Duerkopp Adler 506-3 Service Manual

506-3

Instructions, complete

Operating Instructions

Installation Instructions

Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

10/2008 Rev. index: 01.0 Printed in Federal Republic of Germany 0791 506011

Instructions, complete

506-3

Overview

Operating table

Operating Instructions

Installation Instructions

Service Instructions

Pneumatic circuit plan

9770 506002

Interconnection-diagram

9890 506003 B

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2008

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Contents Page:

Part 3: Service Instructions Cl. 506-3

1. General .................................................... 3

2. Removing the top cover and turning over the upper part of the machine

2.1 Removingthetopcover........................................... 4

2.2 Turning over the upper part of the machine ............................... 6

3. Shuttle, needle bar

3.1 Needle bar height............................................... 7

3.2 Synchronizing the shuttle and needle bar movements ......................... 9

3.3 Shuttle-tip/needle distance ......................................... 10

3.4 Driver/needle distance ........................................... 11

3.5 Loop stroke .................................................. 13

4. Bobbin ejector ................................................ 14

5. Disc cam

5.1 Replacingthedisccam........................................... 17

5.2 Fittingtheintermediatetransmission................................... 20

5.3 Replacing the worm-gear pair and worm screw ............................. 21

5.3.1 Fit/Remove the synchronous motor .................................... 21

5.3.2 Replacing the worm-gear pair and worm screw ............................. 23

5.4 Worm-screw wheel play ........................................... 24

6. Shut-down devices

6.1 Basicstopposition(switchS7)....................................... 27

7. Clamps and table plate

7.1 Position of table plate with respect to the needle ............................ 29

7.2 Positionofclampswithrespecttothetableplate............................ 32

8. Thread advance ............................................... 33

9. Thread-tensioning spring ......................................... 34

10. Needle cooling ................................................ 35

3

Contents Page:

11. Thread-burning device

11.1 Threadextractor ............................................... 36

11.2 Upper burning device ............................................ 38

11.2.1Startingposition................................................ 38

11.2.2 Position of fully-extended burner ..................................... 39

11.2.3Adjustingtheburnerheight-stop...................................... 40

11.2.4 Burner angle.................................................. 41

11.3 Lowerburningdevice ............................................ 42

11.3.1 Adjustment preconditions .......................................... 42

11.3.2Distancebetweenthreadextractorandburner............................. 43

11.3.3Positionofburnerwhenswivelledforwards............................... 43

11.3.4Burnerheight................................................. 44

11.3.5 Thread-extractor height ........................................... 44

12. Thread-suction device ........................................... 45

13. Bobbin-winder adjustment ........................................ 46

14. V-belt tension ................................................ 47

2

1. General

These service instructions describe the adjustment of the automatic

sewing machine in an appropriate order.

CAUTION:

Various adjustments are mutually dependent.

It is therefore essential for adjustments to be carried out in the order

described.

CAUTION:

The activities described in these servicing instructions may be carried

out only by experts or by persons with the appropriate training.

Danger of breakage

It is essential for the adjustments specified in these servicing

instructions to be carried out before the machine is recommissioned

following disassembly.

Never start the machine with the drive motor rotating in the wrong

direction.

A s ewing run may not commence unless the head cover and the

shuttle-area cover are closed.

If either of these is open, all control functions are blocked.

CAUTION: danger of injury

Prior to all repair, modification and maintenance work the main switch

must be turned off and the machine disconnected from the

compressed-air supply.

Adjustment work and function testing carried out with the machine

running require the utmost care and observance of all safety

precautions.

Setting gauges

We can supply the following setting gauges on request:

Setting gauge Use Order No.

Gauge Loop-stroke adjustment 0981 150009

Calliper Loop-stroke adjustment 0981 150006

Gauge Adjusting the arm-shaft 7270 159160

eccentric (optional)

3

3

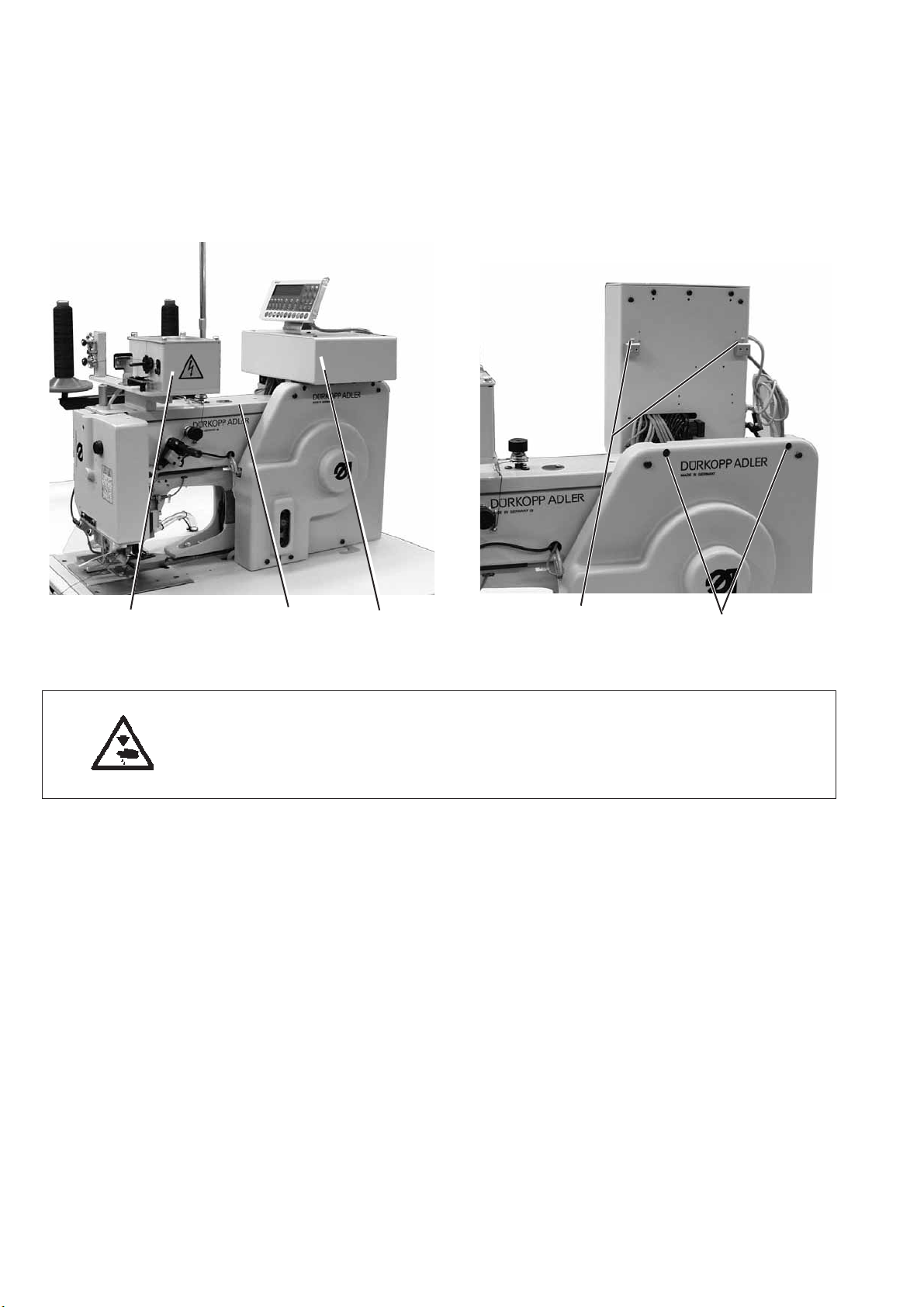

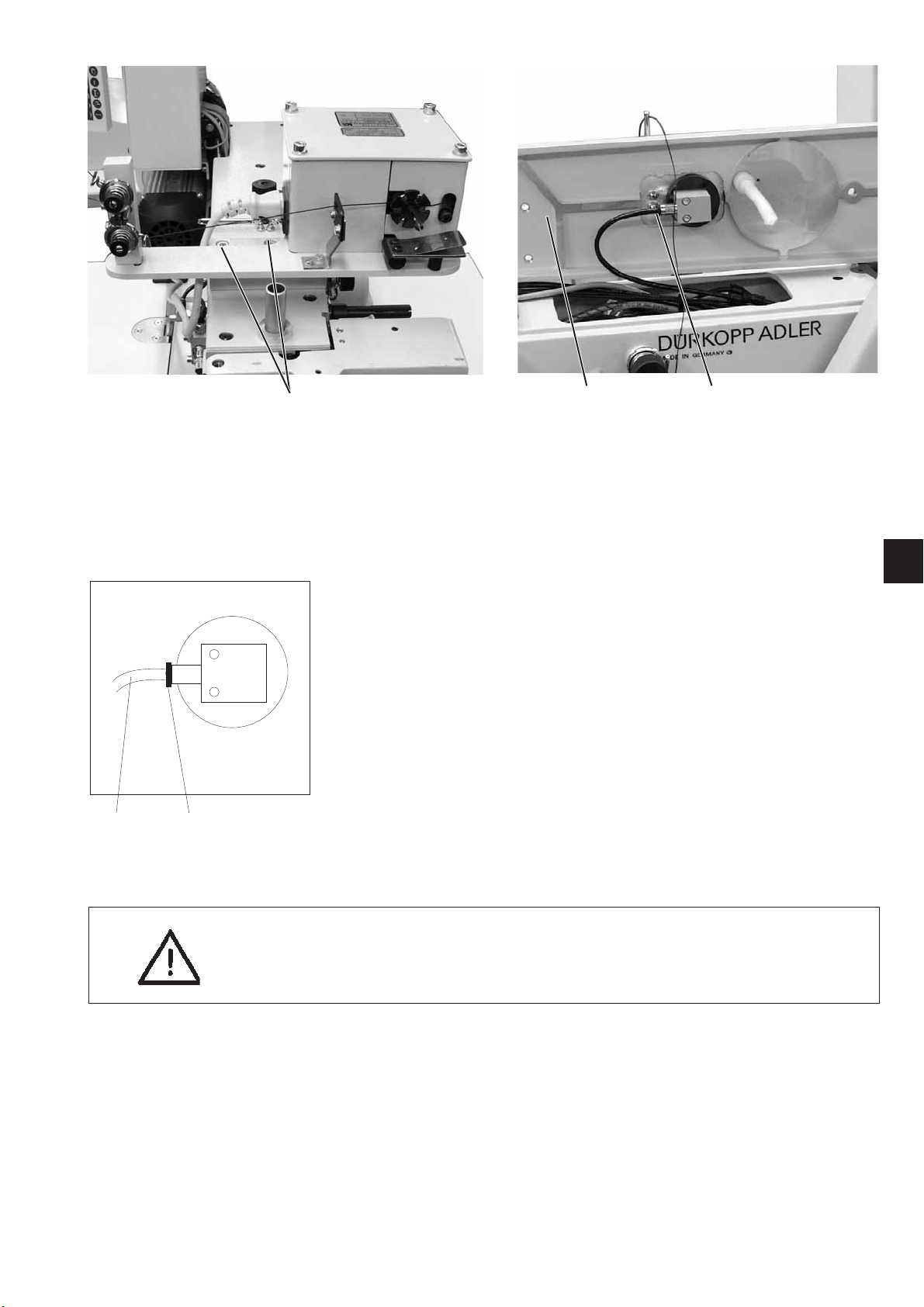

2. Removing the arm cover and Turning over the upper part of the machine

2.1 Removing the arm cover

For service work in the interior of the upper part of the machine the

arm cover 3 must be removed.

First the control unit 1 must be swivelled aside and the bobbin-winder

cartridge 2 removed.

321

CAUTION: danger of injury

Turn off the main switch and disconnect the machine from the

compressed-air supply.

The arm cover must not be removed until both these steps have been

taken.

Swivelling the control unit aside

–

Slightly undo Allen screws 5.

These are accessible through the holes 4 in the casing.

–

Carefully swivel the control unit aside.

54

4

78

6

Removing the bobbin-w inder cartridge

–

Undo fixing screws 6.

–

Lift off bobbin-winder cartridge.

27

3

Removing the arm cover

–

Undo arm-cover fixing screws 2.

–

Carefully raise the arm cover 2 and fold it back.

–

Remove compressed-air hose 7 from the quick-release fastening:

Push the ring 8 to the right and pull the hose out of the

quick-release fastening.

CAUTION :

The use of force to remove the arm cover may cause damage to the

compressed-air line.

5

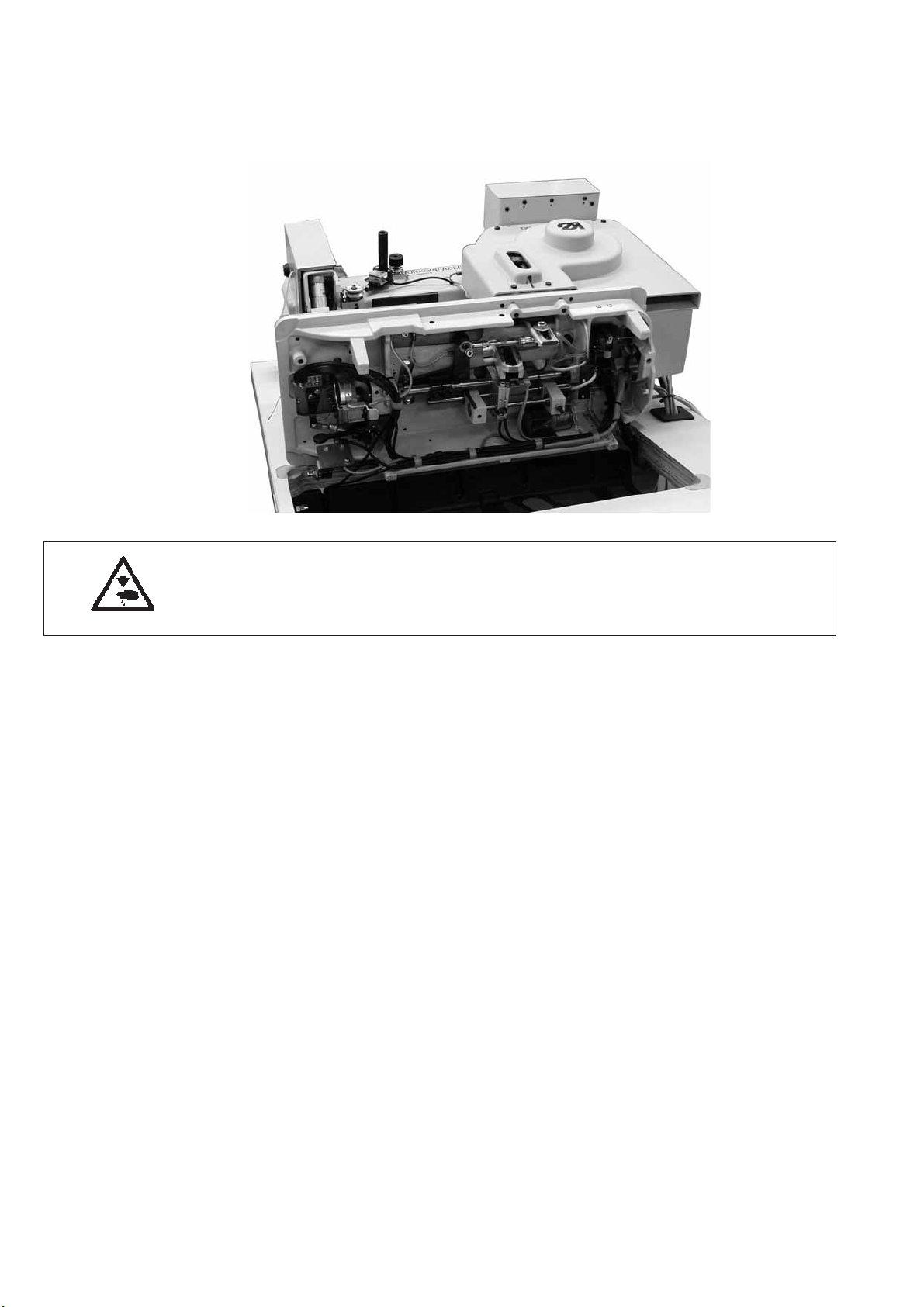

2.2 Turning o ver the upper part of the machine

For service work on the underside of the upper part of the machine the

upper part must be turned over.

CAUTION: danger of injury

Turn off the main switch.

The upper part of the machine must not be turned over unless

themainswitchisoff.

–

Carefully turn over the upper part of the machine until it is

supported by the table-plate prop.

The underside of the upper part of the machine is now accessible

for service work.

6

3. Shuttle, needle bar

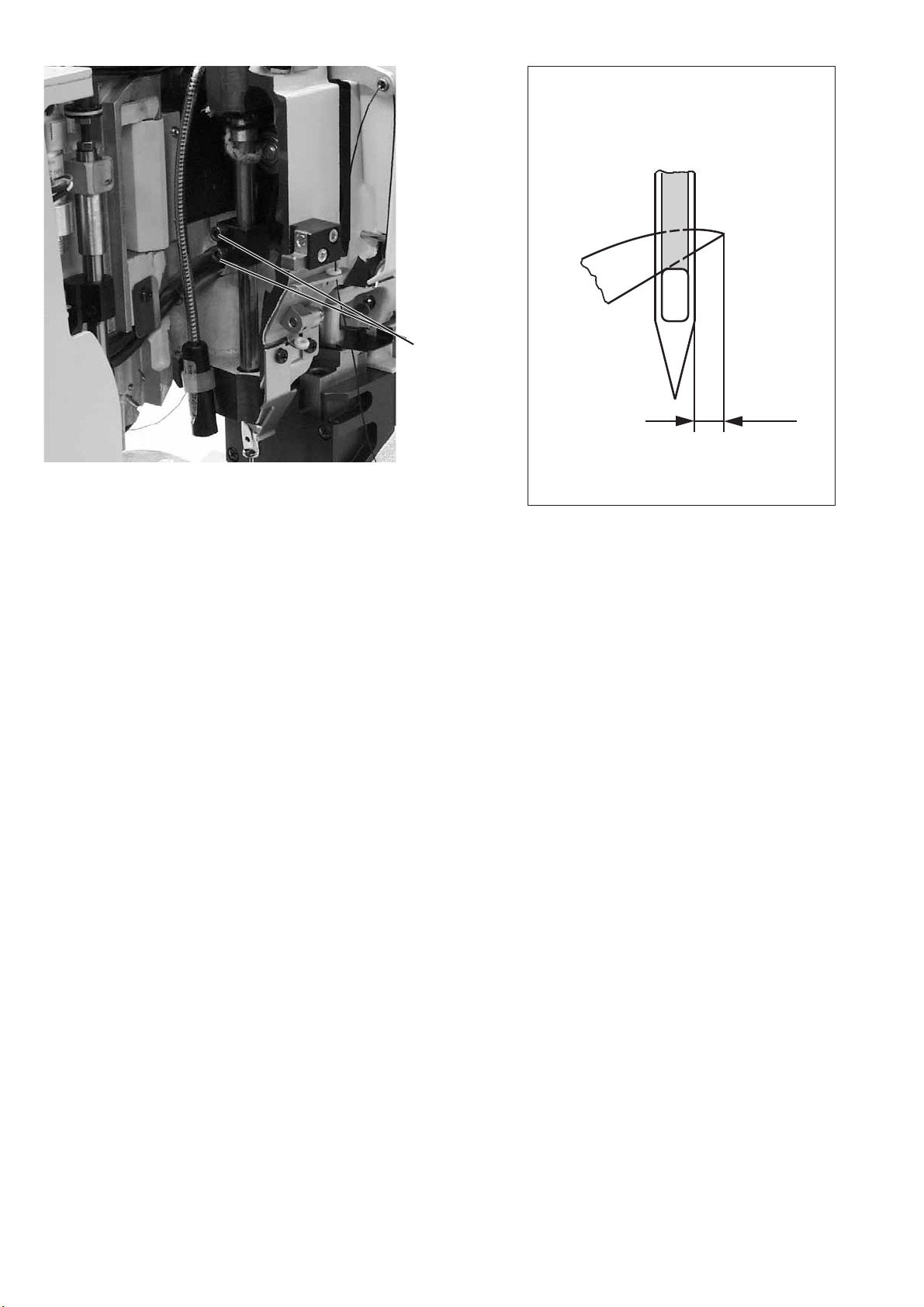

3.1 Needle bar height

CAUTION:

The adjustments described in chapters 3.1 to 3.4 are mutually

dependent. It is therefore essential for the individual adjustments to be

carried out in the order specified in the service instructions.

When the shuttle tip extends 2 mm beyond the right-hand side of the

needle, the eye of the needle must be directly beneath the shuttle tip.

3

2

3

CAUTION: danger of injury

Turn off the main switch.

The needle bar height may only be adjusted with the main switch

turned off.

–

Turn off the main switch.

–

Undo screws 2.

–

Remove clamp 3.

CAUTION: Danger of breakage

It is essential for the clamps to be removed prior to the following

adjustment work.

This prevents the needle from fouling the clamps in the course of

subsequent adjustments.

7

4

2mm

–

Turn the handwheel in the direction of rotation until the shuttle tip

extends 2 mm beyond the right-hand side of the needle.

CAUTION:

Care must be taken that the driver touches the shuttle in the

direction of rotation.

–

Undo locking screws 4.

–

Adjust the height of the needle bar so that the lower edge of the

shuttle tip just becomes visible in the eye of the needle.

–

Fully tighten locking screws 4.

–

Refasten clamp 3 with screws 2.

8

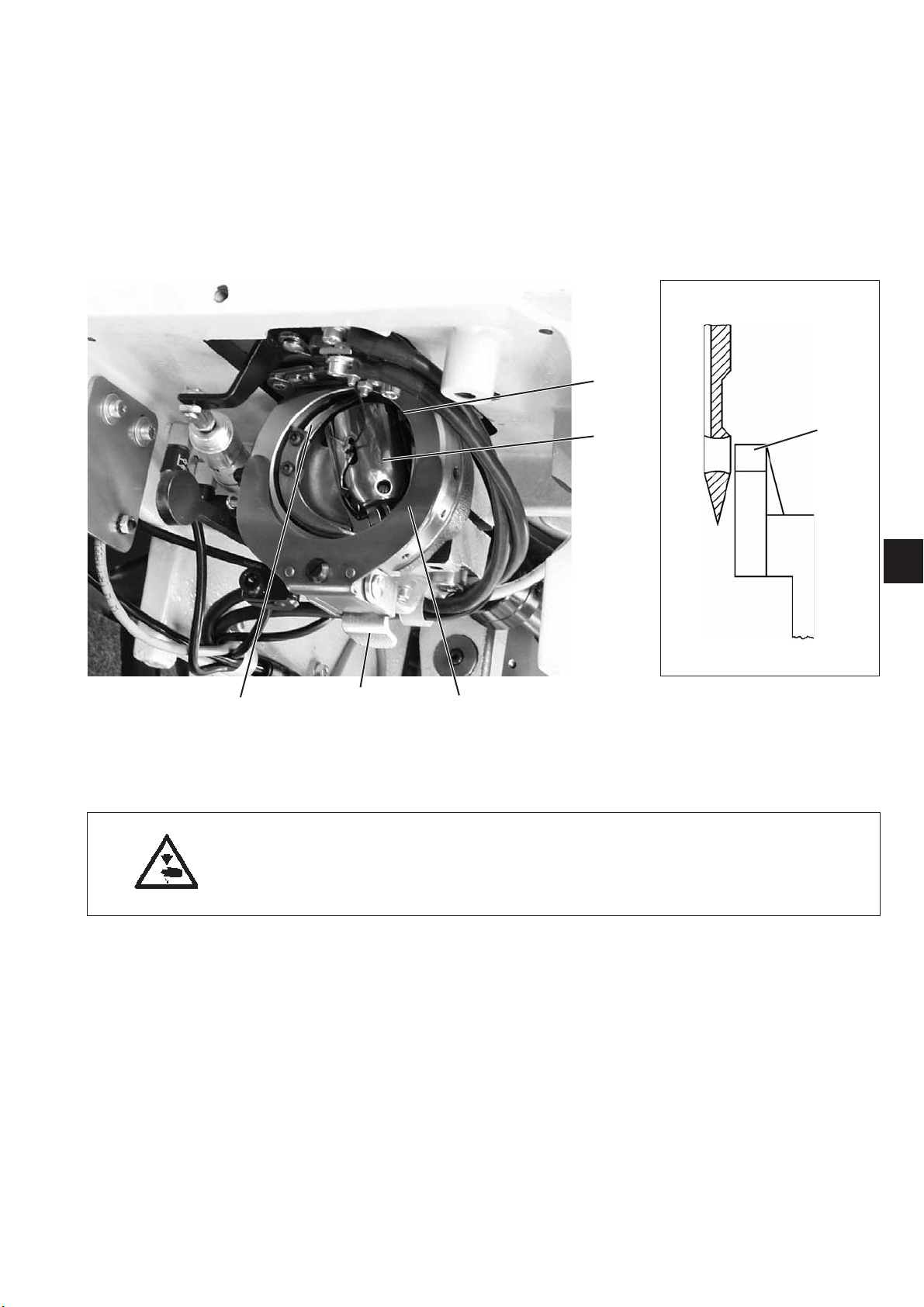

3.2 Synchronizing the shuttle and needle bar movements

The movement of the shuttle is synchronized with that of the needle

bar by means of the locking pin 1 and gauge 2.

11

CAUTION: danger of injury

Turn off the main switch.

The shuttle and needle bar movements may only be synchronized with

the main switch switched off.

–

Insert locking pin 1 in the hole in the housing of the upper part of the

machine.

–

Turn the handwheel in the direction of rotation until the locking pin 1

perceptibly engages in the groove of the arm-shaft handle.

–

Place the gauge 2 on the shaft between the worm-screw wheel 3 and the

eccentric 6 in such a way that the pin 4 points to the eccentric 6.

–

Push the gauge against the eccentric.

The pin 4 must fit into the hole 5.

–

The legs 8 of the gauge must lie flat on the unpainted surface of the arm.

63

7

6

2

5

8

3

4

Adjustment:

–

Remove the top cover.

–

Undo the locking screw 7 on the eccentric.

–

Turn the handwheel until the pin 4 of the gauge fits into the hole 5

of the eccentric.

–

Fully tighten locking screw 7.

–

Replace cover.

9

3.3 Shuttle-tip/needle distance

3

2

1

The shuttle tip 9 must be as close as possible to the groove of the

needle without touching it.

4

5

6

7

CAUTION: danger of injury

Turn off the main switch.

The shuttle-tip/needle distance may only be adjusted with the main

switch turned off.

A

A

A-A

–

Turn the handwheel to bring the shuttle tip 9 close to the needle and check

the position of the shuttle tip with respect to the throat of the needle.

Adjustment:

–

Fold the upper part of the machine aside.

–

Undo locking screws 6.

–

Undo locking screws 4 on adjustment ring 7.

–

8

Extract driver with driver shaft 5 forwards from the shuttle-track

support 3.

–

Undo locking screw 1 on the base plate.

–

Slightly screw in pressure screw 2.

This opens the base-plate jaws.

–

Bring the shuttle tip 8 close to the throat of the needle by axially

shifting the shuttle-track support 3.

The upper surface of the shuttle-track support 3 must be parallel to

the needle plate.

–

Screw pressure screw 2 out again.

–

Fully tighten locking screw 4 (max. 21 Nm).

–

Replace driver with driver shaft 5 in the shuttle-track support 3 and

push back as far as it will go.

–

Push adjustment ring 7 as far as it will go against the end of the

shuttle-track support 3.

–

Fully tighten locking screws 4.

–

Fully tighten locking screws 6.

10

CAUTION:

It is essential to check the loop-stroke setting.

Fitting a stronger needle has the effect of altering the distance

between the shuttle tip and the needle.

This shuttle-tip/needle distance must be corrected.

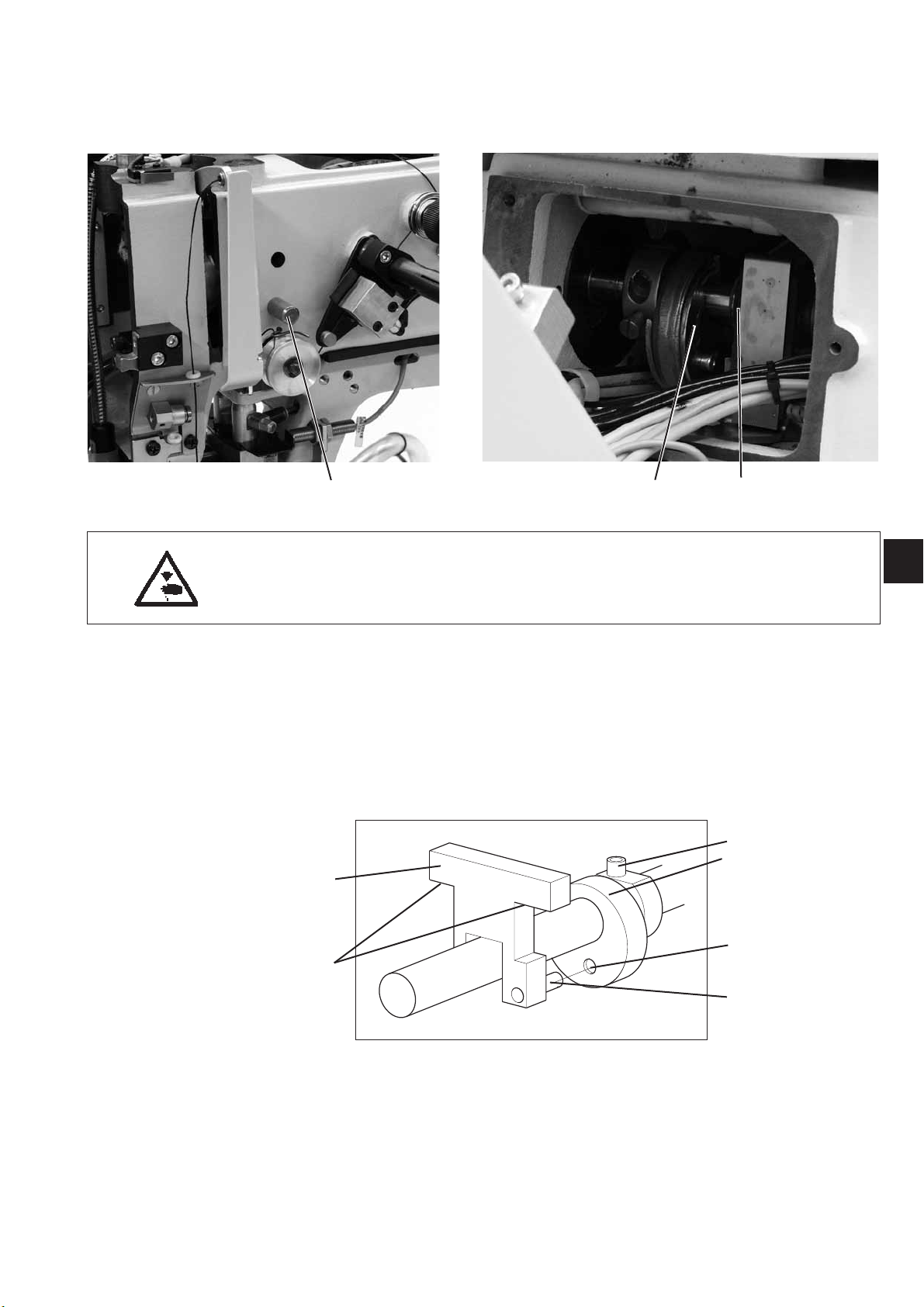

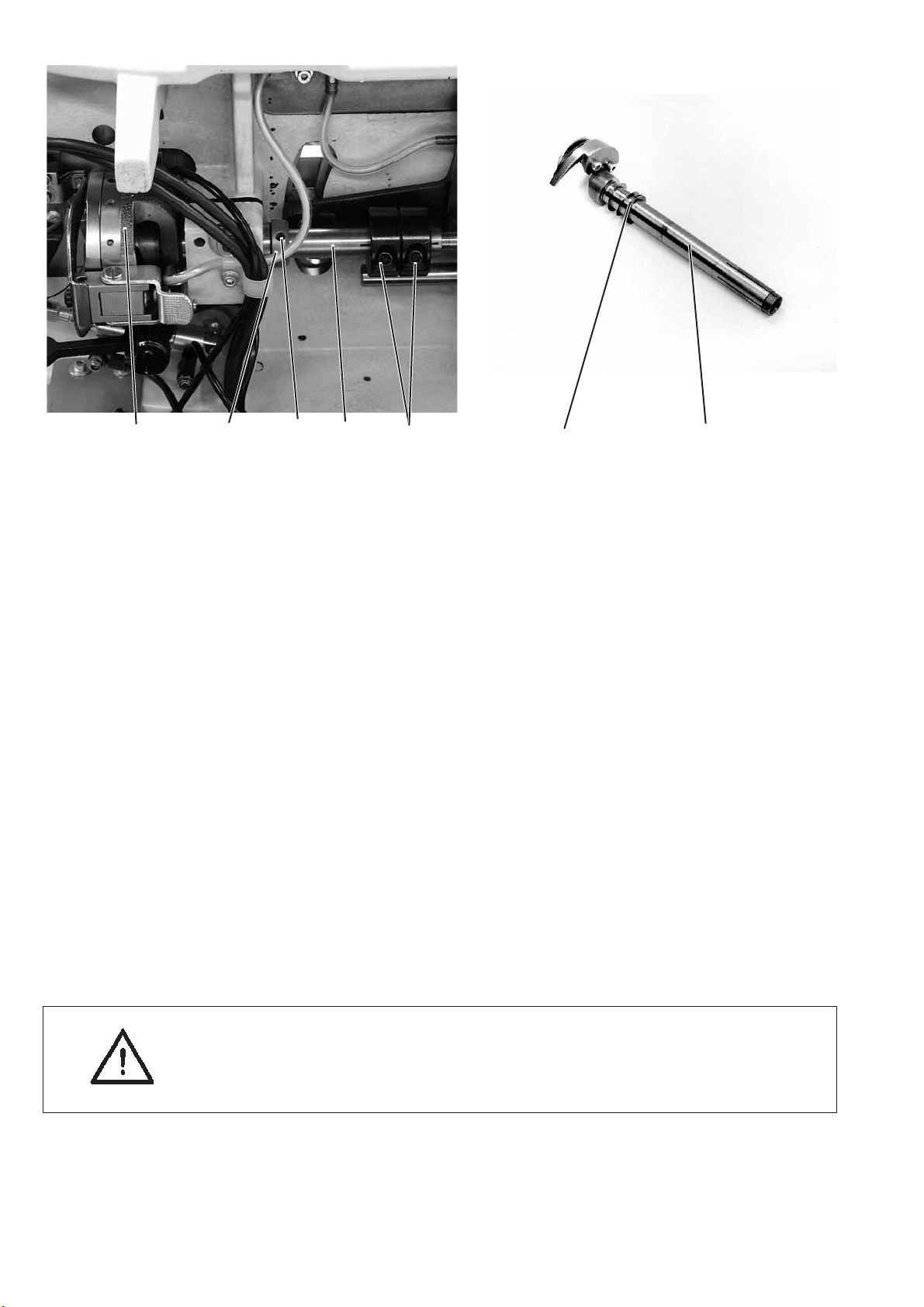

3.4 Driver/needle distance

The oscillating driver 3 moves the shuttle 1 in the shuttle track.

When the setting of the driver is correct it also acts as a needle guide

in the vertical dimension.

This avoids needle “flutter”, which causes dropped stitches.

The right-hand side of the needle must be parallel to the driver 3 and at

a very small distance from it.

For this purpose the driver 3 must be brought close to the needle.

2

345

CAUTION: danger of injury

Turn off the main switch.

The driver/needle distance may only be adjusted with the main switch

turned off.

1

3

3

–

Turn the handwheel to bring the needle to its highest point.

–

Pull the sprung bolt 4 forwards to unlock the shuttle-track spring 5.

–

Swivel back the shuttle-track spring 5.

–

Remove plunger ring 2.

–

Extract shuttle 1.

–

To check the setting turn the handwheel to bring the driver 3 close

to the needle.

11

10 9 8 7 6

Adjustment:

–

Fold the upper part of the machine aside.

–

Undo locking screws 6.

–

Undo locking screws 8 on adjustment ring 9.

–

Extract driver with driver shaft 7 forwards from the shuttle-track

support 10.

–

Once the driver shaft 7 has been dismantled, remove or add

shims 12. The shims can be found in the accessory kit.

Hint

The use of a smaller needle normally requires a shim to be added

and vice versa.

–

Replace driver with driver shaft 7 in the shuttle-track support 10

and push it back as far as it will go.

–

Push adjustment ring 8 as far as it will go against the end of the

shuttle-track support 10.

–

Fully tighten locking screws 8.

This prevents the driver from being axially shifted.

–

Reset the loop stroke (see chapter 3.5).

–

Check the setting by turning the belt pulley on the arm shaft. The

right-hand side of the needle must be parallel to the driver and at a

very small distance from it.

If the setting is not correct the adjustment process must be

repeated.

12 11

12

CAUTION:

After adjusting the driver/needle distance it is essential to readjust the

loop stroke as described in chapter 3.5.

Loading...

Loading...