HOME AND BUILDING AUTOMATION

DFDALI: DALI gateway

DFDALI module allows to manage up to 32 DALI ballasts

(or similar devices) through the Domino bus.

DFDALI module can be successfully employed in domestic

and professional lighting applications, where systems communicating by the DALI protocol are used.

DFDALI module offers the following main features:

✗ all timing functions are accomplished by the module

and it may be controlled by any real or virtual input of

the system, by supervisor or by video terminal

✗ it can operate without DFCP controller

✗ possibility of control from one or more pushbuttons con-

nected to Domino bus

✗ Up/Down and Single commands may be defined for the

manual regulation of lighting level

✗ automatic brightness regulation (also without DFCP)

✗ programmable ramp, in the range 0 to 60 seconds

✗ setting of minimum and maximum output levels

✗ dynamic lights scenes can be easily implemented

through DFCP

✗ the current brightness level may be stored and then re-

called; up to 16 presets are available to create “real

time” lighting scenes; the preset will be stored in the

non-volatile memory of the ballasts

✗ if a Domino or DALI bus failure occurs, the output level

will be automatically set to a user-defined level

✗ diagnostics of short circuit on the DALI line and lamp

failure

✗ galvanic insulation between DALI and Domino buses

Domino

DFDALI

Near to the Domino bus terminal block, the module features a small pushbutton for the assignment of the address

and a green LED that shows the operating status; this

green LED normally flashes every 2 seconds about to signal that the module is properly supplied and operating.

Near to the DALI bus terminal block, the module features a

small pushbutton for the manual command of the connected devices; the function performed by this button are the

continuous regulation of the brightness level and the onetouch switching on and off. Near to this button, a yellow

LED reports the communication activity on the DALI line or

the diagnostic.

Removing the cover of the bus terminal block, a small connector (PRG) can be accessed; this one allows the connection to DFPRO optional tester/programmer.

DFDALI module is housed in a standard DIN 4M box for rail

mounting.

The 32 devices for each line can be controlled as follows:

Broadcast: each command sent on the DALI line will be ex-

ecuted by all the connected devices, therefore all the related devices will behave in the same way.

Individually: the commands will be individually sent to each

device, therefore each single device will behave independently; for this operation, the DALI devices must be addressed as described in the following paragraphs.

Groups: the command will be sent to groups, therefore

each group of devices will behave independently; for this

operation, DALI devices must be addressed and the groups

must be defined as described in the following paragraphs.

DFDALI module can operate in systems with or without

DFCP controller. In all cases, the module can perform Up,

Down and Single Command functions by real or virtual inputs (see in the following of this manual); moreover, saving

and recalling of sceneries can be accomplished by the

module.

The power supply needed for DFDALI module operation is

derived from the Domino bus itself and from an auxiliary

power supply for the DALI section.

Three fixed 2-way terminal block allow the connection of

the module to the Domino bus, to the auxiliary power supply and to the DALI bus.

Note: this technical sheet applies to DFDALI modules

equipped with firmware 2.2 or higher.

Address programming

DFDALI module takes one output address and, if enabled,

one input address. A white label on the front panel allows

the writing of the assigned address for an immediate visual

identification. For details about address programming refer

to the related documentation.

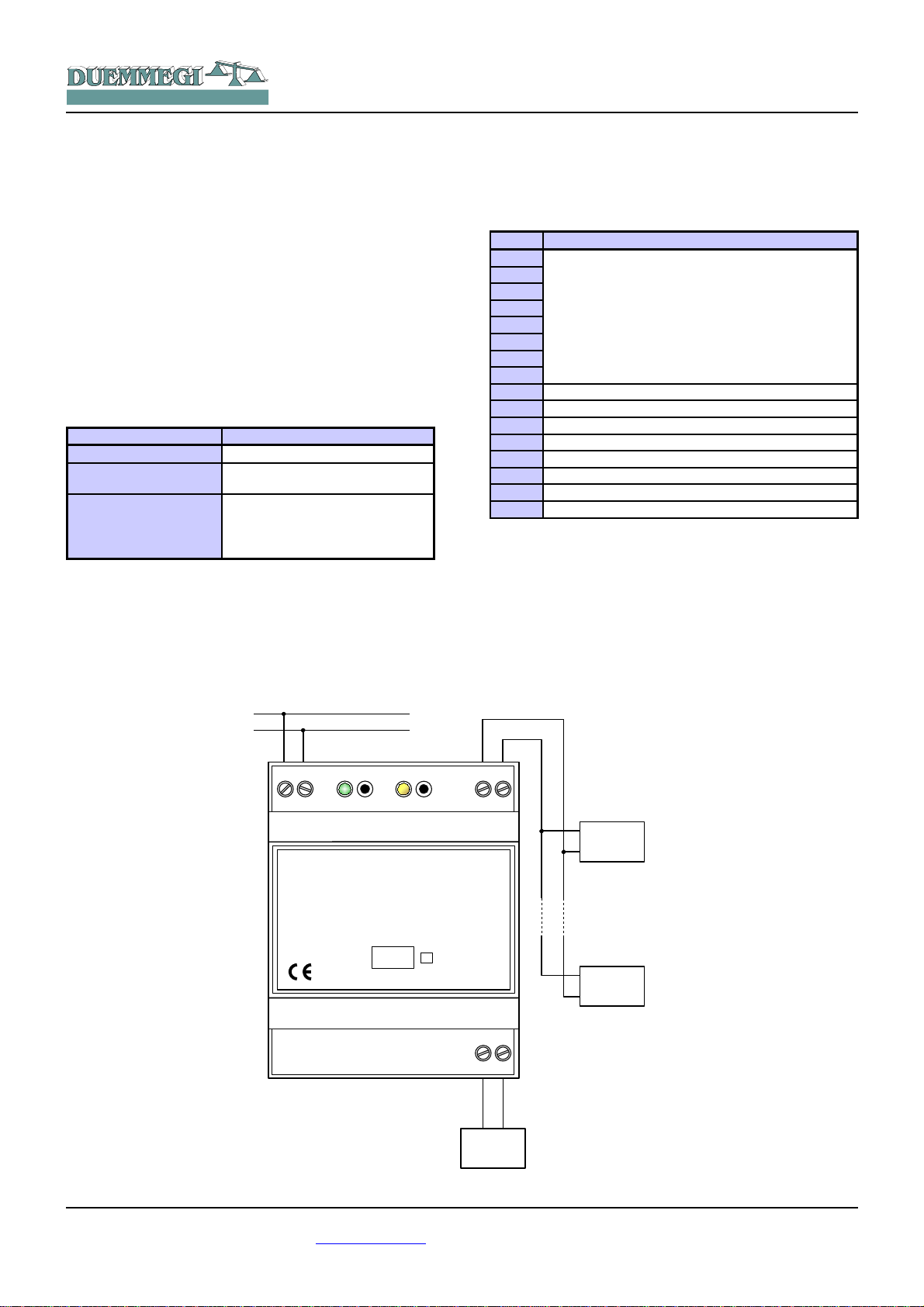

Wiring diagram

The schematic diagram in Figure 1 shows the connections

to be made between DFDALI module and the Domino bus,

the auxiliary power supply and the DALI line, using cables

as described in the table in the following of this same paragraph. As said above, DFDALI module performs galvanic

insulation between DALI section and Domino bus by

means of photo couplers inside the module.

The auxiliary power supply (AUX SUPPLY in the schematic) can be a transformer with 12V~ secondary winding (at

full load) 3VA, or it can be a stabilized dc power supply 12V

± 5% / 0.25A; in this last case the polarity is automatic,

so the positive pole can be connected indifferently to the

terminal 19 or 20.

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 1 of 11

HOME AND BUILDING AUTOMATION

+

BUS

_

DUEMMEGI

MILANO-ITALY

ADDRESS

DFDALI

+

_

Domino

PATENTED

DA+

OUT

DALI

SUPPLY

AUX

SUPPLY

12V~

12V=

DALI

32

DALI

1

+

_

BUS

DA-

IN

It is suggested to use, for the DALI line, a normal 2-core

cable with double insulation. It's allowed to lay these cables

in the same pipe in which there are power cables, provided

that they have double isolation too.

Domino

DFDALI

Input section

On the input address, if enabled, 16 bits are available for

the diagnostics of DALI system, as described in the following table:

It is recommended to avoid the using of multi core cables

carrying both the two DALI signals and ballast supply, because the capacitive coupling between the signal wires and

the power lines may cause very dangerous conditions for

the human safety.

The following table gives some rules for the MINIMUM

cable section. As said above, no special cables are required for the DALI line, provided that they have double insulation. In any case, the distance between DFDALI module and the farthest ballast must not be more than 300m.

Connection Suggested cable

Domino bus 2 x 0.8 mmq unshielded

DALI SUPPLY

DALI line

1 mmq (if the power supply is near

to the module)

Up to120m: 2 x 0.50mmq

Up to 175m: 2 x 0.75mmq

Up to 230m: 2 x 1.00mmq

Up to 300m: 2 x 1.50mmq

Information on the bus

DFDALI takes, inside the Domino bus, 1 output address

and, if enabled, 1 input address. The meaning of the data

field of the two sections will be described in the following.

Point Description

1

2

3

4

5

6

7

8

9 10 11 Polling disabled

12 Power supply loss on DALI side

13 Test button pressed

14 Lamp failure

15 DALI line broken

16 DALI line short circuit

Current brightness

or

Regulation Status of the 8 zones

The first available information (points 1÷8 of the channel)

can be chosen by the option “Regulation Status” in the configuration panel featured by DCP IDE or BDTools; the two

possibilities are:

Case 1(unchecked option):

the brightness level of the ballast having address 1 which is

assumed as reference for all the other ballasts. Thus, to

use this function, the ballasts have to be addressed starting

from address 1.

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Figure 1: DFDALI wiring diagram

Rel.: 2.1 May 2013 Page 2 of 11

HOME AND BUILDING AUTOMATION

The value of the current brightness level is in the range 0 to

100; if no ballast has been addressed as 1, then the reported value will be 255. A lamp failure condition will be instead reported by the value 128; if the answer from the ballast will not be understood the value 129 will be reported.

If the brightness level of each ballast on the DALI line is required by the application, a script for DFCP is available for

this purpose; contact DUEMMEGI for more information.

Case 2 (checked option):

In this case, each point 1¸8 reports the status of the automatic brightness regulation of the relevant zone. For instance, point 1, when activated, reports that the automatic

brightness regulation is currently activated for zone 1.

Output section

The related data field (16-bit) for the execution of the commands on the ballasts, has the following meaning:

Point Data field at output address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Function

Destination

The destination can assume different values depending on

the typology of the addressed target, identified by the value

of the high byte of the channel, as in the following table:

Written data

HEX DEC

0x00 0 All the ballasts on the line

(broadcast)

0x01 ÷ 0x20 1 ÷ 32 single ballast (1÷32)

0x81 ÷ 0x90 129 ÷ 144 single group (1÷16) of ballasts

0x91 ÷ 0x98 145 ÷ 152

Set the setpoint value for the

automatic brightness regulation

for zones 1 ÷ 8

Destination

When the destination is broadcast or single ballast or single

group, the function executed by the module depends on the

value written on the low byte of the output data field, as described in the next table.

If instead the destination is in the range 0x91 to 0x98, then

the value specified by the low byte (Function) assumes the

meaning of “setpoint value” divided by 10 used for the

automatic brightness regulation; for instance, to send 300

as setpoint value on group 3, the value 0x931E has to be

sebt (0x93 means the setpoint setting for group 3 and 0x1E

= 30 is the wanted setpoint value: 30 x 10 = 300).

Domino

DFDALI

Written data

HEX DEC

0x00 ÷ 0x64 0 ÷ 100

0x70 112 Disable polling

0x71 113 Enable polling

0x7D 125

0x7E 126

0x7F 127

0x80 128

0x87 135

0x88 136

0x89 137 Reset MIN value to default (1%)

0x8A 138

0x8B 139

0x8C ÷ 0xAA 140 ÷ 170

0xAB ÷ 0xAD 171 ÷ 173

0xB5 ÷ 0xC4 181 ÷ 196

0xC9 ÷ 0xD8 201 ÷ 216

0xDD 221

0xDE 222

0xDF 223

Set the brightness to 0÷100%

according to the current ramp

Up command without one-touch

function

Down command without onetouch function

Single command without onetouch function

No operation (in this case the

value of the destination must be

zero)

Set the current brightness a

MIN value

Set the current brightness a

MAX value

Reset MAX value to default

(100%)

Save the current brightness as

level to be loaded during bus

failure condition

Set the current ramp to 0 ÷ 30

seconds (1s step)

Set the current ramp to 40 ÷ 60

seconds (step 10 s)

Save the current brightness to

Preset 1÷16

Recall brightness from Preset

1÷16 according to current ramp

enable the automatic brightness

regulation (the destination must

be a group in the range 1 to 8)

Disable the automatic brightness regulation and switch OFF

the lamps (the destination must

be a group in the range 1 to 8)

Disable the automatic bright-

ness regulation (the destination

must be a group in the range 1

to 8)

The value to be written in the output data field to perform a

given function to a given destination will be thus:

✗ in hexadecimal: 0xYYZZ where YY is the destination in

hexadecimal format (HEX) and ZZ is the code of the

function in hexadecimal format (HEX)

✗ in decimal: K where K is given by [(256 x YY) + ZZ],

where YY is the destination in decimal format (DEC)

and ZZ is the code of the function in decimal format

(DEC)

Notes:

✗ DFDALI module, normally, polls all the ballasts connected to

the line; this polling can be disabled sending the code 112 (of

course losing all information about the diagnostic and the current level). The code 113 will enable again the polling; the current status of the polling is reported by the point 11 of the input

section (if enabled). At the module power up or after a reset

the polling is always enabled by default.

Function

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 3 of 11

HOME AND BUILDING AUTOMATION

✗ The code 128 is required only to inform DFDALI when interrupt

a running function. For instance, to perform an Up function, the

code 125 must be sent: the brightness will increase until the

sending of code 128.

✗ The code 139 saves, in the non volatile memory of the bal-

lasts, the brightness level which will be automatically recalled

when a DALI or Domino bus failure occurs.

✗ The change from a brightness level to another one will be ex-

ecuted according to a ramp that can be set as desired by the

codes 140 to 173. The ramp value will be stored in the non

volatile memory of the ballasts, therefore a power failure does

not affect it.

Domino

DFDALI

V1 = !(I1.1 | I1.2 | I1.3)

AO2 = P(0x8180)V1 & \

P(0x817D)I1.1 & P(0x817E)I1.2 & \

P(0x8132)I1.3

The specified value, at each variation, will be transferred to

the DALI devices assigned to group 1. At the releasing of

each pushbutton, the value is always set to 0x8180 (no

operation, but needed to inform the module about the releasing of the buttons).

Of course the commands to DALI devices can be also sent

by DFCP through the using of the Scripts.

Management by DFCP or by I/V table

The sending of commands or values to DALI devices can

be performed through a supervisor simply writing the

memory locations of DFCP related to the output of the installed DFDALI modules.

As option, or in addition, it is possible to send commands or

value from DFCP to the DALI module through proper equations as in the following example:

V1 = !(I1.1 | I1.2 | I1.3)

AO2 = P(128)V1 & \

P(125)I1.1 & P(126)I1.2 & \

P(50)I1.3

where I1.1 and I1.2 are, for instance, the Up and Down

inputs and AO2 is DFDALI module with address 2; I1.3

will set the brightness to 50%. The specified value, at each

variation, will be transferred to the DALI output (AO2). At

the releasing of each pushbutton, the value is always set to

128 (no operation, but needed to inform the module about

the releasing of the buttons). In this case the described Up,

Down and Preset functions acts on all connected ballasts

(broadcast commands).

To get the same result on a ballast individually addressed,

it is easiest (even if not mandatory) to use the hexadecimal

format to write the equations, because the address of the

ballast has to be specified in the high byte of the channel:

V1 = !(I1.1 | I1.2 | I1.3)

AO2 = P(0x0180)V1 & \

P(0x017D)I1.1 & P(0x017E)I1.2 & \

P(0x0132)I1.3

where I1.1 and I1.2 are the Up and Down inputs and

AO2 is DFDALI with address 2; I1.3 will set the brightness

to 50%. The specified value, at each variation, will be transferred to the DALI ballast addressed 1. At the releasing of

each pushbutton, the value is always set to 0x0180 (no

operation, but needed to inform the module about the releasing of the buttons).

A similar example follows to send command to a group of

ballasts:

DFDALI module can however work without DFCP controller, simply linking the desired commands to bus input

points (both real and virtual ones); for details about this

possibility, refer to the paragraph I/V Table.

Manual commands by the module

pushbutton

Near to the terminal block of DALI line, a pushbutton allows

the following functions: a short pulse will cause the complete switching ON and OFF, while holding down the button

the brightness increases or decreases depending on previous action (every next continuous pressing will invert the

previous one).

This pushbutton is useful during the setting up of the plant.

Diagnostic of DALI line by yellow LED

The yellow LED, located near the just described pushbutton, continuously flashes during normal operation. Since

the DALI line is continuously polled in a sequential way,

thus the LED flashes in the same way, even if DFCP controller is not connected.

The yellow LED will be fixed lighted when one or more of

the following events will occur on the DALI line:

• Lamp failure

• DALI line broken or no ballast connected

• Short circuit on DALI line

In the case of short circuit, an automatic procedure will try

to restore the line, thus allowing to module to return to to

the normal operation with a maximum 15 sec delay after

the short circuit condition has been removed.

The LED will be instead switched off if the DALI section of

the module is not supplied or if the polling has been disabled. In any case, the occurred problem can be discriminated by the map of DCP IDE or BDTools or by a supervisor

or video-terminal connected to DFCP (reading input channel as described in the related paragraph).

Note:

✗ In lamp failure condition, it is not possible to know on which

DALI device this event occurred.

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 4 of 11

HOME AND BUILDING AUTOMATION

Mapping

Domino

DFDALI

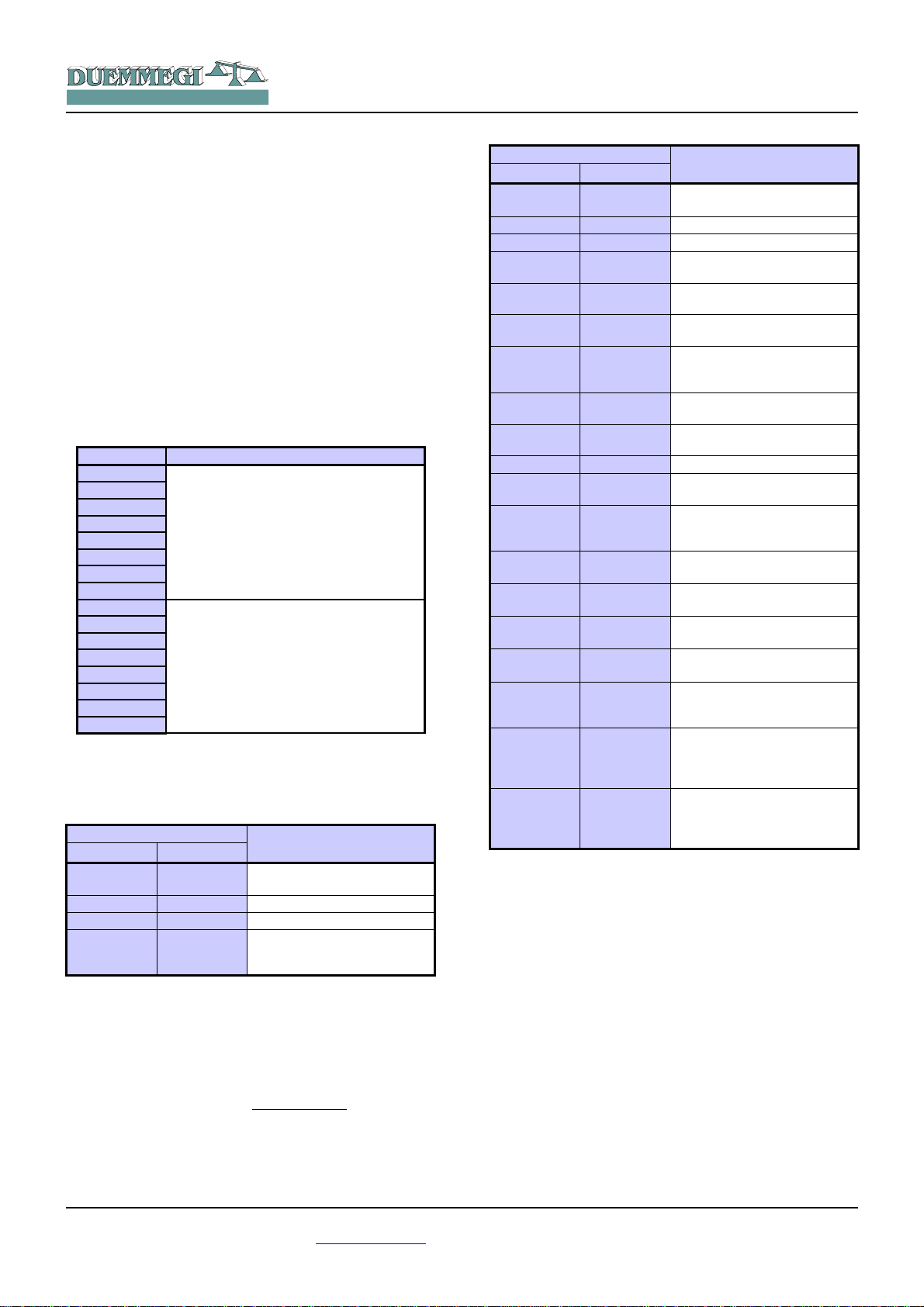

Setting up

DFDALI module is shown into the map of DCP IDE or

BDTools like in the following figure. As for all Domino modules, the background of the module will be in green color if

the module is connected and properly working, otherwise

the background will be in red color.

The portion on the left side is related to the input section

and it reports the diagnostic information and the brightness

level of ballast 1 (text box on the bottom); if the option

“Regulation status” has been checked in the configuration

panel, then this text box reports the automatic regulation

status of the 8 zones (in decimal format to be interpreted in

binary mode).

The portion on the right side is related to the output section

and it features two text boxes for entering the destination

and command values.

DCP IDE and BDTools allow to set the operating parameters of the DALI line during the system setting up and to

perform some diagnostic functions. DFDALI module can be

adapted to any specific application. The setting up is performed via the Domino bus and DFCP (or DFRS or

DFPRO) through a specific configuration panel that can be

accessed from the menu of DCP IDE or BDTools.

From the menu, select Programming, Modules Configuration and then DFDALI. The window shown in Figure 2 will

be opened; the main parameters and options can be here

defined as it will be described in the following of this paragraph.

Before to proceed with any action, the communication

between the PC and, for instance, DFCP has to be opened.

The top side of the configuration panel reports the section

for the addresses management.

After having entered the address of the DFDALI to be managed, it is possible to enable the input address of the module through the check box named “Input Address” and then

clicking on the button Program; by the button Read it is instead possible to check the current setting.

It is also possible to activate the “Regulation Status” information related to the 8 zones by checking the related option

and then pressing the button Program. This option, of

course, requires that the input section have been enabled.

Six tabs in the window allow some well defined functions as

described in the following.

The button ID & Ver. on the lower side allows to read the

firmware version of the selected DFDALI module.

Figure 2: Configuration panel – Addressing TAB

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 5 of 11

HOME AND BUILDING AUTOMATION

Addressing

3 mutually exclusive functions are available:

Set address. In the first case, an address will be assigned

to all the connected ballasts, and the starting address can

be chosen (the typical value is 1).

This type of addressing assigns consecutive values, in the

range 1 to 32, to the ballasts in a random order.

If some ballasts on the line have been previously addressed and some other ballasts have to be added, the addressing procedure can be performed without any modification to the previously assigned addresses. Mainly in this

case, a starting address other than 1 can be useful. A timer

icon will inform that the operation is running.

At the end of the procedure, the normal mouse icon will be

restored. The time required for this procedure is about:

T = 5sec + (6sec x “nr. of ballasts”)

Remove the address. If some addressing or reconfiguration

errors occurred, it can be useful removing the address of all

the ballasts on the line or of a well specified ballast.

Restore the factory setting. The DALI ballasts are factory

set without any address and with a basic configuration for

the main parameters; the following table shows a typical

default configuration:

Parameter Value

Minimum brightness level 1%

Maximum brightness level 100%

Brightness level in failure condi-

tions

Ramp value 0 seconds

Preset None

100%

Domino

DFDALI

These settings can be restored both for all ballasts connected to the line and for a single ballast.

Restoring of the settings does not imply the reset of the

ballast address. The visible result of the factory setting

restoring is the switching on of the lamps at the bus failure

default level, that is typically 100%.

Mapping

Once the ballasts have been random addressed, it can be

useful to reorder the assigned addresses, thus simplifying

the supervision and the management of ballasts, Figure 3.

The address 1 to 32 of each ballast can be changed to a

new desired value (always in the range 1 to 32). For each

address, the program shows a line similar to the following

one: .

The button 0 allows to switch off the ballast with address

specified in the gray text box (1 in this example) while the

button I allows the switching on; this function is useful to

see where the ballast addressed 1 (in this example) is

physically located. In the white text box the new desired address must be entered (23 in this example) for the ballast

whose current address is 1.

The execution of the mapping procedure (pressing the button Start) will take place only for the ballasts selected by

the related checkbox. A timer icon will inform that the operation is running. At the end of the procedure, the normal

mouse icon will be restored. The time require by the mapping procedure is about 1sec per ballast.

If the procedure has not been successfully executed, a window reporting “Error during mapping” will appear.

Figure 3: Mapping

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 6 of 11

HOME AND BUILDING AUTOMATION

In this case, follows these steps:

• click on the button “Recover” to remove the address of

each ballast for which the mapping procedure has not

been successfully completed

• address again the ballasts without address selecting

as starting address a free value followed by a sufficient number of free addresses (see the Status TAB)

• execute again the mapping procedure

The correctness of the changes made can be checked by

switching on and off the ballasts using the buttons identified

as 0 (off) and I (on).

The two big buttons 0 and I on the left side allow to switch

off and to switch on all the ballasts connected to the line.

The buttons Select (select all) and Deselect (deselect all)

and Reset (restore the address value in the consecutive order) complete this TAB.

Domino

DFDALI

The button Deselect remove all the X symbols on the grid.

The execution of the assignment of the groups (clicking on

the button Start) will take in account only the ballast selected by the X symbol. A timer icon will inform that the operation is running. At the end of the procedure, the normal

mouse icon will be restored.

If the procedure has not been successfully executed, the

warning in following window will be shown:

In this case the procedure has to be repeated.

Groups

This TAB, Figure 4, features a grid where each ballast can

be assigned to one or more groups. This choice can be

done by clicking on each cell located at the intersection

between the desired ballast (the columns) and the desired

group (the rows).A X symbol will be shown in the related

cell.

In the example of the figure

here on the right side, the

group 1 contains the ballasts

1-2-5, the group 2 the ballasts 1-3 and the group 3 the

ballasts 2-4-5.

The correctness of the changes made can be checked by

switching on and off the ballasts using the buttons identified

as 0 (off) and I (on); the buttons on the top side act on the

single ballast, the buttons on the left side act on the groups

and the two big buttons 0 and I switch off and on all the ballast on the line.

The buttons From File and To File allow to store and recall

the settings of the groups; take in account that it is not possible to read, from DFDALI module, the current settings of

the groups, therefore it is strongly recommended to save

them into a file for future modifications.

The time required by this procedure is about:

T = 8sec + (0,5sec x “nr. of X in the window”)

Figure 4: Groups

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 7 of 11

HOME AND BUILDING AUTOMATION

Domino

DFDALI

Figure 5: Global Setting

Global Settings

In this TAB, Figure 5, it is possible to set, for all ballasts on

the DALI line, the following parameters:

MIN: minimum brightness value (%); enabling the Reset

check box, the default value will be restored (1%).

MAX: maximum brightness value (%); enabling the Reset

check box, the default value will be restored (100%).

BUS F.: the brightness value (%) to be recalled by ballasts

during failure of Domino and/or DALI bus.

Ramp: the ramp value in seconds.

Preset: writing a value (0 to 100) and clicking on the button

on the right side, the brightness will be forced to that value.

M1 ÷ M16: the value to be loaded into the 16 presets; the

button on the right side allows to recall the related preset

stored into the ballast.

Figure 6: Status

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 8 of 11

HOME AND BUILDING AUTOMATION

Enter the desired parameters and then click on Start to

send the configuration. The time required by this procedure

is about 15 seconds.

If the procedure has not been successfully executed, a

warning window will be shown; in this case the procedure

has to be repeated.

Status

This TAB, Figure 6, shows, if the ballasts have been addressed, the current brightness level of each ballast. These

values are in the range 1 to 100; when a ballast does not

answer to the polling, the reported value will be 255 (and

the table will show “-”).

If a lamp failure occurs, a X symbol on a pink background

will be shown.

In addition it is possible to force the brightness entering the

value in the cell related to the desired device and confirming by the Enter key.

A pair of buttons on the top side of the table allow to enable

and disable the polling on the DALI line. When the polling is

disabled, the label “Base address” will be shown over a red

background.

The buttons “Snapshot to File” and “Restore from File” allow respectively to save and recall a given configuration of

brightness levels; in this way it is possible to save on the

PC one or more sceneries (each scenery will be a file).

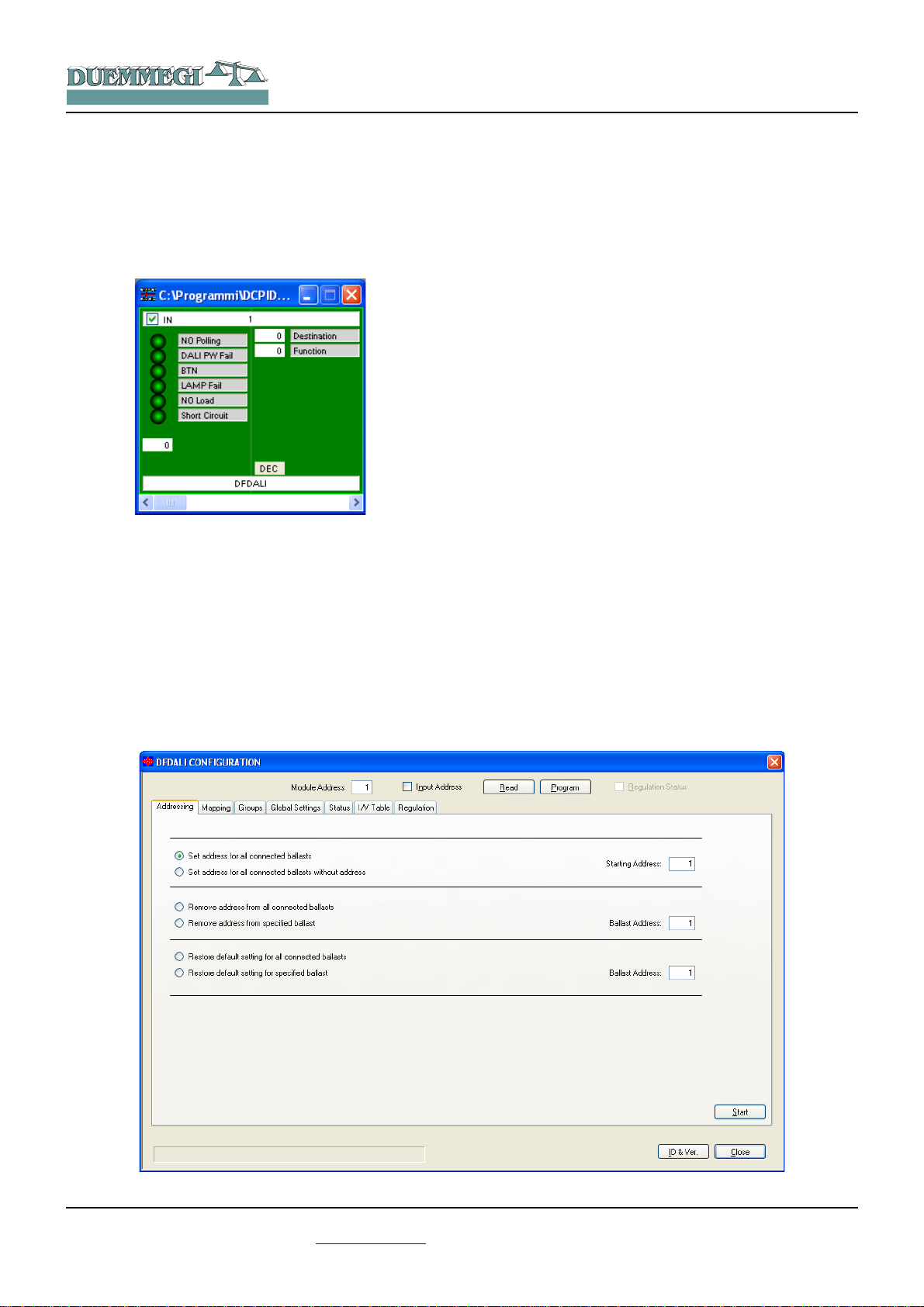

I/V Table

The TAB shown in Figure 7 allows to create up to 58 relationship between real or virtual inputs of the Domino bus

and the following commands: Up, Down, Single Command,

Save scenery and Recall scenery. For each command

simply enter the input point (without I or V, with ! if negation

is required), the function and the channel or the scenery.

Domino

DFDALI

These functions are managed directly by DFDALI module,

thus without the need of any controller and any programming.

To compile the table, left click with the mouse on the first

available cell on the Input column, enter address and point

(without I or V, with ! if needed) and press

Enter. The command list will appear:

choose the desired function among Mono,

Up, Down, Recall, Save; the other two options are related to the automatic brightness regulation, see next paragraph. The

cell of the column Cmd will then show the

symbol of the chosen function; to change

the function, simply click again on the cell.

Select the desired function; the cell of the column Cmd will

then show the symbol of the chosen function (U, D, M, R,

S); to change the function, simply click again on the cell.

The next cell on the column B/G (Broadcast or Group) will

be then automatically highlighted: enter the desired value,

that is 0 for Broadcast or the desired group number number

1 to 15 (note: group 16 cannot be used in the I/V table) and

press Enter. If instead the desired function is Save or Recall scenery, press Enter again: the related cell will be automatically highlighted in the column S (Scenery): enter the

desire number, that is the number of the scenery (1 to 16)

to be saved or recalled, then press Enter.

The buttons Start Prog. and Start Read. in the I/V Table

TAB allow, respectively, to transfer the values currently

shown in the I/V Table to DFDALI module and read the current configuration of DFDALI and report it into the table.

The buttons From File and To File allow, respectively, to

open a file, with .TIV extension, containing a previously

saved I/V table and to save the I/V table shown in the window to a file. The Default button clears the table.

Figure 7: I/V Table

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 9 of 11

HOME AND BUILDING AUTOMATION

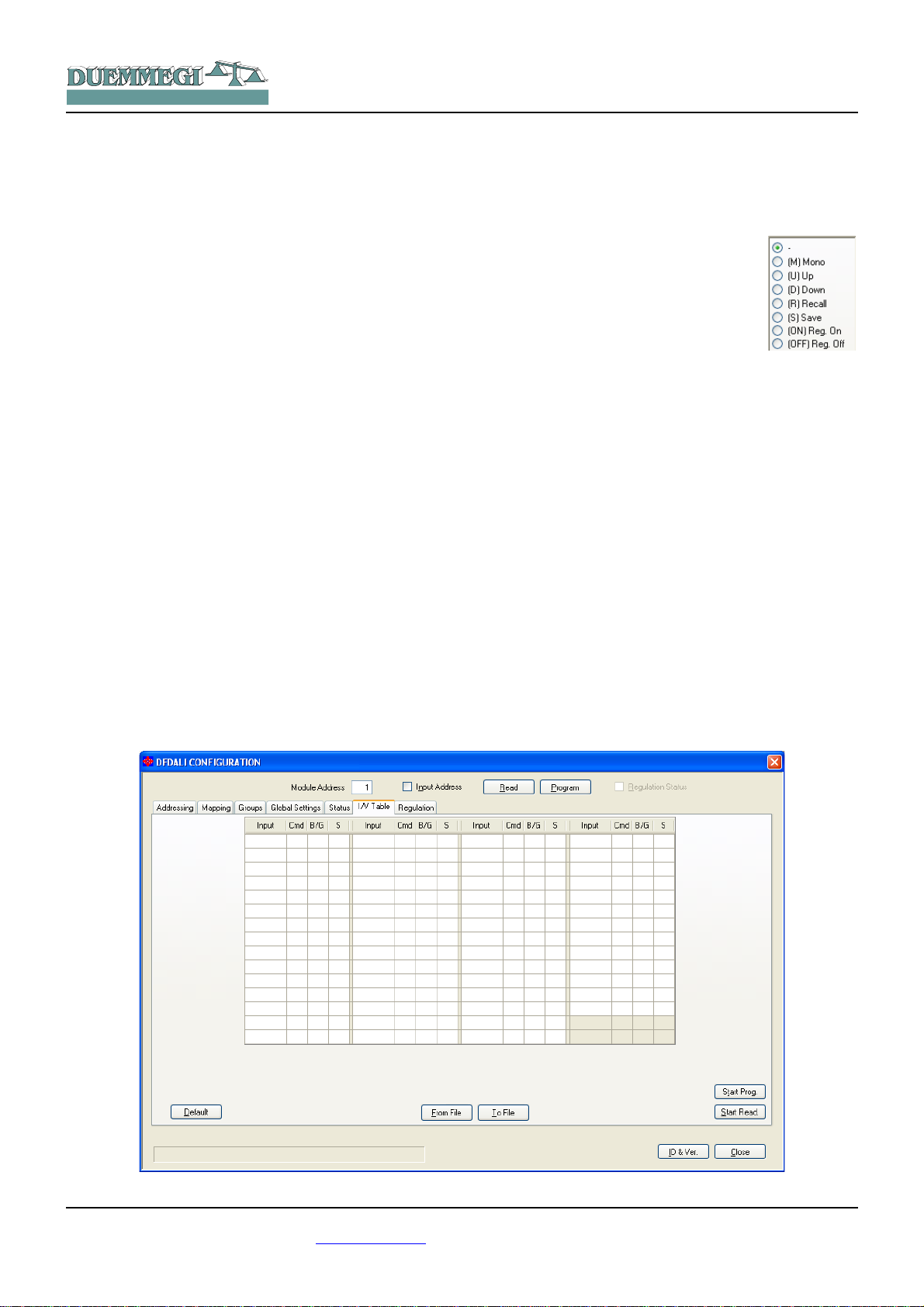

Automatic brightness regulation

DFDALI module, starting from firmware version2.0, implements the automatic brightness regulation as function of a

light sensor connected to the Domino bus (e.g. DFLUX).

The TAB shown in Figure 8 allow to manage up to 8 zones

(each one corresponding to a group in the range 1 to 8).

These functions are managed directly by DFDALI module,

therefore no controller or specific programming is required.

To fill the table, double left click in the cell related to the

zone to be set in the Sensor Address column, enter the address of the light sensor (e.g. DFLUX module) for that zone

and press Enter. The cell related to Setpoint will be then

automatically highlighted: enter the desired value and press

Enter. The sequence is the same also for the next parameters: Hysteresis, T. Regulation, K and Start Value.

Setpoint is the brightness level that has to be kept. The

regulation function works in order to keep the light value

read from the sensor in the range (setpoint - hysteresis) to

(setpoint + hysteresis).

The regulation time, in seconds, is the interval with which

the module compares the light level read by the sensor to

the setpoint.

K is a parameter which, multiplied by the error (defined as

the difference between the setpoint and the brightness

value measured by the sensor), defines the magnitude of

the increase or the decrease, in respect to the previous

value, to be sent to the ballasts. In practice, larger values of

K increase the speed of the approaching to the set point.

Domino

DFDALI

Small values of K allow for greater stability of the regulation

but a slower response, while large values of K make the response faster, but some oscillations can appear.

Start Value is the value from which the regulation starts

when it is activated.

The Auto options, when checked, place that zone in automatic regulation mode at the power up of the ballasts or of

the Domino bus; if the option is not checked, the lights will

go to the value set in the ballasts (typically 100 %).

Figure 8 shows some typical value for the just described

parameters.

The buttons Start Prog. and Start Read. allow, respectively,

to transfer the values currently shown in the table to DFDALI module and read the current configuration of DFDALI

and report it into the table.

The buttons From File and To File allow, respectively, to

open a file, with .TRG extension, containing a previously

saved regulation table and to save the table shown in the

window to a file. The Default button clears the table.

To change the setpoint value of a group from a supervisor

or similar devices, the destinations 0x91 ÷ 0x98 have to be

used, as described in “Commands via bus” paragraph.

The functions 0xDD, 0xDE 0xDF allow to enable and disable the automatic regulation from the bus on the group

specified by the Destination field (0x81 ÷ 0x88)

Figure 8: Automatic brightness regulation

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 10 of 11

90cm

58mm

71mm

DUEMMEGI

MILANO-ITALY

ADDRESS

DFDALI

+

Domino

PATENTED

DA+

OUT

DALI

SUPPLY

+

_

BUS

DA-

IN

HOME AND BUILDING AUTOMATION

Technical characteristics

Supply voltage Domino bus

side

Supply voltage DALI bus

side

Current consumption on

Domino bus side

MAX current consumption

DALI bus side

Number of managed DALI

devices

Number of generic

commands

Operating temperature

Storage temperature

Protection degree IP20

By specific centralized power

supply mod. DFPW2

12V~ (at full load) 3VA MIN, or

12V ±5% 0.25A MIN

Equal to 2 standard Domino

modules

0.25A at 12V , 3VA at 12V~

32 MAX

58 (I/V Table)

-5 ÷ +50 °C

-20 ÷ +70 °C

Outline dimensions

Domino

DFDALI

Correct disposal of this product

(Waste Electrical & Electronic Equipment)

(Applicable in the European Union and other

European countries with separate collection systems). This marking on the product, accessories or

literature indicates that the product should not be

disposed of with other household waste at the end

of their working life. To prevent possible harm to

the environment or human health from uncontrolled waste disposal, please separate these items from other types of waste and recycle them responsibly to promote the sustainable reuse of material resources. Household users should contact either the retailer

where they purchased this product, or their local government office, for details of where and how they can take these items for environmentally safe recycling. This product and its electronic accessories should not be mixed with other commercial wastes for

disposal.

Installation and use restrictions

Standards and regulations

The design and the setting up of electrical systems must be performed according to the relevant standards, guidelines, specifications and regulations of the relevant country. The installation, configuration and programming of the devices must be carried out by

trained personnel.

The installation and the wiring of the bus line and the related

devices must be performed according to the recommendations of

the manufacturers (reported on the specific data sheet of the

product) and according to the applicable standards.

All the relevant safety regulations, e.g. accident prevention regulations, law on technical work equipment, must also be observed.

Safety instructions

Protect the unit against moisture, dirt and any kind of damage during transport, storage and operation. Do not operate the unit outside the specified technical data.

Never open the housing. If not otherwise specified, install in closed

housing (e.g. distribution cabinet). Earth the unit at the terminals

provided, if existing, for this purpose. Do not obstruct cooling of the

units. Keep out of the reach of children.

Setting up

The physical address assignment and the setting of parameters (if

any) must be performed by the specific softwares provided together the device or by the specific programmer. For the first installation of the device proceed according to the following guidelines:

• Check that any voltage supplying the plant has been removed

• Assign the address to module (if any)

• Install and wire the device according to the schematic dia-

grams on the specific data sheet of the product

• Only then switch on the 230Vac supplying the bus power sup-

ply and the other related circuits

Applied standards

This device complies with the essential requirements of the following directives:

2004/108/CE (EMC)

2006/95/CE (Low Voltage)

2002/95/CE (RoHS)

Note

Technical characteristics and this data sheet are subject to change

without notice.

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 May 2013 Page 11 of 11

Loading...

Loading...