Page 1

INSTALLATION AND USER INSTRUCTIONS

BUILT-IN GAS HOB (TOUCH CONTROL)

Page 2

2

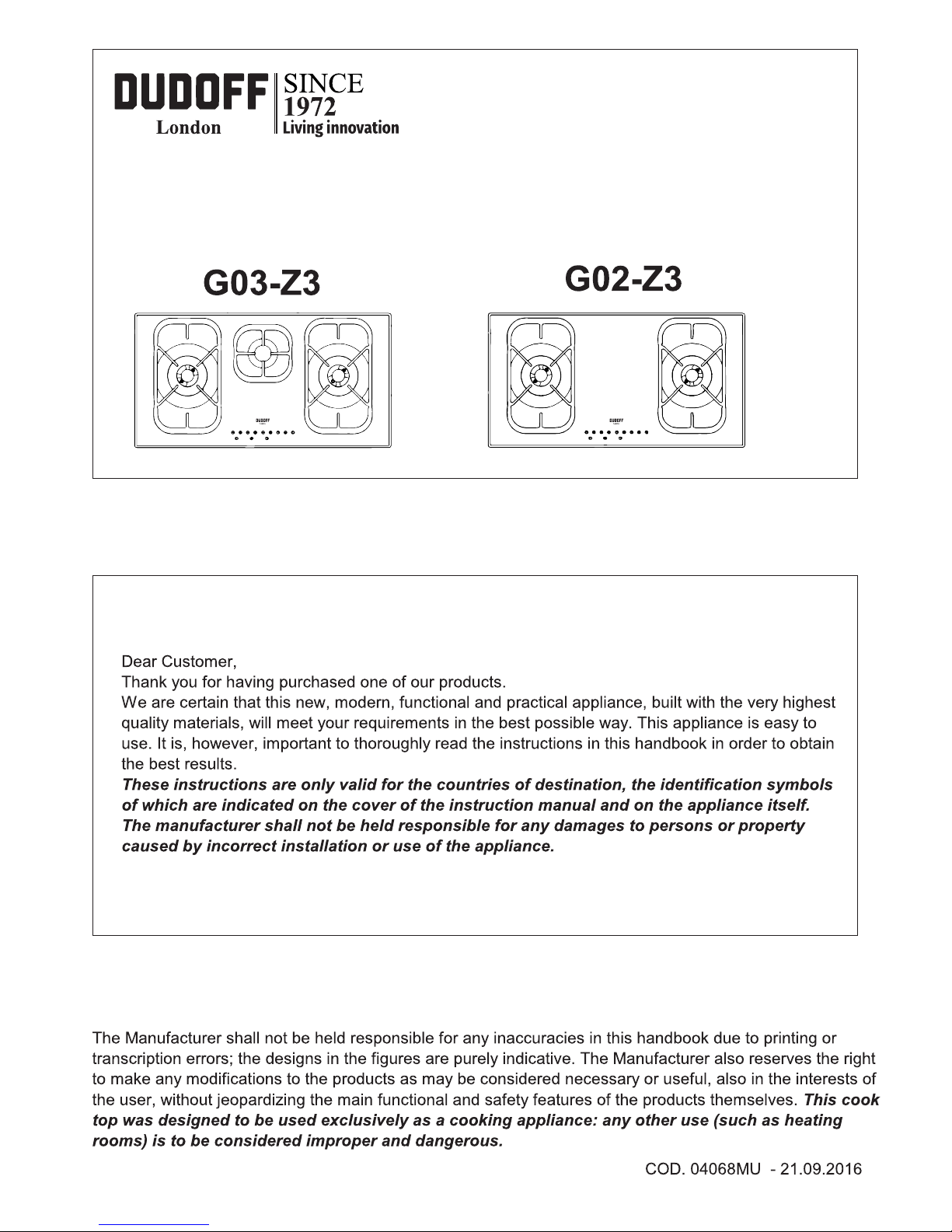

DESCRIPTION OF HOBS

2 Triple Ring 3750 - 3800 W

3 DUAL burner 4200 W

4 Auxiliary burner 1000 W

5 Grid lateral

6 Grid central

7 Touch control

Hob equipped with electronic burner management system, with touch panel burner control.

Caution: this appliance has been designed for domestic use in domestic environments by members

of the general public. It must be used by fully aware adults. Children should not be allowed to

approach or play with the appliance. The easy-to-reach front areas of the appliance may become

extremely hot during use.

Supervise children and incapacitated people during use, making sure that they do not touch hot

surfaces and stay away from the appliance during operation.

TYPE: MCGOG

78 cm.

78 cm.

78 cm.

86 cm.

86 cm.

86 cm.

Page 3

3

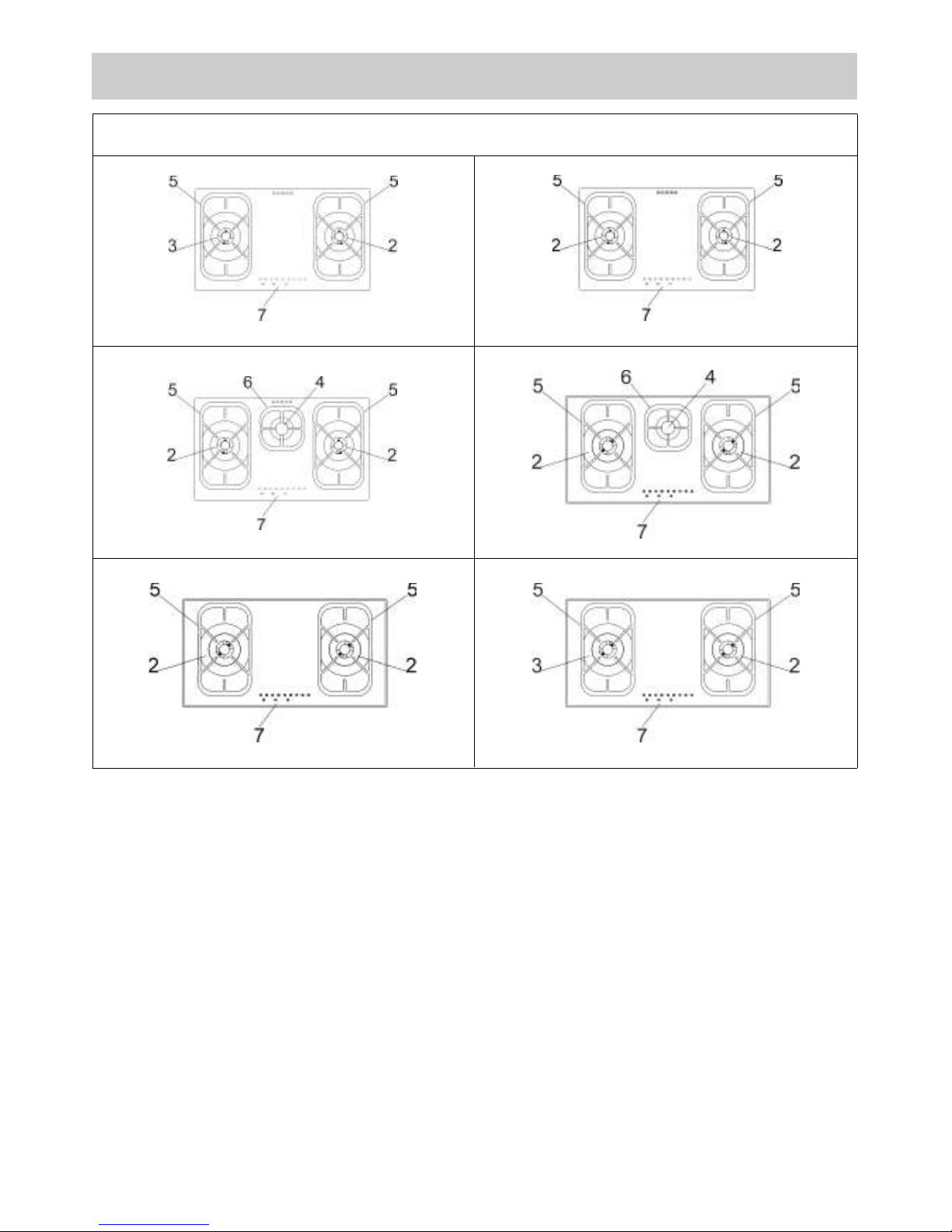

USE

1 - Burner 2 – button (left)

2 - Burner 2 + button (left)

3 - Burner 4 – button

4 - Burner 4 + button

5 - Burner 2 – button (right)

6 - Burner 2 + button (right)

7 - Clock button

8 - Safety lock button

9 - ON/OFF button

10 - Capacity levels display (0 - 9)

11 - Display clock

DESCRIPTION OF THE FRONT PANEL CONTROLS

3F of 78/86 cm.

2F of 78/86 cm. (DUAL)

1 - Burner 3 – button (crown internal and external)

2 - Burner 3 + button (crown internal and external)

3 - Burner 3 – button (crown internal)

4 - Burner 3 + button (crown internal)

5 - Burner 2 – button

6 - Burner 2 + button

7 - Clock button

8 - Safety lock button

9 - ON/OFF button

10 - Capacity levels display (0 - 7)

11 - Display clock

Page 4

4

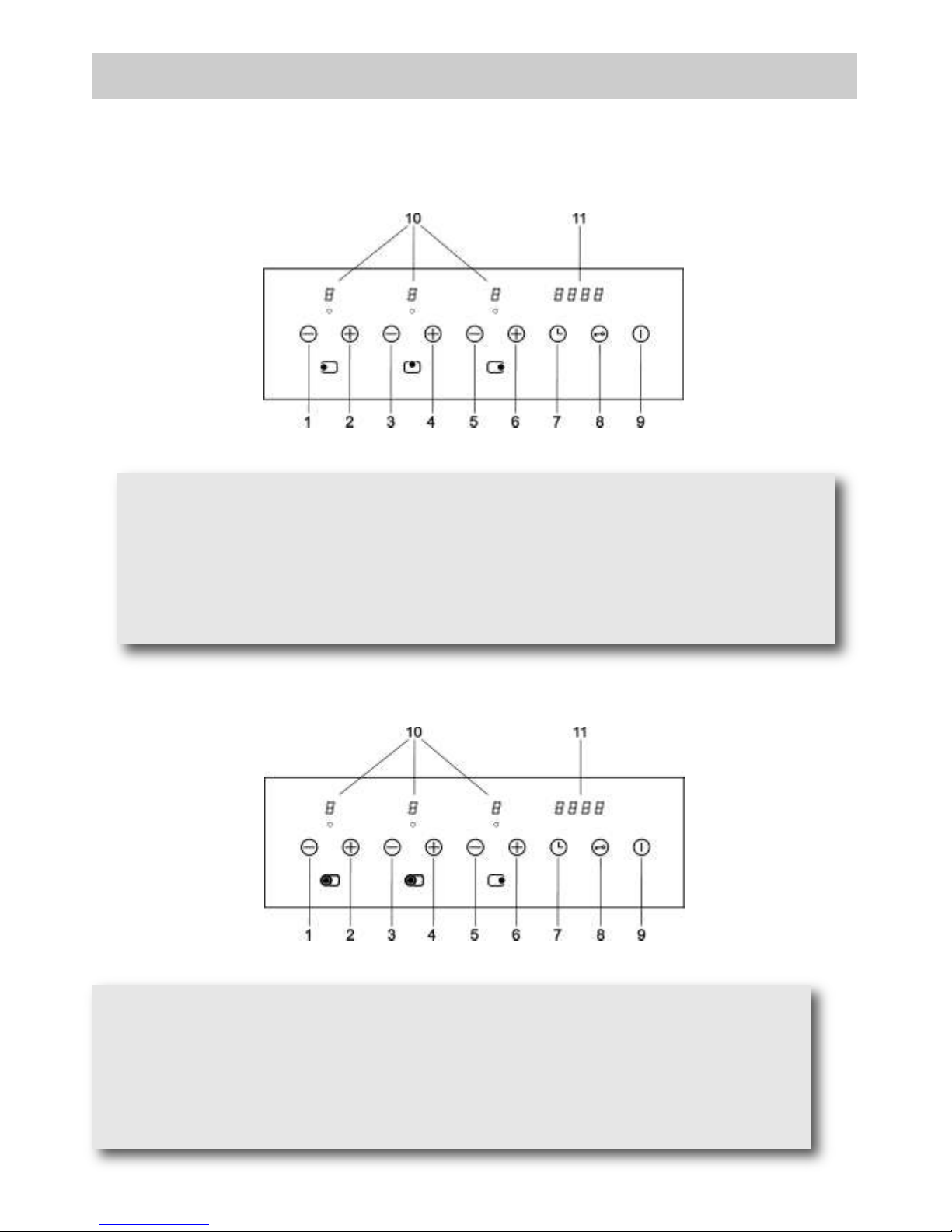

FUNCTIONS available to the user/fitter:

the main functions of the device are:

● standby mode (burners off, control panel active).

● Control panel lock to protect against accidental lighting/programming.

● Regulation of the capacity of every burner at 9 levels (7 levels for the hobs with DUAL burner).

● Safety lock with manual reset via release procedure carried out from the control panel.

● Procedure to regulate the capacity to the minimum level for every burner (for fitter only).

● Programming the type of fuel used: methane/lpg (for fitter only).

● Programming of the switch off time for every burner.

● Maximum duration time for each burner pre-programmed into the FLASH memory equates to 4

hours.

● Temperature measured on the electronic card.

● Management of anomalies/faults via code indicated on display.

2F DA 78/86 cm.

USE

1 - Burner 2 – button (left)

2 - Burner 2 + button (left)

3 - Burner 2 – button (right)

4 - Burner 2 + button (right)

7 - Clock button

8 - Safety lock button

9 - ON/OFF button

10 - Capacity levels display (0 - 9)

11 - Display clock

Page 5

1) BURNERS

On the surface of the hob, there is a serigraphic figure above each knob, indicating the burner to which

the knob refers. After turning on the gas at the main or opening the valve on the gas bottle, light the

burners as indicated below.

Switching on the Hob

To switch on the hob, press the ON/OFF button constantly for at least 2 seconds. The hob will come on

and the displays related to the burners will show level zero, corresponding to the status of burners off.

Lighting a burner

To light the burner 2 (or the burner 4), press and release the + button of the burner you wish to light. You

have 3 seconds to press the + button again to light the burner at level 9, otherwise, if you press the –

button, it will be lit at level 5. The control system will now make a maximum of 3 attempts at intervals of 10

seconds.

Should the burner fail to light after the third attempt, it locks and the corresponding Led displays the letter

“b”. To release the burner, see the relative procedure further ahead.

Every burner for which the relative timer has not been programmed will switch off automatically after 4

hours of constant operation.

The ignition of the burner is also indicated by the relative indicator, which remains active the whole time

the burner is lit.

Regulating the burner flame level

With the burner lit, to increase the capacity level you must press the + button, while it is necessary to

press the - button to reduce the capacity level. To obtain a continuous variation in the capacity level, it is

sufficient to keep the + or - button pressed and release it at the level required. The capacity level varies

from 1 to 9.

5

USE

The Dual burner, instead, can be lit partially (internal ring) or completely (internal and external ring)

depending on which buttons are pressed to light the burner. In particular, to light the internal ring only,

press button 4, and then you will have 3 seconds time to press button 4 again and light the burner at

level 7.

To light the internal and the external ring simultaneously, press button 2, and then you will have 3

seconds time to press button 2 again and light both burner rings at level 7.

If you wish to light the external burner ring when the internal ring is already lit, this will anyway involve

switching off the internal ring and then lighting it again.

The Dual burner, instead, can be adjusted in two ways depending on whether it is lit partially (internal

ring) or completely (internal and external ring). When the internal ring only is lit, press button 4 to

increase the capacity level, or press button 3 to decrease it. To obtain a continuous variation in the

capacity level, you just need to keep button 4 or 3 pressed and then release it at the required level.

The capacity level can vary from 1 to 7.

When the internal ring is lit together with the external one, to increase the capacity level you can press

button 2 or 4 indifferently, as the level variation will occur on both rings simultaneously, while to

decrease the capacity level press button 1 or 3 (to obtain a continuous variation in the capacity level,

you just need to keep the button pressed and then release it at the required level). Also in this case the

capacity level can vary from 1 to 7.

Page 6

Switching off a burner

To switch off a burner it is necessary to press the + and - button simultaneously for a moment.

The corresponding Led will display the letter “H” (hot) for a few minutes to indicate that the burner is hot.

Switching off all the burners

To switch off all the burners at the same time, simply press the ON/OFF button. This will place the hob in

OFF status.

Programming the burner switch-off time

It is possible to independently programme each burner to switch off automatically after a specific length of

time.

To programme the timer of a burner, press the Clock button (7). On time display the writing TIME will

appear. Now pressing - or + button of the burner to be timed, the writing TIME disappears and the writing

0:00 will appear. The burner selected is identified by the relative flashing indicator (flashing fast). The

timer display will indicate 0.00, meaning that the timer related to the burner selected is not active. To

programme the switch-off time of the burner selected, press the Clock button (7) again; the timer display

will indicate 0.00. The flashing digit to the left of the dot indicates the hours, while those to the right

indicate the minutes. By pressing buttons - and + of the burner selected it is possible to increase or

decrease the operating hours from 0 to 9. Keeping buttons + or - pressed (of the burner selected) the

change in the number of hours will take place continuously.

To specify the number of minutes, press the Clock button (7) again. The digits to the right of the dot will

start flashing. Set the minutes in the same way as indicated for the hours.

When programming the time it is possible to zero the current setting at any time by pressing buttons - and

+ (of the burner selected) together. A time equal to zero deactivates the burner timer. To confirm the time

shown on the display, press the Clock button (7). At this point, only the indicators of the burners with the

timer active continue to flash.

Press the Clock button (7) to return to timer programming mode and see the time remaining until switchoff or to change the current settings. If no button is pressed for more than 10 seconds during

programming, the programming procedure is interrupted automatically and the main display returns. Any

settings being changed on the burner selected will not be lost and the relative time is active.

The timer can be programmed both with the burner switched off or lit, and the counter will start

immediately after the time programmed has been confirmed. When the time is up, the timed burner will be

switched off and a sequence of acoustic signals lasting 30 seconds will be emitted (this acoustic signal

can be stopped by pressing the Clock button (7).

If the user switches off a burner, the relative timer is deactivated.

6

USE

The Dual burner, instead, can be switched off in two ways depending on whether it is lit partially

(internal ring) or completely (internal and external ring). Both when the internal ring only is lit and when

the internal ring is lit together with the external one, press button 4 and 3 simultaneously for a short

time to switch off the burner completely. In case the internal ring is lit together with the external one,

and you wish to switch off the external burner ring only, press button 2 and 1 simultaneously for a short

time.

It is possible to programme the timer of a lit burner only, and in the case of a Dual burner, this

possibility is limited to the internal ring.

The timer programme of a Dual burner will always be effective after switching off the burner

completely, both in case the internal ring only was lit and in case both burner rings were lit.

Page 7

7

USE

Regulating the clock

Following interruptions to the power supply, it is necessary to set the time displayed by the clock inside

the hob.

To regulate the clock, press the buttons 7 and 8 together for at least 3 seconds.

The flashing digit to the left of the dot indicates the hours, while those to the right indicate the minutes. It

is possible to increase or decrease the hours using buttons 2 or 1 and by keeping buttons 2 or 1 pressed

the change in the number of hours takes place continuously.

To regulate the minutes, press the Clock button (7) again. The digits to the right of the dot will start

flashing. Now change the minutes in the same way as indicated for the hours.

Press the Clock button (7) to memorise the time programmed.

Releasing the burner

When a burner is locked the relative display shows the letter “b”. The burner is released by pressing

buttons 1 and 8 together constantly for at least 2 seconds. When released, the burners are reset to level

0, ready to be lit again.

N.B: if the release procedure is repeated 5 times in a row during a 15 minute time span, the device will

indicate FLT06 and will accept no further request for release for another 15 minutes.

Locking the control panel

This is activated by pressing button 8 only for at least 2 seconds. All burner levels will remain stable. The

control panel locked status occurs when the decimal points on the display of the capacity level related to

each burner light up. While the control panel is locked it is no longer possible to change the levels of the

burners or change the timer settings, but it is possible to switch off the hob by pressing the ON/OFF

button (safe switch-off).

It is not possible to release a locked burner when the control panel lock is active. It will be therefore

necessary to release the control panel before activating the burner release procedure.

Releasing the control panel

The control panel is released by pressing button 8 and button 2 for at least 2 seconds. The control panel

is released when the flame level points on the display go out.

Child lock function (for the hobs with DUAL burner).

It is activated only with hob off by pressing the button 8 for at least 3 seconds. The activation of the

Child Lock function is visible through the switching on of the decimal points on the flow rate level

displays of each burner and entails the complete lock of the keyboard.

The function is deactivated by pressing again the button 8 for at least 3 seconds (the unlock of the

keyboard is visible through the switching off of the decimal points on the flow rate level displays).

It is not possible to release a locked burner when the control panel lock is active. It will be therefore

necessary to release the control panel before activating the burner release procedure.

Page 8

8

USE

WARNINGS:

- never leave the appliance unattended while the

burners are in use and ensure that children

are kept at a safe distance. Make sure that pan

handles are correctly positioned and

supervise the cooking of foods in oil and fat,

as these are highly flammable.

- Do not use sprays near the appliance

during use.

- Do not drag pans across the glass hob as this

may scratch the surface.

- Should a crack appear on the surface of the

glass, disconnect the appliance from the

electricity supply immediately.

- Do not use the hob as a work surface.

- Do not place pans with an unstable or deformed

bottom on the burner, as these may tip or spill

their contents, causing accidents.

- The pans must not extend beyond the edge of

the hob.

- The machine must not be used by people

(including children) with impaired mental or

physical capacities, or without experience of

using electrical devices, unless supervised or

instructed by an expert adult responsible for

their care and safety. Children should not be

allowed to play with the equipment.

- Containers wider than the unit are not

recommended.

Warning:

during operation the work surfaces of the

cooking area become very hot: keep children

away!

Burners Power W Ø pan cm

DUAL total

4200 22 ÷ 27

DUAL central

900 8 ÷ 16

Auxiliary 1000 16 ÷ 18

Triple Ring

3800-3750 24 ÷ 26

WARNING:

Children less than 8 years of age shall be kept away unless

continuously supervised.

This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children

without supervision.

Page 9

9

FIG. 1 FIG. 2 FIG. 3

(*) AIR INLET: SEE INSTALLATION CHAPTER (PARAGRAPHS 5 AND 6)

USE

WARNINGS AND ADVICE FOR THE USER:

- use of a gas cooking appliance produces heat and moisture in the room in which it is installed. The

room must therefore be well ventilated by keeping the natural air vents clear (fig. 3) and by

activating the mechanical aeration device (suction hood or electric fan fig. 4 and fig. 5).

- Intensive and lengthy use of the appliance may require additional ventilation. This can be achieved

by opening a window or by increasing the power of the mechanical exhausting system if installed.

- Do not attempt to change the technical characteristics of the product because it can be dangerous.

- If you should not to use this appliance any more (or replace an old model), before disposing of it,

make it inoperative in conformity with current law on the protection of health and the prevention of

environmental pollution by making its dangerous parts harmless, especially for children who

might play on an abandoned appliance.

- Do not touch the appliance with wet or damp hands or feet.

- Do not use the appliance barefoot.

- The manufacturer will not be liable for any damage resulting from improper, incorrect or

unreasonable use.

- During, and immediately after operation, some parts of the cook top are very hot: avoid touching

them.

- After using the cook top, make sure that the knob is in the closed position and close the main tap

of the gas supply or gas cylinder.

- If the gas taps are not operating correctly, call the Customer Care Department.

CAUTION:

In case of hotplate glass breakage:

●shut immediately off all burners and any electrical

heating element and isolate the appliance from

the power supply;

●do not touch the appliance surface;

●do not use the appliance.

Page 10

10

CLEANING

CAUTION:

before cleaning the appliance, disconnect it

from the gas and electricity supplies.

2) WORKTOP

It is very important to clean the hob every time you

use it, while the glass is still warm.

Do not clean using abrasive metal scourers, powder

abrasives or corrosive sprays.

Depending on the degree of dirt, we recommend:

- for light stains, a damp sponge is sufficient.

Be aware that the razor can cause wounds.

- Traces of liquid spilled from pans can be

eliminated with vinegar or lemon juice.

- Never allow sugar or sugary foods to fall on the

hob while cooking. Should this occur, switch off

the hob and clean it immediately with hot water.

- As time goes by metallic reflections, colouring or

scratches may appear due to poor cleaning and

the incorrect movement of pans. Scratches are

hard to eliminate but do not affect the correct

operation of your hob.

Periodically wash the hot plate, the enamelled stell

pan support, the enamelled burner caps “A”, “B”

and “C” and the burner heads "T" (see fig. 4 and

5) with lukewarm soapy water. They should also

be cleaned plugs "AC" and flame detection "TC"

(see fig. 4). Clean them gently with a small nylon

brush as shown (see fig. 6) and allow to dry fully.

Do not wash in the dishwasher. It is very important

to clean the surface soon after every use, when

the glass is still tepid.

Do not allow vinegar, coffee, milk, salted water,

lemon or tomato juice from remaining in contact

with the enamelled surfaces for long periods of

time.

WARNINGS:

comply with the following instructions, before

remounting the parts:

●check that burner head slots “T” (fig. 4) have

not become clogged by foreign bodies.

●Check that enamelled burner cap “A-B-C”

(fig. 4-5) have correctly positioned on the

burner head. It must be steady.

●Burned food on an electric plate must be

removed dry.

●After use, pour a little lukewarm oil on the

plate and wipe it with a cloth.

●The pan support must be placed in the

appropriate centering pins verifying the

perfect stability.

●

Correctly preserve the plate after use by

treating it with special products, easily

available at the supermarket. This will keep

the surface of the plate clean and bright. This

operation will also prevent the formation of

rust.

●Don’t use steam jets for the equipment

cleaning.

Note:

continuous use could cause the burners to

change colour due to the high temperature.

FIG. 6

FIG. 5

FIG. 4

Page 11

11

INSTALLATION

FIG. 7 FIG. 8

MEASUREMENTS TO OBSERVE (in mm)

TECHNICAL INFORMATION

FOR FITTERS

Installation and all the regulation,

transformation and maintenance operations

listed in this section must be carried out

exclusively by qualified personnel.

The appliance must be correctly installed in

conformity with current law and the

manufacturer's instructions.

Incorrect installation may cause injury to people

or animals, or damage to items, for which the

manufacturer cannot be held responsible.

Throughout the life of the system, the devices

for the safety and automatic regulation of the

appliances must only be modified by the

manufacturer or the duly authorised supplier.

INDICATIONS FOR INSTALLATION

●The device is designed to remain operational for

less than 24 h (non-permanent operating system).

When this limit is reached, a regulation stoppage

occurs so the device can check its efficiency.

●This automatic device is a safety device and must

not be altered. Interference with this device will

eliminate any responsibility by the manufacturer

and invalidate the warranty.

●Observe the national and European standards

applicable (e.g., EN 60335-1/EN 50165) in

relation to electrical safety.

●Before entry into operation, check the wiring

carefully: incorrect wiring may damage the device

and jeopardise the safety of the system.

●Connect and disconnect the hob only after cutting

off the electricity supply.

●Avoid exposing the device to drops of water.

●Avoid laying the valve wires along with the high

voltage wires of the ignition transformer.

●Ensure that there is nothing on the hob,

particularly on the area of the control panel, before

switching on.

●After switching on the hob, wait a few seconds to

complete the automatic calibration procedure of

the control panel.

●In the event of a “partial” short circuit or insufficient

insulation between the line and earth, the voltage

on the sensor electrode may be reduced so much

that it causes the device to lock, due to the

impossibility to sense the flame signal.

●The extra low voltage (ELV) circuit is not safe to

touch (only main insulation in compliance with

EN 60730-1), so the installation must guarantee

the level of protection against electric shock

equivalent to double insulation for the user

interface.

A B C D E

2F - 3F (78)

705 405 95 95 97.5 min.

2F - 3F (86)

705 405 95 95 97.5 min.

Page 12

12

INSTALLATION

3) INSERTING THE HOB

After removing the outer and inner packing of the

various mobile parts, ensure that the hob is

undamaged. If you are in any doubt, do not use

the appliance and contact qualified personnel.

The packing elements (cardboard, bags,

polystyrene, nails must not be left within the

reach of children as they are potential sources

of danger.

Make a hole in the worktop to accommodate the

hob, using the measurements indicated in fig. 7,

ensuring that the critical dimensions of the space

in which the appliance must be installed are

observed (see fig. 8).

The appliance must belong to class 3 and is

therefore subject to all the indications of the

standards for such appliances.

The appliance can be installed with just one lateral

wall (to the right or left of the hob), higher than the

hob and positioned at a minimum distance as

described in the table below.

3A) CYLINDER HOLDER COMPARTMENT

The dimensions of the cylinder compartment have to

permit the easy loading and unloading of the cylinder.

For an efficient aeration is necessary to make some

small openings in the furniture, as per fig. 9/A

and 9/B.

The cylinder holder compartment must have the

following characteristics:

- resistance to a load.

- No fitment of the cylinder directly on the floor are

allowed.

- The cylinder equipped with governor must be set or

take off from the compartment in a easy way.

- The cylinder cock must be easily accessible.

- The flexible tube musn't be in contact with sharp

edges.

- The cylinder holder compartment and the different

parts of the unit, where the burners are fit, musn't be

in touch inside.

- The aeration openings musn't be occluded when the

unit is installed.

The appliance belongs to class 3 and is therefore

subject to all the provisions established by the

provisions governing such appliances.

IMPORTANT:

a perfect installation, adjustment or

transformation of the cook top to use other

gases requires a QUALIFIED INSTALLER: a

failure to follow this rule will void the

warranty.

FIG. 9/A FIG. 9/B

CAUTION: do not place the glass directly

on the unit. The bottom of the hob must

rest on the unit.

Page 13

13

INSTALLATION

4) FITTING THE HOB

The hob is equipped with a special seal to avoid

any infiltration of liquid into the unit. To apply this

seal correctly, please follow the instructions given

below carefully:

- remove all the mobile parts of the hob.

- Cut the seal into 4 strips of the lengths suitable to

fit it along the 4 sides of the glass.

- Turn the hob upside down and place the adhesive

side of the seal “E” (fig. 10/A) correctly under the

edge of the hob so that the outer edge of the seal

perfectly matches the outer perimeter edge of the

glass. The ends of the strips must match without

overlapping.

- Stick the seal to the glass evenly and securely,

using your fingers to press it into place.

- Position the hob in the hole in the unit and fasten it in

place using the appropriate screws “F” of the

fastening hooks “G” (see fig. 10/B).

- In order to avoid accidental contact with the

surface of the box of the overheated hob during

use, it is necessary to install a wooden divider at a

minimum distance of 70 mm from the top,

fastening it in place with screws (fig. 7).

- To fasten this product to the supporting structure,

we advise you not to use mechanical or electrical

screwdrivers and to exercise moderate pressure

by hand on the fastening hooks.

IMPORTANT INSTALLATION

INSTRUCTIONS

The appliance can be installed with just one

lateral wall (to the right or left of the hob),

higher than the hob and positioned at a

minimum distance as indicated in figure 7.

Moreover, the rear wall and the surfaces

adjacent to and surrounding the hob must

resist an temperature of 90 °C.

The glue which joins the plastic laminate to the

unit must be able to resist temperatures of at

least 150 °C to prevent the coating from

becoming unstuck.

The appliance must be installed in compliance

with the indications of the standards in force.

This appliance is not connected to a device for

the evacuation of the combust products.

Consequently it must be connected in

compliance with the installation instructions

mentioned earlier. Particular attention must be

paid to the information on ventilation and

aeration provided below.

5) VENTILATION

The room where the appliance is installed must be

permanently ventilated to guarantee its correct

operation. The amount of air necessary is that

required for the correct combustion of gas and the

ventilation of the room, which must measure at

least 20 m3. The natural airflow must take place

directly through permanent openings made in the

walls of the room to be ventilated, which lead

outside and have a minimum section of 100 cm

2

(see fig. 3). These openings must be made so that

they cannot be blocked.

Indirect ventilation is also allowed by drawing in air

from rooms next to that to be ventilated, absolutely

observing the indications of the standards in force.

6) POSITIONING AND AERATION

Gas hobs must always eliminate the products of

combustion through hoods connected t o

chimneys, flues or directly outside (see fig. 2). If it

is not possible to fit a hood, a fan installed in a

window or an outside wall can be used

simultaneously with the appliance (see fig. 3), as

long as the provisions concerning ventilation listed

in the standards in force are strictly observed.

FIG. 10/A FIG. 10/B

Page 14

14

INSTALLATION

7) GAS CONNECTION

Before connecting the appliance, ensure that

the data on the label applied to the lower part

is compatible with that of the gas distribution

network.

A printed label of this booklet and one applied

to the underside of the hob indicate the

instructions for regulating the appliance: type

of gas and working pressure.

When the gas is distributed through channels,

the appliance must be connected to the gas

delivery system:

●with hard steel piping compliant with the

standards in force, the joints of which must be

made using threaded fittings compliant

with EN 10226.

●with copper piping compliant with the standards

in force, the joints of which must be made using

mechanical seal fittings compliant with the

standards in force.

●with continuous wall stainless steel flexipipe,

compliant with the standards in force, with a

maximum extension of 2 metres and seals

compliant with the standards in force. This pipe

must be installed so that it cannot come into

contact with the moving parts of the module it is

built into (drawers for instance) and must not

cross compartments that can be filled.

When the gas is delivered directly from a

bottle, the appliance, fed with a pressure regulator

compliant with the standards in force must be

connected:

●with copper piping compliant with the standards

in force, the joints of which must be made using

mechanical seal fittings compliant with the

standards in force.

●With continuous wall stainless steel flexipipes,

compliant with the standards in force, with a

maximum extension of 2 metres and seals

compliant with the standards in force. This pipe

must be installed so that it cannot come into

contact with the moving parts of the module it is

built into (drawers for instance) and must not

cross compartments that can be filled. We advise

the application of a special adapter (easily

available on the market) to the flexipipe, to

facilitate the connection with the hose support of

the pressure regulator mounted on the bottle.

When the connection is complete, check that it is

perfectly sealed, using a soapy solution and never

a flame.

WARNINGS:

- remember that the gas entry fitting of the

appliance is a 1/2” threaded conic gas male

fitting compliant with EN 10226.

- The appliance is compliant with the

indications of the following European

Directives:

CEE 2009/142 in relation to gas safety.

Moreover, the walls and the surfaces adjacent to

and surrounding the hob must resist an

temperature of 90 ° C.

FIG. 10/C

Caution: Do not allow the glass (A)

lay directly on the work top. it is the

bottomshelf (B) that has to be in

touch with the work top (see

fig. 10/C).

Page 15

15

INSTALLATION

8) ELECTRICAL CONNECTION

The electrical connection must be made in

compliance with the standards and legal

provisions in force.

Before making the connection, ensure that:

- the voltage matches the value shown on the

specification plate and the section of the wires of

the electrical system can support the load, which

is also indicated on the specification plate.

- The socket or system has an effective earth

connection in compliance with the standards and

legal provisions currently in force. We cannot

accept any responsibility for failure to observe

these provisions.

When the appliance is connected to the power

supply via socket:

- fit a standard plug suited to the load indicated on

the label to the power cable “C” if necessary.

- Connect the wires in compliance with the diagram

in fig. 11, ensuring that the following are observed:

letter L (phase) = brown wire;

letter N (neutral) = blue wire;

earth symbol = green-yellow wire.

- The power cable must be positioned so that it

does not reach an temperature of 90 °C in any

point.

- Do not use reductions, adapters or shunts for the

connection, as they could make false contacts

causing hazards due to overheating.

- The socket must be accessible after fitting.

When the connection is made directly to the

electricity main:

- insert an omnipolar switch between the appliance

and the power network, in a size suited to the load

of the appliance, with a minimum aperture

between contacts of 3 mm.

- Remember that the earth cable must not be

interrupted by the switch.

- The electrical connection may also be protected

with a highly sensitive differential switch.

We strongly recommend that you connect the

appropriate green-yellow earth wire to an efficient

earth system.

Before performing any service on the electrical

part of the appliance, it must absolutely be

disconnected from the electrical network.

The manufacturer declines all responsibility for

damages suffered by people and items due to

failure to observe the aforementioned indications,

or deriving from interference with a single part of

the appliance.

WARNINGS:

all our products are conform with the

European Norms and relative amendments.

The product is therefore conform with the

requirements of the European Directivesin

force relating to:

- compatibility electromagnetic (EMC);

- electrical security (LVD);

- restriction of use of certain hazardous

substances (RoHS);

- EcoDesign (ERP).

IMPORTANT!

The appliance must be installed following

the manufacturer's instructions. The

manufacturer will not be liable for injury

to persons or animals or property

damage caused by an incorrect

installation. If the installation requires modifications

to the home's electrical system or if the

socket is incompatible with the

appliance's plug, have changes or

replacements performed by

professionally-qualified person. In

particular, this person must also make

sure that the section of the wires of the

socket is suitable for the power absorbed

by the appliance.

FIG. 11

Page 16

16

The regulation operations listed below are reserved to qualified fitters only. After carrying out any

regulation or pre-regulation operations, any seals must be replaced by the technician. The

regulation of primary air to our burners is not necessary.

9) PROCEDURE FOR REGULATING THE MINIMUM CAPACITY OF THE

BURNERS

The procedure for acquiring the minimum capacities allows the modification of the minimum capacity

programmed, adapting every burner to the characteristics of the gas distribution network to which the hob

is connected.

The procedure is activated by pressing the 2, 1 and 4 buttons continuously for 3 seconds, with all the

burners switched off (standby).

The activation of the regulation procedure is indicated on the display with the word “MIN”. At this point it is

possible to select the burner to be regulated using buttons + and -. After confirmation the burner selected

ignites at the minimum and the capacity can be increased or decreased to the minimum level using the +

and - buttons of the burner. During the display regulation procedure, the flame display levels will show the

indication - if the minimum level programmed corresponds with the factory setting, and the indication will

change ⊓or ⊔in flashing mode, indicating a higher or lower capacity than that programmed.

To confirm the minimum capacity required, it is necessary to press the Clock button (7). The word “MIN”

will continue to be present and none of the leds will flash. At this point it is possible to press the Clock

button (7) to exit the procedure, or press buttons + and - to select another burner and programme its

minimum capacity. The minimum capacity levels will then be acquired and memorised by the device, and

will be used in the normal use of the hob (see fig. 12).

Selecting the type of gas

It is possible to configure the hob to work with methane gas of lpg. To activate the gas selection

procedure, the hob must be working and all the burners must be switched off. Simply press the 2, 1 and 3

buttons for at least 3 seconds. The start of the gas selection procedure is indicated by the switch-off of

the burner level displays and the appearance of “Met” or “Lpg” on the timer display, depending on the

current configuration. It is possible to select the setting required, using buttons 2 and 1. To complete the

procedure the operator must press the Clock button (7).

The activation of this function implicates the cancellation of any switch-off times programmed for the

burners (see fig. 12).

THE BURNERS DO NOT REQUIRE ANY REGULATION OF THE PRIMARY AIR.

FIG. 12

REGULATION AND TRANSFORMATION OPERATIONS

Adjusting the minimum capacity of the external ring of the Dual burner will anyway involve lighting the

internal burner ring at its minimum level.

Page 17

17

REGULATION AND TRANSFORMATION OPERATIONS

10) REPLACING NOZZLES

The burners can be adapted to suited different

types of gas by fitting the nozzles that correspond

to the gas used. To do this, it is necessary to

remove the burner heads and use a straight key

“B”, to unscrew the nozzle “A” (see fig. 13) and

replace it with a nozzle corresponding to the gas

used.

We advise you to block the nozzle tightly.

After making these replacements, the

technician must regulate the burners as

described in paragraph 9, seal any regulation

or pre-regulation organs and apply the label

corresponding to the new gas regulation

carried out on the appliance in place of that

previously applied. This label is contained in

the spare nozzle bag.

For the ease of the fitter, we have prepared a table

indicating the flow capacities, the heat capacities

of the burners, the diameter of the nozzles and the

working pressure for the various types of gas.

ARRANGEMENT OF THE BURNERS

TABLE

78 cm.

86 cm.

FIG. 13

BURNERS

GAS

WORKING

PRESSURE

mbar

HEAT

CAPACITY

NOZZLE

DIAMETER

1/100 mm

HEAT

CAPACITY (W)

No.

DESCRIPTION

g/h l/h Min. Max.

2

TIPLE RING

G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20

276

271

357

100 B

100 B

145 A

1800

1800

1800

3800

3800

3750

3

DUAL

total

G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20

345

339

476

2 x 69A + 46 B

2 x 69A + 46 B

2 x 110 A + 71 A

1800

1800

1800

4200

4200

4200

DUAL

central

G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20

65

64

86

46 B

46 B

71 A

450

450

450

900

900

900

4

AUXILIARY

G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20

73

71

95

50

50

72 X

450

450

450

1000

1000

1000

Page 18

18

REGULATION AND TRANSFORMATION OPERATIONS

Display of the temperature inside the hob

There is a temperature sensor inside the electronic card with which it is possible to show the temperature

inside the hob directly on the timer display. The display is activated by pressing the 2 and 1 buttons with

buttons 7 and 8 continuously for at least 3 seconds. In this condition it is no longer possible to use button

7 for settings related to the programming of the burner switch-off time. The same sequence of buttons

used to activate the inner display of the temperature must be used to deactivate it.

Electronic self-diagnosis

The electronic cards constantly control their own status. Should hardware problems or faults inside the

card occur, such as to jeopardise the safety of the end user, the device enters a “safe” status in which the

solenoids are switched off and a code relating to the type of fault appears on the display.

One burner in lockout status

No gas supply

Restore the gas supply and then reset

the burners from lockout

The ionization electrode needs to be

cleaned or is not in contact with the

flame

Clean the electrode or adjust its position

and then reset the burners from lockout

Device not connected to earth

Check the wiring and then reset the

burners from lockout

Extraneous light / flame detection circuit

anomaly on a single burner

Ionization electrode incorrect wiring Check the wiring

Circuit failure Replace the device

Main valve control circuit anomaly Circuit failure Replace the device

Reference voltage circuit anomaly Circuit failure Replace the device

Watchdog circuit anomaly Circuit failure Replace the device

Microcontroller port anomaly Circuit failure Replace the device

EEPROM anomaly Circuit failure Replace the device

Valve driving circuit anomaly Circuit failure Replace the device

Driving anomaly on valve A Valve A incorrect wiring

Cut off the power supply, check valve A

wiring and then restore the power

supply

Driving anomaly on valve B Valve B incorrect wiring

Cut off the power supply, check valve B

wiring and then restore the power

supply

Driving anomaly on valve C Valve C incorrect wiring

Cut off the power supply, check valve C

wiring and then restore the power

supply

Driving anomaly on valve F Valve F incorrect wiring

Cut off the power supply, check valve F

wiring and then restore the power

supply

Max. limit of 5 resets in 15 minutes

exceeded

The burner reset procedure has been

carried out more than 5 times in 15

minutes

Wait 15 minutes and then reset the

burners from lockout

Power supply circuit anomaly Circuit failure Replace the device

Generic anomaly

The power supply to the device has

been cut off further to another type of

failure previously occurred

Reset the burners from lockout

Resonator anomaly Circuit failure Replace the device

All burners in lockout status

No gas supply

Restore the gas supply and then reset

the burners from lockout

The ionization electrodes need to be

cleaned or are not in contact with the

flame

Clean the electrodes or adjust their

position and then reset the burners from

lockout

Device not connected to earth

Check the wiring and then reset the

burners from lockout

Gas leakage from a valve causing the

unwanted ignition of a second burner

during the ignition of the first one.

The flame on in the second burner for

more than 10 seconds causes this type

of anomaly.

Replace the faulty valve

Control logic communication errors Circuit failure Replace the device

Keyboard control error

A mechanical deformation may have

jeopardized the keyboard good

positioning on the glass surface

Wait a few seconds for the keyboard

recalibration; if the error persists, cut off

and then restore the power supply; if the

error still persists, replace the device

Keyboard hardware error Circuit failure

Make sure that the keyboard card is

correctly inserted into the connector.

If yes, replace the device

Keyboard hardware error Circuit failure

Make sure that the keyboard card is

correctly inserted into the connector.

If yes, replace the device

Page 19

19

REGULATION AND TRANSFORMATION OPERATIONS

MEASUREMENTS

(electronic card)

Page 20

20

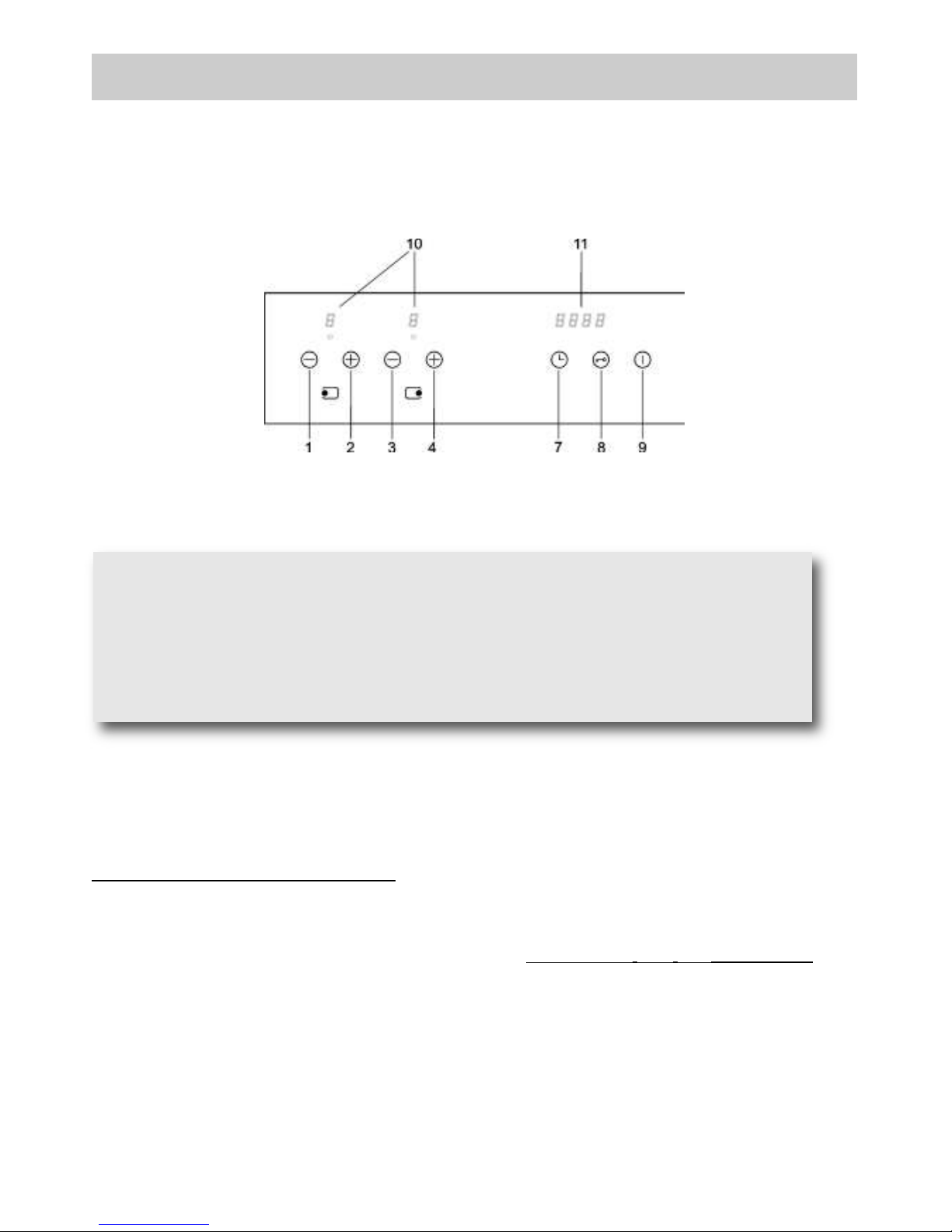

FIG. 17 FIG. 18

FIG. 14 FIG. 15 FIG. 16

MAINTENANCE

Before carrying out any maintenance,

disconnect the appliance from the gas and

electricity supplies.

INDICATIONS FOR INSTALLATION

• The device is designed to remain operational for

less than 24 h (non-permanent operating system).

When this limit is reached, a regulation stoppage

occurs so the device can check its efficiency.

• This automatic device is a safety device and must

not be altered. Interference with this device will

eliminate any responsibility by the manufacturer

and invalidate the warranty.

• Observe the national and European standards

applicable (e.g., EN 60335-1/EN 50165) in

relation to electrical safety.

• Before entry into operation, check the wiring

carefully: incorrect wiring may damage the device

and jeopardise the safety of the system.

• Connect and disconnect the hob only after cutting

off the electricity supply.

• Avoid exposing the device to drops of water.

• Avoid laying the valve wires along with the high

voltage wires of the ignition transformer.

• Ensure that there is nothing on the hob,

particularly on the area of the control panel, before

switching on.

• After switching on the hob, wait a few seconds to

complete the automatic calibration procedure of

the control panel.

• In the event of a “partial” short circuit or insufficient

insulation between the line and earth, the voltage

on the sensor electrode may be reduced so much

that it causes the device to lock, due to the

impossibility to sense the flame signal.

• The extra low voltage (ELV) circuit is not safe to

touch (only main insulation in compliance with

EN 60730-1), so the installation must guarantee

the level of protection against electric shock

equivalent to double insulation for the user

interface.

11) REPLACING COMPONENTS

To replace the components housed inside the hob

it is necessary to remove the flanges by loosening

the screws (fig. 14), removing the ceramic glass

surface.

After carrying out the operations listed above, it is

possible to replace the solenoids (fig. 15 - 16), the

electrical components and the electronic card

(fig. 17 - 18).

We advise you to change the seal “D” (fig. 16) every

time you replace a solenoid, in order to guarantee a

perfect seal between the body and the ramp.

To facilitate the work of the maintenance operator,

we have prepared a table, printed on the next page,

indicating the power cable types and sections.

Page 21

21

FIG. 19

MAINTENANCE

POWER CABLE TYPES AND SECTIONS

TYPE OF HOB TYPE OF POWER

CABLE

MONOPHASE

CAUTION!!!

When replacing the power cable, the fitter must keep the earth conductor “B” longer than the phase

conductor (fig. 19) and must also observe the warnings indicated in paragraph 8.

Gas hob H05 RR-F Section 3 x 0.75 mm

2

WARNING: MAINTENANCE MUST ONLY BE

PERFORMED BY AUTHORISED PERSONS.

In case of failure or cut in the cable, please move

away from the cable and do not touch it. Moreover

the device must be unplugged and not switched on.

Call the nearest authorized service center to fix the

problem.

Page 22

22

TECHNICAL DATA

DESCRIPTION

The electronic card enables the management of a gas hob with 2/3 burners.

This device works in conjunction with the Brahma VPC01 valves, which allow the regulation of the capacity

of each individual burner powered by methane gas or lpg.

The device is also made up of a user interface with display in seven segments and a touch panel.

MAIN FEATURES

The basic features are listed below:

• display in 7 red segments and leds for indication of the capacity level of each individual burner, for

indicating the time and settings.

• A touch panel with 9 touch-sensitive areas to select the level of each individual burner, settings, control

panel lock and light-up/ switch-off.

• Three 24Vdc outputs for Brahma VPC01 modulating valves.

• 24Vdc output for Brahma VPC01 main valve after the gas manifold.

• RS232 interface for the device diagnostics.

• Three faston inputs for the flame sensor electrodes of the five burners.

• Output for piloting a 220-240 Vac igniter.

• Management of modulation levels pre-programmed into the FLASH memory.

• Possibility for the management of two modulation tables (G20 and G30).

• Procedure incorporated into the device for regulating the minimum level for each burner.

• Power supply card created using switching technology.

• Daily clock in 24h format.

TECHNICAL DATA

Power supply:

100 - 240V a.c. ±10%

Frequency:

50 - 60Hz

Absorption:

30VA

Ignition transf. output contacts:

220 - 240V a.c. ±10% – 250mA – cosφ = 0,4

Sensor electrodes connection:

2.8 x 0.8 mm faston

Working temperature:

-10 °C ÷ +85 °C

Degree of protection:

IP 00

Classification code EN298:

Specific Character Code

1° Atmospheric A

2° Direct ignition of the main burner M

3°

Repetition of cycle C

4°

Non-volatile lock L

5°

Set times X

6°

Non-permanent operation N

Maximum length of the wires of external components:

≤1m

Flame control

The flame sensor device using straightening property of the flame.

Minimum ionisation current: 0.2µA

DC

Maximum ionisation current: (power supply voltage 264V

RMS

) 4.5µA

DC

Recommended ionisation current: 3 ÷ 5 times the minimum

Maximum length of cable: 1 m

Minimum insulation resistance of the electrode and the measuring cable towards earth: ≥ 50M

Ω

Max. electrode parasite capacity: ≤1nF

Max. short-circuit current: ≤ 200µA

AC

TIMES

- waiting time (TW):

1s

- safety time (TS):

4s

- intervention time in the event of switch-off: 3s (compliant with EN 30-1-4)

- inter-waiting or inter-ventilation time: 10s

- waiting time for lock caused by parasite flame: 10s

- pre-ignition time: 0s

- number of ignition attempts: 3

Page 23

23

TECHNICAL DATA PRINTED ON THE LABEL

2 BURNERS (86)

( 1 DUAL + 1 Triple Ring )

G30 - BUTANE = 28 - 30 mbar

G31 - PROPANE = 37 mbar

G20 - NATURAL = 20 mbar

Σ

Qn

Natural Gas

G20 = 7.95 kW

Σ

Qn

BUTANE Gas G30 =

8.0 kW

Σ

Qn

BUTANE Gas =

582 g/h (G30)

571 g/h (G31)

Voltage = 220-240 V ~

Frequency = 50/60 Hz

3 BURNERS (86)

( 2 Triple Ring + 1 AUXILIARY )

G30 - BUTANE = 28 - 30 mbar

G31 - PROPANE = 37 mbar

G20 - NATURAL = 20 mbar

Σ

Qn

Natural Gas

G20 = 8.5 kW

Σ

Qn

BUTANE Gas G30 =

8.6 kW

Σ

Qn

BUTANE Gas G30

= 625 g/h (G30)

614 g/h (G31)

Voltage = 220-240 V ~

Frequency = 50/60 Hz

TECHNICAL DATA OF THE APPLIANCE GAS REGULATION

Page 24

24

TECHNICAL ASSISTANCE AND SPARES

Before leaving the factory, this appliance was tested and regulated by specially qualified experts in order to

guarantee the best operating results.

The original spare parts can be found only in our Technical Assistance Centres and authorised shops.

Every repair or regulation operation which should become subsequently necessary must be carried out with

the utmost care and attention by qualified personnel.

This is why we recommend that you always contact the Dealer who sold the appliance or our nearest

Assistance Centre, specifying the brand, the model, the serial number and the type of problem affecting your

appliance. The pertinent data is stamped on the label applied to the underside of the appliance and on the

label applied to the packing box.

This information enables the technical assistance department to acquire the appropriate spare parts and

consequently guarantee prompt and targeted intervention. We recommend that you write this data in the

spaces below and keep it to hand at all times:

BRAND: .......................................................

MODEL: .......................................................

SERIES: .......................................................

This appliance is marked according to the European directive 2002/96/EC on

Waste Electrical and Electronic Equipment (WEEE).

This guideline is the frame of a European-wide validity of return and recycling on

Waste Electrical and Electronic Equipment.

Loading...

Loading...