Page 1

k Paraglidin

Dude

g, u

l. S

era 2/XIp, 85-79

zanc

2 By

zcz, tel. +4

dgos

8 52 348

55 35, info@dud

ek.c

om.p

l

Page 2

NOTE!

Please read this operating manual before the first flight

MPORTANT:

Remember to fill in and send us the registration card, which is sewn on to the

trailing edge of the paraglider. When we receive it, we will send you the

Warranty, AeroCasco or Golden Package confirmation (whichever you

choose). You will also receive small gifts.

If you have bought the paraglider together with the Golden Package, you will

receive:

$ Golden Package, AeroCasco and Warranty confirmation (after you have

sent the registration card),

$ free first technical servicing,

$ Cordura backpack

$ speed system

$ small gifts.

More information about the Golden Package on page 22.

If you have bought the paraglider without the Golden Package, but with

AeroCasco, you will receive:

$ AeroCasco and Warranty confirmation (after you have sent the

registration card)

$ small gifts

More information about AeroCasco on page 21.

If you have bought the paraglider without the Golden Package or AeroCasco,

you will receive:

$ Warranty confirmation (after you have sent the registration card)

$ small gifts

More information about Warranty on page 20.

The above mentioned confirmations will allow us later to identify the

paraglider, to categorize it into a proper insurance group and to determine the

insurance expiry date.

Also, the confirmations are useful, when you want to sell the paraglider (they

allow the new owner to keep all the benefits).

NOTE! If you aren't the first owner of the paraglider, you should send us the

registration confirmation together with a copy of previous users' logbooks (total of

flying hours) within 14 days from the date of purchase, in order to be able to keep

the warranty.

Details on page 21.

Page 3

CONTENTS Page

1. Introduction...........................................................................................3

2. On the wing...........................................................................................4

WHO SHOULD FLY SHARK?

THE CLOTH

RIGGING SYSTEM

RISERS

3. Speed system........................................................................................6

SPEED SYSTEM ADJUSTMENT

SPEED SYSTEM USAGE

4. Harness................................................................................................10

5. Flight....................................................................................................10

PRE-FLIGHT CHECK

LAUNCH

TURNS

THERMALLING AND SOARING

FLYING WITH SPEED SYSTEM ENGAGED

LANDING

WINCHING AND MOTOPARAGLIDING

AEROBATICS

6. Rapid Descents...................................................................................14

BIG EARS

SPIRAL DIVE

B-STALL

7. Extreme Flying Manoeuvres..............................................................15

ONE SIDED COLLAPSE

SPIN AND FULL STALL

WING OVER

FRONTAL COLLAPSE

LINE OVER

PARACHUTAL STALL

EMERGENCY STEERING

8. Canopy Care........................................................................................17

STORAGE

CLEANING

REPAIR

DETERIORATION: A FEW TIPS!

9. Technical data.................................................................................19

10. Tree Star Security Assistance........................................................20

11. What have you bought......................................................................23

12. Rigging tables....................................................................................24

Page 4

Page 5

USER MANUALUSER MANUAL

1. Introduction

CONGRATULATIONS!

We are pleased to welcome you among the number of discerning Dudek

Paragliding pilots. You are now a proud owner of a state-of-the-art

paraglider. Extensive development by using the most modern methods and

thorough tests make the Dudek SHARK a user friendly paraglider without

neglecting performance and fun of flying.

We wish you many enjoyable hours flying your new Dudek MANTA.

DISCLAIMER.

Please read this manual carefully and note the following details:

$ The purpose of this manual is to offer guidelines to the pilot using

the Dudek SHARK wing and it is by no means intended to be used

as a training manual for this or any other paraglider in general.

$ You may only fly a paraglider when qualified to do so or when

undergoing training at an accredited School or Instructor.

$ Pilots are responsible for their own safety and their paraglider's

airworthiness.

$ The use of this paraglider is solely at the user's own risk!

Manufacturer and distributor do not accept any liability.

$ This paraglider on delivery meets all requirements of the

CEN/AFNOR. Any alterations to the paraglider will render its

certification invalid.

33

Page 6

tamed aggression

2. On the wing

WHO SHOULD FLY SHARK?

We have designed this paraglider with following pilots in mind:

$ People, who having acquired experience on recreational wings, would

like to try their hand at flying a paraglider that enables cross country

flights, without giving up joy of flying.

$ Intermediate competitors, who would like to start taking part in

competitions with big safety margin on their side.

$ Motoparagliding enthusiasts.

$ Pilots living rather in flat countryside, who need a very stable wing and

one efficiently gaining altitude when winched.

The Dudek SHARK is a perfect combination of performance and safety.

The SHARK has a slim, elliptical planform with slightly rearward swept tips.

Its triple cells ensure a smooth top surface, exact aerofoil reproduction on

entire wingspan, and yet most importantly, fewer suspension points. The

SHARK has greatly reduced the number of lines used and thus the

associated parasitic drag, which particularly at high speed gives an

exceptional glide angle.Most of the lines used are not sheathed, they are

covered with the impregnate only.

Four extra cells on each side form stabilisers that ensure stable straight flight

and effective and co-ordinated turns. The aerofoil of the SHARK was tested

and analysed using numerical methods, still it owes much to experiences we

gained from designing and everyday use of our previous paragliders. Its

relatively thick shape offers excellent safety and lift coefficient.

The precise shape of leading edge is maintained with internal

reinforcements of laminated cloth, which is used to cover areas close to cell

openings and trailing edge as well. The cell openings of the SHARK are

located on the undersurface of the aerofoil, close to its leading edge. Dacron

flares at the suspension points and between-line reinforcements ensure an

equal distribution of load throughout the canopy.

Large cross ports provide good air movement inside the wing and its quick

inflation. Yet the number of ports was reduced, so that the profile of the

canopy is less affected.

Our paragliders are manufactured using the best materials available. We are

sure it's the safety and reliability that counts, not the price. Such an attitude

allowed us to extend the quarantee period up to three years - more details

on page 20.

44

Page 7

USER MANUALUSER MANUAL

THE CLOTH

Each cloth has its own characteristics, so they must be properly matched in

order to create a harmoniously behaving paraglider. For the upper surface of

SHARK we used a Porcher 9092 cloth, named SkyTex Aquatic (44g/m ).

Basically it's a nylon cloth covered with superb E85A impregate, introduced

into mass production in January 2002, after a series of extensive laboratory

and real flying tests. Such covered cloth is not that stiff and - what's most

important - has increased tear, stretch and UV resistance. It is not silicon, so

minor repairs can be easily done with self-adhesive strips.

The lower surface is made of SkyTex 9017 with E38A impregnate (39g/m).

This cloth has a great weight/resistance ratio and is one of the biggest

Porcher Marine successes in providing proper materials for paragliding

industry.

The ribs must be as rigid and stretch-resistant as possible. We found these

qualities in SkyTex 9017 with E29A impregnate.

RIGGING SYSTEM

We chose latest Cousin Trestec product here, that is Dyneema Ultimate

Prestretched lines. It features high wear resistance and is very strong while

relatively thin.

Dyneema Ultimate is additionally stabilized during production process - each

thread is first stretched with carefully chosen force and then thermally

stabilized in strictly observed temperature. As a result we got a line that is a

lot less elastic, less likely to shrink while wet and with equal load distribution

on entire length. Part of the SHARK lines have coloured polyester sheath

covering a core, while the majority consists of non-sheathed lines covered

with the impregnate only.

The rigging system consists of individual lines looped and stitched at each

end. There is a high diversity of lines used, as we wanted to have best

strength/diameter ratio in each lines group, depending on existing loads (see

table on pages .

The upper level (gallery) lines start at the attachment points. Every three

lines adjoin to one suspension line. The outer lines are first gathered by twos

and threes in a middle level lines, and these in turn by twos in one line. Main

suspension lines attach to risers with triangular quick links (maillons). The

stabilizer lines connect the outer suspension points to the maillons in

cascades as well.

The same story goes as for steering lines. With consecutive cascades they

lead down to main brake lines which then go through pulleys connected to

the C-riser and finish at the brake handles. The outer steering lines in upper

level additionally go through a metal loop to improve steering effectiveness.

25-26)

55

Page 8

tamed aggression

Main brake lines are attached to the brake handles at their optimum

trimming point, marked on the line by a black dot. This adjustment ought not

be altered. Having the handles attached above optimal marks will cause

permanent brake application and possible accidents. Attachment below

these points is not advised too, as it will significantly diminish tension of the

trailing edge, thus changing wing behaviour in some situations.

Suspension lines are coloured depending on their strength and diameter as

follows (colour code can be slightly different):

diameter: 1,9 mm; strength: 328 daN; colour: blue

diameter: 1,5 mm; strength: 216 daN; colour: red

diameter: 1,3 mm; strength: 146 daN; colour: yellow

diameter: 1,1 mm; strength: 128 daN; colour: green

diameter: 0,8 mm; strenght: 87 daN; colour: red

Main suspension lines adjoin to stainless steel triangular quick links

(maillons). Additionally there are rubber "O rings" to prevent slipping of the

lines on the quick link.

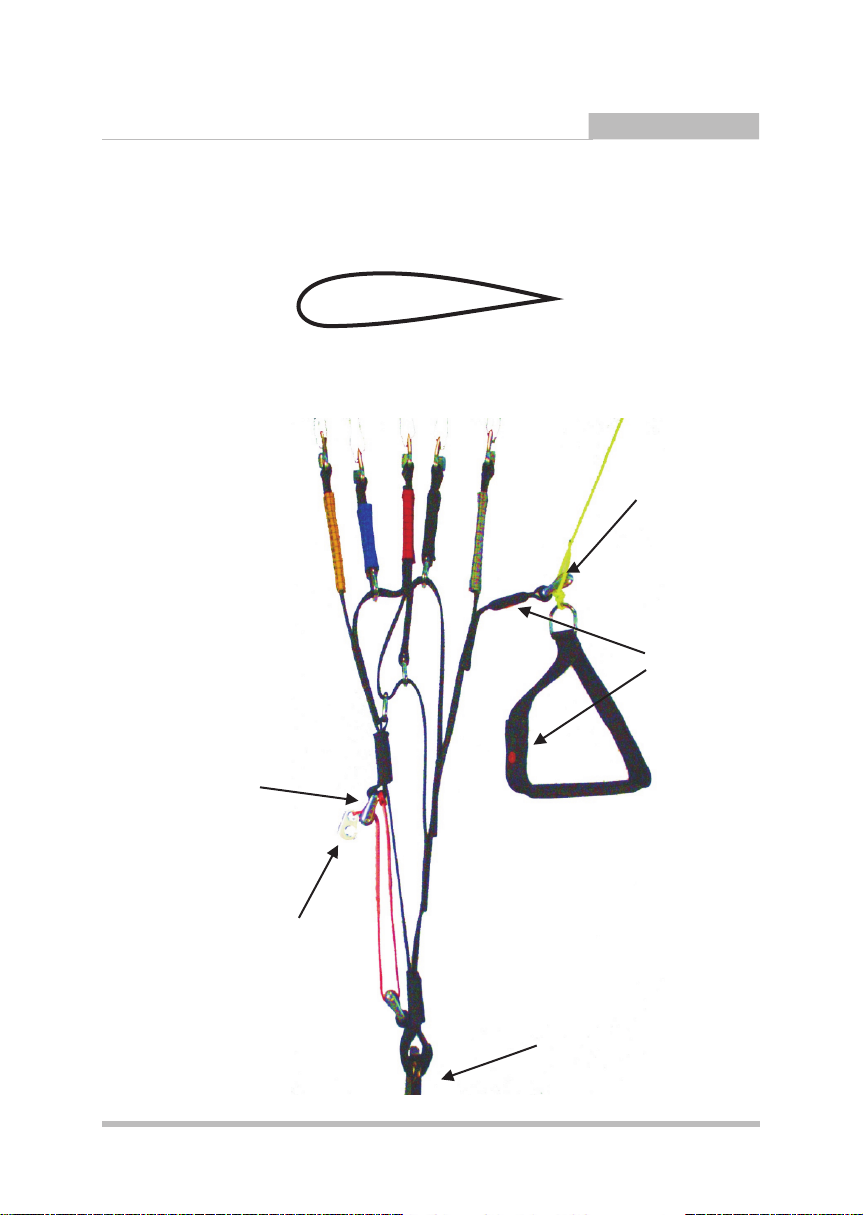

There are 4-way risers in SHARK (with A riser split in two) with presumed

speed-system installation. The outer A suspension line connects to short A'

riser (blue), other A lines to proper A riser (gold), B and stabilizer lines go to

B riser (red), C lines to C riser (black) , and D risers (grey, with pulleys

added) gather D and steering lines.

As mentioned, risers are coloured for differentiation purposes:

A - yellow - used for launching,

A' - blue - used for Big Ears,

B - red - used for B-stall,

D - grey - used for deflating the canopy in strong winds (aborting

launch).

66

Page 9

RISERS

USER MANUALUSER MANUAL

A

A’

B

D

C

BRAKE LINE

PULLEY

MAGNETS

PULLEY

TO SPEED BAR

BRAKE HANDLE

CARABINER

77

Page 10

tamed aggression

3. Speed system

The heart of speed system is a line sewn into A riser, running through two

pulleys and finished with a loop with small hook. There you attach the speed

bar line. In normal flight all risers have an overall length of 50 cm. Speed

system affects risers A, A', B and C. When the bar is being pushed, A and

gradually A' and B riser shorten, until there is a 3-cm difference between A

and B. Their minimal length is respectively 35, 37 and 40 cm. C-risers are

shortened proportionally, up to minimal length of 44 cm. D-riser retains its

original dimensions.

An incorrectly fitted speed system leads to loss of certification!

SPEED SYSTEM ADJUSTMENT

Most of modern harnesses are equipped with special speed system pulleys

and sometimes even its own integrated speedbar. If it's not the case, first

you need to have some pulleys attached in such a way that will allow the

pilot maximize the output of his/her legs with correct power vector, without

pushing the harness back. The speed system cord must be firmly attached

(with bowline or other non-slipping knot) to the speed bar. The other end of

the cord must be ran upward through the harness pulleys, to be firmly

attached to a hook or small carabiner with strong spring action. Overall

length of speed system cord should allow pilot to put his/her feet easily into

the bar when in flight, and yet should be short enough to cover the full speed

range. To exercise full speed with SHARK speed system, double speed bar

is advised.

Make sure that both cords on the speed bar are equal, as even slight

difference can result in constant turning of the paraglider. Test your speed

system thoroughly on the ground before flying with it!

The maximum action is reached when speed system pulleys touch.

SPEED SYSTEM USAGE

Attach paraglider risers to the harness with main carabiners. Then connect

speed system cords with hooks or quick-links. Before launching make sure

that speed system is untangled and runs freely.

To use the speed system simply place your feet on the speed bar and push

forward on a horizontal plane. If you notice a sudden loss of pressure on the

bar, it can be a sign of imminent frontal collapse. In such case release the

88

Page 11

RISERS - FULL SPEED

USER MANUALUSER MANUAL

D

6 cm DECREASE

12 cm DECREASE

13 cm DECREASE

15 cm DECREASE

C

B

A’

A

99

Page 12

tamed aggression

bar and thus speed system immediately. Watch out for such things - quick

wits can spare you most collapses and in general increase your awareness

of what's going on around you. Slight speed-bar operation can also optimize

your flight, i. e. when entering a thermal. Speed system activation diminishes

your paraglider angle of attack, so that its airspeed is increased. Yet

simultaneously the canopy is less stable - that's why you should avoid using

speedsystem in turbulent conditions, close to the ground or near other

airspace users!

Do not use the speed system in any extreme manoeuvres! If the canopy

does collapse, release the speed bar immediately and correct the situation

as usual.

4. Harness

Dudek SHARK pilot will fly happily using any certified harness with hang

point between 35 cm and 49 cm from the seat (however the safest distance

is 40 cm). Distance between carabiners should be between 37 cm and 45

cm, still in this case the best option is 40 cm too.

Please note that any modification of seat/hang point distance changes the

position of the brakes in relation to the pilot's body. You must remember that

in each configuration the effect of your hands' movement will be different.

Caution! Too tight cross straps can affect dramatically the handling, and thus

may not actually contribute to higher safety. Have them tightened just the

correct amount.

5. Flight

PRE-FLIGHT CHECK

A thorough pre-flight check is essential for any aircraft; the Dudek SHARK is

no exception. Having unpacked and laid out the paraglider, following checks

must be made:

$ Canopy, lines and risers condition. Do not start if any damage is

noticed.

$ The paraglider should be arranged in such a way that the centre

section A-lines (of golden risers) will strain earlier that the outer ones.

This ensures an easy and symmetrical launch.

1010

Page 13

USER MANUALUSER MANUAL

$ All lines and risers should be separated. Make sure they are not

tangled and pay special attention to the A-lines, which should run free

from the A (golden band) and A' risers (blue band) to the canopy.

$ It is equally important to untangle the brake lines so that they will not

catch anything on the ground during launch. They must be firmly

attached to the brake handles and run freely through the pulleys to the

trailing edge.

$ See that the risers are not twisted. It is very important not to loop any

lines around the canopy. The so-called "line-over" may have disastrous

consequences during take off.

Before every launch thoroughly check lines, risers and canopy! Do not

launch in case of even the smallest damage!

Always put on and fasten your helmet before clipping in to the

harness.

Check quick links (maillons). They can unscrew, especially when the

wing is new.

Check main carabiners. They must be properly mounted, closed and

locked.

LAUNCH

With little or no front wind you should use a classic start.

Facing the wind you should pick up riser on one side and keeping it flat

place it over your shoulders (A riser must lay on top). Clip it into carabiner

while taking care not to turn the risers in any way, and repeat the actions on

the other side. Lock the carabiners. Grip the brake handles and A-risers

(marked with golden band), holding them at the stitching, just under the

quick-links.

Spread your slightly bent hands out, slightly down and back. All risers but the

A should be placed near your elbow joints.

Apply some tension to check if the A risers stay on top and the lines are not

tangled. Take a step back, bow down a little and run forward. After the initial

inflation smoothly move the hands up and over your head until the wing will

be directly above you. Check the wing and let the A risers loose. Pump out

possible faults and keep an eye on position of the paraglider. Side drift is

corrected best by moving yourself under the canopy, as long as the launch

1111

Page 14

tamed aggression

space permits. In order to keep the wing in the air the suspension lines must

stay taut all the time, so in light winds you will have to run forward. With

stronger winds you can control the wing while standing still. When leaving

the ground apply some brakes, then release it after gaining some distance

from the ground.

Reverse launch can be used when the wind speed rise over 3 m/s. After

clipping the risers into carabiners turn back to face the wing, moving one of

the riser groups over your head. As a consequence, you will have the risers

crossed. Unlock brake handles and grip it outside of the risers without

crossing neither arms, nor lines. Now take corresponding A risers on both

sides. Make sure that the wing inflates symmetrical and the lines are not

tangled. Building up tension with a few steps back and simultaneously lifting

the A risers (without closing them to you) will make the paraglider rise. When

it arrives over your head, stabilize it with the brakes, check again if

everything is OK and turn.

Remember to turn always in the same direction. The turn itself should be

quick and smooth. While turning you have to release the brake handles and

grip them again facing forward. Last check of the wing & free space to

launch and off you go.

CAUTION

When deflating the canopy in strong winds (e. g. aborting a launch), use the

D risers, not the brakes. Using the brakes in strong wind causes more lift,

that eventually can lift the pilot up and drag him/her back.

TURNS:

The Dudek SHARK is a very responsive wing; it has a very easy handling

and reacts instantly to any steering input, with progressive forces on the

brakes. Adding some weight shift will make the paraglider turn really quick

and tight.

The combined technique (weight shifting and brake input) is the most

efficient method. The turn radius is determined by the amount of inside brake

used and weight shift. Additional application of a little outside brake after

initiating the turn with maximum weight shift increases efficiency and the

outboard wing's resistance to collapse (in turbulence, the edge of a thermal

etc).

In case it is necessary to turn the Dudek SHARK in a confined area at slow

speed (e.g. slope soaring), it is recommended to steer the decelerated

canopy by loosening the brake at the outside of the turn while applying a

little more brake on the inside of the turn.

When entering a turbulent area you should brake a little, just to put up the

tension. It will allow you to react instantly in case of a problem.

1212

Page 15

USER MANUALUSER MANUAL

CAUTION: Too hard or too quick pulling of one brake can cause the wing to

enter a spin.

THERMALLING AND SOARING

When flying Dudek SHARK minimum sink is attained with slight brake

pressure applied (10 cm to 15 cm depending on pilot’s weight). In turbulent

conditions the canopy should be flown with a small amount of brake applied.

This improves overall stability by increasing the angle of attack of the

canopy. The canopy should neither rock back nor surge forwards, but always

remain above the pilot. In order to achieve it, a pilot should accelerate the

wing by letting off the brakes when entering a thermal (accordingly to its

strength) and should brake the canopy on exiting. This is part of basic active

flying that can spare you many potential collapses.

When soaring the slope, a minimum height of 50 m above ground is

recommended for safety reasons. It is important to comply with the rules of

air traffic, especially when many pilots share airspace close to a hill. In such

conditions the avoidance manoeuvres often are not possible.

FLYING WITH SPEED SYSTEM ENGAGED

When flying into head wind or through sink it is advisable (for the sake of

best glide angle) to increase speed, as long as conditions are not too

turbulent. Still with application of speed system the angle of attack

diminishes and the canopy may tuck easier than in normal flight. The faster

is your flight, the more dynamic are tucks and stalls. See "Speed system"

section.

LANDING

The Dudek SHARK is easy to land. Final leg of the landing approach must

bring you into wind. At approximately 1 meter above the ground pilot should

flare the canopy, applying the brakes accordingly to conditions. The glider

may even climb again for a while gaining some height, if too much brake is

used.

Strong wind landings hardly requires braking, if any at all! Use D-risers

(coloured grey) to deflate the canopy after landing. Using the brakes will

probably result in pilot being lifted and dragged backwards.

The final glide of the landing approach should be straight and smooth. Steep

or alternating turns can result in a dangerous pendulum effect near the

ground.

WINCHING AND MOTOPARAGLIDING

During tests, numerous flights were made with winch start and backpack

1313

Page 16

tamed aggression

power units, as these are the only means to gain some height in flatlands.

Absolutely no contradictions were found for using SHARK in such flights.

CAUTION

During start, especially after a winch or with a motor, always remember to

bring the wing directly over your head. SHARK's aerofoil and its angle of

attack were arranged to give maximum lift coefficient with relatively high

safety. As a result of its thick aerofoil it can stay behind a pilot, if he neglects

bringing it over head.

AEROBATICS

SHARK was not designed for doing aerobatics.

6. Rapid Descents

BIG EARS

You can deflate the wing tips by pulling down the A' risers (blue band)

approximately 50 cm simultaneously.

It is important not to let go off the brake toggles while entering the Big Ears

manoeuvre. The paraglider will maintain straight course with an increased

sink rate (up to some 5 m/sec). The canopy remains completely controllable

with weight shifting. On releasing the A' risers the canopy usually reinflates

spontaneously, or can be aided by a long pump until the tips get clear.

CAUTION: Check out the Parachutal Stall section.

SPIRAL DIVE

It is characterized by reaching the highest sink rates. Significant G-forces,

however, make it difficult to sustain a spiral dive for long, as it can place high

loads on the pilot and glider.

Never do this manoeuvre in turbulence or at too high bank angles. You have

to watch constantly the situation, in order to prevent your spiral from turning

into a spiral dive (sink rate over 16 m/s).

Usually at excessive and uncontrollable spiral dives the outer wing tip of

SHARK goes into flatter or collapses, thus gradually slowing the dive. Still, if

pilot releases the inner brake and the wing does not start slowing down on

its own, you have to aid this process with the outer brake.

1414

Page 17

USER MANUALUSER MANUAL

Characteristic feature of SHARK is that the outer wing tip goes into flatter at

excessive und uncontrollable spiral dive, gradually slowing the dive.

NEVER DO BIG EARS IN A SPIRAL!

Tests have proven that loads in a dive can be even higher than those

used in certification tests (i.e. 8 G), which could result in structural

failure of the glider, as smaller number of lines is taking these high

loads.

B-STALL

To enter a B-stall simultaneously pull both B-risers (red) by 10 - 20 cm. The

wing collapses on entire span along B-row, the airflow over the top surface

breaks and the canopy surface is decreased. Forward movement stops and

you are descending almost vertically. Further pulling of the B-risers is not

advised, as it increases the wing instability.

To exit B-stall the risers should be released in a smooth and decisive

manner. On quick and symmetrical releasing B-lines the airflow reinstates

and the wing surges forward to return to normal flight. If the canopy forms a

horseshoe with wingtips in front of the pilot, gently apply brakes to recover.

CAUTION: see Parachutal Stall.

All rapid descent techniques should be practised in smooth air and

with sufficient height only! Full stalls and spins are to be avoided as

recovery procedures, since irrespectively of paraglider type they may

have dangerous consequences!

BY FAR THE BEST TECHNIQUE IS WISE, CORRECT AND SAFE

FLYING, SO THAT YOU WILL NEVER HAVE TO DESCEND RAPIDLY!

7. Extreme Flying Manoeuvres

CAUTION

EXTREME FLYING MANOEUVRES SHOULD ONLY BE CARRIED OUT

DURING SAFETY TRAINING COURSE (INSTABILITY TRAINING) UNDER

PROPER GUIDANCE! WHILE PROVOKING OR EXITING REAL

SITUATIONS THERE IS A DANGER THAT YOUR ACTIONS WILL PROVE

TOO QUICK OR TOO STRONG, SO YOU SHOULD EMPLOY GOOD

JUDGMENT, STAY CALM AND TAKE MEASURED ACTIONS.

1515

Page 18

tamed aggression

Since all actions required to exit or prevent dangerous situations on

SHARK are typical and pilots flying this wing should already have

some experience, we are going to describe only the characteristic

features of SHARK. Description of standard dealing with extreme

situations can be found in textbooks.

ONE SIDED COLLAPSE

May happen in strong turbulence. Usually SHARK turns up to 90°.

Pilot has a couple of seconds to react with collapses of some 50%, before

paraglider enters a turn. A countermeasure will be enough to keep it on

course. Under normal conditions SHARK will reinflate instantly and

spontaneously.

SPIN AND FULL STALL

Practically do not occur. It may happen only as a result of serious mistake or

intentional action. In normal flight braking up to the stall point requires much

force and its proximity cannot be overlooked.

Wing recovers spontaneously in initial phase of stall, otherwise use standard

procedures.

WING OVER

You make a wingover by executing a series of consecutive, alternating turns

with growing bank angle. Too much banking with some flaws in coordination

can evoke pretty dynamic collapse.

CAUTION: Steep turn with bank angle over 60 degrees is a prohibited

aerobatic manoeuvre!

FRONTAL COLLAPSE

Can happen in strong turbulence. Active piloting will usually prevent its

occurrence. Under normal conditions SHARK reinflates instantly and

spontaneously. Applying some brakes in the right moment will greatly speed

up the recovery.

LINE OVER and CRAVATTE

Although the chances are not great, due to Shark's considerable aspect ratio

and sparse rigging such incidents can happen. In case of a cravatte

untangle the canopy pulling the brakes and/or lines. If that doesn't work, you

1616

Page 19

USER MANUALUSER MANUAL

can try some repeated big ears. As a last resort some pilots recommend a

full stall, but it can be used only by experienced pilots, having appropriate

height safety margin.

In case of any doubts, do not hesitate to use the rescue chute.

PARACHUTAL STALL

Under normal conditions does not occur. If you want to prevent it, stick to a

couple of rules:

$ after B-stall, release the risers quick and evenly. SHARK does not

jump forward excessively.

$ after Big Ears execution engage speed system. It will increase the sink

rate and safety margin, as big ears constitute an aerodynamic brake

with significant loss of speed.

Nevertheless, if such a situation happens, apply some pressure to speed

bar and/or push the A risers forward.

EMERGENCY STEERING

In case of some malfunction, which renders it impossible to control the

Dudek SHARK with the brakes, you can safely steer and land using the Drisers (recommended) or stabilo lines.

8. Canopy care

Looking after your paraglider will prolong the life of your Shark.

STORAGE.

Store the paraglider in a dry space away from chemicals and UV exposure.

Never pack up or store the glider when wet. This shortens the life of the

cloth. Remember that wing gets wet even while laying on a green grass in

full sun, as the grass evaporate. A good precaution to avoid catching wet

and/or UV is to use quickpack after rigging up, when you have to wait in

start line. Always dry glider thoroughly before any packing or storage. While

drying, never expose your paraglider to direct sunlight.

To avoid excessive paraglider cloth wear, do not pack it too tight.

Please note that with frequent playing with your wing on a field or a small hill

your paraglider will deteriorate quickly due to its repeated rising, falling down

and dragging around.

1717

Page 20

tamed aggression

CLEANING

Clean the paraglider with water and a soft sponge. Do not use any

chemicals or spirit, as these can permanently damage the cloth.

REPAIR

Repairs should only be carried out by the manufacturer, authorised

distributor or authorised workshops. It is acceptable to fix minor cloth

damages with self-adhesive patches included in package.

DETERIORATION: A FEW TIPS!

The Dudek Shark is mainly made of NYLON, a cloth which, like any

synthetic material, deteriorates through excessive exposure to UV. Hence it

is recommended to reduce UV exposure to a minimum by keeping the

paraglider packed away when not in use. Even when packed in the bag, it

should not remain in the sun for long.

The Shark lines consist of Dyneema Ultimate inner core and polyester

sheath. Putting them to excessive loads in flight should be avoided, as it can

cause irreversible damage. Keep the paraglider clean since getting the dust

in lines and cloth will reduce their durability. Be careful to keep snow, sand

or stones away from entering the cell openings: their weight can slow down

or even stall the glider, and sharp edges can damage the cloth!

Prevent lines from catching anything as they can get overstretched or torn.

Do not step onto the lines.

Uncontrolled strong wind takeoffs or landings can result in the leading edge

of the canopy hitting the ground at high speeds, which may heavily damage

the ribs and surface material.

Knots can chafe the suspension and/or brake lines.

Check line lengths after tree or water landings, as they can stretch or shrink.

A line plan is included in this manual or may be obtained from the dealer

when needed.

After landing in water you should check the wing cloth as well, since the

wave forces can cause the fabric to distort in specific areas. When taking

the wing out of water, always do this by the trailing edge, so that water can

flow out freely.

After sea landing rinse the paraglider with fresh water. Since salt crystals

can weaken the suspension lines even after rinsing in fresh water, you

should replace them with new ones immediately after contact with salty

water.

Every second year Shark should undergo inspection by the manufacturer or

authorised distributor.

1818

Page 21

9. Technical data

USER MANUALUSER MANUAL

1919

Page 22

tamed aggression

10. Three-star security assistance «««

We are aware of the fact, that a new paraglider purchase is a big expense

for every pilot. That is why we are offering a security system that will allow

you to insure your paraglider against any damage. We have introduced a

Three-star Security Assistance, which includes:

Warranty - for each glider

« WARRANTY

DUDEK Paragliding guarantees the airworthiness of all paragliders for either

a period of 3 years or for 300 flying hours, whichever comes first. This

warranty also applies to the MANTA paraglider.

EXCEPTIONS:

Paragliders used for educational or professional purposes are subject to a

1.5 years/150 flight hours guarantee.

If the paraglider is used for powered flights, every hour spent in the air

should be counted as two.

The warranty DOES NOT APPLY to any of the following:

$ canopy colour fading

$ damage caused by chemicals or salt water

$ damage caused by incorrect use

$ damage caused in emergency situations

$ damage resulting from accidents (airborne or not)

The warranty IS ONLY VALID if:

$ flight is correctly registered in the logbook (incl. powered flight)

$ the paraglider is handled in accordance with the operating manual

$ the purchaser hasn't carried out any repair by him/herself (excl. minor

repairs with self-adhesive patches - se

$ the purchaser hasn't carried out any modifications

$ the paraglider can be unmistakably identified

$ the purchaser can proof total flying hours of the paraglider

$ the paraglider is inspected every second year

$ the purchaser can present the registration confirmation and the

paraglider card

AeroCasco - optional

Golden Package - optional

e page 23)

2020

Page 23

USER MANUALUSER MANUAL

We shall send you the registration confirmation as soon as we receive the

registration card, which you will find sewn on to the trailing edge of your

paraglider. You should remove it, fill it in legibly, sign and send by registered

letter.

When you sell the paraglider, please hand over this confirmation to the new

owner, together with a copy of your logbook (and previous owners'

logbooks). Only by sending these documents to the manufacturer, can the

new owner keep the warranty.

If you aren't the first owner of the paraglider, you should send us the

registration confirmation together with a copy of previous users' logbooks

(total of flying hours) within 14 days from the date of purchase, in order to be

able to keep the warranty. After receiving the above mentioned documents,

we shall send you a new confirmation that will entitle you to all guarantee

repairs within the remaining warranty period. If the previous user didn't keep

any logbook, the warranty becomes null and void, as we are not able to

check the paraglider's flying hours.

«« AEROCASCO

Normal warranty does not cover any repair of damage caused by the user or

a third party. As costs of such repair can be considerable, Dudek Paragliding

offers an AeroCasco insurance. It covers a one-off repair of all mechanical

damage, no matter how big, caused by the user or a third party.

The only expenses the purchaser has to pay are shipping costs and the

share-of-cost amount.

AeroCasco can be purchased with a brand new paraglider (within two weeks

from the date of purchase) or within a year from the date of purchase,

provided that the paraglider has been inspected by the manufacturer.

NOTE: In case of paragliders used by paragliding schools, the procedure of

AeroCasco granting is different. Also, the extent of insurance and general

conditions may be different.

AeroCasco applies only to damage caused during take-off, flight or landing.

Obviously, all the faults in the material and manufacturing flaws are covered

by normal warranty.

In order to be able to get the AeroCasco repair, the following

REQUIREMENTS must be fulfilled:

2121

Page 24

tamed aggression

When buying a new paraglider:

$ the purchaser must buy the AeroCasco insurance (together with the

Golden Package, which is the best option, or separately)

$ the purchaser should send a correctly filled in registration card (sewn

on to the trailing edge) within 14 days from the date of purchase. After

receiving the registration card we shall send you AeroCasco

confirmation, which must be presented when the paraglider is handled

for the repair. The confirmation is also necessary for a new owner to

keep the insurance.

When handing the paraglider for the repair:

$ the purchaser should present this registration confirmation,

$ the paraglider's serial number should be identical with the one on the

registration confirmation,

$ the purchaser should pay a fee (as a share of cost).

AeroCasco is valid for one repair only.

There is a possibility to extend AeroCasco for one more year, if there was no

damage during the first year. AeroCasco can be extended, provided that the

paraglider was serviced by the manufacturer not later than a year after the

date of purchase and the owner has paid the extension fee (according to the

price list on the day of servicing). Remember to include the AeroCasco

confirmation when you send the paraglider for servicing.

AeroCasco does not apply to any of the following: theft, colour fading,

damage caused by incorrect storage or transport, damage caused by

chemicals, salt water and force majeure.

««« GOLDEN PACKAGE

Golden Package is a package offer of the most popular services.

Golden Package includes:

$ warranty,

$ 1-year AeroCasco (with possibility of a 1-year extension)

$ one free technical servicing prior to expiry of first airworthiness check

Cordura

$ backpack

$ speed system

Golden Package does not include paragliders used for educational or

professional purposes.

2222

Page 25

USER MANUALUSER MANUAL

SUMMARY

If you respect rules of safe flying and proper glider care, you will enjoy many

years of pleasant airtime. Still, you must be aware of present dangers and

stand up to them wisely. You must accept the fact that all air sports are

potentially dangerous and your actual safety depends solely on you.

FLYING THE PARAGLIDER IS ALWAYS YOUR OWN RESPONSIBILITY.

We insist that you fly safely, and this concerns both the weather choice and

safety margin during all manoeuvres.

SEE YOU IN THE AIR!

11. What have you bought

Dudek paraglider that you bought should have the following items:

$ Transport bag (with your wing inside it).

$ Paraglider itself with lines and risers that have speed system

integrated. Note that the speed bar is not included.

$ Compression strap for tightening up a wing before putting it into a bag.

$ Windsock.

$ A pocket with paper work and repair wallet including:

# A piece (10 cm x 37,5 cm) of self-adhesive fabric for small

repairs. Note that even small rips placed in the vicinity of a stitch

have to be repaired by an authorised service.

# A looped and stitched 1.9 mm suspension line. It is equal to the

longest line used in the paraglider and has to be used as

temporary replacement only. Do not cut it if you have to replace

a shorter one, just tie it at the length needed.

# A paraglider passport with entered date of purchase and valid

technical inspection (please check serial number with the sticker

on a wing tip).

# The User Manual you are reading

If you purchased the Golden Package, you receive in addition:

$ one free of charge inspection (first one)

$ one year of AeroCasco

$ paragliding backpack made of Cordura

$ speed-system bar

2323

Page 26

tamed aggression

You will receive some small gifts as well.

Remember to fill out and send us the registration card sewn in the

trailing edge.

12. Rigging tables

Lengths are measured with specialized, computer-operated device. All lines

before cut are stretched with a 5 kg load. Thanks to the abovementioned

device and proper procedures final tolerance of line lengths does not exceed

0.15%.

Line sizes in [cm]. D letter means Dyneema lines.

xP - main suspension line of x row,

xD - secondary line of x row,

xT - tertiary line of x row (near the canopy),

EC - fourth layer of steering lines (near the canopy).

CAUTION!!!

Distances given below are to be understood as distances between

connection points. When cutting a line for repairs, 20 cm more must be

counted, as on each end a 10 cm stitch is required to fix the loop. The only

exception is main steering line (EP1), which is looped only at the upper end,

while down there is 20 cm left for fastening the brake handle (that means 30

cm more is needed).

2424

Page 27

USER MANUALUSER MANUAL

2525

Page 28

LINING SCHEME

A

tamed aggression

A’

AT

BT

CT

DT

EC

AP

2

1

1

2

3

BP

CP

DP

ET

ED

4

B

C

D

3

5

6

EP

1

2

AD

7

8

9

SP

BD

CD

10

11

SD

1

2

3

2626

Page 29

Suspension pointsSuspension points

Trailing edgeTrailing edge

USER MANUALUSER MANUAL

Stabilizer Stabilizer

Leading edgeLeading edge

Cell Cell

Cell openingsCell openings

Speed system barSpeed system bar

Main suspension

Main suspension

lines

lines

Sticker Sticker

2727

Page 30

Page 31

Page 32

v 10.2005

Dudek Paragliding

ul. Szancera 2/XIp

85-792 Bydgoszcz

tel. +48 52 348 55 35

info@dudek.com.pl

Loading...

Loading...