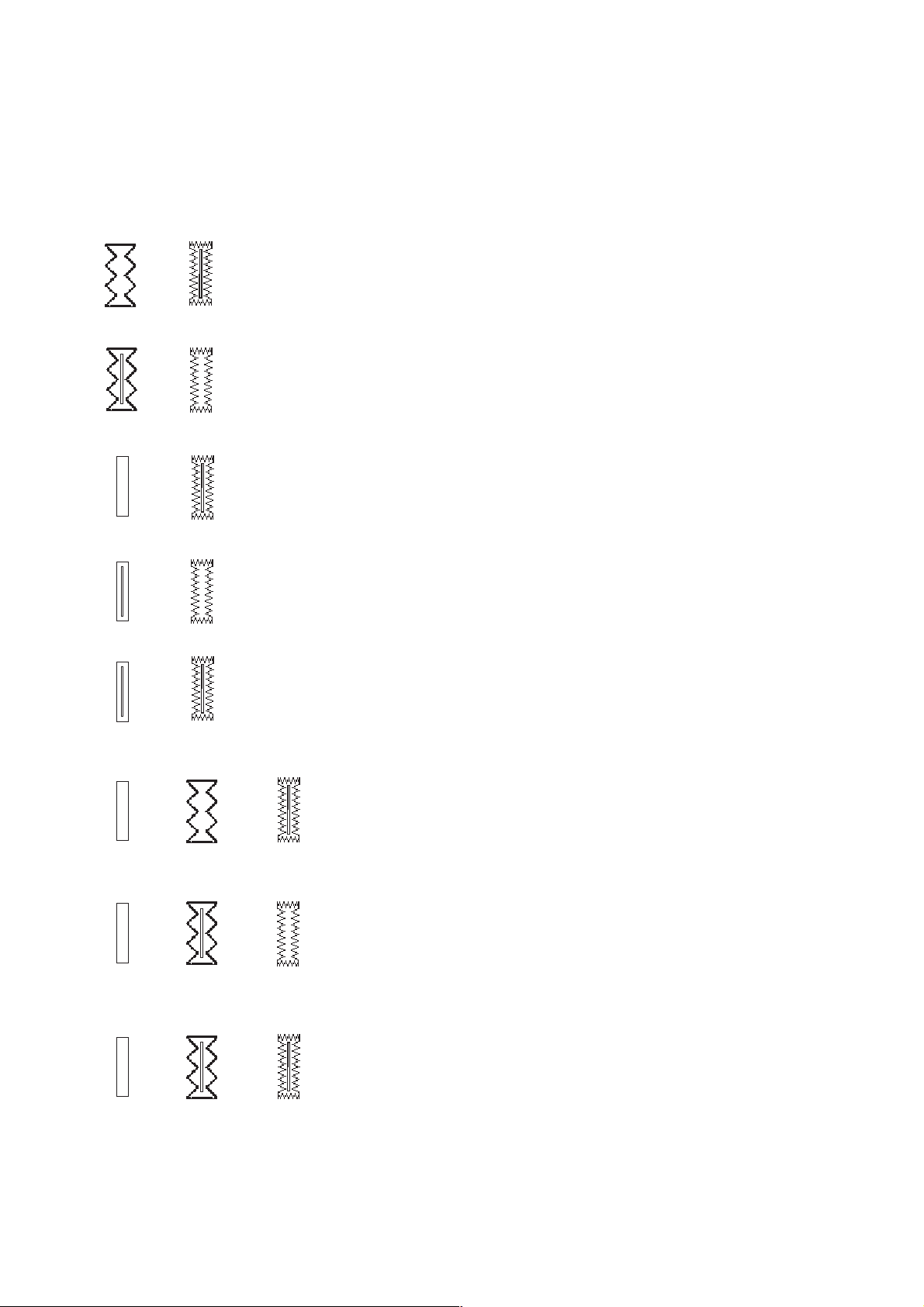

5.7 Setting bartack

5.7.1 Selectable bartack types

A Cross tack (horizontal) top

bottom

B Round tack

(to the middle point)

C Taper tack top

D Round tack (horizontal) top

E Cross tack (vertical) top

F Cross tack (divided) top

top

bottom

bottom

bottom

bottom

bottom

GEyetack top

bottom

H Simple tack (bartack) top

bottom

The upper and lower tacks of the tack types A to G can be freely

combined e.g. G eye tack as the top tack and C taper tack as the lower

tack.

The tack type H simple tack (bar tack) cannot be combined.

always together

30

5.7.2 Programming menu “Bartack”

Select programming menu “Bartack”

–

–

–

–

–

–

–

–

–

–

According to the selected bartack type the following parameters can be

changed for the bartack section.

Press the P-key.

Select line “upper tack”or“lower tack” with the arrow

keys ñ and ò.

Press the OK-key.

Select the desired parameter with the arrow keys ñ and ò.

Press the OK-key.

The curser blinks under a digit of the value.

Change between digits with the arrow keys ï and ð.

Increase or decrease the selected value with the arrow

keys ñ and ò.

Press the OK-key to confirm.

Press the ESC-key.

1

31

P6.1/ P7.1 A cross tack(horizontal) , F Cross tack (divided)

Tack stitch distance

0.2 ... 1.0 mm

P6.2/P7.2

Tack length

0.6 ... 6.0 mm

P6.3/P7.3

Tac k w id t h

-1.0 … 1.0 mm The width of the tack is defined through the

Right offset

P6.4/P7.4

Tac k w id t h

-1.0 … 1.0 mm The width of the tack is defined through the

Left offset

P6.5/P7.5

Tack tension

on / off

P6.7/P7.7

P6.1/ P7.1 B Round tack (to the middle point)

Tack stitch number

2…50

P6.6/P7.6

Distance in the y-axis of a double stitch.

Length of the tack in the y-axis. The input of

parameter P7.3 is only possible when the top

and bottom tack types are not similar!

buttonhole width. With the use of the right

offset the width of the tack to the right can be

increased.

buttonhole width. With the use of the left offset

thewidthofthetacktotheleftcanbe

increased.

on: raised form tack

off: flat form tack

Number of stitches, that form the semicircular

tack.

Tacking tension

on / off

P6.7/P7.7

P6.1/ P7.1 C Taper tack

Tack stitch distance

0.2 … 1.0 mm

P6.2/P7.2

Tack length

0.6 … 9.0 mm

P6.3/P7.3

Tack tension

on / off

P6.7/P7.7

P6.1/ P7.1 D Round tack (horizontal)

Tack stitch distance

0.3 … 1.0 mm

P6.6/P7.6

on: raised form tack

off: flat form tack

Distance in the y-axis of a double stitch

Length of the tack in the y-axis

on: raised form tack

off: flat form tack

Distance in the y-axis of a double stitch

Tack tension

P6.7/P7.7

32

on / off

on: raised form tack

off: flat form tack

P6.1/ P7.1 E Cross tack (vertical)

Tack stitch distance

P6.2/P7.2

Tack length

P6.3/P7.3

Tac k w id t h

Right offset

P6.4/P7.4

Tac k w id t h

Left offset

P6.5/P7.5

Moving tack at

the top

P6.6/P7.6

Moving tack at the

bottom

P6.6/P7.6

Tack tension

P6.7/P7.7

0.2 ... 1.0 mm

0.6 ... 6.0 mm

-1.0 … 1.0 mm The width of the tack is defined through the

-1.0 … 1.0 mm The width of the tack is defined through the

-1.0 … 0 mm

0…1.0mm

on / off

Distance in the y-axis of a double stitch

Length of the tack in the y-axis. The input of

parameter P7.3 is only possible when the top

and bottom tack types at are not similar!

buttonhole width. With the use of right offset

the width of the tack to the right can be

increased.

buttonhole width. With the use of left offset the

width of the tack to the left can be increased.

The position of the tack can be pushed down.

The position of the tack can be pushed up.

on: raised form tack

off: flat form tack

1

P6.1/ P7.1 G Eye tack

Tac k w id t h

P6.5/P7.5

Tack stitch number

P6.3/P7.3

Tack tension

P6.7/P7.7

P6.1/ P7.1 H Simple tack (bartack), seam parameters.

Stitch distance within

the buttonhole seam

P4.2

Buttonhole width

P4.3

Buttonhole seam

tension

P4.4

Stitch length of

tacking stitches

P4.6

Thread tension of

tacking stitches P 4.7

2.0 … 6.0 mm

2…50

on / off

0.2 … 1.0 mm

1.0 … 6.0 mm

on / off

0.2 … 3.0 mm

on / off

External diameter of the eye

Number of outer stitches, that will form the

semicircular tack.

on: raised form tack

off: flat form tack

The parameter of the special tack types H

simple tack are changed with the buttonhole

Distance in the y-axis of a double stitch

Total width of the buttonhole

on: raised form

off: flat form

Stitch distance of tacking stitches

Tacking stitch seam resistance

33

6. Knitwear mode

st

1

cycle 2ndcycle

st

cycle 2ndcycle

1

st

cycle 2ndcycle

1

Use the knitwear mode when stretchable material is to be sewn. In the

knitwear mode buttonholes are seamed several times in order to

ensure a higher stability.

It is possible to combine a straight basting stitch with a following single

or double zigzag. It is also possible to choose whether cutting should

take place during the last seam sewing or the one before.

The following modes are available:

–

Combination “1”

Double zigzag

Cutting during the last cycle.

–

Combination “2”

Double zigzag

Cutting during the cycle before the last one.

–

Combination “3”

Basting stitches on

Cutting during the last cycle.

–

Combination “4”

st

1

cycle 2ndcycle

st

1

cycle 2ndcycle

st

1

cycle 2ndcycle 3rdcycle

st

1

cycle 2ndcycle 3rdcycle

Basting stitches on

Cutting during the cycle before the last one.

–

Combination “5”

Basting stitches on

Cutting during the last cycle and the one before.

–

Combination “6”

Basting stitches on

Double zigzag

Cutting during the last cycle.

–

Combination “7”

Basting stiches on

Double zigzag

Cutting during the cycle before the last one.

34

st

cycle 2ndcycle 3rdcycle

1

–

Combination “8”

Basting stiches on

Double zigzag

Cutting during the last cycle and the one before.

6.1 Selecting or switching off knitwear mode

Select knitw ear mode

–

Press the P-key.

–

Select the parameter “Knitw ear” with the arrow k eys ñ and ò.

–

Press the OK-key.

–

Select the setting “on” with the arrow keys ñ and ò.

–

Press the OK-key to confirm the selection.

While the knitwear mode is activated the following menu points are visible:

P9: Basting stitches

·

P10: Zigzag seams

·

P11: Early cutting (cutting during the cycle before the last one)

·

[Only visible when the seam cycles basting stitch + zigzag >1]

Switching t he knitw ear mode off

–

Press the P-key.

–

Select parameter “knitw ear” with the arrow k eys ñ and ò.

–

Press the OK-key.

–

Select with the arrow keys ñ and ò setting “off”.

–

Press the OK-key.

The knitwear mode is switched off.

1

35

6.2 Submenu basting stitches

Seam cycles

P9.1 0 / 1

Stitch length

P 9.2 0.3 … 3.0 mm

Number of the basting stitch seam cycles

Stitch length of the basting stiches

Thread tension

P 9.3 0...100%

6.3 Submenu Zigzag

Seam cycles

P10.1 1 / 2

Stitch length

P 10.2 0.3 … 3.0 mm

Buttonhole width

P10.3 1.0...P4.3

Speed

P10.4 200 … 4000 RPM

Value of the tread tension for basting stitches.

This parameter can only be selected when

electric thread tension control is available.

Number of the zigzag seam cycles

Stitchlänge of the first zigzag. Only visible

when the number of zigzag seam cycles = 2

The buttonhole width for the first zigzag <_max.

buttonhole width P4.3.

Only visible w hen the number of zigzag seam

cycles = 2

The sewing speed of the first zigzag.

Thread tension

P 10.5 0...100%

Thread tension

P 10.6 0...100%

Thread tension for the leading buttonhole seam

of the first zigzag. Only visible w hen the

number of zigzag seam cycles = 2

This parameter can only be selected when

electric thread tension control is available.

Thread tension for the trailing buttonhole seam

of the first zigzag. Only visible w hen the

number of zigzag seam cycles = 2

This parameter can only be selected when

electric thread tension control is available

36

7. Sewing procedure

7.1 Normal sewing procedure

0

1

2

0

R

Switching on of the automat

–

Check on the maintenance unit that an air pressure of 6 bar is

present.

–

Switch on the main switch of the automat.

–

The machine software will be loaded.

–

The needle goes to the reference position.

–

The sewing basket goes to the reference position and raises.

–

The automat is ready to sew.

Sewing

–

Position material to be sewn under the raised sewing basket.

–

Press the foot pedal forward to position 1. The sewing basket

descends. Releasing the pedal causes the sewing basket to raise

again.

–

Push the pedal forward to position 2. The sewing procedure will begin.

–

After the sewing procedure the automat goes to the reference

position and the sewing basket is lifted.

–

The sewn material can be removed.

1

7.2 Interruption of sewing procedure

7.2.1 Interruption by the operator

Interruption by the operator

–

Push the pedal backwards.

The machine stops and the needle is driven up high, the sewing basket

stays down.

When the material has to be removed:

–

Push the pedal backwards again, the automat goes to the

reference position and the sewing basket is lifted.

When the sewing procedure is to be started again

–

Push pedal forwards to position 2.

–

If during the interruption the handwheel has been turned, a

continuation is no more

7.2.2 Clearing thread breakage

Thread monitoring

A thread breakage in the upper thread is detected by an electronic

upper thread monitor.

possible.

Thread breakage

–

The automat stops after a thread breakage has been detected by

the upper thread monitor. The knife is switched off, the needle is

driven up high, the sewing basket stays down and goes with the

material to the basket reference position.

The message thread breakage is displayed.

–

The automat now has to be turned off.

37

–

Hook and needle thread can now be threaded or checked.

–

Further measures according to the thread breakage modes

Method A, B or C preset in the technician level (see thread

breakage mode).

–

By pressing the ESC-key the thread breakage mode can be ended.

The automat references, the sewing basket is lifted and the

material is released.

Thread breakage mode

There are three possibilities to clear a thread breakage. The respective

method has to be preset in the technician level.

Method A:

The buttonhole has to be undone and re-sewn.

–

After switching the automat on again, the sewing basket is lifted

and releases the material.

The automat is now available for a new sewing cycle.

Method B:

The buttonhole is completely reseamed.

–

After switching on again the sewing basket stays down. The

material under the sewing basket remains in position.

–

Push pedal forwards to position 2 . Sewing begins.

–

After sewing the automat drives to the reference position and the

sewing basket is lifted.

–

The material can be removed.

The automat is now ready for the next sewing cycle.

Method C:

The buttonhole will continue to be sewn beyond the detected thread

breakage spot.

–

After the automat is switched on again, the sewing basket stays

down. Thus the material under the sewing basket remains in

position.

–

Push the pedal forwards to position 2. The sewing basket proceeds

with the material to the thread breakage spot.

–

In order to reach the position to continue sewing without having to

sew, use the arrow keys ñ and ò.

–

Push the pedal forwards to position 2. Sewing begins.

–

After sewing the machine drives to the reference position and the

sewing basket is lifted.

–

The material can be removed.

The automat is now ready for the next sewing cycle.

The number of stitches that the thread breakage monitor does not

register before signaling an error is set in the technician level. With

the setting stitch number “0", the thread breakage monitor is

switched off.

38

8. Error messages

Number Error position Description Cause Error elimination

1052 Sewing motor Overcurrent - Sewing motor cable

- Sewing motor

- Control

1053 Sewing motor Overvoltage Mains too high

1055 Sewing motor Overload - Sewing motor (blocked/

rough running)

- Control

1056 Sewing motor Excess temperature - Sewing motor

(rough running)

- Control

1058 Sewing motor Speed - Sewing motor

1059 Sewing motor Standstill-

monitoring

1120 Sewing motor Initialization - Sewing motor

1205 Sewing motor Not in UDC

(Upper Dead Center)

- Sewing motor

- Reference switch

- Sewing motor cable

- Reference switch

- Sewing motor

- Sewing motor cable

- Reference switch

- Check sewing motor cable

- Check sewing motor

- Check control

- Check mains voltage

- Check sewing motor

- Check control

- Check sewing motor

- Check control

- Check sewing motor

- Check sewing motor

- Check reference switch

- Check sewing motor

- C heck sewing motor cable

- Check reference switch

- Switch machine off/on

- Check sewing motor

- C heck sewing motor cable

- Check reference switch

1

1301 Sewing motor Referencing

timeout

1302 Sewing motor Current feed

error

1310 Sewing motor Communication-

problem

1320 Sewing motor General sewing motor

error

2101 Step motor

x-axis

2152 Step motor

x-axis

2153 Step motor

x-axis

Referencing

timeout

Overcurrent - Step motor

Overvoltage - Step motor

- Reference switch

- Sewing motor

- Control

- Sewing motor

- Sewing motor cable

- Control

- Sewing motor

- Sewing motor cable

- Reference switch

- Sewing motor

- Sewing motor cable

- Reference switch

- Reference switch

- Step motor

- Control

- Control

- Control

- Check reference switch

- Check sewing motor

- Check control

- Check sewing motor

- Check sewing motor cable

- Check control

- Check sewing motor

- C heck sewing motor cable

- Check reference switch

- Check sewing motor

- Check sewing motor cable

- Check reference switch

- Check reference switch

- Check step motor

- Check control

- Check step motor

- Check control

- Check step motor

- Check control

2155 Step motor

x-axis

2156 Step motor

x-axis

Overload - Step motor

- Control

Excess temperature - Step motor

- Control

- Check step motor

- Check control

- Check step motor

- Check control

39

Number Error position Desription Cause Error elimination

2158 Step motor

x-axis

2201 Step motor

y-axis

2252 Step motor

y-axis

2253 Step motor

y-axis

2255 Step motor

y-axis

2256 Step motor

y-axis

2258 Step motor

y-axis

2901 Step motor

x+y-axis

Speed - Step motor

- Control

Referencing

timeout

Overcurrent - Step motor

Overvoltage - Step motor

Overload - Step motor

Excess temperature - Step motor

Speed - Step motor

Referencing: Timeout - Reference switch

- Reference switch

- Step motor

- Control

- Control

- Control

- Control

- Control

- Control

- Step motor

- Control

- Check step motor

- Check control

- Check reference switch

- Check step motor

- Check control

- Check step motor

- Check control

- Check step motor

- Check control

- Check step motor

- Check control

- Check step motor

- Check control

- Check step motor

- Check control

- Check all reference

switches of the SM

- Check step motor

- Check control

3100 Machine Control voltage-

error

3101 Machine Electrical power-

error

3102 Machine Intermediate circuit

voltage error

sewing motor

3103 Machine Intermediate circuit

voltage error

step motor

3107 Machine Excess temperature

DAC III (>80°)

3121 Machine Pressure monitor

pressureless

3210 Machine Upper thread

breakage

3215 Machine Hook thread counter

ran out

- Mains voltagedrop (momentary)

- Mains voltagedrop (momentary)

- Mains voltagedrop (temporary)

- Mains voltagedrop (temporary)

Control ventilation grill

blocked or dirty

- Compressed air supply

- Pressure monitor

- Check mains supply

- Check mains supply

- Check mains supply

- Check control

- Check mains supply

- Check control

Clear or clean ventilation

grill

- Check pressure

- Check the el. connect.

Rethread the machine

Fit in a new hook thread

bobbin

4102 Operation Exceeding the sewing

limits

4301 Memo-Dongle Missing - Memo Dongle missing

4303 Memo-Dongle Empty Memo-Dongle contains

40

e.g. cut length longer

than sew. basket length

- Memo Dongle broken

no data

- Correct value

Insert Memo-Dongle

Number Error position Description Cause Error elimination

4304 Memo-Dongle Wrong type Boot-Dongle is inserted

4307 Memo-Dongle Wrong class Dongle of the wrong

class was inserted

5101 Contour data-

administration

5104 Contour data-

administration

5301 Contour data-

administration

5303 Contour data-

administration

5305 Contour data-

administration

EEPROM not

initialized

Checksum error - Control

Data memory full Too many stitches in

Data memoryoverflow

Invalid data storage

attempt

- Control

- Control contains no

machine program

contour

Too many stitches in

contour

Too many stitches in

contour

Use Memo-Dongle

Insert correct Dongle

Format the Dongle

- Check control

- Install machine program

The machine resets itself

automatically.

Inform DA-Service

Reduce number of

stitches

Inform DA-Service

Reduce number of

stitches

Inform DA-Service

Reduce number of

stitches

Inform DA-Service

1

5306 Contour data-

administration

5315 Contour data-

administration

6151-6952 I²C/ CPU/ Mem-

Manager

7251-7659 ASC/ SSC/

RS485

8151-8351 IDMA/ Xilink/

Test pins

Invalid data request

General error

Carry out buttonhole

contour reset

Inform DA-Service

Carry out buttonhole

contour reset

Inform DA-Service

Fault Switch machine off and

then on again

Inform DA-Service

Fault Switch machine off and

then on again

Inform DA-Service

Fault

(8151-8159: only an

entry in the event

memory – no further

impairment)

Switch machine off and

then on again

Inform DA-Service

41

9. Maintenance

9.1 Cleaning and inspection

1

2

3

4

Check air pressure and adjust

–

The operating pressure is 6 bar.

–

Turn screw 1 to adjust pressure

Reduce pressure: Turn screw 1 anti-clockwise.

Increase pressure: Turn screw 1 clockwise.

Scheduled maintenance Explanation Operating

hours

Places to be cleaned particularly:

Machine head

Remove sewing dust, thread

rests and cutting waste.

Pneumatic system

Check or set air pressure

Check water level in the pressure

regulator.

Clean filter

- Beneath the throat plate

- Sewing basket

- Area under the hook

- bobbin housing

- thread cutter

Water level must not rise to the level of the filter element

2. Screw in drain screw 4 and blow out the water under

pressure.

Through the filter element 2 condensation water and dirt

are expelled. Cut off the machine from the air pressure

system. Screw in drain screw 4. The pneumatic system

of the machine must be without pressure. Unscrew

water trap 3. Unscrew the filter element 2 and wash out

the dirty filter housing and filter element with benzene

(not a solvent!) and blow dry. Reassemble the

maintenance unit and reconnect.

8

8

40

500

Check tightness of systems

42

500

9.2 Oil lubrication

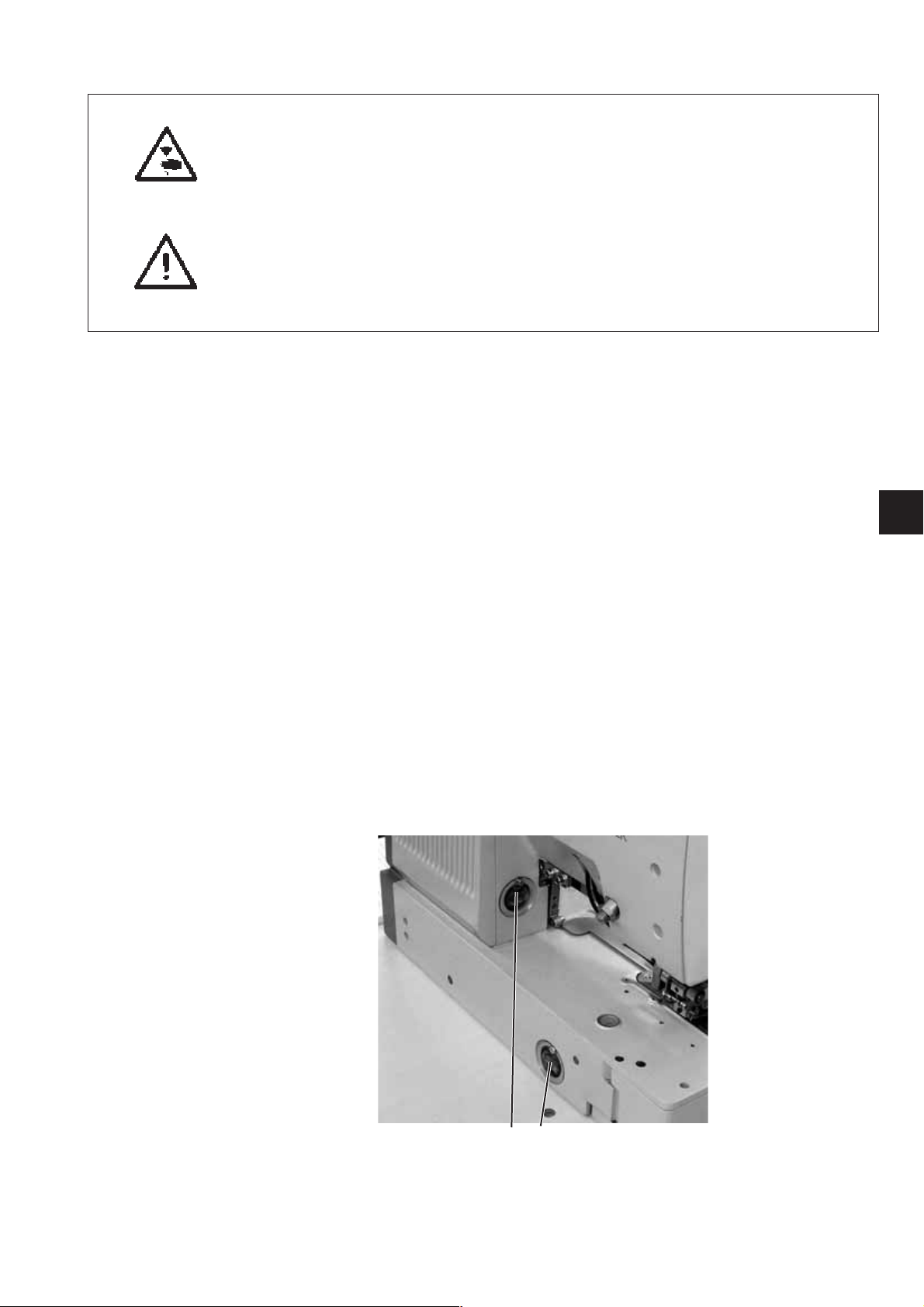

Caution: Danger of injury !

Oil can cause skin eruption.

Avoid protracted contact with the skin.

In the event of cotact, thoroughly wash the affected area.

ATTENTION !

The handling and disposal of mineral oils is subject to legal

regulations.

Deliver used oil to an authorized collecting station.

Protect your environment.

Take care not to spill oil.

Check regularly the oil level in both of the supply containers 1 and 2.

The oil level should not drop below the mark “min” on the glass

inspection!

Fill up the oil reservoirs exclusively with lubricating oil DA-10 or an

equivalent oil w ith the following specification:

–

Viscosity at 40°C: 10 mm²/s

–

Ignition point: 150°C

DA-10 oil can be bought at the sales points of DÜRKOPP ADLER AG

under the following parts numbers:

250-ml-Container: 9047 000011

1-Litre-Container: 9047 000012

2-Litre-Container: 9047 000013

5-Litre-Container: 9047 000014

Refilling oil supply containers

–

Refill the oil supply containers 1 and 2 through the hole in the glass

inspection holes.

–

The oil level has to be above the “min”mark.

Do not fill the oil supply containers beyond the “max”mark.

1

12

43

Notes:

44

Loading...

Loading...