Duerkopp Adler 1281, 5-1 Service Manual

1281/5-1

Sewing unit for closing seams

for trousers and skirts

Operating Instructions

Installation Instructions

Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25 23 40 • Telefax +49 (0) 521 / 9 25 25 83 • www.beisler-sewing.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

01/2011 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 128102

All rights reser ved.

Property of Beisler GmbH and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Beisler GmbH, is prohibited.

Copyright ©

Beisler GmbH - 2011

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Content Page:

Part 3: Service Instructions Class 1281/5-1

(Edition: 01/2011)

1 General Information ............................................ 3

2 Quick start guide for the sewing head

2.1 Adjusttheneedlebarheight........................................ 4

2.2 Adjust the hook ................................................ 5

2.2.1 Distance of the left hook from the needle ................................ 5

2.2.2 Distance of the right hook from the needle ............................... 7

2.3 Adjustingtheneedleguard......................................... 9

2.3.1 Rearneedleguard.............................................. 9

2.3.2 Frontneedleguard.............................................. 10

2.4 Adjustingthefeeddog ........................................... 11

2.4.1 Feeddogposition .............................................. 11

2.4.2 Feeddogheight ............................................... 12

2.5 Presserfoot.................................................. 13

2.5.2 Presser foot upper part EXT 3216 ..................................... 13

2.5.2 Presserfoot.................................................. 14

2.6 Upperandlowerknife ........................................... 15

2.6.1 Changingandadjustingtheupperknife................................. 15

2.6.2 Changingandadjustingthelowerknife................................. 16

2.7 Threadregulationofserginglooper.................................... 17

3

3 Adjusting the sewing unit

3.1 Adjustingthelightbarrier.......................................... 18

3.2 Adjustingtheworkpiecelimitstop .................................... 19

3.3 Adjustingthecontourguide ........................................ 20

3.4 DirectDriveSewingMode ......................................... 21

3.4.1 Adjustingthereference........................................... 21

4 Lubrication

4.1 Oilchangeandoilfilterchange...................................... 22

5 Maintenance ................................................. 23

1 General Information

The service instructions at hand describe the adjustment of the seam

closing unit 1281/5-1.

It comprises:

Quick start guide for the sewing head

·

Service instructions for the sewing unit

·

ATTENTION!

The quick start guide represents an extract from the detailed

operating instruction for the sewing head. These operating

instructions must, in any case, be read completely and all the

instructions must be followed. The company Beisler does not

assume any warranty for the correctness of the following

explanations.

ATTENTION!

The activities described in these service instructions may be

performed only by qualified personnel or appropriately trained

personnel!

Caution: Risk of Injury !

Switch off the main switch when performing repair, rebuild or

maintenance jobs.

Alignment jobs and functional tests may be performed on a running

machine only if all the safety measures are observed and extreme

care is taken.

The service instructions at hand describe the adjustment of the

sewing unit in purposeful sequence.

At this juncture, it must be borne in mind that the various setting

positions are dependent on each other.

Therefore, make absolutely sure that you perform the adjustment in

the described sequence.

A new, faultless needle must be used for all adjustment jobs on

stitch-forming parts.

3

3

2. Quick start guide for the sewing head

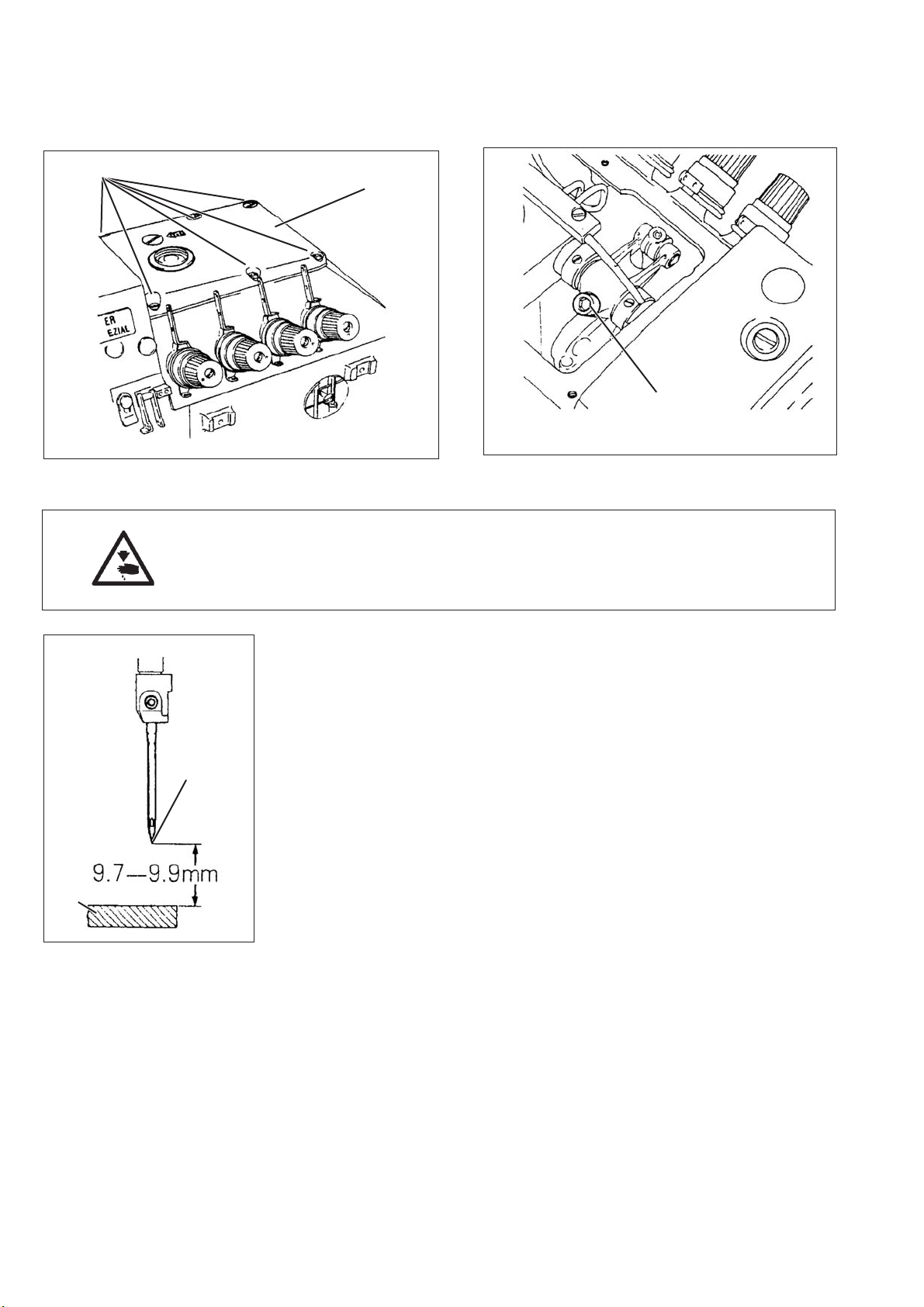

2.1 Adjusting the needle bar height

1

2

3

Caution: Risk of Injury !

Switch off the main switch.

Check and adjust the needle bar height only when the sewing unit is

switched off.

Regulation and Control

At the upper dead center of the needle bar, the distance between

needle point 4 and throat plate must be 9.7 - 9.9 mm.

–

Turn the needle bar in its upper dead center.

–

Check as to whether the distance between needle point 4 and

throat plate 5 is 9.7 to 9.9 mm.

4

Correction

–

Unscrew the lid screw 1 and remove lid 2.

–

Turn the needle bar in its upper dead center.

–

Swivel out the sewing foot.

5

–

Loosen the screw 3 up to the point that the needle bar just about

allows itself to be pushed.

–

Move the needle bar up to the point that the distance between

needle point 4 and throat plate 5 is 9.7 to 9.9 mm.

–

Tighten the screw 3.

–

Screw on the lid 2 once again.

4

2.2 Adjusting the hook

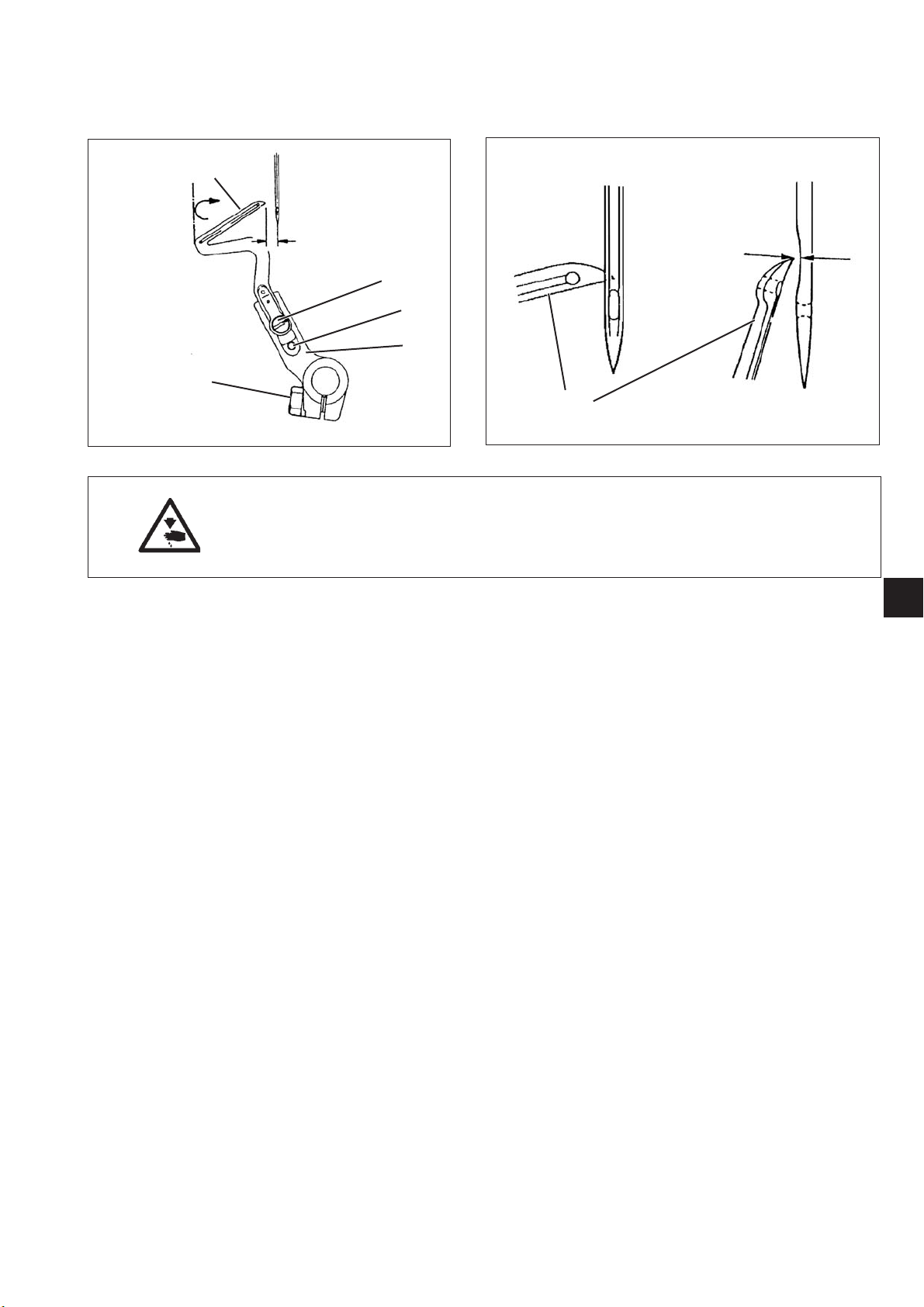

2.2.1 Distance of the left hook from the needle

5

2,3 - 2,5 mm

1

2

3

4

Caution: Risk of Injury !

Switch off the main switch.

Check and adjust the hook only when the sewing unit is switched off.

5

Adjustment crosswise from sewing direction

Regulation and Control

In the left reversal point of the hook 5, the distance between needle

center and hook point should be 2.3 to 2.5 mm.

–

With the hand wheel, tur n the left hook to its left rever sa l poin t.

–

Check as to whether the distance between needle center and hook

point is 2.3 t o 2.5 mm.

Correction

–

Unscrew throat plate, front feed dog, as well as front and rear

needle guard.

–

With the hand wheel, tur n the hook to its left reversal point.

–

Loosen screw 1 and bring the hook to bear against the limit

stop 2.

–

Retighten the screw 1.

–

Loosen the screw 4 up to the point that the hook carrier 3 just

about allows itself to be turned.

–

Turn the hook carrier up to the point that the distance between

needle center and hook point is 2.3 to 2.5 mm.

Note

Do not yet tighten the screw 4.

3

5

Loading...

Loading...