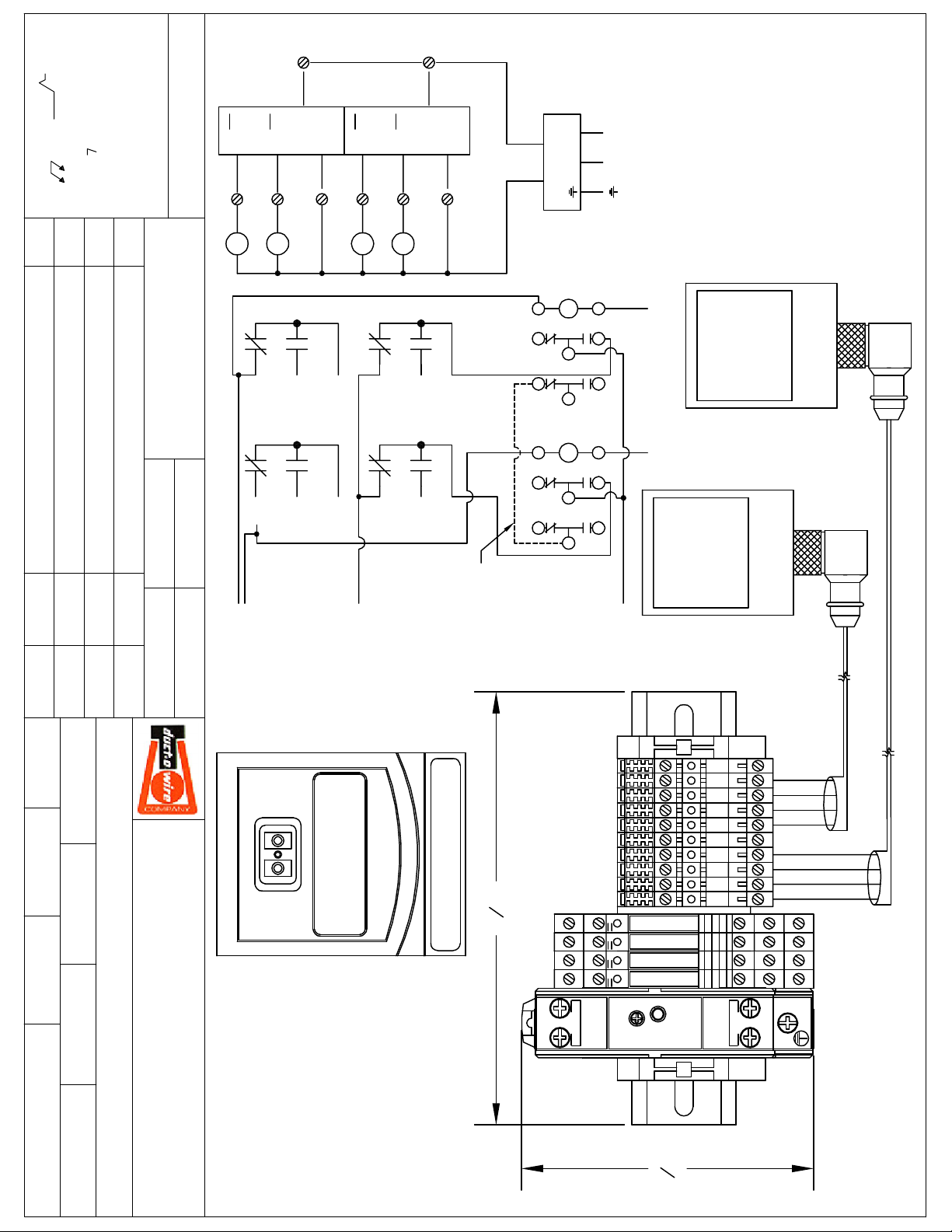

Duct-O-Wire®

CAS-2L100 DUPLEX

BI-DIRECTIONAL LASER COLLISION AVOIDANCE KIT

INSTALLATION AND OPERATING INSTRUCTIONS

This product incorporates IR Laser Protection Class 2; visible laser light.

Do Not Stare Into The Laser Beam!

C1,C2 Relay coils are 120VAC rated.

The Q1,Q2,Q3,Q4 coils are controlled by a 24 VDC laser.

This unit may not be suitable for all applications.

Before installation you will need a qualified technician to verify this unit will work with your

application.

The Duct-O-Wire® CAS-2L100 DUPLEX Two Event Laser Collision Avoidance Kit comes with (2) Laser Sensor Units,

(2) Sensor Mounting Brackets and Hardware, (2) 10 Meter Data Cables, (1) DIN Mounted Power/Relay Module,

(2) Reflector Arrays with Mounting Hardware, Schematic Sheets and Warning Labels.

Laser Class2 Max Power 4.1 mW Time Base 100 s Pulse Duration 1.3 ms

Wave Length 650 mm Compliance: 21 CRF PART 1040 ENC60825-1:2003-10

MAKE CERTAIN THAT THE POWER SUPPLY IS DISCONNECTED BEFORE INSTALLING, REPAIRING, OR MAKING

ADJUSTMENTS TO THIS DEVICE. THIS DEVICE IS TO BE INSTALLED BY QUALIFIED ELECTRICAL PERSONNEL ONLY.

MOUNTING AND ALIGNMENT

1. Mount sensor and reflector using supplied bracket and hardware to suitable locations for stability and

proper alignment. Use 3 point alignment method to ensure the laser and reflector are in a straight line,

both horizontally and vertically true.

2. Connect the supplied data cable to the sensor and power/relay module per the drawing.

3. Attach the supplied Laser Warning Label in the immediate vicinity of the sensor unit.

4. Connect 110 VAC to the transformer per the schematic drawing.

5. A visible red light will be seen from the sensor to the reflector. Do Not Stare Into the Laser Light.

SENSOR PROGRAMMING-FEET MODE (

NOTE: ALL BUTTON PRESSES MST BE DONE WITHIN 15 SECONDS

1. Press and release the Mode/Enter button until EF is displayed. (multiple presses)

2. Press and release the SET button.

3. Press and release the Mode/Enter button until Uni is displayed. (6 button presses)

4. Press and hold the SET button until FEET is displayed, and release.

5. Press and release the Mode/Enter button once to confirm.

6. Wait 15-20 seconds and the unit will return to the “run” mode.

7. When sensor is in Run mode, distance to target is displayed in feet.

SENSOR PROGRAMMING-SET POINT 1

NOTE: If the desired distance is passed, the counter will need to be advanced until the set point is displayed

again. ALL BUTTON PRESSES MUST BE DONE WITHIN 15 SECONDS.

1. Press and release the Mode/Enter button until SP 1 is displayed. (2 presses)

2. Press and hold the SET button until the desired distance for the first event is displayed, then release.

3. NOTE: Minimum distance is 1 meter (3.28 feet).

4. Press and release the Mode/Enter button once to confirm. The display will show SP 1.

Use a pen or small blunt object for improved response

First Event Distance Q1 and Q3

(

)

)

5. Wait 15 to 20 seconds and the unit will return to the “run” mode.

SENSOR PROGRAMMING-ENABLE SET POINT 2

NOTE: ALL BUTTON PRESSES MUST BE DONE WITHIN 15 SECONDS

1. Press and release the Mode/Enter button until OU2 is displayed. (3 presses )

2. Press and hold SET button until Hno is displayed, then release.

3. Press and release the Mode/Enter button to confirm.

4. Wait 15 to 20 seconds and the unit will return to the “run” mode.

SENSOR PROGRAMMING-SET POINT 2 (

Second Event Distance Q2 and Q4

)

NOTE: ALL BUTTON PRESSES MUST BE DONE WITHIN 15 SECONDS

1. Press and release the Mode/Enter button until SP 2 is displayed. (4 presses)

2. Press and hold the SET button until the desired distance for the second event is displayed, then release.

3. NOTE: Minimum distance is 1 meter (3.28 feet).

4. Press and release the Mode/Enter button once to confirm. The display will show SP 2.

5. Wait 15 to 20 seconds and the unit will return to the “run” mode.

**REPEAT STEPS FOR 2ND SENSOR**

YOUR LASER COLLISON AVOIDANCE SYSTEMS SHOULD NOW BE READY TO OPERATE. PLEASE ENSURE THAT THE

LED’S ON THE CONTROL UNIT LIGHT WHEN CRANE IS MOVED TO EACH SET POSITION.

FACTORY RESET-ONLY IF REQUIRED

1. In the event that improper selections were made during the previous sensor programming steps, it may

be necessary to reset the unit to factory settings. Perform the following steps ONLY if required or the

sensor is not responding as intended.

2. Press and release the Mode/Enter button until EF is displayed. (multiple presses required)

3. Press and release the SET button once.

4. Press and release the Mode/Enter button until rES is displayed

5. Press and hold SET button until ---- (4 dashes) is displayed

6. Confirm by pressing the Mode/Enter button once.

7. After performing the factory reset you must repeat the SENSOR PROGRAMMING steps outlined in the

steps above.

*****The Duct-O-Wire CAS-2L100 Duplex includes two extra relays that make it possible to split the 2nd speed

from your pendant into two separate signals to the VFD drive. You may need to change your drive settings

from infinitely variable to stepping. Depending on your drive it may be possible using the extra contacts to use

the infinitely variable setting on your drive. However; this would be decided by a qualified technician. *****

The C1, C2 contacts are rated 120VAC. If you need a 24VDC rated coil please consult factory.

The Q1, Q2, Q3, Q4 relays are controlled by a 24VDC laser.

C1 is controlled from the Q2 Forward relay.

C2 is controlled from the Q4 Reverse relay.

Q1 is Forward 2nd speed.

Q3 is Reverse 2nd speed.

FINISH:

63

MAX.

.002"

REV DESCRIPTION DATE APPROVED

.XXXX -NT'D.

.X -.015

.XX -.010

.XXX -.005

STD. TOL:

including implied warranty of

TOLERANCES: PLUS OR MINUS

FRACTIONS: 1/32"

10

SENSOR 2

10

BRN

Q3

Q4

WHT

HOLES

20

BLK

BLU

40

Q2

WHT

2

30

BLK

Q1

4

BRN

1

BRN BLU

SENSOR 1

1

BLU

L N

POWER SUPPLY

3

V+ V-

24 VDC

120 VAC

X1 X2

fitness for a particular use.

drawings available on an "as

any kind with regard to the

drawing are disclaimed,

This drawing and information

contained herein is for general

DISCLAIMER:

information purposes only.

Note that DOW makes these

is" basis. All warranties of

'S

3

4

2

30

40

20

(A1) (A2)

NOTES:

OVERALL DIMENSIONS: L x W x H

OVERALL DIMENSIONS: 6-7/8" x 3-25/32" x 3-7/8"

C1 AND C2 ARE 120 VAC COIL

PLEASE REVIEW WIRING SCHEMATIC FOR THIS SYSTEM BEFORE

INSTALLATION TO ENSURE COMPATIBILITY FOR YO UR INTENDED

PURPOSE.

Q4

Q3

(A1) (A2)

(A1) (A2)

(A1) (A2)

Q1

Q2

REV. NO: SHEET JOB NO DRAWING NO:

CAS-2L100 DUPLEX1 of 1

C1

A1

FWD FROM

SET

MODE

(14)

(14)

PENDANT

PENDANT

TOP VIEW

(11)

REV FROM

(11)

2ND SPEED

SENSOR

Q2

(12)

Q4

MAT'L: PART NO:

FINISH: ASS'Y NO:

02/26/2018 APL

TITLE:

DATE: DRAWN BY: APPROVED BY: SCALE:

CAS-2L100 DUPLEX LASER COLLISION AVOIDANCE

DUCT-O-WIRE COMPANY

CORONA, CA 92878

P.O. BOX 519

800-543-3885

1351 WEST SECOND ST.

OCONOMOWOC, WI 53066

800-434-0062

(12)

FWD TO DRIVE

REV TO DRIVE

ENTER

TO DRIVE

PHOTO-EYE

Q1

(11)

(14)

(12)

Q3

(11)

(14)

(12)

possible

may be

infinitely

added for

variable

POWER m FEET OUT1 OUT2

jumper wire

12

22

A1

12

22

6

7

8

"

OUTPUT

A2

14

11

24

21

C2

A2

14

11

24

21

A2 A2

A1A1

A2 A2

A1A1

-V +V

24VDC 0.65A

X2 X2

2ND SPEE D FROM PENDANT

50

40

30

20

10

5

4

3

2

1

6-24 6-24

VV

6-24 6-24

VV

PS5R-VB24

ADJ

POWER SUPPLY

VR.

W

Q4

Q3

Q2

Q1

ON

15

0.35-0.19A

14 14

14 14

L N

100-240VAC

PHOTO-EYE

PHOTO-EYE

SENSOR

BLK

BLU

WHT

BRN

12 12

11 11

12 12

11 11

INPUT

50/60Hz

SENSOR

SENSOR CABLE

SENSOR CABLE

BLK

BLU

WHT

BRN

32

3

25

"

Loading...

Loading...