Page 1

531

CNC Knopfannähautomat

CNC Automat for Button Sewing

Bedienanleitung / Operating Instructions

Aufstellanleitung / Installation Instructions

Serviceanleitung / Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 5 21/ 9 25-00 Telefax +49 (0) 5 21/ 9 25 24 35 www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

02/2011 Rev. index: 01.0 Printed in Federal Republic of Germany 0791 531001

Page 2

Alle Rechte vorbehalten.

Eigentum de r Dürkopp Adler AG und urheberrechtlich ge schützt. Jede, auch auszugsweise

Wiederverwendung dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG

verboten.

All rights reser ved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any

manner, even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2011

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 5

Contents Page:

Foreword and general safety instructions

Part 1: Operating Instructions Class 531- Original instructions

(Version: 02.2011)

1 Product description ........................................... 5

2 Intended use ................................................ 6

3 Subclasses ................................................. 6

4 Additional equipment........................................... 7

5 Supporting frame ............................................. 7

1

6 Technical data

6.1 Technicaldataforthesubclasses.................................... 8

7 Operation

7.1 Threadingneedlethreads......................................... 9

7.2 Adjustingneedlethreadtension..................................... 10

7.3 Openingneedlethreadtensioner .................................... 10

7.4 Adjustingthreadregulator......................................... 11

7.5 Winding hook threads ........................................... 12

7.6 Changing hook thread bobbin ...................................... 13

7.7 Adjusting hook thread tension ...................................... 14

7.8 Changingtheneedle............................................ 15

7.9 Buttonshankshaper............................................ 16

7.10 Adjusting the button clamp hook feet .................................. 17

8 Operating the control unit

8.1 Theoperatingterminal........................................... 18

8.1.1 Thebuttons ................................................. 18

8.2 Userinterface................................................ 20

8.2.1 Menustructure ............................................... 20

8.3 Changingnumberandparametervalues,alternativeselection .................. 21

8.3.1 Changingnumbervalues ......................................... 21

8.3.2 Selectingaparameter........................................... 22

8.3.3 Alternativeselection............................................ 22

8.4 Sewingpattern ............................................... 23

8.5 Energysavingmode............................................ 23

Page 6

Contents Page:

8.6 Mainmenu.................................................. 24

8.6.1 Sewingpatternoperation......................................... 24

8.6.2 Programmingmode............................................. 29

8.6.3 Copyingfunctionforsewingpatternprograms............................ 33

8.6.4 Sewingpatternsequence(sequences)................................. 34

8.6.4.1 Switchingsewingpatternsequenceoperationonandoff...................... 34

8.6.4.2 Sequenceprogrammingmode...................................... 37

8.6.5 Technicianmode .............................................. 38

8.6.5.1 Machineconfiguration........................................... 40

8.6.5.2 Userconfiguration ............................................. 48

8.6.5.3 Servicefunction............................................... 52

8.6.5.4 Freecontours................................................ 64

8.6.5.5 Memory dongle ............................................... 73

8.7 Distributorcircuitboard.......................................... 80

8.8 Errormessages............................................... 82

8.8.1 Errorcategories............................................... 82

8.8.2 Applicationmessages........................................... 83

8.8.3 Machineerrors ............................................... 85

9Sewing.................................................... 89

10 Maintenance

10.1 Cleaning and checking ........................................... 90

10.2 Oillubrication................................................ 91

11 Standard sewing pattern ........................................ 92

12 Clamping feet................................................ 95

13 Repair .................................................... 96

Page 7

1 Product description

The Dürkopp Adler 531 is a CNC lockstitch button sewer. The

existing button patterns are scalable and can be saved in this

modified form. In addition it is possible to enter “free” stitch patterns

(programming). The button sewer is fitted with an automatic sewing

foot elevator, a thread cutter, a thread wiper, an electromagnetic

thread tensioner and an integral DC direct drive.

Technical features:

–

The sewing attachment is driven by an integral positioning drive. A

DAC control unit controls not only the sewing drive but also two

step motors for the X and Y movement to create the stitch

geometry.

–

The maximum size of t he sewing area is 40 mm in the X direction

and 20 mm in the Y direction.

–

The thread is tensioned electromagnetically. It can be freely

configured in specific areas of the stitch pattern.

–

The wick is lubricated centrally for the top part and hook. Two

separate oil reservoirs are available for this that are both supplied

by the top container. There is only one refilling point.

–

A maximum of 50 standard button patter ns are available. These

standard patterns can be modified temporarily (changing the

overall length, width, speed). When the machine is switched off

the modified values of the last used bar tack are retained when it

is switched on again.

–

40 modified standard patterns can also be stored.

–

There is also a maximum of 9 free stitch contours with a total of

3000 dynamically managed stitches available. Thus, for example,

free button patterns can be sewn. The co-ordinates of the free

stitch contours are entered on the operating panel. No other

machine is required.

–

25 sewing pattern sequence programs each with up to 20 sewing

patterns can be created and saved.

–

The accuracy of the co-ordinate entry is 0.1 mm.

–

It is possible to block special button and/or button sequence

programs and/ or modifications so that unauthorized use or

modification can be stopped from the technician level.

–

It is possible to perform an intermediate cut without raising the

button clamp so that a connection thread can be avoided.

–

The control unit can respond to exter nal signals (input) and can

also output signals itself (output).

–

There is a hook thread counter and a daily piece counter.

–

The arm shaft on the button sewer is driven directly by a brushless

direct current motor.

–

Speeds of 0 min

and Y drives) up to 2700 min

–

Service and maintenance work is supported by extensive test

-1

(manual operation with full functionality of the X

-1

can be reached in 100 min-1steps.

programs with which the individual functions can be tested

separately.

1

5

Page 8

2 Intended Use

The Class 531 is a button sewer that can be used as intended to sew

light to medium weight material. Such material is normally material

made out of textile fibers or leather. Such sewing materials are used in

the clothing, domestic upholstery and automobile upholstery industry.

In addition it is possible that even so-called technical seams can be

done with this button sewer. However, here the operator (in

co-operation with DÜRKOPP ADLER AG ) must assess the possible

risks because such applications are on the one hand comparatively

rare and on the other hand there is an enormous variety. Depending

on the results of this assessment suitable precautions may need to be

taken.

Normally only dry material must be processed with this button s ewer.

The material must not be thicker than 9 mm if it is to be compressed

through the lowered sewing feet. The material must not contain any

hard objects. The button sewer must not be operated without an eye

guard.

The seam is normally created with sewing threads made of textile

fibers (cotton thread, synthetic thread or braided yar ns) with the

following dimensions:

Class 531-211 50/3 - 120/3 thread thickness

If you want to use other threads you must also the assess risks arising

from this and if necessary take precautions.

This button sewer must only be installed and operated in dry, tidy

premises. If the button sewer is used in other rooms that are not dry

and tidy other measures will be required that will have to be agreed

(see EN 60204-31: 1999).

As a manufacturer of industrial sewing machines we assume that at

least skilled operating personnel work on our product so that a ll the

normal conditions and if necessary their risks can be assumed to be

known.

3 Subclasses

Cl. 531-211 Single needle lockstitch button sewer with automatic sewing foot

elevation, thread cutter and thread wiper and electromagnetic thread

tensioner.

Fitted with a special button clamp for:

- laundry = button sizes of Æ 7-Æ 18 mm

-DOB&HAKA=buttonsizesofÆ 11 - Æ 40 mm together

with optional button shank shaper unit.

The machine has a shank button rest.

6

Page 9

4 Additional equipment

The following additional equipment is available for the button sewer

531:

Order no. Additional accessories

9822 51 002 6 Sewing light

9822 51 002 7 Tab le cla mp

9870 00 102 1 K lead (socket adapter set for sewing light)

0511 59 001 4 Laser marking (3 lights)

0510 59 003 4 Additional laser light

0511 59 003 4 Manual switch

0531 36 064 4 Button shank shaper unit inc. clamping feet

1

5 Frame

The following supporting frame is available for the button sewer 531.

MG55 40 029 4 Frame package

Table plate size 600 x 1060 mm

Frame height 1160 to 1,305 mm

6 Technical Data

Noises: Lc = 78 dB (A)

Work place-related emission value in accordance with DIN

45635-48-A-1-KL-2

Speed: 2,700 min

Material: G1 DIN 23328 2 layers

-1

7

Page 10

6.1 Technical data for the sub classes

Subclass: 211

Sewing stitch type: 301

Hook type: Oscillating hooks

Needle system: DPx17 (135x17)

Needle thickness: [ Nm] 80 - 110

Needle thickness [ Nm] 90

standard:

Thread thickness: 50/3 - 120/3

Stitch length: [mm] Depending on seam construction

Max. speed [min-1] 2700

Clamp elevation [mm] 9

On delivery

maximum 13

Sewing area [mm]

max. in X direction: 40

max. in Y direction: 20

Number of standard 50

button patterns

Number of patterns that can be saved

and/or modified 40

Number of sewing pattern

sequence programs 25

Number of sewing patterns per

sewing pattern sequence program 20

Number of free max. 9

seam contours

Soft start can be switched on and off

Sewing drive: DC motor

Rated voltage: [V] 1 ~ 230V/ 50/60 Hz

Power rating: [ kW ] 0.45

8

Page 11

7 Operation

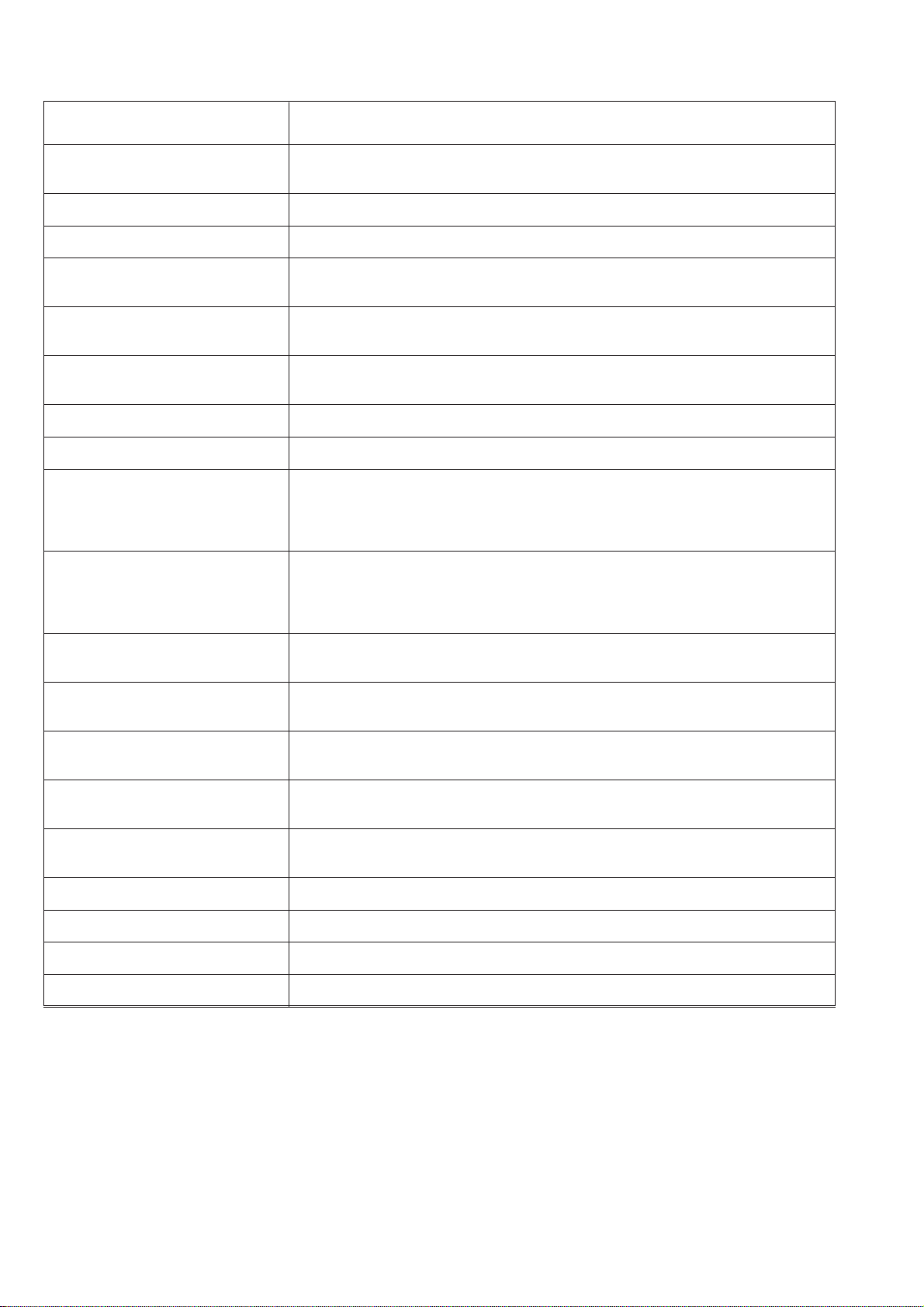

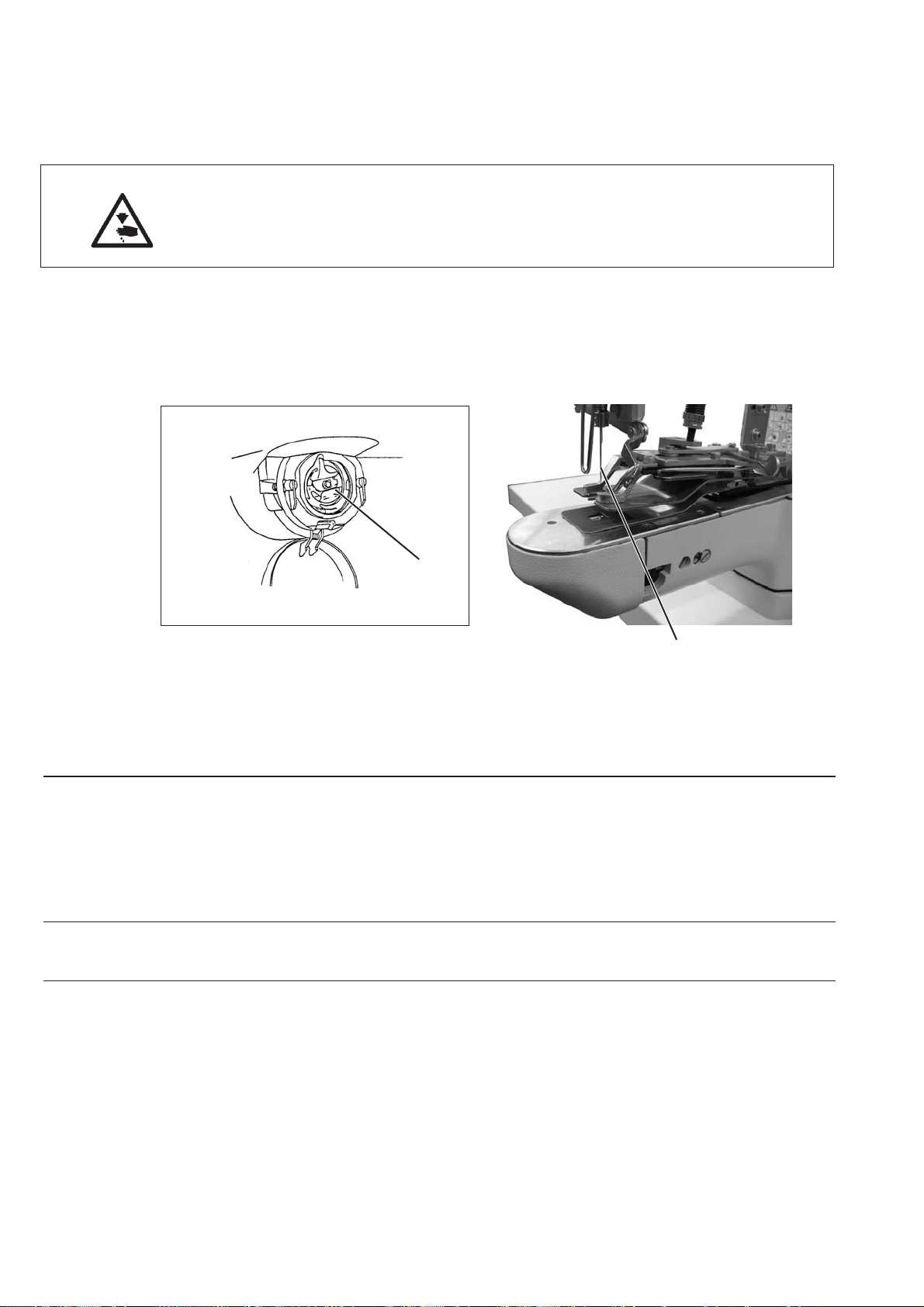

7.1 Threading needle threads

Caution, danger of injury!

Switch the main switch off.

Only thread needle threads when the button sewer is switched off.

–

–

Put reels of thread onto the thread stand and run t he needle and

hook threads through the feed arm.

The feed arm must be vertically above the thread reels.

Thread needle threads as shown in the following illustration

.

1

9

Page 12

7.2 Adjusting needle thread tension

32 1

Pre-tensioning 3

When the main tensioner 2 is open a slight residual tension on the

needle thread is required. The residual tension is created by the

pre-tensioner 3.

At the same time the pre-tensioner 3 affects the length of the cut

needle thread end (starting thread for the next seam).

–

Shorter starting thread:

Turn the knurled nut 1 clockwise.

–

Longer starting thread:

Turn the knurled nut 1 anti-clockwise.

Main tensioner 2

The main tensioner 2 must be set as low as possible.

The threads should intertwine in the middle of the material.

If the thread tensions are too great this could lead to unwanted

crimping and thread tearing with thin material.

–

Adjust the main tensioner 2 so that an even stitch pattern is

achieved.

To increase tension = turn the knurled nut

clockwise

To reduce tension = turn the knurled nut

anti-clockwise

7.3 Opening needle thread tensioner

Automatic

The needle thread tension opens automatically when the thread is cut

and when the material clamping feet are raised.

10

Page 13

7.4 Adjusting thread regulator

1

32 1

Caution, danger of injury!

Switch the main switch off.

Only adjust the thread regulator when the button sewer is switched

off.

The thread regulator 3 adjusts the amount of needle thread required to

form the stitch.

Only a precisely adjusted thread regulator guarantees optimum

sewing results.

If the adjustment is correct the needle thread loop must slide over the

thickest part of the hook with slight tension.

–

Undo screw 1.

–

Change the position of the thread regulator 3.

Thread regulator to the left = greater needle thread quantity

Thread regulator to the right = smaller needle thread quantity.

–

Screw up screw 1.

Adjustment note:

If the greatest amount of thread is required the thread take up spring

2 must be pulled down about 0.5 mm from its final upper position.

This is the case if the needle thread loop passes the maximum hook

diameter.

11

Page 14

7.5 Winding hook threads

:1

: 2000

:35

: 3.4/ 3.4

/ :6-6

/Ó: 0

: Aus

: Ein

5

1

4

3

2

6

–

Put the bobbin on the bobbin winder 4.

–

Pull the thread through the guide 2 and round the tensioner 1 .

–

Wind the thread anti-clockwise about 5 times round the coil

bobbin.

–

Push the bobbin lever 3 onto the bobbin.

–

Sew

The bobbin lever ends the procedure as soon as the bobbin is full.

–

After winding break the thread on the thread clamp 5.

Note!

Should the thread be wound without sewing

the thread winding mode can be switched to in the “Special functions”

sub menu.

12

When the thread winding mode is switched on the sewing motor can

be started with the pedal or the manual switch regardless of the

sewing area drive (here unthread threads on the thread lever).

For settings see Section 8.5.1 “Thread winding mode”.

Page 15

7.6 Changing hook thread bobbin

1

7

4

2

5

6

2

3

1

Caution, danger of injury!

Switch the main switch off.

Only change the hook thread bobbin when the button sewer is

switched off.

Removing the empty bobbin

–

Pull the hook cover 3 downwards.

–

Lift up the bobbin case latch 1.

–

Remove bobbin case 2 with bobbin 6.

–

Take the empty bobbin out of the bobbin case 2.

To insert a full bobbin

–

Insert a full bobbin into the bobbin case 2.

–

Thread the hook thread through slit 5 under the tensioning spring

7 into the hole 4.

–

Pull about 2.5 cm of hook thread out of the bobbin housing.

The bobbin must tur n in the direction of the arrow when the thread

is being pulled out.

–

Replace the bobbin case 2.

–

Close the bobbin case latch 3.

13

Page 16

7.7 Adjusting hook thread tension

1

2

3

Caution, danger of injury!

Switch the main switch off.

Only adjust the hook thread tension when the button sewer is

switched off.

The required hook thread tension should be created by the tensioning

spring 1. The bobbin case 3 should drop slowly under its own weight if

the threaded hook thread is to be held fast.

Adjusting the tensioning spring

–

Remove the bobbin case 3 and the bobbin.

–

Change the tensioning spring 1 with the adjustment screw 2 until

the required tension is reached.

–

Replace the bobbin case.

14

Page 17

7.8 Changing the needle

2

21

Caution, danger of injury!

Switch the main switch off.

Only change the needle when the button sewer is switched off.

–

Undo screw 1.

–

Push the new needle into the hole in the needle bar 2 until it can

go no further.

CAUTION!

The hollow channel 3 on the needle must point towards the hook.

–

Screw up screw 1.

CAUTION!

After changing to a different needle thickness the distance between

the hook and the needle must be adjusted (see Service instructions).

3

1

1

15

Page 18

7.9 Button shank shaper (optional)

1

The button clamp on the button sewer is fitted with a button shank

shaper 1.

Setting the shank length

–

To change the s etting of the button shank shaper 2:

downwards = shank becomes shorter

upwards = shank becomes longer.

2

16

Page 19

7.10 Adjusting the button clamp hook feet

21

Caution, danger of injury!

Take great care when adjusting the button clamp when the button

sewer is switched on.

The button should be pushed as lightly as possible between the hook

feet on the button clamp and can be aligned.

But the button must be securely clamped so that it cannot turn when

it is inserted into the material.

Stop 4 adjusts the amount the hook feet open.

–

Switch the button sewer on.

The button clamp lifts up.

–

Put the button to be sewn on between hook feet 1 and 2.

–

Undo knurled nut 3.

–

Move the stop towards the screw 5.

–

Tighten knurled nut 3.

–

Check whether the button can be inserted easily and aligned.

543

1

17

Page 20

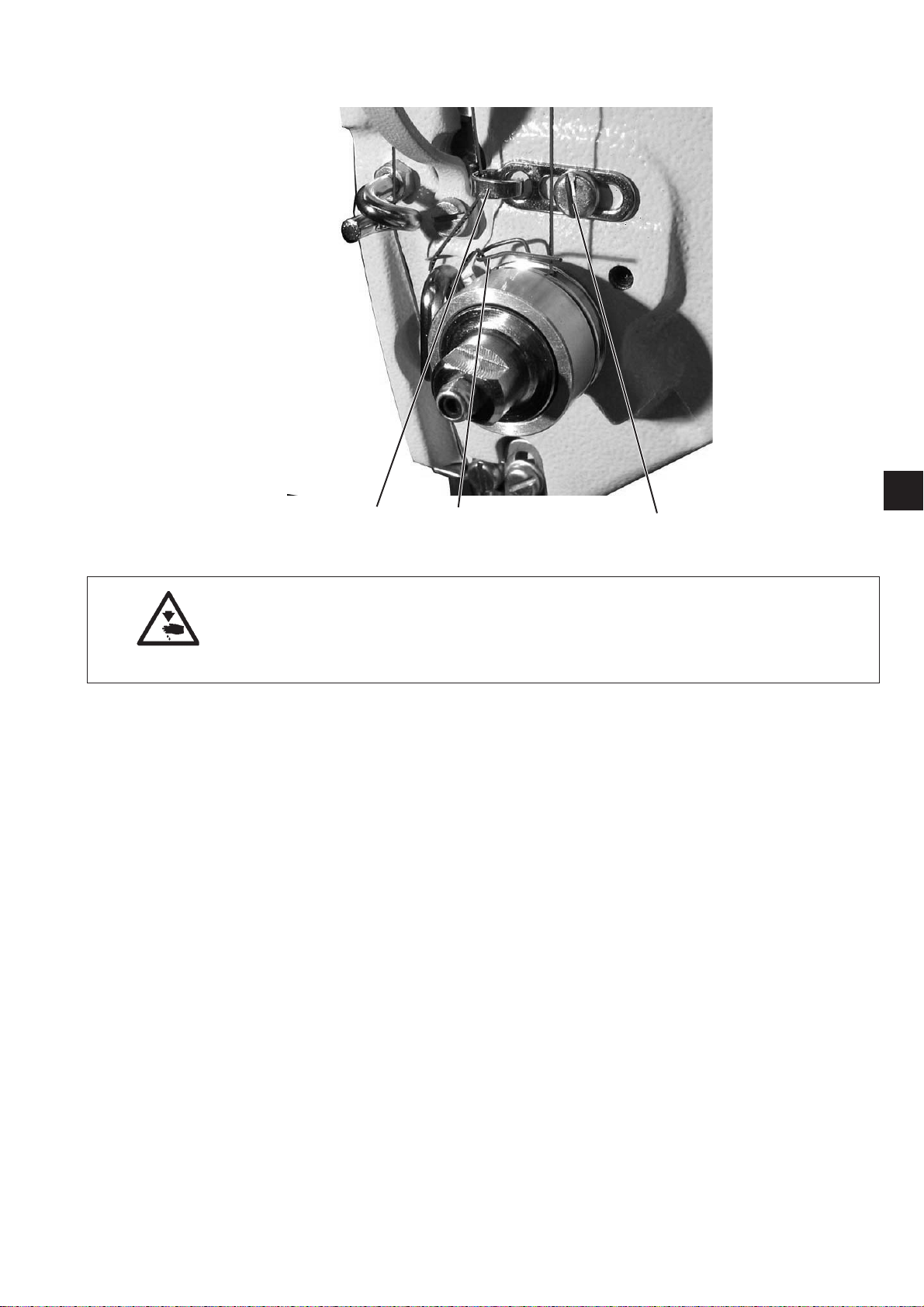

8 Operating the control unit 531

8.1 The operating terminal

An operating terminal with an LCD display and function buttons is

used for entering and outputting data.

P button: S button:

Programming mode Sequence

programming

ESC key F key

Technician mode

Cursor keys

OK key

8.1.1 The buttons

Function button Function

Cursor keys

If no input field is selected:

Press “ï” to get back to a sub menu in the higher menu.

If an input field is selected:

Switch between the positions (not when selecting the sewing patter n

or sequences).

18

In sewing mode with sequence mode:

Switch to the next or previous sewing patter n.

Page 21

Function button Function

If no input box is selected:

Switch between the rows in the menus.

The selected line is shown inversely.

If an input field is selected:

Increase or reduce the value of the relevant position by one or with

functions with several alter native options switch between the

parameters.

OK button If no input field is selected:

Select the input field.

The value can be changed with the “ñ “and“ò ” keys.

If an input field is selected:

The set value will be applied.

If the clamping foot has been lowered by pressing OK + F:

The test sequence starts.

ESC button If the test functions have started (Multitest / 180° disc):

You go back to the selection menu.

If an input box has been selected:

An entry is cancelled.

The previous value is retained.

1

At technician, programming level

The control unit switches to sewing mode.

In sewing mode

raise clamping foot and cancel sewing procedure.

P button The control unit switches from sewing mode to programming mode.

In this mode changed stitch patterns can be saved under a new

program number.

S button The control unit switches from sewing mode or s ewing pattern

programming mode to the sequence programming mode.

In this mode new sequences can be created or existing ones modified.

F button The control unit switches from sewing mode to technician mode.

This mode can only be selected by entering a code.

In this operating mode basic machine parameters can be set and

diagnosis and setting programs can be called up.

19

Page 22

8.2 User interface

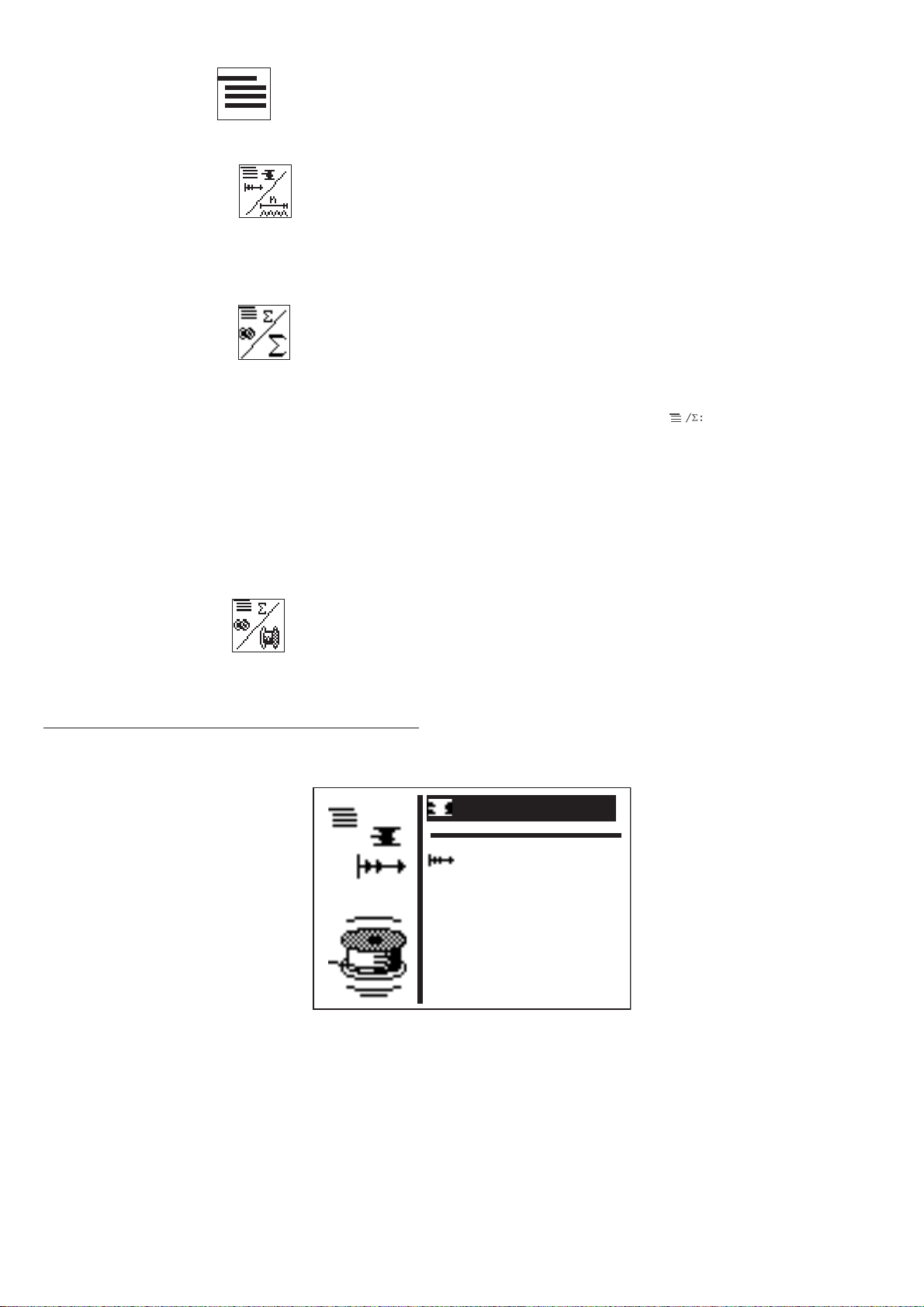

8.2.1 Menu structure

on

ESC key F key

Turn the main switch

F button

Service

menu

Codes 1

Sewing mode

P button Codes 1

Button

ESC

Programming mode Technician mode

S button

S button

P button

Sequence programming mode

Calling up the service menu

–

Press F and hold it down.

–

Turn the main switch on.

The control unit is initialized.

After a short time the window to enter the number code appears.

–

Enter the number code (Code 1 see Section 8.6.4).

The display changes to the service menu (see Section 8.6.4.3).

20

Page 23

Calling up technician mode

:1

: 2000

:35

: 3.4/ 3.4

/ :6-6

/Ó: 0

–

Switch the main switch on.

The control unit is initialized.

The sewing menu appears on the screen.

–

Press “F”.

–

Enter Code 1 (see Section 8.6.4).

–

Press “OK”.

The display changes to technician mode.

8.3 Changing number and parameter values, alternative selection

8.3.1 Changing number values

1

–

Select the required row by pressing “ñ”or“ò”.

–

“Press OK .

The selected number value is indicated by a flashing cursor.

–

Press “ï”or“ð” to toggle between the places.

Press “ñ”or“ò ” to increase or reduce the value of the selected

position.

–

“Press OK.

The value currently set is applied

or

–

“Press ESC.

The original value is retained.

Note

All values can only be changed within the minimum and maximum

values.

21

Page 24

8.3.2 Selecting a parameter

:1

: 2000

:35

: 3.4/ 3.4

/ :6-6

/Ó: 0

With some parameters it is possible to select settings that cannot be

modified.

–

Select the required row with the parameters to be changed by

pressing “ñ”or“ò ”.

–

Press OK.

–

Press “ñ“or“ò ” to switch between the specified options.

Example:

Sewing pattern number.

8.3.3 Alternative selection

–

Press OK.

The parameter currently set is applied.

or

–

“Press ESC.

The original parameter is retained.

Some menu items can be selected as an alternative to each other.

The current selection is indicated by a tick (...ü).

When selecting another alter native the mark on the current selection

is cancelled and the new menu item is indicated.

Items that can be selected as an alternative are visually separated

from the other menu items by a dividing line.

22

Page 25

8.4 Sewing pattern

Energiespar-Modus

There are three different sewing pattern types available for the button

sewer 531.

Fixed standard sewing pattern (type 1) (See section 11)

·

The length, width and sewing speed parameters can be changed

in sewing mode. The laser marking lights can be switched on and

off. The changes are saved.

After selecting another sewing pattern the changes are lost,

however.

Sewing pattern numbers 1 - 50 are available for this sewing

pattern that cannot be deleted or overwritten.

Programmable sewing pattern (type 2)

·

Fixed standard sewing patterns can be changed at programming

level (length, width, sewing speed, laser light 1 - 8) and saved

under a new program number.

Sewing pattern numbers 51 - 90 are available for this sewing

pattern that can be changed or overwritten.

Free seam contours (type 3)

·

Sewing pattern numbers 91 - 99 are available for these seam

contours. How to create free seam contours is described in

Section 8.6.5.4.

The length, width and sewing speed parameters can be changed

in sewing mode. The laser marking lights can be switched on and

off. The changes are saved.

When another sewing patter n is selected the changes are lost,

however.

1

8.5. Energy saving mode

25 sewing pattern sequence programs each with up to 20 sewing

·

patterns for each sewing pattern sequence program can be

created and saved.

The energy saving mode is selected after a time that can be set (1 - 60

minutes) or switched off completely (0 minutes) by using t5 in the

Machine configuration/timesmenu.

When this is selected the clamping foot is lowered to save energy and

thus reduce the amount of heat developed too.

The set time expires if no user entries are made via the control panel,

pedal or manual switch.

Before selecting the energy saving mode the message flashes t wice

as an indication that the clamping foot will be lowered immediately.

Then the message stays on the screen.

Normal mode is enabled again. The clamping foot is raised and the

message deleted if the user makes an entry using the control panel,

pedal or manual switch.

The machine is now ready for operation immediately.

23

Page 26

8.6 Main menu

:1

: 2000

:35

: 3.4/ 3.4

/ :6-6

/Ó: 0

8.6.1 Sewing pattern mode

The parameters for the individual sewing patter ns are arranged in the

main menu.

The sewing patterns can be changed with these parameters.

–

Switch the main switch on.

The control unit is initialized.

The main menu appears.

–

Select the required parameters by pressing “ñ”or“ò”.

The symbol for the selected parameters is shown inversely.

–

Change the selected parameters as described in Section 8.3.

Menu item

The symbol at the top left of the screen describes the currently

selected menu item.

Button image

The symbol at the bottom left of the screen shows the current button

pattern.

Sewing pattern

The sewing pattern to be sewn is selected with these parameters.

Selection:1..51(52-99ifavailable)

Speed

The required speed is set with these parameters.

Enter: 0 - 2700 rpm

24

Page 27

Overstitch thread tension (see Table 1)

: 3.4

: 3.4

: 0.0

: 0.0

The thread tension for overstitches is set with this menu item.

Enter: 0 … 100 0 = lowest thread tension

100 = highest thread tension

The thread tension magnet sets the thread tension in accordance with

the current value so that this can be checked.

If the fixing stitches are active (only with sewing pattern programs),

the thread tension values in all other areas (see Table 1) of t he sewing

pattern is changed too depending on the difference from the previous

value.

With standard sewing patterns (1 - 50) the thread tension in the

different areas is not set separately. If this is necessary a sewing

pattern program must be created.

Sewing pattern size/ s ewing pattern offset sub menu

Switch to this sub menu to set the sewing patter n size of the sewing

pattern offset. The current sewing patter n size is shown in the X and Y

direction.

1

Sewing pattern width

Setting the sewing patter n width

Enter: 0.1 … 40 mm

Sewing pattern length

Setting the sewing patter n length

Enter: 0.1 … 20 mm

Sewing pattern offset in X direction

To set the sewing pattern offset in the X direction

Enter: -20.0 … +20.0 mm

Sewing pattern offset in Y direction

To set the sewing pattern offset in the Y direction

Enter: -10.0 … +10.0 mm

25

Page 28

Sub-menu

: Aus

: Ein

There is a sub menu behind this symbol.

Number of stitches

With standard sewing patterns t his menu line displays the overstitch

distribution with the standard sewing patterns and the total number of

stitches with the free contours (cannot be changed).

Selecting the line by pressing “OK” takes you to the “Special

functions” sub menu.

Daily unit counter or capacity counter sub menu.

Selecting the line by pressing “OK” takes you to the “Daily piece

counter or the capacity counter” sub menu.

Resetting the daily piece counter

–

Press “ñ”or“ò ”toswitchtothe menuitem.

–

Hold “OK” down for 3 seconds until the number displayed goes

back to 0.

The daily piece counter can also be reset in this w ay if the capacity

level is displayed. However, the value does not go back to 0.

or

Capacity counter

Selecting the line by pressing “OK” takes you to the “Daily piece

counter or the capacity counter” sub menu.

Special function and soft start status sub menu

26

Thread winding mode

The hook thread winder can be operated separately.

The sewing motor can be started with the pedal or manual switch

regardless of the step motors if ON is set.

Enter: ON / OFF

Page 29

Winding hook thread bobbins:

With the pedal

–

Move the pedal forwards (position 2).

The sewing motor starts.

–

Move the pedal back.

The sewing motor stops.

Using the control panel

–

Press “F”.

The sewing motor starts.

–

Press “ESC”.

The sewing motor stops.

With manual switch (optional)

–

Press switch 2.

The sewing motor starts.

–

Press switch 1.

The sewing motor stops.

1

Soft start

The soft start can be switched on or off with this parameter.

Enter: ON / OFF

Laser marking lights sub menu (optional)

This menu item is only displayed if the laser light option

is switched on in the Fittings menu (see Section).

Laser lights 1 ...3

Switching the laser marking lights 1 - 3 on or off

Enter: ON / OFF

27

Page 30

Daily piece counter or capacity counter sub menu.

P

Alternative display of daily piece counter or capacity counter.

Both counters work in parallel.

The counter that is to be displayed in the main menu can be selected.

The daily piece counter counts the number of sewing patter ns

·

sewn

Display: 0 … 65000

The hook thread counter works backwards.

·

When the value 0 is reached and a sewing procedure starts a

message appears.

Display: 9999 … 0

–

“Press ESC .

This switches back to the main menu.

If the daily piece counter is set the following appears:

Daily piece counter display in sewing mode

Enter: Select by pressing OK.

Capacity counter display in sewing mode

Enter: Select by pressing OK.

Capacity counter on/off

Enter: ON / OFF

Initial capacity counter value

Enter: 0 … 9999

28

Page 31

8.6.2 Programming mode

:51

:1

: 2000

:35

: 3.4/ 3.4

: 0.0/ 0.0

: 0/ 0.5

: 0/ 0.5

The parameters for programming sewing patterns are arranged under

this menu item.

The shape, length, width and speed etc. of the sewing patter n are

entered using the parameters.

–

Switch the main switch on.

The control unit is initialized.

The main menu appears.

–

When the main menu appears press P.

The display switches to the programming mode display.

–

Select the required parameters by pressing “ñ”or“ò”.

The symbol for the selected parameters is shown inversely.

–

Change the selected parameters as described in Section 8.3.

1

Sewing pattern number

The sewing pattern number that is to be created or changed is

selected using this parameter.

When creating a new program an asterisk (*) is displayed before the

number.

Enter: 51 … 90

–

Select the required sewing pattern program by pressing “ñ”or

“ò”.

–

“Press OK.

The program is selected.

Basic sewing pattern

A default sewing pattern can be selected with this parameter. The

new sewing pattern is to be created based on this.

Enter: 1 … 50 or

91 … 99 if available.

Sewing speed

The required sewing speed is set with this parameter.

Enter: 0...2700 rpm

29

Page 32

Thread tension sub menu

Switch to this sub menu to set the thread tension.

The values displayed correspond to the thread tension in area 2

(overstitches).

Securing stitch sub menu

Switch to this sub menu to change the parameters for the securing

stitches. The current values are displayed (number/ distance between

the stitches).

Interloop stitch sub menu

Switch to this sub menu to change the parameters for the interloop

stitches. The current values are displayed (number/ distance between

the stitches).

Distance betw een button holes sub menu

Switch to this sub menu to set the distance between button holes in the

X and Y direction seePage25).

Display: current distance between button holes X/Y

Sewing pattern offset sub menu

Switch to this s ub menu to move the sewing pattern in the X and Y

direction (see Page 25).

Display: current X offset/ Y offset

Stitch distribution/ number of stitches

Displays the overstitch distribution (with standard sewing patterns) or

total number of stitches (with free contours).

Soft start

The soft start can be switched on or off with this parameter.

Enter: ON / OFF

Laser marking lights sub menu (optional)

This menu item is only displayed if the laser light option is switched on

in the Fittings menu.

Laser lights 1 ...3

Switching the laser marking lights 1 - 3 on or off

Enter: ON / OFF

30

Page 33

Thread tension sub menu

:35

:35

:35

Ó :0

: 0.5

Thread tension for securing stitches

The thread tension for securing stitches is set with this menu item.

This menu item is only displayed if 0 is not set for the number of

securing stitches.

Overstitch thread tension

The thread tension for overstitches is set with this menu item.

Interlooped stitch thread tension

The thread tension for interlooped stitches is set with this menu item.

This menu item is only displayed if 0 is not set for the number of

interlooped stitches.

Thread tension area 2 … 4

With sewing pattern programs with a free seam contour as the basic

sewing pattern these menu items are displayed if they have been

programmed as stitch operations in the free seam contour.

Enter: 0 … 100 0 = lowest thread tension

100 = highest thread tension

Securing stitch sub menu

The number and distance between the securing stitches at the start of

the seam can be set. The distance between the securing stitches

remains at the set amount even if the sewing patter n is scaled.

1

31

Page 34

Number of securing stitches

Ó :0

: 0.5

The number of securing stitches at the start of the seam can be set

here.

Enter: 0 … 3 (0 = no securing stitches)

Distance between securing stitches

The distance between the securing stitches in the X and Y direction

can be set here.

Enter: 0…1.0mm

When sewing a sewing pattern without securing stitches it is possible

that, because of a very small number of stitches, the specified speed

will not be reached particularly with sewing patter ns with interim

cutting. If necessary the soft start function can be switched of or the

soft start speed adjusted to achieve an increase in speed.

Interloop stitch sub menu

The number and distance between the interloop stitches at the start of

the seam can be set. The distance between the interloop stitches

remains at the set amount even if the sewing patter n is scaled.

Number of interloop stitches

The number of interloop stitches at the s tart of the seam can be set

here.

Enter: 0 … 3 (0 = no interloop stitches)

Distance between interloop stitches

The distance between interloop stitches at the end of the seam can be

set here.

Enter: 0…1.0mm

When sewing a sewing pattern without interloop stitches it is possible

that, because of a very small number of stitches, the specified speed

will not be reached particularly with sewing patter ns with interim

cutting. If necessary the soft start function can be switched of or the

soft start speed adjusted to achieve an increase in speed.

32

Page 35

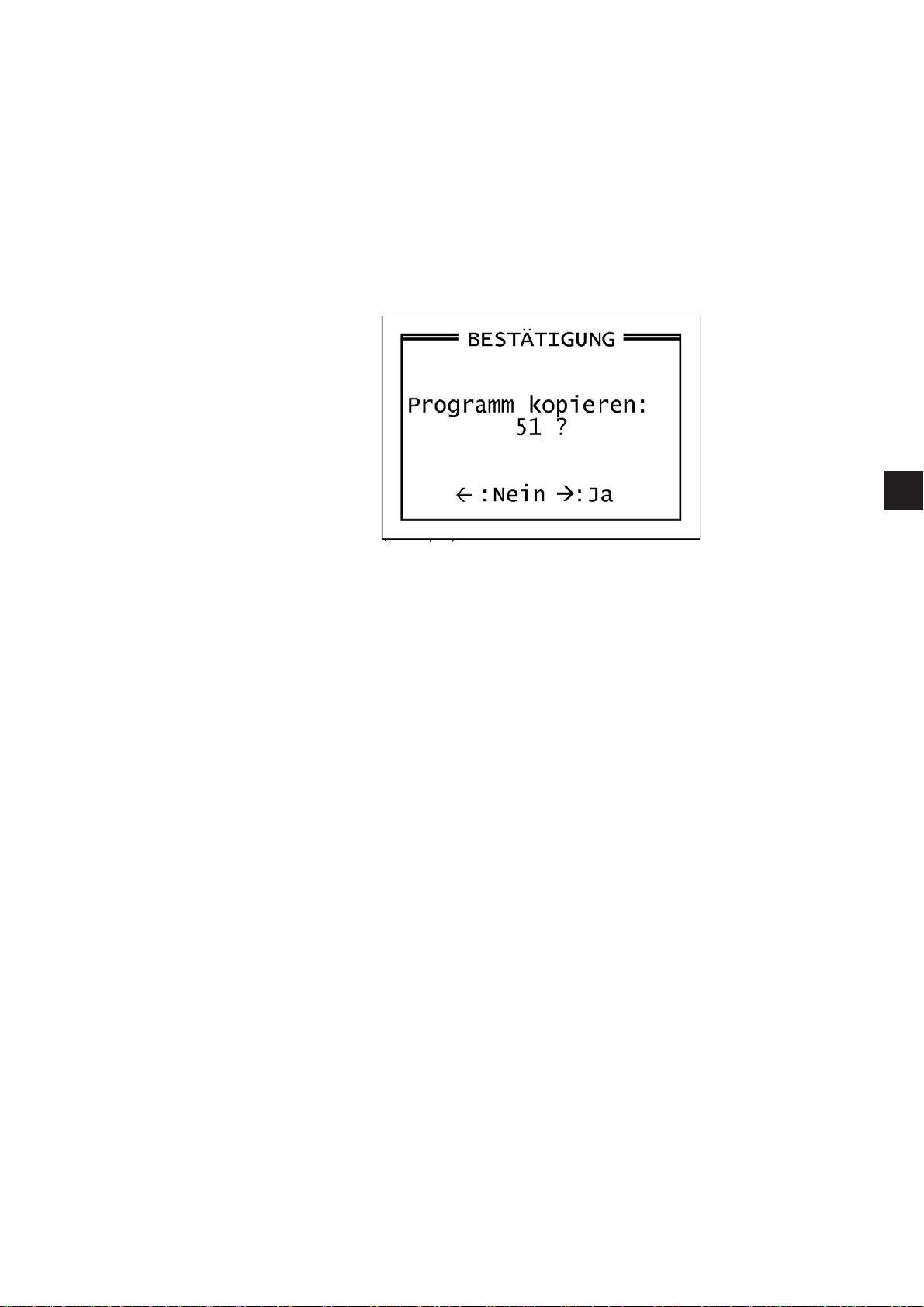

8.6.3 Copying function for sewing pattern programs

Any number of sewing patterns can be copied at programming level:

–

Press P to switch from the main screen to the sewing pattern

programming mode.

–

Press OK to select the sewing pattern program to be copied with

the “ñ”and“ò” cursor keys. Then confirm by pressing OK.

–

Press P to start the copying process. A dialogue box appears to

confirm:

1

(Example)

–

Press “ð” (Yes) to start the copying procedure. A copy of the

selected sewing pattern is attached to the existing ones and

selected as the current one.

–

Press “ï” (No) to cancel the copying procedure.

33

Page 36

8.6.4 Sewing pattern sequence (sequences)

: Aus

:1

01-02-51-91

: 2000

:35

: 3.4/ 3.4

/ :6-6

/Ó: 0

8.6.4.1 Switching sewing pattern sequence operation on and off

Switching from sewing pattern mode to sewing patter n sequence

mode

–

With the main menu displayed press S to go to the sequence

programming mode.

–

Press OK to start editing the sequence numbers.

–

Press ñ to select any sequence (1-25)

–

Press OK to confirm the selection.

The sewing pattern sequence mode is switched on.

–

Press ESC or “ï”.

The main menu for the sewing patter n sequence mode appears.

34

The sequence number and sequence menu items in the main menu are

described at the end of this section.

Page 37

Switching from sewing pattern sequence mode to sewing pattern

:1

01-02-51-91

: 2000

:35

: 3.4/ 3.4

/ :6-6

/Ó: 0

:1

: 2000

:35

: 3.4/ 3.4

/ :6-6

/Ó: 0

mode

–

With the main menu displayed press S to go to the sequence

programming mode.

–

Press OK to start editing the sequence numbers.

–

Press “ò” to select sequence number 0.

–

Press OK to confirm the selection.

The sewing pattern sequence mode is switched off.

–

Press ESC or “ï”.

The main menu for the sewing patter n mode appears.

1

35

Page 38

Menu items in the main menu in sewing pattern mode

01-02-51-91-

...51-91-01-02

...02-51-91-01-...

01-02-51-91

0102 51 91

01-02-51-91

01 02 51 91

01 02 51 91

Sequence

Selecting the sewing patter n sequence.

Enter: 1 (2 - 25, if available)

Sequence

Displaying the sequence.

The current sewing pattern number is indicated with a bar

(underlined).

The display scrolls if there are more than five numbers.

–

More sewing patterns to the right:

More sewing patterns to the left:

More sewing patterns to the left and right:

Automatic mode

After sewing a sewing pattern the control unit automatically switches

to the next sewing patter n.

After sewing the last sewing pattern the control unit switches back to

the first sewing pattern in the sequence.

The current sewing pattern is indicated by a bar under the number.

The design of the s elected sewing patter n is displayed in the left half

of the display.

Manual operation

The control unit does not switch automatically between sewing

patterns.

–

Press “ï”or“ð” to display the next sewing pattern.

The design of the s elected sewing patter n is displayed in the left

half of the display.

Switching between automatic and manual mode

–

Press “ñ”or“ò ” to s elect the second menu line (sequences).

–

Press OK.

–

Press “ñ”or“ò ” to s elect the operating mode.

An arrow will be displayed between the sewing patter ns in

automatic mode.

36

Automatic mode

Manual mode

Page 39

8.6.4.2 Sequence programming mode

: Aus

This menu item combines the individual sewing patterns for the

sewing pattern sequences that can be called up.

There is a total of 25 independent sewing pattern sequences

available. Each sewing pattern sequence can be made up of 20

sewing patterns in any order.

The sewing pattern sequence mode can also be switched on in this

menu.

–

Switch the main switch on.

The control unit is initialized.

The main menu appears.

–

When the main menu appears press S.

The display switches to the sequence programming mode.

–

Select the required menu item by pressing “ñ”or“ò”.

The menu line shown inversely.

–

“Press ESC or ï.

This switches back to the main menu.

Sequence number/ sewing patter n sequence mode

Selecting the sequence to be created or changed.

When creating a new program an asterisk (*) will be displayed before

the number.

Enter: 0 … 25

–

Select the required sequence number by pressing “ñ”or“ò”.

Should sewing pattern sequence mode be switched off select

sequence number 0.

The sequence number is shown inversely.

–

“Press OK.

The program is selected.

Sewing pattern number (1 .. 20)

This menu item is used to select the sewing patter n number that is to

be included in the current sequence.

Enter: 1 … 51 (52 - 99 if available)

1

37

Page 40

8.6.5 Technician mode

The following menus are included in technician mode:

Machine configuration

Machine-specific settings are configured in this menu.

User configurations

Operation-specific settings are configured in this menu.

Service functions

Service functions enable a rapid check of all hardware components.

Free contours

Up to nine freely defined seam contours can be created and sewn with

the button sewer 531. The co-ordinates are entered directly on the

control panel.

Memory dongle

Data can be transferred from the machine to the dongle or loaded

from there onto the machine using the memory dongle support.

Cycle time

Displays the cycle time of the last sewn sewing patter n.

(Time from start to end of sewing).

38

Page 41

Calling up technician mode

0****

Code

Maschine c

Benutzer

Service

Freie Konturen

Memory-Dongle

:----

–

Switch the main switch on.

The control unit is initialized.

The main menu appears.

–

When the main menu appears press F.

The display switches to the code query menu.

–

Enter code number “25483”(Code1).

The display switches to technician mode when the right code

number has been entered.

–

Press “OK” to confirm.

The following menu appears:

1

–

Select the required sub menu by pressing “?”or“?”.

–

Press “OK” to switch to the selected sub menu.

39

Page 42

8.6.5.1 Machine configuration

Parameter c

Softstart

Einrichtung

Zeiten

Ó

:262

Parameters

Various machine parameters can be set using this sub menu.

Soft start

The speeds for the soft start ramp can be set in this sub menu.

Equipment

The parameters for the sewing equipment and optional units can be

set in this sub menu.

Times

The different t imes can be set in t his sub menu.

Machine cycles

The total number of sewn cycles is displayed.

40

Page 43

Machine parameters

Absch.dz.: 210

Max.Dz.: 2500

Stoppos.: -15

Einlegepos.: A

Referenz.: 1

Kl.Fuß-Lüft: A

W.Rückdr.: 0

W.Fsp öf.: 320

–

Select the required parameters by pressing “?”or“?”.

The symbol for the selected parameters is shown inversely.

–

Start the selected parameters by pressing OK or switch to the sub

menu.

Cut off speed

Enter the sewing motor speed in the last three stitches.

Enter: 200 … 300 [rpm]

Maximum sewing speed

Enter the maximum sewing speed that can be set

Enter: 200 … 2700 [rpm]

Stop position

The positioning of the s ewing motor or needle bar can be changed

using the stop position.

Enter: 0 = Thread lever is at the upper dead center

(needle bar is lower)

-15 = Thread lever is 15° off the upper dead center

(Needle bar is higher)

Feed position

Selecting the feed position for the material.

Enter: A = Seam starting point

B = Machine zero point

1

Note

The following advantages or disadvantages arise depending on the

feed position:

Feed point A = low cycle time

Feed point B = easier feed for larger

sewing patterns, longer c ycle time.

41

Page 44

Referencing

The behavior for referencing the step motors after a sewing procedure

can be configured using this menu item.

Enter : 0 = no referenc in g

1 = reference each time

2 – 10 = after every 2nd - 10th sewing procedure.

Raising the clamping foot

Setting whether the clamping foot is to be raised after referencing the

step motors.

Enter: A = the clamping foot is raised before referencing.

B = the clamping foot is raised after referencing.

Sewing motor reverse rotation angle

After the end of t he sewing procedure it is possible to rotate the

sewing motor backwards so that the needle can reach a higher

position. Before the next sewing procedure the needle position is

moved once more to the sewing motor stop position. The angle that

the sewing motor is to be back rotated can be set.

Enter: 0 … 70° ( 0° = back rotation switched off)

(70° = highest needle position)

Opening the thread tension angle

Setting the angle to open the thread tension in the last stitch.

Enter: 200° … 355°

The thread tension is opened before reaching the thread cut off

position. Thus only the mechanical pre-tensioning works in the cutting

procedure.

All angles are given from the sewing motor reference position.

42

Page 45

Soft start

1. Stich: 400

2. Stich: 400

3. Stich: 1000

4. Stich: 2700

5. Stich: 2700

The speed parameters for the soft start can be set in this sub menu.

Speed of 1st stitch

Enterthespeedforthefirststitch.

Enter: 400...900 [rpm]

Speed of 2nd stitch

Enter the speed for the second stitch.

Enter: 400 … 2700 [rpm]

1

Speed of 3rd stitch

Enter the speed for the third stitch.

Enter: 400 … 2700 [rpm]

Speed of 4th stitch

Enter the speed for the fourth stitch.

Enter: 400 … 2700 [rpm]

Speed of 5th stitch

Enter the speed for the fifth stitch.

Enter: 400 … 2700 [rpm]

43

Page 46

Equipment

The parameters for the sewing equipment can be set in this sub menu.

Note

Entering the clamping foot number automatically checks whether the

sewing pattern currently to be sewn is in the material support plate

opening.

If there are no specified clamping feet free dimensions can also be

defined.

Clamping foot

Selecting a fixed clamping foot as a device.

Enter: Alternative:

Free dimensions

Selecting a clamping foot with free sewing field

dimensions.

Enter: Alternative:

Number

Selecting a DA clamping foot number.

Enter: 1

Clamping foot number Material support plate Description

opening

dimensions X x Y (mm)

1 10x10 buttonclamps

For technical reasons and to provide a safety margin t he sewing

field is smaller than the material support plate opening.

44

Page 47

Length

Entering a freely selectable sewing field length.

Entry only possible if “free clamping measurement”

has been selected. Otherwise the length/ width of the

selected clamps are displayed (cannot be changed).

Enter: 0.5 … 20.0

Width

Entering a freely selectable sewing field width.

Entry only possible if “free clamping measurement”

has been selected. Otherwise the length/ width of the

selected clamps are displayed (cannot be changed).

Enter: 0.5 … 40.0

Equipment

Optional units can be

activated using this sub menu.

1

45

Page 48

Fittings sub menu

Handtast.: Aus

El.Fw.: Ein

Laserl.: Aus

Belegung Eing.

Belegung Ausg.

Manual switch

Activating the optional manual switch. If this option has been selected

a menu item to select the operating mode appears in the “User

configuration” menu.

Enter: ON / OFF

Electrical thread wiper

Switching the electrical thread wiper on/off.

Enter: ON/OFF

Laser lights

Activating the 3 optional laser lights.

Enter: ON / OFF

Assigning the inputs

This menu item gives an overview of the assignment of the inputs with

(optional) units.

Assigning the 24V outputs

This menu item gives an overview of the assignment of the 24v

outputs with (optional) units.

46

Page 49

Times sub menu

t1: 100

t2: 120

t3: 50

t4: 70

t5: 15

Waiting time between pedal position 1 (lower clamping foot) and

start of sewing (t1).

Time only relevant with rapid start using the pedal or the hand switch

(optional).

Enter: 50 ...300 ms

Default value: 150 ms

Switch on time for t hread wiper magnet (t2)

This menu item is only displayed if the electrical thread wiper option is

switched on in the Fittings menu.

Enter: 30 ...100 ms

Default value: 40 ms

1

Time when thread wiper magnet off - clamping foot magnet on (t3)

Waiting time between the thread wiper magnets being switched off

and the clamping foot magnets being switched on.

This menu item is only displayed if the electrical thread wiper option is

switched on in the Fittings menu.

Enter: 0 ...300 ms

Default value: 50 ms

Waiting time between clamping foot magnet coming on and the

refere n c e run (t4 ) .

Waiting time between the clamping foot magnets being switched on

and the step motors being referenced.

Enter: 0 ...300 ms

Default value: 70 ms

Time for activating energy saving mode (t5)

Waiting time between any operating component being operated

(control panel, pedal, manual switch) until energy saving mode is

activated.

Enter: 0 … 60 min 0 = energy saving mode

switched off

47

Page 50

8.6.5.2 User configuration

Sprache 0

Handtaster: A

Par.sperr: Aus

Nähm.sperren

Sequ.sperren

Operation-specific settings are configured in this menu.

–

Select the required parameters/ sub menu by pressing “?”or“?”.

The selected parameters/sub menu are shown inversely.

–

Start the selected parameters by pressing OK or switch to the sub

menu.

Language

The language can be selected in this sub menu.

48

German

Selects German for the technician level.

English

Selects English for the technician level.

Parameters

Selects the numbering of the menu items for

technician level.

Page 51

Manual switch operating mode (optional)

Selecting the manual switch mode.

This menu item is only available if the “manual s witch” option is

activated in the Fittings menu.

Enter: A = Rapid start

B=Normal

In the “NORMAL” manual switch mode the switches have the

following functions:

Switch 1:Raising and lowering the clamping foot.

Stopping the sewing procedure.

Cancelling the sewing procedure when it has been stopped.

Switch 2:Start sewing when the clamping foot is lowered.

Stopping the sewing procedure.

Continuing the sewing procedure when it has been stopped.

In the “RAPID START” manual switch mode the switches have the

following functions:

Switch 1:Raising and lowering the clamping foot.

Stopping the sewing procedure.

Cancelling the sewing procedure when it has been stopped.

Switch 2:Start sewing.

If the clamping foot is not lowered it is lowered.

Stopping the sewing procedure.

Continuing the sewing procedure when it has been stopped.

1

Parameter blocking

Switching the ability of parameters to be changed on or off in sewing

and programming modes.

Enter: ON / OFF

Note

If the parameter block is switched on no parameter changes are

possible any more in sewing and programming modes.

49

Page 52

Blocking sewing patterns

Alle sperren 0

Alle freigeben

2: Ein

3: Ein

4: Ein

5: Ein

6: Ein

7: Ein

Individual sewing patterns can be released for selection or blocked in

this sub menu.

The following restrictions normally apply:

1. Sewing pattern mode

The sewing pattern currently selected in sewing mode cannot be

·

blocked.

Blocked sewing patterns cannot be selected from the selection list

·

in sewing mode.

Blocked sewing patterns are indicated by “#”.

2. Sewing pattern sequence mode

A blocked sewing pattern can be selected in a sequence. At the

·

start of the sewing sequence (when the clamping foot is lowered,

an error message appears, however. The sewing sequence cannot

be started.

The last selected sewing pattern in sewing mode cannot be

·

blocked.

Block all

All sewing patterns are blocked with the aforementioned restrictions.

The status of the s ewing pattern numbers displayed switches to

“OFF”.

Activate all

All sewing patterns are activated.

The status of the s ewing pattern numbers displayed switches to

“ON”.

Blocking/ activating individual sewing patter ns

Enter: ON / OFF

50

Page 53

Blocking sequences

Alle sperren 0

Alle freigeben

2: Ein

3: Ein

Individual sequences can be released for selection or blocked in this

sub menu.

The following restrictions normally apply:

1. Sewing pattern mode:

The last selected sequence in sequence mode cannot be blocked.

·

2. Sewing pattern sequence mode:

1

The sequence currently selected in sewing mode cannot be

·

blocked.

Blocked sequences cannot be selected from the selection list in

·

sewing mode.

Blocked sequences are indicated by “#”.

Block all

All sequences are blocked with the aforementioned restrictions.

The status of the sequence numbers displayed switches to “OFF”.

Activate all

All sequences are activated.

The status of the sequence numbers displayed switches to “ON”.

Blocking/ activating individual sequences

Enter: ON / OFF

51

Page 54

8.6.5.3 Service functions

Service functions enable a rapid check of all hardware components.

Note

The service menu can be reached directly when switching the

machine on (see Section 8.2.1).

Multi-test

All hardware components can be checked in the Multi-test menu.

180° disc

This menu item makes a function available to set the referencing of

the sewing motor (180° disc) correctly (see Service instructions).

Events

Initialization

Using this menu the events memory and the permanent data can be

reset to factory settings.

52

Page 55

Multi-test

Ausgangstest e

PWM-Ausg.test

Eingangstest

Auto-Eing-Test

Nähmotortest

Schrittm.test

RAM-Test

EEPROM-Test

Selecting the Multi-test sub menu

Caution, danger of injury!

Do not put your hands into the running machine during the function

check of the output components.

1

Risk of breaking!

When testing individual output components first of all check whether

collisions may occur when the machine moves.

53

Page 56

Output test

Ausgang Y1: -

Ausgangstest

The function of the output components is checked with this test

function.

–

Start the test function by pressing OK.

–

Select the required output component by pressing “?”or“?”.

–

Switch the selected output component on or off by pressing OK.

–

To exit the test function press ESC.

Caution, danger of injury!

Do not put your hands into the running machine during the function

check of the output components.

Output Function

component

Y1 Thread wiper magnet

Y4 Thread tension magnet

Y21 Laser marking light 1, if option is activated

Y22 Laser marking light 2, if option is activated

Y23 Laser marking light 3, if option is activated

Cf. also paragraph 8.7 Distributor circuit board

54

Page 57

PWM output test

Ausgang Y31: 0

PWM-Ausgangstest

The function of the magnets is checked with this test function.

–

Start the test function by pressing OK.

–

Select the required output component by pressing “?”or“?”.

–

Switch the selected output component on or off by pressing OK.

–

The current that is flowing through the clamping foot magnet is

displayed.

–

To exit the test function press ESC.

1

Caution, danger of injury!

Do not put your hands into the running machine during the function

check of the output components.

Output component Function

Y31 Clamping foot magnet

Cf. also paragraph 8.7 Distributor circuit board

55

Page 58

Input test

Eingang S14: -

Eingangstest

The input components to be tested are selected with this test

function.

CAUTION!

The input components are set carefully at the factor.

Configuring and correcting them must only be done by trained service

personnel.

–

Start the test function by pressing OK.

–

Select the required input component by pressing “? ”or“?”.

The switching status of the input component is displayed.

–

Input component Function

S1 Manual switch 1, if the option is activated

S2 Manual switch 2, if the option is activated

S14 Pedal A

S15 Pedal B

S16. Pedal C

S17 Pedal D

N ref. Sewing motor reference switch

X ref. X refe re nc e switch

Y ref. Y refere n ce switch

To exit the test function press ESC.

The Multi-test menu appears.

56

The current assignment of the inputs is specified in the Fittings menu

in the “Assignment of inputs” sub menu.

Cf. also paragraph 8.7 Distributor circuit board

Page 59

Auto input test

Eingang S14: -

Auto-Eing-Test

The function of the input components is checked with this test

function.

–

Start the test function by pressing OK.

–

Operate the required input component.

The switching status and number of the input component operated

are displayed.

–

To exit the test function press ESC.

The Multi-test menu appears.

To assign input components see the Input test table.

1

57

Page 60

Sewing motor test

Nähmotortest

The sewing motor can be checked with this test function.

–

Start the test function by pressing OK.

–

Startthemotorbypressingñ.

–

Change the speed by pressing “?”or“?”.

The speed is displayed.

–

Press ESC.

The test finishes and the motor stops.

The sewing motor control unit performs a reference run and the

clamping foot is raised.

The Multi-test menu appears on the display.

58

Page 61

Step motor test

0

0+

+

Schrittmotortest

The step motors and the associated reference switches can be

checked with this test function.

CAUTION Risk of breaking!

Move the needle upwards with the hand wheel before the test.

–

Start the test function by pressing OK.

–

Check the step motor for transverse movement (X axis).

Move the step motor by pressing “ï”or“ð”.

The number of steps moved is shown by the arrow on the left.

The status of the reference switch is modified by the reference

setting.

–

Check the step motor for lengthwise movement (Y axis).

Move the step motor by pressing “ñ”or“ò”.

The number of steps traveled is shown above the arrow.

The status of the reference switch is modified by the reference

setting.

1

–

Press ESC.

The test finishes.

The Multi-test menu appears on the display.

59

Page 62

RAM test

The memory (SRAM and program data memory) is checked with this

test function.

–

Start the test function by pressing OK.

The test results are displayed.

Display Explanation

SRAM OK The memory is working properly

SRAM ERROR Error in the memory

NV-RAM OK Program data memory is OK

NV-RAM ERROR Error in program data memory

–

Press ESC.

The test finishes.

The Multi-test menu appears on the display.

60

Page 63

EEPROM test

ROM-Gr.: 675k

Klasse: 531

Version: A01.0

Datum: 30.09.09

Checks.: 0x1234 Ok

EEPROM-Test

This test function checks the microprocessor’s programmable read

only memory (ROM).

–

Start the test function by pressing OK.

The display shows the following rest results:

-ROMsize

- Machine class

- Software version

- Software date

- checksum and status

1

Note:

The details change depending on the software version.

–

Press ESC.

The test finishes.

The Multi-test menu appears on the display.

61

Page 64

Events

Ereignissp. .

Letzte Ereign.

E4304 3 x

E8254 1 x

Ereignisspeicher

1 E4304 Z 1154889

S 263

2 E4304 Z 1152558

S 263

3 E8254 Z 1150034

S 263

Letzte Ereignisse

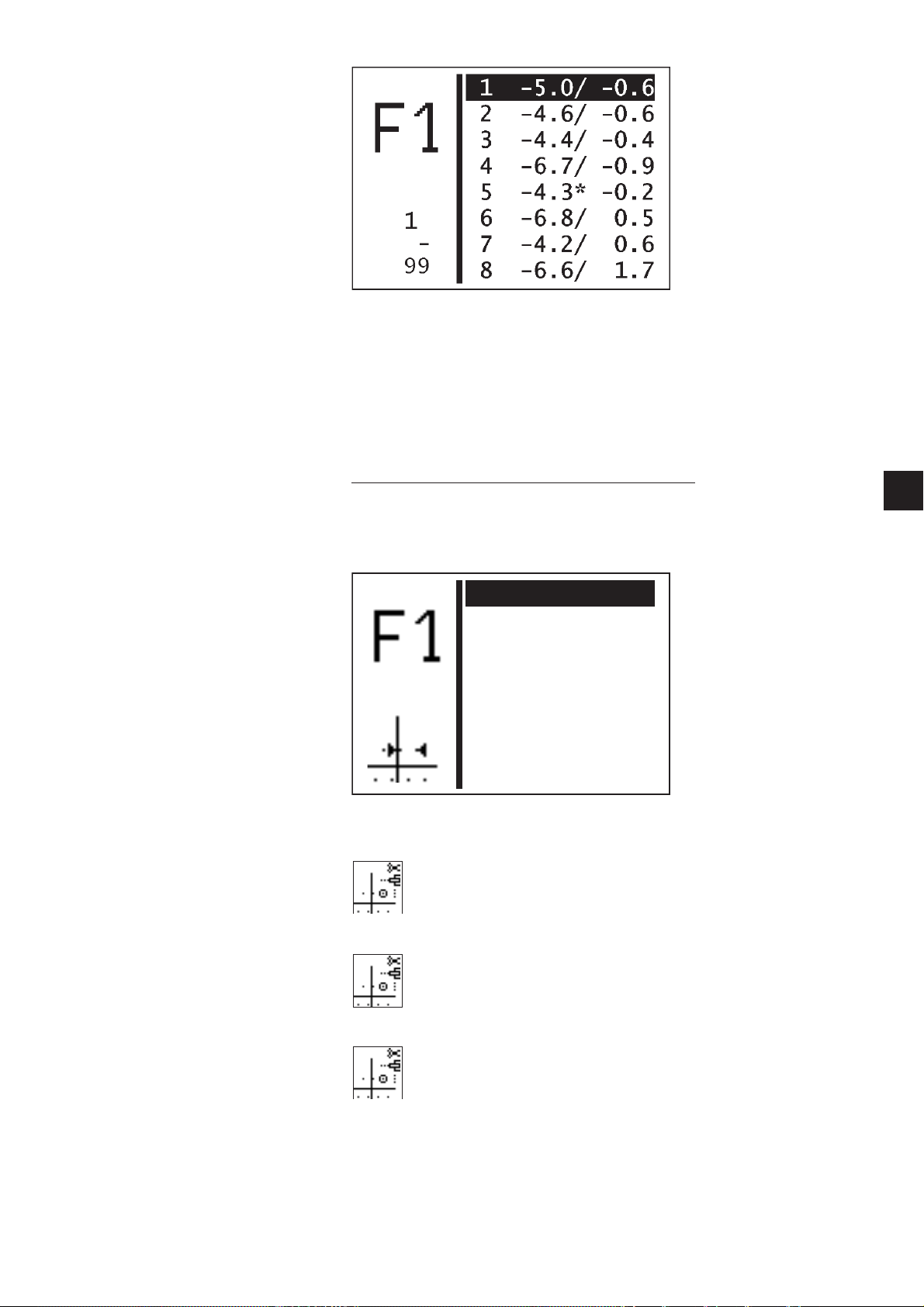

In the event of a malfunction the menu can give important information

on the cause of the malfunction.

Event memory

62

(Example)

All events that have occurred are displayed in this menu item.

–

Exit the menu item by pressing ESC.

–

Display again by pressing ò .

Latest events

(Example)

The latest events that have occurred are displayed in this menu item.

Z = milliseconds after switching the machine on

S = Machine unit c ounter

E = Event/ error number

–

Exit the menu item by pressing ESC.

–

Display again by pressing ? .

Page 65

Initializing (Init)

Ereignissp. e

Progr./Sequ.

Masch./Benutz.

Fr. Konturen

Maschine kpl.

Selecting the sub menu to initialize the event memory and permanent

data.

Event memory

The event memory can be reset using this menu item.

Sewing pattern programs (variations) and sequences

Sewing pattern programs and sequences can be deleted using this

menu item.

Machine parameters

Machine parameters, soft start s peeds, times, user configuration,

hook thread counter data and options can be reset to factory settings

using this menu item.

Free seam contours

All free seam contours can be reset (deleted) using this menu item.

Note

By resetting sewing pattern programs and sequences are also deleted

and the numbers of subsequent programs and sequences modified.

Whole machine

All permanent data can be reset using this menu item. After resetting

the machine is restarted automatically.

1

Note

After the machine has been restarted the clamp number and fittings

must be selected again (see installation instructions Section 9).

63

Page 66

8.6.5.4 Free contours

Maschine

Benutzer

Service

Freie Konturen

Memory-Dongle

:----

Erstellen n

Ändern: 0

Löschen: 0

Kopieren: 0

Anz.v.St.:3000

Anz.v.Kont.: 9

Up to nine freely defined seam contours can be created and sewn with

the button sewer 531. The co-ordinates of the seam contour are

entered on the control panel.

Create

A new seam contour can be created with this menu item.

Note

The seam contour number is allocated automatically.

Modify

After selecting the seam contour to be modified you go to the sub

menu for changing the seam contour.

Delete

A selected seam contour can be deleted with this menu item.

Copy

Any basic sewing patter n number of free seam contour can be copied

and modified. After selecting the sewing patter n number you go to the

“Change seam contour” sub menu.

–

Select the required standard sewing pattern by pressing “ñ”or

“ò”.

–

Select the standard sewing patter n by pressing OK .

Note

The seam contour number is allocated automatically.

64

Number of available stitches:

The number of stitches still available is displayed (max. 3000).

Number of available contours:

The number of contours still available is displayed (max. 9).

Page 67

Determining contour co-ordinates

When creating a seam contour each individual stitch with details of

the position on the co-ordinate cross (S and Y axis) must be entered

into the control unit. The individual co-ordinate points must therefore

be determined in advance.

The co-ordinate points can be determined using millimeter paper.

1

Maximum sewing area stitch to be determined

(grey field)

seam contour recorded

Machine zero point

Co-ord i na t e cross w it h

XandYaxis

Note

The seam contour should be created so that the machine zero point is

in the middle of the contour as far as possible.

–

Draw the maximum sewing field size on the millimeter paper (X =

max. 40 mm, Y = max. 20 mm).

–

Put the co-ordinate cross in the middle of the sewing area.

–

Plot the seam contour.

–

Determine the X and Y co-ordinates for each required stitch.

–

Enter the X and Y co-ordinates into the control unit (see next

page).

65

Page 68

Creating the contour

X1: 0.0

Y1: 0.0

X2: 0.0

Y2: 0.0

X3: 0.0

Y3: 0.0

Stich anfügen

Parameter

The X and Y co-ordinates for each individual stitch are entered in this

menu.

Note:

To enter stitch operations (e.g. interim cutting) first of all complete the

contour (enter co-ordinates) and then insert into the C hange contour

menu by editing the stitch operation.

X1

Entering the X co-ordinates for stitch 1

Enter: -20.0 … +20.0

Y1

Entering the Y co-ordinates for stitch 1

Enter: -10.0 ...+10.0

66

Note:

The value X1 can be changed as shown in Section 8.3.1.

After confirming the value of X1 by pressing OK select menu item Y1

by pressing “ò”.

The values for Y1, X2, Y2, X3 and Y3 can be changed as described for

value X1.

After confirming the entry of Y3 by pressing OK select “Add stitch”

by pressing ò.

After selecting this line by pressing OK the next co-ordinates Xn1 +1

and Yn+1 are specified in the top two menu lines (here: X4 and Y4).

The selection bar switches automatically to the line Xn+1 (here: X4).

The values Xn+1 and Yn+1 can be changed if necessary as described

above. This procedure can be repeated until all the stitch co-ordinates

have been entered.

Adding a stitch

Function to add a stitch.

The co-ordinates for the first three stitches (here: X1/Y1, X2/Y2 and

X3/Y3) are moved upwards and Xn+1/Yn+1 (here: X4/Y4) appears on

the display.

Page 69

Parameter sub menu

Std.dz.: 1500

Abst. X: 0.0

Abst. Y: 0.0

Selecting the sub menu to enter the contour parameters

Default speed:

Default speed

Enter: 100...2700 rpm

Distance X:

Distance from the hole in t he X direction

Enter: 0 ...40.0 mm

1

Distance Y:

Distance from the hole in t he Y direction

Enter: 0...20.0 mm

Default values = exter nal stitches in X and Y direction

Values must be changed depending on the distance between the

button and the hole (refers to correct scaling in the main menu).

If the free seam contour is currently selected in the main display and if

one or both of the X/Y distances have been changed, the value for the

length or width or both must be changed accordingly in the main

menu.

67

Page 70

Change contour

Stichkoord. 0

St.entf.: 0

St.einf.: 0

Stich anfügen

Parameter

Anz.St.: 100

Anz.v.St.:2900

1- 99

100 - 110

Stitch co-ordinates

Selecting the sub menu to change the stitch co-ordinates.

Removing a stitch:

Delete stitch.

Enter: stitch number to be deleted

Inserting a stitch:

Insert stitch.

Enter: Stitch number before which a stitch is to be inserted.

The sub menu to change the stitch co-ordinates appears.

Adding a stitch (at the end)

The sub menu to change the stitch co-ordinates appears.

Parameters

Selecting the sub menu to change the contour parameters

Stitch co-ordinates sub menu

The sub menu appears immediately if the contour to be changed has

99 stitches or fewer.

The following menu appears if the contour to be changed has more

than 99 stitches:

68

–

Select the required stitch area by pressing “?”or“?”.

–