Page 1

100/68

Universal

Piped-Pocket-Sewing unit

Operating instructions

Assembly instructions

Service instructions

Programming instructions

1

2

3

4

Ausgabe / Edition: 11/2007 Printed in Federal Republic of Germany Teile-Nr.:/Part-No.:DOC000045

Page 2

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and ute of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the

machine/sewing unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

Operation, including equipping, troubleshooting during the work cycle,

removing of fabric waste,

–

Service (maintenance, inspection, repair) and/or

–

Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance ot the following satety instructions can

cause bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot,

instruction book and operated by persons with appropriate

training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

It is absolutely necessary to to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safty instructions.

Page 5

Index Page:

Part 1: Operating instructions 100/68

1. Description of product ..............................................3

1.1 Description of proper use .............................................3

1.2 Brief description...................................................3

1.3 Technical data ....................................................4

2. Operating ......................................................5

2.1 Swivelling the folding station aside .......................................5

2.2 Removing the fabric sliding sheet ........................................6

2.3 Needles and threads ................................................7

2.4 Threading the needle thread ...........................................9

2.5 Winding up the hook thread ...........................................10

2.6 Remaining thread monitor ............................................11

2.7 Slanted pocket opening (optional) .......................................12

2.7.1 Swivelling the corner knife station in and out .................................12

1

3. Switching on - Starting the sewing process - Program stop - Switching off ...........14

3.1 Switching on ....................................................14

3.2 Reference position ................................................15

3.3 Starting the sewing process ...........................................15

3.4 Program stop....................................................16

3.5 Switching off ....................................................16

4. Working methods ................................................17

4.1 Working method “Production of trousers” ...................................18

4.2 Working method “Breast welt pocket” .....................................20

5. Quick clamp adjustment and folder monitoring .............................22

6. Function and operation of the optional equipment ..............................23

6.1 Tape feeding unit with automatic trimming and tape monitor........................23

6.2 Endless zipper device ..............................................26

7. Maintenance....................................................27

7.1 Cleaning ......................................................27

7.2 Oil level control ..................................................28

Page 6

2

Page 7

1. Description of product

1.1 Description of proper use

The Beisler 100/68 is a sewing unit which can properly be used for

sewing light to medium-weight material. Such material is, as a rule,

made of textile fibres or leather. These materials are used in the

garment industry.

In general only dry material must be sewn on this machine. The

material must not contain any hard objects.

The seam is generally made with core thread, polyester fibre

or cotton threads.

The dimensions for needle and hook threads can be taken from the

table in chapter 2.4.

Before using any other threads it is necessary to estimate the

consequential dangers and to take the respective safety measures, if

required.

This sewing unit must only be installed and operated in dry and

well-kept rooms. If the sewing unit is used in other rooms, which are

not dry and well-kept, further measures to be agreed upon may

become necessary (see EN 60204-31 : 1999).

We, as manufacturer of industrial sewing machines, assume that at

least semi-skilled operating personnel will be working on our products

so that all usual operations and, where applicable, their risks are

presumed to be known.

1

1.2 Brief description

The Beisler 100/68 is a sewing unit for automated runstitching of piped

pocket, flap pocket and welt pocket openings with rectangular or

slanted pocket corners.

The slanted pocket corners result from the offset of the two seam rows.

It is possible to sew different slants at the seam beginning and at the

seam end.

Depending on the working method various feeding devices, corner

knife stations and optional equipment are used.

Machine head

–

Twin needle lockstitch version

–

Needle bars can be switched/engaged jointly or separately

–

Vertical hook

–

Externally driven centre knife, speed and release time/switching

time programmable

–

Thread trimming device for needle and hook threads

–

Monitor for the needle threads

–

Photoelectric remaining thread monitor for the hook threads

–

DC direct sewing drive

Step motors for the material feed and the length adjustment of the

corner trimming device

The step motor technology allows short machine times and guarantees

an absolutely precise material feed and accurate corner incisions.

3

Page 8

Thus, it contributes to a pocket quality unrivalled as yet combined with

high productivity.

New control generation “DAC III”

The graphic user guidance is exclusively effected by internationally

comprehensible symbols and texts in the language of the respective

country.

The various symbols are arranged in groups within the menu structure

of the sewing and test programs.

The easy operation allows short training times.

20 storage locations with each 6 seam programs are available. Thus it

is possible to generate and store up to 6 different seam programs per

storage location.

6 seam programs can be allocated to every storage location in any

desired order which can be sewn in succession.

All slants to be processed can be programmed by the operator via

parameters.

The comprehensive test and monitoring system MULTITEST is

integrated in the DAC.

A microcomputer does the control tasks, supervises the sewing

process and indicates operating errors and malfunctions in the display.

Optional equipment

Due to a flexible system of optional equipment the sewing unit can be

optimally adapted to the respective application at low cost.

Sewing equipment and folders

Please see parts list of cl. 100/68 for details concerning sewing

equipment and folders for the various applications or contact the

Beisler company.

1.3 Technical data

Needle system: 2134-35

Needle distance: 8, 10, 12, 14, 16,

20, 22, 24, 26, 30 mm

Needle size: Nm 80 to Nm110

Threads: see table chapter 2.3

Stitch type: twin needle lockstitch

Speed: max. 3,000 r/ min

Stitch length: min. 0.5 to 3.0 mm

Number of condensed stitches: 1 - 20

Number of bartack stitches: 0 - 20

Stitch length condensed

stitches/ bartacks 0.5 - 3.0 mm

Pocket length: max. 250mm

Operating pressure: 6 bar

Air consumption: approx. 6 NL per working cycle

Rated voltage: 1 x 230 V / 50/60 Hz

Dimensions: 1750 x 1450 x 1700 mm (L xWxH)

Working height: 830 mm

(upper table top edge)

Weight: 270 kg

4

Page 9

2. Operating

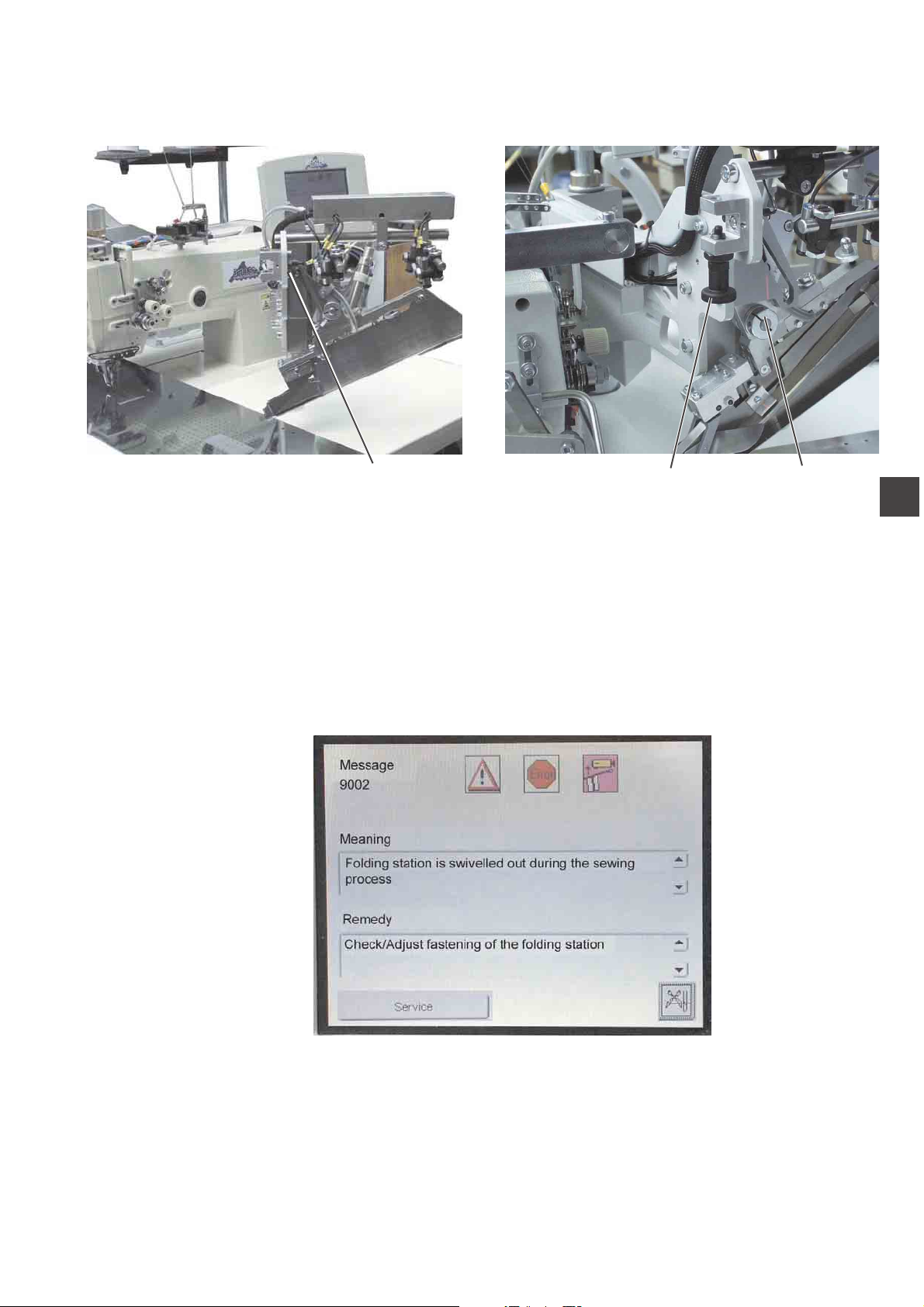

2.1 Swivelling the folding station aside

1

For work at the sewing point (threading the needle threads, needle

change etc.) the entire folding station with folder and laser lamps can

be swivelled to the right.

–

Swivel the entire folding station 1 with folder to the right.

The sewing point is freely accessible.

Note:

When the sewing unit is switched on a

safety message is indicated in the display of the control panel.

32

1

Folding station swivelled out

Swivelling the folding station back

–

Swivel the folding station 1 back.

ATTENTION !

After having been swivelled back the folding station must snap in

catch 2.

5

Page 10

2.2 Removing the fabric sliding sheet

Caution: Risk of injury!

Switch the main switch off.

Remove the fabric sliding sheet only with the sewing unit switched off.

–

Switch the main switch off

21

For changing the hook thread bobbins:

–

Lift the fabric sliding sheet 2 at/with the pin 1 and swivel it to the

left.

For complete removing (for maintenance work and adjustments):

–

Lift the fabric sliding sheet at the hind pin 3c completely.

31

3

6

Page 11

2.3 Needles and threads

Needle system: 2134-85

Recommended

needle size: Nm 90 for thin material

Nm 100 for medium-weight material

Nm 110 for heavy-weight material

High sewing security and good sewability are achieved with the

following

core threads:

–

Two-ply polyester endless polyester core-spun

(e.g. Epic Poly-Poly, Rasant x, Saba C, ...)

–

Two-ply polyester endless cotton core-spun

(e.g. Frikka, Koban, Rasant, ...)

If these threads are not available, the polyester fibre or cotton threads

listed in the table can also be sewn.

Often two-ply core threads are offered by the thread manufacturers

with the same designation as three-ply polyester fibre threads

(3cyl.-spun).This causes uncertainty with regard to twisting and thread

thickness.

When in doubt, unravel the thread and check whether it is twisted 2- or

3-ply.

The label no. 120 on the thread reel of a core thread corresponds e.g.

to the thread size Nm 80/2 (see table values in brackets).

In case of monofilament threads you can use needle threads and hook

threads of the same thickness. The best results are achieved with soft

and elastic threads (software) of the thread thickness 130 Denier.

1

Recommended thread thicknesses:

Needle size Core thread Core thread

Nm

Needle thread Hook thread Needle thread Hook thread

Polyester Polyester Polyester Cotton

endless core-spun endless core-spun

Label No. Label No. Label No. Label No.

90 120 (Nm 80/2) 120 (Nm 80/2) 120 (Nm 80/2) 120 (Nm 80/2)

100 100 (Nm 65/2) 100 (Nm 65/2) 100 (Nm 65/2) 100 (Nm 65/2)

110 75 (Nm 50/2) 75 (Nm 50/2) 75 (Nm 50/2) 75 (Nm 50/2)

Needle size Polyester fibre thre-ad Cotton thread

Nm (3cyl.-spun)

Needle thread Hook thread Needle thread Hook thread

90 Nm 80/3-120/3 Nm 80/3-120/3 Ne

100 Nm 70/3-100/3 Nm 70/3-100/3 Ne

110 Nm 50/3-80/3 Nm 50/3-80/3 Ne

50/3-70/3 NeB50/3-70/3

B

40/3-60/3 NeB40/3-60/3

B

40/4-60/4 NeB40/4-60/4

B

7

Page 12

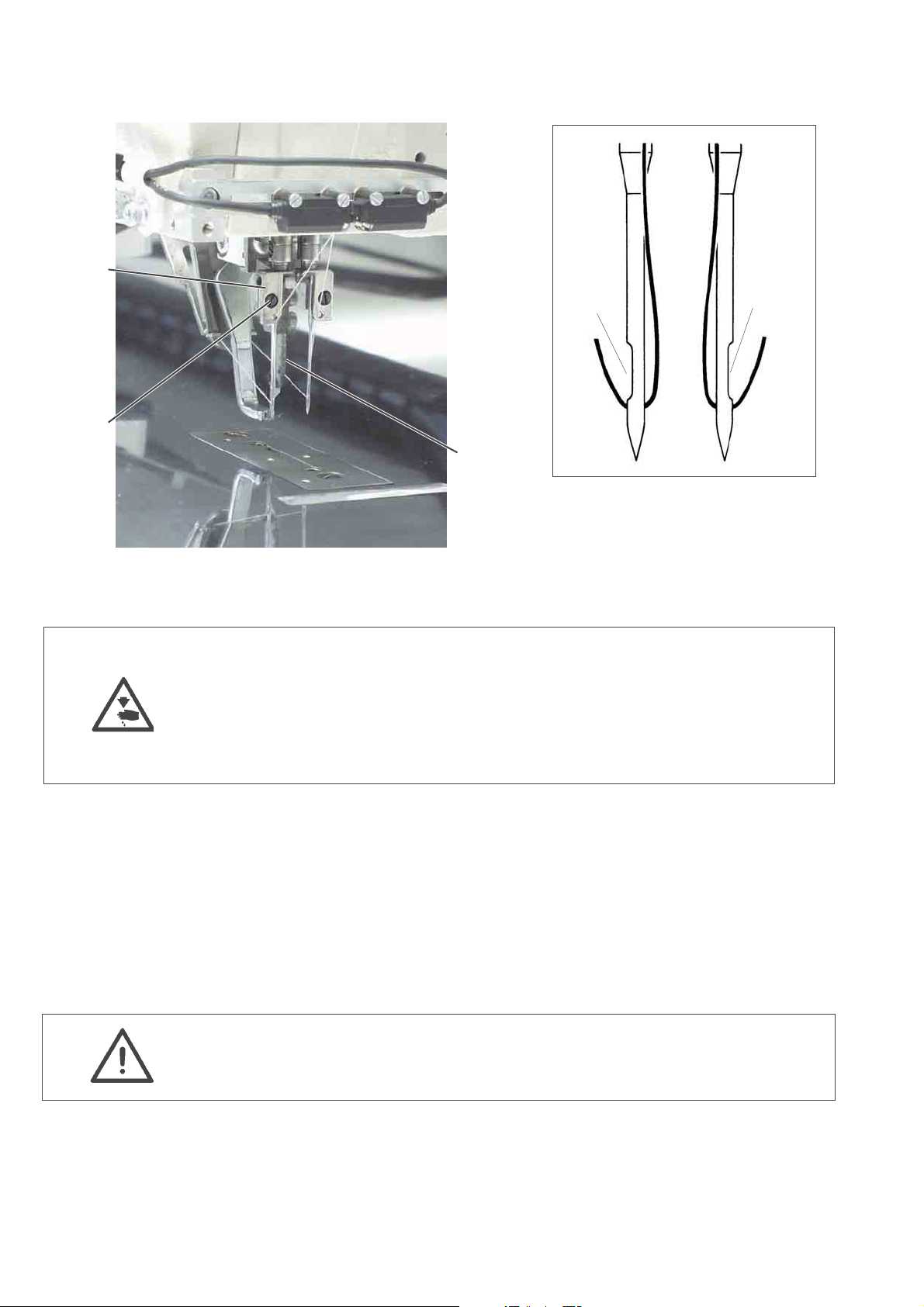

Needle change

1

4

5

2

3

Caution: Risk of injury!

Switch the main switch off.

Change the needles only when the main switch is switched off.

Risk of cuts!

Do not reach into the area of the centre knife 3 when changing the

needles.

–

Swivel the folding station aside (see chapter 2.1)

The needles are freely accessible.

–

Loosen screw 2 and remove needle from needle holder 1.

–

Push a new needle into the drill-hole of needle holder 1 as far as it

will go.

ATTENTION!

Seen from the operator’s side of the sewing unit the hollow groove

4 of the left needle must point to the left and the hollow groove 5 of

the right neele to the right (see sketch).

–

Tighten screw 2.

ATTENTION!

After the changeover to another needle size the needle protection at

the hook has to be readjusted (see service instructions).

8

Page 13

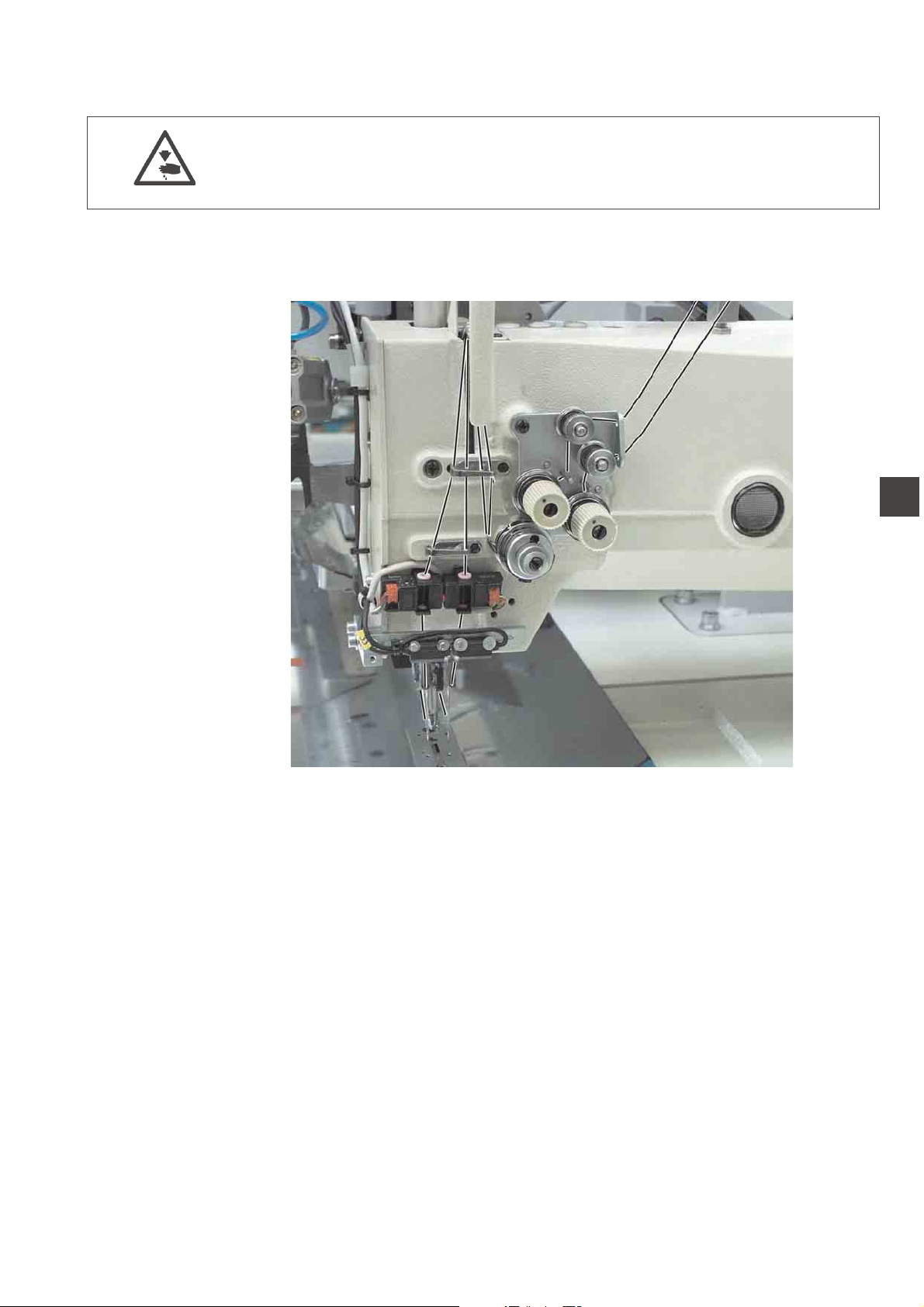

2.4 Threading the needle thread

Caution: Risk of injury!

Switch the main switch off.

Thread the needle threads only with the sewing unit switched off.

See the illustration for threading the needle threads.

1

9

Page 14

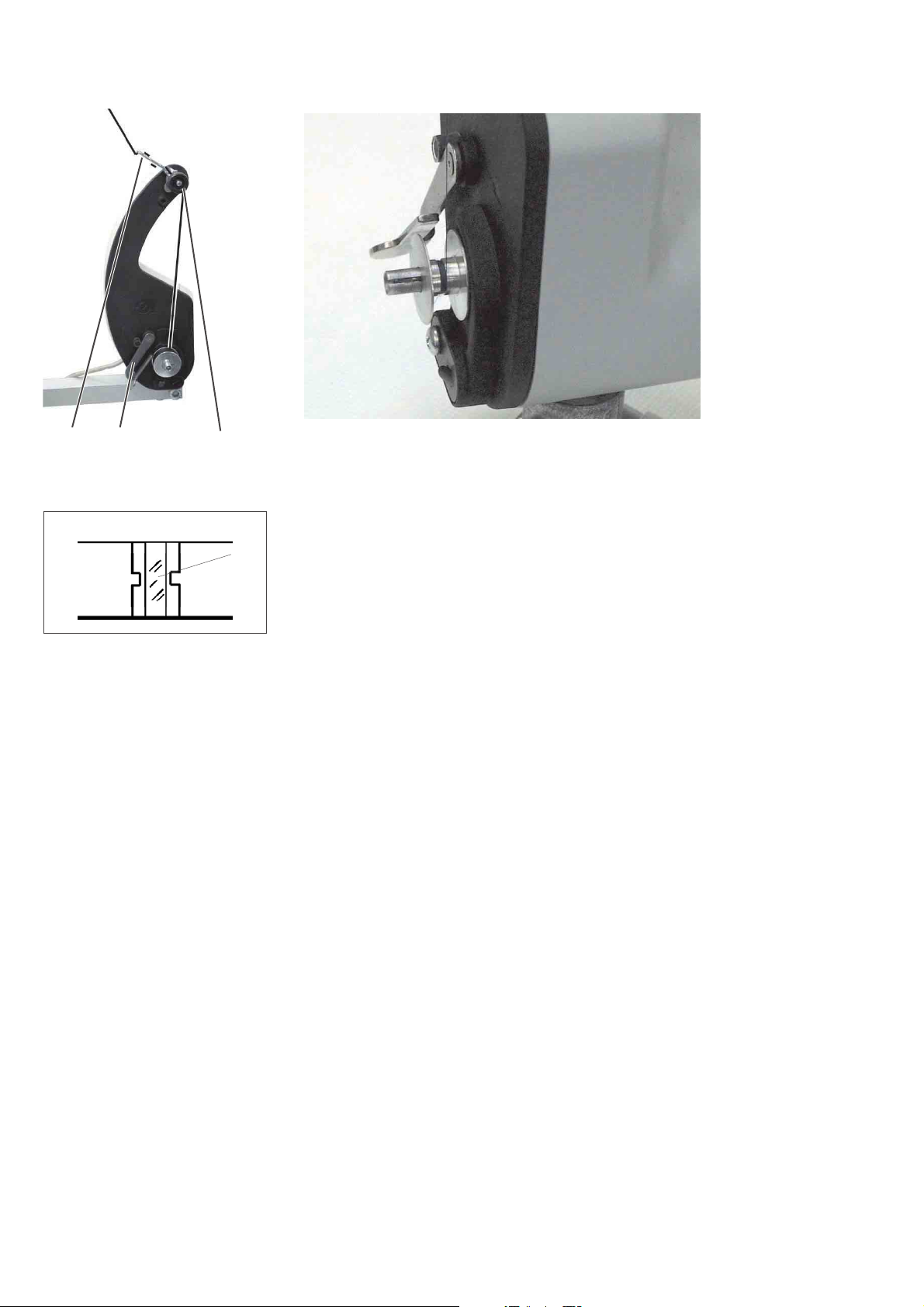

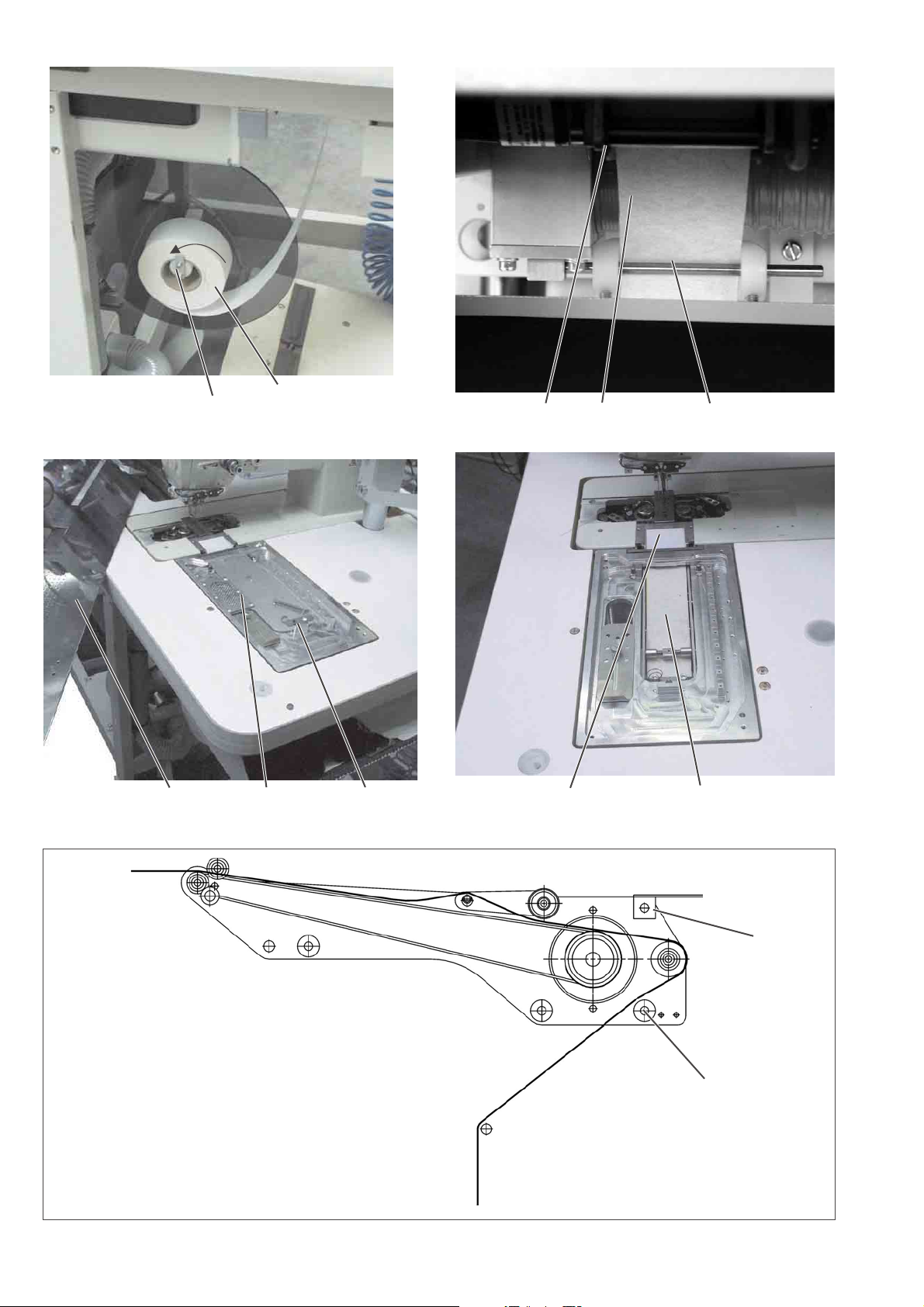

2.5 Winding up the hook thread

32 1

The separate winder allows to wind up up the hook threads

independent of the sewing process.

4

–

–

–

–

–

–

–

Remove thread remainders from the bobbin hubs before winding

up.

Put the thread reel on the thread reel holder.

Thread the thread through the drill-hole 1 of the unwinding arm.

Guide the thread through the guide 3.

Guide the thread through the bobbin thread tension 1.

Prewind the thread in the central supply groove of the bobbin hub

in clockwise direction.

The full supply groove guarantees a secure winding start, even in

case of monofilament threads.

With the thread supply in the supply groove it is ensured that the

pocket opening can be safely finished after the remaining thread

monitor has produced the message “bobbin empty”.

The reflecting surface 4 of the bobbin hub has to be kept clean.

Press the bobbin retainer 2 against the bobbin hub.

The winder starts.

After reaching the set bobbin filling quantity the winder stops

automatically.

See the service instructions for setting the bobbin filling quantity.

10

Page 15

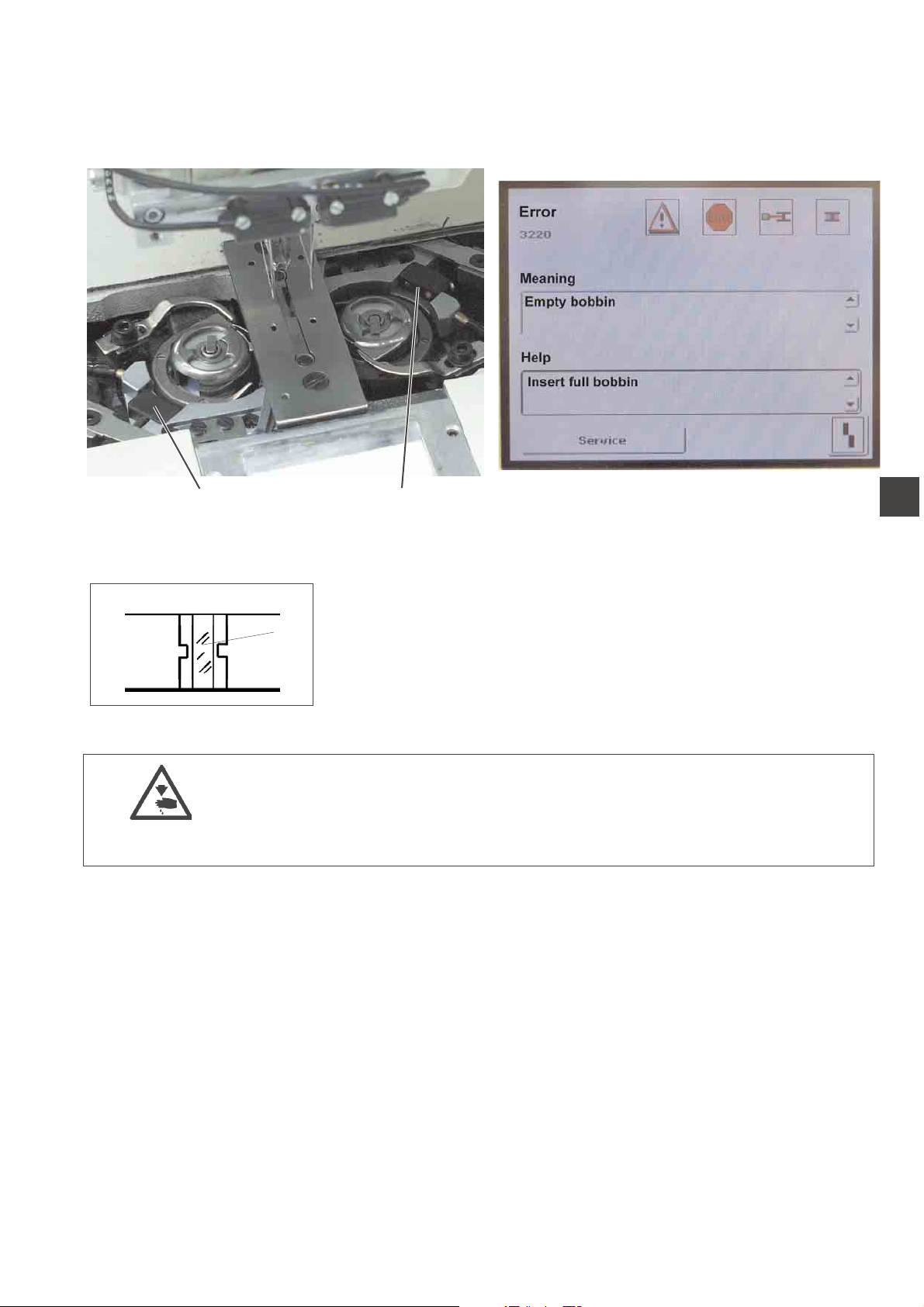

2.6 Remaining thread monitor

The remaining thread monitor supervises the left and right hook thread

bobbin with the infrared reflected light barriers 1 and 2.

21

–

When the bobbin is empty, the light beam emitted by light barrier 1

or 2 is reflected at the free reflecting surface 3 of the bobbin hub.

–

The display of the control unit indicates the message shown in the

right picture.

–

3

The remaining thread in the supply groove of the bobbin hub

guarantees that the pocket opening is safely finished.

The transport carriage stops in its rear end position.

Caution: Risk of injury!

Switch the main switch off.

Clean the lenses of the light barriers only with the sewing unit

switched off.

–

Switch the main switch off.

–

When changing the bobbin always clean the lenses of the light

barrier with a soft cloth.

–

Switch the main switch on.

–

Start the new sewing process.

1

11

Page 16

2.7 Slanted pocket opening (optional)

The 100/68 is optionally equipped with an automatic corner knife

station guaranteeing a precise incision of the corners of slanted

pockets.

For this purpose the machine head is equipped with disengageable

needle bars.

Corner knife station

The adjustment of the corner knives as to the pocket length is

programmable and is realized by a step motor.

The slanted pocket corners result from the offset of the two seam rows

programmable in steps of 1 mm.

The programmable pocket corner incision - adjustable via two step

motors - is freely selectable for the seam beginning and the seam end

and amounts to max. +/- 10 mm in relation to the second seam.

The lateral distance of the corner knives to the seam is manually

adjustable.

The whole unit can be folded out for adjusting and servicing.

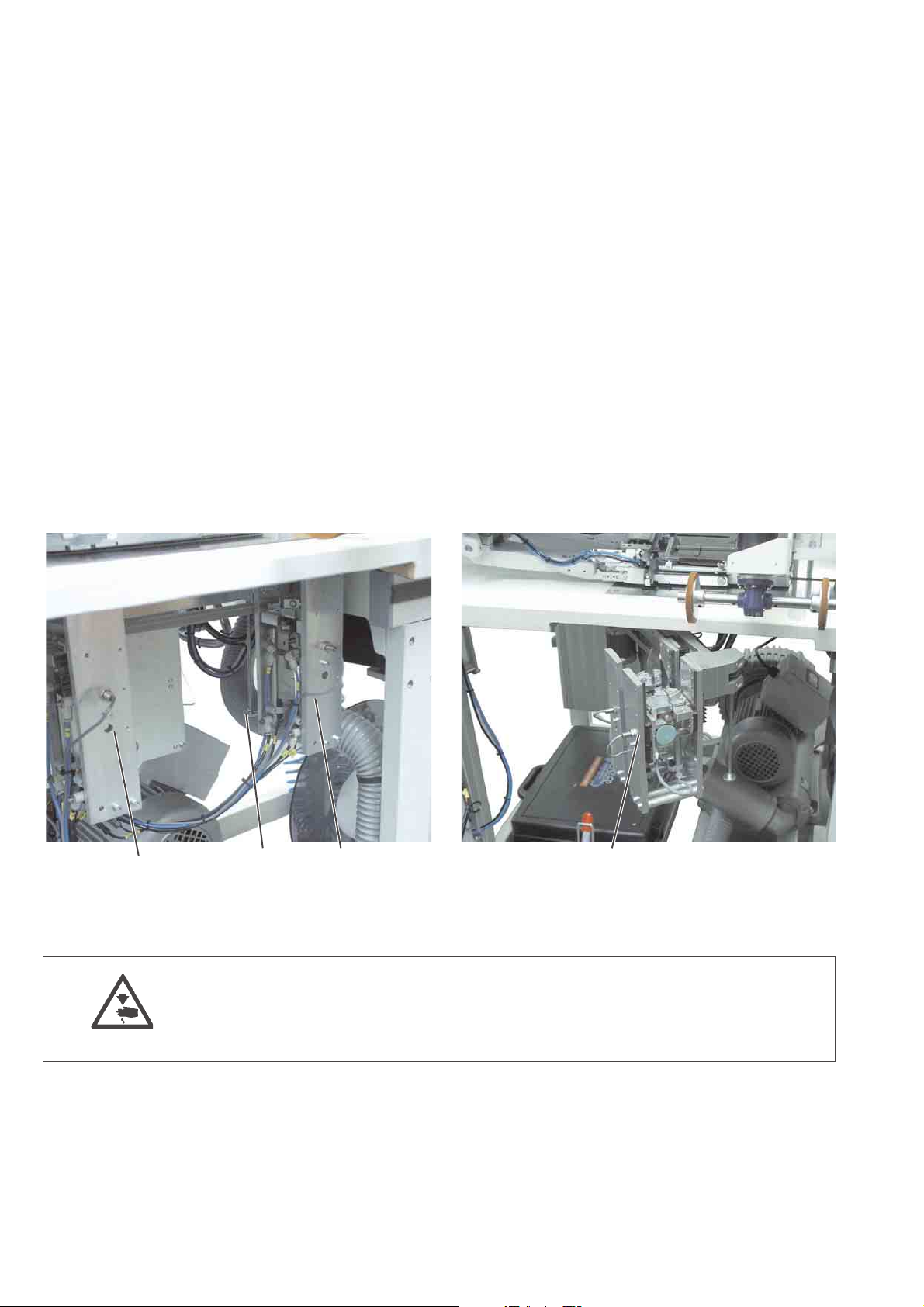

2.7.1 Swivelling the corner knife station in and out

12

321

The corner knife station 1 can be swivelled out completely.

Caution: Risk of injury!

Switch the main switch off.

Swivel the corner knife station out only with the sewing unit

switched off.

Swivelling the corner knife station out

–

Push the rear corner knife support 3 (seam beginning) to the left.

–

Pull catch 2 down.

–

Swivel the corner knife station 1 to the left.

The knives are accessible for adjusting and servicing.

1

Page 17

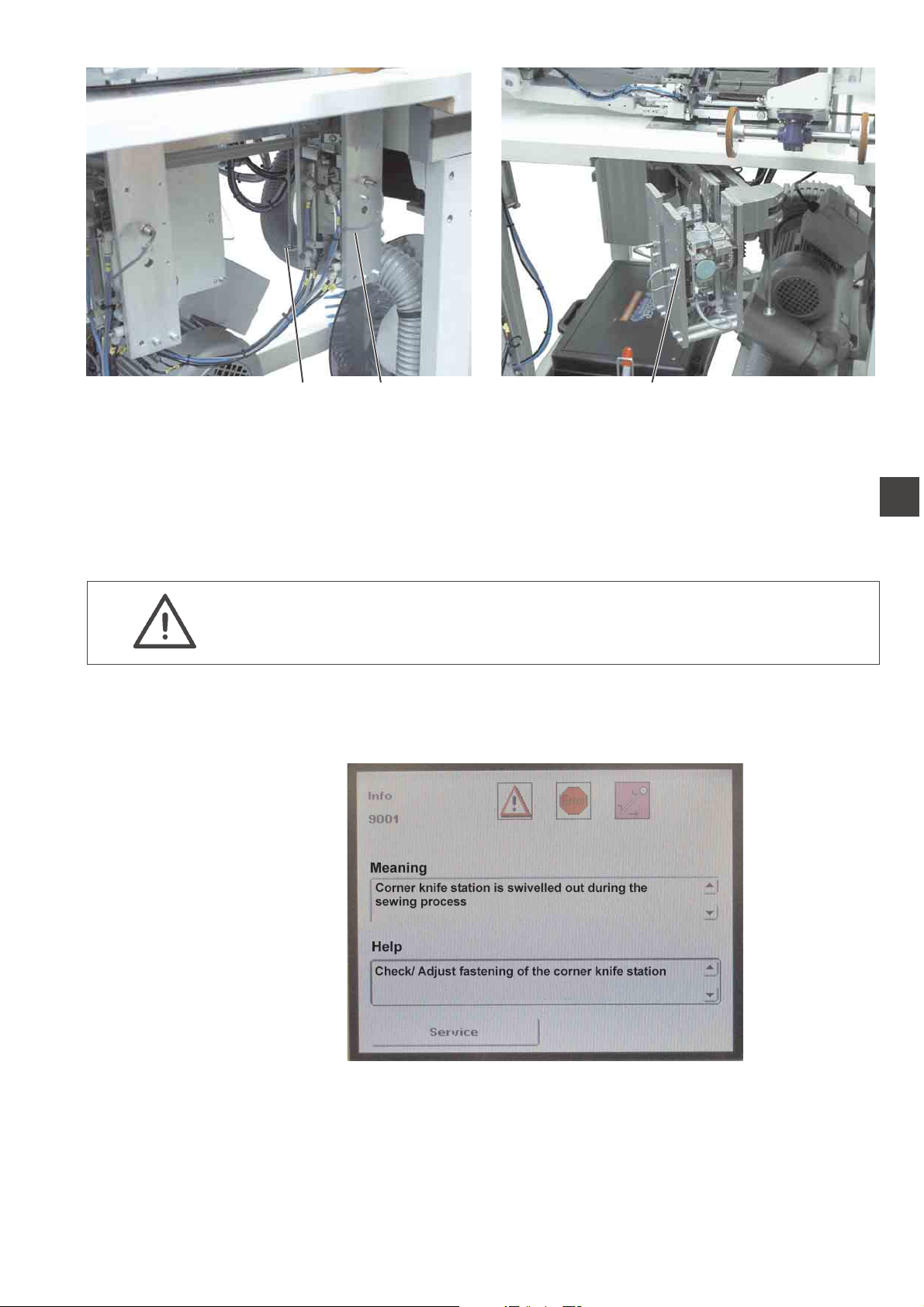

21

Swivelling the corner knife station in

–

Swivel the corner knife station 1 back under the sewing unit.

–

Pull catch 2 down.

–

Swivel the corner knife station 1 in completely.

–

Release catch 2.

ATTENTION: Risk of breakage!

The holder 2 must snap in audibly.

Note:

If the corner knife station is swivelled out with the sewing unit switched

on, the following message appears:

1

1

13

Page 18

3. Switching on - Starting the sewing process - Program stop Switching off

21

3.1 Switching on

–

switch the main switch 1 on (turn in clockwise direction).

The control loads the machine program.

The start screen appears in the display of the control panel and

indicates the following message:

–

Press the program stop switch 2.

If the transport clamps are not at the reference position, a

reference run is made.

14

Page 19

3.2 Reference position

Reference position

The reference position is necessary to reach a defined initial position.

When the sewing unit is switched on, the control checks whether the

transport carriage is in its rear end position.

If this is not the case, the display shows the following message:

1

Caution: Risk of injury !

Risk of bruises between folder and deposit table.

–

–

3.3 Starting the sewing process

–

–

–

The individual steps of the feeding process can be cancelled.

Press the program stop switch.

The reference run starts.

The transport carriage moves to its rear end position.

The display changes over to the main screen of the sewing unit.

Actuate the central foot switch.

By actuating the central foot switch repeatedly the different steps

of the feeding process are started one after the other.

The individual steps depend on the working method and on the

equipment of the sewing unit.

For feeding corrections:

Actuate the right foot switch or press the reset key.

The last step of the feeding process is cancelled.

The workpiece can be fed anew.

Step the central foot switch to the front.

The sewing process starts.

15

Page 20

3.4 Program stop

For an immediate switch-off of the sewing unit in case of operating

errors, needle breakage, material accumulation etc. the safety system

of the 100/68 will react as follows:

–

Press program stop 1.

The sewing process is stopped immediately.

3.5 Switching off

1

–

Switch the main switch 2 off (turn counter-clockwise).

16

2

Page 21

4. Working methods

The individual working methods for trousers and men’s jackets are

described on the following pages.

The description is structured as follows:

Feeding positions

This item indicates the feeding points for the different workpieces (e.g.

left and right parts).

Aligning the positioning aids

Here you will find a description how to adjust and align the positioning

aids (e.g. positioning marks, marking lamps, guides etc.).

Feeding and starting the sewing process

Here you will find a list of the individual feeding steps with

practice-oriented examples.

1

ATTENTION!

The steps of the feeding process are dependent on the equipment of

the respective sewing unit.

So the feeding steps described in the examples apply to sewing units

with the same equipment only.

Caution: Risk of injury!

Do not reach under the downholder, the transport clamp and the folder

during the feeding process.

17

Page 22

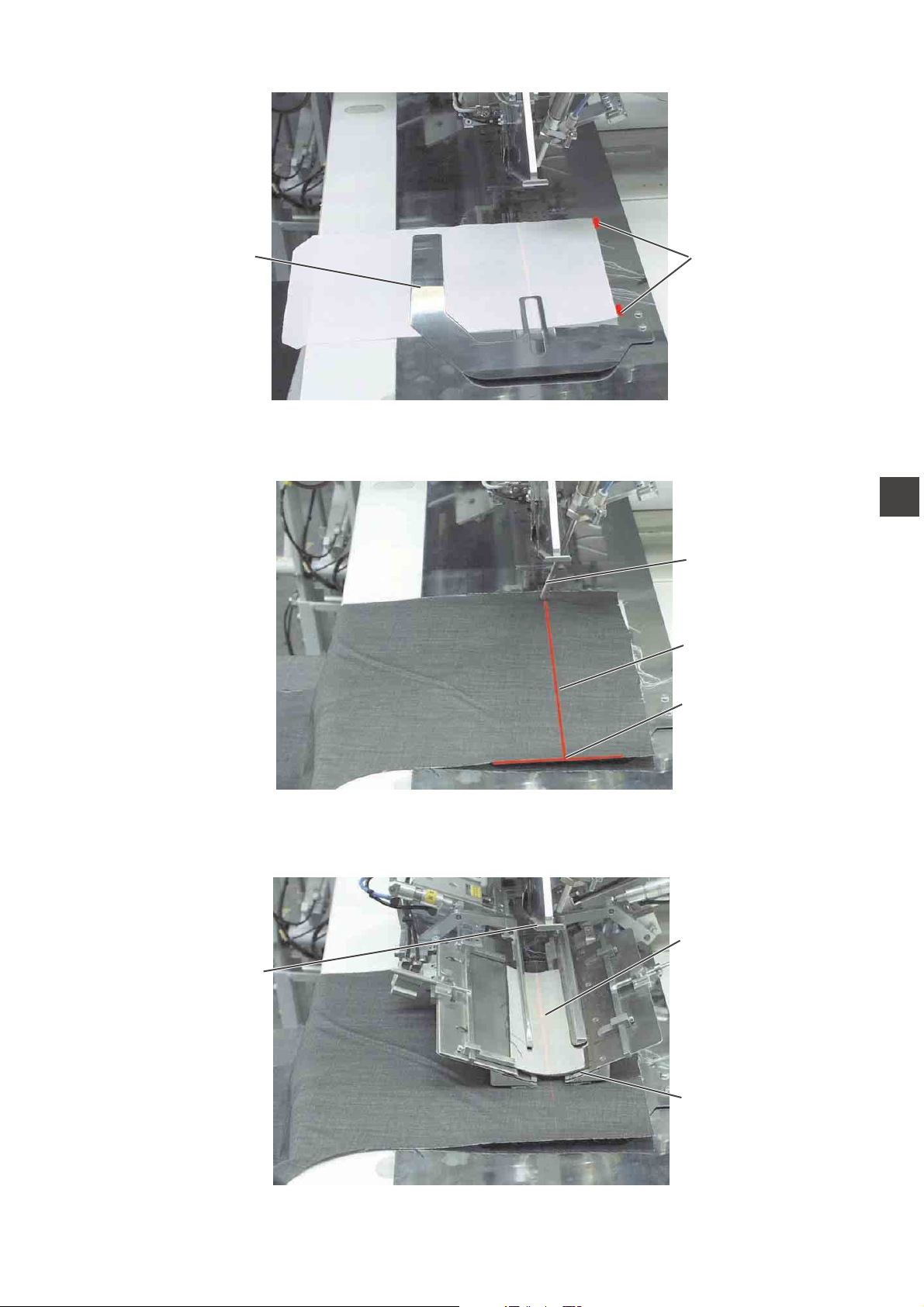

4.1 Working method “Production of trousers”

Possible processing variants

–

Front trousers pockets with pocket bag positioned underneath

–

Hind trousers pockets with or without flap, with pocket bag

positioned underneath

–

Hind trousers pockets with or without flap, with automatically fed

reinforcement strip

Feeding method

Example: Hind trousers without flap, with pocket bag positioned

underneath

1st step:

–

Select the pocket program at the control panel

–

Push the pocket bag under the pocket bag clamp 1 and position it

at the markings 2.

For example adhesive strips fitted on the fabric sliding sheet may

serve as markings.

2nd step:

–

Position the hind trousers at the “central positioning point” 5 and

the marking 4.

–

Actuate the central foot switch.

The hind trousers is clamped by the fabric downholder 3.

–

Smooth out the clamped hind trousers in the dart area.

–

If the machine is additionally equipped with vacuum:

Actuate the left foot switch.

The vacuum is switched on.

3rd step:

–

Actuate the central pedal.

The transport clamps move to the front and lower on the

workpiece.

–

Position the piping strip 6 on the transport clamps flush with the

front edges 7.

The aligning of the various kinds of piping on the transport clamps

is described more exactly in the following.

See “Positioning of piping strips”.

–

Actuate the central pedal once again.

The folder 8 lowers.

–

Actuate the central foot switch once again.

The sewing process starts.

18

Page 23

1

2

1

3

4

5

6

8

7

19

Page 24

4.2 Working method “Breast welt pocket”

Processing patterned or plain-coloured fabrics

When processing plain-coloured fabrics it is not necessary to align

men’s jacket fronts and breast welts as per pattern.

Thus, plain-coloured fabrics can be processed more quickly.

- Align positioning aids

Feeding method

Example: Men’s jacket front with breast welt pocket, patterned fabric

1st step:

–

Select pocket program No. 7 at the control panel.

–

Position breast welt 1 on the jacket front as per the stripes.

–

Align the breast welt of the jacket front at the laser markings 2 and

3 (right and bias laser).

–

Step on the start pedal.

The vacuum is switched on.

The jacket front is sucked.

2nd step:

–

Remove breast welt 1.

–

Position pocket bag 4 at the left laser.

–

Step on the central pedal.

The fabric clamps move to the front.

The right clamp 6 clamps the jacket front.

The left clamp 7 remains pressureless.

3rd step:

–

Position breast welt 8 at the stop of the left fabric clamp (at the

front laser).

–

Fold back seam allowance 10 at the clamp and check the course of

the pattern in longitudinal direction.

Correct the course of the pattern by slightly pulling the jacket front

or by shifting the flap clamp 9.

–

Step on the central pedal.

Pressure is applied on the left fabric clamp 7.

–

Actuate the central pedal.

The folder lowers.

–

Actuate the central pedal once again.

The sewing process starts.

20

Page 25

2

1

3

1

4

5

987 6

10

21

Page 26

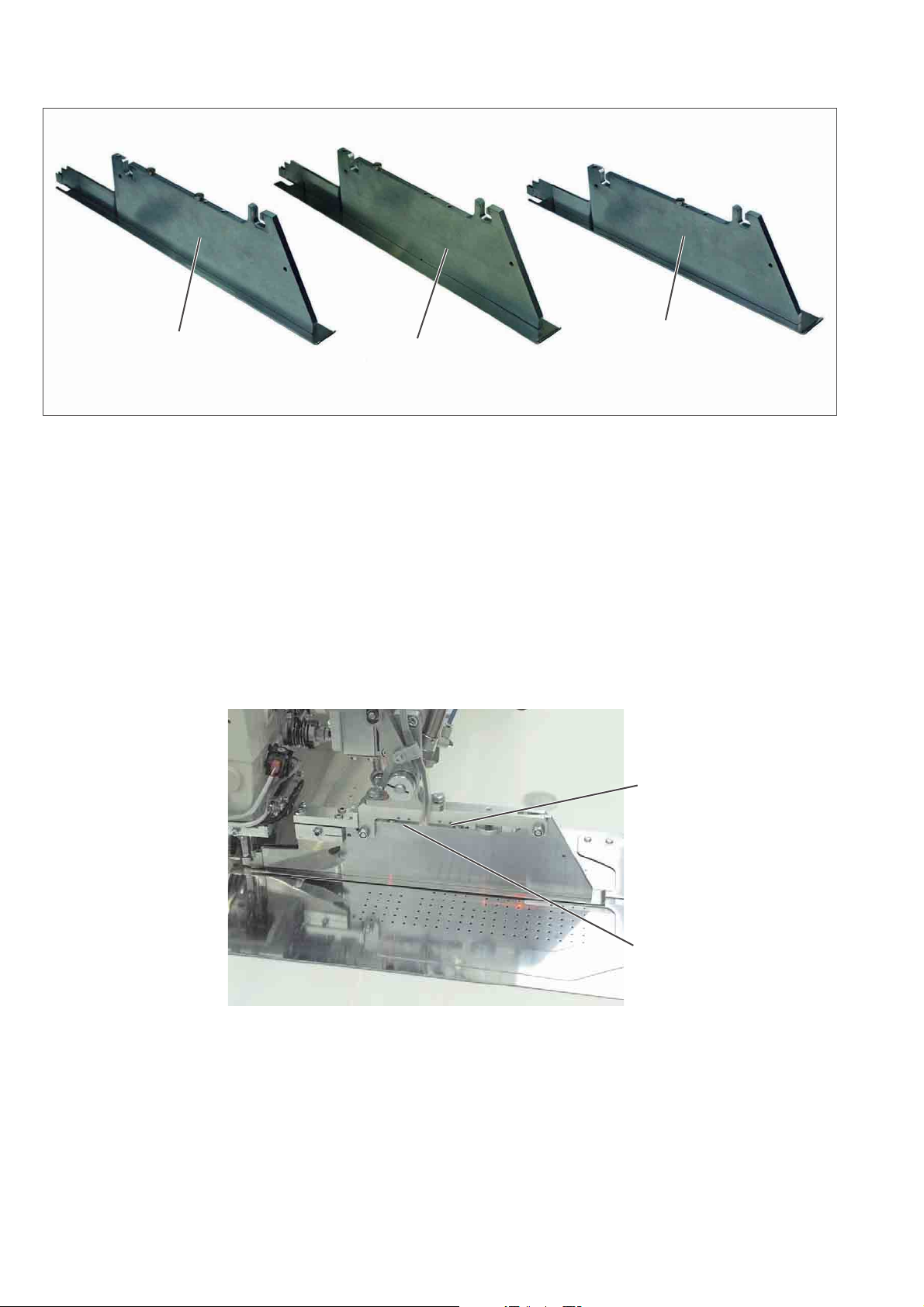

5. Quick clamp adjustment and folder monitoring

1

The lateral position of the transport clamps is influenced by the

solenoid switches SC103 and SC106.

According to the equipment the magnets are fitted on the folders in

different positions.

Depending on the selected folder the clamps are adjusted

automatically.

1 = Folder for double piping

2 = Folder for single piping, left

3 = Folder for single piping, right

2

3

SC103

22

SC106

Page 27

6. Function and operation of the optional equipment

This chapter describes the function and operation of the most

important

optional equipment.

6.1 Tape feeding unit with automatic trimming and tape monitor

The step motor- and length-controlled tape feed with automatic

trimming transports the reinforcement strip under the pocket opening

and cuts it off at the seam end (e.g. when sewing inside and outside

pockets of men’s jackets).

A sensor supervising the tape feed is integrated in the tape feeding

unit.

The whole sequence is realized within the machine time

so that there are no further feeding or secondary processing times.

If the tape is not pulled during the sewing process, e.g. in case of

accumulation or wrong threading, a message is produced by the

control.

1

Activating and switching the tape feed on

–

Activate the tape feed at the control panel in the menu item “Seam

functions”.

–

Tap the icon.

23

Page 28

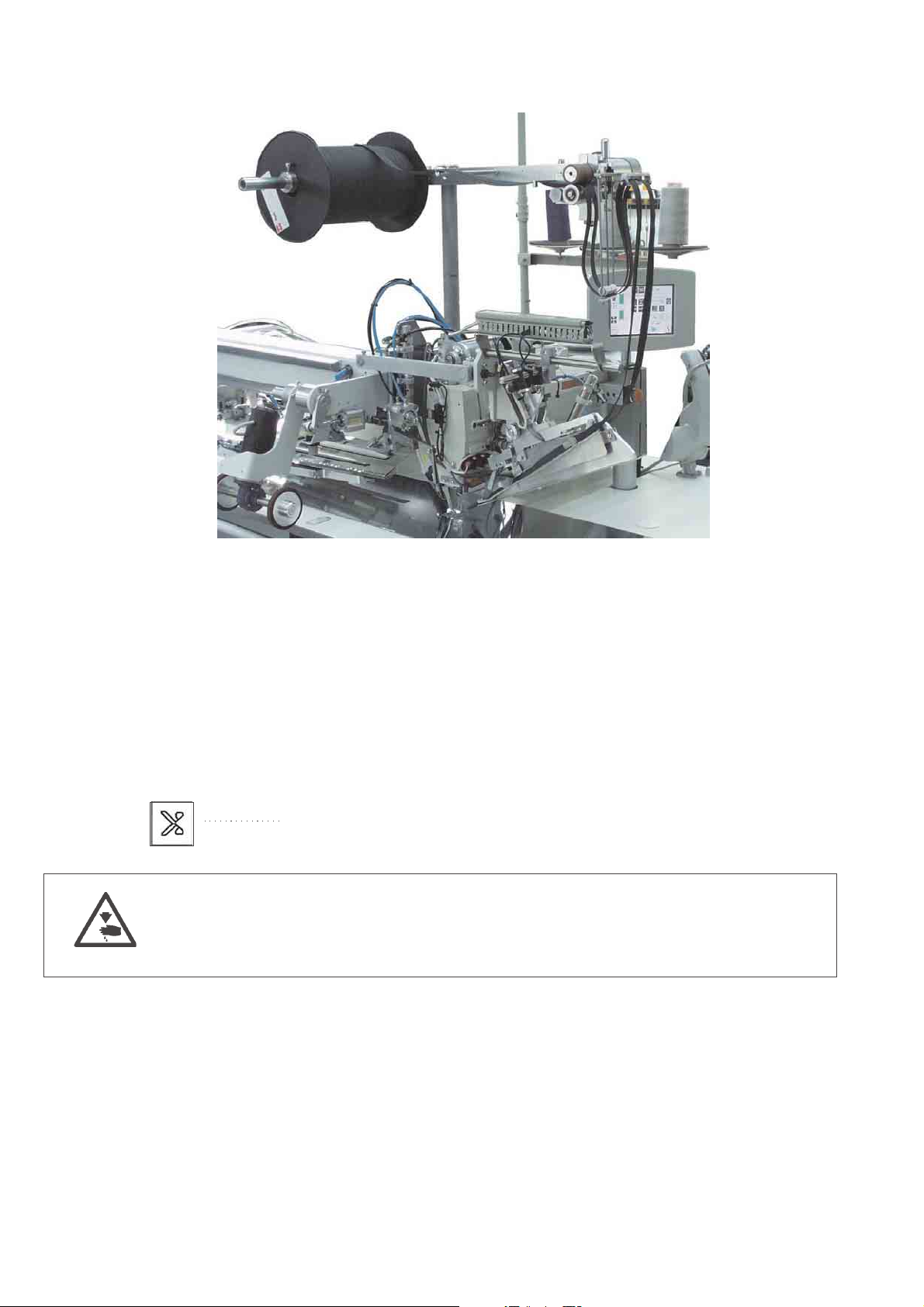

21

54 3

24

98 7

11 10

5

3

Page 29

Inserting the reinforcement strip

–

Put roll 1 on the tape roll holder 2.

The full roll must rotate in the indicated arrow direction

(counter-clockwise) when unwinding.

–

Guide the reinforcement strip via guide 5.

–

Swivel the fabric sliding sheet 9 aside.

–

Press slide 7 backwards and lift off cover 8.

–

Insert the reinforcement strip in the feeding device according to the

sketch.

–

Swivel the fabric sliding sheet 9 back again.

–

Tap the key.

The reinforcement strip is cut off and moved to the initial position.

Function and operation

Before the next sewing cycle the reinforcement strip is fed forward a

little by the transport roller of the feeding device.

When sewing the pocket opening the reinforcement strip is seized and

sewn in according to the set sewing length.

The tape projection at the seam beginning and seam end can be set in

the menu item “Seam parameters” with the parameters 21 and 22 (see

programming instructions).

1

25

Page 30

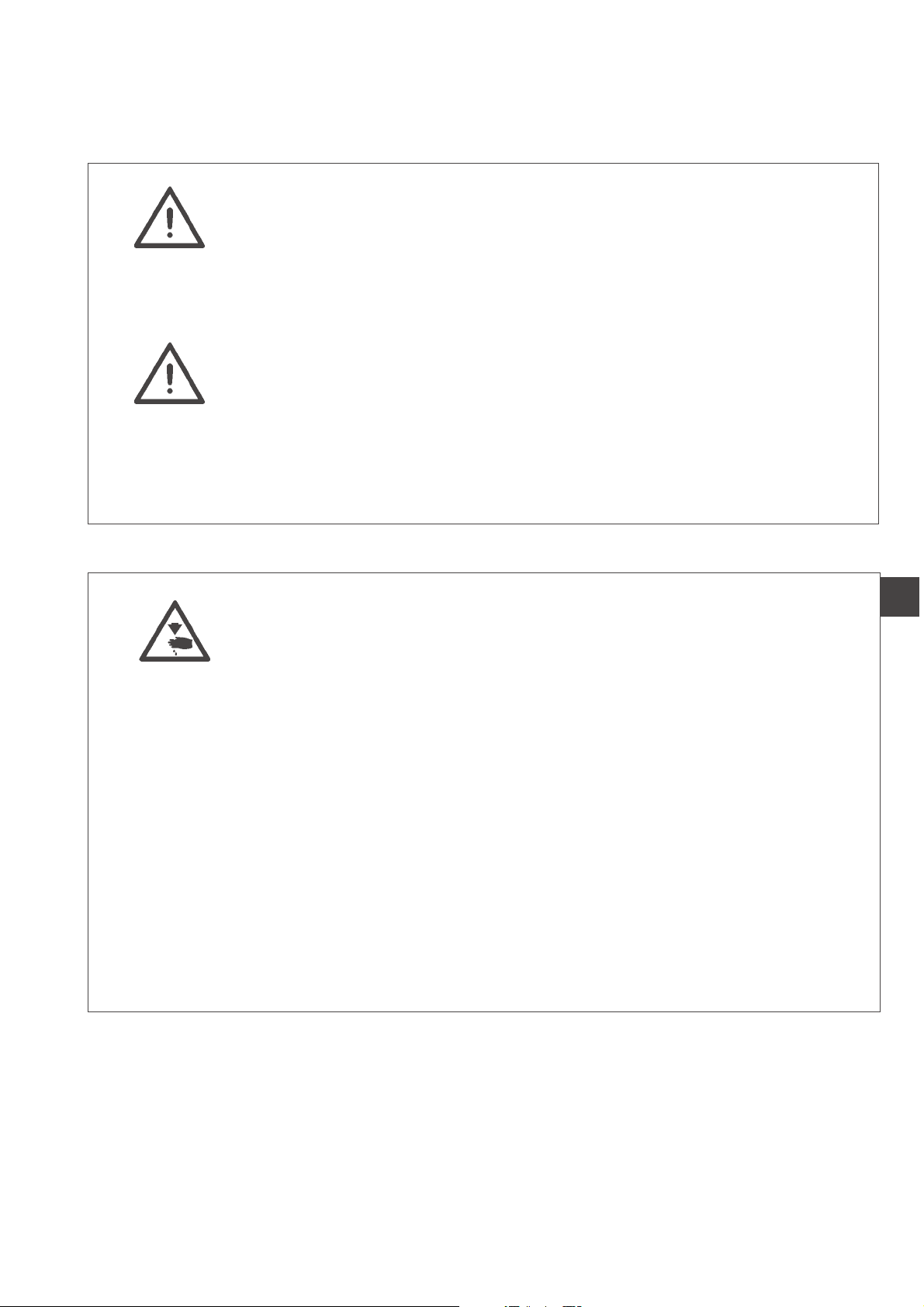

6.2 Endless zipper device

Function

When the zipper halves are pulled by the transport clamps during the

sewing process, the feed rod 6 is pulled upwards by the zipper getting

shorter.

The feed rod switches the zipper feed on and the drive rollers 7 and 8

go on feeding the zipper until the switch rod drops and switches the

feed off again.

Thus it is made sure that there is always enough zipper material

available for sewing.

Activating and switching the zipper device on

–

Tap the key.

The zipper device is activated.

Caution: Risk of injury !

During the swivelling and cutting process.

26

Page 31

7. Maintenance

7.1 Cleaning

Caution: Risk of injury!

Switch the main switch off.

Carry out maintenance work only with the sewing unit switched off.

1

43 21

A clean sewing unit protects from malfunction!

Clean and check daily:

–

Clean the area around the hooks 2 and 3 with the compressed air

pistol.

–

When changing the bobbin always clean the lenses of the light

barriers 1 and 4

of the remaining thread monitor with a soft cloth.

–

Cleaning of the filter ring 6 at the vacuum valve 5:

Blow out with compressed air pistol.

Clean and check daily:

–

Check the water level in the pressure regulator.

The water level must not reach the filter insert.

After screwing in the drain screw 2 blow the water

out of the water separator 1 under pressure.

The filter insert separates dirt and condensed water. After a certain

time of operation

wash the dirty filter tray and the filter insert with benzine and blow

them clean with the compressed air pistol.

21

65

ATTENTION!

Do not use any solvents for washing out the filter tray and the filter

insert!

They destroy the filter tray.

27

Page 32

7.2 Oil level control

For lubrication of the sewing machine head use exclusively the

lubricating oil

ESSO SP-NK 10.

SP-NK 10 can be bought from the sales office of Beisler GMBH

.

Checking the oil level in the oil reservoir 2 for the lubrication of

the machine head

–

The oil level in the oil reservoir 2 must not drop below the marking

“Min”.

–

If necessary, fill oil through the drill-hole 1 up to the upper marking.

21

28

Page 33

Index Page:

Part 2: Assembly instructions 100/68

1. Scope of delivery ............................................. 3

2. General notes ............................................... 3

3. Electrical connection ........................................... 4

3.1 Connecting the DACIII control panel ................................... 4

3.2 Making the mains connection ....................................... 4

4. Pneumatic connection .......................................... 5

5. Connection to the factory-own vacuum unit ............................ 6

6. Putting into operation .......................................... 7

222

Page 34

Page 35

1. Scope of delivery

–

Basic sewing unit for runstitching the openings of piped pockets,

flap pockets and welt pockets with rectangular and slanted pocket

corners, consisting of:

–

Step motors for material feed, length adjustment of the corner

trimming device

DC direct sewing drive

–

Twin needle lockstitch machine

–

DACIII control with control panel

–

Laser marking lamps

–

Sewing lamp (optional)

–

Compressed air maintenance unit with compressed air pistol

–

Thread reel holder

–

Material trays for additional parts to the right of the operator

and under the table top

–

Tools and small parts in the accessories

–

Feeding devices and sewing equipment according to the

working method

–

Optional equipment

2. General notes

ATTENTION !

The sewing unit must only be installed by trained specialist staff.

Any work on the electrical equipment of the sewing unit must

only be carried out by electricians or correspondingly instructed

persons.

The mains plug must be pulled out.

The enclosed operating instructions of the step motor manufacturer

have to be observed by all means.

3

Page 36

3. Electrical connection

ATTENTION!

Any work on the electrical equipment of the sewing unit must

only be carried out by electricians or correspondingly instructed

persons.

The mains plug must be pulled out.

3.1 Connecting the DACIII control panel

321

–

–

–

3.2 Making the mains connection

–

Put the control panel 1 in the holder 2 and screw it tight.

Push the plug 3 into the control panel cautiously.

Secure the plug with the two screws.

Connect the mains plug.

4

Page 37

4. Pneumatic connection

For the operation of the pneumatic components the sewing unit has to

be provided with anhydrous compressed air.

ATTENTION!

For a trouble-free function of the pneumatic control processes the

compressed air net has to be rated as follows:

Even in the moment of maximum air consumption the minimum

operating pressure must not drop below 6 bar.

In case of a too high air pressure decrease:

–

Increase the compressor output.

–

Increase the diameter of the compressed air supply line.

4321

Connecting the compressed air maintenance unit

–

Connect the connecting hose 4 to the shut-off valve 3 and to the

compressed air net.

Setting the operating pressure

–

The operating pressure amounts to 6 bar.

It can be read off at the manometer 2.

–

For setting the operating pressure pull up and turn the rotary

handle 1.

–

Turn in clockwise direction = increase the pressure

–

Turn counter-clockwise = reduce the pressure

2

ATTENTION !

No oil-bearing compressed air must be fed from the compressed air

net.

Behind the filter cleaned compressed air is withdrawn as blowing air

for cleaning machine parts and for blowing workpieces out.

Oil particles contained in the blowing air lead to malfunction and stains

on the workpieces.

5

Page 38

5. Connection to the factory-own vacuum unit

1

The suction unit facilitates the precise feeding and positioning of the

workpiece on the worktable 1.

–

Connect the hose of the factory-own vacuum unit to the connection

2.

Note:

If no factory-own vacuum unit is available, a vacuum unit has to be

ordered additionally.

2

6

Page 39

6. Putting into operation

After completion of the installation work a sewing test should be made.

–

Plug in the mains plug.

Caution: Risk of injury!

Switch the main switch off before threading the needle and hook

thread.

–

Threading the needle thread (see operating instructions).

–

Threading the hook thread (see operating instructions).

–

Switch the main switch on.

The main screen is displayed.

–

By actuating the central foot switch the different steps of the

feeding process are released one after the other and the sewing

process starts.

The individual steps depend on the working method and on the

equipment of the sewing unit.

ATTENTION !

Please take care that material is positioned under the transport clamps

at the sewing start.

Moving the transport carriage without material may damage the coating

of the transport clamps.

2

–

For the selection of the sewing program and for further settings of

the control unit see part 4: Programming instructions 100/68

–

For feeding and operating see part 1: Operating instructions 100/68

7

Page 40

Page 41

Index Page:

Part 3: Service instructions 100/68

1. General notes ................................................ 3

1.1 Raising/ Lowering the sewing machine head .............................. 4

2. Transport carriage ............................................. 6

2.1 Rear end position .............................................. 6

2.1.1 Position of the limit switch in the slotted hole .............................. 7

2.1.2 Distance between switching screw and limit switch .......................... 7

2.1.3 Stop guide for transport carriage ..................................... 7

2.2 Front end position .............................................. 8

2.2.1 Distance between switching screw and limit switch .......................... 9

2.2.2 Front end position of the transport carriage ............................... 9

2.2.3 Stop guide for the transport carriage ................................... 9

2.3 Toothed belt tension ............................................. 10

3. Transport clamps.............................................. 12

3.1 Transport clamp stroke ........................................... 12

3.2 Parallelism of the transport clamps .................................... 13

3.3 Distance between the transport clamps and the sole of the folder ................. 14

3.4 Parallelism of main clamp and sliding sheet .............................. 15

3.5 Folding slides................................................. 16

3.5.1 Adjusting travel and parallelism of the folding slides ......................... 16

3.5.2 Position of the folding slide when retracted ............................... 17

3.5.3 Adapting the folding slide ......................................... 18

3.6 Flap clamp .................................................. 19

3.6.1 Flap clamp position ............................................. 19

3.6.2 Opening stroke of the flap clamp ..................................... 20

3.7 Changing the rubber strips of the clamp ................................. 21

4. Folder ..................................................... 22

4.1 Changing the folder ............................................. 22

4.2 Position of the folder to the needles and to the centre knife ..................... 23

4.3 Lifting motion of the folder ......................................... 24

4.4 Guide plates at the folder ......................................... 26

3

5. Trimming and clamping device for the needle threads ...................... 28

5.1 Function .................................................... 28

5.2 Exchanging and adjusting knife and thread catcher .......................... 29

6. Centre knife ................................................. 30

6.1 Position of the centre knife ......................................... 30

6.2 Needle protection .............................................. 31

Page 42

Index Page:

7. Adjusting the bobbin thread catcher ................................. 32

7.1 Thread catcher ................................................ 32

8. Knives for corner incision

8.1 Presetting ................................................... 33

8.2 Belt tension .................................................. 34

8.3 Aligning the corner knife station as to the seams ........................... 35

8.4 Adjusting the slant of the corner incisions ................................ 37

8.5 Exchanging the corner knives ....................................... 38

9. Laser markings ............................................... 39

10. Photocells for flap scanning....................................... 40

11. Fabric sliding sheet and vacuum plate ................................ 41

11.1 Adjusting the height of the vacuum plate ................................ 41

12. Adjusting the optional equipment ................................... 42

12.1 Downholder .................................................. 42

12.2 Ejector roller ................................................. 43

12.3 Zipper scissors ................................................ 44

13. Hook lubrication .............................................. 48

14. Locator and tooth belt disc ....................................... 49

15. Maintenance................................................. 50

2

Page 43

1. General notes

The service instruction manual on hand describes the adjustment of

the sewing unit 100/68 in an appropriate sequence.

ATTENTION !

Some of the setting positions are interdependent.

Therefore it is absolutely necessary to do the adjustment following the

described order.

The operations described in the service instructions must only be

executed

by qualified staff and correspondingly instructed persons respectively!

Risk of breakage !

Before the sewing unit is put into operation again after having been

disassembled the necessary adjustments have to be carried out

according to the service instructions.

Before any adjusting operations of parts involved in the stitch

formation are made:

–

Insert a new needle without any damage.

Caution: Risk of injury !

Before repair, converting and maintenance work is done:

–

Switch the main switch off and disconnect the sewing unit from the

pneumatic

supply system.

Exception: Adjusting operations carried out with the help of test or

setting programs.

Adjusting operations and function tests when the sewing unit is

running

–

Carry out adjusting operations and function tests of the running

sewing unit

only under observation of all safety measures and with

utmost caution.

Adjusting operations in the needle zone

–

Parts which can lead to injuries have to be removed before

carrying out the adjusting operations.

Exception:

The parts are absolutely necessary for the adjusting operations.

3

3

Page 44

1.1 Raising/ lowering the sewing machine head

For maintenance and repair work the machine head can be raised.

For this purpose the transport carriage must be in its rear position.

Caution: Risk of injury!

Switch the main switch off.

Raise or lower the machine head only with the sewing unit switched

off.

1 2

43

4

Page 45

Raising the machine head

–

Swivel the folding station 1 aside by 90°.

–

Swivel the fabric sliding sheet 2 to the left.

–

Unscrew the fastening screw 6.

–

Loosen the screw at the locking lever 4 and raise the holder.

–

Tighten the screw.

–

Lift the machine head in the area of the head cover 3 and raise it

cautiously.

The area underneath the sewing machine head is accessible for

cleaning and adjusting now.

Caution: Risk of injury!

Do not reach into the cutout of the table top when the machine head is

raised.

Swinging the machine head back

–

Hold the machine head tight.

–

Lift the machine head cautiously until catch 5 releases.

–

Lower the machine head cautiously into the cutout of the table top.

–

Swivel the fabric sliding sheet back again and let it catch.

–

Loosen the screw at the locking lever 4.

–

Swivel the lever downwards.

–

Tighten the fastening screw 6 again.

–

Swivel the folding station back until it snaps in catch 5.

–

Tighten the screw at the locking lever 4.

3

452

6

5

Page 46

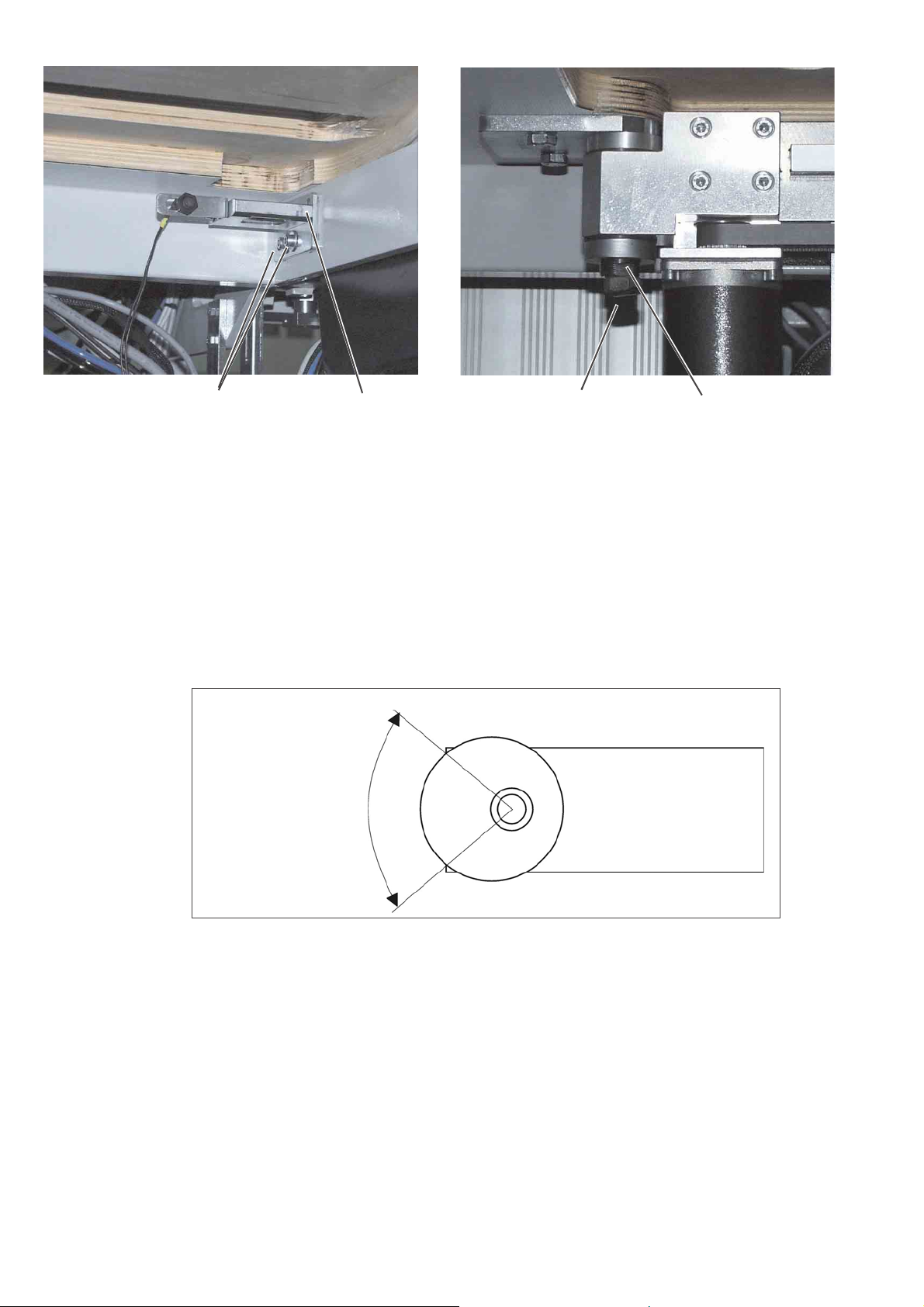

2. Transport carriage

2.1 Rear end position

432 1

Standard and checking

The switch 1 determines the rear end position of the transport carriage.

It must always be in the very rear of the slotted hole 2.

When the transport carriage is in its end position, there must be a

distance of 1 mm between the limit switch 1 and the switching screw 4.

When the transport carriage has gone back so far that the switching

screw 4 stands centrically under the switch 1, there must be a distance

of 2 mm between the transport carriage 5 and the stop 6.

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the switch and the stop for the rear end position of

the transport carriage only with the sewing unit switched off.

76 5

8

9

6

Page 47

2.1.1 Position of the limit switch in the slotted hole

Checking

–

Unscrew the screws 8 and take off the covering cap 9.

–

Check the position of the limit switch 1 in the slotted hole 2.

Correction

–

Loosen the upper counternut at the limit switch 1.

–

Push the limit switch to the very rear of the slotted hole.

–

Tighten the upper counternut again.

Attention: Risk of breakage !

After operations on the limit switch always check the distance to the

switching screw 4.

2.1.2 Distance between switching screw and limit switch

Checking

–

Push the transport carriage 5 to the rear until the switching screw 4

is located under the limit switch 1.

–

Check the distance of 1 mm between limit switch 1 and switching

screw 4.

Correction

–

Loosen the counternut 3 at the switching screw 4.

–

Adjust the height of screw 4.

Distance between switching screw and limit switch=1mm.

–

Tighten the counternut 3.

3

2.1.3 Stop guide for the transport carriage

Checking

–

Push the transport carriage 5 to the rear until the surface of the

switching screw 4 is located centrically above the limit switch 1.

–

Check whether in this transport carriage position the distance

between the stop guide 6 and the transport carriage amounts to 2

mm.

Correction

–

Push the transport carriage to the rear until the surface of the

switching screw 4 is located centrically above the limit switch 1.

–

Loosen the counternut 7.

–

Approach the stop guide 6 to the transport carriage by 2 mm.

–

Tighten the counternut 7.

7

Page 48

2.2 Front end position

1 43 12

Standard and checking

The switch 1 determines the front end position of the transport

carriage.

It must be set in such a way that there is a distance of 325 mm

between the needles and the fronts of the transport clamps when they

have moved to the front.

When the transport carriage is in its front end position, there must be a

distance of 1 mm between the limit switch 1 and the switching screw 4.

When the transport carriage has moved forward so far that the

switching screw 4 stands centrically under the switch 1, there must be

a distance of 2 mm between the transport carriage 7 and the stop 6.

325 mm

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the switch and the stop for the front end position of

the transport carriage only with the sewing unit switched off.

76 5

8

Page 49

2.2.1 Distance between switching screw and limit switch

Checking

–

Push the transport carriage 7 to the front until the switching screw

4 is located under the limit switch 1.

–

Check the distance of 1 mm between limit switch 1 and switching

screw 4.

Correction

–

Loosen the counternut 3 at the switching screw 4.

–

Adjust the height of screw 4.

Distance between switching screw and limit switch=1mm.

–

Tighten the counternut 3.

2.2.2 Front end position of the transport carriage

–

Push the transport carriage 7 to the front until the switching screw

4 is located under the limit switch 1.

–

Measure the distance between the needles and the fronts of the

transport clamp.

This must amount to 325 mm.

–

Adjust the limit switch 1 in the slotted hole accordingly.

2.2.3 Stop guide for the transport carriage

Checking

–

Push the transport carriage 7 to the front until the surface of the

switching screw 4 is located centrically above the limit switch 1.

–

Check whether in this transport carriage position the distance

between the stop guide 6 and the transport carriage amounts to 2

mm.

Correction

–

Push the transport carriage to the front until the surface of the

switching screw 4 is located centrically above the limit switch 1.

–

Loosen the counternut 5.

–

Approach the stop guide 6 to the transport carriage by 2 mm.

–

Tighten the counternut 5.

3

9

Page 50

2.3 Toothed belt tension

12

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the toothed belt tension only with the sewing unit

switched off.

Standard and checking

Over the tightening length S= 300 mm the toothed belt must bend

under the test load FV = 34 N.

Consequences of a too high toothed belt tension

–

Reduced durability

–

Noisy running

Consequences of a too low toothed belt tension

–

No faultless mesh between belt teeth and disc toothing

–

The teeth may skip over under load

–

Non-uniform stitch lengths

–

Loss of steps possible

10

–

Unscrew the screws 1 and take off the covering cap 2.

–

Place the test load in the middle of the toothed belt (e.g. with the

help of a spring balance).

The tension of the toothed belt is correct if the upper belt half just

touches the lower one.

Page 51

43

Correction

–

Loosen the counternut 3.

–

Adjust the toothed belt tension with the Allen screw 4.

–

Tighten the counternut 3.

3

11

Page 52

3. Transport clamps

3.1 Transport clamp stroke

32 1

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the transport clamp stroke only with the sewing unit

switched off.

Standard and checking

When the flap clamps 3 are closed, the raised transport clamps 1 and 2

must pass the machine arm without hitting it.

The distance between the front edges of the raised transport clamps

and the fabric sliding sheet should amount to 28 mm on the left and on

the right.

–

Push the transport carriage under the machine arm.

–

Check the stroke of the two transport clamps.

Correction

–

Loosen screw 4.

–

Adjust the height of the transport clamps.

–

Tighten the screws 4.

4

12

Page 53

3.2 Parallelism of the transport clamps

321 654

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the parallelism of the transport clamps only with the

sewing unit switched off.

standard and checking

The transport clamps 1 and 2 should run parallel to the edge of the

sliding sheet 3.

–

Push the transport carriage to the front.

–

Check the distance of the transport clamps to the edge of the

sliding sheet.

Correction

–

Loosen the screws 4 and 6.

–

Adjust the transport clamps with the screws 5 so that they are in

parallel position to the edge of the sliding sheet.

–

Tighten the screws 4 and 6.

3

13

Page 54

3.3 Distance between the transport clamps and the sole of the folder

21

Standard and checking

There must be a certain distance between the outer edges 1 of the

folder sole and the inner edges 2 of the transport clamps. When

processing medium-weight materials the distance should amount to

approx. 1.0 to 1.5 mm.

The distance is necessary to guarantee uniform piping strips on both

sides as well as an unhindered material feed.

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the transport clamps only with the sewing unit

switched off.

Attention: Risk of breakage !

Before adjusting the folder has to be correctly aligned (see chapter

“4.2 Position of the folder as to the needles and the centre knife”).

–

Push the transport carriage to the front.

–

Let the compressed air off.

–

Lower the folder.

–

Check the distance between folder sole and transport clamps.

54 3

14

Correction

–

Adjust the clamping arm 4 with the knurled nuts 3 and 5.

Page 55

3.4 Parallelism of main clamp and sliding sheet

1

Caution: Danger of injury!

Switch the main switch off.

Check and adjust the transport clamps only with the sewing unit

switched off.

Standard and checking

The main clamp 1 must be in parallel position to the sliding sheet over

its whole length.

–

Move the clamp to the feeding position.

–

Place thin fabric under the clamping arms.

–

Close the main clamp.

–

Pull the fabric out to the side and check for equal distance.

Correction

–

Loosen the counternuts 2.

–

Adjust the pressure with the Allen screws 3.

–

Tighten the counternuts 2 again.

32

3

15

Page 56

3.5 Folding slides

3.5.1 Adjusting travel and parallelism of the folding slides

21

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the folding slides only with the sewing unit

switched off.

Standard and checking

According to the needle distance the folding slides 1 and 2 have to be

shifted by the following values when extending and retracting.

Needle distance 10 mm = approx. 3.5 mm

·

Needle distance 12 mm = approx. 4.5 mm

·

Needle distance more than 14 mm = max. stroke

·

–

Check the distance of the folding slides.

Correction

–

Loosen the screws 3.

–

Adjust the cylinder 4 correspondingly.

–

Align the folding slides in parallel position.

–

Tighten the screws 3.

–

Check distance and parallelism of the folding slides once again.

43

16

Page 57

3.5.2 Position of the folding slide when retracted

21

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the folding slide only with the sewing unit

switched off.

Standard and checking

When retracted the folding slide 2 must be located

0.5 mm behind the edge of main clamp 1.

–

Check the position of the folding slide.

Correction

–

Loosen counternut 3.

–

Adjust the screw 4 in such a way that the folding slide 2 is located

0.5 mm behind the edge of main clamp 1.

–

Tighten the screws 4.

43

3

17

Page 58

3.5.3 Adapting the folding slide

321

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the folding slide only with the sewing unit

switched off.

Standard and checking

The rotation of the folding slide 1 must be guaranteed so that it can

automatically adapt itself to the thickness of the material to be

processed.

The folding slide 1 must have no axial backlash.

–

Check the folding slide 1 in the holder for lateral clearance.

Correction

–

Loosen the counternut 2.

–

Adjust the folding slide with Allen screw 3 in such a way that there

is neither clearance nor rough rotation.

–

Tighten the counternut 2.

18

Page 59

3.6 Flap clamp

3.6.1 Flap clamp position

5mm

21 43

Caution: Danger of injury!

Switch the main switch off.

Check and adjust the flap clamp only with the sewing unit switched off.

Standard and checking

The flap clamps 2 must have a distance of 5 mm parallel to the inside

of the main clamp 1.

–

Close the flap clamp manually.

–

Check the distance between flap clamp 2 and the inside of main

clamp 1.

Correction

–

Loosen the screws 4.

–

Shift the flap clamp holder 3 correspondingly.

–

Tighten the screws 4.

3

19

Page 60

3.6.2 Opening stroke of the flap clamp

32 1

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the flap clamp with utmost caution when the sewing

unit is switched on.

Standard and checking

The opening stroke of the flap clamp 3 must be adjusted in such a way

that the whole length of the flap clamp is pressed against the main

clamp when the flap clamp cylinder 2 is extended.

–

Switch the sewing unit on.

–

Close the flap clamp.

–

Check whether the flap clamp is pressed against the main clamp

over its whole length.

Correction

–

Loosen the screws 1.

–

Shift the cylinder 2 correspondingly.

–

Tighten the screws 1.

20

Page 61

3.7 Changing the rubber strips of the clamp

52 1 34 3

Caution: Risk of injury!

Switch the main switch off.

Dismount and mount the main clamp only with the sewing unit switched

off.

Standard and checking

There are sponge rubber strips under the main clamps. In case of

material processing problems the rubber strips should be checked and

replaced, if required.

–

Check the rubber strips.

Correction

–

Unscrew the screws 5.

–

Take the clamp off.

–

Unscrew the screws 3.

–

Exchange the rubber strips 4 and tighten with the screws 3.

–

Mount the clamp again.

Note

When processing thick fabrics it is of advantage to equip the clamp

with a thicker rubber strip or to fit an elevation.

3

21

Page 62

4. Folder

4.1 Changing the folder

21

Caution: Risk of injury!

Switch the main switch off.

Dismount and mount the folder only with the sewing unit switched off.

Dismounting the folder

–

Loosen the screw 4.

–

Pull the folder 3 to the front out of the drill-holes 1 and 2.

–

Cautiously remove the folder in downward direction.

Inserting the folder

–

Insert the folder 3 in the holder with its fastening drill-holes 1 and 2

on top and push it to the very back.

–

Tighten the screw 4.

43

22

Page 63

4.2 Position of the folder to the needles and to the centre knife

321

Caution: Risk of injury!

Switch the main switch off.

Align the folder as to the needles and to the centre knife only with the

sewing unit switched off.

Standard and checking

If the folder is fitted correctly, the following conditions must be fulfilled:

When the folder is lowered, the needles 4 must penetrate the needle

holes 5 of the folder sole 1 unhindered and without being pushed

aside.

When the centre knife 3 penetrates the centre knife protection 2, the

hind edge of the knife must be flush with the knife protection.

–

Make the machine pressureless.

–

Press the folder down completely by hand.

–

Check the position of the folder sole to the needles and to the

centre knife.

Correction

–

Make the machine pressureless.

–

Press the folder 2 down manually.

–

Loosen the screws 6 slightly.

–

Align the folder 2 as to the centre knife and the needles.

–

26

Tighten the screws 6.

54

3

Attention: Risk of breakage!

After adjusting the distance between the transport clamps and the

folder sole has to be checked (see chapter “3.3 Distance between the

transport clamps and the sole of the folder”)

23

Page 64

4.3 Lifting motion of the folder

21

Caution: Danger of injury!

Switch the main switch off.

Adjust the lifting motion of the folder only with the sewing unit switched

off.

Standard and checking

The distance between sliding sheet 2 and folder sole 1 has to be

adapted to the material to be processed.

If the folder is adjusted too deep, the material is blocked.

If the folder is adjusted too high, the folding slides cannot fold the

material.

When the folder is lowered

In this position there must be a clearance of 0.3 - 0.5 mm between the

guide roller 4 and the lowest point of the guide groove 3.

When the folder is raised

When the folder is raised, there must still be some clearance between

the guide roller 4 and the highest point of the guide groove 3.

–

Press the folder down to the fabric sliding sheet by hand.

–

For this purpose turn the stop 6 back, if required.

–

Check the air gap between guide groove 3 and guide roller 4.

–

65

Lift the folder up to the upper stop 5.

–

Check the air gap between guide groove 3 and guide roller 7.

43

24

Correction

–

Adjust the rod end 5 on the piston rod of the cylinder.

If - with the folder lowered - the guide roller 4 hits the guide groove and

the folder is not lowered as far as required, the guide groove has to be

readjusted (see next page).

Page 65

98

Caution: Risk of injury!

switch the main switch off.

Adjust the guide groove for the folder only with the sewing unit

switched off.

–

Loosen the screws 8 and 9.

–

Shift the cam segment 6 in the slotted holes.

–

Tighten the screws 8 and 9.

12

67

3

10

11

Stop screw with spring

Standard and checking

The stop screw 10 has to be adjusted in such a way that - with the

folder lowered - the distance between the folder sole and the sliding

sheet amounts to approx.1-2mm(dependent on the fabric).

The integrated spring presses the folder back so that the piping strip is

safely seized when sewing (during the last section of the backward

movement the cylinder is pressureless).

–

Turn the stop screw 10 in such a way that - if the folder is lowered the stop screw 10 abuts on the stop 11 (make sure that it snaps in).

–

Adjust the spring pressure with screw 12 in the stop screw 10 so

that the folder is pressed back.

25

Page 66

4.4 Guide plates at the folder

321

Caution: Risk of injury!

Switch the main switch off.

Adjust the guide plates only with the sewing unit switched off.

Standard and checking

The lateral distance between the guide plates 2 and the needles

should be as small as possible. However, the guide plates must not

abut on the needles or the needle holders 3 because this may lead to a

high noise level, damage to the guide plates and the needle head as

well as to thread breakage.

The distance between the sole top 1 and the bottom of the guide plate

2 should not exceed 0.5 mm.

Only when processing especially thick materials the distance has to be

increased.

–

Lower the folder.

–

Check the position of the guide plates as to the needles.

Correction

Aligning the guide plates

–

Cautiously align the guide plates by means of a flat pliers.

54

26

Adjusting the height of the guide plates

–

Loosen the counternuts 4 and 5.

–

Adjust the distance of the guide plates 2 with the Allen screws.

–

Tighten the counternuts 4 and 5.

Page 67

Pressure of the guide plates

76

The spring pressure has to be adjusted in such a way that both plates

are always pressed down safely.

If the pressure is too low, the needles may break during the initial

bartack.

If the pressure is too high, the flap or the additional parts are pushed

back at the seam beginning.

If the pressure is too low, the material may be lifted, the stitch

formation may be incorrect or the needles may break.

3

Adjusting the pressure of the guide plates

–

Loosen the counternut 7.

–

Adjust the pressure on the guide plate with the Allen screw 6.

–

Tighten the counternut 7.

27

Page 68

5. Trimming and clamping device for the needle threads

5.1 Function

21

Caution: Risk of injury!

Switch the main switch off.

Check knife and thread catcher only with the sewing unit switched off.

Function

–

–

–

–

Function check

–

–

–

–

–

43

The cylinder 2 is switched on after the seam end and during the

feed to the corner knives.

The thread catcher 3 lowers and takes the needle threads up.

After a preset time the thread catcher shoots up.

The needle threads are clamped at the clamping piece 1 and cut off

by knife 4.

After the first stitches of the next seam the clamped needle threads

are released.

By means of the springy clamping sheet 1 the thread catcher 3

abuts flat on the knife 4. Thus, the knife is automatically in parallel

position.

Call up the adjustment and test program “Selecting the output

elements” (see programming instructions chapter 5.6.1 Multitest).

Select the output element “Y1”.

Pull the needle threads to the back.

Switch the output element on and off by pressing the function key

“OK”.

Check whether the threads are accurately cut and clamped.

28

Page 69

5.2 Exchanging and adjusting knife and thread catcher

2,5-3mm

765438

Caution: Risk of injury!

Switch the main switch off.

Exchange knife and thread catcher only with the sewing unit switched

off.

3109

Exchanging knife and thread catcher

–

Screw off the complete thread catcher from the machine head.

–

Unscrew the screws 6.

–

Remove knife 5.

–

Unscrew screw 7 and remove knife protection 8.

–

Unscrew screw 4 (on the rear).

–

Take off the needle thread catcher 3.

–

Insert new thread catcher and tighten with screw 4.

–

Put on new knife 5 and tighten with screws 6.

Set the dimensions 2.5-3mmand1.5mm.

–

Make a cutting and clamping test. Adjust the clamping pressure by

means of screw 10, if required.

1mm

3

5

29

Page 70

6. Centre knife

6.1 Position of the centre knife

432 1

Caution: Danger of injury!

Switch the main switch off.

Disconnect the sewing unit from the pneumatic system.

Adjust the centre knife only with the sewing unit switched off.

Standard and checking

In the bottom dead centre the front edge of centre knife 2 must stand

approx. 1 mm under the cutting edge of the stationary knife in the

throat plate.

The centre knife 2 should be in parallel position to the counterknife in

the throat plate.

The center knife 2 must abut on the stationary knife in the throat plate

with a slight pressure.

–

Move the centre knife 2 to the bottom dead centre.

–

Check whether the edge of knife 2 is max. 1 mm under the

stationary knife.

Correction

Adjusting the height of the knife

–

Move the centre knife to the bottom dead centre.

–

Loosen screws 1.

–

Adjust the height of centre knife 2.

–

Tighten screws 1.

30

Adjusting the knife holder

–

Move the centre knife to the bottom dead centre.

–

Loosen screw 4.

–

Turn the knife block 3 in such a way that the centre knife is in

parallel position to the knife in the throat plate.

–

Tighten screw 4.

Page 71

62 5

Contact pressure

–

Loosen the two screws 5.

–

Place the knife holder 6 with the centre knife 2 to the left against

the stationary knife in the throat plate.

The centre knife must abut with slight pressure.

–

Tighten the screws 5.

87 2

6.2 Needle protection

–

Make a cutting test.

Attention !

Disturbances of the machine cycle may occur.

If the centre knife abuts too close on the counterknife edge, the spring

cannot pull it to the initial position any more after the sewing process.

Furthermore, the knife will quickly get blunt which may result in

inaccurate cutting, different seam lengths, inexact corner incision and

fullness within the seam.

The needle protection 7 is fixed on the holder of the needle thread

catcher.

It should be located 1 mm deeper than the point of the centre knife 2

and

1.0 - 1.5 mm from its back.

–

Loosen the screws 8.

–

Adjust the needle protection 7 in such a way that it is located 1 mm

deeper than the point of the centre knife und 1.0 - 1.5 mm from its

back.

–

Tighten the screws 8.

3

31

Page 72

7. Adjusting the bobbin thread catcher

7.1 Thread catcher

1

27,2 mm

32 1

Caution: Risk of injury!

Switch the main switch off.

Adjust the bobbin thread catcher only with the sewing unit switched off.

Standard and checking

The thread catchers are correctly adjusted if the thread catcher point 2

in idle state has a distance of 27.2 mm to the edge 1 and a distance of

0.1 mm to the nose of bobbin case 4.

–

–

–

0,1 mm

4

2

Swivel the thread catcher out.

Check whether the point 2 has a distance of 27.2 mm to the edge

1.

Check whether there is a distance of 0.1 mm between the thread

catcher and the nose of the bobbin case 4.

32

Correction

–

Loosen the screws 3.

–

Adjust the thread catcher 2 correspondingly.

–

Tighten the screws 3.

6

Counterknife

–

5

Regrind or exchange the blunt counterknives 5 and 6.

Page 73

8. Knives for corner incision

Caution: Danger of injury!

Do not reach into the area of the corner knives.

The corner knives shooting up can cause severe cuts.

Carry out adjusting operations with utmost caution when the sewing

unit is running.

8.1 Presetting

1

2

6

5

3

3

7

4

In order to be able to precisely adjust the position of the corner knives

1 all four corner knives are brought to a basic position at first.

–

Loosen screw 6.

–

Turn the corner knife holder 2 in such a way that the face side 3 is

in a line with the face side 4 of the knife support 5.

–

Tighten screw 6.

–

Adjust the other three knife holders as described.

–

Adjust the grub screw 7 in such a way that the edges of the

opposite knives have a distance of 0.1 to 0.3 mm.

–

Grub screw 7 to the right: knives closer together.

–

Grub screw 7 to the left: knives wider apart.

–

Adjust the other knives likewise.

33

Page 74

8.2 Belt tension

1

Standard and checking

Over half the tightening length S = 185 mm the toothed belt 1 must

bend under the test load FV = 50 N so that the loaded belt just touches

the other belt.

Consequences of a too high toothed belt tension

–

Reduced durability

–

Noisy running

Consequences of a too low toothed belt tension

–

No faultless mesh between belt teeth and disc toothing

–

The teeth may skip over under load

–

Non-uniform corner stitches

–

Check the belt tension with a spring balance.

Correction

–

Loosen the counternut 3.

–

Adjust the belt tension with the eccentric screw 2.

–

Tighten the counternut 3.

32

34

Page 75

8.3 Aligning the corner knife station as to the seams

Caution: Risk of injury!

Switch the main switch off.

Adjust the corner knife station only with the sewing unit switched off.

Standard checking

The corner incisions must be symmetrical to the seams.

–

Set the maximum sewing length at the control.

–

Iron a piece of interfacing on a workpiece.

Thus the corner incisions are better visible.

–

Make a test seam.

–

Check seam and cutting pattern.

Correction of the corner incision at the seam end

–

Swivel the corner knife station 1 out completely.

3

1

35

Page 76

32

–

Loosen the screws 3 slightly.

–

Shift the holder 2 correspondingly.

–

Tighten the screws 3.

–

Swivel the corner knife station back again.

Correction of the corner incision at the seam beginning

–

Loosen the screw 5 slightly.

–

Adjust the corner knife station with the hexagon screw 4.

ATTENTION !

Observe the position of the eccentric.

Setting range

54

36

–

Tighten the screw 5.

–

Make a test seam.

–

Check seam and cutting pattern.

Page 77

8.4 Adjusting the slant of the corner incisions

Caution: Risk of injury!

Switch the main switch off.

Adjust the corner knives only with the sewing unit switched off.

Standard and checking

The incisions of the corner knives should be as close to the seam as

possible (approx. 1 mm), but must not cut it.

–

Set the maximum sewing length at the control.

–

Sew a test seam.

It is advisable to iron a piece of interfacing on the workpiece

before. Thus the corner incisions are better visible.

–

Check seam and cutting pattern.

3

6

2

–

Loosen screw 6.

–

Adjust the corner knife holder 2 correspondingly.

–

Tighten screw 6.

–

Adjust the other three knife holders according to the seam pattern.

37