Duerkopp Adler 2180-1 Service Manual

Instructions for service

2180 - 1

Minerva Boskovice, a.s., Sokolská 60, CZ - 680 17 Boskovice

Tel.: +420-516-453434, 453433, 494111 Fax: +420-516-452165 http://www.minerva-boskovice.com

Edition: 09/2006 Printed in Czech Republic S735 000746

CONTENTS:

1. General safety instructions ............................................................................................................................................... 1

Introduction .......................................................................................................................................................................... 1

2.

3. Head of the sewing machine .............................................................................................................................................. 2

3. 1 Hook and hook post ................................................................................................................................................................ 2

.. 3.1.1

3.1.2 Height setting of the hook

3.1.3 Setting the distance of the hook from the needle

3.1.4 Angular setting of the hook (timing)

3.1.5 Protection of the needle and of the hook point

3.1.6 Setting of the bobbin case opener

3.1.7 Setting the regulation of the hook lubrication

3.1.8 Replacement of the hook

3.1.9 Setting the gear

3.1.10 Dismantling of the hook post

3.2 Needle and thread mechanism ................................................................................................................................. 5

3.2.1 Description

3.2.2 To check the handwheel angular adjustment

3.2.3 Height setting of the needle bar

3.2.4 Side setting of the needle bar holder

3.2.5

3.3 Throat plate and its post ....................................................................................................................................................... 7

3.3.1 Description

3.3.2 Mounting and removing the throat plate

3.3.3 Side setting of the throat plate post

3.4 Thread tensioner ...................................................................................................................................................................... 8

3.4.1 Description

3.4.2 Setting the tension and switching off the main and the auxiliary tensionmer

3.4.3 Setting of the adjusting spring

3.5 Feeding mechanism of the needle feed and of the lower feed wheel ........................................................................ 9

3.5.1 Description

3.5.2

3.5.3

3.5.4

3.6 Feeding mechanism of the top roller ................................................................................................................................11

3.6.1 Description

3.6.2 Side setting of the indented lower pulley

3.6.3 Side setting of the indented upper pulley

3.6.4 Setting the tensioning roller

3.6.5 Replacement of the indented belt

Description

Setting the needle (the needle bar holder) in the direction of sewing

Stitch length mechanism

3.5.2.1 Setting of the stitch length eccentric

3.5.2.2 Setting of the stitch length button

Lower feed wheel

3.5.3.1 Feeding clutches

3.5.3.2 Wheel feeder and its post

3.5.3.2.1 Height setting of the feeder and tensioning of the chain

3.5.3.2.2 Replacement of the feeder

Setting the top roller (pressing force, height)

3.6.6 Top roller

3.6.6.1 Selection of the top roller diameter

3.6.6.2 Forward, rearward and side setting

3.6.6.3 Setting the gear clearance and in the mounting of the top roller

3.6.6.4 Replacement of the top roller

3.7 Setting the presser foot lift ...................................................................................................................................................15

Bobbin winder ....................................................................................................................................................................... 16

3.8

Description

3.8.1

3.8.2 Setting the bobbin winder stop

3.8.3 Setting the friction gear

3.9 Safety clutch .......................................................................................................................................................................... 17

Description

3.9.1

3.9.2 Setting the disengaging moment

3.10 Indented belt transmission ................................................................................................................................................. 17

Setting the tensioning roller of the indented belt

3.10.1

3.10.2 Replacing the indented belt

3.11 V-belt, motor - head .............................................................................................................................................................. 18

Tensioning

3.11.1

3.11.2 Replacing the V-Belt

3.12 Lubrication .............................................................................................................................................................................. 19

Description

3.12.1

3.12.2 Refilling oil

3.12.3 Multiple oil use

4. Maintenance (table of operations) ............................................................................................................................................... 20

Setting the machine according to the sewing category ............................................................................................................ 20

5.

Introduction

5.1

5.2 Table of setting the machine according to the sewing category

1. General safety instructions

The non-observance of the following safety instructions can cause bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the instruction book and operated by persons with appropriate

training.

2. Before putting into service also read the safety rules and instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of the machine without the safety devices is not permitted.

Observe all the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, top roller, needle plate, feed dog and bobbin) when treading, when the

workplace is left, and during service work, the machine must be disconnected from the mains by switching off the master

switch or disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately trained persons.

6. Repairs, conversion and special maintenance work must only be carried out by technicians or persons with appropriate

training.

7. For service or repair work on pneumatic systems the machine must be disconnected from the compressed air supply system.

Exceptions to this are only adjustments and function checks made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted, except as specified in regulations DIN VDE 0105.

10. Conversions or changes to the machine must be authorized by us and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as the entire sewing unit is found to comply with EC

directives.

It is absolutely necessary to respect the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

IMPORTANT WARNING

In spite of all safety measures made on the machines, inappropriate actions of the operator may lead to dangerous situations. In

industrial sewing machines, attention should be paid to the following still remaining possible sources of injury:

1. Moving sewing needle

- risk of injury when sewing with raised pressure foot or top roller, because the finger guard is then positioned too high,

- risk of injury when inadvertently threading down of the motor threadle.

2. Moving thread take-up lever

- risk of injury when inadvertently or intentionally inserting the finger(s) between the thread take-up lever and its guard.

3. Moving pressure member

- risk of injury when holding sewn work in immediate vicinity of the pressure member and beginning to insert under the

pressure member a considerably thicker sewn work portion,

- risk of injury when sinking the pressure member.

4. When switched off, the clutch motor slows down by inertia but would be reactivated by an accidental treading down of the

motor treadle. To avoid such risk, it is advised to hold the handwheel by hand and slightly to depress the motor treadle.

2. Introduction

This service book contains instruction for regulating the mechanisms of the sewing machine head.

Instructions for use and for putting the machine into operation are not included in this service book, but they are supplied as

separate publication.

This sewing machine disposes of a large extent of its use. The machine should be set with respect to the parameters of the sewn

material, the sewing thread etc. The setting for the individual categories is given in the chapter 5.2.

1

1. General safety instructions

The non-observance of the following safety instructions can cause bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the instruction book and operated by persons with appropriate

training.

2. Before putting into service also read the safety rules and instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of the machine without the safety devices is not permitted.

Observe all the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, top roller, needle plate, feed dog and bobbin) when treading, when the

workplace is left, and during service work, the machine must be disconnected from the mains by switching off the master

switch or disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately trained persons.

6. Repairs, conversion and special maintenance work must only be carried out by technicians or persons with appropriate

training.

7. For service or repair work on pneumatic systems the machine must be disconnected from the compressed air supply system.

Exceptions to this are only adjustments and function checks made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted, except as specified in regulations DIN VDE 0105.

10. Conversions or changes to the machine must be authorized by us and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as the entire sewing unit is found to comply with EC

directives.

It is absolutely necessary to respect the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

IMPORTANT WARNING

In spite of all safety measures made on the machines, inappropriate actions of the operator may lead to dangerous situations. In

industrial sewing machines, attention should be paid to the following still remaining possible sources of injury:

1. Moving sewing needle

- risk of injury when sewing with raised pressure foot or top roller, because the finger guard is then positioned too high,

- risk of injury when inadvertently threading down of the motor threadle.

2. Moving thread take-up lever

- risk of injury when inadvertently or intentionally inserting the finger(s) between the thread take-up lever and its guard.

3. Moving pressure member

- risk of injury when holding sewn work in immediate vicinity of the pressure member and beginning to insert under the

pressure member a considerably thicker sewn work portion,

- risk of injury when sinking the pressure member.

4. When switched off, the clutch motor slows down by inertia but would be reactivated by an accidental treading down of the

motor treadle. To avoid such risk, it is advised to hold the handwheel by hand and slightly to depress the motor treadle.

2. Introduction

This service book contains instruction for regulating the mechanisms of the sewing machine head.

Instructions for use and for putting the machine into operation are not included in this service book, but they are supplied as

separate publication.

This sewing machine disposes of a large extent of its use. The machine should be set with respect to the parameters of the sewn

material, the sewing thread etc. The setting for the individual categories is given in the chapter 5.2.

1

12

3. Head of the sewing machine

3.1 Hook and the hook post

3.1.1 Description

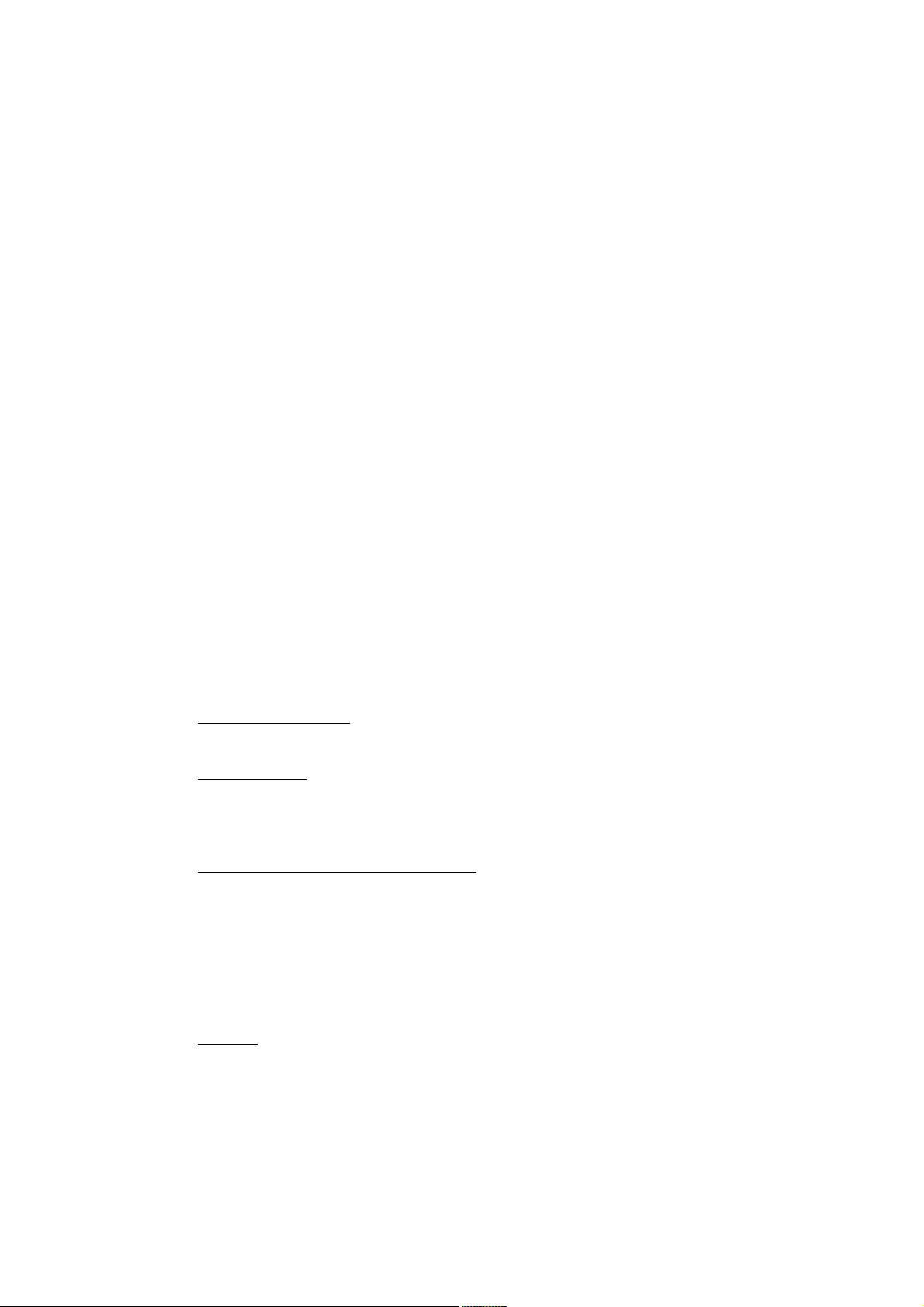

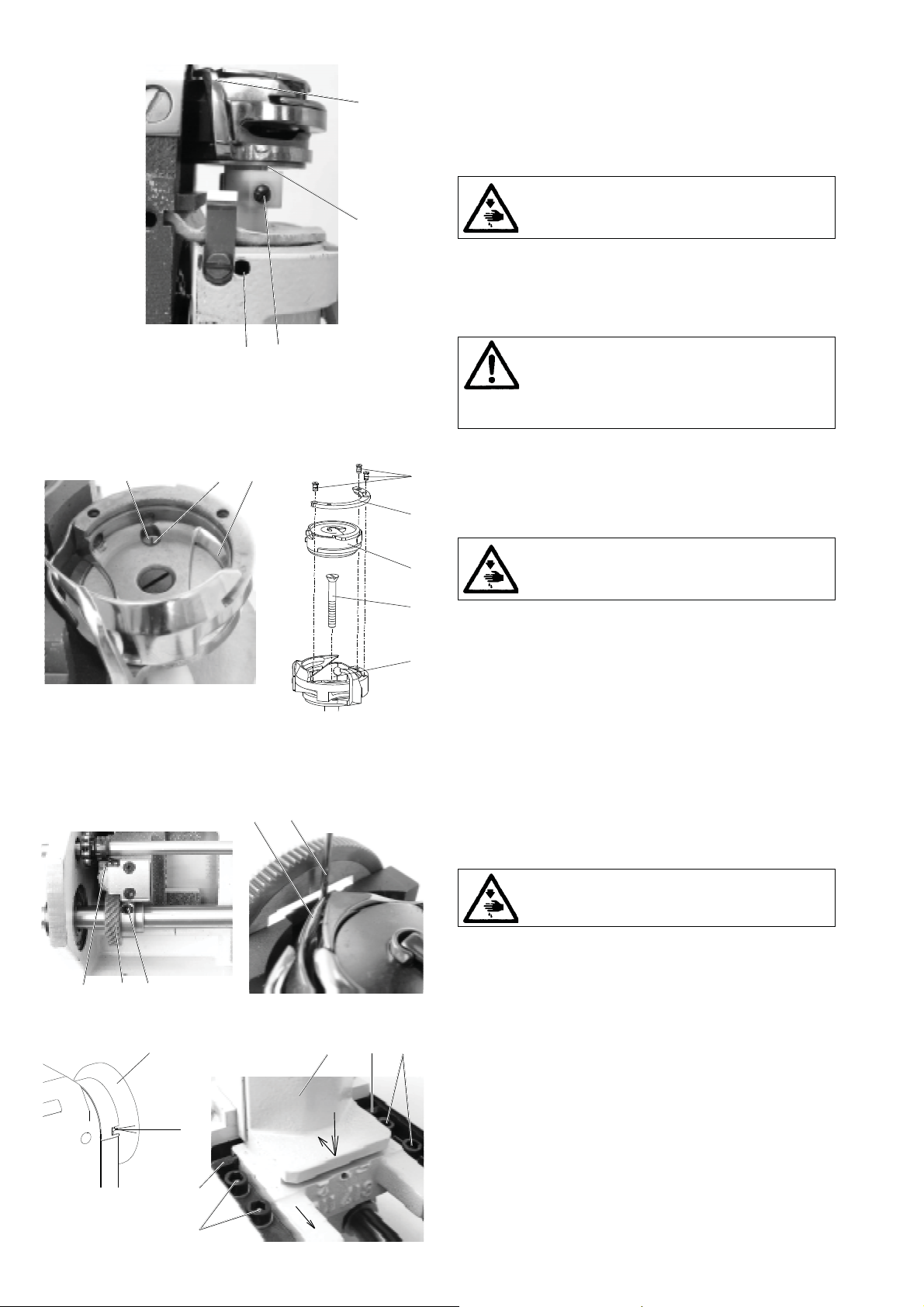

The hook (1) is mounted on the shaft (2) and is driven by the gear (3)

from the shaft (4).

The shaft of the hook (2) is slidably mounted on the top, in post and,

on the bottom, in a needle bearing.

13

8

16

5

234

7

9

10

11

The hook is provided with a lever (5) which is tilted when removing the

bobbin (6). The protecting sheet (7) protects against the collision of

the needle with the hook point. The bobbin case opener (8) is driven by

the eccentric (9) on the shaft (2).

The oil tank (10) contains oil supply for the hook lubrication. Superfluous

oil is taken by thefelt piece (11) used to lubricate sliding mounting

hook shafts.

The screws (12) serve for taking up the clearance of the gear. The

screws (13) fasten the post to the bedplate.

4

A

1

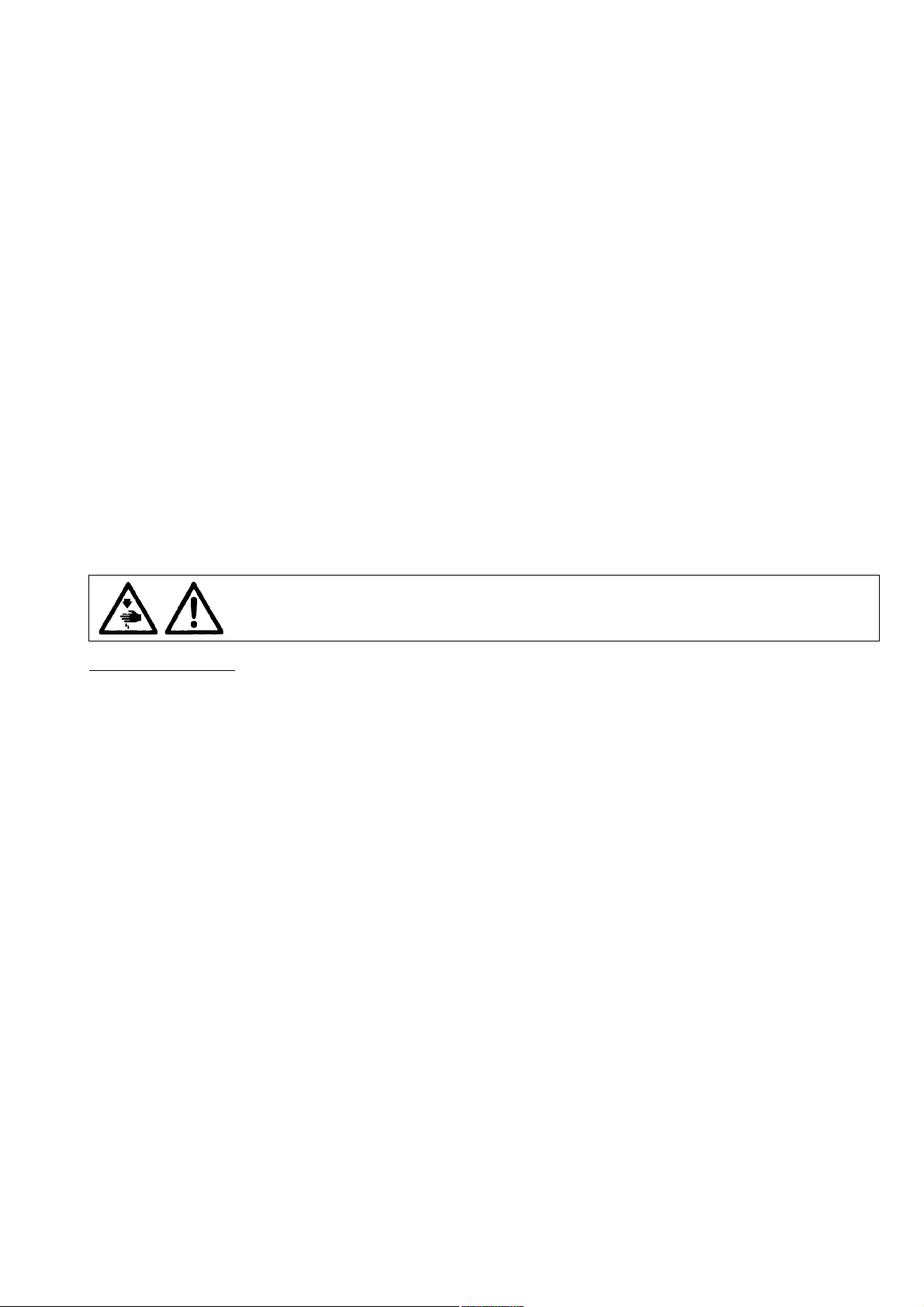

The designated distance A should be for sewing category 100 - 1.5

mm and for sewing category 200 - 2.0 mm.

Caution! Danger of injury!

Switch off the main switch ! Before starting the setting

operation, wait until the motor stops!

- Loosen both screws (1).

- Shift axially the shaft (2) with the hook (3) so as to obtain the

required distance A. For setting up use the setting gauge (4) as per

the repective figure.

- Carefully retighten the screws (1) after the adjustment. Caution! One

of these screws must bear on the flat of the shaft (2).

3 2

3.1.3 Setting the distance of the hook from

the needle

3.1.2 Height setting of the hook

max. 0,1

2

1

7

6

54

The hook point (1) is set up to the maximum distance of 0.1 mm from

the bottom of the needle recess (2). For the sewing categories 100, the

needle size 100 is set, for the sewing categories 200, it is the needle

size 130.

Caution! Danger of injury!

Switch off the main switch ! Before starting the setting

operation, wait until the motor stops!

- Loosen only one screw (4).

- Loosen the screws (5) and tighten them only slightly.

- Shift the hook post (6) at the determined distance between the needle

and the hook point.

- Tighten carefully the screw (4) (be sure not to damage the threads!)

- Tighten duly the screws (5).

- Check up the setting using a narrow strip of thin paper and proceed

to the eventual correction of setting.

Caution!

4

When changing substantially the sewing categry, the

protecting sheet of the hook (7) should be set up.

5

2

2

1

3.1.4 Angular setting of the hook (timing)

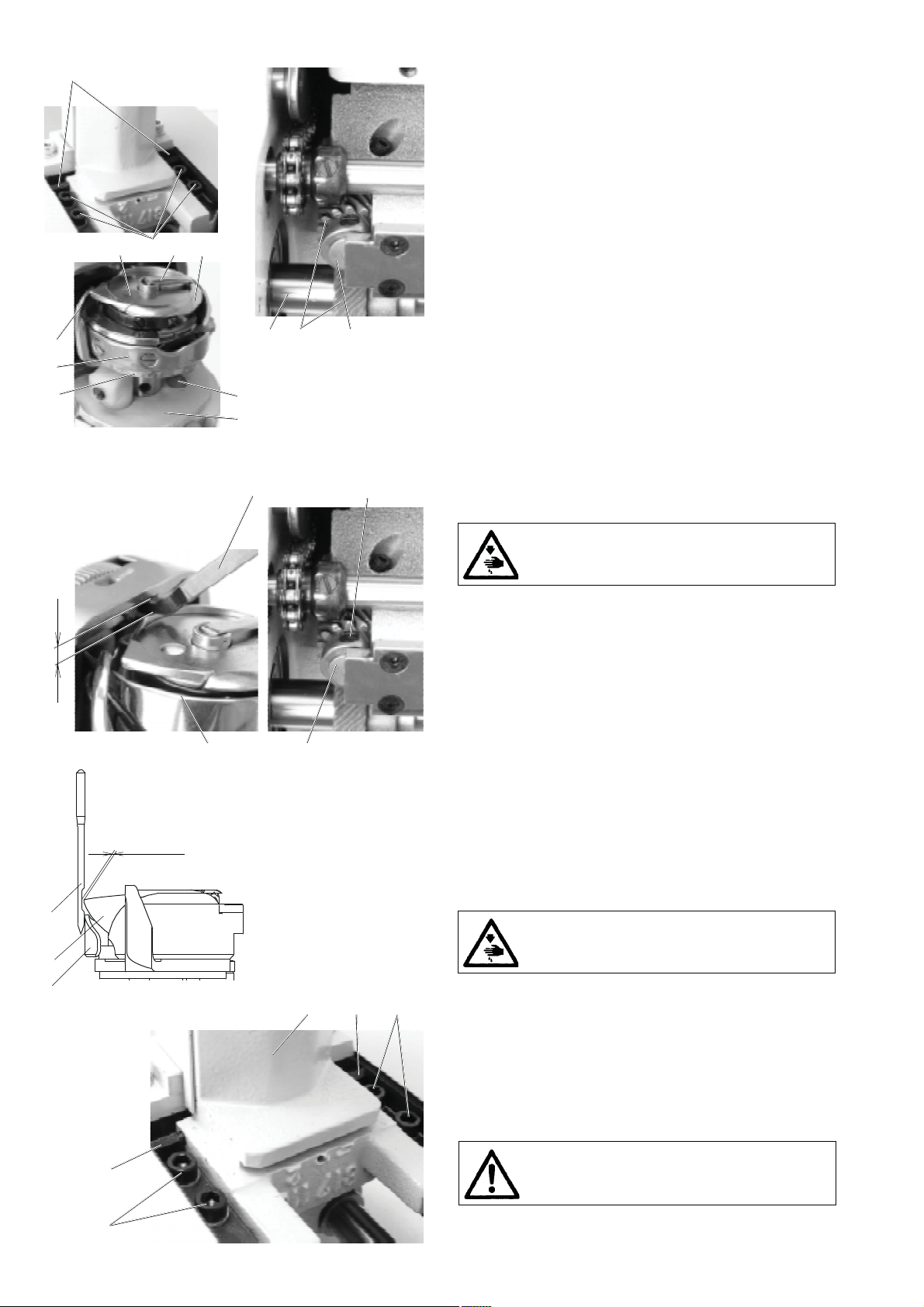

The hook is to be angularly set in such a way that the hook point (1) is

opposite the needle at the moment, when the needle shifts by 2.5 mm

(sewing category 100) or 2.2 mm (sewing category 200) from its

bottom dead center. This corresponds to the 2O9° (sewing category

100) or 207

o

sewing category 200) on the scale of the handwheel (3).

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

3

209

6

o

- Remove the throat plate.

- Turn the handwheel (3) to the 2O9° ( 2O 7°).

- Loosen the screws (5).

- Turn the hook into the required position.

- Set the toothed wheel (6) on the centre of the wheel (7).

- Tighten to the maximum the screws (5).

(207o)

3.1.5 Protection of the needle and of the hook point

7

5

The protecting sheet (1) is to be set up in such a way that the clearance

between the protecting sheet and the needle (2) is the least possible.

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

2

5

4

1

3

- Remove the throat plate.

- In deforming the protective sheet (1) set the required play between

the sheet and the needle (2). After having introduced a suitable

screwdriver between the protective sheet and the hook body (3) we

shall reduce the play by levering, in applying the pressure on the

protective sheet in the sense of the arrow (4), we shall increase the

play.

- Check up the protecting effect in pushing against the needle in the

sense of the arrow (5). The hook point must not catch the needle. If

so, set up the protecting effect, correct eventually the setting of the

distance of the hook point from the needle according to the paragraph

3.1.3.

3.1.6 Setting of the bobbin case opener

3

4

1

A

B

2

5

7

o

325

869

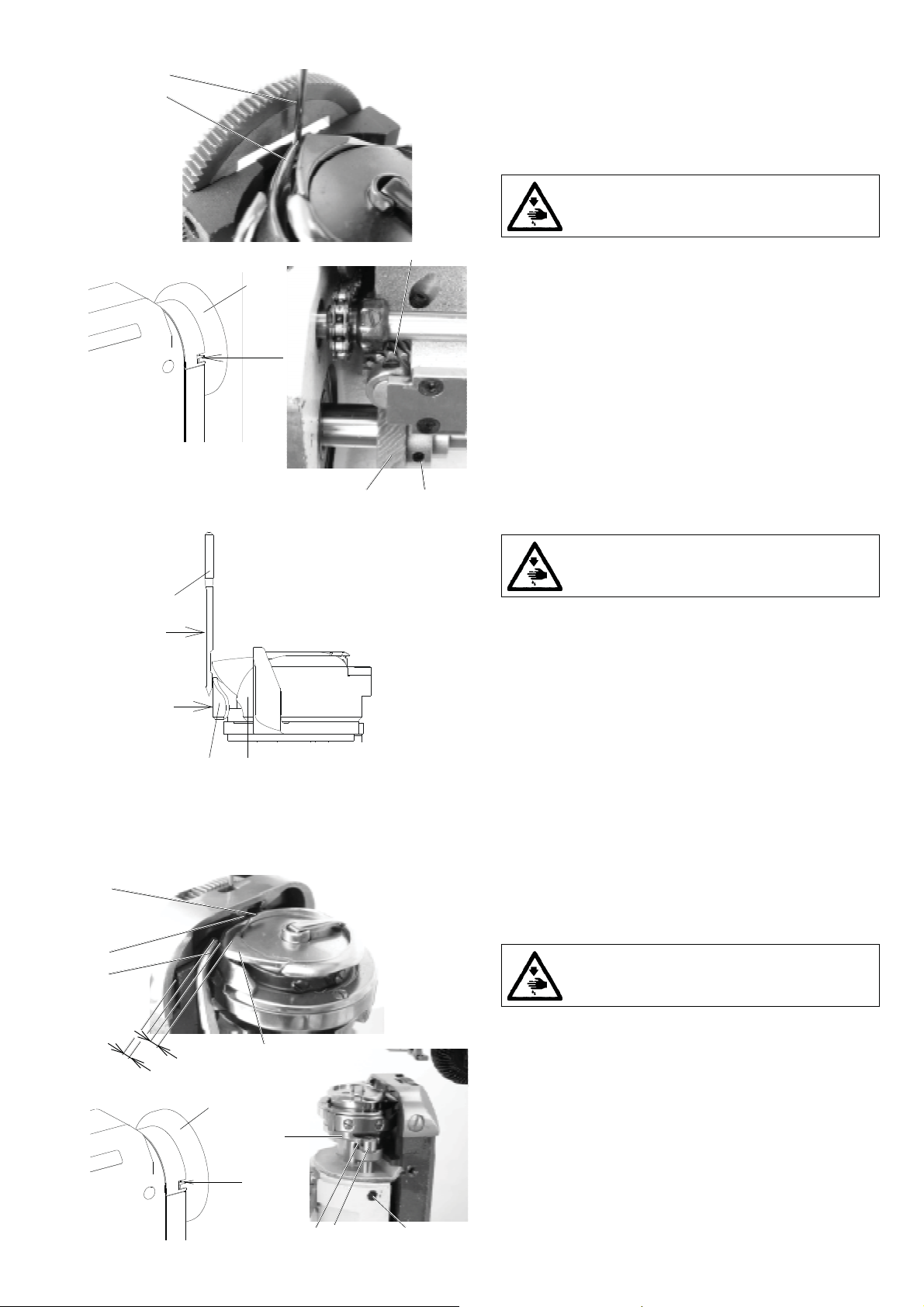

The bobbin case opener (1) is to be set in such a way that, at the

moment when the opener is in its dead centre, there would be a clearance

A between the opener (1) and the projection (2), whereas the finger

(3) bears on the projection (4).

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- By turning the hand wheel (5), set the bobbin case opener (1) into

its dead centre (the clearance B is maximal, the value thereof on

the hand wheel is approximative 325

- Loosen the screw (6).

- Turn the eccentric (7) in such a way, so that the desired clearance

A between the bobbin case opener (1) and of the part (2) of the

central portion of the hook is attained /the finger (3) bears against

the projection (4)/. For the sewing category 200, set the minimum

clearance A .

- Set the height of the eccentric (7) in such a way that it is in its

highest position in retaining the minimum clearance between the

slide (8) and the fork (9).

- Tighten duly the screw (6).

o

).

3

3.1.7 Setting the regulation of the hook lubrication

1

2

Oil is wiped from the lubricating wick by the face of the hook eccentric

and is then fed by the centrifugal force between the bobbin case lifter

(1) and the hook eccentric (2). With the hook R 810, oil is fed also into

the hook path.

screw (3).

- To reduce the oil supply, turn the screw (3) to the right.

- To increase the oil supply, turn the screw (3) to the left.

- After the adjustment, loosen the screw (4) and set the height of the

oil tank so as toensure reliable contact between the surface of the

eccentric and the lubrication wick.

The intensity of oil supply is regulated by turning the

Caution! Danger of injury!

Switch off the main switch ! Before starting the setting

operation, weit until the motor stops!

521

6

209

(207o)

3

4

emergency events. A bad setting of the quantity of the fed oil or of the

height of the lubrifying tube may cause a rapid wear or a seizure.

Caution!

The quantity of the fed oil has been set up in the manufacturing factory. This setting is to be done only in

3.1.8 Replacement of the hook

76 8

The hook DSH 820 must be mounted on the hook shaft in such a way,

1

so that the gauge mark (7) of the hook eccentric (8) is visible through

the hole (6) of the hook body. The hook R 810 is positioned against the

2

hook eccentric (8) by the lubricating tube.

3

4

- Remove the throat plate.

- Unscrew the screws (1) and remove the splice (2).

- After having suitably turned a bit the hook, remove the bobbin case

5

(3).

- Unscrew thorougly the screw (4).

- Remove the body of the hook (5) upwards.

- When mounting, the procedure is inverse.

Caution! Danger of injury!

Switch off the main switch ! Before starting the setting

operation, weit until the motor stops!

3.1.9 Setting the gear

The mutual angular orientation of the gear wheel (1) relative to the gear

wheel (2) should ensure the accessibility of the screw (5) at the moment

34

8

o

10

9

9

10

when the hook point comes to lie opposite the needle (4). The wheel

(2) is to be set with its gear rim symmetrically to the centre of the gear

wheel (1). The clearance between the gear wheels is to be the least

possible.

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Set the hook timing angle of 2O9° (207

- On the removed post of the hook (8), according to the pa-ragraph

3.1.10, the hook point (3) is to be turned a bit according to the

illustration.

- Turn the gear wheel (2) into the suitable position and insert the post

of the hook into the machine according to the respective arrows.

Check up, whether the screw (5) is acces-sible and, if not, repeat the

procedure.

- Set the the distance of the hook from the needle according to the

paragraph 3.1.3.

- Set the precise angular displacement of the hook according to the

paragraph 3.1.4.

- Loosen the screw (10) and tighten them slightly.

- Set the clearence in the gear in turning the screws (9). Check up,

whether the gear has a clearance during the whole revolution of the

hook. Turn the handwheel step by step by 15° and, with each step,

grasp the hook and try, if there is an angular dead travel. Tighten

carefully the screws (9).

- Tighten duly the screws (10) and try anew the clearance of the gear.

o

) on the hand wheel (6).

4

Loading...

Loading...