© 2015 Thomas Dudley Ltd SISLF323990 | 11644 iss D

Thomas Dudley Ltd, P.O.Box 28, Birmingham New Road, Dudley, West Midlands, DY1 4SN

www.dudleybathroomproducts.co.uk

sales@thomasdudley.co.uk

0121 557 5345

0121 530 7000

4

TROUBLESHOOTER

Ensure collet is fully engaged.Collet not located correctlyButton sticking on Vantage with

Niagara valve.

Re-connect weight.

Substitute pipes.

Adjustable weight not retained on locating studs

Wrong position of pneumatic pipes

Full flush volume when operating

partial flush button.

Substitute pipes.Wrong position of pneumatic pipesPartial flush volume when

operating full flush button.

Replace ‘O’ rings.

Trim seam with knife.

Replace flush pipe and cut square.

Replace flush pipe.

Damaged ‘O’ rings on cistern outlet

Flush pipe seam protruding

Flush pipe cut at angle

Flush pipe cracked

Leaking from flush pipe

connection.

Re-connect pipes.

Push-fit bellows into lever mount.

Replace bellows.

Replace push button.

Pneumatic pipes not connected

Bellows poorly fitted to lever mount

Bellows leaking

Push button leaking

Outlet valve not operating with

push button.

Check for leaks on bellows and push button.

Check push button for leaks.

Replace push button.

Push-fit bellows into lever mount.

Seal not clearing window

Lack of air to inflate bellows

Push button leaking

Bellows poorly fitted to lever mount

Outlet valve closing before full

volume delivered.

Relieve by removing pipe to valve.

Clean surfaces.

Bellows not evacuating all air

Build up of debris on seal face of housing or seal

Outlet valve not closing. (Water

continually running into pan).

See ‘B’ above.

Lower float on inlet valve.

Inlet valve not shutting off

Water level set too high

Internally overflowing.

Fit blue restrictor.

Replace lay flat tube.

Re-fit lay flat tube.

Blue restrictor not fitted when water supply is

mains fed

Lay flat tube missing

Lay flat tube not hanging vertically

Turbulent and noisy flow from

inlet valve.

Remove blue restrictor.

Clean filter.

Blue restrictor fitted when water supply is tank fed

Filter blocked

Low flow from inlet valve.

Replace seal in arm.

Replace filter and ‘O’ ring.

Re-engage valve in bracket.

Adjust float chamber/float position.

Re-fit or replace lever arm.

Tighten nut.

Fit blue restrictor.

Replace diaphragm assembly.

Seal missing on float lever arm

Filter and ‘O’ ring missing

Valve has become dislodged from mounting

bracket

Float chamber/float set too high

Float lever arm dislodged from mounting

Front nut loose

Blue restrictor not fitted at very high mains pressure

Monitoring pin seized

Inlet valve not shutting off.

Open supply tap.

Open isolating valve.

Remove filter and clean.

Mount valve correctly, straighten bent float stem.

Adjust float/float chamber height (ensure float

remains inside float chamber at all times).

Mains supply tap not open.

Isolating valve not open

Filter blocked

Float arm not free to move

Float stuck on/in float chamber

No water flow from inlet valve.

RemedyPossible CauseSymptom

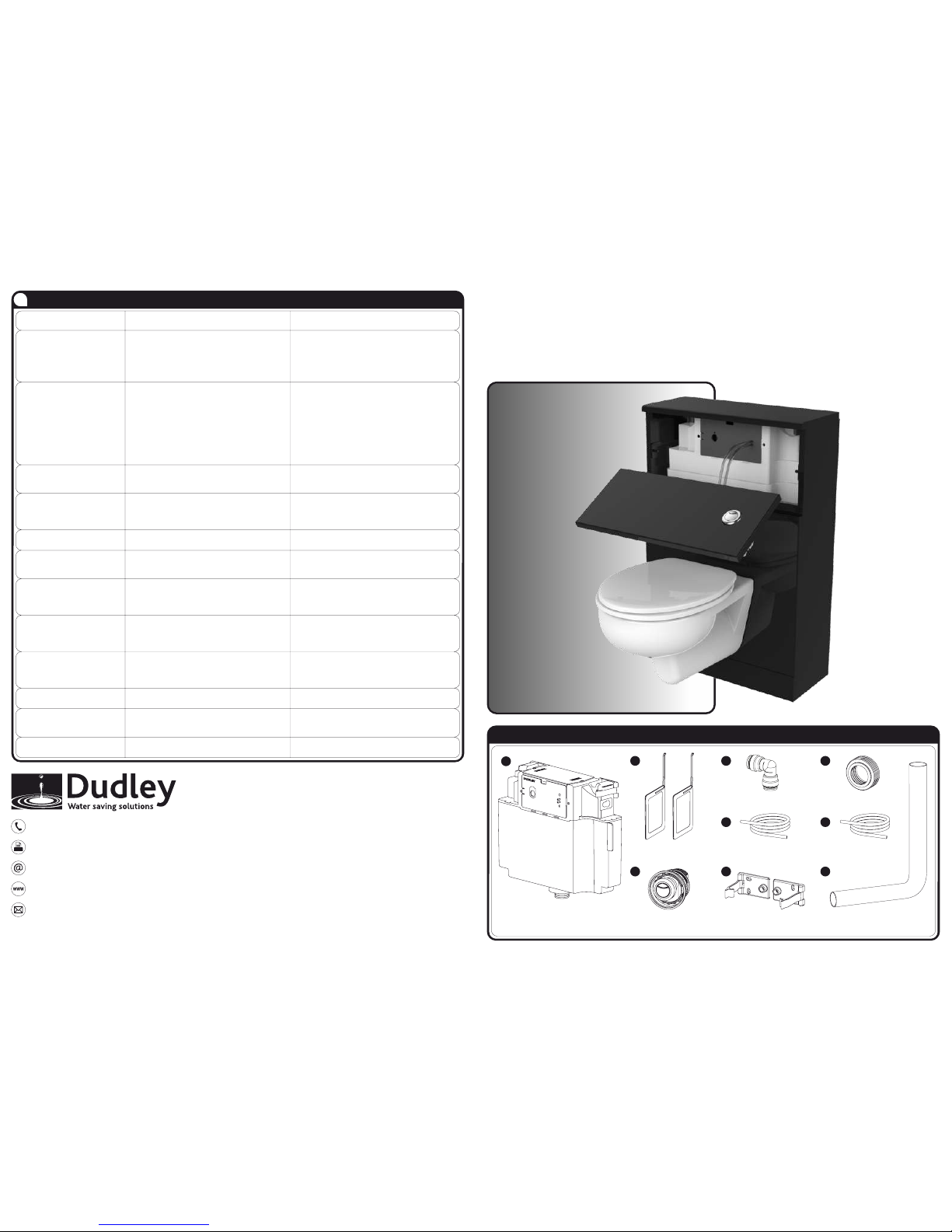

PACK CONTENTS

Push-fit flushpipe

9

2 x Mounting bracket

8

Push button

(Style may vary)

7

750mm Clear tube

6

750mm Green tube

(Dual Flush Only)

5

Pan Connector

4

Push-fit elbow

3

2 x Partition

(Not supplied with 6L Mono)

2

Vantage cistern

Complete with flush valve, inlet valve,

isolating valve and flow restrictor.

1

Concealed WC Cistern

Installation Instructions

Vantage

Clean the sealing face of

the valve body that is

located in the bottom

of the cistern

2

Carefully clean the outlet valve

seal under cold running water

Important:

Take care not to damage the seal

1

Niagara outlet valve maintenance

Filter Assembly

Filter

Clean the diaphragm and filter

assy under cold running water

3

2

Remove filter assembly

using filter removal tool

Diaphragm

Float Assembly

Front Nut

Carefully remove front nut,

pressure chamber and

diaphragm

1

Hydroflo inlet valve maintenance

Remove the Niagara valve through the service aperture

6

Twist the Niagara valve anti-clockwise to release

5

Remove the Hydroflo valve through the service aperture

4

Remove the Hydroflo valve from mounting clip

3

Close

90°

Close isolation valve and flush to empty cistern

2

Pull here to remove

PULL

Remove front service cover

1

Removal of internal components

2

VANTAGE CISTERN MAINTENANCE

Technical Help @ Thomas Dudley Ltd on 0121 530 7000

FINAL INSTALLATION CHECK LIST:

Check all moving components operate freely and the inlet valve shuts off correctly.

If overflowing or poor flushing subsequently occurs, check that the float and arm move freely up and down and that the water level is correct.

Check all joints are tightened correctly.

Check carefully for leaks.

Hold the inlet valve float down, causing the cistern to internally overflow. Ensure the overflow pipe is capable of discharging all incoming water

without the cistern overflowing. If water overflows the cistern make sure that the flow restrictor is fitted. If overflowing persists contact:

WARNING: No sealing compound, paste, flux or solvent to be used in contact with plastic or rubber surfaces to avoid damage. Rubber washers

or ‘O’ rings should provide an adequate seal. PTFE tape may be used on threads. Do not over tighten plastic nuts.

No chemical block or additive is to be used in this cistern.

Level 3: 6/4L Dual flush

Level 5: 5/3.3L Dual flush

Level 10: 4/2.6L Dual flush

Slide to required level and

relock into position

Twist adjustable weight

anti-clockwise to unlock

Adjust weight

Reverse operation to re-fit

Twist Niagara valve

anti-clockwise to release

from Vantage cistern

Remove Niagara Valve

Configure Niagara valve

2

Mono Flush

6 Litre - No Partitions

5 Litre - One Partition

4 Litre - Two Partitions

Dual Flush

6/4 Litre - No Partitions

5/3 Litre - One Partition

4/2.6 Litre - Two Partitions

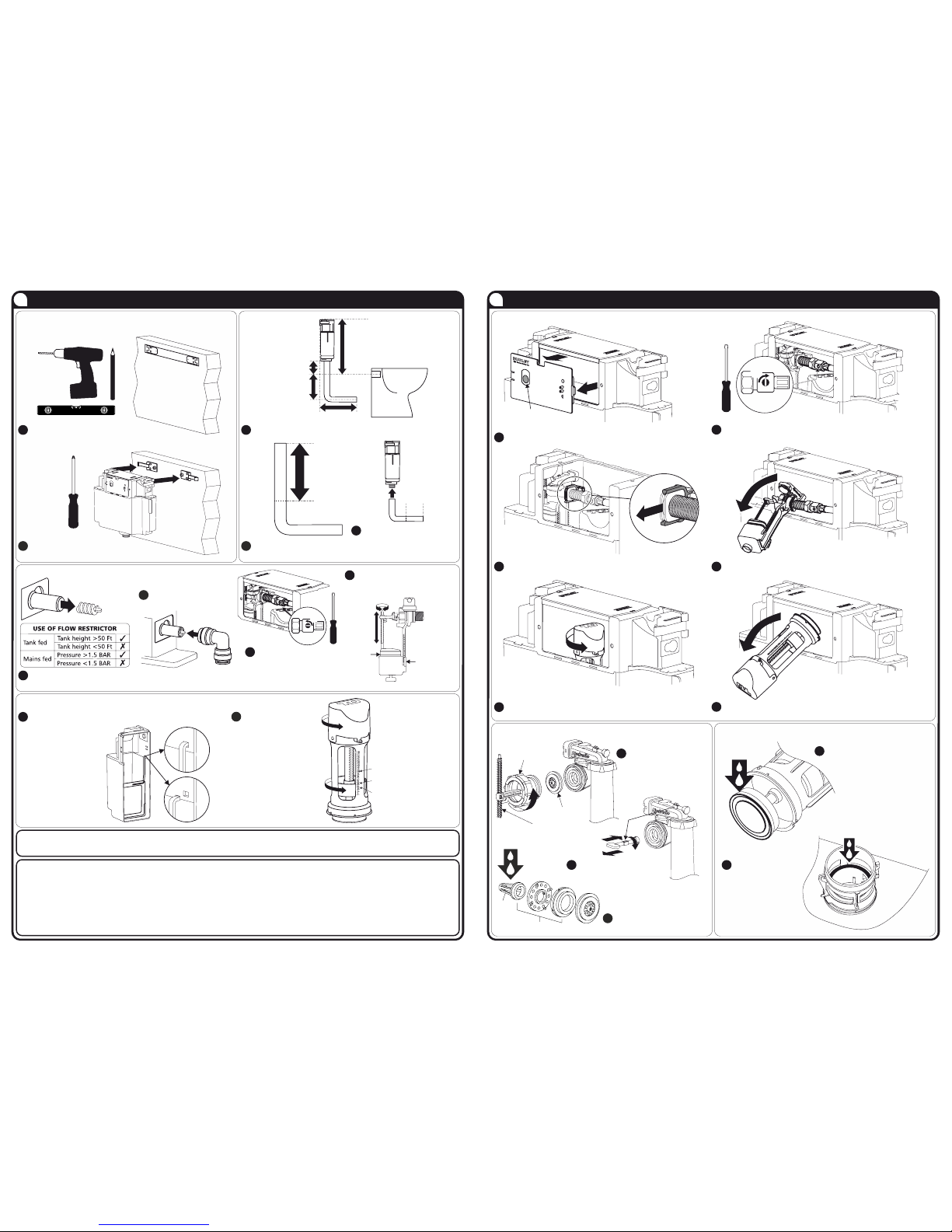

Fit or remove partitions as required

1

Converting the Vantage cistern flush capacity (if required)

Check water level and adjust if

necessary by rotating float

adjuster stem

4

Water

Level

Set chamber

to lowest

position

Open

90°

Open isolation valve

(factory set to closed)

Note: Bottom entry cisterns

require an external isolation

valve (not supplied)

3

Push-fit the elbow and

connect the mains supply

2

Remove factory fitted flow restrictor

if necessary (See table above)

1

Connect inlet and check water level

Trim

Trim horizontal section of flush

pipe to suit WC pan installation.

Re-fit flush pipe to Vantage

cistern and connect to WC pan

3

Distance A

Cut Line

Cut Distance A from larger

diameter section of flush pipe

2

328mm MAX

70mm MIN

740mm MAX

440mm MIN

Distance A

Fit flush pipe to Vantage cistern and measure Distance A

1

Fit flush pipe

Fit the mounting brackets and secure the

cistern to the wall (screws not supplied)

2

TEMPLA

TE

Use provided hole guide to mark and drill holes

to suit No.8 CSK screws ensuring template is level

(Guide located on front flap of box)

1

Fit Vantage cistern to wall

Note: Prior to installation ensure there is sufficient space

for the Vantage to be installed

1

VANTAGE CISTERN INSTALLATION

Loading...

Loading...