Page 1

INSTALLATION AND USER INSTRUCTIONS

BUILT-IN MIXED HOB, INDUCTION DOMINO HOB

Page 2

2

WARNING:

The appliance and its accessible parts become hot

during use.

Care should be taken to avoid touching heating elements.

Children less than 8 years of age shall be kept away unless

continuously supervised.

This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe

way and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without

supervision.

WARNING:

Unattended cooking on a hob with fat or oil can be

dangerous and may result in fire. NEVER try to extinguish a fire with

water, but switch off the appliance and then cover flame e.g. with a lid

or a fire blanket.

WARNING: Danger of fire: do not store items on the cooking

surfaces.

WARNING: If the surface is cracked, switch of the appliance to

avoid the possibility of electric shock.

WARNING: do not use a steam cleaning unit of: stoves, hobs

and ovens.

WARNING: the hob is not designed to work with an external timer,

or with a remote control system.

WARNING: Use only hob guards designed by the manufacturer of

the cooking appliance or indicated by the manufacturer of the

appliance in the instructions for use as suitable or hob guards

incorporated in the appliance. The use of inappropriate guards

can cause accidents.

WARNING:The cooking process has to be supervised. A short

term cooking process has to be supervised continuously.

Page 3

3

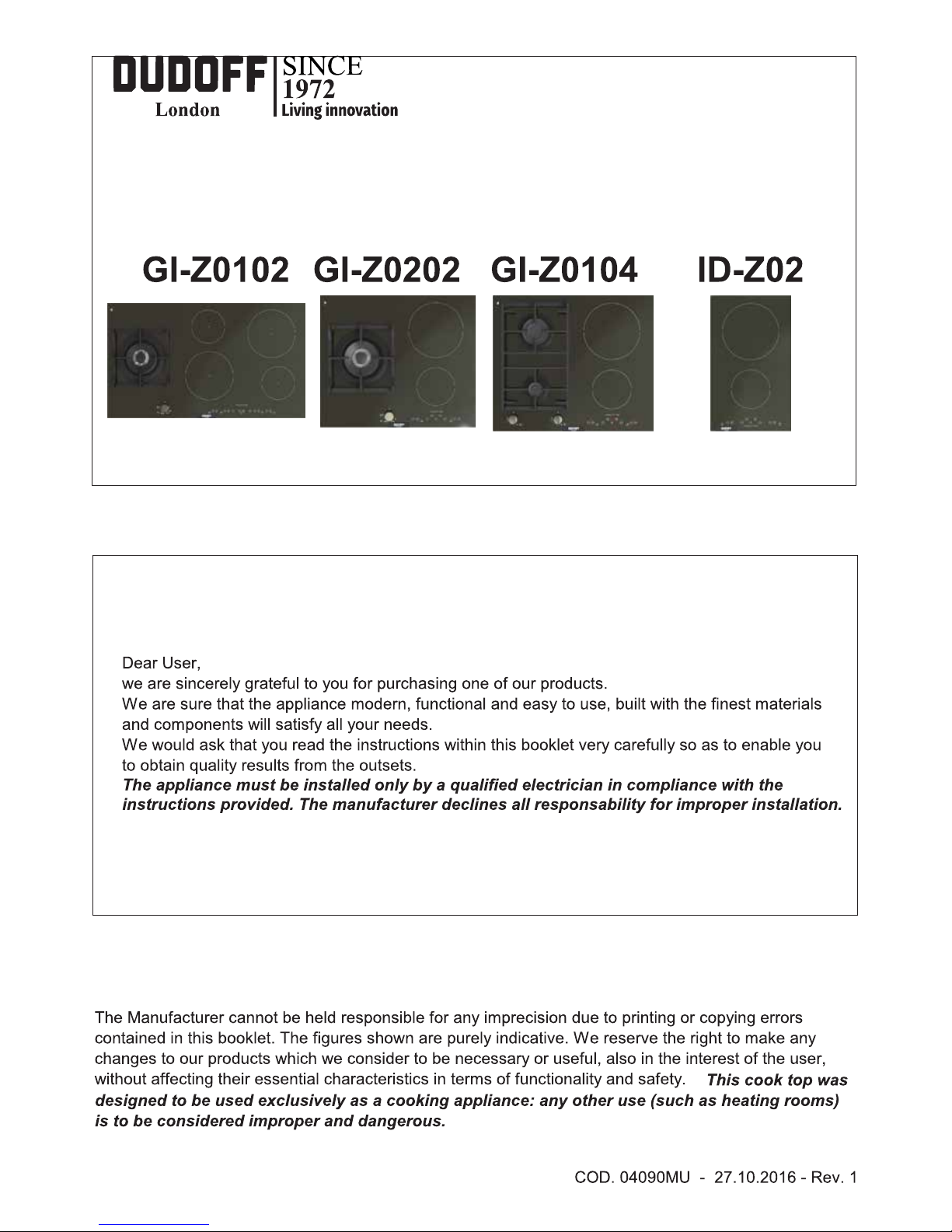

DESCRIPTION

The appliance has 2 cooking areas with different sizes and different power levels. The induction

elements are of the magnetic induction type, which come on after selecting the heating element, and the

heat can be regulated using the controls on the front panel, from a minimum of 1 to a maximum of 9

(depending on the models).

The cooking areas have concentric discs with the following diameters.

COOKING AREA

TYPE: PCZ VTCI

with booster

1 Induction element Ø 14,5 cm 1200 W 1600 W

2 Induction element Ø 21,0 cm 1500 W 2000 W

3 Touch control

Page 4

4

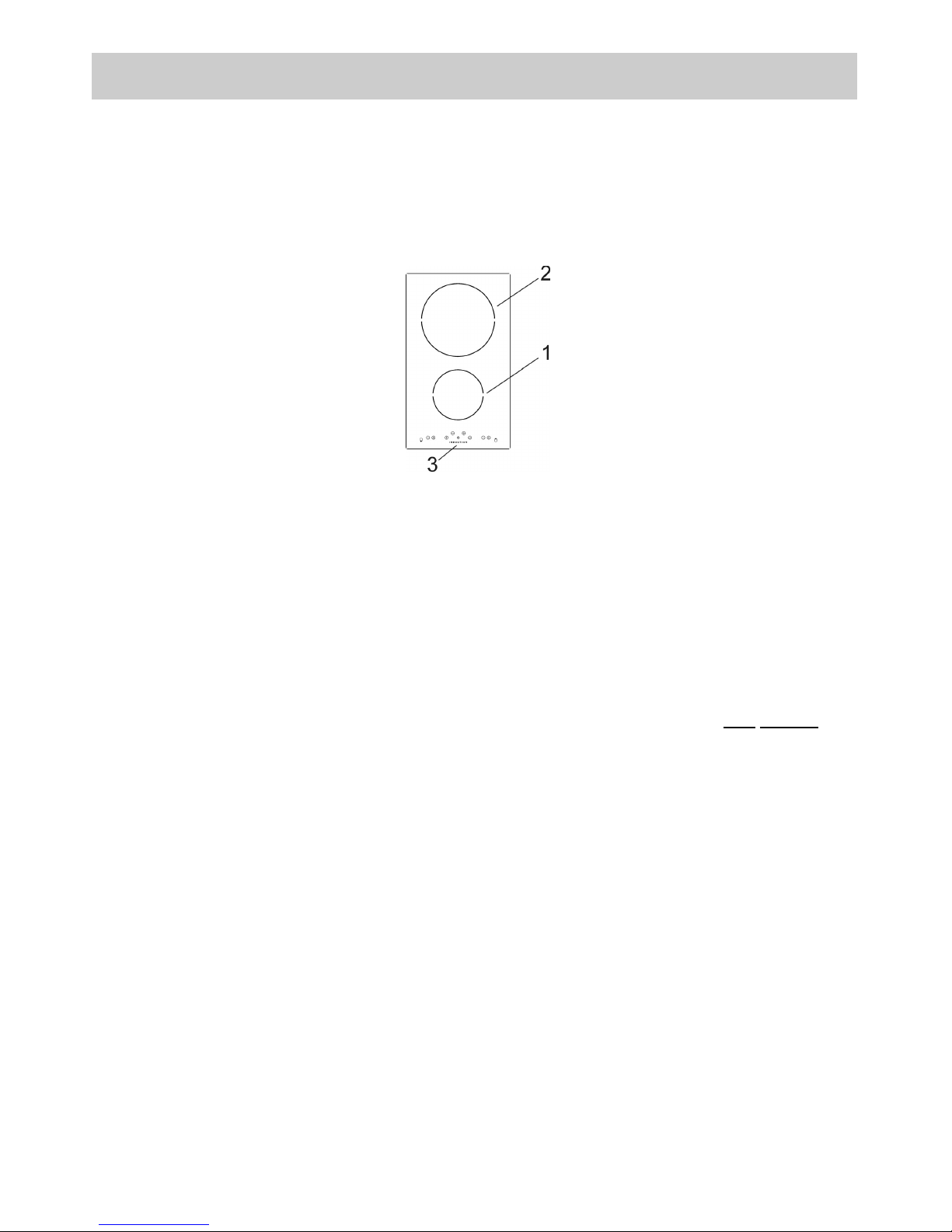

DESCRIPTION

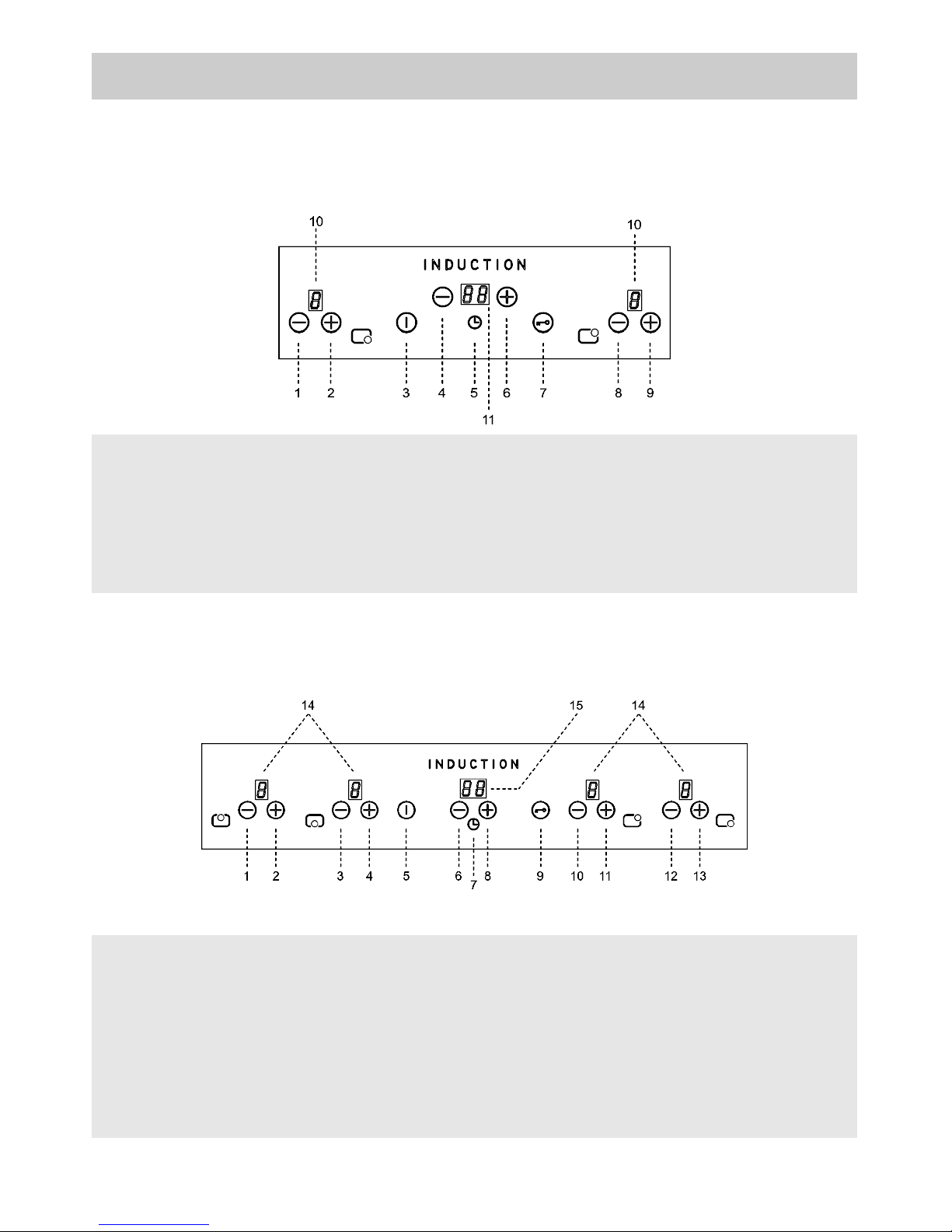

DESCRIPTION OF FRONT PANEL CONTROLS

2 INDUCTION ELEMENT

1 - Induction element 1 – button

2 - Induction element 1 + button

3 - ON/OFF button

4 - TIMER programming – button

5 - Clock levels display

6 - TIMER programming + button

7 - Safety lock button

8 - Induction element 2 – button

9 - Induction element 2 + button

10 - Display cooking levels (0 - 9)

11 - Symbol TIMER

Page 5

5

INITIAL LIGHT CONDITIONS

When power is initially applied to the Cooktop, the touch control conducts a calibration process for the

touch keys, which requires a low level of ambient light in the area of the touch keys.

If during this calibration process excessive ambient lighting is detected the User Interface displays “FL”

(Infrared Ambient Light Error) and the control calibration process is suspended. In order to rectify the

process any lighting that could effect the calibration process should be switched off (e.g. halogen cooker

hood lighting). The error will disappear when satisfactory ambient lighting is detected and the touch

control calibration procedure will now complete satisfactorily.

Notes:

● the “FL” error can only be generated within approx 3s of initial power being applied to the cooktop.

● We recommend that the user switches off all cooker hood lighting and lighting directed towards the

cooktop when power is initially applied to the cooktop.

● After the touch control has conducted its initial calibration process (approx 3s), any cooker hood or

other lighting can be switched on as normal and will not affect the operation of the touch control.

INSTRUCTIONS FOR THE USER

Every time a symbol is pressed it is confirmed by a beep. The functions of hobs that use this type of

technology are activated by gently pressing the symbols printed on the surface. When connecting to the

electricity supply for the first time, an operating check will be run and all the warning lights will light up for

a few seconds.

Model: 30 cm.

ARRANGEMENT OF THE HEATING ELEMENTS

FRONT BACK

Every time the hob is reconnected to the electricity supply, the control panel lock is active and the

relative led in on.

After removing the control panel lock (by pressing the symbol for 1 second), switch on the hob by

pressing the symbol for a few seconds. If no function is activated within 10 seconds, the hob will

switch off automatically. The associated heating element is indicated next to every control area.

Identify the heating element to activate ( ) and then activate it using the and

symbol, regulating the level of cooking required on a scale o 1 to 9. With the heating element set

on 9 it is possible, pressing the key, to activate the “fast boil” function (booster), indicated with a

P

on the display. The heating element will work at maximum power for 10 minutes, after which it will return

to level 9, issuing a beep.

DESCRIPTION

Page 6

6

TIMER

There is a timer for setting cooking times from 1 to 99 minutes (symbol ).

After activating the cooking area required, selecting it on the display, activate the timer by pressing the

or symbol above the symbol. Then return to the heating element to be programmed by pressing its

or symbol. Return to the timer and set the programming time using the or symbol. The

programmed heating element is highlighted by the corresponding led above the cooking level indicator.

The timer will start 5 seconds after the last symbol has been pressed and the heating element will operate

until the number on the display reaches 0. The heating element will then switch off automatically. When the

time ends a sequence of beeps will be repeated at 3 second intervals for 1 minute.

During timed cooking it is possible to change the operating power and the cooking time. Every time the

or symbols of the cooking area are pressed, the heating element operating power is increased or

reduced. To change the amount of time remaining, it is necessary to press the or symbol of the

heating element until the led position in the cooking area switches on. Then the operating time can be

changed using the and symbols of the timer.

KEY LOCK FUNCTION

Lock Function (

): this function prevents the hob from being accidentally switched on (child safety lock).

To activate it, the sensor must be pressed for about three seconds (the warning light comes on). It is

not possible to make the heating areas work if is active. If the heating elements are still working, it is

possible to switch them off while is active. This function is deactivated by pressing the sensor for

two seconds, for all the configurations.

RESIDUAL HEAT

Every plate has a device which indicates the presence of residual heat. On the display, after switching off

any plate, an may appear. This signal indicates that the cooking area is still very hot. It is possibile

to start cooking food again even when the is visibile, by reactivating the heating element required.

SWITCHING OFF THE PLATES

The plates switch off when the relative operating power display indicates 0. The plate will be

automatically deactivated five seconds after the 0 appears on the display. If the plates are hot, the

indicating the presence of residual heat will appear. To immediately switch off an element, simply touch

the and keys together, or the

key until 0 appears on the display.

SWITCHING OFF THE HOB

The hob is switched off by pressing the symbol for one second, even if the plates are operating; all

the plates will be deactivated and the hob will switch off completely. If the plates are hot, the

indicating the presence of residual heat will appear after switching off. There is a heat protection system

installed inside the hob. If the temperature exceeds 95 °C, the hob switches off automatically. This is to

prevent excessive temperature from damaging the internal components.

DESCRIPTION

Page 7

7

WARNINGS:

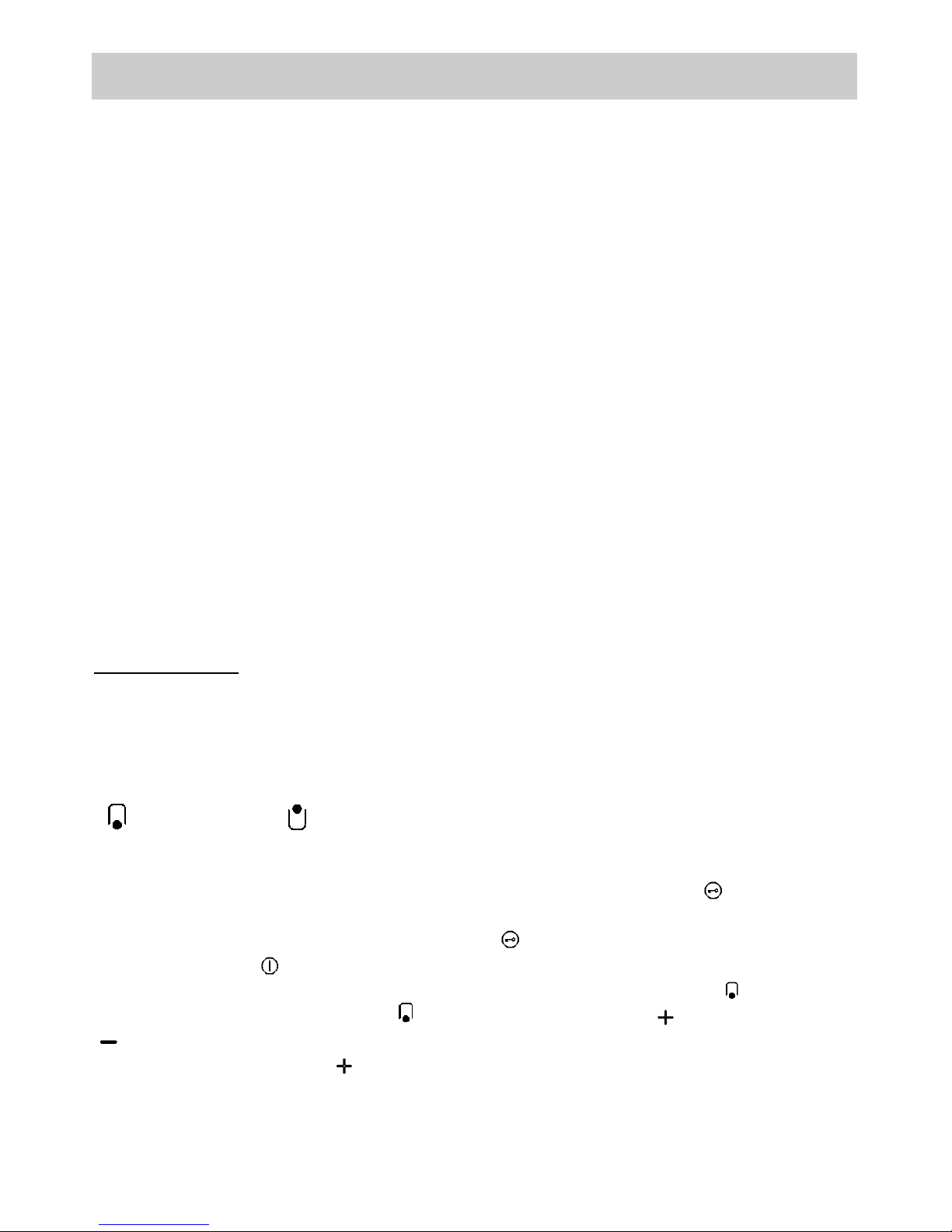

see figure 1 for correct use, and remember:

- only connect the power supply after placing

the pan on the cooking area.

- Use pans with a thick, flat bottom.

- Dry the bottom of the pan before placing it on

the cooking area.

- Do not drag pans across the glass hob as

this may damage the surface.

- Never leave the appliance unattended while

the cooking areas are in use and ensure that

children are kept at a safe distance. Pay

close attention to children because they are

unlikely to see the “H” indication of residual

heat. After use, the cooking areas remain

very hot for a while, even when they have

been switched off. Do not allow children to

rest their hands on them. After using the hob,

always make sure that the controls are in the

“zero” position (off). Make sure that pan

handles are correctly positioned towards the

inside and supervise the cooking of foods in

oil and fat, as these are highly flammable.

- After use, the cooking areas remain hot for a

long time; do not rest your hands or other

objects on them to avoid the risk of burns,

until the “H” indicating the presence of

residual heat has switched off.

- Should a crack appear on the surface of the

glass, disconnect the appliance from the

electricity supply immediately.

- Do not rest sheets of aluminium or plastic

containers on the hot surface.

- Do not use the hob as a work surface.

- The pans must be properly centred on the

heating elements (see fig. 2). If the pan is not

properly centred over the corresponding

printed area or is removed without switching

the element off, a sensor automatically

switches off the hob after a few seconds and

the symbol appears on the display

indicating the absence of the pan. If the pan

is not returned to or correctly positioned on

the cooking area within 1 minute, the hob

resets and if no control is pressed, it

switches off after 20 seconds.

- If the power level does not change during a

set period of time, the corresponding heating

element switches off automatically. The

maximum time that a heating element can

remain switched on depends on the cooking

level selected (see table below: HOB

AUTOMATIC SWITCH-OFF). glass, terracotta,

aluminium without a special finish on the

bottom, copper or non-magnetic steel pans

are not suitable for use with the induction

hob. We recommend using thick-bottomed

pans so that the heat is distributed properly

and the food cooks more evenly. Always use

pans bearing the logo indicating that they are

suitable for use with an induction hob, with

the word INDUCTION. Use a magnet to check

that your pans are compatible: if the magnet

is attracted to the pan, it is compatible for

use.

See the following table for the pan diameters

to use:

Pans with smaller diameters risk non being

detected and therefore not activating the

inductor.

USE

Power level selected

Corresponding time

(in hours)

1 10

2 10

3 10

4 10

5 10

6 10

7 10

8 10

9 3

HOB AUTOMATIC SWITCH-OFF

Coil Ø Minimun pan Ø

14,5 cm 9,0 cm

21,0 cm 13,0 cm

FIG. 2

Page 8

8

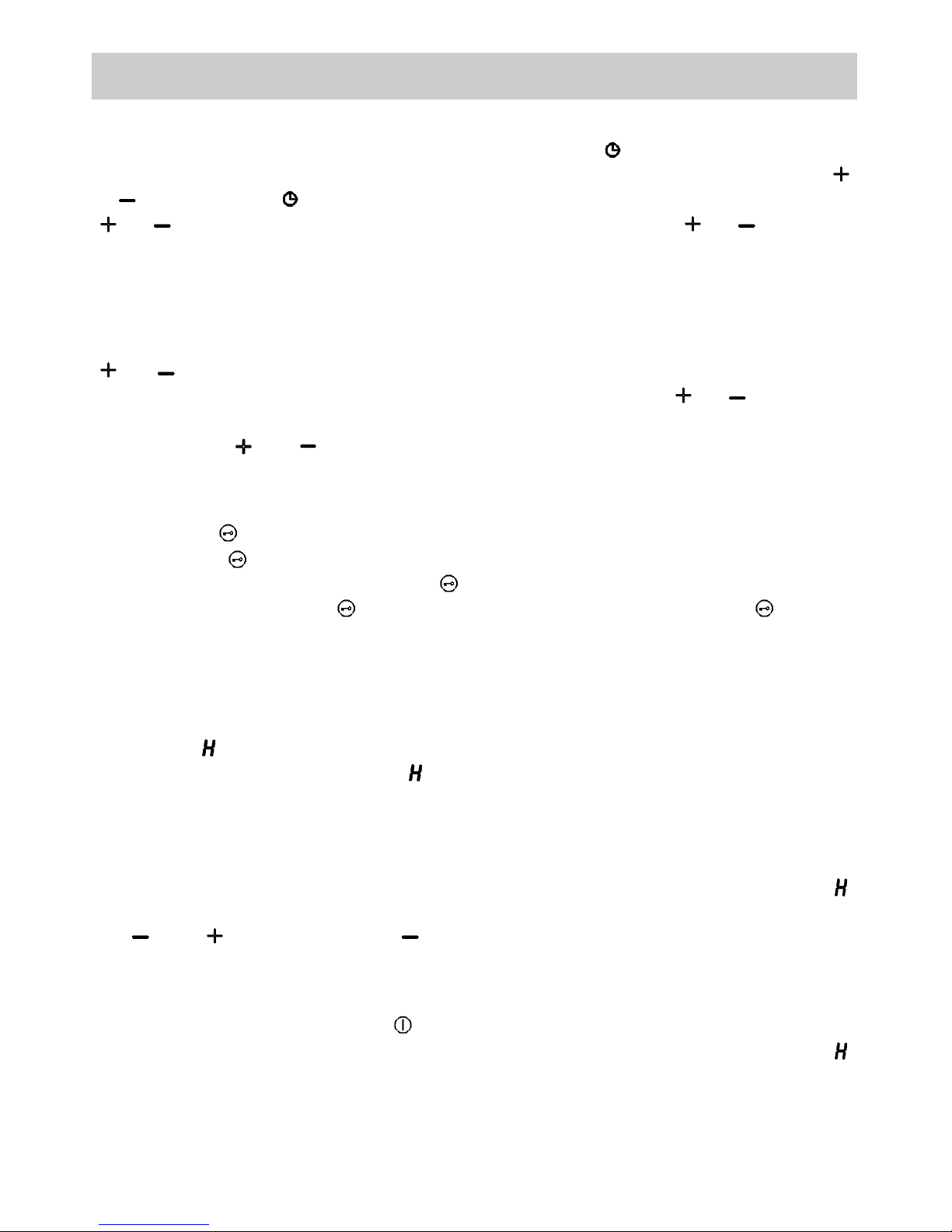

TYPE: PCZVB

1 Double crown burner of 5000 W

2 Triple crown burner of 4000 W

4 Rapid burner of 2800 W

5 Auxiliary burner of 1000 W

6 Electric heating element induction Ø 14,5 cm

of 1200 W (booster function 1600 W)

7 Electric heating element induction Ø 21,0 cm

of 1500 W (booster function 2000 W)

8 Pan support

9 Burner n° 1 control knob

10 Burner n° 2 control knob

12 Burner n° 4 control knob

13 Burner n° 5 control knob

14 Touch control

Attention: this appliance has been manufactured for domestic use only and it employment by

private person.

The appliance has 2/4 cooking areas with different sizes and different power levels. The heating

elements are of the magnetic induction type, which come on after selecting the heating element, and the

heat can be regulated using the controls on the front panel, from a minimum of 1 to a maximum of 9

(depending on the models). There is also a fast boiling function (booster) indicated by the letter Pon the

display. The cooking areas have concentric discs with the following diameters.

DESCRIPTION

Page 9

9

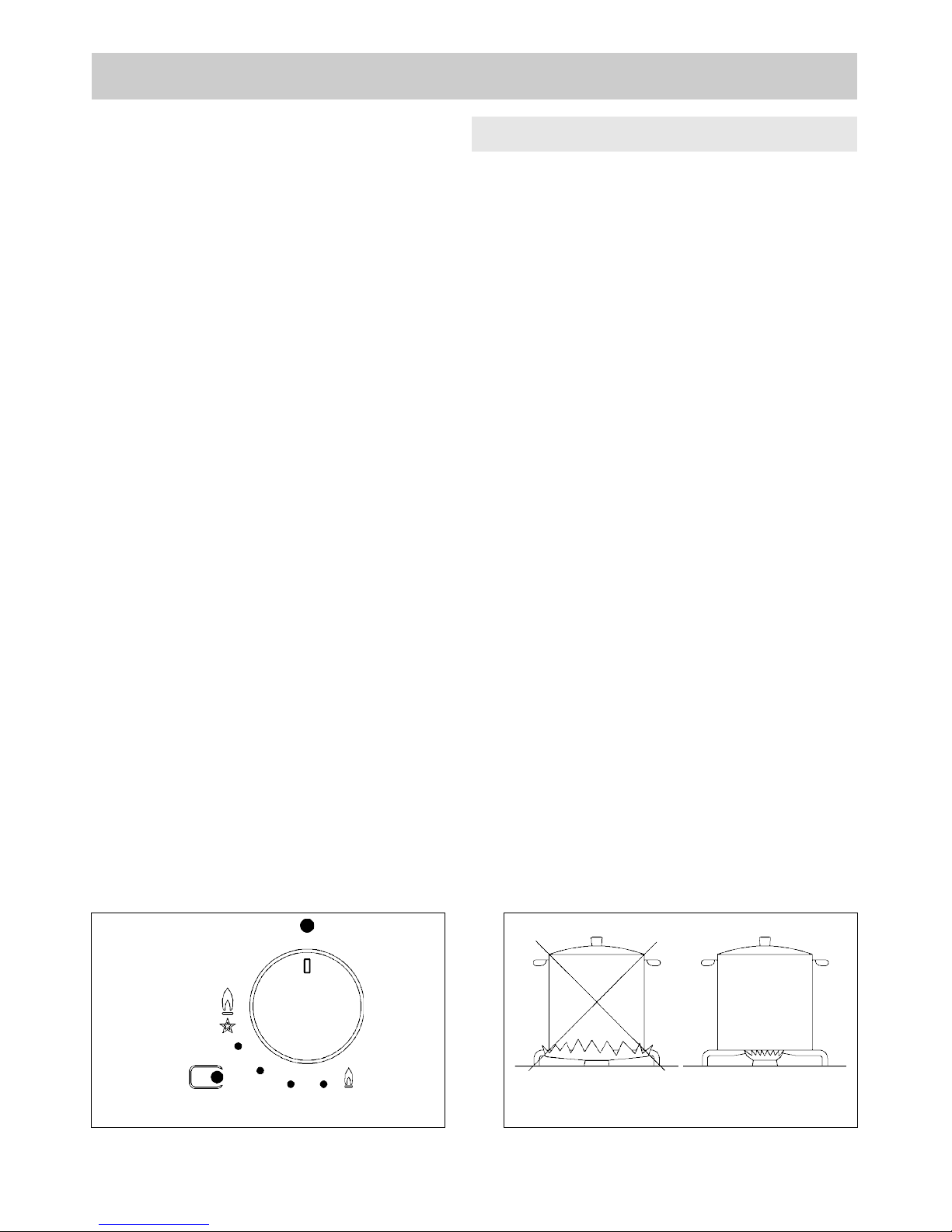

DESCRIPTION OF FRONT PANEL CONTROLS

DESCRIPTION

DESCRIPTION OF FRONT PANEL CONTROLS

1 - Induction element 6 – button

2 - Induction element 6 + button

3 - ON/OFF button

4 - TIMER programming – button

5 - Symbol TIMER

6 - TIMER programming + button

7 - Safety lock button

8 - Induction element 7 – button

9 - Induction element 7 + button

10 - Display cooking levels (0 - 9)

11 - Display clock

1 - Induction element 7 – button (left)

2 - Induction element 7 + button (left)

3 - Induction element 6 – button (left)

4 - Induction element 6 + button (left)

5 - ON/OFF button

6 - TIMER programming – button

7 - Symbol TIMER

8 - TIMER programming + button

9 - Safety lock button

10 - Induction element 7 – button (right)

11 - Induction element 7 + button (right)

12 - Induction element 6 – button (right)

13 - Induction element 6 + button (right)

14 - Display cooking levels (0 - 9)

15 - Display clock

60 cm.

90 cm.

Page 10

10

USE

FIG. 2

1) TRADITIONAL BURNERS

A diagram is screen-printed above each knob on

the front panel. This diagram indicates to which

burner the knob in question corresponds. After

having opened the gas mains or gas bottle tap,

light the burners as described below:

- manual ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1),

then place a lighted match near the burner.

- Automatic electrical ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1),

then depress the knob.

- Lighting burners equipped with flame failure

device

The knobs of burners equipped with flame failure

device must be turned in an anticlockwise direction

until they reach the full on position (large flame

fig. 1) and come to a stop. Now depress the knob

in question and repeat the previously indicated

operations.

Keep the knob depressed for about 10 seconds

once the burner has ignited.

Note: you are advise not to try and light a

burner if the flame divider (Burner Cap) is not

correctly place.

In the event of the Burner flames being

accidentally extinguished, turn off the burner

control and do not attempt to re-ignite the

burner for a least 1 minute.

HOW TO USE THE BURNERS

Bear in mind the following indications in order to

achieve maximum efficiency with the least possible

gas consumption:

- use adequate pans for each burner (consult the

following table and fig. 2).

- When the pan comes to the boil, set the knob to

the reduced rate position (small flame fig. 1).

- Always place a lid on the pans.

- Use only pan with a flat bottom and in thick

metal.

WARNINGS:

- burners with flame failure device may only be

ignited when the relative knob has been set to

the Full on position (large flame fig. 1).

- Matches can be used to ignite the burners in

a blackout.

- Never leave the appliance unattended when

the burners are being used. Make sure there

are no children in the near v i c i n i t y.

Particularly make sure that the pan handles

are correctly positioned and keep a check on

foods requiring oil and grease to cook since

these products can easily catch f i r e .

- Never use aerosols near the appliance when it

is operating.

- Containers wider than the unit are not

recommended.

Closed position

Full on position

Reduced rate

position

Burners Power W Ø Pan cm

Double crown 5000

24 ÷ 26

Triple crown 4000

24 ÷ 26

Rapid 2800

20 ÷ 22

Auxiliary 1000

10 ÷ 14

FIG. 1

Page 11

11

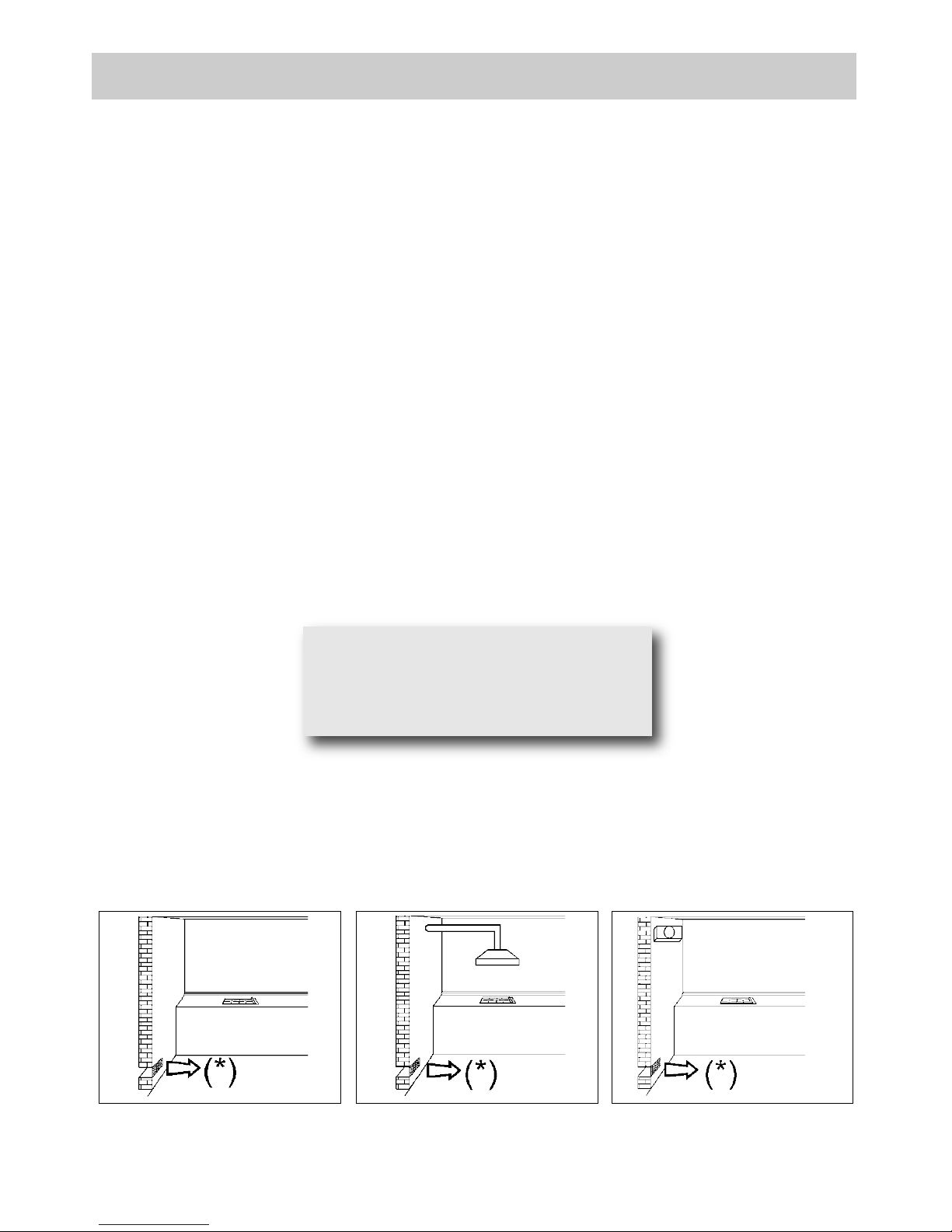

USE

During, and immediately after operation,

some parts of the cook top are very hot:

avoid touching them.

FIG. 3 FIG. 4 FIG. 5

(*) AIR INLET: SEE INSTALLATION CHAPTER (PARAGRAPHS 7 AND 8)

WARNINGS AND ADVICE FOR THE USER:

- use of a gas cooking appliance produces heat and moisture in the room in which it is installed.

The room must therefore be well ventilated by keeping the natural air vents clear (fig. 3) and by

activating the mechanical aeration device (suction hood or electric fan fig. 4 and fig. 5).

- Intensive and lengthy use of the appliance may require additional ventilation. This can be

achieved by opening a window or by increasing the power of the mechanical exhausting system

if installed.

- After using the cook top, make sure that the knob is in the closed position and close the main

tap of the gas supply or gas cylinder.

- If the gas taps are not operating correctly, call the Customer Care Department.

Page 12

2) INSTRUCTIONS FOR THE USER

Every time a symbol is pressed it is confirmed by a beep. The functions of hobs that use this type of

technology are activated by gently pressing the symbols printed on the surface. When connecting to the

electricity supply for the first time, an operating check will be run and all the warning lights will light up for

a few seconds.

USE

WARNING FOR USE:

►

The appliance is built to perform the following function: cooking and heating food.

Every other use must be considered improper.

►

Never use this appliance to heat the environment.

►

Do not attempt to change the technical characteristics of the product because it

can be dangerous.

►

If you should not to use this appliance any more (or replace an old model), before disposing

of it, make it inoperative in conformity with current law on the protection of health and the

prevention of environmental pollution by making its dangerous parts harmless, especially

for children who might play on an abandoned appliance.

►

Do not touch the appliance with wet or damp hands or feet.

►

Do not use the appliance barefoot.

►

The manufacturer will not be liable for any damage resulting from improper, incorrect or

unreasonable use.

►

If the ceramic hob is not cleaned immediately there is a risk of forming encrustations which

are impossible to remove after the hob has cooled or has been reheated several times.

►

Do not use gloves when programming the hob. Press with clean fingers and touch the

glass gently.

►

Do not leave any type of metallic object, such as forks, knives, spoons or lids on the hob, as

they might accumulate heat, posing a hazard.

►

The hob operates in compliance with the current legislation on electromagnetic fields and

interference deriving from their use. The appliance in fully compliant with the legal

requirements in force. Wearers of pacemakers or other similar devices must ensure that

these appliances have been built or operate in compliance with the above legislation.

►

Wearers of pacemakers or other similar devices must be certain that the operation of these

devices is not disturbed by the magnetic field generated by the hob, which has a frequency

between 20 KHz and 50 KHz.

12

Page 13

13

USE

ARRANGEMENT OF THE HEATING ELEMENTS

Model: 60 cm.

FRONT BACK

Every time the hob is reconnected to the electricity supply, the control panel lock is active and the

relative led in on.

After removing the control panel lock (by pressing the symbol for 1 second), switch on the hob by

pressing the key for a few seconds.

If no function is activated within 10 seconds, the hob will switch off automatically.

The associated heating element is indicated next to every control area. Identify the heating element to

activate and then activate it using the and keys, regulating the level of cooking required on a

scale o 1 to 9. With the heating element set on 9 it is possible, pressing the , key, to activate the “fast

boil” function (booster), indicated with a P on the display. The heating element will work at maximum power

for 10 minutes, after which it will return to level 9, issuing a beep.

TIMER

There is a timer for setting cooking times from 1 to 99 minutes (symbol ).

After activating the cooking area required, selecting it on the display, activate the timer by pressing the

or symbol above the symbol. Then return to the heating element to be programmed by

pressing its or symbol. Return to the timer and set the programming time using the or

symbol. The programmed heating element is highlighted by the corresponding led above the cooking level

indicator.

The timer will start 5 seconds after the last symbol has been pressed and the heating element will operate

until the number on the display reaches 0. The heating element will then switch off automatically. When the

time ends a sequence of beeps will be repeated at 3 second intervals for 1 minute.

During timed cooking it is possible to change the operating power and the cooking time. Every time the

or symbols of the cooking area are pressed, the heating element operating power is increased or

reduced. To change the amount of time remaining, it is necessary to press the or symbol of the

heating element until the led position in the cooking area switches on. Then the operating time can be

changed using the and symbols of the timer.

Page 14

USE

KEY LOCK FUNCTION

Lock Function (

): this function prevents the hob from being accidentally switched on (child safety

lock). To activate it, the sensor must be pressed for about three seconds (the warning light comes

on). It is not possible to make the heating areas work if is active. If the heating elements are still

working, it is possible to switch them off while is active. This function is deactivated by pressing the

sensor for two seconds, for all the configurations.

RESIDUAL HEAT

Every plate has a device which indicates the presence of residual heat. On the display, after switching off

any plate, an may appear. This signal indicates that the cooking area is still very hot. It is possibile

to start cooking food again even when the is visibile, by reactivating the heating element required.

SWITCHING OFF THE PLATES

The plates switch off when the relative operating power display indicates 0. The plate will be

automatically deactivated five seconds after the 0 appears on the display. If the plates are hot, the

indicating the presence of residual heat will appear. To immediately switch off an element, simply touch

the and keys together, or the key until 0 appears on the display.

SWITCHING OFF THE HOB

The hob is switched off by pressing the symbol for one second, even if the plates are operating; all

the plates will be deactivated and the hob will switch off completely. If the plates are hot, the

indicating the presence of residual heat will appear after switching off. There is a heat protection system

installed inside the hob. If the temperature exceeds 95 °C, the hob switches off automatically. This is to

prevent excessive temperature from damaging the internal components.

Model: 90 cm.

FRONT LEFT BACK LEFT BACK CENTRAL

FRONT RIGHT BACK RIGHT FRONT CENTRAL

Every time the hob is reconnected to the electricity supply, the control panel lock is active and the

relative led in on.

After removing the control panel lock (by pressing the symbol for 1 second), switch on the hob by

pressing the key for a few seconds. If no function is activated within 10 seconds, the hob will switch

off automatically. The associated heating element is indicated next to every control area. Identify

the heating element to activate ( ) and then activate it using the and keys, regulating the

level of cooking required on a scale o 1 to 9. With the heating element set on 9 it is possible, pressing the

key, to activate the “fast boil” function (booster), indicated with a

P

on the display. The heating

element will work at maximum power for 10 minutes, after which it will return to level 9, issuing a beep.

14

Page 15

15

USE

TIMER

There is a timer for setting cooking times from 1 to 99 minutes (symbol ).

After activating the cooking area required, selecting it on the display, activate the timer by pressing the

or symbol above the symbol. Then return to the heating element to be programmed by pressing its

or symbol. Return to the timer and set the programming time using the or symbol. The

programmed heating element is highlighted by the corresponding led above the cooking level indicator.

The timer will start 5 seconds after the last symbol has been pressed and the heating element will operate

until the number on the display reaches 0. The heating element will then switch off automatically. When the

time ends a sequence of beeps will be repeated at 3 second intervals for 1 minute.

During timed cooking it is possible to change the operating power and the cooking time. Every time the

or symbols of the cooking area are pressed, the heating element operating power is increased or

reduced. To change the amount of time remaining, it is necessary to press the or symbol of the

heating element until the led position in the cooking area switches on. Then the operating time can be

changed using the and symbols of the timer.

KEY LOCK FUNCTION

Lock Function (

): this function prevents the hob from being accidentally switched on (child safety

lock). To activate it, the sensor must be pressed for about three seconds (the warning light comes

on). It is not possible to make the heating areas work if is active. If the heating elements are still

working, it is possible to switch them off while is active. This function is deactivated by pressing the

sensor for two seconds, for all the configurations.

RESIDUAL HEAT

Every plate has a device which indicates the presence of residual heat. On the display, after switching off

any plate, an may appear. This signal indicates that the cooking area is still very hot. It is possibile

to start cooking food again even when the is visibile, by reactivating the heating element required.

SWITCHING OFF THE PLATES

The plates switch off when the relative operating power display indicates 0. The plate will be

automatically deactivated five seconds after the 0 appears on the display. If the plates are hot, the

indicating the presence of residual heat will appear. To immediately switch off an element, simply touch

the and keys together, or the key until 0 appears on the display.

SWITCHING OFF THE HOB

The hob is switched off by pressing the symbol for one second, even if the plates are operating; all

the plates will be deactivated and the hob will switch off completely. If the plates are hot, the

indicating the presence of residual heat will appear after switching off. There is a heat protection system

installed inside the hob. If the temperature exceeds 95 °C, the hob switches off automatically. This is to

prevent excessive temperature from damaging the internal components.

Page 16

USE

FIG. 6

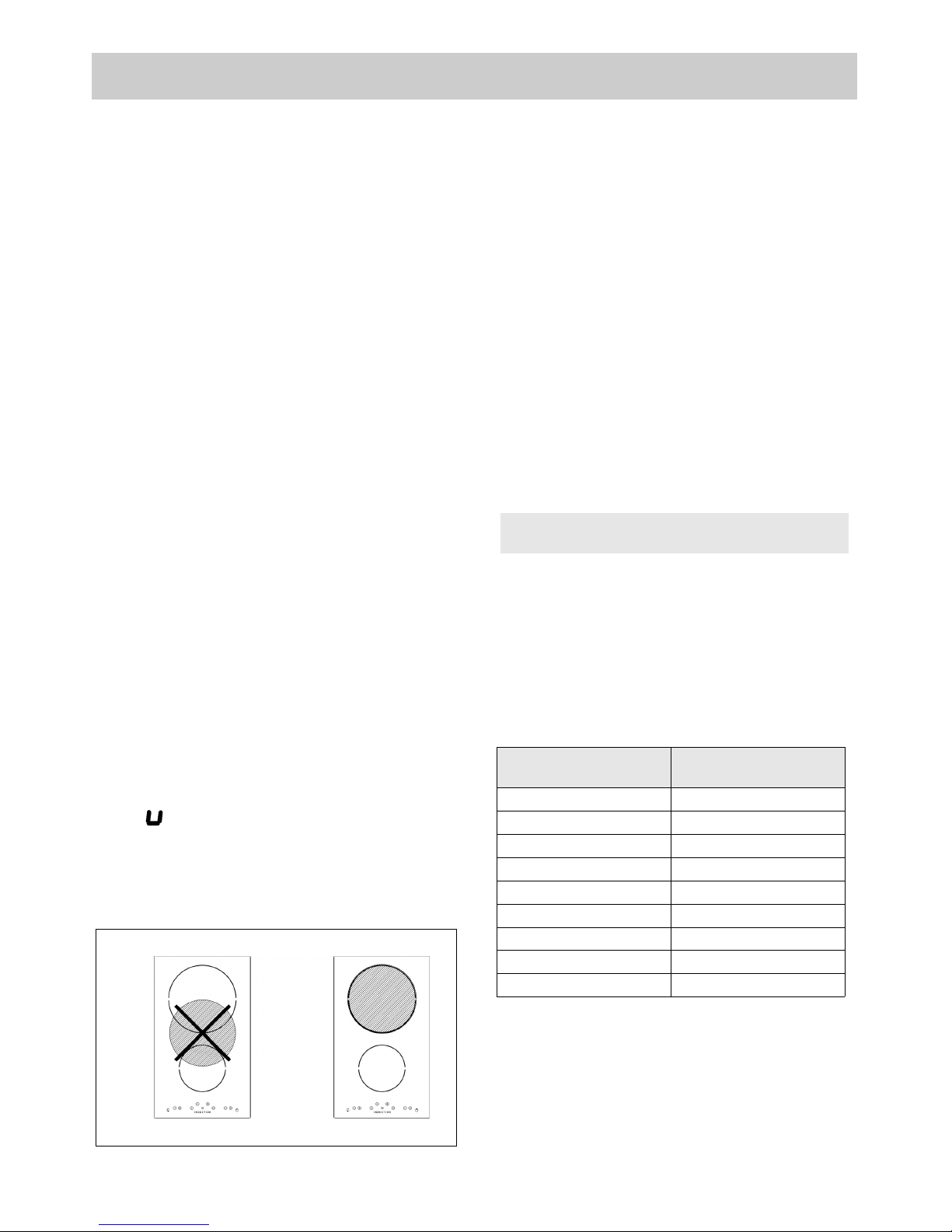

Power and dimensions

of the cooking area

Area

no.

Diameter

in cm

Power

W

Touch control

positions

Cooking

operations

with booster

6 14,5 1200 1600 1

To melt butter, chocolate,

etc.; to heat small

amounts of liquid.

7 21,0 1500 2000 1 - 3

To heat larger amonts of

liquid; to prepare creams

and sauces reuiring

lenththy cooking times.

4 - 8

To thaw frozen foods and

prepare stews, heat to

boiling point or simmer.

5 - 9

To cook foods that have

to be boiled, for delicate

roastmeats and fish.

9 - P

To boil large amounts of

liquid, to fry..

3) GUIDE TO COOKING

The table below indicates the power values that can be set and the type of food to prepare is shown next

to each one. The values can change according to the amount of food and consumer preference.

TABLE

In order to cook with the heating element

efficiently using the least amount of energy,

use: thick, flat-bottomed pots of a width

suited to that of the heating element (see

picture). Cook with the lid on to also save

energy. Turn down the heating element

when it reaches boiling point.

16

Page 17

17

USE

WARNINGS:

see figure 7 for correct use, and remember:

- only connect the power supply after placing

the pan on the cooking area.

- Use pans with a thick, flat bottom.

- Dry the bottom of the pan before placing it on

the cooking area.

- Do not drag pans across the glass hob as

this may damage the surface.

- Never leave the appliance unattended while

the cooking areas are in use and ensure that

children are kept at a safe distance. Pay

close attention to children because they are

unlikely to see the “H” indication of residual

heat. After use, the cooking areas remain

very hot for a while, even when they have

been switched off. Do not allow children to

rest their hands on them. After using the hob,

always make sure that the controls are in the

“zero” position (off). Make sure that pan

handles are correctly positioned towards the

inside and supervise the cooking of foods in

oil and fat, as these are highly flammable.

- After use, the cooking areas remain hot for a

long time; do not rest your hands or other

objects on them to avoid the risk of burns,

until the “H” indicating the presence of

residual heat has switched off.

- Should a crack appear on the surface of the

glass, disconnect the appliance from the

electricity supply immediately.

- Do not rest sheets of aluminium or plastic

containers on the hot surface.

- Do not use the hob as a work surface.

- The pans must be properly centred on the

heating elements (see fig. 7). If the pan is not

properly centred over the corresponding

printed area or is removed without switching

the element off, a sensor automatically

switches off the hob after a few seconds and

the symbol appears on the display

indicating the absence of the pan. If the pan

is not returned to or correctly positioned on

the cooking area within 1 minute, the hob

resets and if no control is pressed, it

switches off after 20 seconds.

- If the power level does not change during a

set period of time, the corresponding heating

element switches off automatically. The

maximum time that a heating element can

remain switched on depends on the cooking

level selected (see table below: HOB

AUTOMATIC SWITCH-OFF).

- Glass, earthenware, aluminium without a

special finish on the bottom, copper or nonmagnetic steel pans are not suitable for use

with the induction hob.

- We recommend using thick-bottomed pans

so that the heat is distributed properly and

the food cooks more evenly.

- Always use pans bearing the logo indicating

that they are suitable for use with an

induction hob, with the word INDUCTION.

Use a magnet to check that your pans are

compatible: if the magnet is attracted to the

pan, it is compatible for use.

See the following table for the pan diameters

to use:

Pans with smaller diameters risk non being

detected and therefore not activating the

inductor.

Power level

selected

Corresponding time

(in hours)

1 10

2 10

3 10

4 10

5 10

6 10

7 10

8 10

9 3

HOB AUTOMATIC SWITCH-OFF

Cooking zone Ø Minimun pan Ø

14,5 cm 9,0 cm

21,0 cm 13,0 cm

FIG. 7

Page 18

IMPORTANT:

always disconnect the appliance from the gas

and electricity mains before carrying out any

cleaning operation.

4) CERAMIC WORKTOP

It is very important to clean the hob every time you

use it, while the glass is still warm.

Do not clean using abrasive metal scourers,

powder abrasives or corrosive sprays.

Periodically wash the hot plate, the pan support,

the enamelled burner caps “A”, “B” and “C” and

the burner heads "T" (see fig. 8/A - 8/B) with

lukewarm soapy water.

They should also be cleaned plugs "AC" and flame

detection "TC" (see fig. 8/B).

Clean them gently with a small nylon brush as

shown (see fig. 8) and allow to dry fully.

Do not wash in the dishwasher.

Following this, all parts should be thoroughly

rinsed and dried. Never wash them while they are

still warm and never use abrasive powders.

WARNINGS:

comply with the following instructions, before

remounting the parts:

●check that burner head slots “T” (fig. 8/A)

have not become clogged by foreign bodies.

●Check that enamelled burner cap “A”, “B”

and “C” (fig. 8/A - 8/B) have correctly

positioned on the burner head. It must be

steady.

●The exact position of the pan support is

established by the rounded corners, which

should be set towards the side edge of the

cooktop.

●Do not force the taps if they are difficult open

or close. Contact the technical assistance

service for repairs.

●Don’t use steam jets for the equipment

cleaning.

FIG. 8

FIG. 8/B

FIG. 8/A

CLEANING

18

Note:

continuous use could cause the burners to

change colour due to the high temperature.

Page 19

19

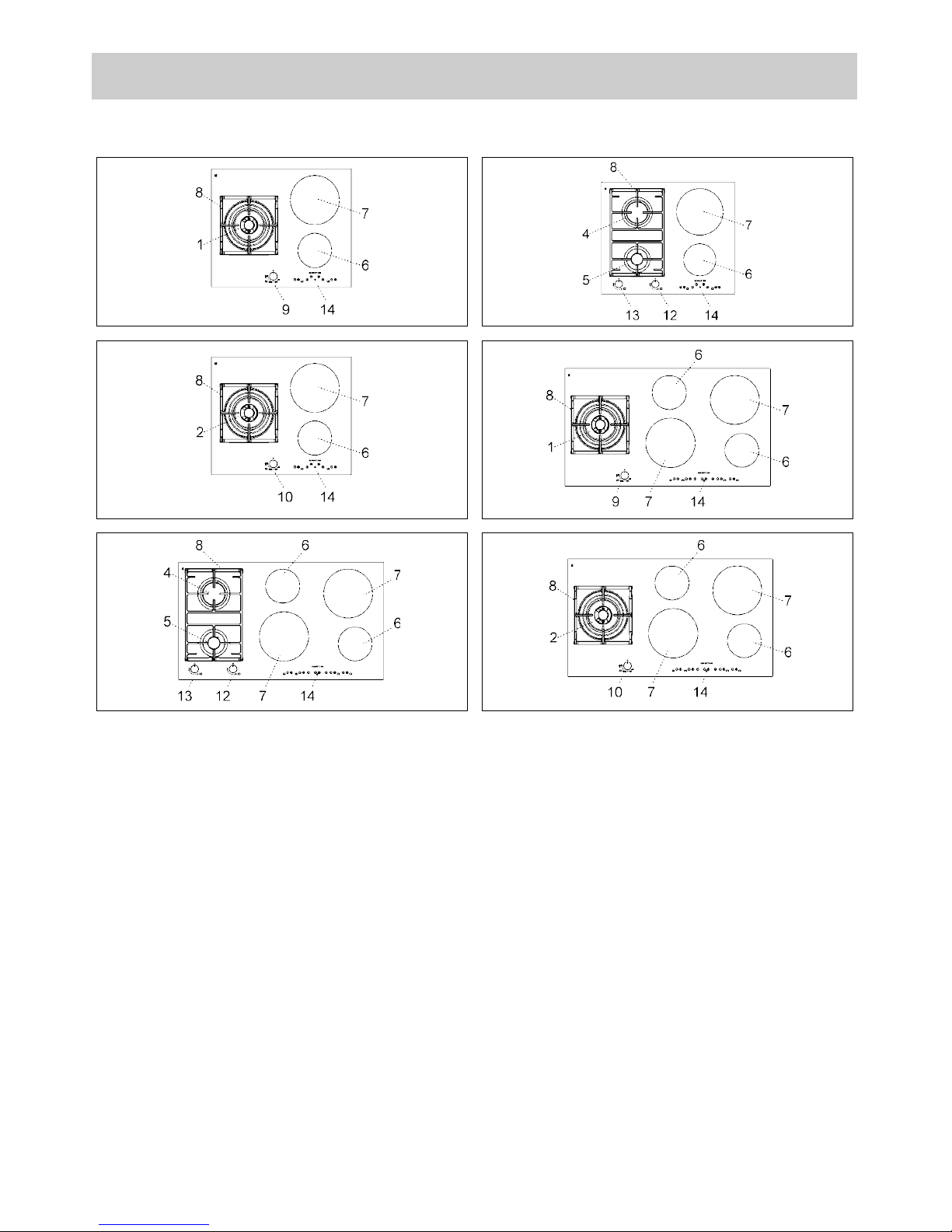

MEASUREMENTS TO OBSERVE (in mm)

A B C D E F G

30 cm

282 482 59 59 100 min. 30 - max 50 min. 120 mm

60 cm

560 490 55 55 60 min. 30 - max 50 min. 120 mm

90 cm

860 490 55 55 60 min. 30 - max 50 min. 120 mm

INSTALLATION

FIG. 9/A

ADDITIONAL WARNINGS

Depending on the degree of dirt, we recommend:

- for light stains, a damp sponge is sufficient.

- Tough, encrusted dirt is easily eliminated using a

scraper (see fig. 9). Use the scraper carefully

to avoid damaging the hob.

- Traces of liquid spilled from pans can be

eliminated with vinegar or lemon juice.

- Never allow sugar or sugary foods to fall on

the hob while cooking.

Should this occur, switch off the hob and clean

it immediately with hot water, using a scraper

on hot spills.

- As time goes by metallic reflections, colouring or

scratches may appear due to poor cleaning and

the incorrect movement of pans. Scratches

are hard to eliminate but do not affect the correct

operation of your hob.

- After a period of time may appear metal reflex

and scratches (fig. 9/A) due to the wrong

cleaning and the wrong use of the pots. The

scratches are difficultly removable, but they do

not compromise the good working of the hob.

- Do not use jets of steam to clean the

appliance.

INDUCTION COOKING

The induction cooking principle is based on a

magnetic phenomenon. When we put a pan on the

heating element, we switch on the hob and

activate the element, the electronic circuit inside

the appliance generates an induced current which

heats the bottom of the pan and the food

(see fig. 10).

FIG. 10

CAUTION:

do not place the glass directly on the unit.

The bottom of the hob must rest on the unit.

FIG. 9

Page 20

FIG. 13

FIG. 11

FIG. 12

Safety distances furniture

INSTALLATION

TECHNICAL INFORMATION

FOR FITTERS

The installation, transformation and

maintenance operations listed in this section

must be carried out exclusively by qualified

personnel.

The appliance must be correctly installed in

conformity with current law and the

manufacturer's instructions.

Incorrect installation may cause injury to

people or animals, or damage to items, for

which the manufacturer cannot be held

responsible.

Throughout the life of the system, the devices

for the safety and automatic regulation of the

appliances must only be modified by the

manufacturer or the duly authorised supplier.

5) INSERTION

After removing the outer and inner packing of the

various mobile parts, ensure that the hob is

undamaged. If you are in any doubt, do not use the

appliance and connect qualified personnel.

The packing elements (cardboard, bags,

polystyrene, nails...) must not be left within the

reach of children as they are potential sources

of danger.

It is necessary to make a hole in the kitchen unit to

house the hob, observing the measurements in

mm indicated in fig. 12 and ensuring that the

critical distances between the hob, the lateral

walls, the rear wall and the upper surface are

respected (see fig. 11, 12 and 13).

The prospective walls (left or right) that exceed the

working table in height must be at a minimum

distance from the cutting as mentionned both in the

columns “E” of the scheme.

The appliance belongs to class 3 and is

therefore subject to all the provisions

established by the provisions governing such

appliances.

IMPORTANT:

a perfect installation, adjustment or

transformation of the cook top to use other

gases requires a QUALIFIED INSTALLER: a

failure to follow this rule will void the

warranty.

20

Page 21

21

INSTALLATION

6) FITTING THE HOB

The hob is equipped with a special seal to

avoid any infiltration of liquid into the unit. To

apply this seal correctly, please follow the

instructions given below carefully:

- remove all the mobile parts of the hob.

- Turn the hob upside down and place the

adhesive putty “E” (fig. 14) under the edge of the

hob so that perfectly matches the outer perimeter

edge of the glass. The ends of the strips must

match without overlapping.

- Stick the putty to the glass evenly and securely,

using your fingers to press it into place.

- For the gas: fix the hob with the proper hooks

“S” and fit the prominent part into the porthole

“H” on the bottom; turn the screw “F” until the

hook “S” stick on the top (fig. 15).

- For the induction: position the hob in the hole in

the unit and fasten it in place using the

appropriate screws “F” of the fastening hooks “G”

(see fig. 15/A).

- In order to avoid accidental contact with the

surface of the box of the overheated hob during

use, it is necessary to install a wooden divider at

a minimum distance of 120 mm from the top,

fastening it in place with screws (fig. 12).

FIG. 14

CAUTION:

In case of hotplate glass breakage:

●shut immediately off all burners and any

electrical heating element and isolate the

appliance from the power supply;

●do not touch the appliance surface;

●do not use the appliance.

Page 22

INSTALLATION

Positioning hooks

60 cm.

30 cm.

90 cm.

gasinduction

hook A (gas) hook B (induction)

induction

gas

FIG. 15/A

FIG. 15

22

TYPE: PCZ VTCI

TYPE: PCZVB

Page 23

23

INSTALLATION

IMPORTANT INSTALLATION

SPECIFICATIONS

The installer should note that the appliance

that side walls should be no higher than the

cooktop itself. Furthermore, the rear wall, the

surfaces surrounding and adjacent to the

appliance must be able to withstand an

temperature of 90 °C.

The adhesive used to stick the plastic laminate

to the cabinet must be able to withstand a

temperature of not less than 150 °C otherwise

the laminate could come unstuck.

The appliance must be installed in compliance

with the provisions in force.

This appliance is not connected to a device

able to dispose of the combustion fumes. It

must therefore be connected in compliance

with the above mentioned installation

standards. Particular care should be paid to

the following provisions governing ventilation

and aeration.

7) ROOM VENTILATION

It is essential to ensure that the room in which the

appliance is installed is permanently ventilated in

order to allow the appliance itself to operate

correctly. the necessary amount of air is that

required for regular gas combustion and

ventilation of the relative room, the volume of

which must not be less than 20 m

3

. Air must

naturally flow through permanent openings in the

walls of the room in question. These openings

must vent the fumes outdoors and their section

must be at least 100 cm2(see fig. 3). Construction

of the openings must ensure that the openings

themselves may never be blocked. Indirect

ventilation by air drawn from an adjacent room is

also permitted, in strict compliance with the

provisions in force.

8) LOCATION AND AERATION

Gas cooking appliances must always dispose of

their combustion fumes through hoods. These

must be connected to flues, chimneys or straight

outside. If it is not possible to install a hood, an

electric fan can be installed on a window or on a

wall facing outside (see fig. 4). This must be

activated at the same time as the appliance (see

fig. 5), so long as the specifications in the

provisions in force are strictly complied with.

9) GAS CONNECTION

Before connecting the appliance, check that

the values on the data label affixed to the

underside of the cooktop correspond to those

of the gas and electricity mains in the home.

A label on the appliance indicates the

regulating conditions: type of gas and working

pressure. Gas connection must comply with

the pertinent standards and provisions in

force.

When gas is supplied through ducts,the

appliance must be connected to the gas supply

system:

●with a rigid steel pipe. The joints of this pipe must

consist of threaded fittings conforming to the

standards.

●With copper pipe. The joints of this pipe must

consist of unions with mechanical seals.

●With seamless flexible stainless steel pipe. The

length of this pipe must be 2 meters at most and

the seals must comply with the standards.

When the gas is supplied by a bottle,

the

appliance must be fuelled by a pressure governor

conforming to the provisions in force and must be

connected:

●with a copper pipe. The joints of this pipe must

consist of unions with mechanical seals.

●With seamless flexible stainless steel pipe. The

length of this pipe must be 2 meters at most and

the seals must comply with the standards.

This pipe must be installed so that it can not

come into contact with moving parts of the built

form (eg drawers) and must not cross

compartments that could be crammed.

It is advisable to apply the special adapter to the

flexible pipe. This is easily available from the

shops and facilitates connection with the hose

nipple of the pressure governor on the bottle.

WARNINGS:

remember that the gas inlet union on the

appliance is a 1/2" gas parallel male type in

compliance with EN 10226 standards.

- The appliance complies with the provisions

of the following EC Directives:

2009/142 regarding gas safety.

Page 24

INSTALLATION

10) ELECTRICAL CONNECTION

The electrical connections of the appliance

must be carried out in compliance with the

provisions and standards in force.

Before connecting the appliance, check that:

- the voltage matches the value shown on the

specification plate and the section of the wires of

the electrical system can support the load, which

is also indicated on the specification plate.

- The electrical capacity of the mains supply and

current sockets suit the maximum power rating of

the appliance (consult the data label applied to

the underside of the cooktop).

- The socket or system has an efficient earth

connection in compliance with the provisions and

standards in force. The manufacturer declines all

responsibility for failing to comply with these

provisions.

When the appliance is connected to the

electricity main by a socket:

- apply to the input cable “C”, if unprovided

(see fig. 16) a normalized plug adequate to the

load indicated in the identification label. Connect

the cables according to the scheme of fig.16 (60

cm.) - 16/A - 16/B - 16/C - 16/D (90 cm.), making

sure to respect the undermentioned

respondences (only for the two burners gas

and induction two elements):

Letter L (live) = brown wire;

Letter N (neutral) = blue wire;

Earth symbol = green - yellow wire.

- The power supply cable must be positioned so

that no part of it is able to reach an temperature

of 90 °C.

- Never use reductions, adapters of shunts for

connection since these could create false

contacts and lead to dangerous overheating.

- The outlet must be accessible after the built-in.

When the appliance is connected straight to

the electricity main:

- install an omnipolar circuit-breaker between the

appliance and the electricity main. This circuitbreaker should be sized according to the load

rating of the appliance and possess a minimum

3 mm gap between its contacts.

- Remember that the earth wire must not be

interrupted by the circuit-breaker.

- The electrical connection may also be protected

by a high sensitivity differential circuit- breaker.

You are strongly advised to fix the relative yellowgreen earth wire to an efficient earthing system.

Before performing any service on the electrical

part of the appliance, it must absolutely be

disconnected from the electrical network.

WARNINGS:

all our products are conform with the

European Norms and relative amendments.

The product is therefore conform with the

requirements of the European Directivesin

force relating to:

- compatibility electromagnetic (EMC);

- electrical security (LVD);

- restriction of use of certain hazardous

substances (RoHS);

- EcoDesign (ERP).

IMPORTANT: the appliance must be

installed following the manufacturer's

instructions. The manufacturer will not be

liable for injury to persons or animals or

property damage caused by an incorrect

installation.

If the installation requires modifications to

the home's electrical system or if the

socket is incompatible with the appliance's

plug, have changes or replacements

performed by professionally-qualified

person. In particular, this person must also

make sure that the section of the wires of

the socket is suitable for the power

absorbed by the appliance.

24

Page 25

25

INSTALLATION

FIG. 16

Type of cable

Monophase

power supply

220 - 240 V

~

Hob gas B

H05 RR-F 3 x 0.75 mm

2

Hob induction A

H07 RN-F

H05 VV-F

3 x 1.5 mm

2

gasinduction

30 cm. - 60 cm.

TYPE AND SECTION OF THE POWER CABLES (see figure above)

ATTENTION!!!

If the power supply cable is replaced, the installer should leave the ground wire (B) longer than the

phase conductors (fig. 24) and comply with the recommendations given in paragraph 10.

Page 26

INSTALLATION

90 cm.

(*) Taking into account the contemporaneity factor

TYPE AND SECTION OF THE POWER CABLES (see figure above)

ATTENTION!!!

If the power supply cable is replaced, the installer should leave the ground wire (B) longer than the

phase conductors (fig. 24) and comply with the recommendations given in paragraph 10.

26

FIG. 16/D

FIG. 16/C

FIG. 16/A

induction

gas

Type of cable

Monophase

power supply

220 - 240 V

~

Three-phase

power supply

380 - 415 V 3N

~

Two-phase

power supply

380 - 415 V 2N

~

Hob gas B

H05 RR-F 3 x 0.75 mm

2

Hob induction A

H05 RR-F

H07 RN-F

3 x 4 mm2 (*) 5 x 2.5 mm2 (*) 4 x 2.5 mm2 (*)

FIG. 16/B

Page 27

27

SETTING THE POWER

FIG. 17

FIG. 18

11) SETTING THE POWER

The maximum power limit of the hob is 7200 W.

This power limit can be reduced to 2800 W, 3500

W or 6000 W.

“CookTop ECO” Power Limit Setting

The sequence for setting a new Power Limit for

the hob is:

● during the first 30 seconds, after connecting the

hob to the electricity supply the hob must be

unlocked and all the heating elements must be

switched off;

● press the front left heating element 7 and the

front right heating element 6 selection keys

together (see fig. 17);

● after performing this operation, an acoustic

signal sounds and the current Power Limit of the

hob will be shown on the heating element display

(see fig. 18).

To choose a new Power Limit

● with the and keys, the Power Limit is

increased. The power levels that can be selected

are: 2800 W, 3500 W, 6000 W or 7200 W.

● When the power is 7200 W, if the or

key is touched, the power changes to 2800 W

(see fig. 19).

FIG. 19

Page 28

28

SETTING THE POWER

The sequence for registering the new Power Limit for the hob is:

● press the front left heating element 7 and the front right heating element 6 selection keys together (see fig.

20);

● after performing this operation, the new Power Limit of the hob is registered and the system resets itself.

To end without registering any change

● If no action takes place within 60 seconds, the changes are not registered and the system reseti itself.

FIG. 20

Functions of the hob ECO power

For the ECO power of the hob, every time the user tries to increase the power, the total level of the latter

is calculated. If this total power level is higher than the total Power Limit set, the increase in power is not

allowed. An acoustic signal sounds and the hob display shows an “r” for 3 seconds (see fig. 21).

FIG. 21

Page 29

29

FIG. 22/A

FIG. 22

Always disconnect the appliance from the

electricity main before making any

adjustments.

All seals must be replaced by the technician at

the end of any adjustments or regulations.

Our burners do not require primary air

adjustment.

12) TAPS

“Reduced rate” adjustment

- Switch on the burner and turn the relative knob

to the “Reduced rate” position (small flame

fig. 1).

- Remove knob “M” (fig. 22 and 22/A) of the tap,

which is simply pressed on to its rod. The by-pass

for minimal rate regulation can be: beside the tap

(fig. 22) or inside the shaft. In any case, to access

to regulation, it can be done trought the insertion

of a small screwdriver ‘’D’’ beside the tap (fig. 22)

or in the hole ‘’C’’ inside the shaft of the tap

(fig 22/A). Turn the throttle screw to the right or left

until the burner flame has been adequately

regulated to the “Reduced rate” position.

The flame should not be too low: the lowest small

flame should be continuous and steady. Reassemble the several components.

It is understood that only burners operating

with G20 gas should be subjected to the above

mentioned adjustments. The screw must be

fully locked when the burners operate with G30

or G31 gas (turn clockwise).

TAPS LUBRIFICATION

Should a tap being blocked,

do not force and ask

for Technical Assistance.

ADJUSTMENTS

Page 30

30

13) REPLACING THE INJECTORS

The burners can be adapted to different types of gas by

installing injectors suited to the type of gas required. To

do this, first remove the burner tops using a wrench “B”.

Now unscrew injector “A” (see fig. 23) and fit a injector

corresponding to the type of gas required.

It is advisable to tighten the injector in place.

After the injectors have been replaced, the burners

must be regulated as explained in paragraphs 12.

The technician must reset any seals on the

regulating or pre-regulating devices and affix the

label corresponding to the new gas regulation on

the appliance instead of the already existing one.

This label is supplied in the packet containing the

spare injectors.

The envelope with the injectors and the labels can

be included in the kit, or at disposal to the

authorized Customer Care Department.

For the sake of convenience, the nominal rate chart also

lists the heat inputs of the burners, the diameter of the

injectors and the working pressures of the various types

of gas.

FIG. 23

CONVERSIONS

TABEL

BURNERS

GAS

NORMAL

PRESSURE

mbar

NORMAL

RATE

INJECTOR

DIAMETER

1/100 mm

NOMINAL HEAT

INPUT (W)

No.

DESCRIPTION

gr/h l/h Min. Max.

EEgas burner*

1

DOUBLE

CROWN

G 30 - BUTANE

G 31 - PROPANE

G 20 - NATURAL’

28 - 30

37

20

345

339

476

2 x 72 B + 46 B

2 x 72 B + 46 B

2 x 115 A + 71 A

1800

1800

1800

4750

4750

5000

61,6%

2

TRIPLE

CROWN

G 30 - BUTANE

G 31 - PROPANE

G 20 - NATURAL’

28 - 30

37

20

291

286

381

100 B

100 B

145 A

1800

1800

1800

4000

4000

4000

54,3%

4

RAPID

G 30 - BUTANE

G 31 - PROPANE

G 20 - NATURAL

28 - 30

37

20

204

200

267

83

83

117 Y

800

800

800

2800

2800

2800

56,0%

5

AUXILIARY

G 30 - BUTANE

G 31 - PROPANE

G 20 - NATURAL

28 - 30

37

20

73

71

95

51

51

75 X

450

450

450

1000

1000

1000

N.A.

*In accordance with Regulation No. 66/2014 EU measures for the implementation of Directive2009/125/EC, the

performance (EEgas burner) was calculated according to EN 30-2-1 last review with the G20.

EE

gas hob

61,6%

EE

gas hob

54,3%

EE

gas hob

56,0%

EE

gas hob

61,6%

EE

gas hob

54,3%

EE

gas hob

56,0%

DISPOSITION OF THE BURNERS

Page 31

31

FIG. 24

DENOMINATIONS Ø (cm)

POWER

(W)

with booster

Element heating induction

14,5 1200 1600

Element heating induction

21,0 1500 2000

POWER RATINGS OF THE ELECTRICAL COMPONENTS

WARNING: MAINTENANCE MUST ONLY BE

PERFORMED BY AUTHORISED PERSONS.

MODEL 4 EL. HEATING (90 cm)

Voltage 220-240/380 - 415 V 3N~

Frequency 50/60 Hz

Total rated power 7200 W

MODEL 2 EL. HEATING (30 cm - 60 cm)

Voltage 220 - 240 V ~

Frequency 50/60 Hz

Total rated power 3600 W

IF THE POWER CABLE IS DAMAGED, SHOULD

BE REPLACED BY THE MANUFACTURER OR

ITS AFTER SALES SERVICE.

SERVICING

Page 32

32

DISPLAY OF ERRORS

Event

(Visualization

Priority Order)

Start

conditions

End

conditions

Action

Heater

status

Heater

display

fore

(1 sec.)

Heater

display

back

(1 sec.)

Power increment

not allowed

(only for

ECO models)

Asked Cooktop

power > Cooktop

ECO Power limit

2 sec.

Power

increment

not allowed

On/Off

“r”

Heater without

suitable pan

or

without pan

No pan or not

suitable pan over

the heater

Suitable pan

over the heater

After

1 minute

heater off

On

“Power”

Induction

heater

overtemperature

COIL

TEMPERATURE

> T1

(1)

COIL

TEMPERATURE

< T2

(1)

No power

is delivered

to the heater

Off

ʻ ʼ

or

ʻHʼ

ʻCʼ

On

ʻ

Power

ʼ

Induction

generator

overtemperature

HEATSINK

TEMPERATURE

> T3

(1)

HEATSINK

TEMPERATURE

> T4

(1)

No power

is delivered

to the heater

Off

ʻ ʼ

or

ʻHʼ

ʻcʼ

On

ʻ

Power

ʼ

Hot glass over

a heater

(residual heat)

COIL

TEMPERATURE

> T5

(1)

COIL

TEMPERATURE

< T6

(1)

-------

Off

ʻHʼ

DISPLAYING SPECIAL STATUSES

The corresponding heater display alternates between two characters depending on the status.

(1)

For T1, T2, T3, T4, T5 and T6 values see the corresponding drawing.

Page 33

33

DISPLAY OF ERRORS

Heater errors

Heater errors are the errors which generate the switch off of one or more heaters.

When a heater error is detected, the involved heaters are switched off, a beep sounds (only if one or

more heaters are active) and the displays corresponding to these heaters show a “F” letter and the error

code alternately.

While in error status the keys of the corresponding heaters are not operative.

All errors are recoverable. That is, when the cause of the error disappears the corresponding displays

are deactivated and the heaters return to normal operation.

(**) Heater switched off and locked.

(***) All the Induction heaters switched off and locked.

(****)Left or right side heaters switched off and locked.

Heater errors

Event

(Visualization Priority Order)

Error recovery Action

Heater display

(

fore 0.5 sec./back 0.5 sec.)

Communication fault

When the fault

disappears

Left or right

side heaters

Off (****)

F5

Heater temperature sensor

short-circuit

When the fault

disappears

Heater

Off (**)

F1

Heater temperature sensor

open-circuit

When the fault

disappears

Heater

Off (**)

F2

Heater temperature sensor

error 1

When the fault

disappears

Heater

Off (**)

F7

Heater temperature sensor

error 2

When the fault

disappears

Heater

Off (**)

F8

Bus relay fault

When the fault

disappears

Heater

Off (**)

F9

Power unit temperature sensor

short-circuit

When the fault

disappears

All heaters

Off (***)

F3

Power unit temperature sensor

open-circuit

When the fault

disappears

All heaters

Off (***)

F4

Mains zero crossing loss

When the fault

disappears

Left or right

side heaters

Off (****)

F6

Page 34

34

DISPLAY OF ERRORS

Errors/Alarms

Appliance errors

Appliance errors are the errors which generate the deactivation of the whole cooktop.

When an appliance error is detected, all heaters are switched off, a beep sounds (only if one or more

heaters are active) and all displays show a “F” letter and the error code alternately.

While in error status all the heater keys are not operative.

Except EEPROM and microcontroller errors, all errors are recoverable. That is, when the cause of the

error disappears all displays are deactivated and the cooktop return to normal operations.

Appliance errors

Error

(Visualization Priority Order)

Error recovery Action

All Heater display

(

fore 0.5 sec./back 0.5 sec.)

Microcrontroller fault ----------------- App. off

F0

On/Off key emitter fault

When the fault

disappears

App. off

FA

On/Off key receiver fault

When the fault

disappears

App. off

FC

User interface temperature

sensor short-circuit

When the fault

disappears

App. off

FE

User interface temperature

sensor open-circuit

When the fault

disappears

App. off

Ft

User interface overtemperature

When user interface

temperature < 90 °C

App. off

Fc

EEPROM fault ----------------- App. off

FH

Microcontroller A/D converter

multiplexer fault

When the fault

disappears

App. off

FJ

Ambient Light fault

When satisfactory

ambient lighting

is detected

App. off

FL

Microcontroller A/D converter

conversion fault

When the fault

disappears

App. off

FU

Page 35

35

1 BURNER (60)

(double crown 5.0 kW)

CATEGORY = II

2H3+

G 30 - BUTANE = 28 - 30 mbar

G 31 - PROPANE = 37 mbar

G 20 - NATURAL = 20 mbar

Σ

Qn Gas Natural = 5.0 kW

Σ

Qn GPL = 4.75 kW

Σ

Qn GPL = 345 gr/h (G30)

Σ

Qn GPL = 339 gr/h (G31)

TENSION = 220 - 240 V

˜

FREQUENCY = 50/60 Hz

Rated power el. induction 3600W

2 BURNERS (60)

(Aux + Rapid)

CATEGORY = II

2H3+

G 30 - BUTANE = 28 - 30 mbar

G 31 - PROPANE = 37 mbar

G 20 - NATURAL = 20 mbar

Σ

Qn Gas Natural = 3.8 kW

Σ

Qn GPL = 3.8 kW

Σ

Qn GPL = 276 gr/h (G30)

Σ

Qn GPL = 271 gr/h (G31)

TENSION = 220 - 240 V

˜

FREQUENCY = 50/60 Hz

Rated power el. induction 3600W

1 BURNER (90)

(double crown 5.0 kW)

CATEGORY = II

2H3+

G 30 - BUTANE = 28 - 30 mbar

G 31 - PROPANE = 37 mbar

G 20 - NATURAL = 20 mbar

Σ Qn Gas Natural = 5.0 kW

Σ

Qn GPL = 4.75

Σ

Qn GPL = 345 gr/h (G30)

Σ Qn GPL = 339 gr/h (G31)

TENSION = 220 - 240 V

˜

FREQUENCY = 50/60 Hz

Rated power el. induction 7200W

1 BURNER (90)

(triple crown 4.0 kW)

CATEGORY = II

2H3+

G 30 - BUTANE = 28 - 30 mbar

G 31 - PROPANE = 37 mbar

G 20 - NATURAL = 20 mbar

Σ

Qn Gas Natural = 4.0 kW

Σ

Qn GPL = 291 gr/h (G30)

Σ

Qn GPL = 286 gr/h (G31)

TENSION = 220 - 240 V

˜

FREQUENCY = 50/60 Hz

Rated power el. induction 7200W

1 BURNER (60)

(triple crown 4.0 kW)

CATEGORY = II

2H3+

G 30 - BUTANE = 28 - 30 mbar

G 31 - PROPANE = 37 mbar

G 20 - NATURAL = 20 mbar

Σ

Qn Gas Natural = 4.0 kW

Σ

Qn GPL = 291 gr/h (G30)

Σ

Qn GPL = 286 gr/h (G31)

TENSION = 220 - 240 V

˜

FREQUENCY = 50/60 Hz

Rated power el. induction 3600W

2 BURNERS (90)

(Aux + Rapid)

CATEGORY = II

2H3+

G 30 - BUTANE = 28 - 30 mbar

G 31 - PROPANE = 37 mbar

G 20 - NATURAL = 20 mbar

Σ

Qn Gas Natural = 3.8 kW

Σ

Qn GPL = 3.8 kW

Σ

Qn GPL = 276 gr/h (G30)

Σ

Qn GPL = 271 gr/h (G31)

TENSION = 220 - 240 V

˜

FREQUENCY = 50/60 Hz

Rated power el. induction 7200W

TECHNICAL DATA ON THE DATA LABEL

Page 36

36

TECHNICAL DATA FOR THE

APPLIANCE GAS REGULATION

TECHNICAL ASSISTANCE AND SPARE PARTS

Before leaving the factory, this appliance will have been tested and regulated by expert and specialized

personnel in order to guarantee the best performances.

Any repairs or adjustments which may be subsequently required may only be carried out by qualified

personnel with the utmost care and attention.

For this reason, always contact your Dealer or our nearest After Sales Service Center whenever repairs or

adjustments are required, specifying the type of fault and the model of the appliance in your possession.

Please also note that genuine spare parts are only available from our After Sales Service Centers and

authorized retail outlets.

The above data are printed on the data label put on the inferior part of the appliance and on the packing

label.

The above informations give to the technical assistant the possibility to get fit spare parts and a heaven-sent

intervention. We suggest to fill the table below.

MARK: .............................................................................

MODEL: ...........................................................................

SERIES: ...........................................................................

This appliance is marked according to the European directive 2002/96/EC on

Waste Electrical and Electronic Equipment (WEEE).

This guideline is the frame of a European-wide validity of return and recycling on

Waste Electrical and Electronic Equipment.

Loading...

Loading...