1281/5-1

Sewing unit for closing seams

for trousers and skirts

Operating Instructions

Installation Instructions

Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25 23 40 • Telefax +49 (0) 521 / 9 25 25 83 • www.beisler-sewing.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

01/2011 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 128102

All rights reser ved.

Property of Beisler GmbH and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Beisler GmbH, is prohibited.

Copyright ©

Beisler GmbH - 2011

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Content Page:

Preface and General Safety Notes

Part 1: Operating Instructions Cl. 1281/5-1 – Original Instructions

(Edition: 01/2011)

1. Product Description

1.1 Descriptionofusefortheintendedpurpose............................. 2

1.2 BriefDescription.............................................. 2

1.3 TechnicalData............................................... 3

2 Optional Equipment ........................................... 4

3 Switching On - Switching Off - Program Stop

3.1 SwitchingOn................................................ 5

3.2 SwitchingOff................................................ 5

3.3 ProgramStop ............................................... 6

3.4 Renewedsettinginmotionafterprogramstop ........................... 6

1

4 Operation of the sewing machine head

4.1 GeneralInformation............................................ 7

4.2 Recommendedyarn........................................... 8

4.3 Detaching/Attachingthefabricslidingplate............................. 9

5 Operating the sewing unit

5.1 Positioningtableandworktable.................................... 10

5.2 Mousewithguiderailandretractionmechanism.......................... 11

5.3 Insertingthesewingpartsandstartingthesewingoperation................... 13

5.4 Adjustingtheblowairforthenozzlesinthetabletop....................... 16

5.5 Adjustingtheretractionspeedofthemouse............................. 17

5.6 Adjustingthepressureofthepuller.................................. 18

5.7 Stacker ................................................... 19

6 Operation of the control unit

6.1 Operationofthetouch-screenmonitor................................ 20

6.3 Mainscreen ................................................ 21

6.4 Sewing programs

6.4.1 Selectingtheprogramandseamnumber............................... 24

6.4.2 Creatinganewseamprogramwithseamnumber ......................... 25

6.4.2.1 Numberofseamprogramsandseams ................................ 26

6.4.3 Editing,deletingtheseamprogramorseams............................ 27

6.4.4 Manualsewing,drivenbythepedal.................................. 32

6.4.5 Changingtheseamprograms...................................... 33

6.4.5.1 SeamParameters............................................. 35

6.4.5.2 MachineParameters........................................... 39

Content Page:

6.4.5.3 Roll-outDevice .............................................. 40

6.4.5.4 Puller..................................................... 41

6.4.5.5 GlobalParameters ............................................ 42

6.4.5.6 Input-OutputTest............................................ 44

6.4.5.7 StepperMotorTest............................................ 46

6.4.8 VersionData................................................ 48

7 Data protection by means of USB stick

7.1 GeneralInformation............................................ 49

7.2 FormattingtheUSBstick ........................................ 49

7.3 SavingtheseamprogramsandseamparametersontheUSBstick............... 50

7.4 LoadingtheseamprogramsandseamparametersfromtheUSBstick............. 52

7.5 SavingglobalparametersonUSBstick................................ 53

7.6 LoadingglobalparametersfromtheUSBstick........................... 53

7.8 RemovingtheUSBstick......................................... 53

8 Maintenance

8.1 CleaningandTesting........................................... 54

8.2 Lubrication................................................. 56

8.3 Repair.................................................... 57

1 Product Description

1.1 Description of use for the intended purpose

The 1281/5-1 is a sewing unit which can be used according to the

intended purpose of sewing of light to medium-heavy workpieces.

Such workpieces are as a rule materials made of textile fibers. These

sewing materials are used in the apparel industry.

In general, only dry sewing fabrics may be processed with this sewing

unit. The material must not contain any hard objects.

In general, the seam is prepared from core thread, polyester fibre

or cotton yarn.

The dimensions for needle thread and looper thread may be derived

from the tables in Chapter 4.2.

If you wish to use other threads, you must first estimate the inherent

risks and take safety measures, where required.

This sewing unit may be set up and operated only in dry and well-kept

rooms. If the sewing unit is used in other rooms that a re not dry and

well-kept, further measures may become necessary that must be

agreed to by the manufacturer (see EN 60204-31: 1999).

As manufacturers of industrial sewing machines, we assume that our

products are operated by at least trained personnel, so that all the

usual operations, and possibly dangers, can be presumed to be

known.

1

1.2 Brief Description

The Beisler 1281/5-1 is a sewing unit for closing of long seams such

as e.g.

® trouser side seams and inside seams,

® Side seams without vent in outer fabric and lining in skirt parts

Depending upon the machine head used,

®

Double chain stitch seams (401),

®

Safety seams 4-thread (515) or 5-thread (516)

can be generated.

All the workplace components are arranged on a rack welded from

square-cut steel tubes and are controlled by a micro-processor

system.

The sewing workplace is operated by means of the operating panel.

Various control programs can be called up, new programs can be

defined and all the inputs and outputs can be checked here for

maintenance and repair jobs.

Machine head

–

Pegasus Serging Machine EXT 3216-03

–

Direct-Drive Efka Type DC 1500 /AB 425S

–

Microprocessor control, freely programmable

–

Light barrier for detecting seam start and seam end for automatic

seam start and stop.

–

Programmable edge guide for different material strengths, moving

crosswise from feeding direction.

–

External Operating Panel Efka V900 with:

-MenuGuide

3

- Freely programmable parameters for

“Differential lower feed (optional)”, “Upper feed

(optional)”, “Roll-out Device”, “Puller”, “Machine

Parameters”,

“Global Parameters”, “Program Sequences”

- Input and Output Tests

- Test routine for stepper motors

- 20 Program Memory Capacity

- up to 7 seam programs per program storage space

–

Vertical cutter with suction device for overseaming and serging in

aworkstep.

–

Programmable chain cutting device with suctioning.

–

Adjustable blow nozzles in the table top for supporting the sewing

material feed, mechanical regulation of the blow strength by

means of adjusting knob, duration of table blowing is

programmable.

–

Positioning table with mouse and retraction device for the

workpiece;

for uniform workpiece guidance and higher productivity.

–

Special sewing equipment for trouser side seams with side seam

pockets and slant pockets.

–

Narrow gauge parts including narrow sewing foot for problem-free

feed/ sewing of the pocket openings.

–

Automatic contour control through programmable puller.

–

Height-adjustable rack, infinitely variable from 850 mm up to 1200

mm.

–

Automatic fullness distribution through stepper motor controlled

upper and lower feed (optional).

Within a seam program, the fullness of the upper and lower feed

can be programmed at the operating panel by means of 3 freely

selectable segments.

User-friendly adjustment option for fullness in a segment by

means of one control each.

–

Integrated destacking device.

–

Manual destacking by means of the shortcut key.

1.3 Technical Data

Machine Head: Pegasus EXT 3216-03/233-K 5x5-KH-021A

Type of stitch: 401, 515, 516

Number of needles: 1 or 2

Needle system: B27

Needle thickness: Nm 80 to Nm 110

Type of hook: Looper crosswise to feeding direction

Serging looper

Yarn: see table in Chapter 4.2

Speed: 6,500 min

Speed at delivery: 6,500 min

-1

-1

Stitch length:

min. 0.5 mm

max. 3.5 mm

Seam width: 10 mm

Optional 8 - 12 mm

Workpiece: Light weight to medium weight

Operating pressure: 6 bar

Air consumption: 20 NL per working cycle

4

Rated voltage: 1 x 230 V 50/60 Hz

Rated power: 1.00 KVA

Dimensions: 2300 x 1300 x 1500 mm (L x B x H)

Work height: 850 … 1200 mm

(upper edge of table top)

Weight: 125 kg

Rated noise level: LC = 81 dB (A)

Workplace-related emission value according to DIN 45635-48-B-1

Stitch length: 2.6 mm

Seam length: 1,000 mm

Number of stitches: 6,500 min

Workpiece G1 DIN 23328: 2-ply

Measuring point according to DIN 4895

Part 1 X = 550 mm Y = 350 mm Z = 600 mm

X - axis = crosswise to direction of feed

Y - axis = main feed direction

Z - axis = height

-1

1

2 Optional Equipment

See Appendix.

5

3 Switching On - Switching Off - Program Stop

1

3.1 Switching On

3.2 Switching Off

–

Switch on the main switch 1 (turn in clockwise direction).

The control unit loads the machine program.

The starting screen is displayed on the display screen of the

operating panel.

–

Switch off the main switch 1 (turn in anti-clockwise direction).

6

3.3 Program Stop

2

1

The safety system of 1281/5-1 foresees the following options for

immediate stoppage in case of faulty operation, needle breakage etc.:

–

Press the program stop switch 2 a t the operating panel.

Ongoing work steps at the sewing unit are immediately aborted.

–

Turn main switch 1 in anti-clockwise direction.

The sewing unit is powered off immediately;

all the movements at the sewing unit stop immediately.

3.4 Renewed setting in motion after program stop

Caution: Risk of Injury!

Switch off the main switch.

Repair the fault only when the sewing unit is switched off.

Renewed setting in motion of the machine is allowed only after the

fault has been repaired.

–

Switch on the main switch 1 (turn in clockwise direction).

–

Unlock the program stop switch.

The control unit loads the machine program.

The start screen appears on the display screen of the operating

panel.

The sewing unit is once again ready for operation.

7

4 Operation of the sewing machine head

4.1 General Information

The operation of the sewing machine head (inserting the needle,

threading the needle thread and looper thread etc.) is described in the

separately enclosed Pegasus operating instructions.

The operating instructions are in t he accessories pack of the sewing

unit.

Caution: Risk of Injury!

Kindly read the operating instructions of the sewing machine head

carefully and follow all the safety instructions.

8

4.2 Recommended yarn

Needle system: B27

Recommended

needle thickness: Nm 80 for very thin sewing material

Nm 90 for thin s ewing material

Nm 100 for medium weight sewing material

High sewing safety and good sewability are achieved with the

following covering

threads:

–

Double polyester continuous polyester core spun

(e.g. Epic Poly-Poly, Rasant x, Saba C, ...)

–

Double polyester continuous cotton core spun

(e.g. Frikka, Koban, Rasant, ...)

In case these yar ns cannot be procured, even polyester fibers or

cotton yarn specified in the table can be sewed up.

Double core threads are often offered by yarn producers under the

same designation as triple polyester fibre yarn (3-cyl. spun). This

results in doubts in respect of twist and yarn thickness.

In case of doubt, untwist the yarn and check as to whether it is double

or triple twisted.

The Label No. 120 on the yarn roll of a core thread e.g. corresponds to

the yarn thickness Nm 80/2 (see table values in brackets).

In case of monofil threads, needle threads and looper threads of the

same thickness can be used. In doing so, the best results are

achieved with soft and elastic threads (software) with thread thickness

of 130 Denier.

1

Recommended yarn thicknesses:

Needle Thickn. Core thread Core thread

Nm

Needle thread Looper thread Needle thread Looper thread

Polyester- Polyester- Polyester- Cotton

continuous core spun continuous core spun

Label No. Label No. Label No. Label No.

80

90 120 (Nm 80/2) 120 (Nm 80/2) 120 (Nm 80/2) 120 (Nm 80/2)

100 100 (Nm 65/2) 100 (Nm 65/2) 100 (Nm 65/2) 100 (Nm 65/2)

Needle Thickn. Polyester fibre yarn Cotton yarn

Nm (3cyl.-spun)

Needle thread Looper thread Needle thread Looper thread

80 Nm 120/3 Nm 120/3 Ne

90 Nm 80/3-120/3 Nm 80/3-120/3 Ne

60/3-80/3 NeB60/3-80/3

B

50/3-70/3 NeB50/3-70/3

B

100 Nm 70/3-100/3 Nm 70/3-100/3 Ne

40/3-60/3 NeB40/3-60/3

B

9

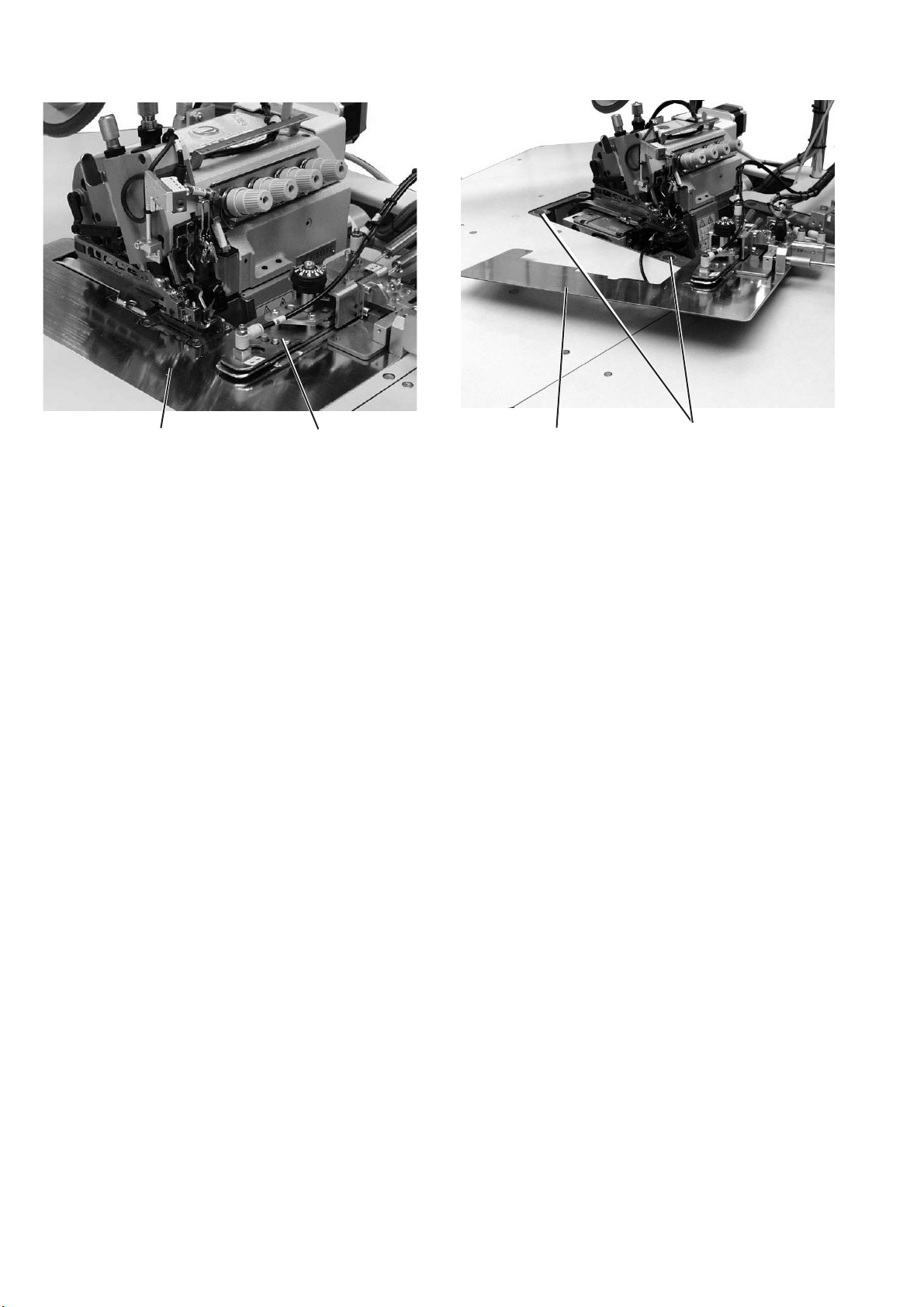

4.3 Detaching/ Attaching the fabric sliding plate

23

The fabric sliding plate 2 is held in the recess of the table top with the

help of the magnet 1.

The edge guide 3 is fastened to the fabric sliding plate.

Detaching the fabric sliding plate

–

Detach the edge guide 3 carefully upwards from the magnet.

–

Swivel the fabric sliding plate to the side.

The lower area of the sewing machine head is now accessible.

Attaching the fabric sliding plate

–

Push the fabric sliding plate into the recess of the table top and

insert downwards.

21

10

5 Operating the sewing unit

5.1 Positioning table and work table

21

The sewing unit is equipped with two positioning tables 1 and 2. The

skirt parts or trouser parts are prepared on them respectively.

On work table 4, the trouser parts or skirt parts are positioned and

clamped with the mouse 3.

43

1

11

5.2 Mouse with guide rail and retraction mechanism

321

The mouse is used for clamping of the trouser parts or skirt parts, in

order to prevent them from sliding.

The guide rail 3 is flexible and must be adjusted to the contour of the

sewing part.

Caution: Risk of Injury !

Do not reach into the mouse when it is open.

Insert sewing part

–

Place the sewing part between the mouse plate 2 and the

clamping arm 1.

–

Press shut the mouse.

During the sewing operation, the mouse is drawn along the guide

rail 3 until the o pening of the clamping arm 1 is actuated by a limit

switch.

Then, the mouse is drawn back by the retraction mechanism 4 until

the adjustable limit stop 5 is contacted.

76 5 4

12

93

Adjusting the guide rail 3

–

Place the sewing part 8 on the work table in opposite direction to

the feed direction.

–

Loosen the toggle screw 9.

–

Advance the guide rail 3 towards the contour of the sewing part.

–

Retighten the toggle screw 9.

Opening the mouse manually

98

1

–

Actuate lever 10.

The mouse opens.

10

13

5.3 Inserting the sewing parts and starting the sewing operation

The closing seam sewing unit 1281/5-1 works semi-automatically at

high production speed.

In the process, the operator of the sewing unit must perform the

following tasks:

Call up the desired seam program;

®

Insert the workpiece neatly;

®

Actuate the sewing operation with the foot switch;

®

Monitor the sewing operation of the sewing unit;

®

Remove the finished parts from the stacker.

®

Side Seam M02 5_7

1

1) Select the s eam program at the operating panel.

2) Lay out and adjust the trouser parts on the positioning table.

3) Insert the s ewing parts in the mouse 1.

4) Close the mouse.

5) Insert the t rouser parts under the sewing foot up to the point that

the feed dogs securely grasp the trouser parts.

6) Hold the trouser parts to be sewed up with the left hand.

7) Sew the hip curve manually with the “forward” pedal.

14

8) With the right hand, grasp the trouser parts to be sewed such that

the middle finger is below the lower trouser part, the index finger is

between the two and the thumb is on the upper trouser part.

9) With pedal “-1” “backwards”, the contour guide moves forward.

10) Should a correction be needed, the contour guide can be moved

back with the reset button.

Once the trouser parts have been corrected, t he contour guide can

once again be moved forward with the “backwards” pedal.

11) Step on forward pedal.

The automatic sewing operation starts.

12) The transport puller is lowered and transports the workpiece.

- At the seam end, the roll-out device is lowered in order to

secure chain separation and prevent the trouser parts from sliding.

- The completely sewed trouser parts are destacked.

1

15

Inside seam M 01 4_6

1) Select the seam program at the operating panel (see Chapter 6.3).

2) Lay out and adjust the trouser parts on the positioning table.

3) Insert the t rouser parts in the mouse.

4) Close the mouse.

5) Insert the t rouser parts under the sewing foot up to the point that

the feed dogs securely grasp the trouser parts.

6) With the left hand, hold the trouser parts to be sewed.

7) With the right hand, grasp the trouser parts to be sewed such that

the middle finger is below the lower trouser part, the index finger is

between the two and the thumb is on the upper trouser part.

8) Step on the forward pedal.

The sewing operation is performed automatically.

9) The transport puller is lowered and transports the workpiece.

- At the seam end, the roll-out device is lowered in order to

secure chain separation and

prevent the trouser parts from sliding.

The completely sewed trouser parts are destacked.

16

5.4 Adjusting the blow air for the nozzles in the table top

1

The blow nozzles 1 in the table top support the neat destacking of the

workpiece.

–

Adjust the blow air strength with the hand wheel 2 under the table

top.

Turning the hand wheel to the right

= blow air is stronger

Turning the hand wheel to the left

= blow air is weaker

2

1

17

5.5 Adjusting the reverse motion speed of the mouse.

321

The cylinder 2 presses the mouse mechanism 3 downwards and thus

draws the mouse back into insertion position.

The return speed can be adjusted.

–

Adjust the speed with the hand wheel 1.

Turning the hand wheel to the right

= speed is higher

Turning the hand wheel to the left

= speed is lower

18

5.6 Adjusting the pressure of the puller

2

1

The pressure of the puller rollers 1 can be influenced using the turning

knob 2.

–

Turning the knob 2 to the right.

Pressure is increased.

–

Turning the knob 2 to the left.

Press ure is re du c ed .

1

19

5.7 Stacker

21

The finished sewing parts are destacked on the flip stacker 2.

The destacked and clamped sewing parts can be removed by

actuating the foot switch 1.

The triggering of the s tacker is done by means of a control impulse.

The pneumatic functions are shown in the pneumatic circuit diagram.

Caution: Risk of Injury !

Do not reach into the operating range of the flip stacker while the

stacking operation is on.

Manual destacking

–

Press button 3 on the operating panel.

A destacking operation is performed.

Removal of destacked parts

–

Actuate foot switch 1 and hold it in that position.

–

Remove the destacked parts.

3

20

6 Operating the control unit

6.1 Operating the touch-screen monitor

To start a function, the display screen is touched with the finger-tip at

the point where the respective icon is shown.

Tap directly on the desired function symbol with the finger-tip.

The symbol will appear against a yellow background.

1

21

6.3 Main screen

–

Switch on the main switch 1 (turn in clockwise direction).

The control unit loads the machine program.

The start screen is displayed on the display screen of the

operating panel.

= Seam patter n is active seam in program

= Pedal Start

= Designation of the program (M01)

A program can comprise several seams ( 4, 6)

= Seam number of t he active program

= Adjusting the upper feed (only stepper motor version)

Increasing or decreasing the value using the plus/minus symbols

= Adjusting the lower feed (only stepper motor version)

Increasing or decreasing the value using the plus/minus symbols

= Calling up the machine parameters

= Automatic seam change

= Adjusting the puller

22

= Adjusting the puller transport

= Daily pieces counter

= Display of the current seam

= Calling up the main menu

= Increasing (+) or

decreasing (-) values for the upper and differential feed

(only stepper motor version)

= Activating manual s ewing

= Manual stacking

= Contour guide back to home position

Note:

When the symbols are tapped, the highlighting of the symbols in white

background signifies that the function is activated.

1

23

6.4 Sewing programs

4

6

5

The sewing unit is pre-programmed with four programs ex-works.

Program

No.

1

2

34

4

Seam-

No.

4

6

7

5

6

7

5

Operation Trouser position

Closing the inside seam

Closing the inside seam

Closing the inside seam

Closing the inside seam

Closing the inside seam

Closing the inside seam

Closing the inside seam

with fullness

Closing the inside seam

with fullness

Hind trouser top

Hind trouser bottom

Hind trouser top

Hind trouser bottom

Hind trouser top

Hind trouser bottom

Hind trouser top

Hind trouser bottom

Remarks

Automatic sewing with

contour guide

Manually guiding and

sewing over the hip curve,

then automatic sewing

Automatic sewing with

contour guide

Manually guiding and

sewing over the hip curve,

then automatic sewing

24

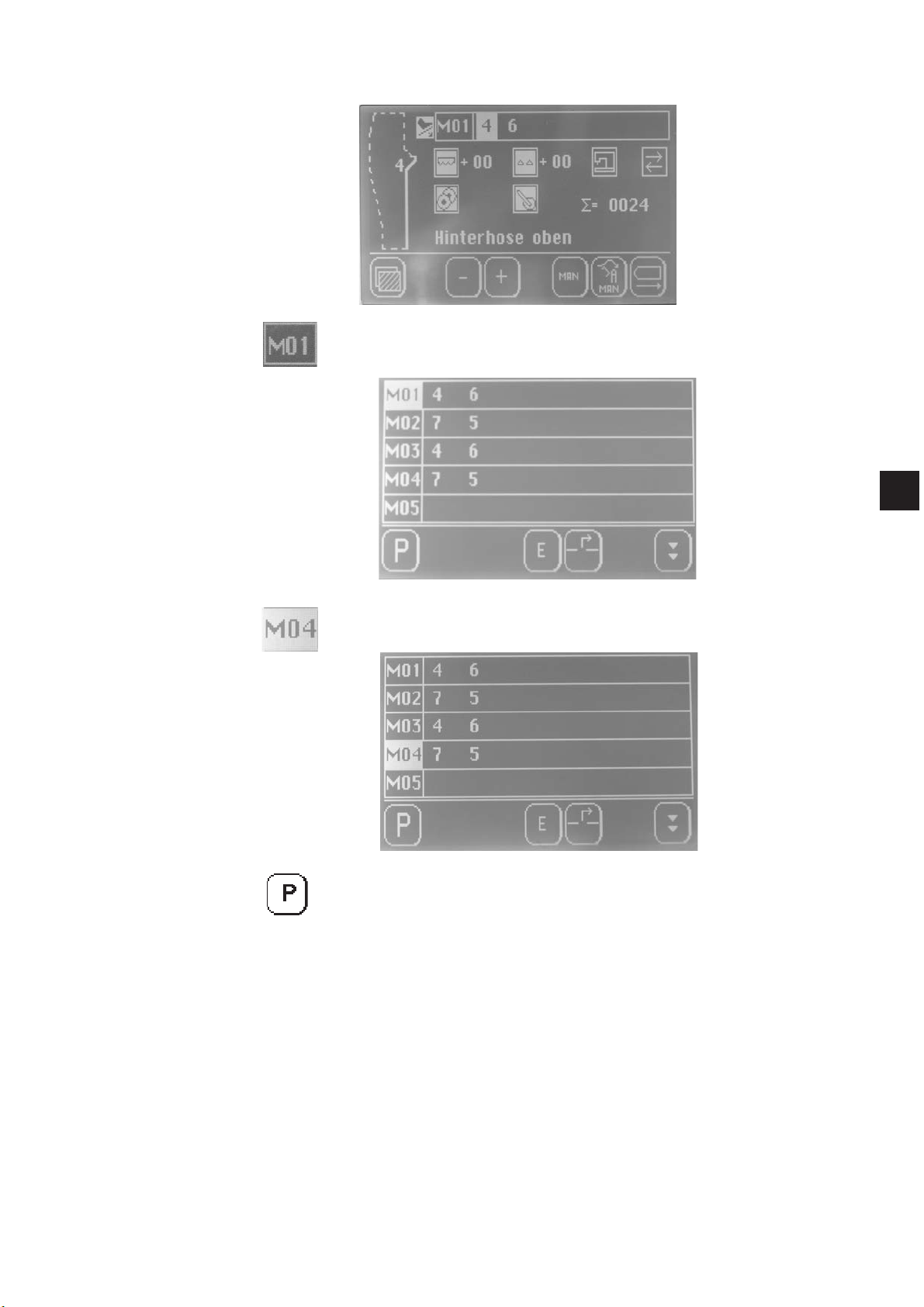

6.4.1 Selecting the program and seam number

–

Press the symbol when the main screen is displayed.

The display changes to the screen programs.

1

–

Tap the symbol for the desired program, e.g. “M04”.

The symbol appears in inverted image.

–

Tap the symbol “P” in order to adopt the selection and in order to

return to the main screen.

25

6.4.2 Creating a new seam program with seam number

–

Press the symbol on the displayed main screen.

The display changes to the screen programs.

–

Tap the symbol for the new seam program (e.g. “M05”).

The program number appears in inverted image.

–

Tap the symbol in order to adopt the selection.

The display changes to the seam program “M05”.

–

Tap the symbol.

The display is inverted.

–

Select a seam (e.g. “4”).

The display changes to confirmation prompt.

Selection: Yes/ No

–

Confirm with “Yes” in order to adopt the selection and in order to

return to the seam program “M05".

26

–

Tap the symbol.

The display is inverted.

–

Select a seam (e.g. “6”).

The display changes to confirmation prompt.

Selection: Yes/ No

–

Confirm with “Yes” in order to adopt the selection and in order to

return to the seam program “M05".

1

–

Tap the symbol “P” in order to adopt the selection and in order to

return to the display screen program.

–

Tap the symbol “P” in order to return to the main screen.

6.4.2.1 Number of seam programs and seams

Seam programs max: M01 – M20

Seams per seam program: 1 - 7

27

6.4.3 Editing, deleting the seam program or seams

Symbol Meaning

Save

Delete

Enter

Insert

Scroll pages

Exchanging

Delete seam

Example: Seam “6”

–

Press the symbol when the main screen is displayed.

The display changes to the screen programs.

–

Tap the symbol for the new seam program (e.g. “M05”).

The program number appears in inverted image.

–

Tap the symbol “E” in order to adopt the selection.

The display changes to the seam program “M05”.

28

–

Tap the seam “6”.

The display is inverted.

–

Tap the symbol “Delete”.

The display changes to the confirmation prompt Yes / No.

–

Confirm with “Yes” in order to delete the seam 6.

1

29

Inserting a seam

Example: No. “1”

The seam to be inserted is always inserted in front of an existent

seam.

–

Tap the seam “6”.

The display appears inverted.

–

Tap the symbol ”Insert”.

The seam or several seams are shifted one place to the right and

the free storage space flashes in negative image.

–

Select one seam, e.g. N umber “1”.

The display changes to confirmation prompt Yes/ No.

–

Confirm with “Yes” in order to insert the seam “1”.

–

Tap the symbol “P” in order to adopt the selection and in order to

return to the display screen program.

30

Exchanging the seam

Example: No. “6” with No. “4”

–

Tap the seam “6”.

The seam “6”flashes.

–

Tap the symbol ”Exchange”.

The other seams are marked for selection.

1

–

Tap one seam “4”.

The seams “4”and“6” flash in inverted image.

–

Confirm with “Yes” in order to exchange the seams “4”and“6”.

–

Tap the symbol “P” in order to adopt the selection and in order to

return to the display screen program.

31

Deleting the seam program

Example: M05

–

Tap the symbol “Delete”.

The display changes to the confirmation prompt Yes/ No.

–

Confirm with Yes in order to delete the seam program M05.

The display changes to the program screen.

–

Select the desired seam program, e.g. 04.

The seam program is displayed in inverted image.

32

–

Tap the symbol “P” in order to adopt the selection and in order to

return to the display screen program.

6.4.2 Manual sewing, driven by the pedal

Switching on the function

–

Tap the symbol “MAN”.

The display changes to the “manual mode”.

1

Switching off the function

–

Tap the symbol “P” in order to return to the main screen.

Note

The maximal speed in “Manual Mode” can be changed in the global

parameters with the help of Parameter No. “103”.

33

6.4.5 Changing the seam programs

·

·

Seam parameters

Global parameters

Automatic seam change

Seam parameters are parameters that can be changed for

individual seams (e.g. “4” or “6”).

Global parameters are parameters that are identical for all the

seam programs and seams.

34

Note

The quick access keys

function only for the option “Fullness regulation by means of stepper

motors”.

1

35

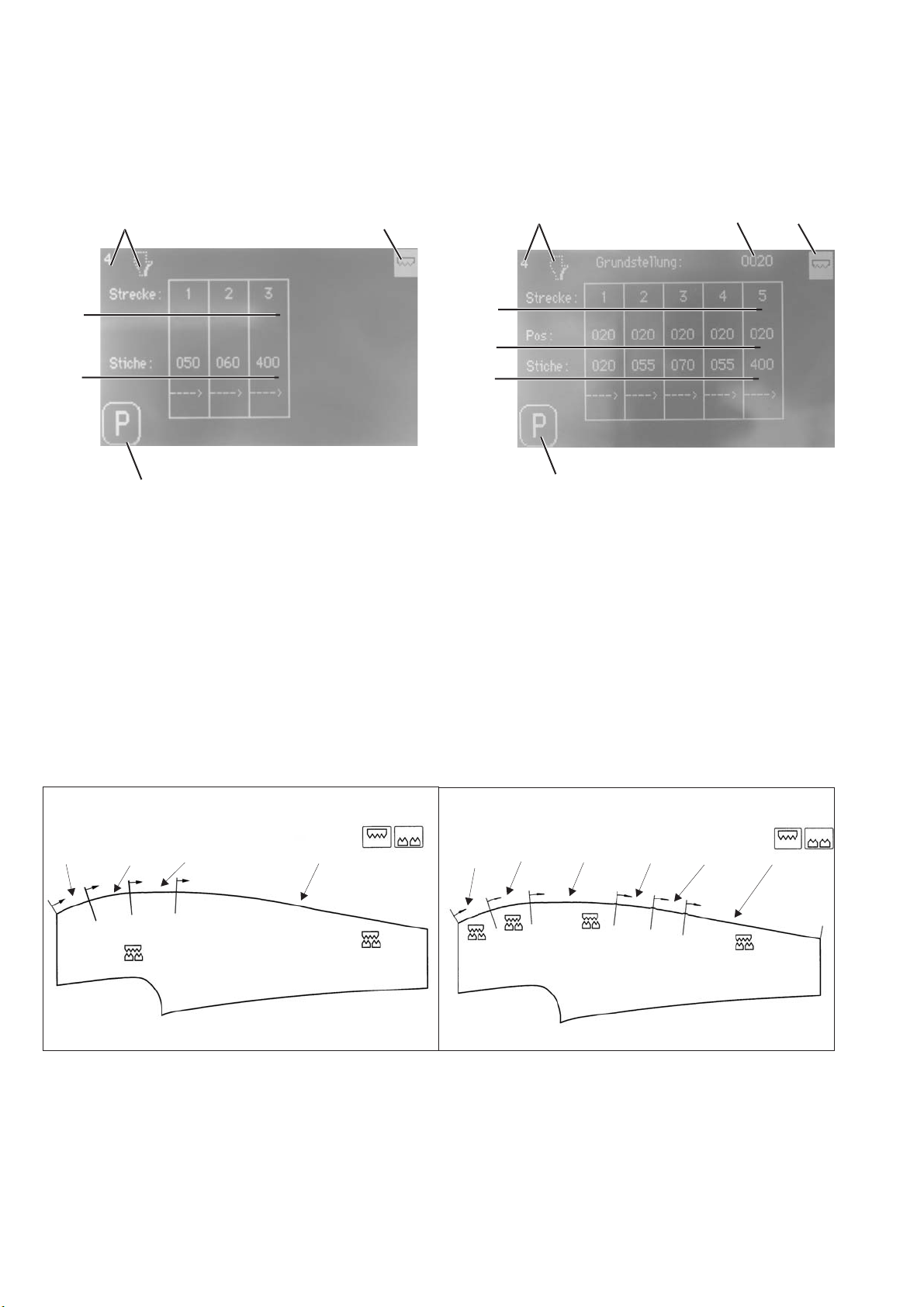

6.4.5.1 Seam Parameters

6.4.5.1.1 Editing the fullness regulation

–

Tap the symbol for upper or lower feed.

The following display screen appears.

13

4

123

5

6

7

With cylinder With stepper motor

8

1 = Display of the current s eam

2 = Display of the fullness in the home position (stepper motor)

3 = Fullness regulation is enabled

4=Switchingonthesegments

5 = Switching on t he segments for quick adjustment on the

main display screen (stepper motor)

6 = Fullness in t he 5 segments towards which the sewing motor

moves

7 = Number of stitches in the segments 1 - 5

8=Saving

7

8

With cylinder With stepper motor

Segment 1 Segment 2 Segment 3 Segment 1 Segment 2 Segment 3 Segment 4 Segment 5

Stitches Stitches Stitches Basic seam Stitches Stitches Stitches Stitches Stitches Basic seam

Note

The parameters of the home positions 2 are located in the “Global

Parameters” with the numbers “40” and “42”.

36

Switching on the fullness regulation

–

Tap the symbol 3.

The display is inverted.

–

The fullness regulation is therewith enabled and is also displayed

in inverted image on the main screen on exiting the fullness

regulation.

Programming the stitches and quantities

–

Tap on the symbols for the stitches “6” or Item “5”.

The display changes to input mode.

–

Enter the desired values.

–

Save the values with the key “P”.

The display changes back to fullness regulation.

1

Machine with fullness regulation by means of cylinder

–

Tap on the symbol for the segment 2.

The display appears inverted.

In segment 2,fullnessisswitchedonbymeansof

the number of programmed stitches

.

Machine with fullness regulation by means of stepper motor

–

Tap on the symbols 1, 3, 5

.

The display appears inverted.

–

The segments 1, 3, 5 are switched on for the

quick adjustment in the main view

.

ATTENTION !

The following must be borne in mind while working with fullness by

means of stepper motor:

The enabling of the fullness always applies to all 5 segments.

37

Quick adjustment of fullness regulation

–

Tap on the symbol for the desired

quick adjustment.

The display appears inverted.

–

Enable the fullness with the keys “+”and“-”.

Change segments 1, 3 a nd 5.

–

Tap on the symbol “+17”.

The value is saved.

Parameters of fullness regulation by means of cylinder

Upper feed

Parameter 01: Segment 1

Number of stitches before the upper feed is

switched on

Parameter 02: Quantity of fullness 1 OFF/ ON

Parameter 03: Segment 2

Number of stitches, the length of time during

which the upper feed

is switched on

Parameter 04: Quantity of fullness 2 OFF/ ON

Parameter 05: Segment 3

Number of stitches, the length of time during

which the upper feed

is switched on

Parameter 06: Quantity of fullness in segment 3 OFF/ ON

Differential lower feed

Parameter 07: Segment 1

Number of stitches before

differential feed is switched on

Parameter 08: Quantity of fullness 1 OFF/ ON

Parameter 09: Segment 2

Number of stitches, the length of time during

which

differential transport is switched on

Parameter 10: Quantity of fullness 2 OFF/ ON

Parameter 11: Segment 3

Number of stitches, the length of time during

which

differential transport is switched on

Parameter 12: Quantity of fullness in segment 3 OFF/ ON

38

Parameters of fullness regulation by means of stepper motor

Upper feed

Parameter 01: Segment 1

Number of stitches

Parameter 02: Quantity of fullness in segment 1

Parameter 03: Segment 2

Number of stitches

Parameter 04: Quantity of fullness in segment 2

Parameter 05: Segment 3

Number of stitches

Parameter 06: Quantity of fullness in segment 3

Parameter 107: Segment 4

Number of stitches

Parameter 108: Quantity of fullness in segment 4

Parameter 109: Segment 5

Number of stitches

Parameter 110: Quantity of fullness in segment 5

1

Differential upper feed

Parameter 07: Segment 1

Number of stitches

Parameter 08: Quantity of fullness in segment 1

Parameter 09: Segment 2

Number of stitches

Parameter 10: Quantity of fullness in segment 2

Parameter 11: Segment 3

Number of stitches

Parameter 12: Quantity of fullness in segment 3

Parameter 113: Segment 4

Number of stitches

Parameter 114: Quantity of fullness in segment 4

Parameter 115: Segment 5

Number of stitches

Parameter 116: Quantity of fullness in segment 5

39

6.4.5.2 Machine parameters

–

Tap the symbol.

The display changes to the machine parameters.

–

Select the desired parameter with the arrow keys.

–

Tap the symbol “E” in order to adopt the selection.

–

Changing the value.

–

Tap the symbol “P” in order to save the selection.

Parameter 30: Adjusting the main speed

Parameter 31: Manual sewing on/ off

Parameter 32: Length of time during which table blowing

remain s swit ch e d on

Parameter 33: Number of stitches before start of sewing is followed

by

automatic start

Parameter 34: Number of stitches until the contour guide is

lowered

Parameter 35: Number of stitches until the contour guide

moves in sideways

Parameter 36: Number of stitches until the transport unit

is lowered

Parameter 37: Start mode for contour control

0 = front right

1 = front left

2 = rear right

3 = rear left

Parameter 60: Soft-start speed

Parameter 61: Switching on or switching off t he soft-start

Parameter 77: Switching on or switching off the auto-start

Parameter 78: Number of stitches before the auto-start begins

Parameter 120: Sewing foot lift in the seam

Parameter 121: Sewing foot lift at seam start

40

6.4.5.3 Roll-out Device

–

Tap the symbol.

The display changes to the

parameters.

–

Select the desired

parameter with the arrow keys.

–

Tap the symbol “E” in order to adopt the selection.

–

Changing the value.

–

Tap the symbol “P” in order to save the selection.

Parameter 16: Number of stitches for the length of which the thread

chain

is suctioned (seam start)

Parameter 17: Switching on or switching off the stacker

Parameter 20: Number of stitches before the roll-out device is

lowered

Parameter 21: Number of stitches, for the length of which the

roll-out device

is switched on.

Parameter 22: Number of stitches after unblocked light barrier

before the

roll-out device stops.

Parameter 23: Period of time during which the smoothening takes

place.

Parameter 47: Point of time of stacker movement

Parameter 53: Point of time when the roll-out device is lifted.

1

41

6.4.5.4 Puller

–

Tap the symbol.

The display changes to the

parameters.

For programming, see

Chapter 6.5.6.2 Roll-out Dev ice

Parameter 26: Number of stitches before the puller is lowered

Parameter 27: Number of stitches, for the length of which the

puller

is lowered.

Parameter 51: Puller speed

Value lower = Puller is quicker

Value higher = Puller is slower

Parameter 100: Number of stitches, for the length of which the

puller is opened.

42

6.4.5.5 Global Parameters

–

Tap the symbol for “Main Menu”.

The display changes to main menu.

–

Tap the symbol for global parameters.

The display changes to the

global parameters.

–

Select the desired

parameter with the arrow keys.

–

Tap the symbol “E” in order to adopt the selection

.

–

Changing the value.

1

–

Tap the symbol “P” in order to save the selection.

Parameter 29: Upper feed max imum track (option

of stepper motor)

Parameter 38: Delayed start of light barrier

Parameter 39: Differential feed (option of stepper motor)

Maximum track

Parameter 40: Base value for upper feed (option of stepper motor)

Parameter 42: Base value for differential lower feed

(option of stepper motor)

Parameter 45: Number of stitches before table blowing

is switched on.

Parameter 46: Duration of the stacker impulse

Parameter 48: Max. speed

Parameter 49: Speed during warp thread separation

Parameter 50: Number of stitches before thread tensioning

is opened (seam end).

Parameter 52: Speed of roll-out device

Parameter 54: Impulse duration of retracted mouse

Parameter 55: Time until after the roll-out device is lifted on the

transport unit.

Parameter 58: Display of the software version

Parameter 59: Number of stitches, for the length of which the

roll-out device

suctions the thread chain (seam start)

Parameter 65: Thread tension lift

43

Parameter 79: Soft-start after “Stop in the seam”

Parameter 80: Resetting the daily pieces counter.

Parameter 102: Language

Parameter 103: Manual speed

Parameter 126: Chaining-off speed

44

6.4.5.6 Input - Output Test

–

Tap the symbol for “Main Menu”.

The display changes to main menu.

–

Tap the symbol for Input-Output.

The display changes to Input.

Checking the inputs

e.g. Start light barrier In1

–

Switching the light barrier to dark.

The display In1 appears

inverted.

In 1 = Start light barrier

In 5 = Program Stop

In 8 = Upper Feed Switch (Option)

In 9 = Differential Lower Feed Switch (Option)

1

Checking the pedal

–

Actuate the pedal.

The display 2 to 12 appears in stepped mode.

0 to 2 = backwards

0to12=forwards

45

Checking the outputs

–

Tap the symbol for the outputs.

The display changes to Outputs.

–

Tap the symbol “Y 1”.

The display appears inverted

and the output is switched on at the same time.

–

Tap the symbol “Y 1” once again.

The output is returned to its original position.

–

Tap the symbol.

The subsequently selected output is automatically switched

on/off.

Output element

Switch Designation

Y01 Sewing foot up/ down

Y02 Thread tension lift

Y03 Contour guide up/ down

Y04 Stacker off / on

Y05 Roll-out device up/ down

Y06 Transport unit up/ down

Y07 Contour guide forward / backward

Y08 Contour guide blowing on

Y09 Move contour guide sideways

Y10 Differential lower feed on / off

Y11 Upperfeedon/off

Y12 Warp thread separator off / on

Y13 Table blowing off / on

Y14 Dirt suctioning off / on

Y15 Puller up/ down

Y16 Mouse retracted

46

6.4.5.7 Stepper Motor Test

–

Tap the symbol “Stepper Motor Test”.

The display changes to the inputs.

–

Tap the symbol.

The display screen for the stepper motor test appears.

–

Tap the symbol “Differential Feed”.

The display screen for the differential transport test appears.

–

Tap on the symbol once again.

The stepper motor for differential transport moves to reference

position.

1

–

Tap the symbol once again.

The stepper motor moves through its steps.

47

–

Tap the symbol “Upper Feed”.

The display screen for the upper feed test appears.

–

Tap on the symbol once again.

The stepper motor for differential feed moves to reference

position.

–

Tap the symbol once again.

The stepper motor moves through its steps.

48

6.4.8 Version Data

–

Tap the symbol Global Parameters in the main menu.

The following display screen appears.

–

Tap the symbol Version .

The version data appears.

1

49

7. Data protection using the USB stick

7.1 General Information

The USB stick 1 s erves the purpose of preserving and transferring the

sewing unit software.

With its help, program and parameter data can be transferred even to

other sewing units and workplaces.

Even customary USB sticks can be used.

1

7.2 Formatting the USB stick

Before a new USB stick is used, it must be formatted accordingly.

The file format is the “FAT 16” system.

Format the USB stick using a PC with the FAT 16 system.

50

7.3 Saving the seam programs and seam parameters on the USB stick

–

Switch off the main switch.

–

Insert the USB stick in the slot of the operating panel.

–

Switch off the control element.

–

Tap the symbol.

The display changes to the main menu.

–

Tap the symbol.

The display changes to the display screen “Saving the seam

parameters”.

1

–

Tap the symbol “Control on USB stick ”.

The display screen changes to selection.

–

Tap one file out of the five file options.

–

Tap the symbol “Control on USB stick ”.

The display changes to the screen “Save”.

–

Tap the symbol.

The display changes to the main menu without saving.

Or

–

Tap the symbol.

The seam program and all the parameters are saved.

51

This is followed by t he message:

–

Confirm with “OK”.

The display changes to the main menu.

–

Tap the button “P” in order to return to the main screen.

Note

Five variously programmed files can be saved.

The files can be renamed using the PC.

ATTENTION: In the process, make sure that the file name does not

exceed 8 characters.

52

7.4 Loading the seam programs and seam parameters from the USB stick

–

Switch off the main switch.

–

Insert the USB stick in the slot of the control element.

–

Switch on the main switch.

–

Tap the symbol.

The display changes to the main menu.

–

Tap the symbol.

The display changes to the display screen “Saving the seam

parameters”.

1

–

Tap the symbol “USB stick in the control unit”.

The display screen changes to selection.

–

Select the desired file with the arrow keys.

–

Tap the symbol.

The display changes to the main menu without saving.

Or

–

Tap the symbol.

The seam program and all the parameters are loaded.

53

This is followed by t he message:

–

Confirm with “OK”.

The display changes to the main menu.

–

Tap the button “P” in order to return to the main screen.

7.5 Saving global parameters on USB stick

Procedure:

See Chapter 7.3

7.6 Loading global parameters from the USB stick

Procedure:

See Chapter 7.4

7.8 Removing the USB stick

–

Switch off the main switch.

Pull out the USB stick from the slot of the Efka control unit

54

8. Maintenance

8.1 Cleaning and Testing

Caution: Risk of Injury !

Switch off the main switch.

The sewing unit may be serviced only when it is switched off.

The maintenance jobs must be performed latest after the maintenance

intervals specified in the tables (see column “Operating Hours”).

Shorter maintenance intervals can ensue for the processing of lint

collecting materials.

A clean sewing unit protects against faults.

1

1

2

6543

55

Operating hours Explanation Operating Job

Maintenance Job to be performed

Remove machine head

- Lint and thread waste

.

(e.g. with air blow gun)

Suctioning Device

Pneumatic System

- Check the water level in the

pressure regulator

3

- Clean the filter insert 4

- Check the leak tightness of the

system

Clean

the entire area 1 of the thread guides

under the thread sliding plate

Empty the container 2 of the suctioning

device

- Turn the lower part of t he container

to the left and remove the lower part

- Empty the container

- Screw back the lower part

by turning it to the right.

Make sure that the water level does not

rise up to the filter insert 4.

- After pressing the drain screw 5,

blow out the water under pressure

from the water separator.

Dirt and condensate are discharged by

means of filter insert 4.

- Separate the sewing unit from the

compressed air supply.

- Press in the drain screw 5.

The pneumatic system of the sewing

unit

must be pressureless.

- Unscrew the water separator 6

- Extract the filter insert 4.

Wash and blow out the contaminated

filter cup and filter insert

with petroleum ether

(no solvent!).

- Reassemble the water separator

and connect the maintenance unit.

8

8

40

500

500

56

8.2 Lubrication

1

Caution: Risk of Injury !

Oil can induce skin rashes.

Avoid long-term skin contact.

Wash yourself thoroughly after contact.

ATTENTION !

The handling and disposal of mineral oils is subject to legal regulation.

Deliver used oil to an authorised collection point.

Protect your environment.

Take care not to spill oil.

For lubrication the sewing unit head, use exclusively the lubricant

DA 10 or an equivalent oil with the following s pecification:

–

Viscosity at 40° C: 10 mm²/s

–

Flash point 150° C

DA 10 can be ordered from the sales outlets of DÜRKOPP ADLER AG

while referring to the following part numbers:

250-ml container: 9047 000011

1-litre container: 9047 000012

2-litre container: 9047 000013

5-litre container: 9047 000014

1

Maintenance work Explanation Operating

to be carried out hours

Lubrication

Check the oil level in the sewing unit head

regularly (inspection glass 1 and 2).

For more detailed information, kindly refer to

the enclosed operating instructions for the

sewing machine head.

8

57

8.3 Repair

When the machine is damaged or parts are worn please contact:

Dürkopp Adler AG

Potsdamer Str. 190

33719 Bielefeld

Tel.: +49 (0) 180 5 383 756

Fax: +49 (0) 521 925 2594

E-mail: service@duerkopp-adler.com

Internet: www.duerkopp-adler.com

58

Loading...

Loading...