DuctSox U-Track Installation Manual

Installation Guide

U-Track

Thank you for selecting a DuctSox System. This guide will be helpful for the installation of a U-Track

System. Sections of fabric will be labeled, assembled, bagged, and boxed for shipping. More

complicated systems will include a CAD detail of the system identifying what is in each package.

Overview

Inventory

The rst step on any installation project is to read through this guide thoroughly and review the

components that need to be installed. The best way to do this is to review the drawings of the project

while reading the guide, including the CAD detail if applicable.

Shipping/Receiving

In some cases the DuctSox support system is delivered to the job site ahead of the DuctSox fabric

sections. Depending on the size of a project or order, a DuctSox system will be shipped by common

courier in a single brown box or several boxes. Larger orders will be shipped in crates by a common

freight courier. Each DuctSox length should be packaged into individual plastic bags and labeled

according to size and number of pieces. Other markings or labeling may also be incorporated for

larger or more complicated systems. Be sure you have determined all boxes are accounted for.

Unpacking

Inspect shipment carefully and make sure all pieces are accounted for. Account for everything by

emptying the box and examining all contents. Note any missing or damaged pieces listed on the Bill of

Lading.

Labeling

Each DuctSox section will be marked with the size and section number either inside the belt of the

inlet or on a tag inside the DuctSox near the zipper. The marking shall be the diameter, section length

and total length. If custom labeling has been used, locate an identication sheet that will be included

with the delivery.

Equipment Required:

• Drill/driver and magnetic #2 Phillips driver bit

• Level

• #2 Phillips screwdriver

• Tape measure

• Marker or pencil

• Wrenches for cable-to-track connection (7/16” and 7/32” or pliers)

• Flat (standard) screwdriver

• Cable cutter

1

Installation Guide:

U-Track

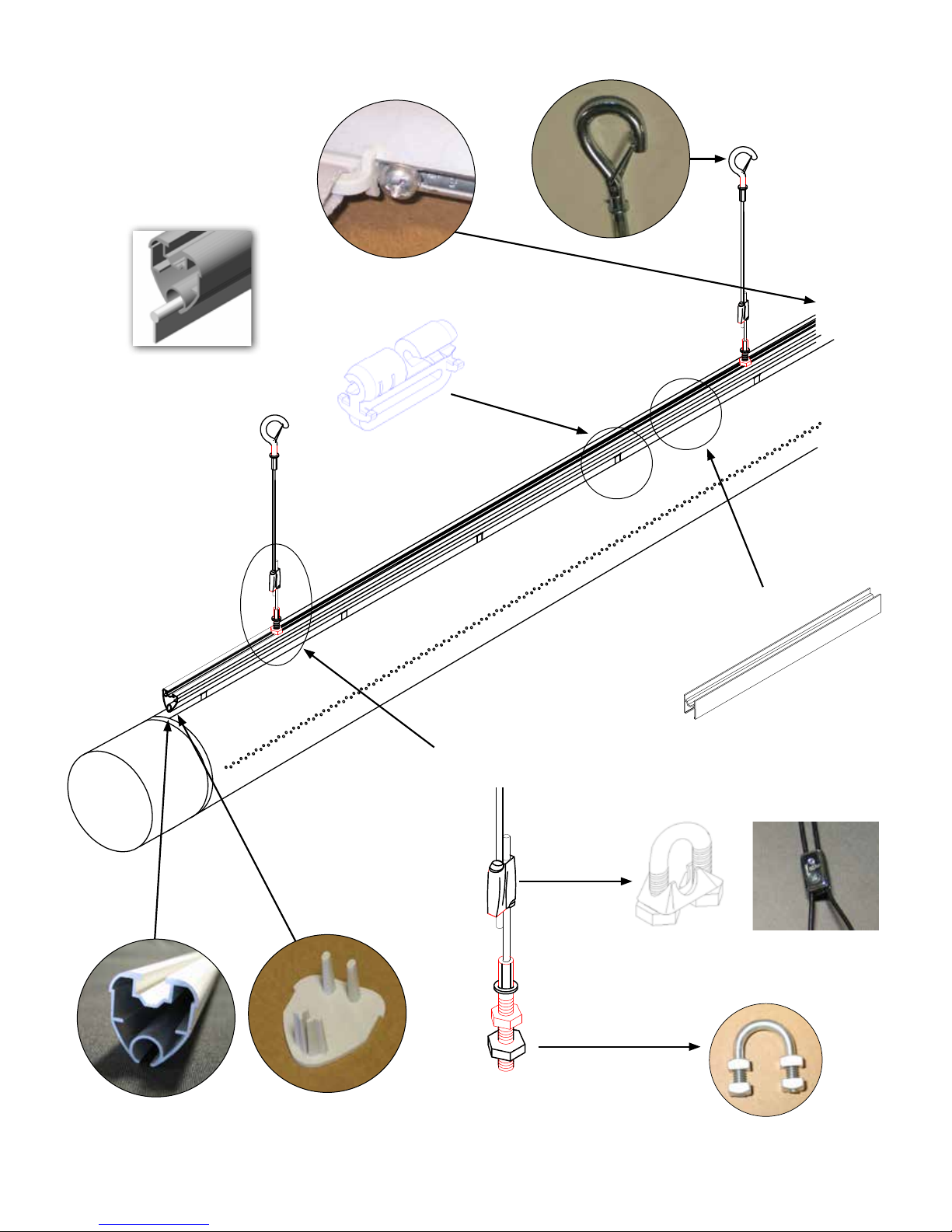

Component Details

Optional:

Cord-In Attachment

may be used as an

alternative to Gliders

Glider Attachment

Hook of Cable Support

Track Stop

Quick-Connection and

Stud Cable End

Cable Clamp for

U-Bolt option

U-Track

Coupler

Alternate clamp for

Pool applications

Aluminum

U-Track

U-Track Endcap

2

U-Bolt for

U-Bolt option

Installation Guide:

U-Track

Installation Steps

1. Review materials in box, including the CAD drawing and installed location of the DuctSox

2. Prepare metal inlet collar for fabric connection

3. Mark placement of track. (1 Row, 2 Row, and 3 Row Style) Install track (with couplers and track supports

OR surface mount clips)

4. Install and assemble DuctSox components

5. Start up AHU

6. Balance airow

Step 1

Review materials in box, including the CAD drawing and installed location of the DuctSox. READ

INSTRUCTIONS THOROUGHLY BEFORE BEGINNING.

Step 2

Prepare metal inlet collar for fabric connection.

• Conrm inlet air supply location.

• Conrm inlet air supply size.

• DuctSox inlets are manufactured 1/2” (12mm) larger than

specied to t over metal inlet collar.

• Metal collar length should be 6”–10” (150 to 250cm) for

secure fabric attachment.

• Edge Guard (provided) should be installed on the edge of

the metal collar to reduce fabric wear from the metal edge.

6”–10”

(150 – 250cm)

Edge Guard

(Supplied)

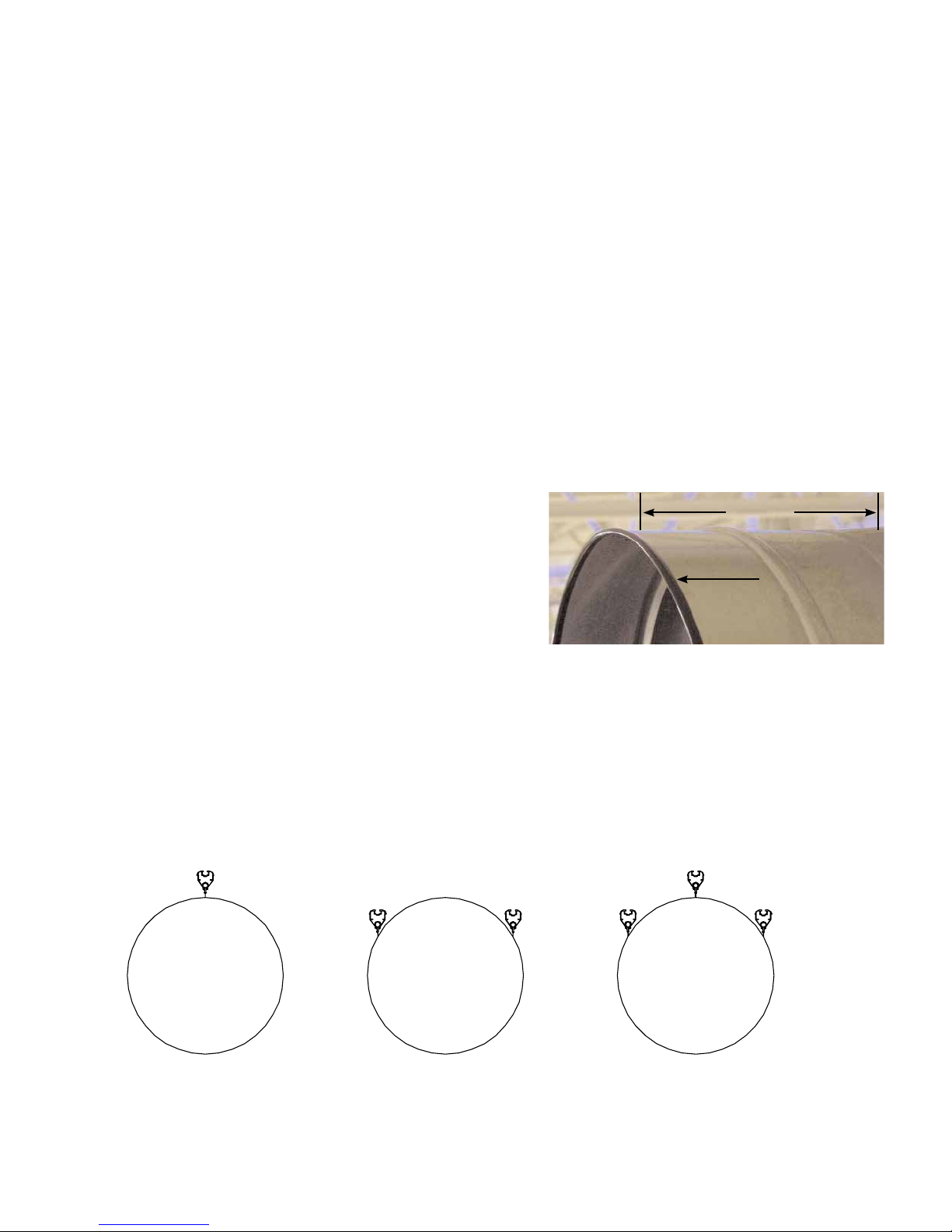

Step 3

Mark Placement of Track. Step 3 is broken into three types of suspension points: 1 Row, 2 Row, and 3

Row. One job may use multiple styles.

Step 3 – 1 Row Style Step 3 – 2 Row Style Step 3 – 3 Row Style

10 and 2 O’clock 10, 2, and 12 O’clock

3

Installation Guide:

U-Track

The following three details (Track and Internal Couplers, Track Supports, and End Caps) are used for

ALL styles.

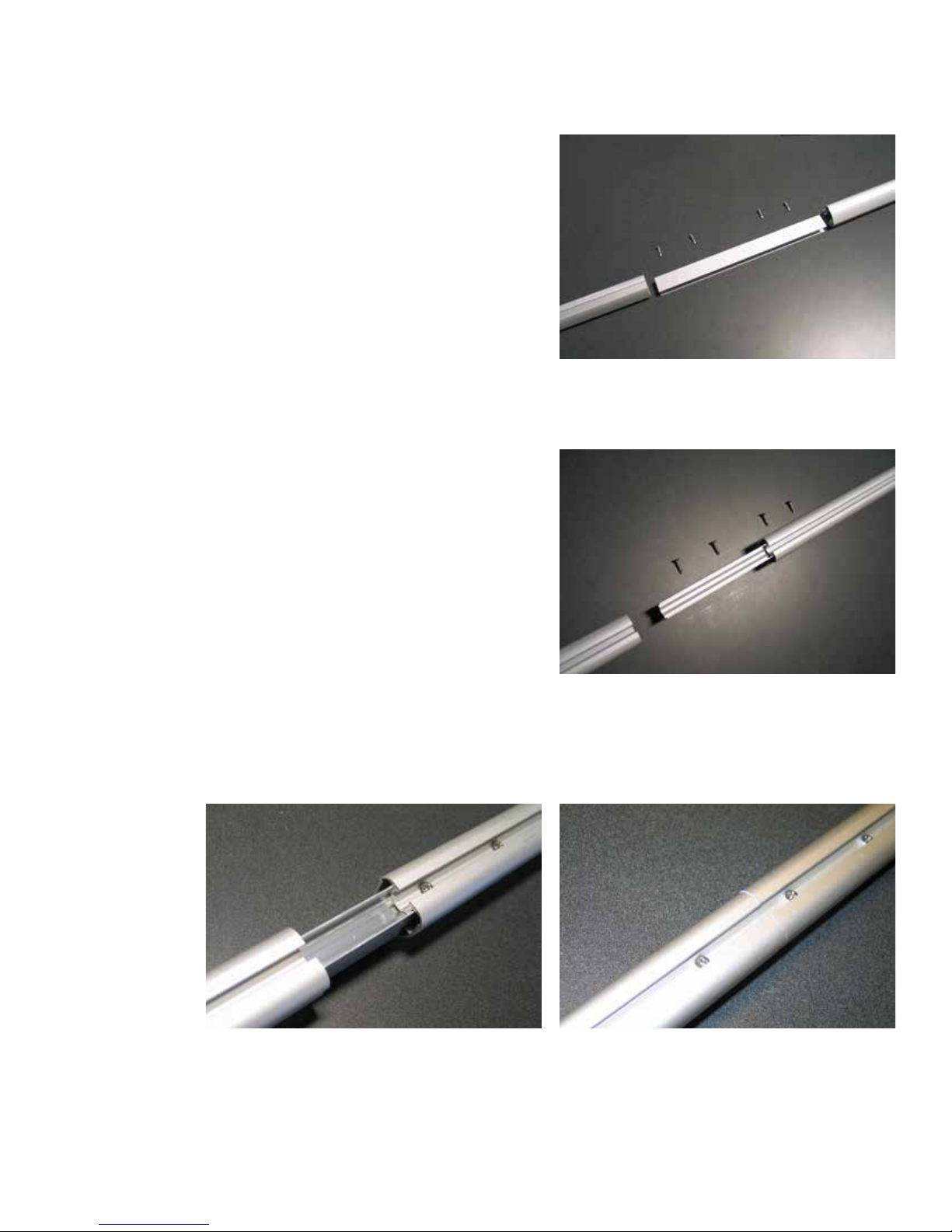

Track and Internal Coupler

Track sections are shipped in 8 ft (2440mm) standard

lengths.

Coupler assembly consists of a 12” (305mm) long coupler

and 4 self-drilling screws as pictured.

Coupler is inserted into one track about 6” (150mm) and

secured with two screws. Screws are driven through the top

of the track to secure coupler and track in place. Note: Use

screws supplied.

Insert the rest of the coupler into the other track. Be sure to get each section of track as close together as

possible so that the coupler is not visible. Secure the coupler in the tracks with two screws for each track.

4

Installation Guide:

U-Track

Track supports: Quick-connection or U-Bolt

The Track Supports are the main structural support between the U-track & DuctSox and the structure of

the building. A Quick-Connection Track Support OR a U-Bolt Track Support are the available options.

Standard

Pools

Quick-Connection Track Support Option U-Bolt Track Support Option OR Pool Applications

Hook end is attached

to structure above the

DuctSox. DO NOT loop

the hook back onto the

cable, this could cause

the hook to detach. Hook

must be hooked into part

of the building structure,

for example an eyebolt

attached to the ceiling. Nut

on the end of the stud is

permanently xed and is

not adjustable. This nut is

slid into the top channel

of the track. After stud

and cable are in their proper location the top nut

(7/16”wrench) on the stud must be tightened onto

the track while holding the stud with a pliers. After

adjusting the track height trim excess cable as

needed.

A roll of cable, U-bolts,

square nuts for U-bolts,

regular nuts for U-bolts

and cable clamps are

supplied. Length from the

ceiling support and the

top of the track needs to

be determined by installer.

A cable loop is created

at the top of the cable

length by a cable clamp.

Be sure the installed

cable does not contact

any sharp edges; for

example, loop the cable

through an eyebolt attached to the ceiling. Be sure

all of the threads of the square nuts are engaged

to the U-bolt. The square nuts on the end of the

U-bolt are slid into the top channel of the track.

After U-bolt and cable are in their proper location

the nuts (7/16”wrench) on the U-bolts must be

tightened onto the track. A cable loop is created at

the top of the track by the cable through the U-bolt

clamp. After adjusting the track height trim excess

cable as needed.

NOTE for both supports: Placing track at the proper elevation (this could be an angle for a sloped

ceiling) and straightness is critical for a good installation.

5

Installation Guide:

U-Track

Loading...

Loading...