Duerkopp Adler 52Xi Service Manual

52Xi

Industrial sewing machine

Service Instructions

Serviceanleitung

GB

D

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Aenderungsindex Teile-Nr./Part.-No.:

07/2009 Rev. index:00.0 Printed in Czech Republic S735 000805

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise Wiederverwendung

dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner, even

in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2009

Introduction

This service booklet contains the instructions for setting the sewing machine

head mechanisms.

The directions for putting the machine into operation and for setting the

positioning drive are contained in another publication.

The service booklet is common for all subclasses of the machine and

contains also the instructions for setting optional accessories of the machine,

if this is necessary owing to their complexity. Provided the machine supplied

does not contain some elements, then the respective chapters may be

ignored.

The succession of the setting operations is expressed here by sequencing

the paragraphs of this booklet. When setting, check up, if the setting

operations related to this setting have already been performed.

General safety regulations

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate training.

2. Before putting into service also read the safety rules and instructions of

the motor supplier.

3. The machine must be used only for the purpose intended. Use of the

machine without the safety devices is not permitted. Observe all the

relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

plate, feed dog and bobbin) when treading, when the workplace is left,

and during service work, the machine must be disconnected from the

mains by switching off the master switch or disconnecting the mains

plug.

5. Daily servicing work must be carried out only by appropriately trained

persons.

6. Repairs, conversion and special maintenance work must only be carried

out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems the machine must be

disconnected from the compressed air supply system.

Exceptions to this are only adjustments and function checks made by

appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by electricians

or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversions or changes to the machine must be authorized by us and

made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as the

entire sewing unit is found to comply with EC directives.

13. The connecting cable must be provided with a permissible local specific

network socket. This work requires trained and qualified professionals

(see point 8 too).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

List of contents Page

Introduction and safety regulations

Instructions for the machine setting - class 52X

1. Zigzag stitch mechanism of machines 523, 524, 527

1.1. Introduction .................................................. 5

1.2 Tooth clearance setting of zigzag stitch gear .............................. 5

1.3 Straightstitchalignment .......................................... 6

1.4 Zigzagstitchwidth.............................................. 7

1.5 Needle stab position setting in feeding direction ............................ 8

1.6 Lateral setting of needle stab position .................................. 9

1.7 Lateralsettingofcentralstraightstitchposition ............................ 10

1.8 Lateral setting of straight stitches on throat plate needle hole edges,

arresting of zigzag stitch setting mechanism .............................. 11

2. Form stitch mechanism of machine 525

2.1 Introduction .................................................. 12

2.2 Tooth clearance setting of form stitch gear ............................... 12

2.3 Rollerboltpositionofformstitchsteeringcam ............................ 13

2.4 Setting of needle stab position ...................................... 14

2.5 Timing of form stitch steering cam to needle motion ......................... 14

3. Feeding and presser foot

3.1 Stitch length setting mechanism ..................................... 15

3.2 Zero stitch length............................................... 16

3.3 Feeddogpositioninthroatplaterecessanditsheight........................ 17

3.4 Timingoffeeddogmotioneccentricinsewingdirection ....................... 18

3.5 Timingoffeeddogverticalmotion .................................... 19

3.6 Backtacking with solenoid ......................................... 20

3.7 Manual foot lifting .............................................. 21

3.8 Footliftingwithkneelever......................................... 22

3.9 Foot lifting with solenoid .......................................... 23

4. Setting of needle bar and hook

4.1 Hooktiming(loopstroke) ......................................... 24

4.2 Needle bar height, space between needle and hook point ...................... 25

4.3 Bobbin case driver .............................................. 26

4.4 Bobbin case lifting .............................................. 27

GB

5. Thread mechanism

5.1 Threadlimiter,checkspring........................................ 28

5.2 Bobbin winder................................................. 29

6. Thread trimmer

6.1 Trimmingpressureoftrimmingknives.................................. 30

6.2 Threadtrimmerlever ............................................ 31

6.3 Driver...................................................... 32

6.4 Threadtrimmercam............................................. 33

7. Machine electronic control and drive ................................. 34

1. Zigzag stitch mechanism of machines 523, 524, 527

1.1 Introduction

The machine setting must be carried out in the sequence as described

herein.

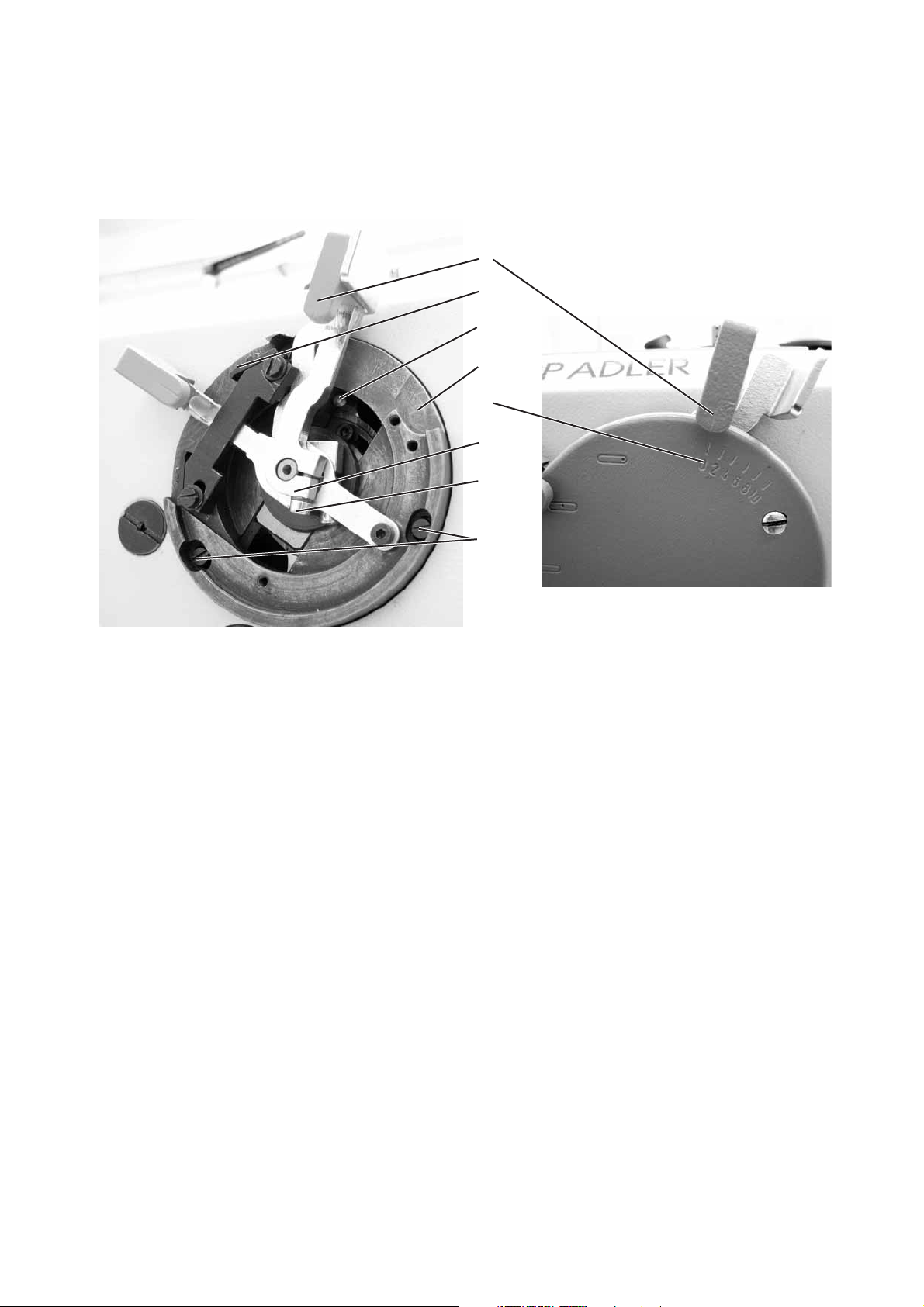

1.2 Tooth clearance setting of zigzag stitch gear

Regulation

The tooth clearance of zigzag stitch should be as small as possible.

No overlap instead of clearance, however, may arise in any mutual

position of the gears.

132

GB

–

Dismantle the machine top cover.

–

Loosen the screw (1) and turn the eccentric bolt (2) until the gear

fitted on it strikes the gear (3). With regard of the gear runout,

caused by manufacturing inaccuracy, turn the hand wheel by 1/4

revolution, and set the clearance again.

Repeat this 8 times (2 revolutions of the main shaft), until the

eccentric bolt (2) position with the smallest tooth clearance is

found. Locate the bolt (2) in this position and fix it with a screw (1).

5

1.3 Straight stitch alignment

Regulation

The centrally positioned straight stitch must be fully aligned, i. e. the

needle must not have any lateral motion.

6

4

2

3

7

5

1

4

–

Set the zero stitch length.

–

Loosen the screw (1).

–

Place the stop pin (2) to the stop onto the casing (3).

–

Place a piece of paper onto the throat plate and turn the hand

wheel there and back until the needle point makes 2 holes in the

paper.

–

Loosen 3 screws (4) and try to set the casing (3) angle position

until the needle, when being turned, stabs there and back in the

same hole in the paper.

–

Tighten the screws (3).

–

Fix the lever (5) so that the mark (6) is located opposite the zero on

the zigzag stitc h scale (7).

6

1.4 Zigzag stitch width

Regulation

The zigzag stitch width setting must be limited to the value prescribed

for the applied sewing equipment with the setting tolerance -5% of the

prescribed value.

2

1

GB

–

Set the zero stitch length.

–

Place a piece of paper onto the throat plate.

–

Loosen the screw (1).

–

Try to set the lever (2) in the position corresponding with the

required zigzag stitch width. Turn the hand wheel there and back

until the needle makes 2 holes in the paper. Measure their

distance. Change the lever position (2) until the distance of the

holes complies with the regulation.

–

Shift the screw (1) to the stop and tighten it.

7

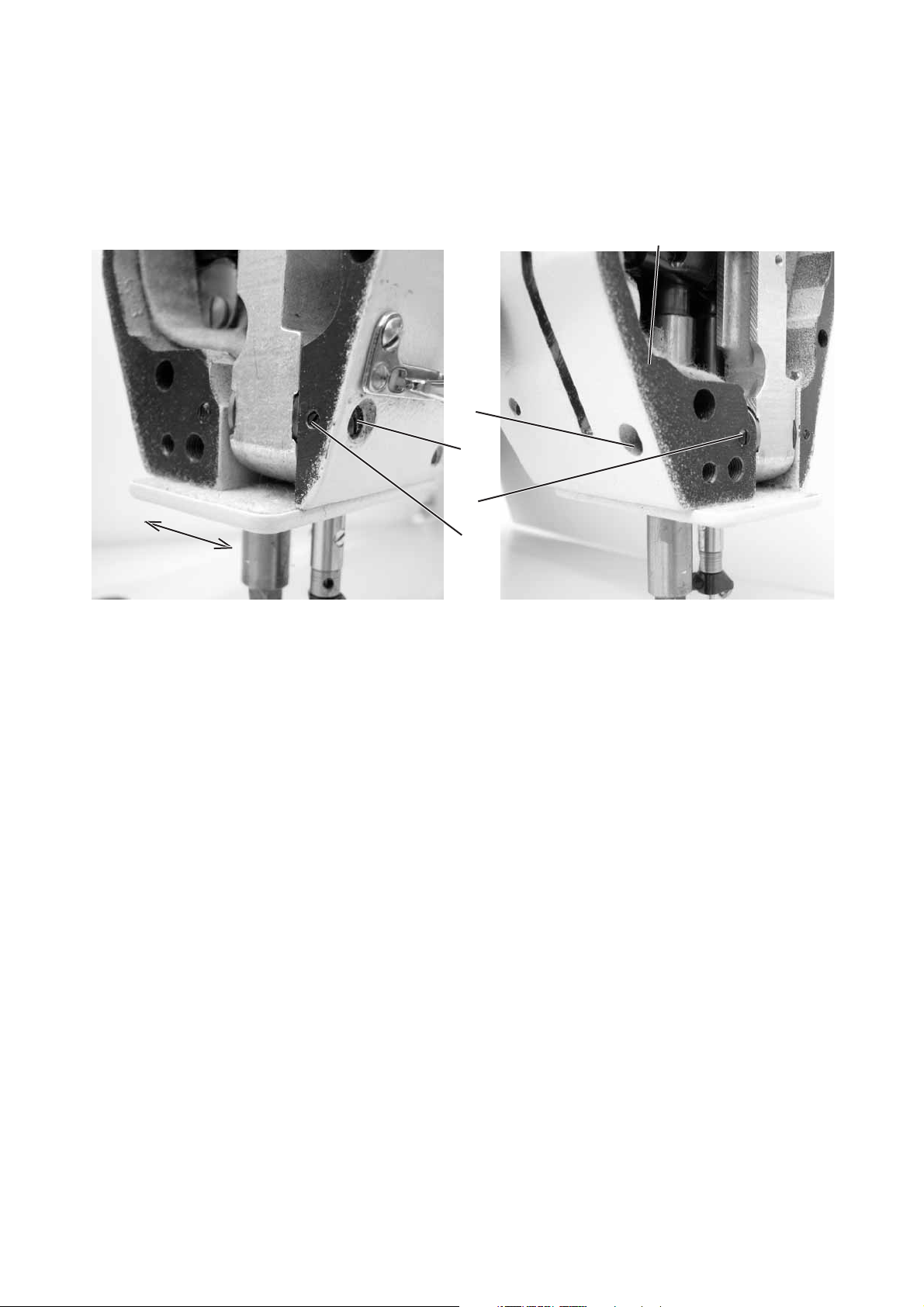

1.5 Needle stab position setting in feeding direction

Regulation

If the needle is in the bottom dead center, it should be positioned in the

throat plate needle hole center in feeding direction and its lost motion

in the feeding direction should be as small as possible.

4

3

1

2

–

Place the needle in the bottom dead center.

–

Loosen the arresting screws (1), (2), and the regulating screw (3).

–

Adjust the screw (4) so that the regulation is complied with and

arrest it with the screw (1).

–

Adjust the regulating screw (3) s o that the lost motion (play) of the

needle bar holder in the arrow direction is the smallest achievable

one; rubbing must not occur.

–

Tighten the screw (2).

8

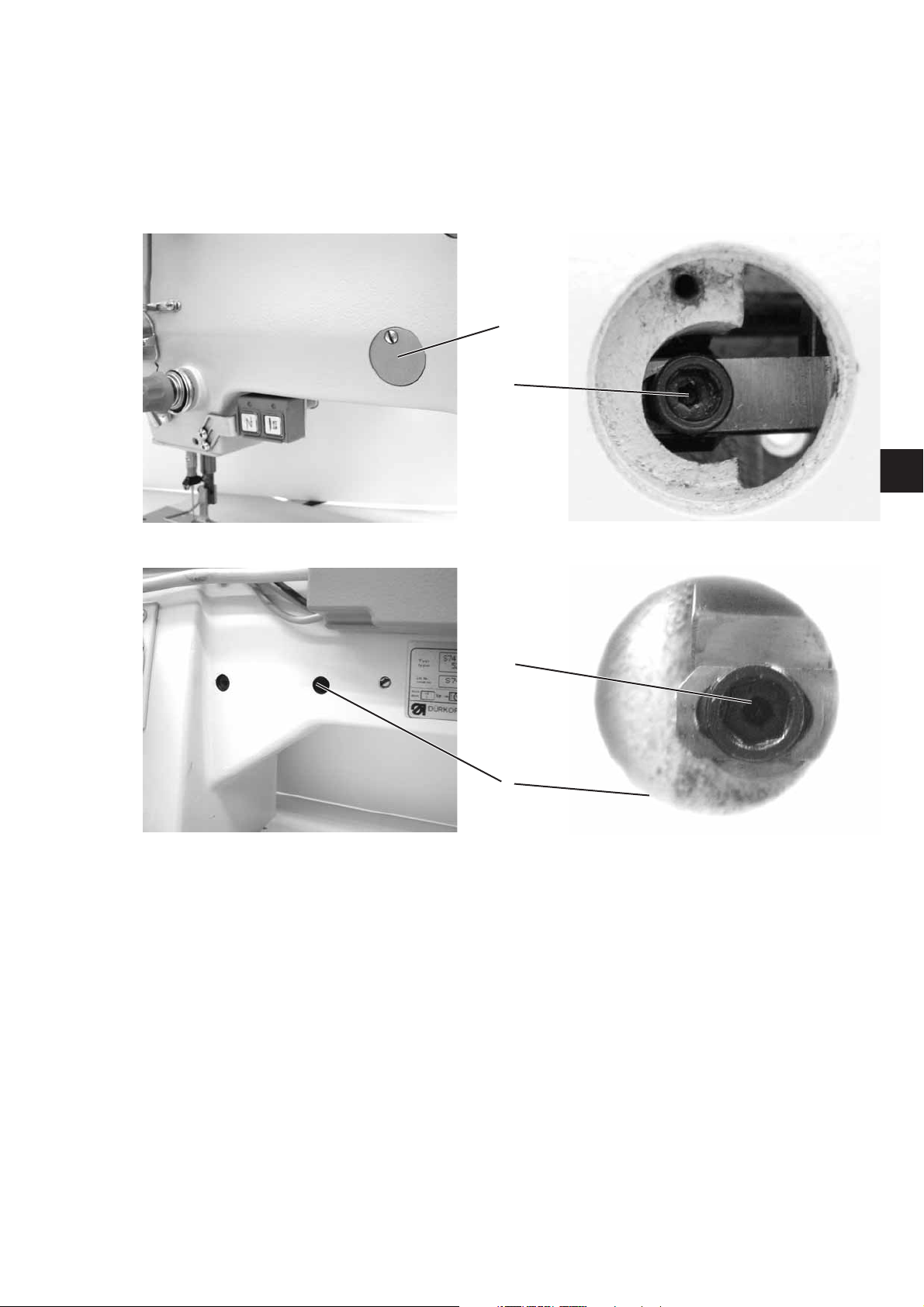

1.6 Lateral setting of needle stab position

Regulation

Both dead centers of the needle lateral motion at the zigzag stitch

sewing should be at the same distance from the throat plate needle

hole edges.

1

3

G

B

3

2

–

Dismantle the cover (1) and the hole stop (2) from the rear side.

–

Loosen both screws (3).

–

Set the maximum zigzag stitch width and adjust the positions of the

needle lateral motion dead centers as per regulation.

–

Tighten both screws properly (3).

9

Loading...

Loading...