Page 1

Instructions for service

4180i - 1

Minerva Boskovice, a.s., Sokolská 60, CZ - 680 17 Boskovice

Tel.: +420-516-453434, 453433, 494111 Fax: +420-516-452165 http://www.minerva-boskovice.com

Edition: 10/2005 Printed in Czech Republic S735 000662

Page 2

CONTENTS:

1. General safety instructions .............................................................................................................................................................. 1

2.

Introduction .......................................................................................................................................................................... 1

3. Head of the sewing machine .............................................................................................................................................. 2

Hook and hook post ................................................................................................................................................................ 2

3. 1

.. 3.1.1

3.1.2 Height setting of the hook

3.1.3 Setting the distance of the hook from the needle

3.1.4 Angular setting of the hook (timing)

3.1.5 Protection of the needle and of the hook point

3.1.6 Setting of the bobbin case opener

3.1.7 Setting the regulation of the hook lubrication

3.1.8 Replacement of the hook

3.1.9 Setting the gear

3.1.10 Dismantling of the hook post

3.2 Needle and thread mechanism ................................................................................................................................. 5

3.2.1 Description

3.2.2 To check the handwheel angular adjustment

3.2.3 Height setting of the needle bar

3.2.4 Side setting of the needle bar holder

3.2.5

3.3 Throat plate and its post ........................................................................................................................................................ 7

3.3.1 Description

3.3.2 Mounting and removing the throat plate and its insert

3.3.3 Side setting of the throat plate post

3.4 Thread tensioners and limiter ................................................................................................................................. 8

3.4.1 Description

3.4.2 Setting the tension of main and auxiliary tensioners

3.4.3 Setting the tensioning mechanisms of the main tensioners

3.4.4 Setting the adapting spring

3.4.5 Setting the thread limiter

3.4.6 Setting the

3.5 Feeding mechanism of the needle feed and of the lower feed wheel ........................................................................ 10

3.5.1 Description

3.5.2

3.5.3

3.5.4

3.6 Feeding mechanism of the top roller ....................................................................................................................15

3.6.1 Description

3.6.2 Side setting of the indented lower pulley

3.6.3 Side setting of the indented upper pulley

3.6.4 Setting the tensioning roller

3.6.5 Replacement of the indented belt

Description

Setting the needle (the needle bar holder) in the direction of sewing

additional thread limiter

Stitch length mechanism

3.5.2.1 Setting the upper eccentric

3.5.2.2 Setting the prop

3.5.2.3 a Forward and rearward stitch length distribution (rough)

3.5.2.3 b Forward and rearward stitch length distribution (fine)

3.5.2.4 Setting of the control knob (including the stitch length limitation)

Lower feed wheel

3.5.3.1 Feeding clutches

3.5.3.1.1 Description

3.5.3.1.2 Setting the lever of the second step of feeding(angle, position)

3.5.3.1.3 Setting of the lower eccentric

3.5.3.1.4 Setting the engagement and disengagement of the clutches

3.5.3.2 Wheel feeder and its post

3.5.3.2.1 Height setting of the feeder and tensioning of the chain

3.5.3.2.2 Replacement of the feeder

Setting the top roller (pressing force, height)

Page 3

3.6.6 Top roller

3.6.6.1 Selection of the top roller diameter

3.6.6.2 Forward, rearward and side setting

3.6.6.3 Setting the gear clearance and in the mounting of the top roller

3.6.6.4 Replacement of the top roller

3.7 Setting the presser foot lift .................................................................................................................................... 19

Bobbin winder ....................................................................................................................................................... 20

3.8

Description

3.8.1

3.8.2 Setting the bobbin winder stop

3.8.3 Setting the friction gear

3.9 Safety clutch .......................................................................................................................................................... 21

Description

3.9.1

3.9.2 Setting the disengaging moment

3.10 Indented belt transmission ................................................................................................................................... 21

Setting the tensioning roller of the indented belt

3.10.1

3.10.2 Replacing the indented belt

3.11 V-belt, motor - head .............................................................................................................................................. 22

Tensioning

3.11.1

3.11.2 Replacing the V-Belt

3.12 Driving toothed belt ............................................................................................................................................................... 22

To exchange the driving toothed belt

3.12.1

3.13 Lubrication .............................................................................................................................................................................. 23

Description

3.13.1

3.13.2 Refilling oil

3.13.3 Multiple oil use

4. Thread trimming .................................................................................................................................................................................24

Description of the trimming mechanism

4.1

4.2 Setting the pickup roller

4.3 Setting the cam

4.4 Setting the fork

4.5 Setting the moving knife

4.6 Setting the height of the fixed knife and of the retaining spring of the lower thread

4.7 Setting the fixed knife

4.8 Setting the retaining spring of the hook thread

4.9 Setting switching of the electromagnets

5. Lifting the top roller by electromagnet ........................................................................................................................... 26

Description

5.1

5.2 Setting the electromagnet pin

5.3 Setting the electromagnet current

5.4 Assembly of the top roller lifting electromagnet

6. Backtacking using electromagnet .................................................................................................................................... 27

Description

6.1

6.2 Electromagnet height setting

6.3 Setting the position of push-buttons

6.4 Change of the function of push-buttons

7. Connecting the electric elements on the machine head ................................................................................................ 28

Drive, control panel, position sensor ......................................................................................................................................... 28

8.

Maintenance (table of operations) ............................................................................................................................................... 29

9.

Setting the machine according to the sewing category ............................................................................................................ 29

10.

Introduction

10.1

10.2 Table of setting the machine according to the sewing category

Page 4

1. General safety instructions

The non-observance of the following safety instructions can cause bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the instruction book and operated by persons with appropriate

training.

2. Before putting into service also read the safety rules and instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of the machine without the safety devices is not permitted.

Observe all the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, top roller, needle plate, feed dog and bobbin) when treading, when the

workplace is left, and during service work, the machine must be disconnected from the mains by switching off the master

switch or disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately trained persons.

6. Repairs, conversion and special maintenance work must only be carried out by technicians or persons with appropriate

training.

7. For service or repair work on pneumatic systems the machine must be disconnected from the compressed air supply system.

Exceptions to this are only adjustments and function checks made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted, except as specified in regulations DIN VDE 0105.

10. Conversions or changes to the machine must be authorized by us and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as the entire sewing unit is found to comply with EC

directives.

It is absolutely necessary to respect the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

IMPORTANT WARNING

In spite of all safety measures made on the machines, inappropriate actions of the operator may lead to dangerous situations. In

industrial sewing machines, attention should be paid to the following still remaining possible sources of injury:

1. Moving sewing needle

- risk of injury when sewing with raised pressure foot or top roller, because the finger guard is then positioned too high,

- risk of injury when inadvertently threading down of the motor threadle.

2. Moving thread take-up lever

- risk of injury when inadvertently or intentionally inserting the finger(s) between the thread take-up lever and its guard.

3. Moving pressure member

- risk of injury when holding sewn work in immediate vicinity of the pressure member and beginning to insert under the

pressure member a considerably thicker sewn work portion,

- risk of injury when sinking the pressure member.

4. When switched off, the clutch motor slows down by inertia but would be reactivated by an accidental treading down of the

motor treadle. To avoid such risk, it is advised to hold the handwheel by hand and slightly to depress the motor treadle.

2. Introduction

This service book contains instruction for regulating the mechanisms of the sewing machine head.

The instructions for use and for putting the machine into operation and for the control of the stopmotor are not included in this

service book, but they are supplied as separate publications.

This service book is universal for all subclasses of the machine - it contains setting procedures for all elements which may be

placed on the machine of the given class. When the supplied subclass of this machine does not include some element, then it is

possible to leave out the respective parts of the instructions. The optional equipments of the machine and the respective

configurations of the subclasses of the machine are given in the operating instructions.

This sewing machine disposes of a large extent of its use. The machine should be set with respect to the parameters of the sewn

material, the sewing thread etc. The setting for the individual categories is given in the chapter 10.2.

For setting the machine, simple setting aids are used which are included in the accessory of the machine. Besides these aids,

universal measuring devices are used, such as slide calliper, feeler gauges and dynamometer for measuring the thread tension.

1

Page 5

3. Head of the sewing machine

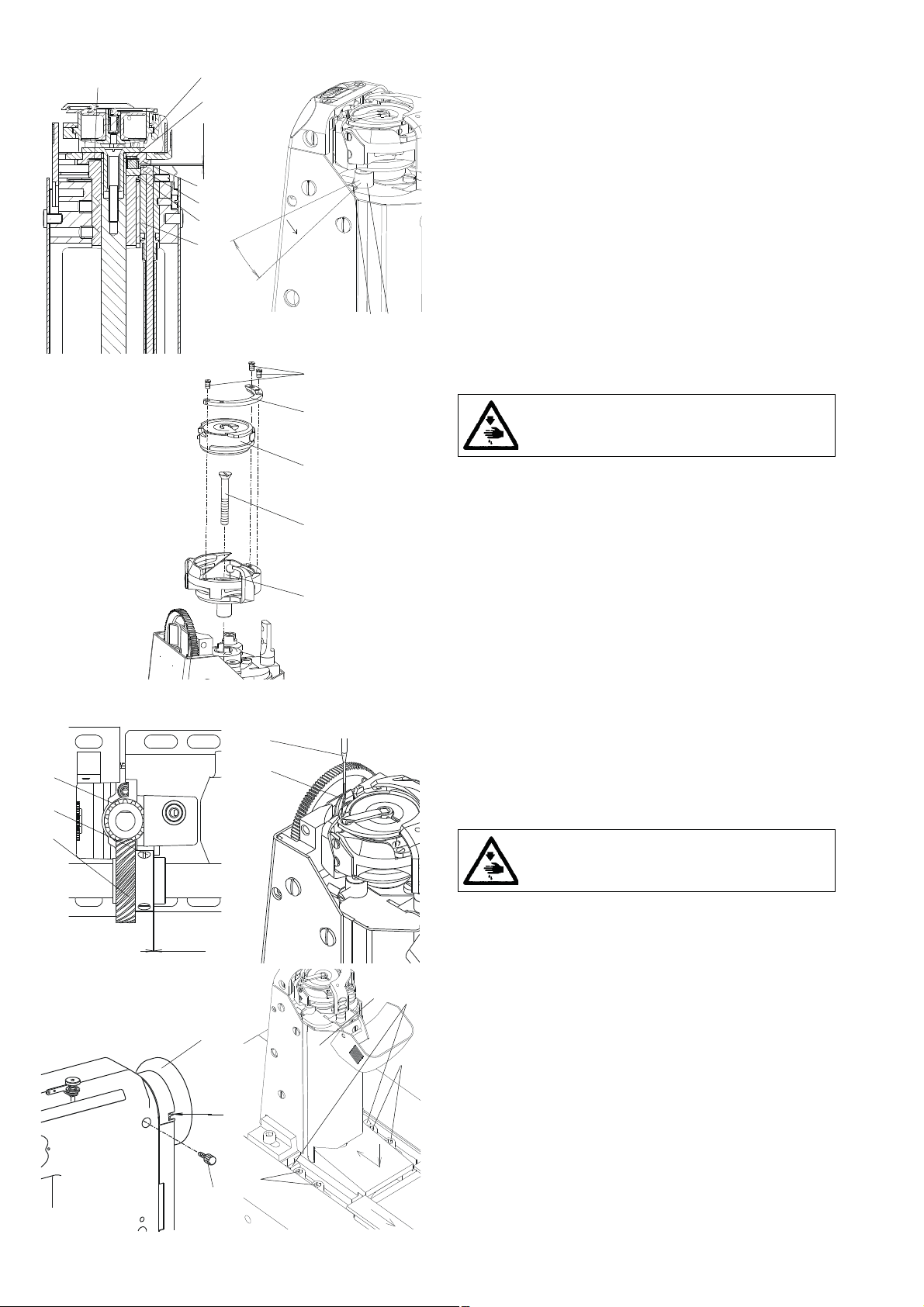

3.1 Hook and the hook post

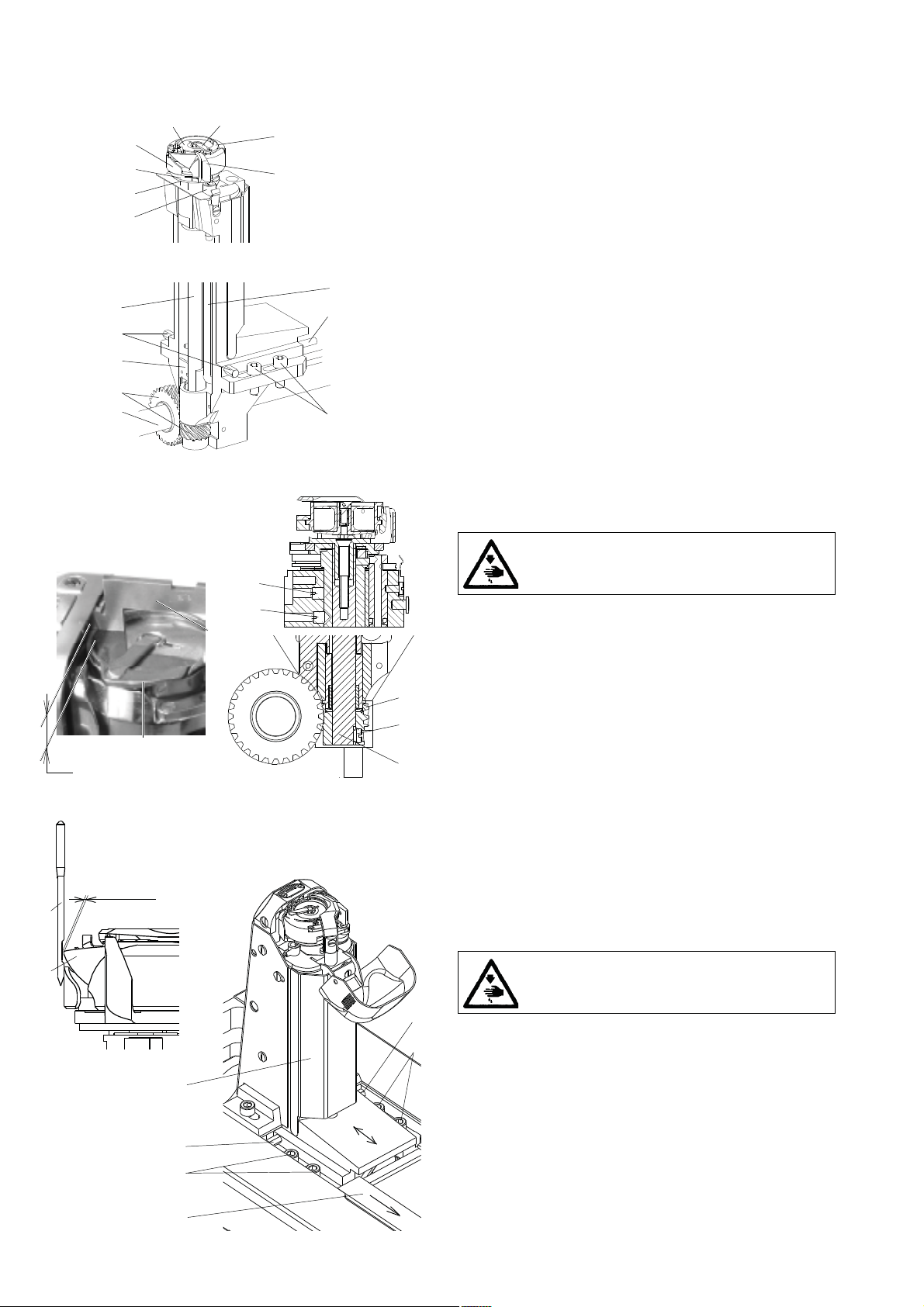

3.1.1 Description

The hook (1) is mounted on the shaft (2) and is driven by the gear (3)

from the shaft (4).

The shaft of the hook (2) is mounted on the top in a sliding bearing

and, on the bottom, in a needle bearing.

The hook is provided with a lever (6) which is tilted when removing the

bobbin (7). The protecting sheet (8) protects against the collision of

the needle with the hook point. The bobbin case opener (9) is driven by

the eccentric (10) on the shaft (2).

The lubricating tube (11), on which a lubricating wick is fastened in the

tube (12), feeds oil for lubricating the sliding bearing (5) of the eccentric

(10) and the hook path.

The screws (13) serve for taking up the clearance of the gear. The

screws (14) fasten the post to the bedplate.

The lubricating felt (15) is connected by the wick (16) with the lubricating

system and serves for lubricating the gear (3).

13

15

67

8

10

1

9

5

11

12

2

16

3

4

14

3.1.2 Height setting of the hook

The designated distance A should be 5 mm.

Caution! Danger of injury!

Switch off the main switch ! Before starting the setting

3

4

7

5

2

6

A

6

- Loosen both screws (2).

- By turning the screws (3 and 4), set the required distanceA.

setting up use the setting gauge (7) as per the repective

figure. After having set it, tighten carefully the screws.

- By axial shifting of the gear wheel (5), set the axial clearance in

such a way that this clearance is the least possible, but sufficient for

turning easily the hook.

- Tighten carefully the screws (2). Caution ! One of these screws must

bear on the flat of the shaft 6).

operation, wait until the motor stops!

For

3.1.3 Setting the distance of the hook from

max. 0,1

2

The hook point (1) is set up to the maximum distance of 0.1 mm from

the bottom of the needle recess (2). For setting up use the needle size

100.

1

4

- Shift the plate (3).

5

- Loosen only one screw (4).

- Loosen the screws (5) and tighten them only slightly.

6

4

- Shift the hook post (6) at the determined distance between the needle

- Tighten carefully the screw (4) (be sure not to damage the threads!)

- Tighten duly the screws (5).

- Check up the setting using a narrow strip of thin paper and proceed

5

3

2

the needle

Caution! Danger of injury!

Switch off the main switch ! Before starting the setting

operation, wait until the motor stops!

and the hook point.

to the eventual correction of setting.

Page 6

2

1

57

208

3

o

4

~ 0,5

6

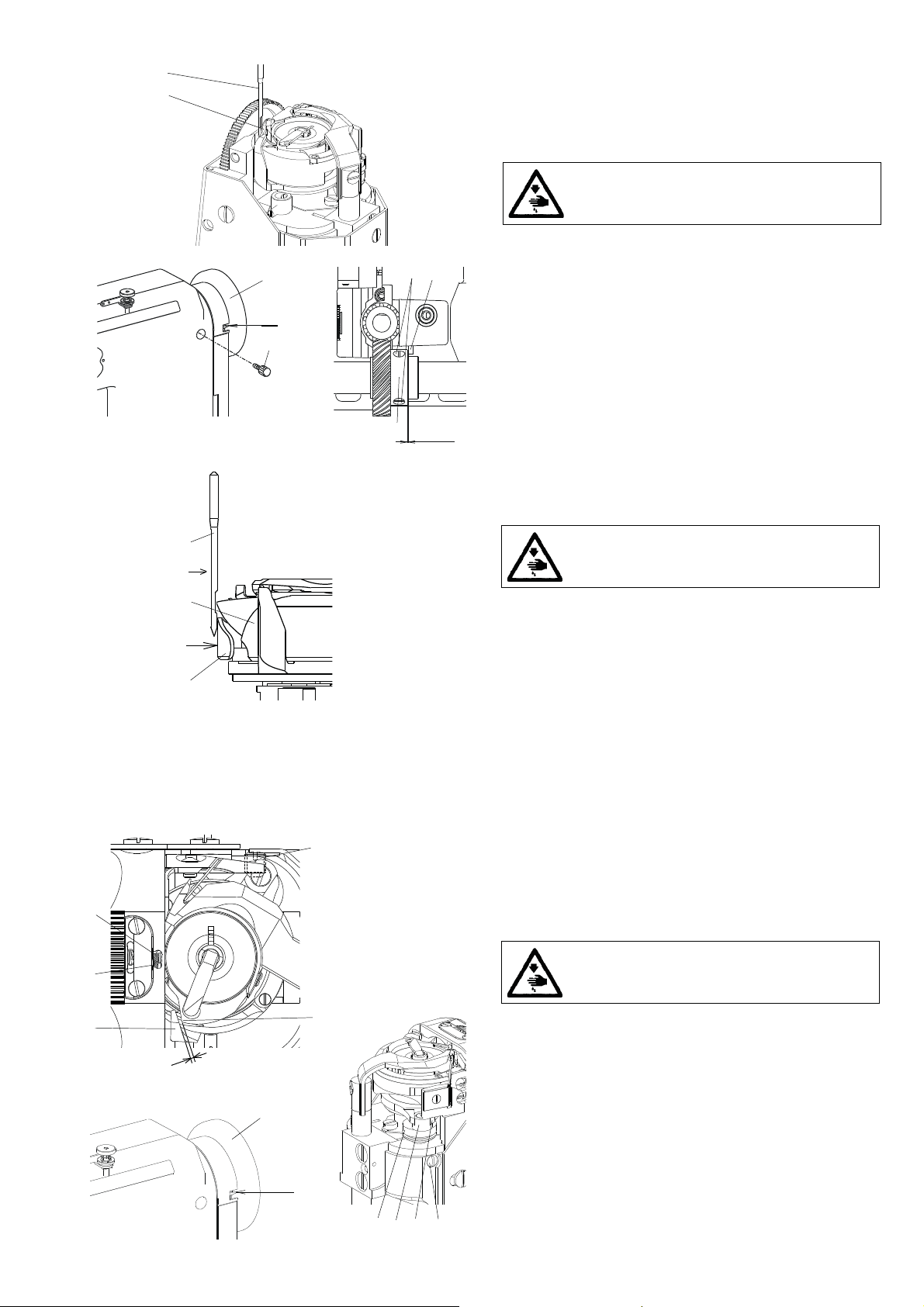

3.1.4 Angular setting of the hook (timing)

The hook is to be angularly set in such a way that the hook point (1) is

opposite the needle at the moment, when the needle shifts by 2.5 mm

from its bottom dead center. This corresponds to the 2O8

of the handwheel (3).

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Remove the throat plate.

- Turn the handwheel (3) to the 2O8

which is component part ot the accessory of the machine (tighten

it carefully).

- Loosen the screws (5).

- Turn the hook into the required position.

- Set up the distance of about 0,5 mm between the gear wheel (6) and

the pin (7).

- Tighten to the maximum the screws (5).

° and fix it with the screw (4)

° on the scale

3.1.5 Protection of the needle and of the hook point

The protecting sheet (1) is to be set up in such a way that the clearance

between the protecting sheet and the needle (2) is the least possible.

2

5

3

4

1

6

3

- Remove the throat plate.

- In deforming the protective sheet (1) set the required play between

the sheet and the needle (2). After having introduced a suitable

screwdriver between the protective sheet and the hook body (3) we

shall reduce the play by levering, in applying the pressure on the

protective sheet in the sense of the arrow (4), we shall increase the

play.

- Check up the protecting effect in pushing against the needle in the

sense of the arrow (5). The hook point must not catch the needle. If

so, set up the protecting effect, correct eventually the setting of the

distance of the hook point from the needle according to the paragraph

3.1.3.

3.1.6 Setting of the bobbin case opener

The bobbin case opener (1) is to be set in such a way that, at the

moment when the opener is in its dead centre, there would be a clearance

A between the opener (1) and the projection (2), whereas the finger

(3) bears on the projection (4), A = 0.7 mm .

4

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

1

2

A

5

o

295

- Remove the sheet guard of the hook post.

- On the handwheel (5), set the angle of 295

centre).

- Loosen the screw (6).

- Turn the eccentric (7) in such a way that the required clearance

between the elements (1) and (2) is attained.

- Set the height of the eccentric (7) in such a way that it is in its

highest position in retaining the minimum clearance between the

slide (8) and the fork (9).

- Tighten duly the screw (6).

° (the hook is in its dead

78 69

3

Page 7

6 7

0,4

11

3.1.7 Setting the regulation of the hook lubrication

5

3

4

9

15

1

2

o

10

1

8

By turning the lubricating tube (1) in the sense of the arrow (2), the

size of the contacting surface between the wick (3) and the felt insert

(4) is regulated. In this way, the speed of the capillary lift of oil into the

felt insert (5) is influenced, from which oil is wiped on the surface (6)

and is driven by centrifugal force into the hook path (7).

Setting of full lubrication

- Turn the screw (8) into the position (9).

Setting of limited lubrication

- Turn the screw (8) into the position (10).

After having ended the regulation, set the height of the lubricating tube

(1) at 0.4 mm from the eccentric (11).

1

2

3

4

3.1.8 Replacement of the hook

Caution! Danger of injury!

Switch off the main switch ! Before starting the setting

operation, weit until the motor stops!

- Remove the throat plate and the trimming knife.

- Unscrew the screws (1) and remove the gib (2).

- After having suitably turned a bit the hook, remove the bobbin case

(3).

- Unscrew thorougly the screw (4).

- Remove the body of the hook (5) upwards.

- When mounting, the procedure is inverse.

5

3.1.9 Setting the gear

4

1

3

5

The mutual angular orientation of the gear wheel (1) relative to the gear

wheel (2) should ensure the accessibility of the screw (5) at the moment

when the hook point comes to lie opposite the needle (4). The wheel

(2) is to be set with its gear rim symmetrically to the centre of the gear

wheel (1). The clearance between the gear wheels is to be the least

possible.

2

- Set the angle of 2O8

screw (7).

~0,5

208

8

9

6

10

o

10

7

- On the removed post of the hook (8), according to the paragraph

3.1.10, the hook point (3) is to be turned a bit according to the

illustration.

- Turn the gear wheel (2) into the suitable position and insert the post

of the hook into the machine according to the respective arrows.

Check up, whether the screw (5) is accessible and, if not, repeat the

procedure.

- Set the the distance of the hook from the needle according to the

paragraph 3.1.3.

- Set the precise angular displacement of the hook according to the

paragraph 3.1.4.

- Loosen the screw (10) and tighten them slightly.

- Set the clearence in the gear in turning the screws (9). Check up,

whether the gear has a clearance during the whole revolution of the

hook. Turn the handwheel step by step by 15

grasp the hook and try, if there is an angular dead travel. Tighten

carefully the screws (9).

- Tighten duly the screws (10) and try anew the clearance of the gear.

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

° on the handwheel (6) and lock it with the

° and, with each step,

4

Page 8

7

8

1

32

5

6

9

6

3.1.10 Dismantling of the hook post

When dismantling the post (1), the supplies of lubricating oil are to be

disconnected first, the fastening screws unscrewed and, thereafter, the

post is removed.

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Unscrew the screw (2).

- Push the lubricating tube (3) downwards into the post.

- Unscrew the screw (7) from the oil tank (8) and pull the tank out

from the machine.

- Disconnect the hose with the wick (9) from the oil tank (8).

- Loosen only one screw (5).

- Unscrew the screws (6).

- Shift the post in the sense of the arrows and remove it out from the

machine.

- When mounting it, proceed inversely.

3

8

9

10

11

4

5

2

7

13

1

12

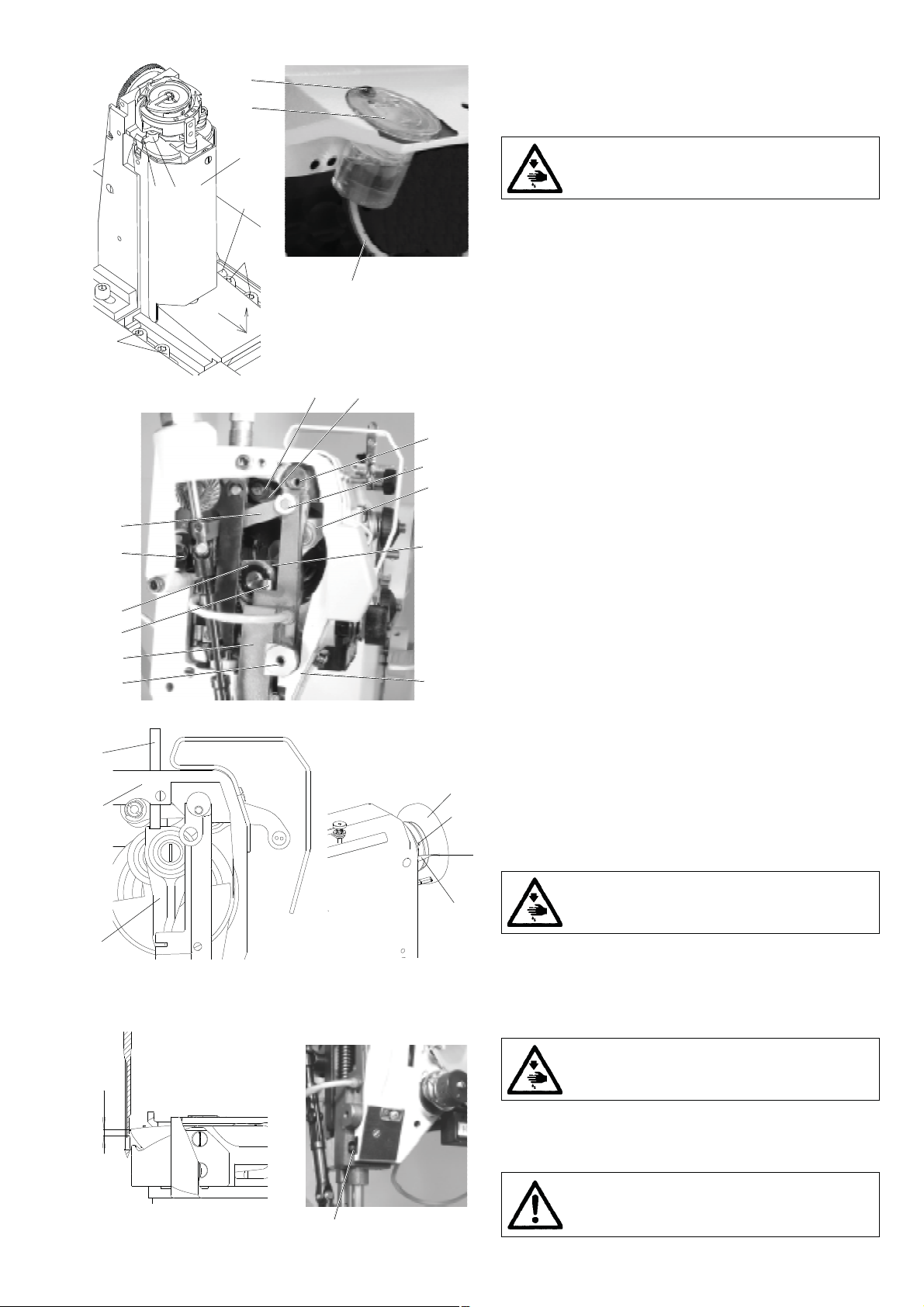

3.2 Needle and thread mechanism

3.2.1 Description

The take-up lever (1) is mounted in ball bearings, both at the spot of its

suspending on the connecting rod (2) and in the mounting on the loop

(12). The take-up lever is of aluminum and is provided with a stuck-in

eye for two threads. The connecting rod (2) is mounted on the eccentric

pin (3). The needle rod holder (4) is mounted through the pivot (5) in

a rotating way in the arm (6). In its top part, the holder is guided by the

guide pin (7). The movement for the needle feed is given to it by the

connecting rod (8) driven by the feeding shaft (9). The connecting rod

(8) is mounted by pin (13) with needle bar holder (4).

The connecting rod (10) of the needle bar (11) on the loop (12) is

mounted in a ball bearing and it is slidingly mounted on the needle bar

carrier. The mechanism is lubricated by means of a central-wick

lubricating system.

6

3.2.2 To check the handwheel angular adjustment

2

5

3

4

The handwheel (5) must be situated in its precise position relative to

the needle and thread mechanism. This position is given by a pin (2),

which locks the connecting rod of the needle rod (1) through a hole in

the arm (3). In this position, the indicator (6) of the handwheel must

show O. The position is fixed by the handwheel screw (4) contacting

a small flat surface provided on the upper shaft.

The correct adjustment of the angular position has been car-ried out at

o

0

the producers.

Caution ! Danger of injury!

6

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

1

3.2.3 Height setting of the needle bar

At the moment, when the hook point passes around the needle, the

upper edge of the needle eye must be about 1 mm below the hook

point. In an opposite case, it is necessary to set the height of the needle

bar as follows:

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Remove the front guard.

1

1

- Loosen the screw (1) of the needle bar carrier

- Set the correct height of the needle bar and tighten anew the screw

(1).

Caution !

An incorrect setting of the needle bar height may cause

the striking of the hook point against the needle.

5

Page 9

4

A

1

2

5

3

3.2.4 Side setting of the needle bar holder

The correct position of this holder is in such case, when the needle bar

is lined up with the presser-foot bar. The needle bar holder can be set

as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Loosen the screw (1) of the pin (2).

- Loosen the screw (3) of the guide pin (4).

- In shifting the pin (2) set the needle bar holder on the measure A

(distance between the front face of the arm and the front face

= 8 mm

of the safety bolt (5) of the needle bar holder)

pin (4) shifts/.

- The guide pin (4) is to be set in such a way that the needle bar holder

moves easily.

- Tighten the screws (1 and 3).

/at the same time the

1

3

3.2.5 Setting the needle (the needle bar holder)

in the direction of sewing

o

246

2

A

5

4

When shifting out the needle from the throat plate insert, at the moment,

when the needle eye is at the level of the top surface of the throat plate

insert (3), the distance between the needle and the wall of the throat

plate insert must be A = 0.2 mm.

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Set the maximum allowed stitch length.

- Set the handwheel (1) to the angle of 246° and lock it with the screw

(2).

Loosen the screw (4) of the lever (5).

-

- By turning the needle bar holder (6) on the pin (7) set the required

distance A = 0,2 mm.

- Tighten up the screw (4) and check up the setting.

6

Caution!

7

A faulty setting may cause bending or breaking of needles

against the throat plate insert.

6

Page 10

3.3 Throat plate and its post

4

2

4

1

32

5

6

3

1

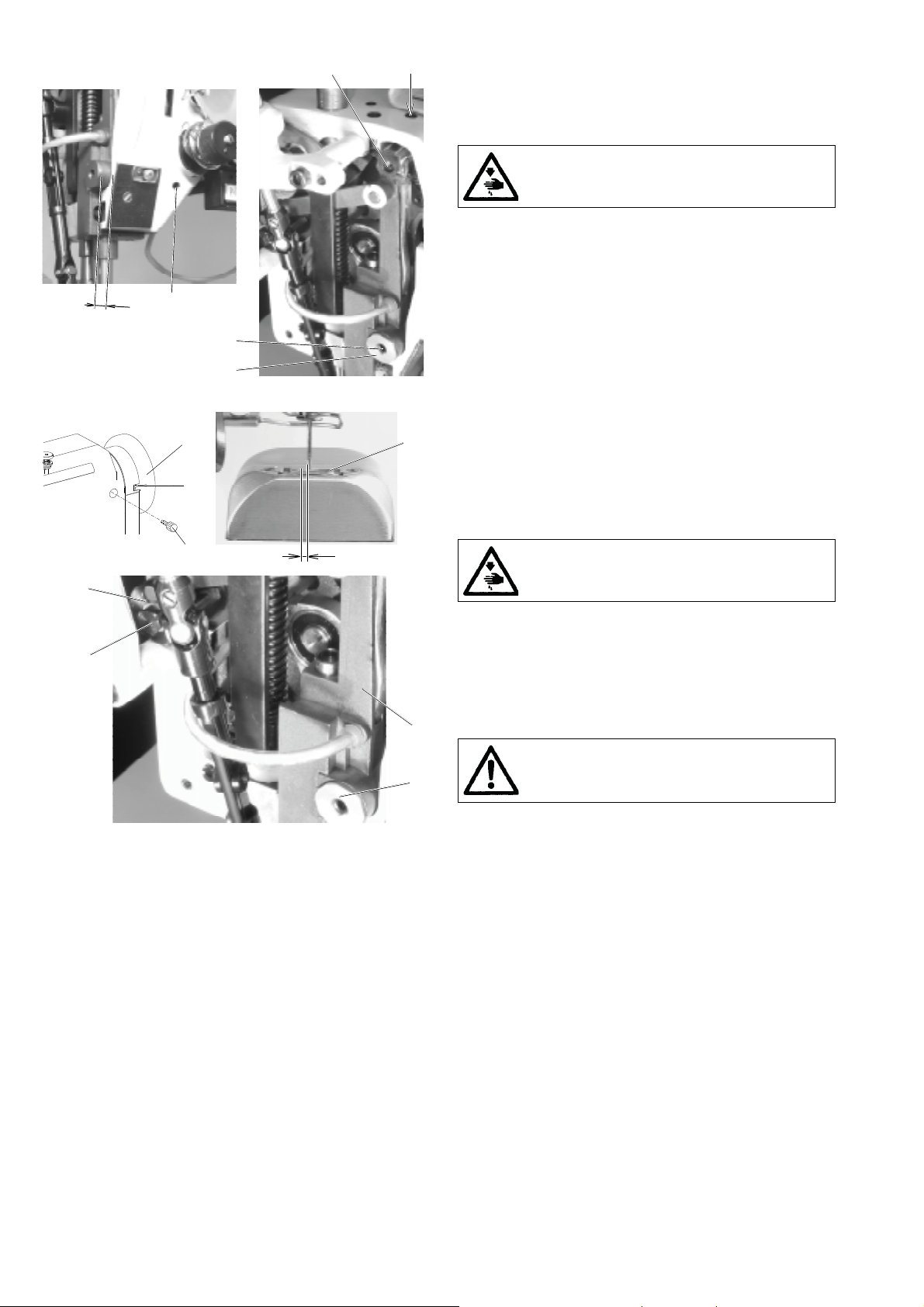

3.3.1 Description

The throat plate (1) is equal for both categories of sewing. In the throat

plate there is fixed by means of two screw (3), (4) the exchangeable

throat plate insert (2). Each category of sewing has its own insert of the

throat plate which differ one from another by the length and width of

the piercinghole.

3.3.2 Mounting and removing the throat plate and

its insert

When mounting the throat plate (1), the finger of the hook (2) must fit

into the recess (3) of the throat plate. When demouting or replacing the

throat plate insert (4), both screws (5), (7) are to be unscrewed and the

insert romoved.

7

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

6

- Turn slightly the finger (2) in the sense towards the throat plate (1).

- Place the throat plate (1) and screw in the screws (6).

- Place the insert (4) and screw in the screws (5), (7).

3.3.3 Side setting of the throat plate post

The post of the throat plate (1) is to be side set in such a way that the

axis of the hole in the insert of the throat plate (2) is at the distance A

= 0.1 mm to the right from the axis of the needle (3).

3

A

4

- Loosen the screws (4 and 5) (from the rear side of the post as well).

2

1

- Shift the post (1) in the sense required for attaining the distance A

= 0.1 mm.

- Tighten the screws (4 and 5) and check up for the correct setting.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

5

7

Page 11

13

12

14

3

4

6

5

10

2

8

A

7

1

3

2

1

0,1

4 1 7

3 2

9

5

6

8

3.4.1 Description

The main tensioners (1) serves for creating the tension of the thread

when tightening the stitch. The auxiliary tensioner (2) reduces the risk

of pulling out of the thread after the thread trimming when removing

the sewn material, when the thread is passed through this material and

when the main tensioner is relieved.

the mechanism controlled by the shaft of the presser bar lifting (3)

holding the lever (4) with a pulley. The motion is then transmitted by

the lever (5) and the tie rod (6) on the thread tensioner plate (7) whose

displacement (motion) relieves thethread tensioner springs (8). In

machines provided with a thread trimming device, the main tensioners

(1) are relieved as well upon the switching on of the electromagnet

(10) whose electromagnetic field will attract the thread tensioner plate

The mechanism of the adapting spring (12) maintains the upper

(7).

thread in its tensioned state when passing through the hook

entering the needle into the sewn material

limits the length of the thread fed by the take-up lever when moving

from the upper to the bottom dead centre to get a controlled passing of

the thread through the hook.

upper thread in front of the needle in a tensioned condition and helps

against pulling the thread from the needle after thread trimming.

The main tensioner is relieved by

and when

. The thread limiter (13)

The auxiliary guide (14) maintains the

3.4.2 Setting the tension of the main and auxiliary

tensioners

The tension of the main thread tensioners is regulated by means of the

nuts (1).

dynamometer (2) as it is shown on the illustration.

force differs according to the category, and its orientation value is

indicated in the par. 11.2.

The tension of the auxiliary tensioner is regulated using the nut (3). It

should be the least possible, but sufficient for unthreading the thread

from the sewn material when removing the sewn material from the

pressing element without leaving the tensioner.

The force of tensioning the thread is measured by the

The size of this

3.4.3 Setting the tensioning mechanisms

of the main tensioners

In the rest position of the tensioners, when pushing the plate of the

tensioners on the spot A 3.4.1, this plate must have the socalled dead

travel of about 0,5 mm. At this lifting, the tension discs of the tensioners

must not be relieved. This can be attained by a suitable shaping of the

relieving disc of the tensioners-this has been set up in the manufacturing

factory. In the maximum opened position of the tensioners, the plate of

the tensioners, when pushing it at the spot A 3.4.1, must still have

the minimum lifting. This can be attained when axially shifting the lever

(3) with the roller (5) on the shaft (4).

The disengagement of the main tensioners must be coordinated with

the top roller lift. To achieve this, turn the lever (3) with the roller (5) on

the shaft (4). The movement of the roller (5) on the slanting surface (6)

of the lever (7) disengages the tensioners. In this way, also alag of the

upper thread tension disengagement after the top roller lift can be

obtained.

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

Remove the rear cover with the top roller lift magnet.

-

- Loosen the screws (1) and (2) of the lever (3).

- In the rest state of the machine (with not relieved tensioner discs) set

the lever (3) in turning it slightly on theshaft (4) to a position in

which the roller (5) of the lever (3) is in contact with theslanting

surface (6) of the lever (7) and is about 0.1 mm distant from the flat

surface (8) of thelever.

- At the maximum lift of the top roller, the roller (5) moves on the flat

surface (9) of the lever (7); in this condition, there must be a minimal

play at the tensioner plate lift (when pushing qat the spot A (3.4.1),

the plate must still have a minimum lifting - between the roller (5)

and the surface (9) there is a minimum clearance). Retighten the

screws (1) and (2), check the play, and correct it in case of need.

3.4 Thread tensioners and limiter

8

Page 12

3.4.4 Setting the adapting spring

The mechanism of the adapting spring is in the machine arm set by the

3

4

8

1

6

9

7

8

2

3

A

pin (1) and fixed by the screw (2). The axial adjustment shall ensure

that the surfaces of the parts (3) and (4) are aligned (the threaded

thread must in no place break on edges). The initial position of the

adapting spring (5) shall ensure that B = 1 to 1.5 mm (see the

Figure).

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

Loosen the screw (2) and take the mechanism out of the machine

-

arm.

- Turning the body (6) relative to the pin (1), set the required initial

position of the adapting spring /the screw (7) has been set at the

producer´s so as to permit the turning movement of the body (6) the

screw must not be fully tightened/.

- During the installation of the mechanism into the machine arm take

care of the axial adjustment of the mechanism.

- Retighten the screw (2) and check the adjustment.

- Loosen the nut (8) of the mechanism, insert a screwdriver into the

notch of the screw (9) and set the required value of the adapting

spring. By turning the screw clockwise you increase the spring

force, and vice versa.

- Retighten the nut (8) and check the function of the adapting spring.

5

4

9

3

1

2

3.4.5 Setting the thread limiter

The thread limiter is to be set in such a way that, when sewing and

passing the thread through the most distant point of the hook, the

spring (2) shifts by about 1/4 to 1/2 length of its total length. This

means that the thicker will be the sewn material and the longer will be

the stitch length, the more will be the limiter shifted in the sense of the

arrow and inversely. Under standard sewing conditions, the thread

limiter is set in its tested positions depending on the sewing category

in accordance with the chapter 11.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Tighten the screw (3).

Set the thread limiter (1) so as to ensure a minimum motion of the

-

adapting spring (2) when the thread passes around the bottom of

the hook.

- Tighten the screw (3).

3.4.6 Setting the additional thread limiter

For improving the uniformity of stitch interlocking with some (e.g. too

thin) materials, the machine is provided with an additional thread limiter

which is to be set as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

1

2

- Set the stitch length to the required value.

- Sew an approximately 5 cm long seam along the edge of sewn work,

switch off the machine, and tilt away the hook cover.

- Rotate the handwheel until the thread taken up by the hook will be

stretched across its bottom, i.e., across the full diameter of the hook.

- Adjust the position of the additional limiter (1) so as to obtain an

almost complete stretching of the thread (2) at that moment, as shown

in the drawing.

- Sew next stitch and check the adjustment.

9

Page 13

15

13

12

3

1

3.5 Feeding mechanism of the needle feed

and of the lower feed wheel

2

14

4

5

6

8

9

7

11

10

10

143

2

3.5.1 Description

The feeding mechanism is formed by the leverage (1) which is driven

from the main shaft through the eccentric with connection rod (2). The

feeding motion is transmitted by the shaft (3) on the clutch of the

bottom feed (7).

The engaging and the disengaging function of the clutch (7) is controlled

from the lower shaft (8) through the eccentric with the connecting rod

(9) and through the wedge coupling (10).

The feeding movement is transmitted by the shaft (11) through the

chain transmission (12) onto the wheel feeder (13).

The stitch length is set by the knob (14) through the leverage (15) to

the feeding mechanism (1).

3.5.2 Stitch length mechanism

3.5.2.1 Setting the upper eccentric

The eccentric (1) must be set in its angular position in such a way that

the horizontal component of the needle motion is in a phase delay from

the vertical component of this movement. This refers to the angle of

90° on the handwheel (2), when the setting stick (3) is engaged into

the eccentric (1) and leans from above against the feeding shaft (4).

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

Set the angle 90° on the handwheel (2) and fix it with the screw (5)

-

o

90

5

6

7

D

C

1

B

A

which is component part of the accessory of the machine (tighten it

with care).

- Loosen the gripping joints of the levers (6) and (7).

- Turn the feeding shaft (4) in such a way, so that the recesses (flats)

point towards the bedplate (owing to the unambi-guous setting of

the eccentric by means of the setting bar).

- Insert the setting bar (3) into the hole in the eccentric (1) and prop

it from above against the feeding shaft (4).

- Shift axially the eccentric (1) on the shaft into its extreme positions

and place it in the middle.

- Tighten the screws of the eccentric (1) to the maximum (one screw

first and, after having turned slightly the hand-wheel, the second

screw as well).

- Turn the feeding shaft (4) back into the position for setting the

leverage in such a way, so that the levers (10) of the mechanism pass

in the spots of the recesses.

- Tighten the gripping joints of the levers (6) and (7).

- Test the sufficient clearance in the recesses of the feeding shaft (4)

and, using the levers (10) with the maximum stitch length forward

and rearward push against the reverse stitching lever.

- Correct eventually the position of the feeding shaft.

3.5.2.2 Setting the prop

In this machine with a wheel feed, the prop (1) is mounted in the pits

(A and C) as per the drawing.

3.5.2.3aForward and rearward stitch length

3

The cam (1) is to be set at the respective angle in such a way that the

2

678

stirrup (6) is oriented in such a position, so that the connecting rods (7

and 8) are in a line with a thoroughly screwed in knob (9) and with

turning the handwheel at 0°. This setting can be done only after having

set the top eccentric according to the paragraph 3.5.2.1.

19

o

0

4

- Set the zero stitch /screw in the knob (9) to the bottom of the cam

(1)/.

- Set the angle 0° on the handwheel and lock it with the screw (4).

- Turn the screw (3) in the respective sense in such a way that the

connecting rods (7 and 8) are in a line and tighten the screw (2).

distribution (rough)

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

10

Page 14

3.5.2.3bForward and rearward stitch length

distribution (fine)

When setting the maximum length of the stitch, the forward and the

rearward stitch length must be equal with the maximum error of ± 5 %.

This setting can be done only after having set the needle bar holder in

3

2

the direction of sewing (par. 3.2.6) and the wheel feed (par. 3.5.3.1.2).

Caution! Danger of injury!

switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Set the maximum stitch length .

- Place a suitable material under the presser foot and mark therein the

forward and the rearward stitch length.

- With an unequal length of the stitch, proceed to the correction

of setting by turning the screws (2 and 3). When tightening the

screw (3), the forward length of the stitch is shortened and inversely.

When tightening the screw (2), the forward stitch length is lenghtened.

Each time first loosen one screw and then retighten the

-

other one.

3.5.2.4 Setting the control knob

(including the stitch length limitation)

The control knob (1) is to be set up in such a way that, when turning it

in counterclockwise sense up to the stop, the maximum stitch length

valid for the given sewing category is attained (cat. 1: 3 mm, cat. 2:

5 mm). The scale of the control knob is to be oriented in such a

position, so that the scale end corresponds to the maximum stitch

length, excepting the first sewing category, where the stitch length of

the indicator is 3 mm.

1

2

5

8

2

3

4

- Screw in the screw of the control knob in such a way, that the

spherical surface of the screw (3) bears on the seat of the cam (4).

- Loosen the screw (5) and turn the control knob in the clockwise

direction, until the pin (6) of the knob (1) bears on the pin (7).

Tighten firmly the screws (5).

- Turn the knob in the counterclockwise direction up to the stop, when

the pin (6) of the knob (1) bears on the pin (7).

- In a sewing test check up the length of the stitch, if this corresponds

1

5

7

6

to the maximum stitch length valid for the given sewing category.

- If the stitch is longer, loosen then the screws (5) and turn the knob

in the clockwise direction and inversely. Tighten firmly the screws

(5).

- Insert a screwdriver into the hole (8) of the scale (2) and adjust the

scale in such a way that the maximum length on the scale is against

the marking of the stitch length on the machine arm.

- For the sewing category 1, set the control knob (1) on the stitch

length of 3 mm and check it by a sewing test.

- Loosen the screws (5) and turn the control knob (1) in the

counterclockwise direction, until the pin (6) of the knob (1) bears

on the pin (7). Tighten firmly the screws (5).

- Put a screwdriver into the hole (8) of the scale (2) and adjust the

scale in such a way that the value of the stitch length on the scale

against the marking on the arm is 3 mm.

Caution! Danger of injury

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

11

Page 15

3

9

13

7

2

8

10

1

11

5

6

4

12

3.5.3.1 Feeding clutches

3.5.3.1.1

The feeding clutch is formed by the clutch cover (1) driven from the

connecting bar (2), by the clutch star (4) driven from the connecting

rod (3) and by the carrier plate (5) firmly connected with the shaft (6).

Of the clutch give the connecting rods (2 and 3) an opposite direction

swinging movement. The clutch is coupled by means of the wedge (7)

on the connecting rod (8) through the eccentric (9) which is placed on

the lower shaft (10).

In the position, when the wedge is disengaged, the star (4) is

shifted out from the frictioning engagement with the lining of the carrier

plate (5) by means of the spring washer (11). The plate (5) lining is

then pushed by means of a flat profiled spring (12) against the cover of

the clutch (1).

In the position, when the wedge is disengaged, the star (4) i s

pushed against the plate (5) lining and, at the same time, the friction

connection with the cover of the clutch (1) is disconnected. Within a

short instant, when engaging and disengaging with the carrier plate

(5), there are in a friction engagement both the cover (1) and also the

star (4), namely in the dead centre of the connecting rods (2 and 3).

The setting of the change-over of clutches is done by tightening or by

loosening the nut (13).

Description

3.5.3 Lower feed wheel

1

4

4.1

5

3.5.3.1.2 Setting the lever of the second step of

feeding (angle, position)

The lever of the second step (1) must be set in such a way

that, in the bottom dead centre of the needle, the axis of the

spider part (2) lies in the screw axis (3).

mounted into the position - 4.1 - corresponds to the maximum stitch

length of 5 mm.

6

Caution! Danger of injury!

8

5

3

2

2

Lever (1) displacement.

- Loosen the screw (6).

A

- Set the maximum stitch length.

- Set the angle 180

- Unscrew the screw (5) and put the needle shank in its hole.

- Turn the lever (1) until the needle drops into the clutch disk (2).

- Side set the lever (1) to the measure A= 0.5 to 1 mm.

- Tighten the screw (6).

- Screw in the screw (5) and seal it with the Loctite cement.

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

° on the handwheel.

The pin screw (4) can be

4

1

12

Page 16

244

1

o

45

3.5.3.1.3 Setting of the lower eccentric

The rotation of the eccentric (3) must be delayed in phase by 1/4

revolution against the rotation of the eccentric of the stitch length. This

corresponds to the angle of 244

setting pin (4) is put into the eccentric (3) which is in contact with the

indented belt (5).

° on the handwheel (1), when the

2

- Set 244

is included in the accessory of the machine (tighten it carefully).

- Put the setting stick (4) into the hole in the eccentric (3) and prop it

from below against the indented belt (5).

6

3

A

1

o

90

2

- Set eccentric (3) axially.

- Tighten it the utmost the screws of the eccentric (6).

- By means of the handwheel, turn the eccentric (3) into the marked

position and check in this position the clearance A = 0.05, proceed

eventually to its correction by a new side setting of the eccentric.

3.5.3.1.4 Setting the engagement and

The nut (7) is to be side set in such a way that the shifting of the

clutches is done at the moment when the clutch disks (3) do not move,

which means, when they are at the dead center of their oscillating

movement. This corresponds to the angle 90

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

° on the handwheel (1) and lock it with the screw (2), which

disengagement of the clutches

° on the handwheel.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Loosen the screws of the indented pulley of feeding and shift it to the

left.

- Set the maximum stitch length.

- Set the angle 90

(2). which is included in the accessory of the machine (tighten it

carefully).

- Loosen three screws (6) in the nut (7) and unscrew it by 2 mm to the

left.

- Tighten slowly the nut (7), until it strikes against the axial bearing

(9). (At this moment, the tightening moment increases in jumps)

and tighten the screws (6).

- Set the the handwheel on 85

feeder is to turn against the movement of the needle. Set then the

handwheel on 95

needle movement. If not being so, correct the side setting of the nut

(7). When the clutches shift too soon, turn a bit the nut (7) to the

right and inversely.

7

6

9

3

- Tighten the screws (6).

- Return the indented pulley in its original place according to the

paragraph 3.6.2.

° on the handwheel (1) and lock it with the screw

° and push the backtacking lever, the

°, the feeder is to be turned in the sense of the

13

Page 17

3.5.4.2 Wheel feeder and its post

3.5.4.2.1 Height setting of the feeder and tension-

1

X

1

The wheel feeder (1) is to be set in such a way that the points of its teeth

overtop the insert of the throat plate by X= 0.3 to 0.7 mm. When

sewing soft and thick materials, it is necessary to increase the value

X, until a good quality of feeding is attained, but only to the measure

of not deteriorating the beginning of sewing after the carried out thread

trimming.

With every correction of the teeth height, the tension of the chain (2) is

to be corrected.

4

- Loosen the screw (3).

- Loosen the screw (4).

5

- Loosen or tighten the screw (5) and push simultaneously with

finger the feeder (1) downwards, until the required height of the

teeth X of the wheel feeder is attained.

- Tighten then still the screw (5) by 45

- Tension the tensioner (6) up to the stop. Be careful in side shifting it

to the centre of the chain. Tighten the screw (3).

- Loosen the screw (5) by 45

position. In this way, the optimal clearance of the chain transmission

is attained.

- Tighten the screw (4).

- Correct the set height of the top roller according to the par. 3.5.4.

ing of the chain

Set the height of the feed dog using a setting gauge.

Caution! Dangere of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

° (1/8 revolution).

° (1/8 revolution), into its original

3

6

2

14

Page 18

3.5.3.2.2 Replacement of the feeder

For the replacement of the wheel feeder (change of the wheel feeder

according to the machine setting - see par. 11.2 - setting of the machine

- feeder - pitch of the teeth).

3

4

- Unscrew the screws (1) and remove the throat plate (2).

5

6

9

17

2

2

4

3

- Unscrew the guard (7).

- In pulling upwards (securing by a spring), pull out the feeder (3)

8

with the guide (4).

- Replace the feeder (3).

- Insert the feeder with the guide into the groove of the holder (5).

- Mount the throat plate (2) and tighten up the screws (1).

- Check up, if the spring (6) pushes the guide (4) with the feeder (3)

against the wheel (8).

- In the opposite case, loosen the screws (9), tense up the spring (6)

in such a way,so that the guide (4) with the feeder (3) is pushed

against the wheel (8) and tighten the screws (9).

- Mount the guard (7) and tighten the screws.

3.5.4 Setting the top roller (pressing force, height)

When lowering the top roller (1), set the clearance A between the

feeder (5) and the top roller to the maximum of 0.2 mm. Set the pressing

force of the top roller (1) so as to avoid the slippage of the sewn material

when feeding it.

Method of setting the height of the top roller:

- Lower by hand the presser bar (3) with the top roller (1) above the

wheel feeder (5).

- Loosen the screw (4) and set the required value A=0.2 mm.

- Tighten the screw (4).

Setting the force of the top roller (1).

- In screwing in the screw (2),the force of the top roller is increased and

inversely.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

1

A

5

8131214

62

3.6 Feeding mechanism of the top roller

3.6.1 Description

The starting movement for the drive of the top roller feeder is the

bottom feeding shaft. From this shaft, the movement is transmitted by

the indented belt (1) onto the top feeding shaft (2). A component part

of the transmission by indented belt is the pulley (3), the tensioning

roller (4), the roller (5) and the pulley (6). Starting from the shaft (2),

the movement is further transmitted through the wheels (7 and 8)

ontothe articulated shaft (9). From this articulated shaft, the movement

is transmitted by a cone transmission, situated in the holder (10), onto

the feeder wheel (11). The shaft of the wheel (8) is mounted in the

screw (12) on bearings. The articulated shaft (9) contains two joints

(15) and a telescopic part (16). Both these

and the tilting of the top roller.

elements secure the lifting

15

16

15

10

11

7

5

9

1

4

3

15

Page 19

3.6.2 Side setting of the indented lower pulley

6

2

1

The pulley must be set up in such a way that the belt passes through the

centre of the passing hole in the bedplate. The setting operation is to be

done as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

5

3

4

- Loosen the screws (1) of the pulley (2).

- Loosen the screw (3) of the tensioning roller (4)

- Set the pulley (2) in such a way that the belt (5) passes through the

centre of the passing hole in the bedplate (6).

- Tighten the screws (1).

- Set the tensioning roller (4) axially in such a way that the belt (5) is

set at the middle of the tensioning roller (4).

- Set the tensioning roller (see par. 3.6.4).

- Tighten up the screw (3) of the tensioning roller (4).

5

3.6.3 Side setting of the indented upper pulley

The pulley is to be set in such a way that the indented belt is not crossed

1

2

and the pulleys are in line. The setting thereof is to be done as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Loosen the screws (1) of the pulley (2).

- Set the pulley (2) in such a way that the distance of 5 mm is

attained in accordance with the illustration.

- Tighten the screws (1).

3.6.4 Setting the tensioning roller

The tensioning roller of the indented belt of the top feeding is

mounted in a rotary way on the bedplate. The belt must be ten-sioned

as needed in such a way that there is ensured the correct function of the

transmission. Insufficient tension can cause skipping of the teeth, on

the contrary, excessive tensioning enormously loads the mounting of

the top shaft. The setting thereof is to be done as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

1

- Loosen the screw (1) securing the lever of the tensioning roller (2).

- Tension the belt as needed (theoretically, in applying the force of 10

2

N in the middle of the belt with the deflection of 4 mm).

- Tighten the screw (1).

16

operation, wait until the motor stops!

Page 20

16

18

1110

56

12

12

9

7

21

15

14

438

19

20

3.6.5 Replacement the indented belt

Before replacing the indented belt, the bottom feeding shaft is to be

removed. The procedure is as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Loosen the screw (1) of the tensioning roller (2) and loosen it.

- Loosen the screws (3) of the pulley (4) and shift it to the left in such

a way that the screws (5 and 6) of the feeding clutch (7) are accessible.

- Loosen the screws (5 and 6).

- Loosen the screws (8) of the axial ring (9).

- Loosen the screws (10) of the chain wheel (11).

- Push the shaft (12) to the left in such a way that it is out of the pulley

(4).

- Remove the pulley (4).

- Remove the front guard.

- Loosen and unscrew the screw (14) of the holder of the wheel (15)

and remove it from the holder (21).

- Loosen the screws (16 and 17) of the holder (18).

- Remove the holder (18) together with the holder (15) and articulated

shaft (13) from the machine.

- Loosen the screws (19) of the pulley (20).

Loosen the screw (24) of the ring (25).

-

- Hold the pulley (20) and pull out the feeding shaft (22) from the arm

in such a way that it is possible to remove the indented belt (23) from

the arm of the machine.

- Replace the belt with a new one and proceed to the assembly (inverted

procedure of dismantling).

- Proceed to the setting operation according to the par. 3.6.2, 3.6.3

and 3.6.4.

23

17

13

22

24

25

17

Page 21

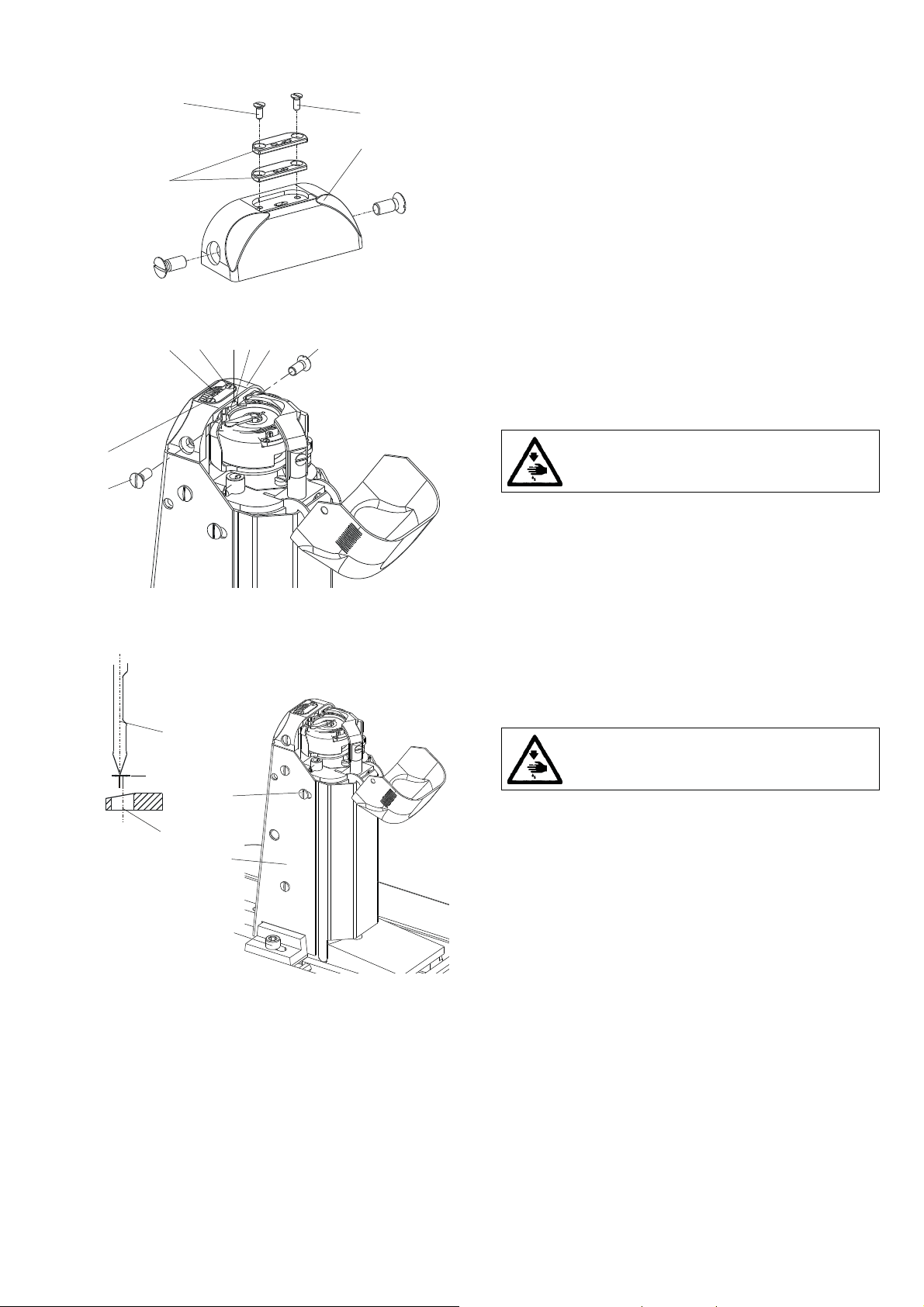

3.6.6 Top roller

3.6.6.1 Selection of the top roller diameter

The machine can be supplied with two types of top roller, namely with

the diameter of 25 mm and with the diameter of 35 mm. The suitability

of the diameter used depends on the type of sewing and on the concrete

technological operation.

There are in general valid the following principles for the selection of

the wheel diameter:

ø 25 mm - for sewing small radii

ø 35 mm - for sewing straight sections or big radii

- for sewing with great passages to thicker materials

3.6.6.2 Forward, rearward and side setting

The top roller must be in a defined position in relation to the needle:

a) view (see Fig. 1) - the value X depends on the diameter of use top

ø 25 - 6.5 mm; ø 35 - 10.5 mm), it is measured from the the

roller (

Fig. 1

Fig. 2

4

1

2

3

5

6

X

needle bar up to the roller edge when turning the handwheel to the

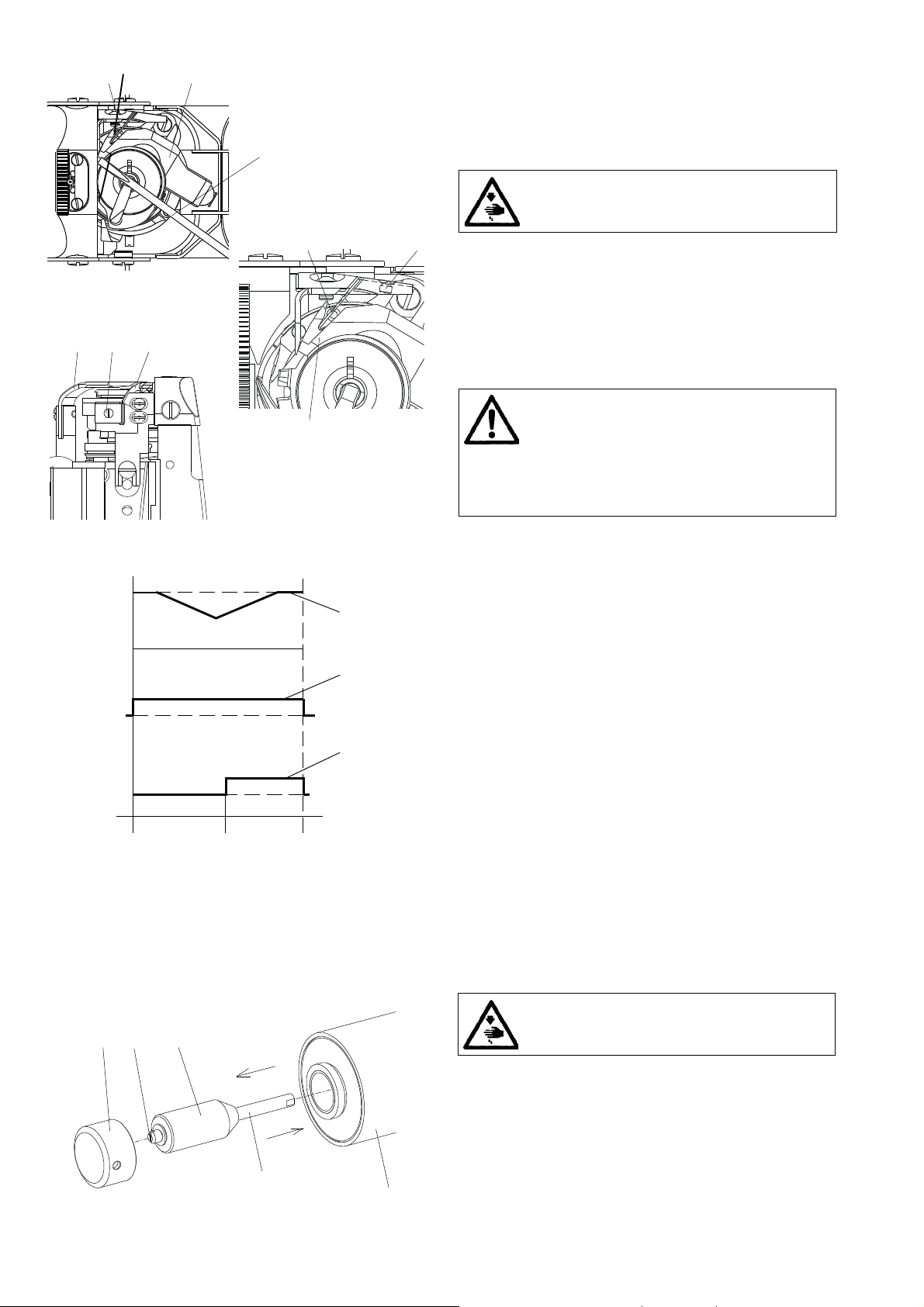

° of the scale against the indicator

180

b)view (see Fig. 2) - the wheel edge must fit with the edge of the needle

operture at the spot of the needle punch.

These values are to be set as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Loosen the screw (1).

- By shifting the holder (2) with the top roller (3) in the groove of the

holder (4) set the required value X and tighten the screw(1).

- Loosen the screw (5)

- By shifting the holder (2) in the holder (6) set the bottom edge of the

roller to the edge of the needle operture.

- Tighten the screw (5).

3.6.6.3 Setting the gear clearance

and in the mounting of the top roller

In the cone gear of the drive of the top roller foot, the minimum clearance

must be set. A too small clearance will increase the friction resistance

of the gear, the excessive clearance will influence the inaccuracy of

7

6

3

2

4

5

1

feeding. The top roller itself is mounted on balls. With this type of

mounting,it is also necessary to set the minimal possible radial

clearance.

The given clearances are set as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

Clearance in the wheel mounting

- Loosen three screws (5) /only slightly/.

- Using the screw (4) set the minimum clearance in the top

roller mounting (2) /it must easily rotate without any rubbing

and with a minimum clearance/.

- Tighten the screws (5), check the set up clearance, eventually, repeat the setting procedure.

Clearance in the conic gear

- Loosen the screw (1), in shifting the wheel, resp. the holder

(3) in the holder groove (6), set the minimum clearance,

the pinion (7) must be pushed up to the holder bottom (6).

- Tighten the screw (1), check the set up clearance.

18

Page 22

6

1

5

2

4

3

When replacing the top roller, proceed as follows:

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Unscrew the screw (1).

- Unscrew the screw (3) with the washer (2).

- Remove the driven top roller with the holder (4) from the holder (5)

and from the articulated shaft (6).

- Mount another top roller in inverted procedure to dismantling.

- Set the top roller according to the par. 3.6.6.2.

3.6.6.4 Replacement of the top roller

53

2

4

1

A

3.7 Setting the presser foot lift

The maximum lift of the presser foot when lifting the foot with knee

lever or with electromagnet is to be A = 12.5 mm.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Place a cube (1) having the height of A = 12.5 ± 0.7 mm under the

presser foot.

- Screw in thoroughly downwards the screw (2).

- Tighten slightly the screw (3) in such a way that the lever (4) turns

on the shaft (5) with a certain friction moment.

- Push with the screwdriver on the lever (4), until it attains the wall

inside the arm of the sewing machine.

Return the lever (4) back by about 1 mm and tighten the

-

screw (3). With the maximum top roller lifting, the lever will

not strike into the machine arm.

- Check the axial clearance of the shaft (5) which should be the least

possible.

- Using the screw (2) set the normal pressure force of the presser foot.

19

Page 23

3.8 Bobbin winder

4

5

3

3.8.1 Description

The winder (bobbin winder) winds a reserve of the hook thread.

It is driven by a spring-mounted friction gear, which stops after having

filled the bobbin.

An ideal winding is attained with a sufficient pretension of the thread

obtained on the thread guide (4) and with 1 mm under the diameter of

the bobbin. The shaft is mounted in a swinging way and the friction

gear is put into engagement by means of a pickup lever (1) and a cam.

The winder is fixed on the machine arm by two screws (3). The thread

is passed through according to the illustration, the thread is cut off

after having stopped the winding operation using the cutting device

(5).

3

1

3.8.2 Setting the bobbin winder stop

The moment of interrupting the winding is determined by the mutual

position of the pickup lever (1) and the cam (5) on a common shaft.

The cam is locked in its functional position by the screw (6). The

mutual position is to be set on a not incorporated winder in such a way

that in the moment, when the pickup lever leaves the space of the

6

5

2

1

bobbin, the pressing function of the cam on the winders shaft is

interrupted and it moves in the sense of the arrow. A fine setting is to

be done on an incorporated condition in the machine. Using the screw

(2), the position of the friction part of the pickup lever (1) is adapted. In

opening the lever, the stopping function is accelerated. Its inverse

function delays it. A test is to be done after having inserted the bobbin,

when passing the thread through the device and when winding at the

running of the machine.

3.8.3 Setting the friction gear

7

8

9

A

B

The friction gear is formed frontally by the disk (8) on the main top

shaft of the machine and by the disk (7) with a rubber ring on the shaft

of the winder.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Proceed to the setting operation with a removed rear guard.

- The winder is in its stopped position.

- Loosen two screws (9) in the disk (8) through the hole in the arm.

- By shifting axially the disk in the sense A, B, set the disks of the

winder (7) at the distance of 0.5 mm from the rubber ring.

- Tighten the screws (9) in the disk (8).

- Put the winder in its working position and proceed to a winding test.

- Mount the rear guard.

20

Page 24

2

3

1

3.9 Safety clutch

4

3.9.1 Description

The machine is provided with a safety clutch which enables the turning

through of the lower belt wheel (1) on the hub of the lower shaft (2),

5

when the hook is blocked. This blocking occurs due to the penetration

of thread into the hook path. With current running, this clutch should

not disengage during the normal running.

belt wheel (1) and the hub (2) is effected by means of the bills (3)

which are firmly connected with the belt wheel (1). The bills fit in the

conic holes of the hub (2) and are pushed therein by means of the

springs (4).

Putting the clutch in its working position, eventual checking its correct

position are to be done in blocking the hook using a screwdriver and in

turning a bit the handwheel.

The mutual coupling of the

3.9.2 Setting the disengaging moment

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

The correct value of the tensioning moment (8 Nm) has been set up by

the manufacturer. when this value is lower, in a current running, the

clutch may disengage. In an opposite case (the moment is higher), the

clutch will not disengage. In both cases it is necessary to proceed to a

correction of the moment. In turning the nut (5) to the right, the moment

will increase and on the contrary. The value of the tensioning moment

is very sensible to the turning of the nut (5). When setting it, it is

necessary to proceed very carefully, set it up only in emergency cases!

Check the moment using a torque-limiting wrench.

Caution!

The clutch guarantees only one mutual position

of the hub of the lower shaft (2) and that of the

belt wheel (1). No checking according to the gauge marks

is needed. Putting the clutch out of operation by excessive tightening

of the nut (5) can cause, when blocking the hook, the destruction of

the gear within the drive of the hook.

3.10 Indented belt transmission

3.10.1 Setting the tensioning roller of the

indented belt

The optimum tension of the indented belt (1) is attained in setting the

tensioning roller (2) in such position, when the roller applies the

pressure of F = 20 N against the belt. The roller must be side set in such

a way that the edge of the indented belt does not overlap over the edge

of the roller.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

4

- Remove the handwheel and the belt guard, remove the V-belt.

- Unlock the fastening of the loop, on which the roller (2) is mounted

in such a way that the loop turns freely.

- Lift the roller (2) upwards and, thereafter, using the dynamo-meter

(4), pull horizontally the roller in applying the force of 2O N. In this

2

position, tighten the fastening screw (3).

- Check the side shifting of the roller.

3

1

21

Page 25

432

3.10.2 Replacing the indented belt

To observe: in machines with Mini-stop first remove the driving toothed

belt as instructed in par. 3.12.

When replacing the indented belt, the mutual position of the pulleys (4

and 5) should be maintained.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Remove the handwheel, the belt guard and the V-belt.

- Remove the retaining ring (1) and remove the backtacking lever (2).

- Mark with a pencil the instantaneous position of the indented pulleys

against the machine head in any position.

- Remove the indented belt (3) from the bottom indented pulley

(4) first, and then remove the whole belt.

51

- Apply a new indented belt on the top indented pulley (5) first.

- Turn both indented pulleys in the formerly marked positions and

apply the indented belt on the indented pulley (4).

- Tension the belt and mount the dismantled components in the inverse

order.

3.11 V-belt, motor - head

3.11.1 Tensioning

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

The belt is correctly tensioned, when the opposite sides of the belt

approach one to another by up to 20 mm in applying the force of 10 N.

The belt is tensioned in turning respectively the motor in its holder.

10 N

l - 20mm

10 N

3.11.2 Replacing the V-Belt

Caution! Danger of injury!

Switch off the main switch! before starting the setting

operation, wait until the motor stops!

- Loosen the screw (1) of the positioner arrest (2) and tilt the arrest.

- Unscrew the screws (3) of the handwheel.

- Unscrew the screws (4) of the belt guard and tilt the guard.

- Remove the belt guard of the motor and tilt the protections against

falling out the belt from the motor pulley.

- Replace the belt.

- Tension the belt (see par. 3.11.1).

2

3

1

4

3.12 Driving toothed belt

3.12.1 To exchange the driving toothed belt

1

- Remove the machine head from the stand (uncouple the motor cables,

the machine head cable and screw off the wood screw and the screw

2

from the hinges).

- Remove the belt guard (1).

- Replace the belt (2).

22

Caution! Danger of injury!

Switch off the main switch! before starting the setting

operation, wait until the motor stops!

Page 26

2

4

3.13 Lubrication

3.13.1 Description

From the oil tank (1) there issue three suction wicks. The wick (2)

lubricates the pin of the thread mechanism, the wick (3) lubricates the

3

1

5

6

7

needle mechanism and the wick (4) lubricates the stitch length

mechanism. The superfluous oil from the needle and thread mechanisms

is sucked off by the wick (5) and lubricates the shifting wedge of the

feeding clutch.

The hook has its own oil reservoir (6). The driving gear of the hook is

lubricated from oil tank (7).

3.13.2 Refilling oil

For lubricating the machine oil Esso SP-NK 10, DA 10 is used or other

oil with the same quality. When putting the machine into operation,

each mechanism of the machine is to be lubricated with several drops

1

of oil. Oil is only refilled thereafter into the oil reservoirs using an oil

can into the holes in the oil level indicators.

The oil tanks (1, 2, 3) of the central distribution is to be filled

up to the mark max.

2

3

3.13.3 Multiple oil use

Oil which runs into the oil cup is collected in the collector (1) and may

be reused for refilling the oil reservoirs in the machine - see par.

2

3.13.2.

The oil collector (1) with the collected oil is uscrewed and the top part

of the oil can (2) which is added in the machine packing is screwed in.

Oil is then refilled into the reservoirs on the machine head and everything

is put into the original condition.

1

1

23

Page 27

3

2

1

4. Thread trimming

4.1 Description of the trimming mechanism

A

4

12

B

C

During the trimming cycle, the moving trimming knife (1), in an

opportune moment, hooks up the sewing threads and pulls them in the

sense of the arrow (A) against the fixed knife (2) until the threads are

trimmed. The spring (3) holds the hook thread after being trimmed off.

The moving knife (1) is mounted on the shaft (4) which turns by means

of the lever (5) under the effect of the fork (6) fixed on the shaft (7)

which is shifted by the electromagnet (8) from its starting position in

the sense of the arrow (B). When moving back in the sense of the arrow

(C), the shaft (7) is shifted by the cam (9) through the pickup roller

(10) into the starting position. The spring (11) maintains the mechanism

in its starting position. The electromagnet (12), in an opportune

moment, loosens the main tensioner. At the end of the trimming

cycle, both electromagnets (8 and 12) are switched off.

65

97

11 10

8

4.2 Setting the pickup roller

1

4

2

5

3

A

6

The holder of the pickup roller (1) is to be fixed in such a way that it is

positioned, in its starting position, between the shaft (2) and the shaft

(3), the respective gap A = 0.2 to O.4 mm.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- With the loosened screw (4), put the holder of the pickup roller (1)

up to the stop against the bracket (5) and, at the same time, t h e

shaft (2) up to the stop against the shaft (3).

- With the holder (1) held on the stop, shift the shaft (2) in such a way

that there appears the gap A = 0.2 to 0.4 mm, and tighten the

screw (4).

- Check the gap A in shifting the armature (6).

4.3 Setting the cam

The position of the cam (1) against the shaft (2) is to be such, so that

when the adjusting pin is in contact with the shaft (4), the protractor

scale of the handwheel (6) shows just the angle of 108

roller (5) is in its starting position of rest, the clerarance between the

roller (5) and the cam (1) should be as small as possible but sufficient

to prevent the cam from getting into accidental contact with the roller.

°. If the pickup

5

- Set the angle of 108

(7) which is included in the accessory of the machine (tighten with

care).

- Shift the pickup roller (5) in the sense of the arrow up to the stop.

4

382

1

6

108

- Insert the adjusting pin (3), which is included in the accessory, into

the cam and turn the cam, until the pin (3) gets the contact with the

shaft (4).

- Insert a gauge having the thickness of 0.1 mm between the cam (1)

o

and the pickup roller (2) and shift the cam against the gauge up to

the stop. Tighten then the screw (8).

- Loosen the blocking of the handwheel, turn a bit the cam and tighten

the second fastening screw of the cam too.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

° on the handwheel (6) and lock it with the screw

7

24

Page 28

4

1

2

563

4.4 Setting the fork

In the starting position of rest of the trimming mechanism, when the

holder (1) is in contact with the bracket (2), the axis of the fork (3)

must intersect the axis of the shaft (4).