Page 1

281

Spezialnähmaschine

Serviceanleitung

Service Instructions

Service Instructions

D

GB

CN

Manufacturer: Dürkopp Adler Manufacturing (Shanghai) Co., Ltd.

Conta c t: Dürkopp Adler AG, PO Box 17 03 51, D-33703 Bielefeld, Potsdamerstr. 190, D-33719 Bielefeld,

Manufacturer: Dürkopp Adler Manufacturing (Shanghai) Co., Ltd.

Conta c t: Dürkopp Adler AG, PO Box 17 03 51, D-33703 Bielefeld, Potsdamerstr. 190, D-33719 Bielefeld,

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

01/2009 Rev. index: 00.0 PrintedinChina 0791 281641

1201 Luoshan Road, Pudong New Area, Shanghai 200135, China

Phone +49 (0) 521 9 25 00, Fax +49 (0) 521 9 25 24 35, www.duerkopp-adler.com

1201 Luoshan Road, Pudong New Area, Shanghai 200135, China

Phone +49 (0) 521 9 25 00, Fax +49 (0) 521 9 25 24 35, www.duerkopp-adler.com

Page 2

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler und urheberrechtlich geschützt. Jede, auch auszugsweise Wiederverwendung

dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler verboten.

All rights reserved.

Property of Dürkopp Adler and copyrighted. Reproduction or publication of t he content in any manner, even in

extracts, without prior written permission of Dürkopp Adler, is prohibited.

All rights reserved.

Property of Dürkopp Adler and copyrighted. Reproduction or publication of t he content in any manner, even in

extracts, without prior written permission of Dürkopp Adler, is prohibited.

Copyright ©

Dürkopp Adler - 2009

Page 3

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 4

Page 5

Contents Page:

Part 3: Service Instructions Class 281

(Edition 01/2009)

1. General

1.1 Tools and Gauges .............................................. 3

1.2 Adjustingaids................................................. 4

2. Feeding and sewing equipment

2.1 Timingofthethrusteccentric ....................................... 5

2.2 Timingoftheliftingcam........................................... 6

2.3 Feeddogheightandinclination...................................... 7

2.4 Feeddogpositionwithinthethroatplate................................. 8

2.5 Stitch length limitation ............................................ 9

2.6 Stitch length symmetry ........................................... 10

3. Sewing foot height and sew ing foot lifting

3.1 Pressure-barheight............................................. 11

3.2 Mechanical sewing foot lifting ....................................... 12

3.2.1 Liftingmotionandliftedsewingfootheight ............................... 12

3.3 Electromagnetic sewing foot lifting .................................... 13

3.3.1 Sewing foot lifter solenoid position .................................... 13

3.3.2 Mounting the sewing foot lifting solenoid ................................. 14

3.3.3 Replacing the shock absorbing washer of the sewing foot lifter solenoid ............. 16

3.4 Sewingfootpressure ............................................ 18

4. Thread-guiding parts

4.1 Releasing the needle thread tension ................................... 19

4.2 Threadtake-upspring............................................ 20

4.3 Thread regulator ............................................... 21

5. Needle bar height .............................................. 22

6. Hook setting

6.1 Looping stroke and distance between the hook point and needle .................. 23

6.2 Bobbin case holder.............................................. 24

GB

7. Thread trimmer

7.1 Controlcamfortheknifemotion...................................... 25

7.1.1 Controlcamposition............................................. 25

7.1.2 Distancebetweentherollerandthreadtrimmercam ......................... 26

7.2 Hookedknife ................................................. 27

7.3 Settingthecuttingpressure ........................................ 28

Page 6

Contents Page:

8. Setting the bobbin w inder

8.1 Switching off the bobbin winder ...................................... 29

8.2 Winding form of the bobbin ......................................... 30

8.3 Windingtightness .............................................. 30

9. Filling up oil (gear box) .......................................... 31

10. Hook lubrication

10.1 Setting the oil quantity for the hook .................................... 33

11. Maintenance ................................................. 34

Page 7

1. General

The present service instruction describes the adjustment of the special

sewing machine 281.

ATTENTION!

The operations described in the service instructions must only be

executed by qualified staff or correspondingly instructed persons

respectively!

Caution: Risk of injury !

In case of repair, alteration or maintenance work turn off the main

switch and make sure to protect the machine from powering up

accidentally.

Carry out adjusting operations and functional tests of the running

machine only under observation of all safety measures and with

utmost caution.

The present service instruction describes the adjustment of the sewing

machine in an appropriate sequence. Please observe in this

connection that various setting positions are interdependent. Therefore

it is absolutely necessary to perform the adjustment following the

described order.

For all setting operations of parts involved in the stitch formation use a

new needle without any damage.

Machine covers having to be screwed off and on again for checking

and adjusting operations are not mentioned in the text.

GB

Please note:

The shaft of the special sewing machine 281 is provided with flat spots.

This facilitates the adjustment considerably.

In case of adjustments on flat spots the first screw in rotation direction

is put on such a flat spot.

3

Page 8

1.1 Tools and Gauges

Art Size Figure

Allen key

Screw driver

Flat tip 0.7 x 4,5

Flat tip 0.3 x 3

Flat tip 0.7 x 4.5

5

4

3

2.5

2

1.5

Cross tip B2 -H

Open-end wrench 10

Gauge Needle bar height

0281 801819 for needle diameter 1.62 mm

Gauge Needle bar height

0281 800300 for needle diameter 2.00 mm

Setting pin For locking the machine at position 1 - 6

9301 022608

0281 800290

4

Gauge Feed dog height / Needle bar height

Page 9

1.2 Adjusting aids

1

2

4

3

The sewing machine can be locked in six different setting positions

with the locking pin 1 and the arresting notches 2 on the arm shaft

crank 3.

The crank has six notches which are marked on the handwheel by the

figures 1, 2, 3, 4, 5 and 6. In conjunction with marking 4 the figures

indicate the position of the notches in which the machine can be locked

with locking pin 1.

The figures simplify the finding of the arresting notches. A precise

setting can only be ensured by arresting the machine at the provided

notches.

GB

The following items should be adjusted in the various positions:

Pos. Symb. Description

Loop stroke

Distance between the hook point and needle

Feed dog standstill when stitch-length regulator moves

feed dog height

nd

2

needle position (thread lever upper dead centre)

Reference position machine head / Control cam for thread trimmer

st

1

Needle position

Needle in lowest position

5

Page 10

2. Feeding and sewing equipment

2.1 Timing of the thrust eccentric

2

1

Caution: Risk of injury !

Turnthemainswitchoff!

Check and set the feed standstill only when the machine is switched

off.

ATTENTION!

The thrust eccentric in the gear box 3 is already optimally set

ex factory.

The setting should preferably not be modified.

Standard checking

With the sewing machine arrested at locking position “2", there should

be no feeding movement if the reverse feed lever 2 is actuated and the

greatest stitch length is selected.

Correction

–

Set the greatest stitch length at the setting wheel 1.

–

Loosen the screws 5 at the lower toothed belt wheel 4.

–

Turn the lower shaft accordingly.

–

Fasten the screws 5 at the lower toothed belt wheel 4.

3

ATTENTION!

Should the lower shaft be misaligned, the following

positions must also be re-adjusted again:

4

5

6

l Hook (see chapter 6.1)

l Thread trimmer cam (see chapter 7.11)

l Lifting cam (see chapter 2.2)

Page 11

2.2 Timing of the lifting cam

5

1

2

3

3

4

1

GB

4

Caution: Risk of injury !

Turnthemainswitchoff!

Check and set the lifting cam only when the machine is switched off.

Standard checking

With the sewing machine arrested at locking position “2", align the

notches 1 (of the lifting cam 2) and 4 (of the traction rod 5).

Correction timing of the lifting cam

–

Arrest the sewing machine at locking position “2".

–

Loosen both screws 3 of the lifting cam 2.

–

Turn the lifting cam 2.

The notches 1 and 4 muss be aligned.

–

Tighten both screws 3 of the lifting cam 2 again.

7

Page 12

2.3 Feed dog height and inclination

Fig. A

7

8

Fig. B

Standard checking

Fig. A

The emerging height of the feed dog over the throat plate, its angle of

climb or the parallelism to the throat plate can be set via eccentrics 7

and 8.

With the sewing machine arrested at locking position “2", the height of

the centre of the throat plate (at the needle hole) is set ex factory:

0.9 mm with fine toothed feed dog

·

1.1 mm with coarse toothed feed dog

·

Thereby the feed dog is slightly rising from front to rear.

Fig. B

With this setting, the feed dog is parallel to the throat plate when

emerging.

8

Page 13

10

7

8

9

6

11

Caution: Risk of injury !

Turnthemainswitchoff!

Check and set the feed dog height and inclination only with the sewing

machine switched off.

Correction feed dog height

–

Arrest the sewing machine at locking position “2".

–

Loosen screws 6 and 9.

–

Turn the eccentric bolts 7 and 8.

In its highest position, the feed dog should protrude

by 0.9 (1.1) mm from the throat plate in the region of the needle hole.

–

Adjust the height and the inclination via the eccentrics 7 and 8.

Keep in mind that the adjusting of both eccentrics are

interdependent from each other.

–

Fasten screws 6 and 9 again.

GB

2.4 Feed dog position within the throat plate

Rule

With the sewing machine arrested at locking position “2", the feed dog

should be symmetric.

The distance is s imilar at the front and the rear.

Correction

–

Arrest the sewing machine at locking position “2".

–

Loosen screw 11.

–

Adjust the symmetry.

–

Fasten the screws 11.

The lateral clearance b must still be kept.

9

Page 14

2.5 Stitch length limitation

5

423

1

Caution: Risk of injury!

Turn off the main switch!

Check and set the stitch length limitation only with the sewing machine

switched off.

Standard checking

The maximum stitch length for the sewing machine is 4.5 mm.

With sewing equipment designed for smaller stitch length, the stitch

length must also be limited accordingly, in order to avoid damaging the

sewing machine or the sewing equipment.

Limiting the maximum stitch length

–

Set the allowed maximum stitch length for the sewing equipment on

the setting wheel 1.

–

Loosen both screws 3 of the limiting block 2.

–

Turn the limiting block clockwise against the threaded pin 5.

–

Fasten both screws 3 again.

10

Page 15

2.6 Stitch length symmetry

2

3

4

1

5

Caution: Risk of injury!

Turn off the main switch! Check and set the stitch length symmetry

only with the sewing machine switched off.

GB

Standard checking

The forward and reverse stitch length (4.0 mm) are already set ex

factory.

A verification can be done by using a cardboard as a sewing material

and sewing 10 stitch length (11 stitching) forward and next to it 10

stitch length (11 stitching) reverse without thread with the slowest

speed.

The total length of the 10 stitches in both directions should be the

same.

It may be necessary to re-adjust the symmetry of the stitch length after

repairs.

Correction

–

Set the maximum stitch length on the setting wheel 1.

–

Loosen the screw 3 in the clamping block 4.

–

Turn the shaft 2 in the clamping block 4.

–

Fasten the screw 3.

–

Check the stitch length again and set it anew if necessary.

Please note:

Even a slight twisting of the shaft leads to an essential change of the

stitch length.

This task must be carried out meticulously.

Furthermore it is important to make sure that when latching (with the

greatest stitch length set), the latch solenoid 5 does not hit its inside or

outside end position in order to avoid knocking noises or to prevent

from wearing out.

11

Page 16

3. Sewing foot height and sewing foot lifting

The maximum sewing foot lifting stroke amounts to:

12 mm with machines with electromagnetic sewing foot lifting.

·

14 mm with machines with knee lever.

·

9 mm factory setting.

·

3.1 Pressure-bar height

1

2

3

Caution: Risk of injury!

Turn off the main switch!

Check and set the pressure-bar height only with the sewing machine

switched off.

Standard checking

When the sewing foot sole 4 rests on the throat plate, a gap of 0.5 mm

should be available between the block 2 and the traction bracket 1.

Correction

–

Remove the face cover.

–

Loosen the screw 3.

–

Press the sewing foot downward against the throat plate.

This setting should not take place against the emerging feed dog!

–

Shift the block 2 in a way that a gap of 0.5 mm is available between

the block 2 and the draw angle 1.

–

Align the sewing foot so that the needle can stitch in the middle of

the slit of the sewing foot and fasten the screw 3 again.

–

Fix the face cover again.

12

4

Page 17

3.2 Mechanical sewing foot lifting

3.2.1 Lifting motion and lifted sewing foot height

5

2

34

1

6

GB

Caution: Risk of injury!

Turn off the main switch! Check and set the knee lever only with the

sewing machine switched off.

Standard checking

With the sewing foot resting on the throat plate, before the lifting

movement begins a lost motion should be perceptible at the knee lever.

The sewing foot lifting should be s et so high in a way that the needle

point 5 in arrested position (locking position 3) must not come above

the slit of the sewing foot 6.

Correction lifter motion (low er position)

–

Loosen the nut 3.

–

Adjust the screw 4.

With the sewing foot resting on the throat plate, a lost motion

should be perceptible at the knee lever.

–

Fasten the nut 3 again.

Correction lifted sewing foot height

–

Arrest the sewing machine at locking position “3".

–

Loosen the nut 1.

–

Adjust the lifting height through stop screw 2.

–

Fasten the nut 1 again.

13

Page 18

3.3 Electromagnetic sewing foot lifting

3.3.1 Sewing foot lifter solenoid position

2

4

1

Caution: Risk of injury!

Turn off the main switch!

Check and set the sewing foot lifting only with the sewing machine

switched off.

Standard checking

When operated, the anchor 2 of the solenoid 1 must always reach its

internal final position, because its power consumption will be reduced

to 30% after a sewing foot lifting.

The sewing foot lifting should be s et so high in a way that the needle

point 5 in arrested position (locking position 3) must not come above

the slit of the sewing foot 6.

Correction

–

Loosen screw 3.

–

Introduce a screw driver through the hole 4 and put it in the bracket

of the sewing foot lifting solenoid.

–

Change the position of the solenoid by swivelling the screw driver

upwards or downwards:

® Swivel the screwdriver handle upwards = smaller s troke

® Swivel the screwdriver handle downwards = greater stroke

–

Fasten both screws 3 again.

3

14

5

6

Page 19

3.3.2 Mounting the sewing foot lifting solenoid

3

2

10

1

654

–

Unscrew the handwheel 3, covering 2 and cover 1.

–

Unclamp the spring 4.

–

Loosen the screws 6 and remove the mounting flange 5.

GB

7

11

6a

9

8

–

Screw the holder 10 to the solenoid 8 u sing the screws 9 provided.

–

Fit the push rod 7 to the solenoid.

–

Screw the mounting flange 11 that has been removed to the holder

10 using one of the screws 6.

10

15

Page 20

14 13 8 18 17 16 15

–

Tilt the machine head backwards.

–

Loosen screw 14.

–

Using the mounting aid 13, push the pre-assembled sewing foot

lifting solenoid upwards in a way that the push rod 15 gets engaged

in the upper guide bore hole.

–

Fasten the mounting aid 13 with the screw 14.

–

Unscrew the threaded pin 17.

–

Push all the cables to the left of the shaft 16 of the threaded pin 17

and fasten the threaded pin again.

–

Lead the cable of the sewing foot lifting solenoid to the rear side of

the machine through the drilled hole 18.

16

66a4

–

Tilt the sewing machine head to the front.

–

Screw the holder 10 to the housing using one of the screws 6.

–

Unscrew the screw 6a and screw it into the second mounting hole

of the holder.

–

Loosen the screw 14, remove the mounting aid and fasten the

screw 14 again.

–

Put in the spring 4.

Page 21

1-3

5

–

Connect the cable of the sewing foot lifting solenoid to the terminal

blocks, one wire to one of the terminal from 1 to 3 and the second

one to the terminal 5.

–

If necessary, set the sewing foot height anew (see chapter 3.3.1).

–

If necessary activate the sewing foot lifting solenoid (see operating

instructions for the control unit).

Please note!

The removal of the sewing foot lifting solenoid is the reverse of the

mounting procedure.

GB

3.3.3 Replacing the shock absorbing washer of the sewing foot lifter solenoid

Caution: Risk of injury!

Turn off the main switch!

Proceed to the removal of the sewing foot lifting solenoid with the

sewing machine switched off!

After years of intensive use, a dimensional change of the shock

absorbing washer 5 may occur.

6

5

4

3

1

2

This is noticeable by the slower lowering of the sewing foot or an

impact noise when the solenoid is operated.

It may signify that before the foot has reached the material to be sewn

completely it has already started to sew (risk of skipped stitches at the

seam beginning).

–

Remove the lifting solenoid 1.

–

Remove the lock washer 6.

–

Remove spring 4 and bush 5.

–

Remove the anchor 2 from its housing.

–

Replace the shock absorbing washer 3 (0271 001767).

–

Put on spring 4 and bush 5.

–

Fix the lock washer 6 again.

–

Mount the lifting solenoid again (see chapter 3.3.2).

17

Page 22

3.4 Sewing foot pressure

1

Standard checking

The figures on the setting wheel 1 gives the sewing foot pressure

in “N”.

(1kp = approx. 10N).

The required sewing foot pressure depends on the following

parameters:

Sewing speed

·

Damping characteristics of the material to be sewn

·

Number of plies (layers forming the material to be sewn)

·

The material that is to be sewn must not “swim”.

However, the sewing foot should not exert more pressure than

necessary, otherwise a strong shifting of the ply occurs (ruffling).

Correction

–

Set the sewing foot pressure by turning the handwheel 1.

Increase the pressure = Turn it clockwise.

Decrease the pressure = Turn it counter-clockwise.

18

Page 23

4. Thread-guiding parts

4.1 Releasing the needle thread tension

3

1

2

GB

Caution: Risk of injury!

Turn off the main switch!

Check and set the releasing of the needle thread tension only when

the machine is switched off.

Standard checking

Pressing on the axle 3 opens the thread tensioner by approx. 1 mm.

With the thread tensioner closed and with no thread between the

tension discs the axle 3 should have a clearance of approx. 0.3 mm.

Correction

–

Loosen the threaded pin 2.

–

Move the solenoid 1 axially.

Check the following: distance approx. 1.0 mm / clearance 0.3 mm.

–

Fasten the threaded pin 2 again.

19

Page 24

4.2 Thread take-up spring

2

6

5

1

4

4

3

2

Caution: Risk of injury!

Turn off the main switch!

Check and set the thread take-up spring only with the sewing

machine switched off.

Standard checking

The thread take-up spring 2 should keep the needle thread under

tension at least until the needle point has penetrated the material to be

sewn.

Correction spring tension

When removing the complete thread tension unit, please make

absolutely sure not to lose the release pin 6 and to include it again

when mounting the thread tension unit.

–

Loosen the threaded pin 4.

–

Unscrew the complete thread tension unit.

–

Loosen the threaded pin 3.

–

Adjust the tension strength by turning the tension bolt 1.

The tension of the thread take-up spring depends on the material

being sewn and the thread used. The value should be between 20

and 50 cN (1 cN = 1 g).

–

Fasten the threaded pin 3.

–

Insert again the complete thread tension unit including the release

pin 6.

Correction spring travel

–

Loosen the threaded pin 4.

–

Twist the bush 5.

The spring 1 must should keep the needle thread under tension at

least until the needle point has penetrated the material to be sewn.

Recommended spring travel: 6.5 mm.

–

Fasten the threaded pin 4 again.

20

Page 25

4.3 Thread regulator

1

2

3

Caution: Risk of injury!

Turn off the main switch!

Check and set the thread regulator only when the machine is switched

off.

GB

Standard checking

The setting of the thread regulator 2 depends on:

Material thickness

·

Thread size

·

Stitch length.

·

It has to be set that the thread is guided around the hook and kept

under control.

In the position “0” occurs the highest thread output as needed with

particularly large stitch lengths and thick sewing threads.

The thread regulator is set ex factory between position “2" “ and “3”

–

Insert a fabric.

–

Thread the needle and hook thread.

–

Tilt the machine head backwards.

–

Turn the handwheel slowly and check how tight the thread is

guided around the hook.

If the thread regulator is set correctly the thread looping will run

smoothly (without surplus), without jumping over the largest hook

diameter.

In the process the thread take-up spring moved at most 0.5 mm.

Correction

–

Loosen screw 1.

–

Shift the thread regulator 2.

Thread regulator to the left = more thread.

Thread regulator to the right = less thread.

–

Fasten screw 1.

21

Page 26

5. Needle bar height

1

4

2

3

Caution: Risk of injury!

Turn off the main switch!

Check and set the needle bar height only with the sewing machine

switched off.

ATTENTION RISK OF BREAKAGE!

It is not permitted to fix an adjusting block on the needle bar of

the class 281. Doing so may damage the surface of the needle bar.

Standard checking

There are two types of needle bar for the class 281:

Needle shank diameter 1.62 mm, needle system DB x1

·

Needle shank diameter 2.0 mm, needle system 134

·

Should a setting of the needle bar height occur without using the

gauge, use the following reference value: 0.8 mm distance between

the hook point (lower edge) and the needle eye (upper edge).

22

Correction

–

Remove the throat plate and the sewing foot.

–

Place the gauge 4 on the surface of the throat plate.

–

Fit the gauge 3 as far as it will go into the needle bar instead of a

needle and fix it by tightening the fastening screw.

Gauge 0281 801819 Needle bar height for

needle diameter 1.62 mm

Gauge 0281 800300 Needle bar height for

needle diameter 2.00 mm

–

Arrest the sewing machine at locking position “6".

–

Loosen the screw 1.

–

Push the needle bar 2 downwards.

The foot of the gauge 3 must rest on the gauge 4 without a gap.

–

Fasten the screw 1 again.

ATTENTION !

The screw retaining the needle must point to the right (seen from

the operator’s side).

–

Fix the throat plate and the sewing foot again.

Page 27

6. Hook setting

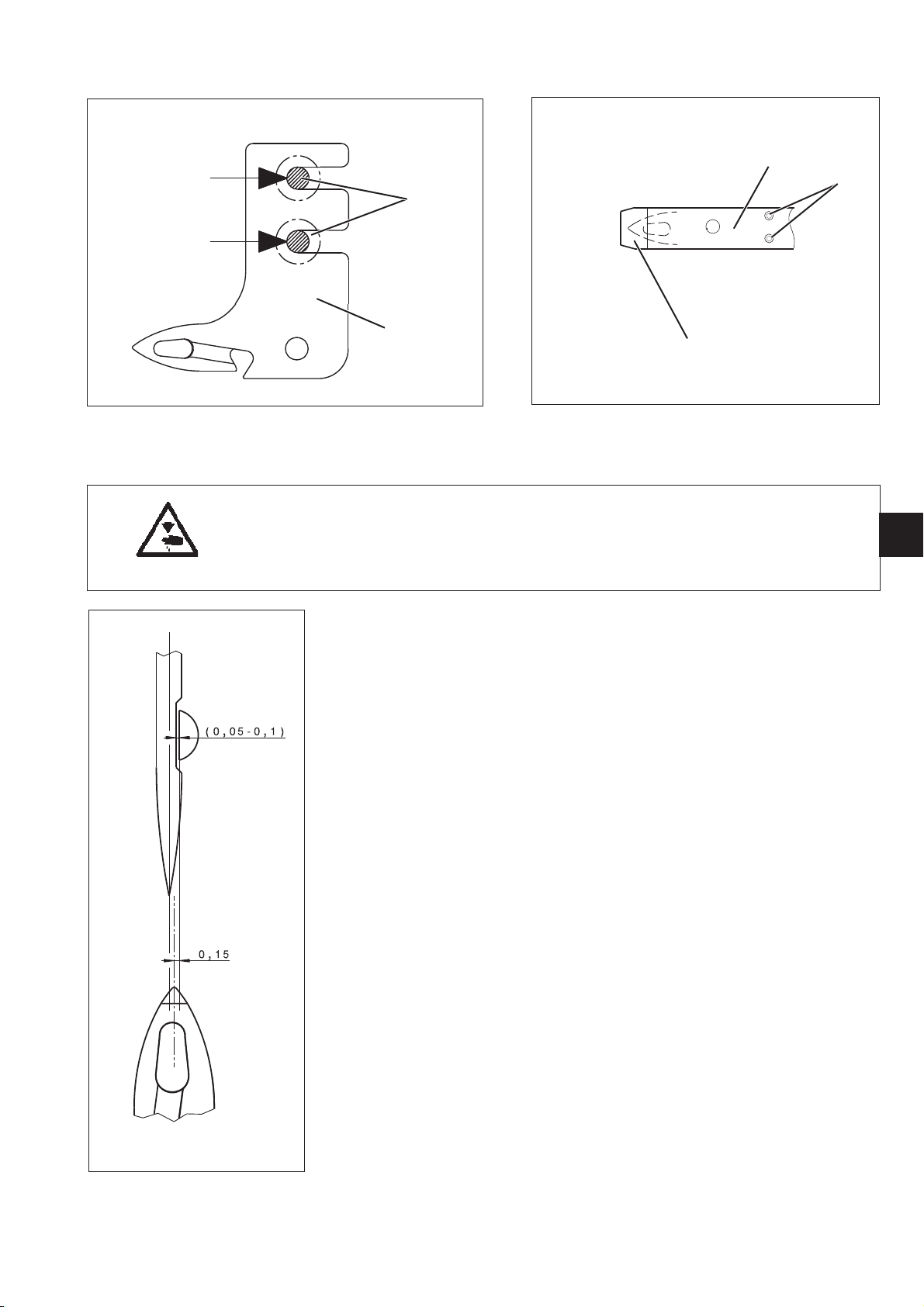

6.1 Looping stroke and distance between the hook point and needle

2

3

2

3

1

GB

Caution: Risk of injury!

Turn off the main switch!

Check and set the looping stroke and the distance between the hook

point and needle only with the sewing machine switched off.

Standard checking

The loop stroke is the distance covered by the needle bar from the

bottom dead center up to the point where the hook tip 2 coincides with

the middle of the needle

(line A-A).

The looping stroke amounts to 1.8 mm.

With the sewing machine arrested at locking position “1", the hook

point 2 should be at the center of the needle.

The lateral distance between the hook point 2 and the needle scarf 3

should amount between 0.05 to 0.1 mm.

1

Correction

–

Remove the sewing foot, the throat plate and the feed dog.

–

Insert a new needle.

–

Arrest the sewing machine at locking position “1".

–

Loosen the fastening screw 1 of the hook.

–

The distance between the hook point 2 and the needle scarf 2

should amount between 0.05 to 0.1 mm.

–

Fasten the fastening screw 1 of the hook again.

–

Fix the sewing foot, the throat plate and the feed dog again.

23

Page 28

6.2 Bobbin case support

23

1

2

4

3

Caution: Risk of injury!

Turn off the main switch!

Check and set the bobbin case support only with the sewing machine

switched off.

Standard checking

The bobbin case support is factory set.

After a replacement of the support, the new support may eventually

need to be adjusted.

ATTENTION RISK OF BREAKAGE!

The adjustment can only be carried out within the hatched area 4.

(see sketch)

Due to the extreme hardness within the area of the retaining tab 1, a

risk of breakage is there.

Correction

–

Remove the bobbin case support 1.

–

Align the bobbin case support 1.

The distance between the retaining tab 2 of the bobbin c ase

support and the lower part of the bobbin case 3 should be 0.6 mm.

–

Mount the bobbin case support 1.

24

Page 29

7. Thread trimmer

The control cam 3 determines the stroke and the timing of the knife

motion. The timing thus coincides with the motion of the needle.

The thread trimmer is switched on electromagnetically.

7.1 Control cam for the knife motion

7.1.1 Control cam position

2

3

4

321

Caution: Risk of injury!

Turn off the main switch!

Check and set the control cam only with the sewing machine

switched off.

Standard checking

With the sewing machine arrested at locking position “4", the roller 1

must engage in the indentation 4 of the control cam 3 when manually

pressed downwards.

Correction

–

Arrest the sewing machine at locking position “4".

–

Loosen the fastening screws 2 of the control cam 3.

–

Turn the control cam of the lower shaft.

The roller 1 must engage in the indentation 4 of the control cam 3

when manually pressed downwards.

–

Tighten the fastening screws 2 again.

GB

1

25

Page 30

7.1.2 Distance between the roller and thread trimmer cam

2

3

7

5761

Caution: Risk of injury!

Turn off the main switch.

Check and set the control cam only with the sewing machine

switched off.

Standard checking

At the external end position of the thread trimmer lever 5 there should

be a distance of 0,2 + 0,1 mm between the external diameter of the

control cam 3 and the roller 1.

It must be checked in a position of the cam between both fastening

screws 2.

Correction

–

Turn the handwheel until the roller 1 stands between both screws 2

of the thread trimmer control cam.

–

Loosen the fastening screw 6.

–

Turn the lever 5 on the shaft 7 so that the roller 1 has a distance of

0,2 + 0,1 mm to the external diameter of the control cam 3.

–

Tighten the fastening screw 6.

6

1

5

26

Please note:

The following risks may be encountered if a greater clearance is set

here:

The thread cannot be caught

·

The thread cannot be cut

·

Page 31

7.2 Hooked knife

4

1

2

3

Caution: Risk of injury!

Turn off the main switch.

Check and set the hooked knife only with the sewing machine

switched off.

5

GB

Standard checking

The hooked knife 2 must lie against both screws 1 in the direction of

the arrow.

Hereby the cut through the tip of the hooked knife is ensured.

At the same time, the tip of the hooked knife has the correct position in

the axial direction.

A virtual line lengthening the hooked knife point will then be in the

center between the needle center and the hook tip.

Correction

–

Unwind the clamping pressure of the fixed knife against the hooked

knife through loosening the set screws 5.

–

Manually swivel in the hooked knife 2.

–

Loosen the fastening screws 1 of the hooked knife.

–

Shift the hooked knife 2 against the fastening screws 1 in the

direction of the arrow.

–

Tighten the fastening screws 1 again.

–

Check the eccentrically rising of the hooked knife.

–

Set the counter knife (see chapter 7.3).

27

Page 32

7.3 Setting the cutting pressure

321

Caution: Risk of injury!

Turn off the main switch.

Check and set the cutting pressure only with the sewing machine

switched off.

1

4

When performing setting tasks within the hook area, both knives

should preferably remain in the machine. Thus avoiding unnecessary

adjustment work.

Standard checking

The threads must reliably be cut with the lowest pressure possible.

Low cutting pressure reduces the wear!

Two of the thickest threads to be sewn must reliably be c ut

simultaneously.

Correction

–

Turn back the cutting pressure screws 1.

–

Swivel forwards the hooked knife 3.

–

Set the fixed knife 2 against the hooked knife 3 by screwing in the

cutting pressure screws 1.

–

Alternately lay the thread to be cut to the right and to the left.

–

Adjust appropriate cutting pressure screw.

–

If the return spring 4 does no longer bring the cutting mechanism to

its starting position, then the cutting pressure is too high!

The fixed knife must be replaced against a new one.

Please note!

A regrinding of the fixed knife is allowed to a minor degree!

If the knife loses a lot of its length, it can no longer cut.

A new setting of the hooked knife cannot compensate it.

28

Page 33

8. Setting the bobbin winder

8.1 Switching off the bobbin winder

2

1

3

4

+

+

-

Caution: Risk of injury!

Turnthemainswitchoff!

Check and set the bobbin winder only with the sewing machine

switched off.

GB

Standard checking

The bobbin winder should stop automatically, when the bobbin is filled

up to approx. 0.5 mm below the edge of the bobbin.

Correction

1. Minor changes of the bobbin wind-on quantity

–

Bend the thread guide tab 3.

2. Major changes of the bobbin wind-on quantity

–

Loosen the screw 2.

–

Adjust the thread guide tab 3.

In the direction of the arrow - :

less quantity

In the direction of the arrow + :

more quantity

–

Fasten the screw 2 again.

After a removal of the release lever 4, a pre-setting at the clamping

screw 1 must be done first.

ATTENTION RISK OF BREAKAGE!

Lift the sewing foot with the hand lever and remove the bobbin case

from the hook when winding without sewing.

29

Page 34

8.2 Winding form of the bobbin

4

1

3

2

Caution: Risk of injury!

Turnthemainswitchoff!

Check and set the bobbin winder only with the sewing machine

switched off.

8.3 Winding tightness

Standard checking

The winding form depends on the position of the gap 3 between both

thread guide sleeves. It should be cylindrical in order to evenly fill the

bobbin to its whole width.

In the case a the gap is set too low.

·

In the case c the gap is set too high.

·

Correction

–

Loosen the knurled nut 2.

–

Shift the guide bolt 1 axially through turning it with a screw driver.

Make sure not to alter the position of the adjusting knob 4.

–

Tighten the knurled nut 2 again.

Standard checking

A minimum pretension of the bobbin thread is required in order to get a

regular winding result (accurate winding on the bobbin).

This depends on the sliding qualities and the thickness of the thread.

A too strong tightness of the winding is favourable to the formation of

ruffs.

30

Correction

–

Turn the adjusting knob 4 clockwise = increase the pretension

–

Turn the adjusting knob 4 counter-clockwise = decrease the

pretension

Page 35

9. Filling up oil (gear box)

Caution: Risk of injury!

Oil can cause skin eruptions.

Avoid protracted contact with the skin.

In event of contact, thoroughly wash the affected area.

1

2

GB

ATTENTION !

The handling and disposal of mineral oils is subject to legal regulation.

Deliver used oil to an authorised collection point.

Protect your environment.

Take care not to spill oil.

Rule

Check the oil level with the machine tilted to the back.

The machine head rest on the machine head support and the surface

of the base plate is vertical to the table top.

The filling up check is intended for lifetime.

Upon delivery the oil level is in the middle of the monitor window 1.

Filling up oil (gear box)

–

Tilt the machine backwards.

–

Unscrew the plug screw 2 with its seal ring.

–

Fill up with DA 32 oil up to the middle of the monitor window 1.

For this purpose use a hose connected to a oil can nozzle.

Oil grade being used

Special lubricating oil DA 32 / resistant to light and ageing resistant /

high wear protection

Viscosity / 40°C: 32 mm²/s - ISO VG32

The oil can be obtained from Dürkopp Adler under the part number

9047 000032 in a 0.9l container.

31

Page 36

10. Hook lubrication

2

(only subclasses with oil lubricated hook)

1

Caution: Risk of injury!

Oil can cause skin eruptions.

Avoid protracted contact with the skin.

In event of contact, thoroughly wash the affected area.

ATTENTION !

The handling and disposal of mineral oils is subject to legal regulation.

Deliver used oil to an authorised collection point.

Protect your environment.

Take care not to spill oil.

Maintenance work Explanation Operating

to be carried out hours

Lubrication of

the hook

The oil level shall not fall below the MIN level of the oil

reservoir 1.

Fill up the DA 10 oil through the bore hole 2 up to the

marking line “Max”.

Oil grade being used

Special lubricating oil DA 10 / colourless / resistant to light and ageing

resistant / high wear and corrosion protection

Viscosity / 40°C: 10 mm²/s - ISO VG10

The oil can be obtained from Dürkopp Adler with the following parts

numbers:

8

32

1 litre container 9047 000012

·

5 litre container 9047 000014

·

Please note !

In the machine equipped with an oil-free hook (subclass 281-140442)

no oil filling up is necessary.

Page 37

10.1 Setting the oil quantity for the hook

1

The hook lubrication is insured by the oil wick inside a s ilicone rubber

hose, going from the hook oil reservoir to the spray cone on the back of

the hook.

The oil quantity can be reduced through the adjustment screw 1.

By pressing the hose, the adjustment screw throttles the oil quantity for

the hook.

1

GB

Rule

Put a piece of paper instead of the throat plate above the throat plate

cutout, and sew with the machine with the maximum speed for 15 sec.

The paper should have a fine oil sprayed on it.

Correction

–

Remove the throat plate.

–

Remove the feed dog.

–

Take out the bobbin case.

–

Turn the adjustment screw 1.

Clockwise = less oil for the hook

Counter-clockwise = more oil for the hook

–

Fix the throat plate, the feed dog and the bobbin case again.

Please note:

The reduction of the desired oil flow-rate does not happen instantly

after the turning of the adjustment screw, this is because the residual

oil in the wick between the throttle and the hook needs to be used up

first.

A verification makes only sense if carried out a couple of hours later.

33

Page 38

11. Maintenance

Caution: Risk of injury!

Turnthemainswitchoff!

The maintenance of the sewing machine must only be done when the

machine is switched off.

The daily or weekly maintenance work (cleaning and oiling) to be

carried out by the operators of the sewing machine is described in the

operating instructions (part 1). It is only listed in the following table for

the sake of completeness.

Maintenance work to be carried out Operating hours

8 40 160 500

Sewing machine head

- Remove dust in the area under the throat plate .................... X

- Removedustfrombetweenthefeed dogelements................. X

(remove the throat plate)

- Remove dust in the area under the bobbin brake spring............. X

- Checkoillevel.................................................. X

- Check oil level in oil reservoir for the hook lubrication .............. X

- Check hook lubrication .......................................... X

- Checktoothedbelt.............................................. X

Sewing motor

- Cleanthemotoraeratorfilter .................................... X

34

Page 39

L1

L2

L3

N

PE

F

F

F

3x380-415V+N

50/60Hz

F

max 16A

L1

N

PE

L2

N

PE

L3

NPEPE

Terminal to three-phase

power supplies:

Anschluß an Drehstromnetze:

Several dc-drives must be

distributed evenly amog all phases.

Mehrere DC-Antriebe sind

1x220-240V 50/60Hz

gleichmäßig auf alle Phasen zu verteilen.

Power Switch

Netzschalter

9800 360104

BN

BU

GN-YE

Q0

L1 L

N1 N

BN

BU

BN

BU

GN-YE

L1

L2

L3

PE

F

L1L2PE

F

L1

L3

PE

F

L2

L34PE

1x220-240V 50/60Hz

PE

X0

L

N

1x 200-240V

50/60Hz

BN

BU

GN-YE

3x220-240V

50/60Hz

F

max 16A

LED1: 24V/70mA

LED2: 400mA

IN:

190-240V

50/60Hz

10VA

F1

M0,63A

9850 001083

OUT:

X1

GN

1

LED 1

YE

GY

PK,

WH

BN

2

3

4

1

2

3W

LED 2

BK

GY

RD

GY

WH

BN

T1

Z

9890 281001 B

LED 3W

sewing light

Nähleuchte

Z

9822 560000

H1

BU

BN

GN-YE

A2

Operation Box

Bedienfeld

C200: 9800 360105

Speed Control Unit

ext. Geber

9800 370003

A3

X10blue

1

2

3

4

X14

X11

1

X12

2

3

4

VT

5

BK

6

7

10

BU

11

12

13

RD

14

15

PK BN

16

17

18

RD-BU

19

20

26

YE

27

28

GY-PK

31

32

WH

33

GY

34

GN

35

BN

36

37

GN

1

BN

2

GY

3

4

WH

5

YE

9

shield

WH

9870 281000

Encoder cpl.

9850 281002

WH

BN

GN

YE

GY

(*1)

9870 001117 CN

1

2

3

M1.1

4

5

+5V

N1

L1

PE

blue

0V_Logic

RM_IN

NHT_IN

KNEE_SWITCH_IN

LSP_IN

RU/RAB_IN

+24V/+30V

+24V/+30V

0V

+24V=

FW_OUT

LED_OUT

+24V/+30V

RA_OUT

FL_OUT

FA/FS_OUT

FA_OUT

A PH

B PH

IND.

VCC

VCC

GND

Sewing Machine

Nähmaschine

281-140342

281-140442

WH

BN

GN

YE

GY

PK

BU

RD

BK

VT

GY-PK

RD-BU

X2

1

+24V/+30V

2

FA/FS_OUT

3

FL_OUT

4

FW_OUT

5

RA_OUT

6

+24V TRANSF.

7

LSP_IN

8

RU/RAB_IN

9

NHT_IN

10

RM_IN

11

LED_OUT

12

0V

X1

S4

PCB cpl. 9850 281001

Leiterplatte k

A4

9870 281002

X3

WH

RM_IN

0V

1

BN

2

GN

3

YE

4

GY

5

PK

6

7

8

9

BU

10

S1

FA/FS_OUT4

FL_OUT5

V1

1N4007

V2

1N4007

FW_OUT6

+24V/+30V

RU/RAB_IN

RA_OUT7

+24V_LED

LED_OUT

NHT_IN

LSP_IN

+24V/+30V3

X1

WH

1

BN

2

GN

3

YE

4

GY

5

6

PK

7

BU

8

PCB cpl., keypad

9850 281003

S1

V1

LED sewing light ON/OFF

S1

RM

S2

NHT

S3

RU/RAB

V1

LED yellow

S2

R1

4K7

1

0V

+24V_LED

S4

S3

2

(*1)

1

1

5

2

2

6

7

3

8

8

1

2

A1

Control Unit

Steuergerät

HVP20-4

9800 370005

Z

= Optional Equipment

Sonderausstattung

white

X13 white

PE

U

V

W

1

2

3

4

Ground

GN

WH

BN

YE

9870 001409 CN

d

c

b

a

No.

Modifications/

Date Signature

WH

YE

BN

GN

shield

Confirmation

WH

YE

BN

M1

Sewing Motor

Nähmotor

drawing valid from April 2009

D PPÜRK O

ADLER AG

Bie le f el d

www.duerkopp-adler.com

Date/

Designer/

Checker/

Release/

Y1.2

2008-09-08

Czytrich

Priemer

/0145 05

Y1.1

Y2

Z

Cl. 281-140342; -140442

Control Unit HVP-20-4-28-CE

triple keypad with LED-sewinglight

Y3

Y4

A6

Switch cpl., LED

9880 281000

Denomination

PCB cpl., LED

9850 281004

connection diagram

Part Number/

9890 281001 B

V

Page

/1 2

Page 40

L1

L2

L3

N

PE

F

F

F

3x380-415V+N

50/60Hz

F

max 16A

L1

N

PE

L2

N

PE

L3

NPEPE

Terminal to three-phase

power supplies:

Anschluß an Drehstromnetze:

Several dc-drives must be

distributed evenly amog all phases.

Mehrere DC-Antriebe sind

1x220-240V 50/60Hz

gleichmäßig auf alle Phasen zu verteilen.

Power Switch

Netzschalter

9800 360104

BN

BU

GN-YE

Q0

L1 L

N1 N

BN

BU

BN

BU

GN-YE

L1

L2

L3

PE

F

L1L2PE

F

L1

L3

PE

F

L2

L34PE

1x220-240V 50/60Hz

PE

X0

L

N

1x 200-240V

50/60Hz

BN

BU

GN-YE

3x220-240V

50/60Hz

F

max 16A

LED1: 24V/70mA

LED2: 400mA

IN:

190-240V

50/60Hz

10VA

F1

M0,63A

9850 001083

OUT:

X1

GN

1

LED 1

YE

GY

PK

WH

BN

2

3

4

1

2

3W

LED 2

BK

GY

RD

GY

T1

Z

9890 281001 B

LED 3W

sewing light

Nähleuchte

Z

9822 560000

H1

BU

BN

GN-YE

A2

Operation Box

Bedienfeld

C200: 9800 360105

Speed Control Unit

ext. Geber

9800 370003

A3

X10blue

1

2

3

4

X14

X11

+5V

N1

L1

PE

blue

0V_Logic

RM_IN

NHT_IN

KNEE_SWITCH_IN

LSP_IN

RU/RAB_IN

+24V/+30V

+24V/+30V

0V

+24V=

FW_OUT

LED_OUT

+24V/+30V

RA_OUT

FL_OUT

FA/FS_OUT

FA_OUT

X12

A PH

B PH

IND.

VCC

VCC

GND

GY-PK

1

2

3

PK

4

VT

5

BK

6

7

10

BU

11

12

13

RD

14

15

16

17

18

RD-BU

19

20

26

YE

27

28

31

32

WH

33

GY

34

GN

35

36

BN

37

GN

1

BN

2

GY

3

4

WH

5

YE

9

shield

9870 281000 CN

Encoder cpl.

9850 281002

WH

BN

GN

YE

GY

(*1)

9870 001117 CN

1

2

3

M1.1

4

5

Sewing Machine

Nähmaschine

281-140342

281-140442

WH

BN

GN

YE

GY

PK

BU

RD

BK

VT

GY-PK

RD-BU

X2

1

2

3

4

5

6

7

8

9

10

11

12

+24V/+30V

FA_OUT

FL_OUT

FW_OUT

RA_OUT

OV Logic

LSP_IN

RU/RAB_IN

NHT_IN

RM_IN

AS

0V

X1

S1

PCB cpl. 9850 281001 CN

Leiterplatte k

A4

R1

100R

R2

2K7

+24V/+30V

+24V/+30V

RM_IN

GND/LED

NHT_IN

RU/RAB_IN

AS

0V Logic

LSP_IN

0V

X3

4

10

9870 281001 CN

1

2

3

5

6

7

8

9

WH

BN

GN

YE

pushbutton

Taster

0281 350354

BN

GN

YE

yellow

WH

A5

S2

41

V1

Power

ON

V1

(*1)

FA_OUT4

FL_OUT5

FW_OUT6

RA_OUT7

+24V/+30V3

S2

1

1

5

2

2

6

7

3

8

8

A1

Control Unit

Steuergerät

HVP20-4

9800 370005

Z

= Optional Equipment

Sonderausstattung

white

X13 white

PE

U

V

W

1

2

3

4

Ground

GN

WH

BN

YE

9870 001409 CN

d

c

b

a

No.

Modifications/

Date Signature

WH

YE

BN

GN

shield

Confirmation

WH

YE

BN

M1

Sewing Motor

Nähmotor

drawing valid to March 2009

D PPÜRK O

ADLER AG

Bie le f el d

www.duerkopp-adler.com

Date/

Designer/

Checker/

Release/

Y1.2

2008-09-08

Czytrich

Priemer

/0145 05

Y1.1

Y2

Z

Cl. 281-140342; -140442

Control Unit HVP-20-4-28-CE

and single pushbutton

Y3

Y4

Denomination

connection diagram

Part Number/

9890 281001 B

Page

/2 2

Loading...

Loading...