Duerkopp Adler 540-100 Service Manual

Manual, complete

540 - 100

CNC double lockstitch buttonholer

Operating Instructions

Installation Instructions

Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Phone + 49 (0) 5 21 / 9 25-00 • Fax + 49 (0) 5 21 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: 04/2006 Printed in Federal Republic of Germany Teile-Nr./Part.-No.: 0791 540001

540 - 100

Manual, complete

Contents

Operating Instructions

Installation Instructions

Service Instructions

Interconnection-diagram

9890 540001 B

Software version

A04.1

B04.1

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruc ti o n m an ual contains i m po rt a nt i nf orm ation on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruc ti o n m an ual must alway s be available at the

machine/sewing unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, i ncl u di n g e qu i pp i ng , t r ou bl e s ho ot i ng du r ing the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair and/or

– Transport.

The user also has to assure that only authorized personnel work on

the machine.

The user is o bl i g ed to c he ck th e m ac h i ne at l ea s t o nc e pe r shi f t f or

apparent da ma ge s and to immedia tl y r e po r t a ny c h an ge s ( inc l u di n g

the performanc e i n se r vi c e), wh i c h im pa i r th e sa fe ty.

The user comp an y mu s t e ns u re that the machi n e i s o nl y o pe r at ed i n

perfect working order.

Never remove or disable any safety devices.

If safety dev i c e s ne ed to be removed for equi pp i ng , r e pa i ri ng or

maintaining, the safety devices must be

remounted directly after completion of the maintenance and repair

work.

Unauthorized modification of the machine rules out liability of the

manufacture r fo r da ma ge res u l ti n g f r om th i s .

Observe all safety and danger recommendations on the machine/unit!

The yellow -and-black str i pe d surfaces desig na t e pe rma ne nd danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate

training.

2. Before putting into service also read the safety rules and

instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot,

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time

as the entire sewing unit is found to comply with EC directives.

It is absolutely necessary to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Index Page:

Part 3: Service Instructions Class 540-100

1. Elements of the control panel

1.1 Alteringparametervalues......................................... 4

1.1.1 Numericalvalues.............................................. 4

1.1.2 Selectionofaparameter.......................................... 4

2. Menu structure technician mode (overview)

2.1 Submenumachineconfiguration(overview).............................. 6

3. Calling up the technician mode and entering the code ..................... 7

4. Main menu of the technician mode

4.1 Submenumachineconfiguration..................................... 7

4.1.1 Submenuuser................................................ 8

4.1.2 Submenuforsoftstartsetting....................................... 8

4.1.3 Submenu for determining the equipment ................................ 8

4.1.4 Submenuforthreadmonitorconfiguration............................... 9

4.1.5 Submenu for the configuration of condensed stitches ........................ 10

4.1.6 Submenuforenteringmachinetimes.................................. 11

4.2 Submenu for the configuration of the operating elements ...................... 11

4.2.1 Submenu for selecting the menu language ............................... 11

4.2.2 Submenuforsettingdateandtime ................................... 11

4.3 Submenufortestfunctions........................................ 12

4.3.1 SubmenuMultitest ............................................. 12

4.3.1.1 Submenuoutputtest............................................ 13

4.3.1.2 Submenu input test ............................................. 13

4.3.1.3 Submenu automatic input test ...................................... 14

4.3.1.4 Submenusewingmotortest........................................ 14

4.3.1.5 Submenustepmotortest ......................................... 14

4.4.1.6 SubmenuRAMtest............................................. 14

4.4.1.7 SubmenuEPROMtest........................................... 14

4.4.2 SubmenuDACIII.............................................. 15

4.4.3 Submenu memo-dongle .......................................... 15

4.4.3.1 Dongle contents ............................................... 15

4.4.3.2 Submenu loading .............................................. 16

4.4.3.3 Submenusaving .............................................. 17

4.4.3.4 Formatting.................................................. 18

3

5. Knife setting

5.1 Aligningtheknifeandadjustingtheknifeheight ........................... 19

5.2 Settingoftheknifeincisiondamper................................... 20

Index Page:

6. Hook and needle bar

6.1 Needle position ............................................... 21

6.2 Reference position of the needle bar .................................. 21

6.3 Setting the adjusting sheet ........................................ 22

6.4 Loop formation stroke position and distance between hook and needle ............. 23

6.5 Needle bar height .............................................. 24

6.6 Needle protection .............................................. 25

6.7 Alignment of the bobbin case holder................................... 25

7. Aligning the throat plate as to the needle .............................. 26

8. Thread tension plate

8.1 Threadpulleradjustment ......................................... 26

8.2 Thread controller spring and thread regulator ............................. 27

9. Sewing basket

9.1 Settingoftheclothpresserblock(liftingstroke) ........................... 28

9.2 Lifting / Lowering speed of the sewing basket ............................. 28

9.3 Alignmentofthesewingbasketastothethroatplate ........................ 29

9.4 Referencepositionofthesewingbasket................................ 30

10. Bobbin thread scissors

10.1 Settingoftheclosingpath......................................... 31

10.2 Adjusting the spring sheet of the thread rest .............................. 32

11. Needle thread scissors

11.1 Function sequence ............................................. 33

11.2 Removal and check of the needle thread scissors .......................... 34

11.3 Alignmentofthescissorsblock...................................... 35

11.4 Scissorsswivelledin............................................ 37

11.5 Heightadjustment.............................................. 38

11.6 Scissorsswivelledout........................................... 38

11.7 Distance to the needle ........................................... 39

11.8 Opening the scissors ............................................ 39

11.9 Settingoftheclosingpath......................................... 40

11.10 Setting the time for opening the scissors ................................ 40

12. Machine stop position .......................................... 41

13. Bobbin winder ............................................... 42

14. Solenoid valves .............................................. 43

15. Exchange of the sewing basket .................................... 44

16. Stretching the drive belts ........................................ 45

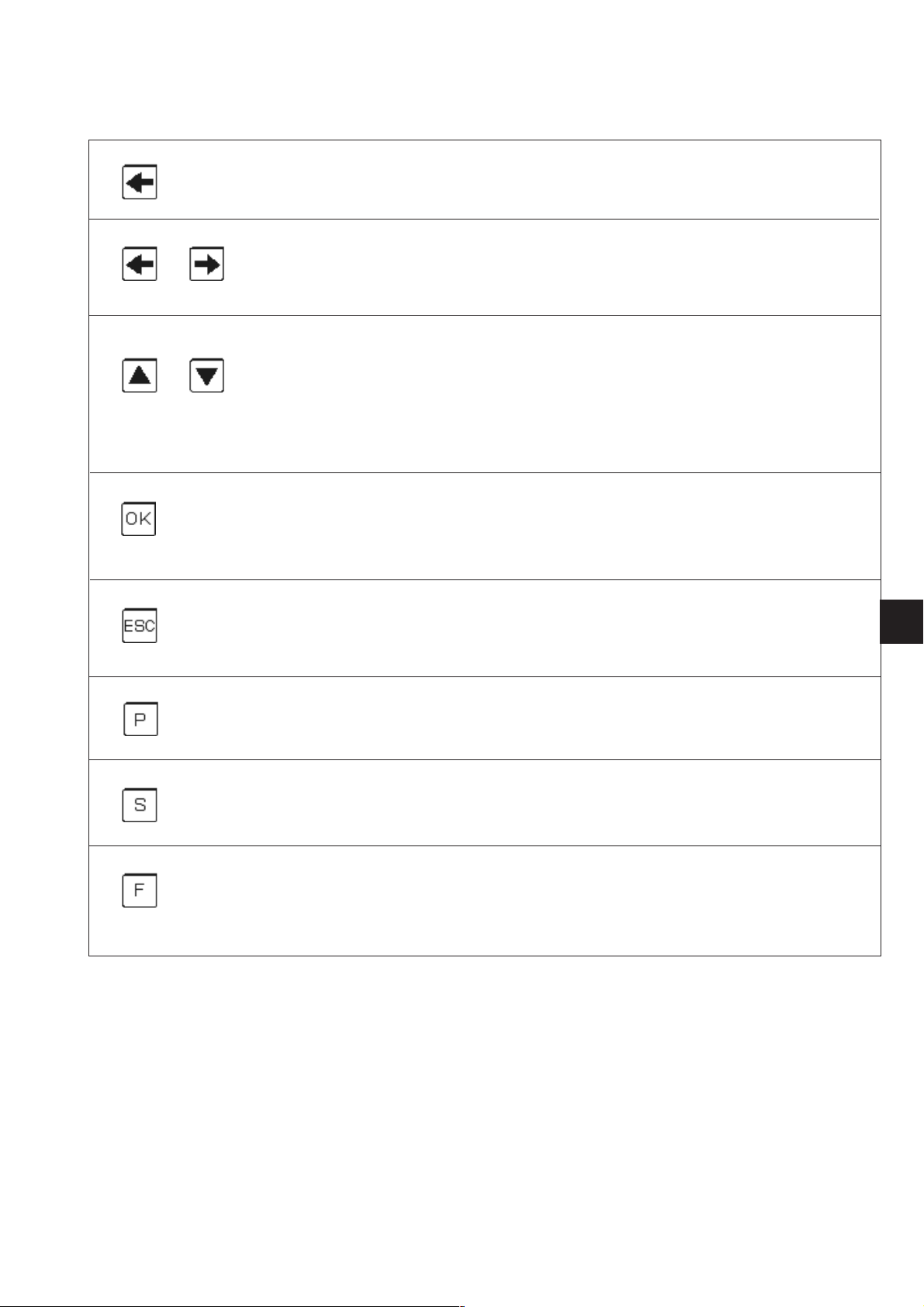

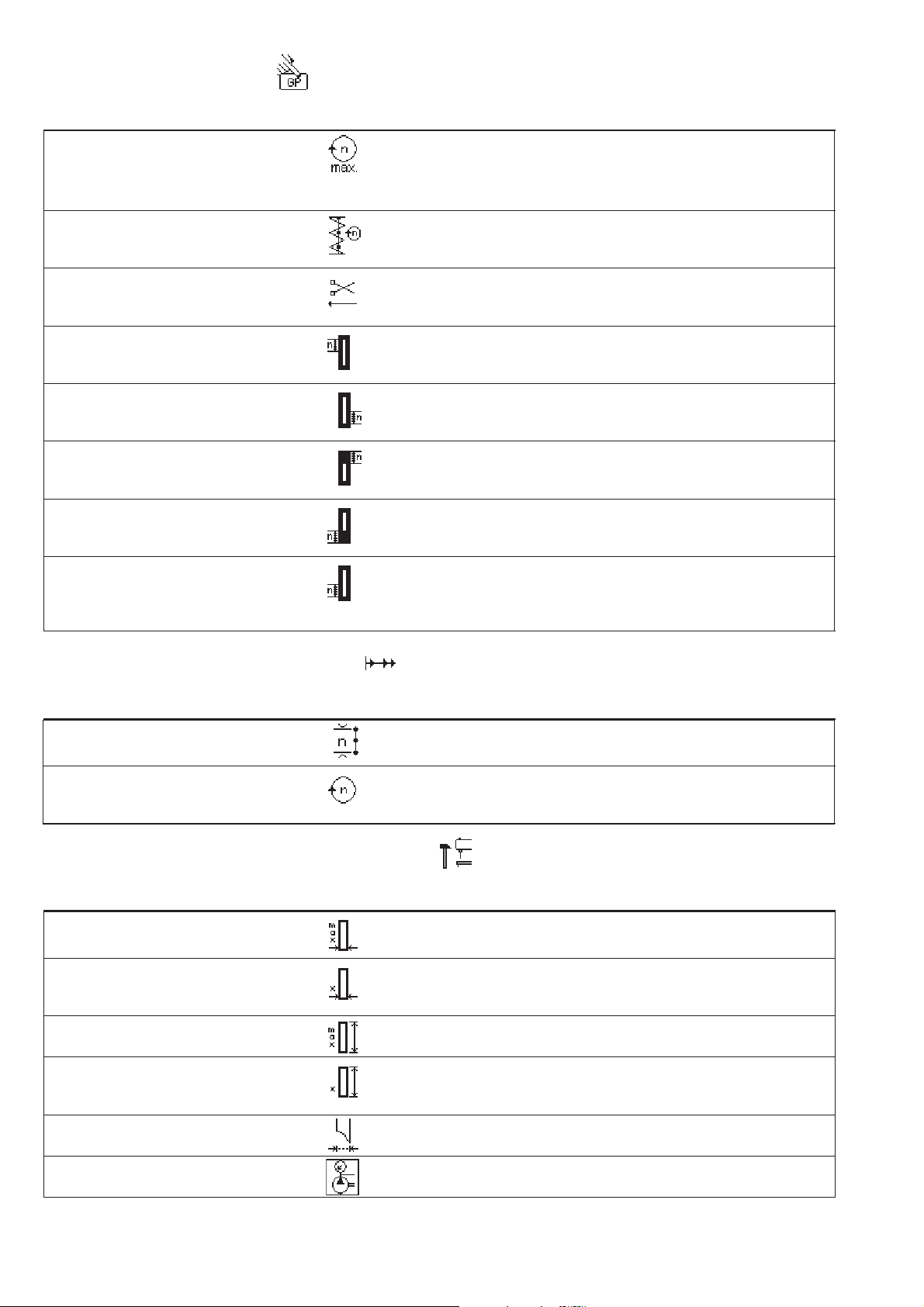

1. Elements of the control panel

Key Function

If no text field is activated:

–

Change to the parent menu.

If a text field is activated:

–

Change between the figures tenth, unit, ten etc.

–

Change between the lines in the menus. The selected line is

always dark-shadowed.

If a text field is activated:

–

Increase or reduce the value of the respective figure by one or

change between the parameters in case of functions with several

choices, e.g. between “Push button on“ and “Push button off“.

–

Activate the text field. The value can be altered with the keys “ñ“

and “ò“.

If a text field is activated:

–

The set value is taken over.

–

You get back to the main menu from a submenu.

If a text field is activated:

–

An input is aborted. The previous value remains unchanged.

–

The control changes from the sewing mode to the programming

mode. The buttonhole parameters can be altered in this mode.

–

The control changes from the sewing mode or programming mode

to the sequence programming mode.

–

The control changes from the sewing mode to the technician mode.

This mode can only be activated by entering a code 25483.Inthis

operating state it is possible to set basic machine parameters and

to call up diagnosis and adjusting programs.

3

3

1.1 Altering parameter values

1.1.1 Numerical values

1.1.2 Selection of a parameter

Numerical values can be altered as follows:

–

Selectthelinewiththevaluetobealteredwiththecursorkeysñ

and ò.

–

Actuate the OK key.

The cursor flashes under a digit of the numerical value.

–

Change between the digits with the cursor keys ï and ð.

–

Increase or reduce the value of the selected digit with the cursor

keys ñ and ò.

In case of parameters which cannot optionally be altered another

possible parameter value is indicated by actuating the cursor keys

ñ and ò.

–

Actuate the OK key.

The set value is taken over.

–

If the set value is not to be taken over, actuate the ESC key.

The initially set value is restored

Some parameters allow to choose between several possibilities.

The parameter can be altered as follow s:

–

Selectthelinewiththevaluetobealteredwiththecursorkeysñ

and ò.

–

Actuate the OK key.

–

Change between the possibilities with the cursor keys ñ and ò.

The selected parameter is displayed.

–

Actuate the OK key. The set parameter or value is taken over.

–

If the set parameter or value is not to be taken over, actuate the

ESC key.

The initially set parameter or value is restored.

4

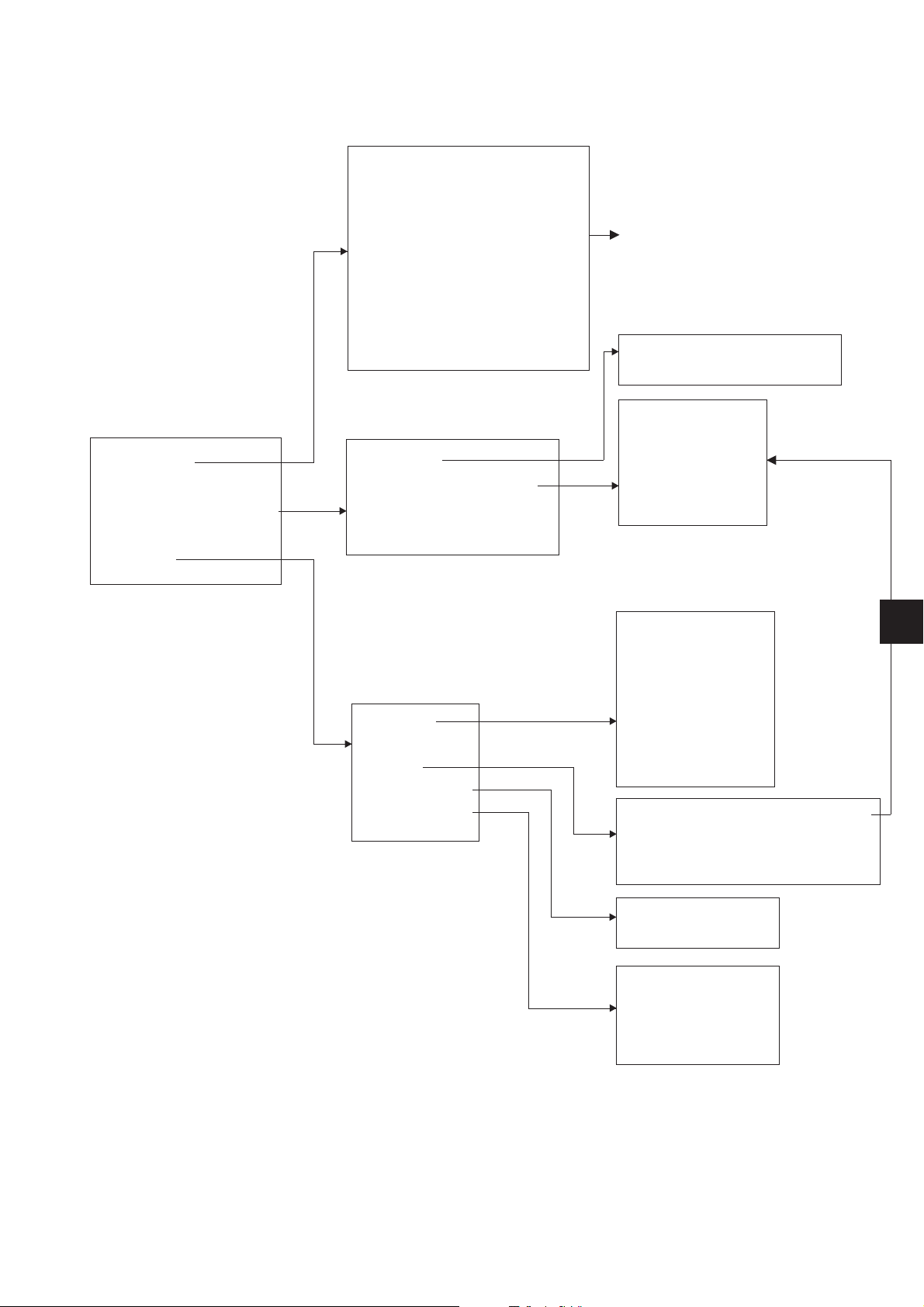

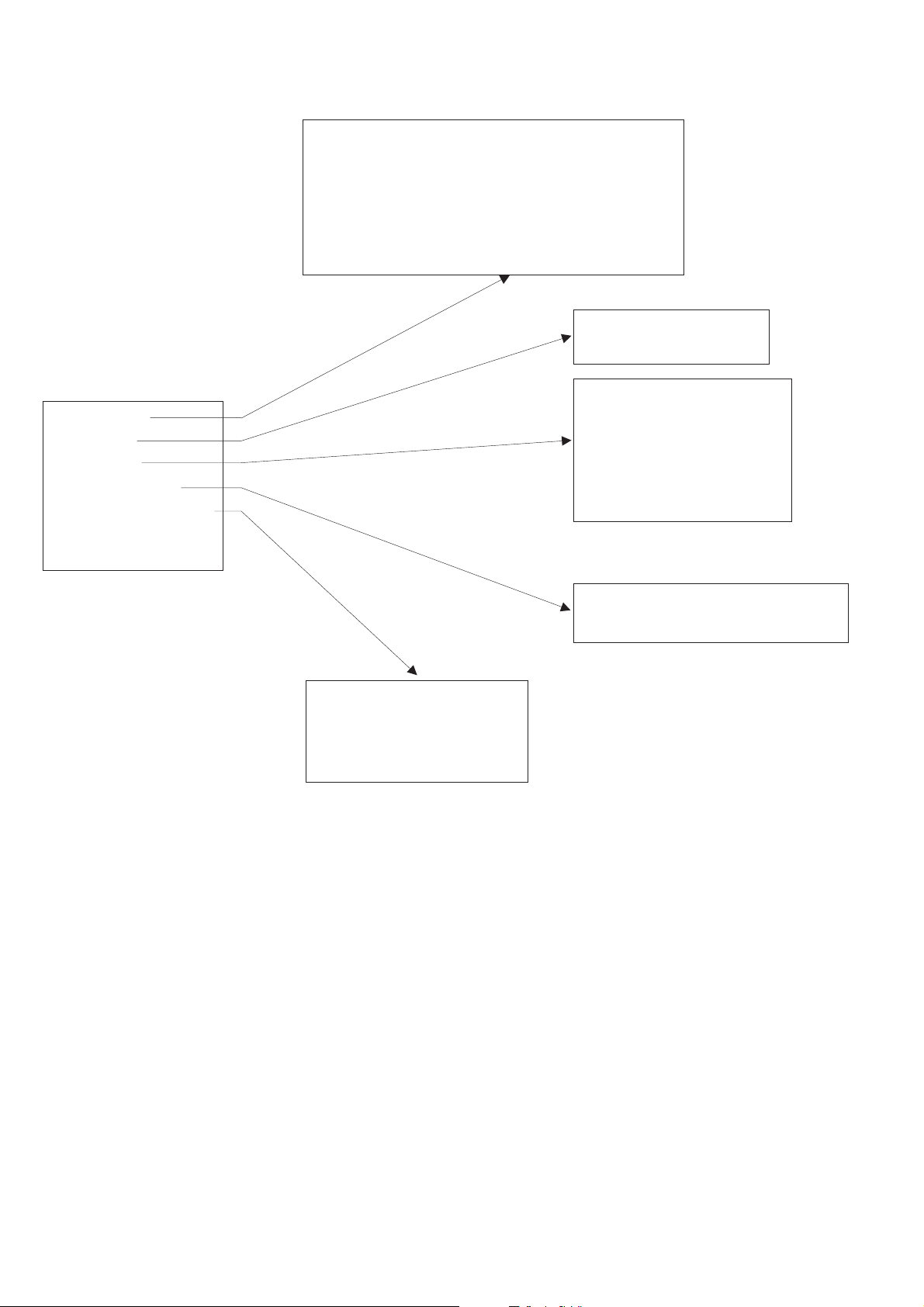

2. Menu structure technician mode (overview)

Parameter

Soft start

Equipment

X- /Y- Correction Submenu:

Thread monitor

Condensed stitches

Subclasses

Times

Display

Machine

User configuration

Service

Counter (totalizer) :

Language

Set date/time

Lock P: Selection

Hand switch: Selection

Machine configuration

Selection: German, English,

Italian, Parameter

Hour : Input

Minute: Input

Day:

Month:

Year: Input

Input

Input

Multitest

Events

DAC III

Data reset

Memo dongle

Output test

Input test

Auto input

Sewing motor test

Step motor test

RAM test

EPROM test

Time/Date:

Temperature DAC III: Display

Interm. circuit voltage: Display

Buttonhole data

Machine compl.

Content

Loading

Save

Format

Display

3

5

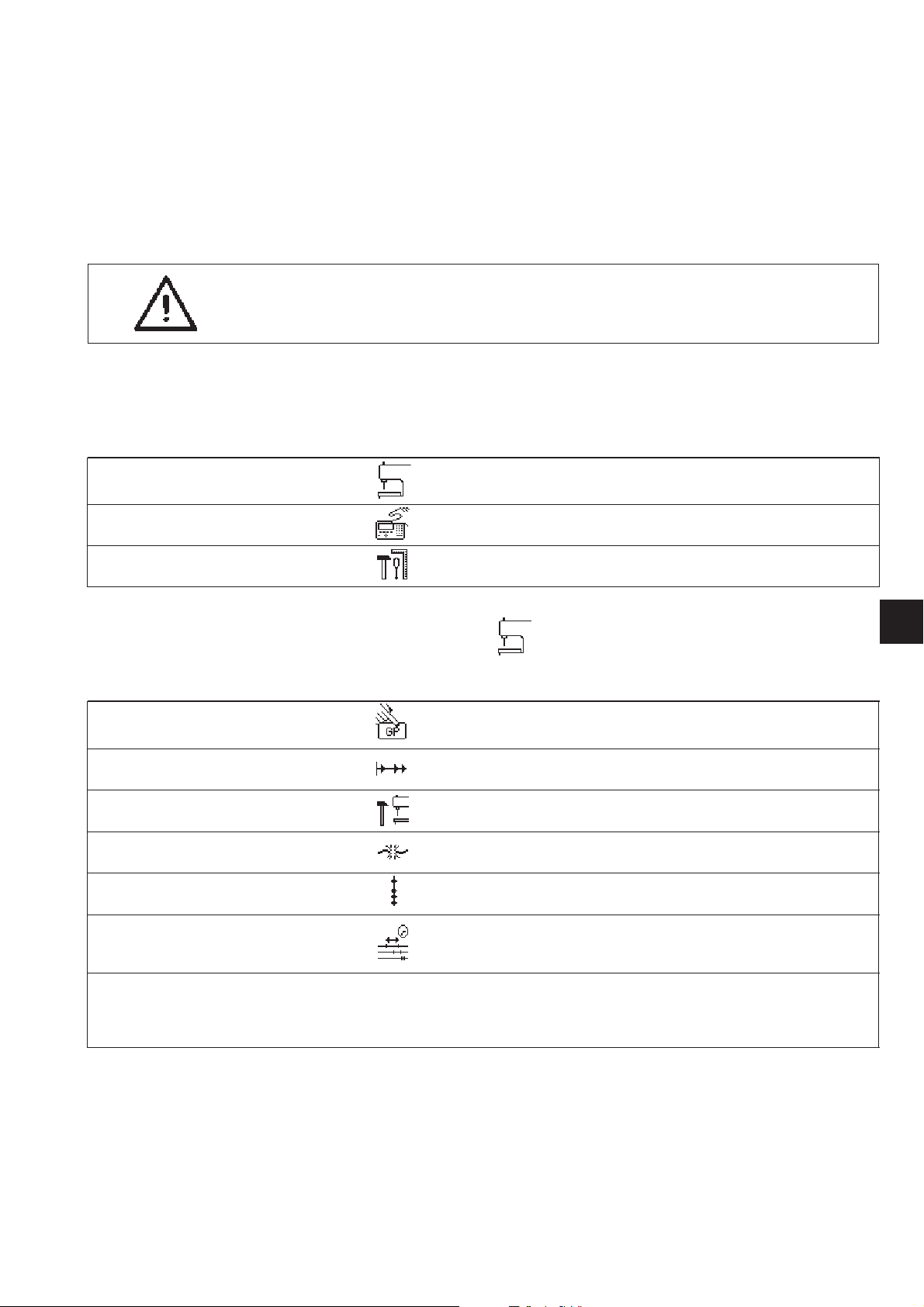

2.1 Submenu machine configuration (overview)

Max. speed: Input

Speed basting stitches: Input

Scissors is moved out: Input

n-stitches b. u. bartack/bartack tension on: Input

n-stitches b. l. bartack/bartack tension on: Input

n-stitches b. lip there/lip tension on: Input

n-stitches b. lip back/lip tension on: Input

n-stitches b. seam beginning/lip tension on: Input

Parameter

Soft start

Equipment

Thread monitor

Condensed stitches

Times

Counter (totalizer)

Number of stitches: Input

Speed: Input

Cage length: Selection

Free cage length:

Cage width:

Free cage width:

Knife length:

Pressure monitor:

Input

Selection

Input

Input

Input

Number of stitches: Input

Stitch length x: Input

Stitch length y: Input

Position last stitch: Input

Repair mode:

Selection

Needle thread mon. on/off: Selection

6

3. Calling up the technician mode and entering the code

In order to get into the technician mode a code has to be entered. For

this purpose please proceed as follows:

–

Press the F key in the sewing mode.

A window for entering the code appears.

–

Enter the technician code 25483.

Confirm with the OK key.

Note

If a wrong code has been entered, the automate returns to

the sewing mode.

4. Main menu of the technician mode

No. Parameter name Symbol Description

T1 Machine

T2 User configuration

T3 Service

Selection of the submenu for the machine

configuration

Selection of the submenu for the configuration

of the control elements

Selection of the submenu for test functions

4.1 Submenu Machine configuration

No. Parameter name Symbol Range Description

T1.1 Parameter -

T1.2 Soft start -

T1.3 Equipment -

T1.4 Thread monitor -

T1.5 Condensed stitches -

T1.7 Times -

Selection of the submenu for

parameter setting

Selection of the submenu for soft

start setting

Selection of the submenu for

equipment definition

Selection of the submenu for thread

monitor options

Selection of the submenu for setting

of condensed stitches

Selection of the submenu for

entering machine times

3

T1.8 Counter (totalizer) -

buttonholes ever sewn

0 … 99.999.999

Display of the counter of all

buttonholes ever sewn

The value cannot be selected or

edited.

7

4.1.1 User submenu

No. Parameter name Symbol Range Description

T1.1.1 Max. speed 200 … 4000

T1.1.2 Speed basting stitches 200 … 4000

T1.1.3 Move out the scissors 0 … 10

T1.1.4 Lip tension before the

0…10

upper bartack

T1.1.5 Lip tension before the

0…10

lower bartack

T1.1.6 Lip tension before the

0…10

lip back

T1.1.7 Lip tension before the lip

0…10

there

T1.1.8 Lip tension after the

0…10

seam beginning

Setting of the maximum speed in the

sewing mode.

The speed can be altered in steps of

100.

Setting of the speed for the basting

stitches

Number of stitches after which the

scissors moves out and releases the

clamped needle thread

Number of stitches before the upper

bartack with the bartack tension

switched on

Number of stitches before the lower

bartack with the bartack tension

switched on

Number of stitches before the lip

back with the lip tension switched on

Number of stitches before the lip

there with the lip tension switched

on

Number of stitches after the seam

beginning after which the lip tension

is switched on.

Only valid for taper bars.

4.1.2 Submenu for soft start setting

No. Parameter name Symbol Range Description

T1.2.1 Number of stitches 0 … 10

T1.2.2 Speed 200 … max.

Number of stitches of the soft start

Speed for the soft start

sewing speed

according to T1.1.1

4.1.3 Submenu for determining the equipment

No. Parameter name Symbol Range Description

T1.3.1 Cagewidth 3,4,6,Xmm

T1.3.2 Free cage width 1,0 … 6,0 mm

Selection of the cage width

Only visible if cage width X has been

selected for T1.4.1.

Enter value for cage width.

T1.3.3 Cage length 17, 22, 35, 48,

Selection of the cage length

70, X mm

T1.3.4 Free cage length 10,0 … 70,0 mm

Only visible if cage length X has

been selected for T1.4.3.

Enter value for cage length.

T1.3.5 Knife length 1,0 … 70,0 mm

Length of the knife used.

(Default-Value: 3.5 mm)

T1.3.6 Pres sure monitor 0 / 1

Pressure monitor available

8

4.1.4 Submenu for the thread monitor configuration

No. Parameter name Symbol Range Description

T1.4.1 R epair mode A, B, C

T1.4.2 Needle thread monitor 0 … 10

Description repair modes T1.4.1

Method A:

The buttonhole has to be unstitched and sewn again.

–

After switching the automate on again the sewing basket lifts and

releases the material.

The automate is ready for a new sewing cycle.

Method B:

The buttonhole is completely stitched around anew.

–

After switching the automate on again the sewing basket remains

lowered. The material under the sewing basket remains in its

position.

–

Step the pedal forward (2nd step). The sewing cycle is started.

–

After the sewing cycle the automate runs in reference position and

the sewing basket is lifted.

–

The material can be taken out.

The automate is ready for a new sewing cycle.

Selection of the repair mode to be

used.

Number of stitches not registered by

the thread breakage monitor before

an error message is displayed.

At the value 0 the thread breakage

monitor is switched off.

3

Method C:

The buttonhole is continued to be sewn from the recognized point of

thread breakage.

–

After switching the automate on again the sewing basket remains

lowered. The material under the sewing basket remains in its

position.

–

Step the pedal forward (2nd step). The sewing basket moves to the

recognized point of thread breakage with the material.

–

With the cursor keys ñ and ò you can move - not sewing - to the

position to continue the sewing cycle.

–

Step the pedal forward (2nd step). The sewing cycle is started.

–

After the sewing cycle the automate runs in reference position and

the sewing basket is lifted.

–

The material can be taken out.

The automate is ready for a new sewing cycle.

9

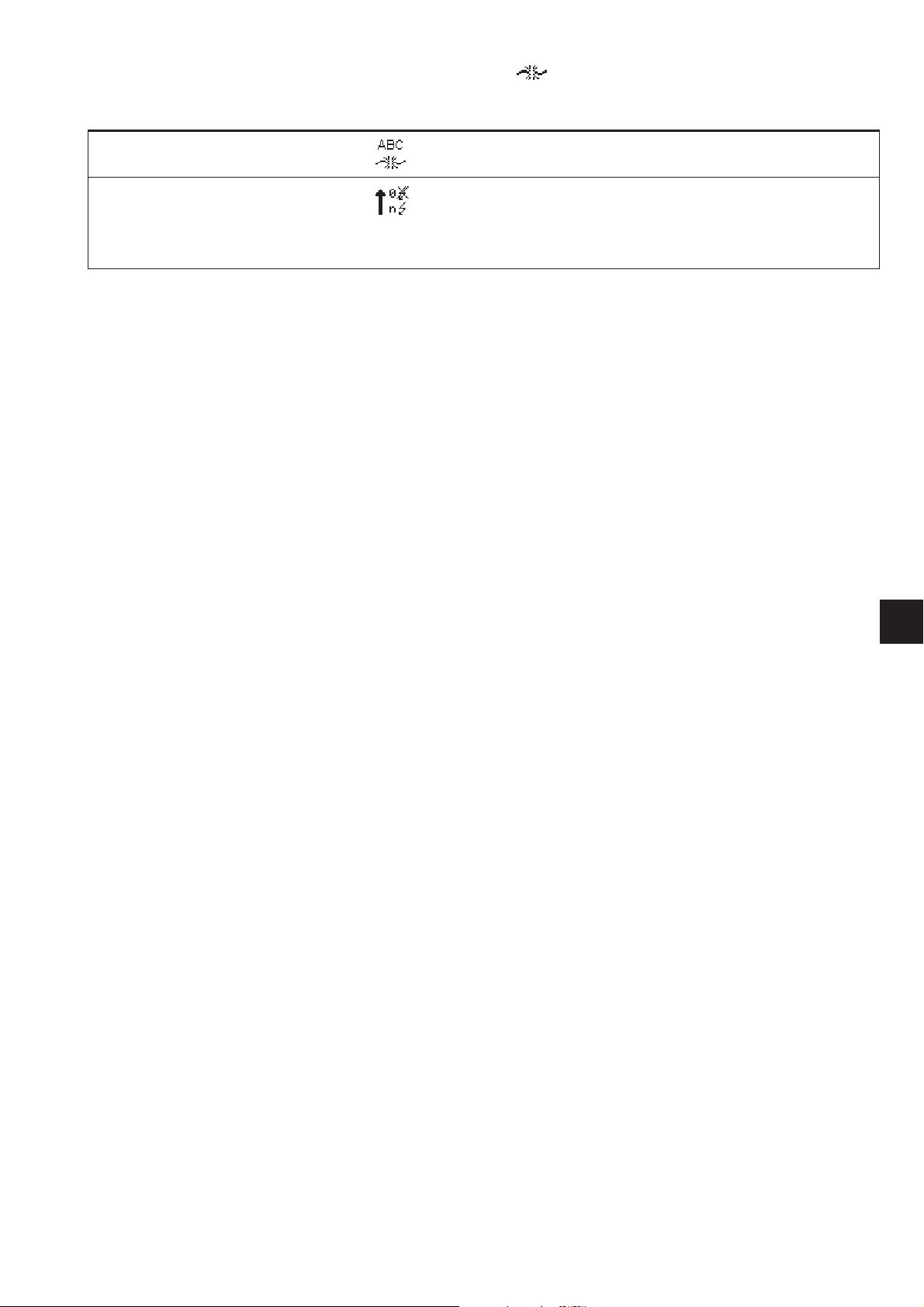

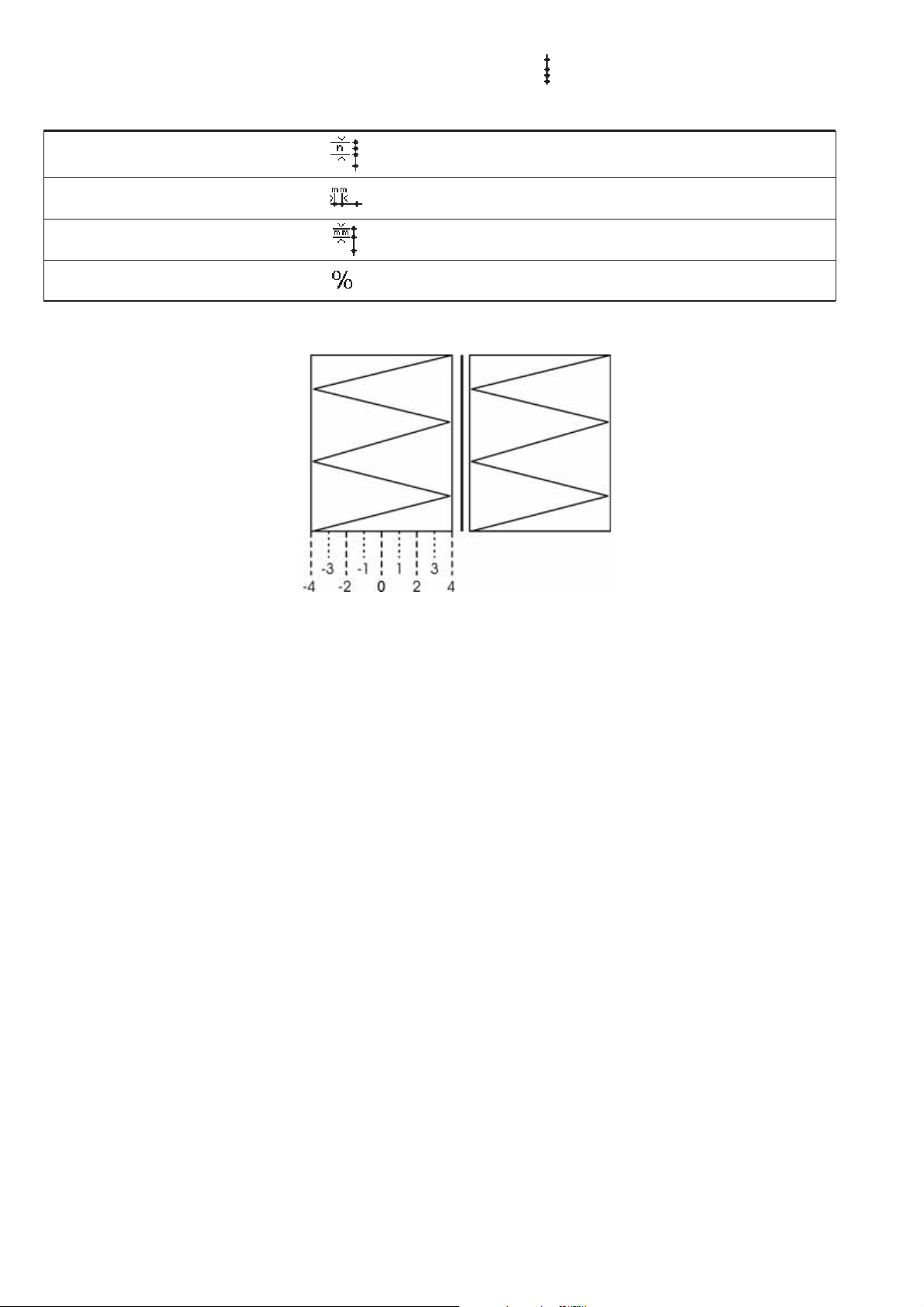

4.1.5 Submenu for the configuration of condensed stitches

No. Parameter name Symbol Range Description

T1.5.1 Number of stitches 0 … 9

T1.5.2 Stitch length X 0,3 … 2,0 mm

T1.5.3 Stitch length Y 0,0 … 0,8 mm

T1.5.4 Position last stitch -4 … 4

Lip there Lip back

Enter the number of condensed

stitches

Enter the stitch distance of the

condensed stitches in direction X

Enter the stitch distance of the

condensed stitches in direction Y

Enter the position of the last knotting

stitch according to fig. 1

Fig. 1

10

4.1.6 Submenu for entering machine times

No. Parameter name Symbol Range Description

T1.7.1 Ped ðStart 0 … 9000 ms

T1.7.2 End ðCage 0 … 9000 ms

T1.7.3 C ageðRef 0 … 9000 ms

Delay time between stepping down

the pedal position 2 and the sewing

motor start

Delay time between sewing end and

lifting of the cage

Delay time between lifting of the

cage and reference start

4.2 Submenu for the configuration of the operating elements

No. Parameter name Symbol Range Description

T2.1 Language -

T2.2 Set date/time -

T2.3 Locking P on / off

T2.4 Push-button on / off

Select the submenu for the choice

of the menu language

Select the submenu for setting date

and time

Switch the keyboard blocking for the

P key on or off. If the key blocking is

switched on, no buttonhole

programs can be established or

altered.

Select the push-button instead of

the foot pedal or in addition to the

foot pedal.

3

4.2.1 Submenu for selecting the menu language

You can choose among the following languages:

–

German

–

English (Default setting)

–

Parameter display

(e.g.: T2.1 instead of Language, T2.3 instead of Locking P ,

T1.4.1 instead of Repair mode)

4.2.2 Submenu for setting date and time

No. Parameter name Symbol Range Description

T2.2.1 Minutes - 1 … 59 min

T2.2.2 Hours - 1 … 23 h

T2.2.3 D ay - 1 … 31

T2.2.4 Month - 1 … 12

T2.2.5 Year - 0 … 99

Tim e:

Input of the minutes

Tim e:

Input of the hours

Date:

Input of the day

Date:

Input of the month

Date:

Input of the year

11

Loading...

Loading...