Page 1

275

Spezialnähmaschine

mit Direktantrieb

Betriebsanleitung

Instruction manual

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521/ 9 25 - 00 • Telefax +49 (0) 521/ 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

02/2002 Rev. index: 00.0 PrintedinGermany 0791 275740

D

GB

Page 2

Alle Rechte vorbehalten.

Eigentum der Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch

auszugsweise Wiederverwendung dieser Inhalte ist ohne vorheriges schriftliches

Einverständnis der Dürkopp Adler AG verboten.

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the

content in any manner, even in extracts, without prior written permission of

Dürkopp Adler AG, is prohibited.

Copyright © Dürkopp Adler AG - 2002

Page 3

Foreword

This instruction manual is intended to help the user to become

familiar with the machine and take advantage of its application

possibilities in accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically.

Observation of the instructions eliminates danger, reduces costs

for repair and down-times, and increases the reliability and life of

the machine.

The instruction manual is intended to complement existing

national accident prevention and environment protection

regulations.

The instruction manual must always be available at the

machine/sewing unit.

The instruction manual must be read and applied by any person

that is authorized to work on the machine/sewing unit. This

means:

–

Operation, including equipping, troubleshooting during the

work cycle, removing of fabric waste,

–

Service (maintenance, inspection, repair and/or

–

Transport.

The user also has to assure that only authorized personnel work

on the machine.

The user is obliged to check the machine at least once per shift

for apparent damages and to immediatly report any changes

(including the performance in service), which impair the safety.

The user company must ensure that the machine is only operated

in perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be

remounted directly after completion of the maintenance and

repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the

machine/unit! The yellow-and-black striped surfaces designate

permanend danger areas, eg danger of squashing, cutting,

shearing or collision.

Besides the recommendations in this instruction manual also

observe the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance of the following safety instructions can cause bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the instruction

book and operated by persons with appropriate training.

2. Before putting into service also read the safety rules and instructions of the

motor supplier.

3. The machine must be used only for the purpose intended. Use of the machine

without the safety devices is not permitted. Observe all the relevant safety

regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot, needle plate, feed

dog and bobbin) when threading, when the workplace is left, and during

service work, the machine must be disconnected from the mains by switching

off the master switch or disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately trained persons.

6. Repairs, conversion and special maintenance work must only be carried out by

technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the machine from

the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made by

appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by electricians or

appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us and made

only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as the entire

sewing unit is found to comply with EC directives.

It is absolutely necessary to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 5

Contents page:

Part 2: Installation instructions Cl. 275 direct drive

1. Scope of delivery .............................. 7

2. General and transport packing ...................... 7

3. Assembling the stand ........................... 9

3.1 Assemblingthestandparts......................... 9

3.2 Completingthetabletopandfittingittothestand............ 9

3.2.1 Machines with no edge cutter........................ 9

3.2.2 Machines with an edge cutter ....................... 11

3.2.3 Machines with an edge cutter and fullness control ........... 13

3.3 Settingtheworkingheight.......................... 14

4. Assembling the machine head ...................... 15

4.1 Fitting the machine head .......................... 15

5. Sewing drive ................................. 16

5.1 Itemssupplied................................. 16

5.2 Fittingthecontrol............................... 16

5.3 Fitting the set-point generator ....................... 16

5.3.1 All subclasses except 275-742642..................... 16

5.3.2 Subclass 275-742642 ............................ 17

5.4 Fitting the knee-switch ............................ 17

5.4.1 All subclasses except 275-742642..................... 17

5.4.2 Subclass 275-742642 ............................ 17

5.5 Fitting the cable conduit ........................... 17

5.6 Fitting the pedal ................................ 17

GB

6. Electrical connection ............................ 19

6.1 Checkingthemainsvoltage......................... 19

6.2 Earthing .................................... 19

6.3 Fitting and connecting the sewing-light transformer

6.3.1 Connection to the DA220C control ..................... 20

6.4 Connection sockets on the DA220C control ............... 21

6.5 Connecting the DA220C control ...................... 21

6.6 Checkingthedirectionofrotationofthesewingdrive ......... 22

6.7 Checkingthepositioning........................... 23

6.8 Machine-specificparameters........................ 23

6.8.1 General ..................................... 23

6.8.2 Autoselect................................... 23

6.9 Masterreset.................................. 23

(optional equipment) ............................. 20

Page 6

Contents page:

7. Operating and adjusting the DC1500/DA220C direct-current

7.1 DA220C control operating and display elements ............ 25

7.1.1 Changing parameter values at operator level with the DA220C control. . . 26

7.1.1.1 Calling and changing operator-level parameters one after the other

7.1.1.2 Calling and changing operator-level parameters directly with the

7.1.2 Reducing the maximum speed with the DA220C control ........ 27

7.1.3 DA220C control operator-level parameter list .............. 28

7.1.4 Changing technician-level and manufacturer-level parameter values . . 29

7.1.5 Setting positions with the DA220C control ................ 30

7.1.6 Setting machine-specific parameters with the DA220C control .... 32

7.1.6.1 General ..................................... 32

7.1.6.2 Autoselect................................... 32

7.1.6.3 Table of DA220C control machine-specific parameters......... 32

7.1.7 Master reset with the DA220C control................... 33

7.1.8 Condition and error messages ....................... 34

7.2 V810 operating panel (optional equipment)................ 35

7.2.1 Operating and display elements on the V810 operating panel..... 35

7.2.2 Key functions on the V810 operating panel................ 35

7.2.3 Meaning of the symbols on the V810 operating panel ......... 36

7.2.4 Changing parameter values at operator level .............. 37

7.2.5 Reducing the maximum speed ....................... 37

7.2.6 Changing technician-level and manufacturer-level parameter values

7.2.7 Setting positions with the V810 operating panel ............. 39

7.2.8 Setting machine-specific parameters with the V810 operating panel . . . 40

7.2.9 Master reset with the V810 operating panel ............... 40

7.2.10 Condition and error messages on the V810 operating panel...... 40

7.3 V820 operating panel............................. 41

7.3.1 Operating and display elements on the V820 operating panel..... 41

7.3.2 Key functions on the V820 operating panel................ 41

7.3.3 Meaning of the symbols on the V820 operating panel ......... 43

7.3.4 Changing parameter values at operator level .............. 44

7.3.5 Reducing the maximum speed ....................... 44

7.3.6 Quickinformationandquicksettingsentry(HIT) ............ 44

7.3.7 Changing technician-level and manufacturer-level parameter values

7.3.8 Setting positions with the V820 operating panel ............. 46

7.3.9 Setting machine-specific parameters with the V820 operating panel . . . 47

7.3.10 Master reset with the V820 operating panel ............... 47

7.3.11 Condition and error messages on the V820 operating panel...... 48

7.3.12 Seam programming with the V820 operating panel ........... 48

positioning actuator ............................ 24

with the DA220C control ........................... 26

DA220C control ................................ 27

with the V810 operating panel ....................... 38

with the V820 operating panel ....................... 45

Page 7

Contents page:

8. Fullness control in classes 275-142342 and 275-742642 ...... 49

8.1 Checkingthebasiccontrolsetting..................... 49

8.1.1 AdjustingtheLEDanddisplaybrightness ................ 49

8.1.2 Movingtothereferencepositionaftereachthreadcut......... 49

8.1.3 Activating the next seam sequence when the thread is cut ...... 50

8.2 Rotationinthereferenceposition..................... 50

9. Pneumatic connection ........................... 51

10. Lubrication .................................. 52

11. Sewing test .................................. 52

GB

Page 8

Page 9

Notes

GB

5

Page 10

1

2

9

3

10

8

11

4

7

5

6

6

Page 11

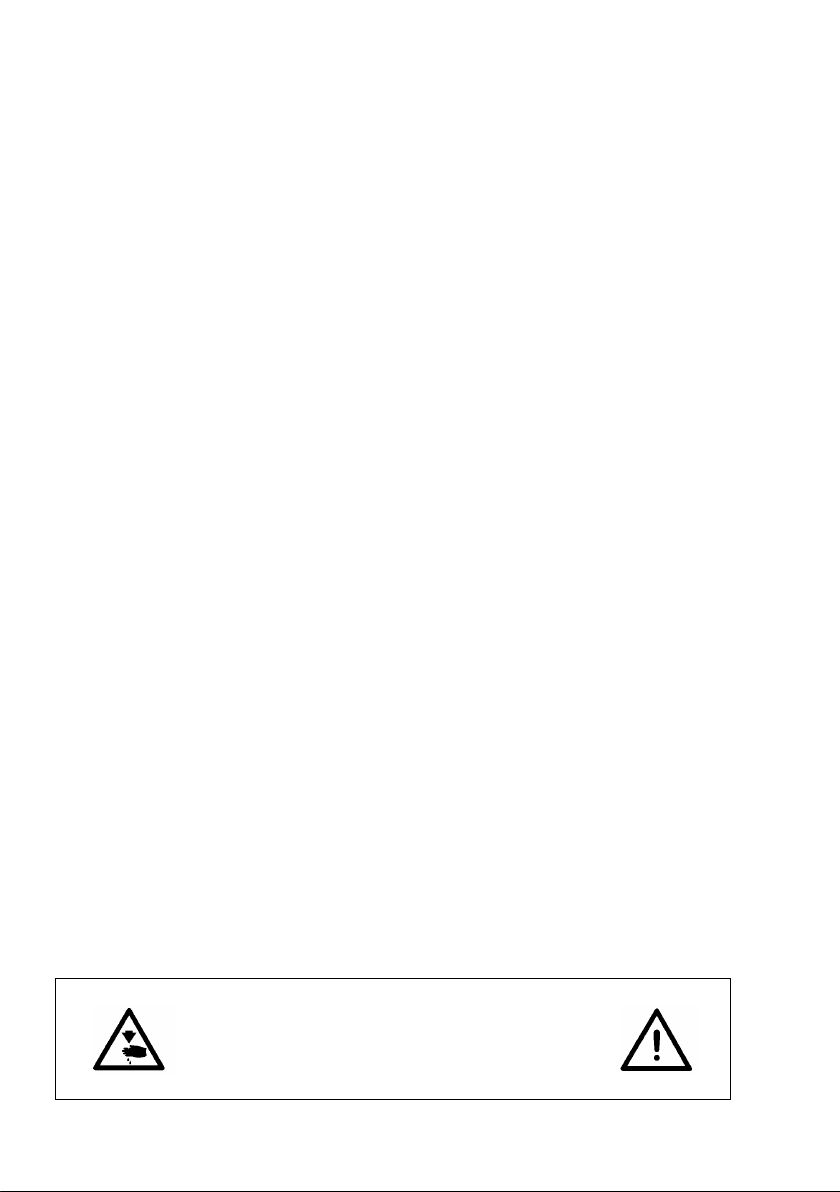

1. Scope of Delivery

What items are supplied depends on your order.

Before setting-up please check that all the required components are present.

Equipment (depending on subclass):

–

1 Reel stand

–

2 Table plate

–

3 Control with main switch

–

4 Maintenance unit

–

5 Pedal linkage

–

6 Pedal

–

7 Frame

–

8 Drawer

–

9 Upper part of the machine with sewing drive

–

10 Aattachment bracket for set-point generator (packed with the control)

–

11 Set-point generator (packed with the control)

–

Minor components in the accessory pack

–

Fullness control (depending on subclass)

2. General and transport packing

GB

CAUTION:

The special sewing machine must be set up by trained

specialist personnel.

Transport packing

If the special sewing machine you have bought is already set up, the following transport

packing must be removed:

–

safety straps and battens on the upper part of the machine, table and frame

7

Page 12

1

15

14

13

12

11

10

14

2

3

4

9

8

5

6

7

8

Page 13

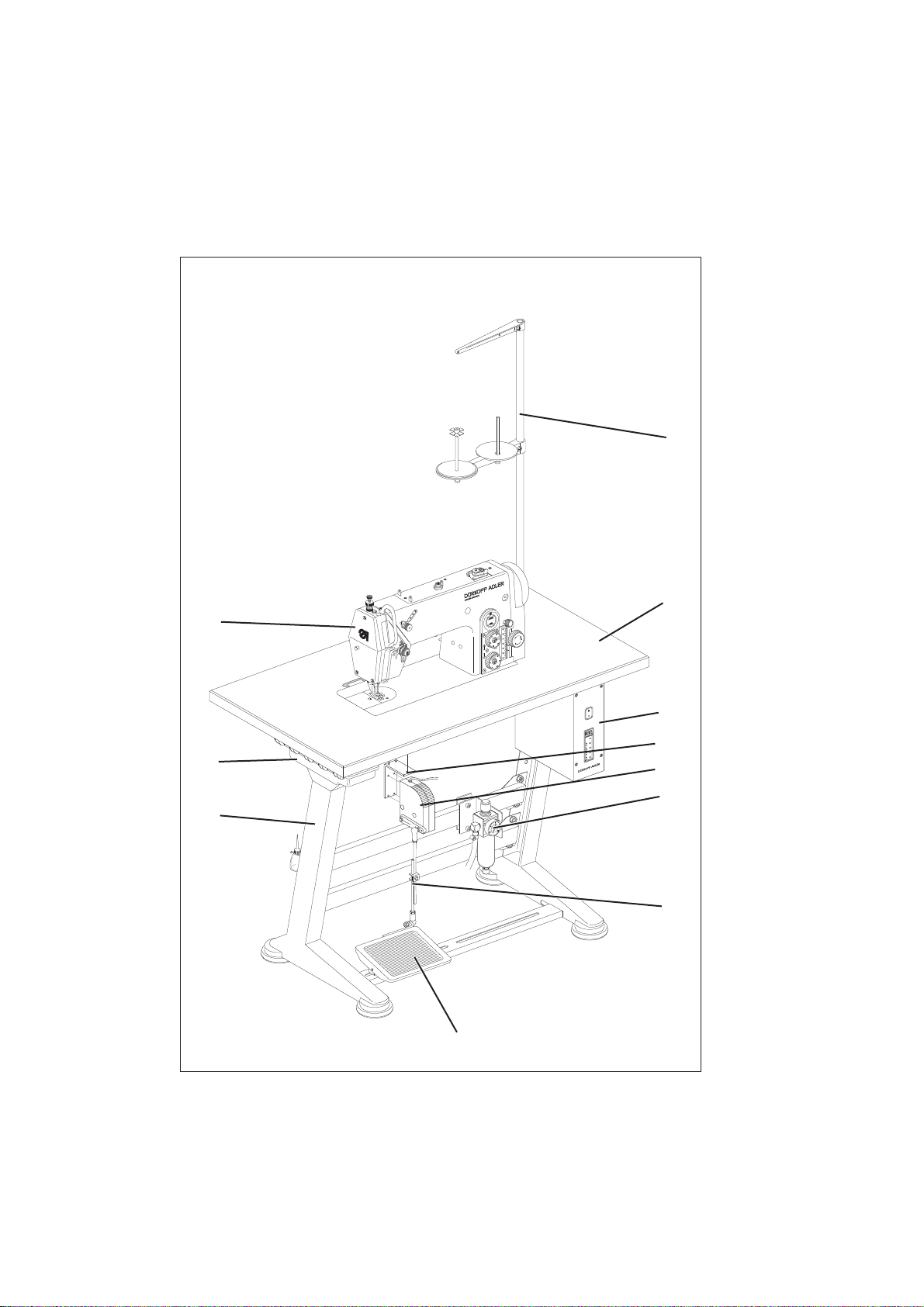

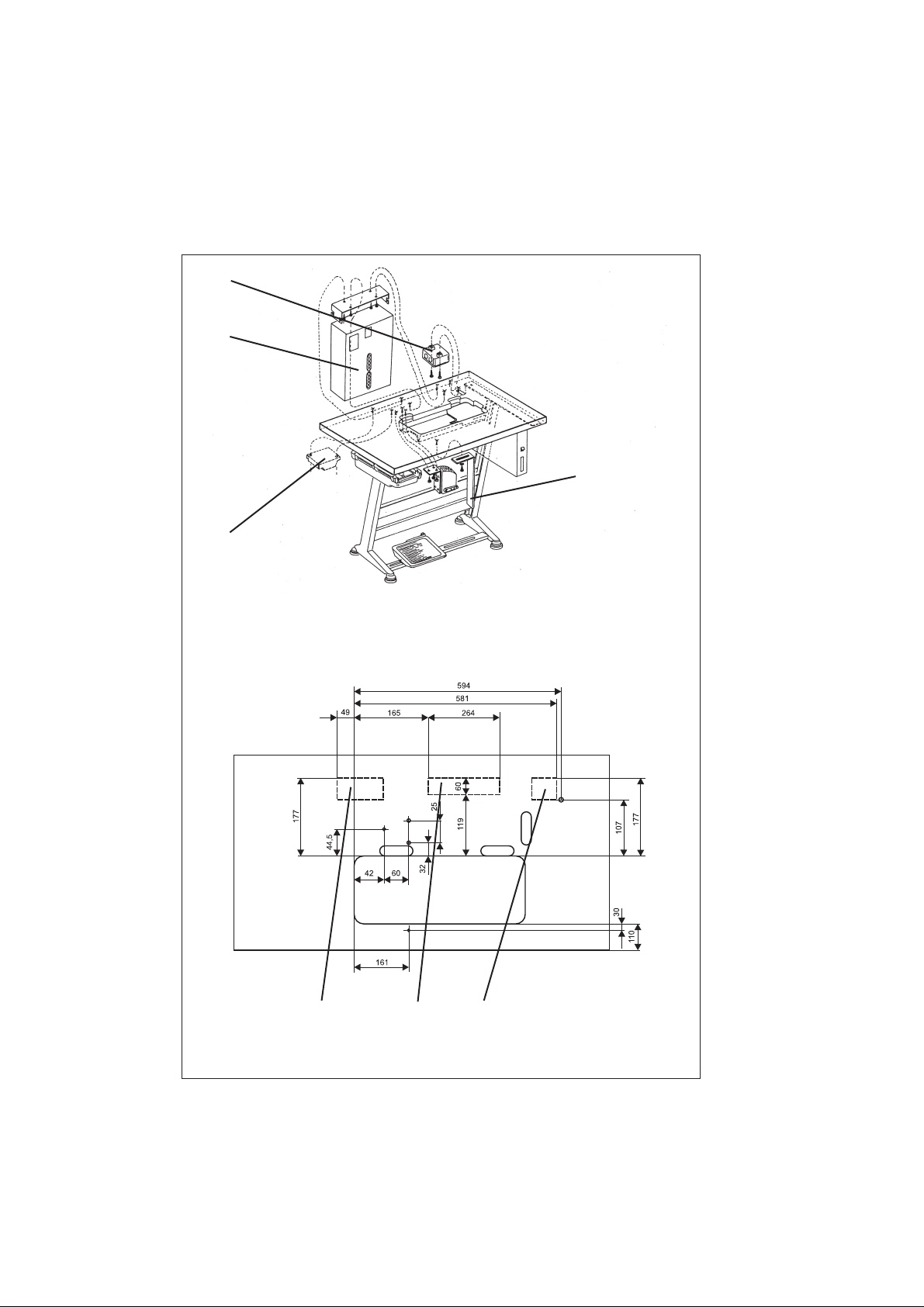

3. Assembling the stand

6 7 m m

5 0 0 m m

1 0 6 0 m m

1 0 0 m m

3.1 Assembling the stand parts

–

Assemble the frame components as shown in the illustration.

–

Fit the four enclosed feet 6 to the frame.

–

Slightly loosen screws 5 on both sides of the cross-brace 7 and make sure the

frame is firm and stable.

All four of the frame supports must be firmly on the ground.

–

Retighten screws 5.

–

Screw the oilcan holder 8 onto the left-hand upright of the frame.

3.2 Completing the table top and fitting it to the stand

3.2.1 Machines with no edge cutter

(classes 275-140332, 275-140342, 275-142342)

–

Fit the top support 15 into the hole in the table plate.

–

Fit the rubber rests 14 for the upper part of the machine into the recesses in the

table plate 12.

–

Fit the rest plug 13 and push on the pressure springs.

–

Screw on the drawer 11 with its brackets under the left-hand side of the table plate.

–

Screw on the cable conduit 10 under the back of the table plate.

–

Mark the positions of the screw connections of the oil collector 2 and attach it under

the table-plate opening with wood screws.

–

Attach the table plate 12 to the frame with wood screws (B8 x 35).

Its position on the frame can be seen from the dimensions in the sketch.

–

Fit the reel stand 1 into the hole in the table plate and attach with nuts and

washers.

Fit and align the yarn-reel holder and thread-guide arm.

The yarn-reel holder and thread-guide arm must be vertically aligned.

GB

9

Page 14

1

15

14

13

12

11

10

14

2

3

4

9

8

5

6

10

7

Page 15

3.2.2 Machines with an edge cutter

(classes 275-740642 and 275-742642)

–

Fit the top support 15 into the hole in the table plate.

–

Fit the rubber rests 14 for the upper part of the machine into the recesses in the

table plate 12.

–

Fit the rest plug 13 and push on the pressure springs.

–

Screw on the drawer 11 with its brackets under the left-hand side of the table plate.

–

Screw on the cable conduit 10 under the back of the table plate.

–

Mark the positions of the screw connections of the oil drip pan 2 and fix it under the

table-plate opening with wood screws.

–

Mark the positions of the screw connections of the waste chute 16 and attach it

under the table-plate opening with wood screws.

Screw the oil drip pan 2 and waste chute together.

–

Attach the table plate 12 to the frame with wood screws (B8 x 35).

Its position on the frame can be seen from the dimensions in the sketch

(see page 9).

–

Fit the reel stand 1 into the hole in the table plate and attach with nuts and

washers.

Fit and align the yarn-reel holder and thread-guide arm.

The yarn-reel holder and thread-guide arm must be vertically aligned.

GB

16

11

Page 16

17

18

19

20

12

21 22 23

Page 17

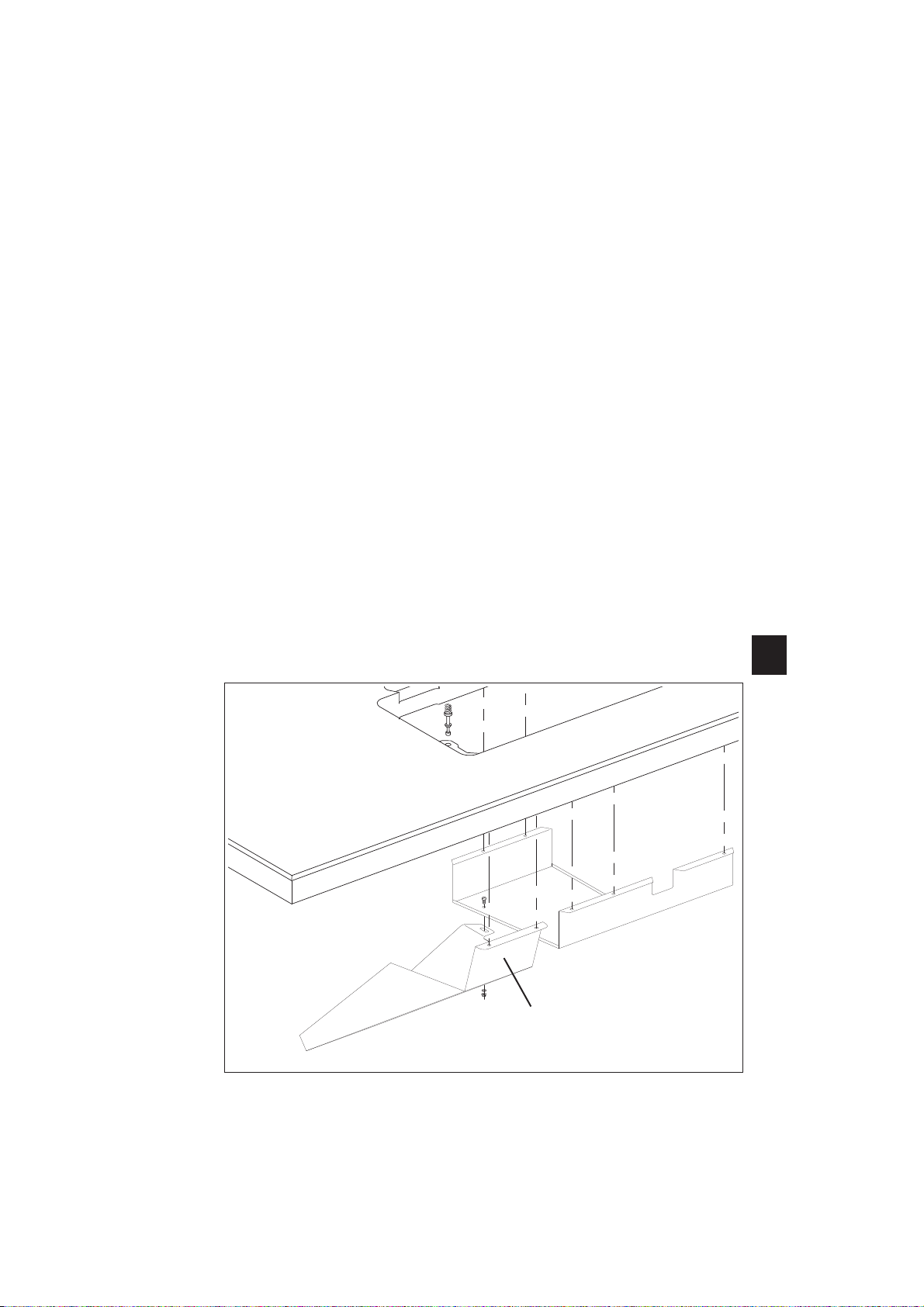

3.2.3 Machines with an edge cutter and fullness control

(class 275-742642)

(for items 1-16 see the preceding pages)

–

Attach items 1-16 as described in the previous section.

–

Fit the junction box 17 into item 23.

–

Fit the control 18 into item 22.

–

Fit the sewing-light transformer 19 into item 21.

–

Screw on the knee-switch 20 under the table top 1.

GB

13

Page 18

3.3 Adjusting the working height

The working height can be adjusted between 750 and 950 mm (measured to the upper

edge of the table top).

–

Undo screws 1 on both legs of the stand.

–

Adjust the table top vertically to the desired working height.

To prevent tilting, pull out the table top or push it in uniformly

on both sides.

–

Tighten both screws 1.

14

1

Page 19

4. Assembling the machine head

4.1 Fitting the machine head

CAUTION:

Remove the front and centre support screws before tilting

into the working position.

–

Fit the upper part of the machine 1, tilted, into the opening in the table top.

–

Remove the front and centre support screws 2.

1

2

GB

15

Page 20

5. Sewing drive

1

2

3

4

10

5.1 Items supplied

DC1500/DA220C positioning actuator

–

DC1500 motor

–

DA220C control

–

EB301 A set-point generator

–

pedal linkage

–

attachment items

–

V810 operating panel (optional equipment)

–

V820 operating panel (optional equipment)

11

5

6

7

7

8

2

9

3

5.2 Fitting the control

–

Fit the control 8 with 4 screws under the table top 5.

–

Attach the mains cable of the control with its cleat under the table top.

5.3 Fitting the set-point generator

5.3.1 All subclasses except 275-742642

–

Screw on the bracket 2 under the table top 5 (see illustration above left).

–

Screw the set-point generator 3 onto the bracket 2 (see illustration above left).

16

Page 21

5.3.2 Subclass 275-742642

With this subclass a large number of assemblies are fitted under the table top, so it is

essential to comply with the dimensional sketch in section 3.2.3.

–

Screw on the bracket 2 under the table top 5 (see illustration above right).

–

Screw the set-point generator 3 onto the bracket 2 (see illustration above right).

5.4 Fitting the knee-switch

5.4.1 All subclasses except 275-742642

–

Screw on the knee-switch 7 under the table top (illustration above left).

5.4.2 Subclass 275-742642

–

Screw on the knee-switch 7 under the table top (illustration above right).

5.5 Fitting the cable conduit

–

Screw on the cable conduit 1 under the table top 5.

5.6 Fitting the pedal

–

Attach the pedal 10 to the frame brace 11.

–

For ergonomic reasons the lateral alignment of the pedal 10 should be such that

the middle of the pedal is roughly beneath the needle.

The frame brace 11 is fitted with slots for pedal alignment.

–

Attach the pedal linkage 9 with ball sockets to the set-point generator 3 and

pedal 10.

–

Slightly undo screw 4.

–

Adjust the height of the pedal linkage:

when not under load the pedal must be at an angle of approx. 10°.

–

Tighten screw 4.

GB

17

Page 22

1

2

2

18

3

Page 23

6. Electrical connection

CAUTION:

All work on the electrical equipment of this special sewing

machine may only be carried out by qualified electricians

who have undergone appropriate training.

The mains plug must be removed.

It is essential to comply with the sewing-drive

manufacturer’s operating instructions (supplied).

6.1 Checking the mains voltage

CAUTION:

The design voltage range for the sewing drive is 190-240V

50/60Hz. The mains voltage must be within this range. You

must ensure that the mains-cable fuse is rated no higher

than 16A (see data sheet 9800 331101 DAT).

CAUTION:

The machine must be connected to the mains by a plug

connection.

6.2 Earthing

The earth cable 2 (in the accessory pack) takes static charges from the upper part of the

machine to earth (control housing).

–

Attach the earth cable 2 to the motor with screw 3.

–

Lay the earth cable.

–

Screw the cable lug of the earth cable 2 onto the control 1 with the screw.

19

GB

Page 24

6.3 Fitting and connecting the sewing-light transformer (optional equipment)

–

Remove the mains plug.

–

Connect the mains cable of the sewing-light transformer to the mains-input side in

the control (see data sheet 9800 331101 DAT).

CAUTION:

The sewing-light transformer is directly connected to the

mains. It is therefore live even when the main switch is

switched off.

The mains plug must be removed before carrying out any

work on the sewing-light transformer, e.g. changing the

fuse.

6.3.1 Connection to the DA220C control

12

–

Undo 4 screws on the front plate of the control.

–

Remove the front plate.

–

Push the cable forwards from behind through the cable conduit 2 into the control.

–

Remove the black rubber bushing 1.

–

Pierce the round opening in the rubber guide with a screwdriver.

–

Pass the cable of the sewing-light transformer through the resulting hole in the

rubber guide.

–

Replace the rubber guide.

–

Press on the terminal opening 5 or 6 with a small screwdriver to open terminal 3 or 4.

–

Connect the blue cable to terminal 3 and the brown cable to terminal 4.

–

Re-attach the front plate with the 4 screws.

345 6

20

Page 25

6.4 Connection sockets on the DA220C control

B 7 7 6

V 8 . .

B 1 8

L S M . . .

B 2

M

B 8 0

E B .. .

B 4 1

M

A

1

2

B41

B2

B80

A

B776

6.5 Connecting the DA220C control

–

Plug the set-point generator (pedal) lead into socket B80 of the control.

–

Plug the lead of the motor sensor 2 into socket B2 of the control.

–

Plug the lead 1 of the motor into socket B41 of the control.

–

Plug the machine lead into socket A of the control.

–

Lay all leads through the cable conduit.

–

Plug the lead of the operating panel (optional equipment) into socket B776.

GB

21

Page 26

6.6 Checking the direction of rotation of the sewing drive

CAUTION:

Before the special sewing machine is started it is essential

to check the direction of rotation of the sewing drive.

Switching it on can cause damage if the direction of rotation

is incorrect.

The arrow on the belt guard indicates the correct direction of rotation.

The direction of rotation of the direct-current positioning actuator is set to run from right

to left by the pre-set value of the relevant parameter in the control. Even so, the

direction of rotation must be checked before the machine is started. A possible

procedure is as follows:

First lock the sewing foot in the up position

(see Operating instructions, section 6.13).

DA220C control

–

The plugs of the set-point generator, motor, motor sensor and operating panel

(if present) must be plugged in (see section 6.5).

–

Unplug the 37-pin plug of the upper part of the machine.

–

Turn on the main switch.

The operating panel shows “Inf A5” or “A5”, which means that no valid Autoselect

resistance has been detected and the maximum speed will therefore be limited.

–

Press the pedal slightly forwards; the drive turns: check the direction of rotation.

–

If the direction of rotation of the drive is incorrect, parameter 161 at “technician

level” must be set to 1. See section 7.1.4.

–

Turn off the main switch.

–

Plug in the 37-pin plug of the upper part of the machine.

22

Page 27

6.7 Checking the positioning

Needle positions are correctly set prior to delivery, but they should still be checked

before starting the machine.

NB:

The sewing foot must be locked in the up position (see Operating instructions,

section 6.13).

The machine must move to an intermediate halt in position 1 (needle down).

See section 7.1, LED 7.

Position 1

–

Turn on the main switch.

–

Briefly push the pedal forwards and return it to its original position. The needle

moves to position 1 = handwheel point “F”.

–

Check the position of the needle.

Position 2

–

Move the pedal forwards, then fully back.

–

The needle moves to position 2 = handwheel point “C”.

–

Check the position of the needle.

If either or both needle positions are incorrect, they must be corrected:

see section 7.1.5 or 7.2.7.

6.8 Machine-specific parameters

GB

6.8.1 General

The functions of the sewing-drive control are determined by the program and the

parameter settings.

All parameter values for the relevant machine class and subclass are correctly set prior

to delivery. This entails changing some pre-set control values (e.g. the maximum

speed). If the control is replaced, the machine-specific parameters must be restored to

their correct values. See section 7.1.6, 7.2.8 or 7.3.9.

6.8.2 Autoselect

The control “recognises” which machine series is connected by measuring the

Autoselect resistance in the machine. Autoselect selects control functions and the

pre-set parameter values.

Caution: If the control fails to recognise a valid Autoselect resistance (or any at all), the

drive runs only with the so-called emergency operating functions to prevent machine

damage.

6.9 Master reset

A master reset (see section 7.1.7, 7.2.9 or 7.3.10) resets all parameters to their pre-set

values. After a master reset the machine-specific parameters must be restored to their

correct values. See section 7.1.6, 7.2.8 or 7.3.9.

23

Page 28

7. Operating and adjusting the DC1500/DA220C

direct-current positioning actuator

Operation

The DA220C control contains all operating components necessary to switch functions

and set parameters. It can be operated without an operating panel, but seam

programming is not possible.

The V810 and V820 operating panels (optional equipments) can also be connected to

the control. Seam programming can be carried out with the V820 operating panel.

A detailed description of the control can be found in the

“EFKA DC1500/DA220C control 5300” operating instructions.

DA220C control functions

The functions of the DA220C control are determined by the program and the parameter

settings. With the correct parameter settings the control is ideally matched to the class

and subclass of the machine. The parameter values are pre-set in the controls. For

each class and subclass some parameters must be changed from their pre-set values.

All parameters are correctly set prior to delivery.

Access authorisation for command entry

To prevent the unwanted alteration of pre-set functions there are three levels of

command entry.

Access:

-theoperator at “operator level” with no code

-thetechnician at “technician level” and “operator level” with a code.

-themanufacturer at “manufacturer level” and all lower levels with a code.

24

Page 29

7.1 DA220C control operating and display elements

P

+

E

> >

LED 1

LED 8

Key Function in sewing mode (main switch on)

P enter / leave programming mode

E starting bar tack single / double / off

(displayed by LED1 and LED2)

+ ending bar tack single / double / off

(displayed by LED3 and LED4)

- automatic sewing-foot lift on halt in seam on/off

(displayed by LED5)

automatic sewing-foot lift after thread cut on/off

(displayed by LED6)

>> basic needle position: position 1 (displayed by LED7)

or position 2 (displayed by LED8)

GB

Key Function in programming mode

(see section 7.1.1)

P enter / leave programming mode

E call parameter value or confirm change

+ increase number or parameter value

- reduce number or parameter value

>> Shift function

25

Page 30

LED Function

LED1 on display for single starting bar tack

LED2 on display for double starting bar tack

LED1 and LED2 off starting bar tack off

LED3 on display for single ending bar tack

LED4 on display for double ending bar tack

LED3 and LED4 off ending bar tack off

LED5 on display for automatic sewing-foot lift on halt in seam

LED6 on display for automatic sewing-foot lift after thread cut.

LED7 on display for basic needle position = down

LED8 on display for basic needle position = up

display3-figure display for rpm, parameters and code

7.1.1 Changing parameter values at operator level with the DA220C control

Operator-level parameter values (see parameter list in section 7.1.3) can be changed

without entering a code.

7.1.1.1 Calling and changing operator-level parameters one after the other with

the DA220C control

–

Turn on the main switch.

–

The value for the maximum speed appears in the display, e.g. “480” for 4800 rpm.

–

Press “P”: the first parameter, “0.0.0.”, is displayed.

–

Press “E”: its associated parameter value, e.g. “002”, is displayed.

–

Press “+”: the parameter value is increased.

–

Press “-”: the parameter value is reduced.

–

Press “E”: the next parameter, “0.0.1.”, is displayed.

–

Press “E”: the value of parameter “0.0.1.”, e.g. “004”, is displayed, and so on.

In this way all the operator-level parameters can be displayed and changed one

after the other. After the last parameter programming at operator level terminates.

You can leave programming at operator level at any time:

–

Press “P”: the same parameter, “0.0.1.”, is displayed.

–

Press “P” again to leave programming at operator level. The value for the maximum

speed appears in the display, e.g. “480” for 4800 rpm.

–

On termination of programming at operator level the changed values are saved.

26

Page 31

7.1.1.2 Calling and changing operator-level parameters directly with the

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

DA220C control

Turn on the main switch.

The value for the maximum speed appears in the display, e.g. “480” for 4800 rpm.

Press “P”: the first parameter, “0.0.0.”, is displayed.

Press “>>”: the first figure of the parameter flashes, “0.0.0.”

Press the “+”or“-” keys to change the value of the flashing figure.

Press “>>”: the second figure of the parameter flashes, “0.0.0.”

Press the “+”or“-” keys to change the value of the flashing figure.

Press “>>“: the third figure of the parameter flashes, “0.0.0.”

Press the “+”or“-” keys to change the value of the flashing figure.

The required parameter is set.

Press “E”: the value of the set parameter is displayed, e.g. “on”.

Press “-”toswitchfrom“on”to“oFF”.

Press “+”toswitchfrom“oFF”to“on”.

Press “E”: the next parameter is called.

Once a parameter has been set the next one can be called and changed, or

programming terminated by pressing “P”. The value for the maximum speed

appears in the display, e.g. “480” for 4800 rpm.

7.1.2 Reducing the maximum speed with the DA220C control

The maximum speed can be reduced to adapt it to particular applications.

During sewing, and if the machine halts, the maximum speed is shown in the display.

The three-figure value displayed must be multiplied by 10. While it is displayed the

maximum speed can be changed by pressing the “+/-” keys. The adjustment range lies

between the values of parameters F-111 (maximum) and F-121 (minimum). See

sections 7.1.4 and 7.1.6.

NB: there are two settings for the maximum speed, the value of parameter 111 and the

reduction in maximum speed with the “+/-” keys. The lower value always has priority. If

the maximum speed is reduced with the “+/-” keys, an increase in the value of

parameter 111 takes effect only if the reduction is cancelled during sewing by pressing

the “+” key.

Caution: the maximum speed (the value of parameter 111) should not be set higher

than the figure shown in the parameter sheet (in the accessory kit) for machines of the

relevant class and subclass.

GB

27

Page 32

7.1.3 DA220C control operator-level parameter list

Parameter adjustment range

No. Abb. Name/Function min max 100R

000 c2 starting-bar-tack stitches forwards 0 254 2

001 c1 starting-bar-tack stitches backwards 0 254 4

002 c3 ending-bar-tack stitches backwards 0 254 3

003 c4 ending-bar-tack stitches forwards 0 254 3

004 LS number of light-barrier equalising stitches 0 254 4

(large stitch length)

005LSF number of light-barrier filter stitches for 0 254 0

knits

006LSn number of seams terminated with 0 15 1

the light barrier

007Stc number of stitches in the 0 254 10

automatically-produced seam section

008 -F- assigning a function to key 9 (on the 1 5 2

V820 operating panel)

1 = Softstart ON/OFF

2 = ornamental-stitch bar tack ON/OFF

3 = stroke adjustment

press and release = ON /

press and hold = OFF

4 = needle cooling ON/OFF 1 5 2

009 LS light barrier ON/OFF 0 1 0

010cLS number of light-barrier equalising stitches 0 254 8

(small stitch length)

013 FA thread cutter ON/OFF 0 1 1

014FW thread retractor ON/OFF 0 1 0

015StS stitch count ON/OFF 0 1 0

080Sav number of stitches, starting 0 254 3

decorative-stitch bar tack forwards

081 SAr number of stitches, starting 0 254 3

decorative-stitch bar tack backwards

082SEr number of stitches, ending 0 254 3

decorative-stitch bar tack forwards

083SEv number of stitches, ending 0 254 3

decorative-stitch bar tack backwards

pre-set value

28

Page 33

7.1.4 Changing technician-level and manufacturer-level parameter values

CAUTION:

Great care must be taken when changing parameter values,

as an incorrectly-set drive control may damage the

machine.

NB:

A master reset restores all parameters to the values pre-set by the drive manufacturer.

See section 7.1.7.

Entering the technician-level code with the DA220C control

–

Turn off the main switch.

–

Press and hold down the “P”key.

–

Turn on the main switch: “cod” appears in the display.

–

Release the “P”key.

–

Press the “>>“key:“000” appears in the display. The left-hand figure flashes.

–

Enter code 190. Press the “+” or “-” keys to change the value of the flashing figure.

Press the “>>“ key to move to the next figure.

–

Press the “E” key: the first technician-level parameter, “1.0.0.”, is displayed.

Selecting parameters and changing values

–

Use the “+”, “-” and “>>” keys to set the required parameter

(see section 7.1.1.2).

–

Press the “E” key: the value of the parameter is displayed.

–

Press the “+”or“-” keys to change the value of the parameter.

–

Press the “E” key to display the next parameter or the “P”key

to display the same parameter.

GB

Saving changed parameter values

–

Press the “P” key to end programming.

–

Sew a complete seam, i.e. push the pedal forwards, then all the way back: the

change is saved.

–

If no seam is commenced, the change is lost.

–

Press the “P” key again to return to programming level.

29

Page 34

Entering the manufacturer-level code with the DA220C control

–

Turn off the main switch.

–

Press and hold down the “P”key.

–

Turn on the main switch: “Cod” appears in the display.

–

Release the “P”key.

–

Enter code 311. Press the “+” or “-” keys to change the value of the flashing figure.

Press the “>>” key to move to the next figure.

–

Press the “E” key: the first manufacturer-level parameter, “2.0.0.”, is displayed.

–

Continue as described under “Selecting parameters and changing values”.

CAUTION:

The changed parameter values are not saved unless a

complete seam is sewn after leaving the programming

level, i.e. the pedal is pushed forwards and then all the way

back.

If the drive is switched off straight after leaving the

programming level, the changes are lost.

7.1.5 Setting positions with the DA220C control

Setting the reference position

Prerequisite:

The technician-level code has been set (see section 7.1.4).

–

Press the “E” key: the first technician-level parameter, 1.0.0., is displayed.

–

Use the “+”, “-” and “>>“ keys to enter parameter 1.7.0..

–

Press the “E”key:“Sr1” appears in the display.

–

Press the “>>“key:“Po” appears in the display (the “o” character rotates).

–

Turn the handwheel in the normal direction of rotation until the rotating character

“o” in the display goes out, then turn it further until the handwheel reaches its

reference position (position “F”).

–

Press the “P” key: the reference position is saved. The current parameter number

is displayed.

–

Press the “P” key to terminate technician-level programming.

30

Page 35

Setting positions 1 and 2

Prerequisite:

The reference position has been set (see section 7.1.5, “Setting the reference

position”).

NB:

The position values are pre-set, so there is normally no need to set them. The pre-set

values (see the parameter sheet in the accessory kit) are equivalent to the number of

increments after the reference position (in the correct direction of rotation). One

revolution of the motor shaft is equal to one revolution of the handwheel , equivalent to

512 increments.

The positions are:

P1E = handwheel at point “F” = position 1.

P2E = handwheel at point “C” = position 2.

P1A = about 100 increments after P1E (important for internal control functions).

P2A = about 100 increments after P2E (important for internal control functions).

If the positions have to be reset, proceed as follows:

–

After entering the technician-level code (see section 7.1.4):

Press the “E” key: the first technician-level parameter, 1.0.0., is displayed.

–

Use the “+”, “-” and “>>“ keys to enter parameter “1.7.1.”.

–

Press the “E”key:“Sr2” appears in the display.

–

Press the “>>“key:“P1E” appears in the display.

–

Turn the handwheel in the correct direction until “P1E” in the display changes to

increments. Turn the handwheel to point “F” (position 1E).

–

Press the “E”key:“P2E” appears in the display.

–

Turn the handwheel in the correct direction until “P2E” in the display changes to

increments. Turn the handwheel to point “C” (position 2E).

–

Press the “E”key.“P1A” appears in the display.

–

Turn the handwheel in the correct direction until “ P1A” in the display changes to

increments. Turn the handwheel about 100 increments beyond position “P1E”to

position “P1A”.

–

Press the “E”key:“P2A” appears in the display.

–

Turn the handwheel in the correct direction until “ P2A” in the display changes to

increments. Turn the handwheel about 100 increments beyond position “P2E”to

position “P2A”.

–

Press the “P” key twice to terminate position setting and leave the programming

level.

–

Check the positions: see section 6.7.

GB

NB:

If position checking establishes that, for example, positions 1 and 2 are being “overrun”

by about the same amount with respect to the setting, the reference position can be

advanced by this amount.

31

Page 36

7.1.6 Setting machine-specific parameters with the DA220C control

7.1.6.1 General

The sewing-drive control functions are determined by the program and the parameter

settings.

Parameter values are pre-set by the drive manufacturer prior to delivery. For each class

and subclass a number of technician-level or even manufacturer-level parameters must

be changed so that the control exactly matches the machine. The relevant parameters

are listed in table 7.1.6.3 and the parameter sheet (see table 7.1.6.2). The parameter

sheet is in the accessory kit. All parameters are correctly set by Dürkopp Adler prior to

delivery.

7.1.6.2 Autoselect

The control “recognises” which machine series is connected by measuring the

Autoselect resistance in the machine. Autoselect selects control functions and the

pre-set parameter values. If the control fails to recognise a valid Autoselect resistance

(or any at all), the drive runs only with the so-called emergency operating functions to

prevent machine damage (see “EFKA DA220C 5300” operating instructions).

Autoselect classes control parameter sheet

resistance sewing drive

100R (100 ohms) 275 DA220C 9800 331101 PB11

7.1.6.3 Table of DA220C control machine-specific parameters

The values of the parameters listed below must be changed from their pre-set values.

The values to be set (x) can be found in the 9800 331101 PB11 parameter sheet (in

the machine’s accessory kit).

Parameter * Name 275- 275- 275- 275-

F-111 T upper limit for maximum speed

F-250 A function module for output A **x

F-251 A output A and LED A after x x x x

thread cut **

F-252 A output A inverted? 0=no, 1=yes **

F-255 A function module for output B ** x x

F-256 A output B and LED B after x

thread cut **

F-282 A cut-out switch function x x

0=closing, 1=opening

F-283 A cut-out function x x

0=off

1 = cut-out 1 with no positioning

2 = cut-out 2 with positioning

F-289 A rpm limit DB3000 for x

manual bar tack

* T = technician-level parameters, A = manufacturer-level parameters.

140342 142342 740642 742642

140332

32

Page 37

** A function module is a part of the control that handles one of the machine’s facilities,

e.g. raising and lowering the transport roller. The control contains two function modules,

A and B.

Each function module has the following hardware:

–

one output (A or B), e.g. to control a solenoid valve

–

one input ( A or B), e.g. to connect a key

–

one output for an LED (A or B), e.g. displaying a switch status.

Each function module can be assigned various functions by the software. Each function

module has additional parameters, e.g. to activate counts or switch functions after the

thread is cut.

CAUTION:

Great care must be taken when changing parameter values,

as an incorrectly-set drive control may damage the

machine.

7.1.7 Master reset with the DA220C control

Any parameters that have been changed are restored to their pre-set values by a master

reset.

–

Turn off the main switch.

–

Press the “P” key, hold it down and turn on the main switch until “C.o.d.” appears.

–

Release the “P”key.

–

Enter the technician-level code. See section 7.1.4.

–

Press the “E” key: the parameter “1.0.0.” is displayed.

–

Press the “E” key: the value of parameter “1.0.0.” is displayed.

–

Set the value to 170.

–

Press the “P” key twice.

–

Turn off the main switch.

–

After a brief pause, turn the main switch on again. All parameters except 1.1.1.,

1.6.1., 1.7.0., 1.7.1. and 1.9.0. to 1.9.3., have been restored to their pre-set values.

GB

CAUTION:

A few parameters, such as 1.7.0. (reference position),

1.7.1. (needle position) and 1.6.1. (direction of motor

rotation) are unaffected by a master reset.

After a master reset all machine-specific parameters

must be readjusted in accordance with the parameter

sheet. See section 7.1.6.

33

Page 38

7.1.8 Condition and error messages

General information

DA220C V810 V820 Meaning

A1 InF A1 InFo A1 The pedal is not in its zero position

A2 “StoP” flashes “StoP” flashes The cut-out is active

+ Symbol

“cut-out”

A3 InF A3 InFo A3 The reference position is not set.

A5 InF A5 InFo A5 No valid Autoselect resistance has been

Programming error messages (parameters)

If an incorrect code or parameter is entered, the following error message appears

(depending on the operating panel used):

DA220C returns to “000” or the last parameter number

V810 returns to “0000” or the last parameter number

V820 as with V810, plus display “InF F1”

Hardware and software error messages

DA220C V810 V820 Meaning

E2 InF E2 InF E2 Mains voltage too low or time between

E3 InF E3 InF E3 Machine blocked or not reaching the

E4 InF E4 InF E4 Control problem due to defective earthing

h1 InF h1 InF h1 The commutating-transducer lead is defective or

h2 InF h2 InF h2 Processor faulty.

when the sewing drive is switched on

For programming see sections 7.1.5, 7.2.7

and 7.3.8.

detected.

Emergency-operation function:

for information see section 6.8.2.

main switch OFF and main switch ON too brief.

required rpm

or faulty plug connections (contact faults).

the power electronics that generate the

rotating field are faulty.

34

Page 39

7.2 V810 operating panel (optional equipment)

7.2.1 Operating and display elements on the V810 operating panel

7.2.2 key functions on the V810 operating panel

Functions can be turned on and off by briefly pressing the keys on the operating panel.

The functions are effective on machine only if the relevant devices (e.g. magnetic or

electro-pneumatic sewing-foot lift) are present.

Key Function Display

1 double starting bar tack on right arrow above the key on

starting bar tack on both arrows on

single starting bar tack on left arrow above the key on

2 double ending bar tack on right arrow above the key on

ending bar tack on both arrows on

single ending bar tack on left arrow above the key on

3 auto. foot lift on halt in seam on left arrow above the key on

auto. foot lift on halt in seam on left arrow above the key on

auto. foot lift after thread cut on right arrow above the key on

auto. foot lift after thread cut on right arrow above the key on

4 basic needle position = down left arrow above the key on

basic needle position = up right arrow above the key on

A suppress bar tack or invoke bar tack no display

if starting or ending bar tack is switched on,

pressing the key switches the next bar tack off

if starting or ending bar tack is switched off,

pressing the key switches the next bar tack on

GB

35

Page 40

Symbol Function Display

B needle up/down no display

or shift function in programming mode

pressing this key executes a needle movement

that can be programmed with parameter 140.

See the parameter list in the Set-up instructions.

this key has a different function in

programming mode. See section 7.2.6

P programming mode on/off parameter number/standard display

See sections 7.2.4 and 7.2.6

E switch from parameter number to parameter number/parameter value

parameter value

confirmation of parameter value and

switch to the next parameter

See section 7.2.4 and 7.2.6.

+ increase the valued displayed in display value is increased

programming mode

- reduce the valued displayed in display value is reduced

programming mode

7.2.3 Meaning of the symbols on the V810 operating panel

Symbol Function Display

C automatic rpm effective symbol on

only with seam sections

processed automatically

D light barrier switched on symbol on

E sewing drive switched on symbol on

F rpm limit effective symbol on

G bobbin-thread monitor switched on symbol flashes when

bobbin is running out

36

Page 41

7.2.4 Changing parameter values at operator level

The operator-level parameters are given in the parameter list in section 7.1.3.

–

Turn on the main switch.

–

Press the “P” key: the first operator-level parameter, F-000, is displayed.

–

Press the “+”or“-” keys to call the next or preceding parameter.

–

Press the “E” key: the value of the selected parameter is displayed.

–

Press the “+”or“-” keys to change the value of the parameter.

–

Press the “E” key to save the change and display the next parameter, or

the “P” key to save the change and leave the programming level.

CAUTION:

The changed parameter values are not saved unless a

complete seam is sewn after leaving the programming

level, i.e. the pedal is pushed forwards and then fully back.

If the drive is switched off straight after leaving the

programming level, the change is lost.

7.2.5 Reducing the maximum speed

The maximum speed can be reduced to adapt it to particular applications.

During sewing the control type “dA220C” is constantly shown in the display. Press the

“+”or“-” keys to display the maximum speed, and also to change it. The adjustment

range lies between the values of parameters F-111 (maximum value) and F-121

(minimum value).

GB

NB:

There are two settings for the maximum speed, the value of parameter 111 and the

reduction in maximum speed with the “+/-” keys. The lower value always has priority. If

the maximum speed is reduced with the “+/-” keys, an increase in the value of

parameter 111 takes effect only if the reduction is cancelled.

CAUTION:

The maximum speed (the value of parameter 111) should

not be set higher than the figure shown in the parameter

sheet (in the accessory kit) for machines of the relevant

class and subclass.

37

Page 42

7.2.6 Changing technician-level and manufacturer-level parameter values with

the V810 operating panel

Entering the technician-level code

–

Turn off the main switch.

–

All plugs on the sewing-drive control must be plugged in.

–

Press and hold down the “P”key.

–

Turn on the main switch: “C-0000” appears in the display.

–

Release the “P”key.

–

Enter code 1907.Pressthe“+”or“-” keys to change the value of the flashing

figure. Press the “>>” key to move to the next figure.

–

Press the “E” key: the first technician-level parameter, “F-100”, is displayed.

Selecting parameters and changing values

–

Press the “+”or“-” keys to select the next or previous parameter.

–

Parameters can be directly entered with the “>>”, “+”or“-”keys.

–

Press the “E” key: the value of the selected parameter is displayed.

–

Press the “+”or“-” keys to change the value of the parameter.

–

Press the “E” key to display the next parameter or key “P” to display the same

parameter.

Saving changed parameter values

–

Press the “P” key to end programming.

–

Sew a complete seam by pushing the pedal forwards and then all the way back.

The change is saved.

–

If no seam is sewn, the change is lost.

–

Press the “P” key again to return to the programming level.

Entering the manufacturer-level code

–

Turn off the main switch.

–

All plugs on the sewing-drive control must be plugged in.

–

Press and hold down the “P”key.

–

Turn on the main switch: “C-0000” appears in the display.

–

Release the “P”key.

–

Enter code 3112.Pressthe“+”or“-” keys to change the value of the flashing

figure. Press the “>>“ key to move to the next figure.

–

Press the “E” key: the first manufacturer-level parameter, F-200, is displayed.

–

Continue as described under “Selecting parameters and changing values”.

38

Page 43

CAUTION:

The changed parameter values are not saved unless a

complete seam is sewn after leaving the programming

level, i.e. the pedal is pushed forwards and then all

the way back.

If the drive is switched off straight after leaving the

programming level, the changes are lost.

7.2.7 Setting positions with the V810 operating panel

Setting the reference position

Prerequisite:

The technician-level code has been entered. See section 7.2.6.

–

Press the “E” key: the first technician-level parameter, “F-100”, is displayed.

–

Use the “+”, “-” and “>>” keys to set the “F-170” parameter.

–

Press the “E”key:“Sr1 (o)” appears in the display.

–

Press the “>>“key: “PoS0 o” appears in the display (the o character rotates).

–

Turn the handwheel in the normal direction of rotation until the rotating character

“o” in the display goes out, then turn it further until the reference position is

reached (turn the handwheel to point “F”).

–

Press the “P” key: the reference position is saved and the current parameter

number is displayed.

–

If the error message “A3” is displayed, the setting must be repeated.

–

Press the “P” key to terminate programming at technician level.

Settings positions 1 and 2

Prerequisite:

The reference position has been set and the technician-level code has been entered

(see above).

–

Enter the parameter “F-171”.

–

Press the “E”key:“Sr2 (o)” appears in the display.

–

Press the “>>”key: “P1E xxx” appears in the display (xxx = parameter value of

position 1E).

–

Correct the parameter value * if necessary, either with the “+”or“-”keysorby

turning the handwheel to point “F”.

–

Press the “E”key:“P2E xxx” appears in the display (xxx = parameter value of

position 2E).

–

Correct the parameter value * if necessary, either with the “+”or“-”keysorby

turning the handwheel to point “C”.

–

Press the “E”key:“P1A xxx” appears in the display (xxx = parameter value of

position 1A).

–

Correct the parameter value * if necessary, either with the “+”or“-”keysorby

turning the handwheel.

–

Press the “E”key:“P2A xxx” appears in the display (xxx = parameter value of

position 2A).

GB

39

Page 44

–

Correct the parameter value * if necessary, either with the “+”or“-”keysorby

turning the handwheel.

–

Press the “P” key twice to leave the programming level when the settings are

complete.

–

Check the positions: see section 6.7.

* NB:

The parameter values for positions 1E, 2E, 1A and 2A can be found in the parameter

sheet (accessory kit).

NB:

If position checking establishes that, for example, positions 1 and 2 deviate from the

required handwheel point by about the same angle, the problem can be solved by

altering the reference position by this angle.

7.2.8 Setting machine-specific parameters with the V810 operating panel

Machine-specific parameters can be set with the V810 operating panel. They are given

in section 7.1.6 and in the parameter sheet (in the accessory kit). The process is

described in section 7.2.6.

7.2.9 Master reset with the V810 operating panel

Any parameters that have been changed are restored to their pre-set values by a master

reset.

–

Turn off the main switch.

–

Press the “P” key, hold it down and turn on the main switch.

–

Release the “P”key.

–

Enter the technician-level code. See section 7.2.6.

–

Press the “E” key: the parameter “F-100” is displayed.

–

Press the “E” key: the value of parameter “F-100” is displayed.

–

Setthevalueto“170”.

–

Press the “P” key twice.

–

Turn off the main switch.

–

After a brief pause, turn the main switch on again. All parameters except 111, 161,

170, 171 and 190 to 193 have been restored to their pre-set values.

CAUTION:

A few parameters, such as F-170 (reference position),

F-171 (needle position) and F-161 (direction of motor

rotation) are unaffected by a master reset.

After a master reset all machine-specific parameters

must be readjusted in accordance with the parameter

sheet. See section 7.2.8.

7.2.10 Condition and error messages on the V810 operating panel

See section 7.1.8

40

Page 45

7.3 V820 operating panel (optional equipment)

7.3.1 Operating and display elements on the V820 operating panel

7.3.2 Key functions on the V820 operating panel

Functions can be turned on and off by briefly pressing the keys on the operating panel.

The functions are effective on machine only if the relevant devices (e.g. magnetic or

electro-pneumatic sewing-foot lift) are present.

Key Function Display

1 double starting bar tack on right arrow above the key on

starting bar tack on both arrows on

single starting bar tack on left arrow above the key on

2 stitch count, backwards seam right arrow above the key on

stitch count on both arrows on

stitch count, forwards seam left arrow above the key on

3 light-barrier function “light - dark” right arrow above the key on

= switch from: “no material available”

to “material available”.

light barrier on both arrows on

light-barrier function “dark - light” left arrow above the key on

= switch from: “material available” to

“no material available”.

4 double ending bar tack on right arrow above the key on

ending bar tack on both arrows on

single ending bar tack on left arrow above the key on

5 thread cutter on left arrow above the key on

thread retractor on right arrow above the key on

thread cutter and thread retractor on both arrows on

thread cutter and thread retractor off both arrows off

6 auto. foot lift on halt in seam on left arrow above the key on

auto. foot lift on halt in seam on left arrow above the key on

auto. foot lift after thread cut on right arrow above the key on

auto. foot lift after thread cut off right arrow above the key off

GB

41

Page 46

Key Function Display

7 basic needle position = down left arrow above the key on

basic needle position = up right arrow above the key on

8 residual-thread monitor on xxxx - - I I - -

the function of the residual-thread monitor

can be changed with the parameter 195

(see Efka parameter list)

9 function key

the function of the key can be changed with

parameter F-008 (see parameter list,

section 7.1.3)

1 = Softstart ON/OFF SSt ON*/OFF < — > SSc xxx

2 = ornamental-stitch bar tack ON/OFF SrS ON*/OFF

3 = stroke adjustment hPr ON*/OFF

function of the knee-switch or key:

“press and release” = ON /

“ press and hold” = OFF

4 = needle cooling ON/OFF nh ON*/OFF

0 teach in or program number

run the saved sewing program seam-section number

see programming instructions in the operating seam-section stitch number

instructions

EFKA DA220C 5300 number of stitches after

A suppress or invoke bar tacks no display

if the starting or ending bar tack is switched on,

pressing the key switches the next bar tack off

if the starting or ending bar tack is switched off,

pressing the key switches the next bar tack on

B needle up/down no display

or Shift function in programming mode

pressing this key executes a needle movement

that can be programmed with parameter 140.

See the Efka parameter list. In programming

mode this key has a different function.

See section 7.3.8

P programming mode on/on parameter number/standard display

see sections 7.3.4 and 7.3.7

E switch from parameter number to parameter number/parameter value

parameter value.

Confirm parameter value and

switch to next parameter.

See sections 7.3.4 and 7.3.7

+ increase the value displayed displayed value is increased

in programming mode

- reduce the value displayed displayed value is reduced

in programming mode

* when ON the left arrow above

the key is switched on

light-barrier detection

42

Page 47

7.3.3 Meaning of the symbols on the V820 operating panel

Symbol Function Display

C abbreviation for code symbol on when a code is

displayed, e.g. C 1907

D abbreviation for parameter number symbol on when a parameter

number is displayed, e.g. F-111

E program number in teach-in mode symbol on when the program

number of a sewing program

is displayed

F seam-section number in teach-in mode symbol on when a sewing-

program seam-section number

is displayed

G cut-out active symbol flashes on active cut-out

H entry via keys blocked symbol on when entry via

keys is blocked

I error message symbol on (for fault list see

section 7.1.8)

J entering number of stitches in teach-in mode symbol on when the number

of stitches in a seam section

is displayed

K bobbin-thread monitor on symbol flashes when bobbin is

running out only on machines

with a residual-thread monitor

L rpm limit effective symbol on when one of the

possible rpm limits is effective

M * right needle switched off symbol on when right

needle bar is switched off.

only on machines with automatic

needle-bar switch-off

N equalising stitches for light barrier symbol on

O machine running symbol on

P automatic rpm effective symbol on when a seam section

in a sewing program is being

automatically executed

at constant rpm

Q * left needle switched off symbol on when left needle bar

is switched off

only on machines with automatic

needle-bar switch-off

GB

* These functions are not used on class 275.

43

Page 48

7.3.4 Changing parameter values at operator level

The operator-level parameters are given in the parameter list in section 7.1.3.

–

Turn on the main switch.

–

Press the “P” key: the first operator-level parameter, “F-000 c2”, is displayed.

–

The parameters can be selected by pressing the “+”or“-”key.

–

Press the “E” key: the value of the selected parameter, e.g. “F-000 c2 002”, is

displayed.

–

The value “002” can be changed by pressing the “+”or“-”key.

–

Press the “E” key to save the changed value provisionally and display the next

parameter, or the “P” key to save the changed value provisionally and display the

same parameter.

–

Press the “P” key to save the change permanently and leave the programming

level.

7.3.5 Reducing the maximum speed

The maximum speed can be reduced to adapt it to particular applications.

After each completed seam the current value of the maximum speed is shown in the

display. This value can be directly changed with the “+”or“-”keys.

The adjustment range lies between the values of parameters F-111 (maximum value)

and F-121 (minimum value).

NB:

There are two settings for the maximum speed: the value of parameter 111 and the

reduction in maximum speed with the “+/-” keys. The lower value always has priority. If

the maximum speed is reduced with the “+/-” keys, an increase in the value of

parameter 111 takes effect only if the reduction is cancelled.

CAUTION:

The maximum speed (the value of parameter 111) should

not be set higher than the figure shown in the parameter

sheet (in the accessory kit) for machines of the relevant

class and subclass.

7.3.6 Quick information and quick settings entry (HIT)

When functions are switched on with keys 1, 2, 3, 4 and 9 the associated values are

displayed to the operator for about 3 seconds. During this period the value can be

changed immediately with the “+”or“-”keys.

44

Page 49

7.3.7 Changing technician-level and manufacturer-level parameter values with

the V820 operating panel

Entering the technician-level code

–

Turn off the main switch.

–

All plugs on the sewing-drive control must be plugged in.

–

Press and hold down the “P”key.

–

Turn on the main switch: “C-0000” appears in the display.

–

Release the “P”key.

–

Enter code 1907 with number keys 0 to 9.

–

Press the “E” key: the first technician-level parameter, “F-100”, is displayed.

Selecting parameters and changing values

–

After the code is entered the first parameter, “F-100”, is displayed.

–

Enter the required parameter number with number keys 0 to 9.

–

Press the “E” key: the value of the selected parameter is displayed.

–

Press the “+”or“-” keys to change the value of the parameter.

–

Press the “E” key to display the next parameter

or the “P” key to display the same parameter.

Saving changed parameter values

–

Press the “P” key to end programming.

–

Sew a complete seam, i.e. push the pedal forwards and then fully back. The

change is saved.

–

If no seam is sewn, the change is lost.

–

Press the “P” key again to return to the programming level.

Entering the manufacturer-level code

–

Turn off the main switch.

–

Press and hold down the “P”key.

–

Turn on the main switch: “C-0000” appears in the display.

–

Release the “P”key.

–

Enter code 3112 with number keys 0 to 9.

–

Press the “E” key: the first manufacturer-level parameter, “F-200”, is displayed.

–

Continue as described under section 7.3.7, “Selecting parameters

and changing values”.

CAUTION:

The changed parameter values are not saved unless a

complete seam is sewn after leaving the programming

level, i.e. the pedal is pushed forwards and then

all the way back.

If the drive is switched off straight after leaving the

programming level, the changes are lost.

GB

45

Page 50

7.3.8 Setting positions with the V820 operating panel

Setting the reference position

Prerequisite:

The technician-level code has been set. See section 7.3.7.

–

After entering the code press the “E” key: the first technician-level parameter,

F-100, is displayed.

–

Set parameter F-170 withkeys0to9.

–

Press the “E”key.”F-170 Sr1 (o)” appears in the display.

–

Press the “B” key (see illustration 7.3.1).”PoS0 o” appears in the display

(the o character rotates)

–

Turn the handwheel in the normal direction of rotation until the rotating character

“o” in the display goes out, then turn it further until the reference position is

reached (turn the handwheel to point “F”).

–

Press the “P” key: the reference position is saved and the current parameter

number is displayed.

–

If the error message “A3” is displayed, the setting must be repeated.

–

Press the “P” key: programming at technician level is terminated.

Setting positions 1 and 2

Prerequisite:

The reference position has been set and the technician-level code entered (see above).

–

Enter parameter “F-171”.

–

Press the “E”key:“Sr2 (o)” appears in the display.

–

Press the “B” key (see illustration 7.3.1). “P1E xxx” appears in the display.

(xxx = parameter value of position 1E)

–

Correct the parameter value * if necessary, either with the “+” and “-”keys,with

keys 0 - 9 or by turning the handwheel to point “F”.

–

Press the “E”key:“P2E xxx” appears in the display.

(xxx = parameter value of position 2E)

–

Correct the parameter value * if necessary, either with the “+” and “-”keys,with

keys 0 - 9 or by turning the handwheel to point “C”

–

Press the “E”key:“P1A xxx” appears in the display.

(xxx = parameter value of position 1A)

–

Correct the parameter value * if necessary, either with the “+” and “-”keys,with

keys 0 - 9 or by turning the handwheel.

–

Press the “E”key:“P2A xxx” appears in the display.

(xxx = parameter value of position 2A)

–

Correct the parameter value * if necessary, either with the “+” and “-”keys,with

keys 0 - 9 or by turning the handwheel.

–

Press the “P” key twice to leave the programming level when the settings are

complete.

–

Check the positions: see section 6.8.

46

Page 51

*CAUTION

The parameter values for positions 1E, 2E, 1A and 2A can

be found in the parameter sheet (accessory kit).

NB:

If position checking establishes that, for example, positions 1 and 2 deviate from the

required handwheel point by about the same angle, the problem can be solved by

altering the reference position by this angle.

7.3.9 Setting machine-specific parameters with the V820 operating panel

Machine-specific parameters can be set with the V820 operating panel; they are given

in section 7.1.6 and in the parameter sheet (in the accessory kit). The process is

described in section 7.3.7.

7.3.10 Master reset with the V820 operating panel

Any parameters that have been changed are restored to their pre-set values by a master

reset.

–

Turn off the main switch.

–

Press the “P” key, hold it down and turn on the main switch.

–

Release the “P”key.

–

Enter the technician-level code. See section 7.3.7.

–

Press the “E” key: the “F-100” parameter is displayed.

–

Press the “E” key: the value of parameter “F-100” is displayed.

–

Setthevalueto“170”.

–

Press the “P” key twice.

–

Turn off the main switch.

–

After a brief pause, turn the main switch on again. All parameters except 111, 161,

170, 171 and 190 to 193 have been restored to their pre-set values.

GB

CAUTION:

A few parameters, such as F-170 (reference position),

F-171 (needle position) and F-161 (direction of motor

rotation) are unaffected by a master reset.

After a master reset all machine-specific parameters

must be readjusted in accordance with the parameter

sheet. See section 7.3.9.

47

Page 52

7.3.11 Condition and error messages on the V820 operating panel

See section 7.1.8.

7.3.12 Seam programming with the V820 operating panel

A maximum of 8 programs with a total of up to 40 seam sections may be saved.

The starting-bar-tack, ending-bar-tack, stitch-count, thread-cut and foot-lift functions

can be individually assigned to each seam.

For a description see the “EFKA DA220C 5300” operating instructions.

48

Page 53

8. Fullness control in classes 275-142342 and 275-742642

8.1 Checking the basic control setting

Once the machine has been set up the basic control setting

should be checked and adjusted if necessary. In order to

change the basic setting the machine must switched on while

pressing the “F” key.

As soon as the green LED above the “F” key lights up

the key can be released: the LED flashes. On completion of the

internal system check the “special functions” selection is

displayed.

The various special functions are called by pressing keys 1 to 7;

the green LEDs above the keys indicate the function called.

The following sections describe special key functions 2, 4

and 5. The other special functions are described in the

Servicing instructions. Press the “F” key to leave special

functions and switch to normal operation: the LED above the

key goes out.

8.1.1 Setting the LED and display brightness

After calling special functions (see section 8.1), press the key 2.

All the LEDs are switched on. The brightness can be adjusted to

any of 8 levels by pressing the “+/-” keys. Press the “F” key twice

to save the brightness setting and switch to normal operation.

Brightness is factory-set to level “03”.

GB

8.1.2 Moving to the reference position after each thread cut

When the machine is switched on the step motor that sets

the overfeed length moves to the reference position. In order to

check the position of the step motor more often, the step motor

can also be moved to the reference position after each thread

cut. The procedure is as follows:

–

After calling the special functions (see section 8.1)

press the 4 key.

–

The function can now be switched with the +/- keys:

–

display 00 = move to the reference position only when the

machine is switched on.

–

display 01 = move to the reference position after each thread

cut.

–

Press the “F” key twice to save the setting and terminate the

function.

The machine is factory-set to “00”.

49

Page 54

8.1.3 Activating the next seam sequence when the thread is cut

When the program contains fullnesses the next seam sequence

is normally activated by the thread cut. There are three options

when the thread is cut. The procedure for selecting them is as

follows:

–

After calling special functions (see section 8.1)

press the 5 key.

–

The function can now be switched with the +/- keys:

display 00 = the next sequence is not activated

when the thread is cut.

display 01 = the next sequence is activated after each thread

cut.

display 02 = as 01, but when change-of-direction is switched

on the direction is changed in the first and last sequence by

the first thread cut and the next sequence activated by the

second thread cut.

–

Press the “F” key twice to save the setting and terminate

the function.

The machine is factory-set to “02”.

8.2 Rotation in the reference position

Every time the machine is switched on the step motor that sets the overfeed length

rotates to the reference position, then back to the current overfeed length. This is

necessary for the display to coincide with the overfeed length.

Caution: danger of injury

When checking the reference position take care to avoid

moving parts.

The procedure for checking this function is as follows:

–

swivel the machine back

–

switch it on

–

after the internal system check the step motor rotates to the reference position

–

the LED in the inductive key briefly lights up when the reference position has been

reached

–

the motor then rotates to the current overfeed-length position.

50

Page 55

9. Pneumatic connection

2

4

6

8

10

CAUTION:

The pneumatic units will only operate properly at a supply

pressure of 8 to 10 bar.

The special sewing machine’s operating pressure is 6bar.

1

2

3

4

Pneumatic system-connection pack

A pneumatic-system connection pack for frames with compressed-air maintenance units

is available (order no. 0797 003031).

It contains the following components: - connection hose, 5 m long, Æ =9mm

- hose nozzles and ties

- plug-and-socket connector

- maintenance unit with pressure gauge