DUCTMATE Ultimate Door II Installation Instructions Manual

DESCRIPTION

Weld on style access door for grease duct or high

temperature applications.

BASIC USE

To provide easy access into high temperature air ducts

and grease duct systems. This door was designed for

applications requiring UL 1978 Listing.

INSTALLATION INSTRUCTIONS

SPECIAL CHARACTERISTICS

UL 1978 Listed

•

• Available with optional hinge

• No special tools to remove

• Minimal penetration into the duct

• Dramatically reduces installation time

• Grease and air tight

• Meets NFPA 96 Standards

• Union made in the U.S.A.

• Available in a variety of sizes

• Can be used with all types of duct wrap insulation systems

• No need for any clips

• No need for any drilling

• Unique collapsible handle design for easy installation

• Top plate is completely removable for easy cleaning

TECHNICAL INFORMATION

PANELS

The ULtimate II WELD ON access door consists of two

layers of 11 gauge steel (also available in stainless 304).

Steel door must be used on steel duct and stainless door

must be used on stainless duct.

GASKET

High temperature ceramic board, rated to 2300°.

FASTENERS

Zinc plated fasteners.

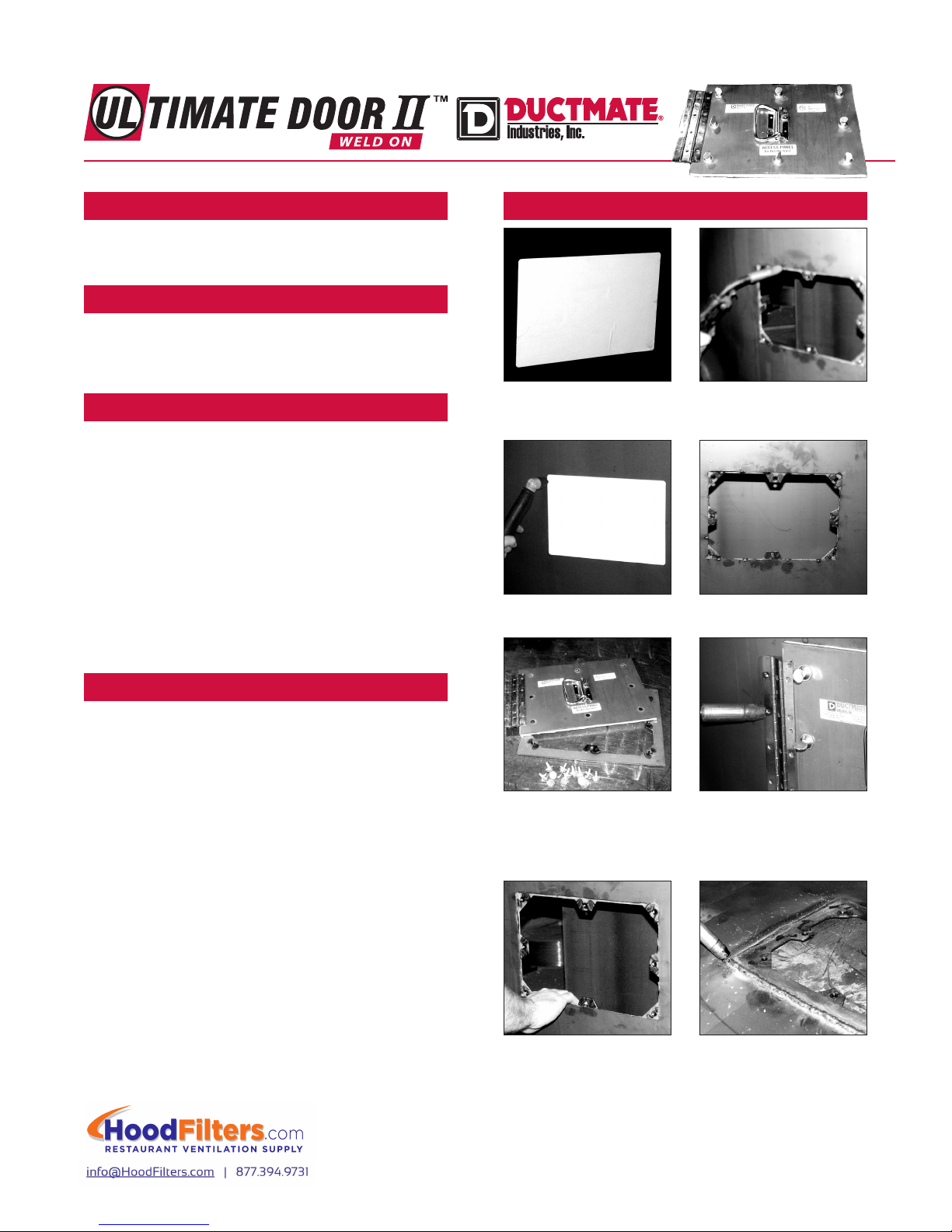

1. Peel backing off template

and apply to duct in

desired location.

2. Cut around edge of

the template.

3. Remove the fasteners

and separate door

from frame.

5. Attach with tack welds

2” apart.

6. Correctly installed frame.

7. Install the fasteners with

washers. For hinged

door, position hinge on

duct wall and plug weld.

TEMPLATE

Self adhesive template is provided for the exact size of duct

opening required.

UL DOOR INSULATION OUTER PLATE

Manufactured from 16 gauge black iron. For us with a

wrap system. (Sold separately or as a kit)

UL DOOR INSULATION HARDWARE

Consists of four 8” extension studs, washers, fasteners, “Do

Not Obstruct” Sticker, and installation instructions.

(Sold separately or as a kit)

4. Center the frame

around the opening.

* If using the frame on

the outside of the duct,

a continuous liquid

tight weld is required.

Care should be taken to

not warp the frame

when welding.

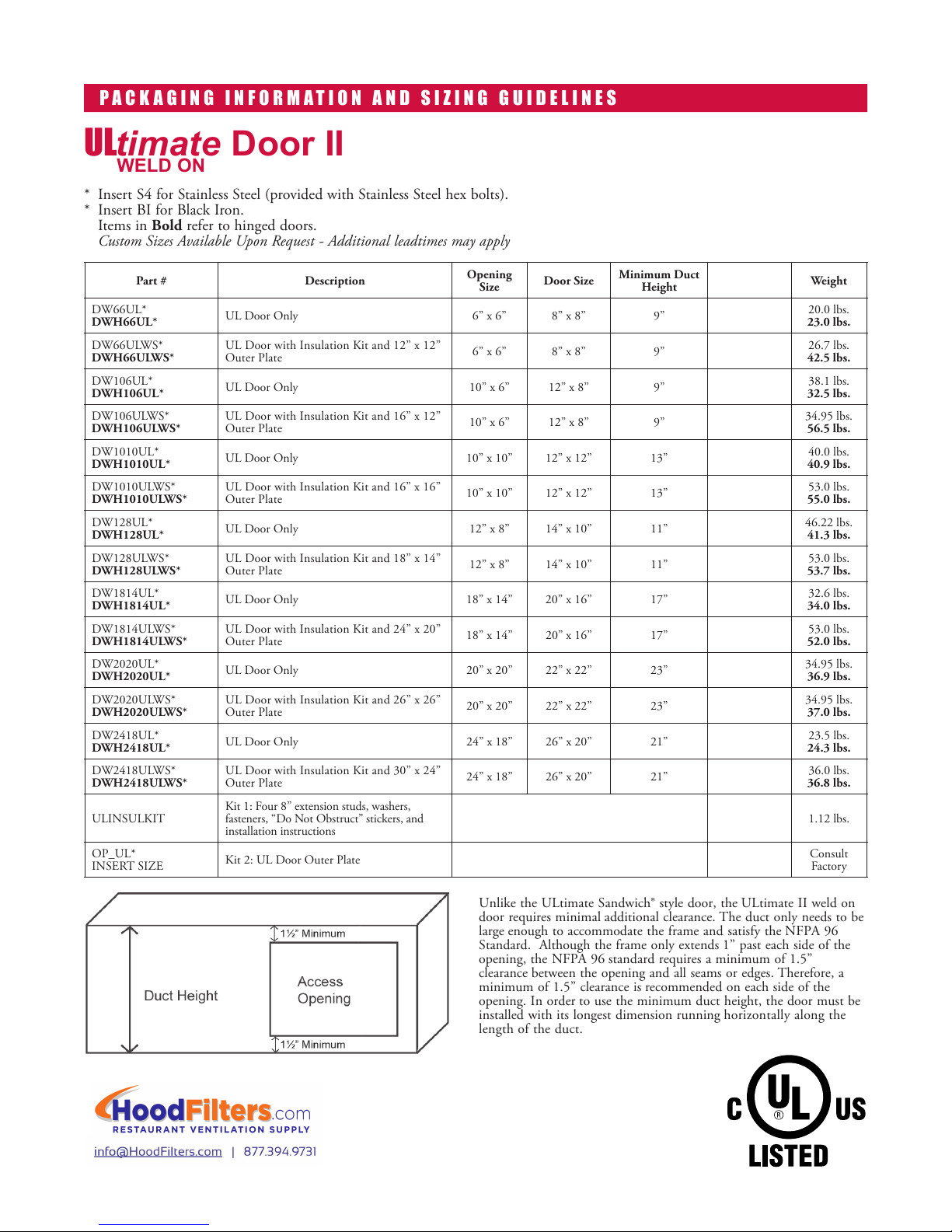

ULtimate Door II

WELD ON

Part # Description

Opening

Size

Door Size

Minimum Duct

Height

Weight

DW66UL*

DWH66UL*

UL Door Only 6” x 6” 8” x 8” 9”

20.0 lbs.

23.0 lbs.

DW66ULWS*

DWH66ULWS*

UL Door with Insulation Kit and 12” x 12”

Outer Plate

6” x 6” 8” x 8” 9”

26.7 lbs.

42.5 lbs.

DW106UL*

DWH106UL*

UL Door Only 10” x 6” 12” x 8” 9”

38.1 lbs.

32.5 lbs.

DW106ULWS*

DWH106ULWS*

UL Door with Insulation Kit and 16” x 12”

Outer Plate

10” x 6” 12” x 8” 9”

34.95 lbs.

56.5 lbs.

DW1010UL*

DWH1010UL*

UL Door Only 10” x 10” 12” x 12” 13”

40.0 lbs.

40.9 lbs.

DW1010ULWS*

DWH1010ULWS*

UL Door with Insulation Kit and 16” x 16”

Outer Plate

10” x 10” 12” x 12” 13”

53.0 lbs.

55.0 lbs.

DW128UL*

DWH128UL*

UL Door Only 12” x 8” 14” x 10” 11”

46.22 lbs.

41.3 lbs.

DW128ULWS*

DWH128ULWS*

UL Door with Insulation Kit and 18” x 14”

Outer Plate

12” x 8” 14” x 10” 11”

53.0 lbs.

53.7 lbs.

DW1814UL*

DWH1814UL*

UL Door Only 18” x 14” 20” x 16” 17”

32.6 lbs.

34.0 lbs.

DW1814ULWS*

DWH1814ULWS*

UL Door with Insulation Kit and 24” x 20”

Outer Plate

18” x 14” 20” x 16” 17”

53.0 lbs.

52.0 lbs.

DW2020UL*

DWH2020UL*

UL Door Only 20” x 20” 22” x 22” 23”

34.95 lbs.

36.9 lbs.

DW2020ULWS*

DWH2020ULWS*

UL Door with Insulation Kit and 26” x 26”

Outer Plate

20” x 20” 22” x 22” 23”

34.95 lbs.

37.0 lbs.

DW2418UL*

DWH2418UL*

UL Door Only 24” x 18” 26” x 20” 21”

23.5 lbs.

24.3 lbs.

DW2418ULWS*

DWH2418ULWS*

UL Door with Insulation Kit and 30” x 24”

Outer Plate

24” x 18” 26” x 20” 21”

36.0 lbs.

36.8 lbs.

ULINSULKIT

Kit 1: Four 8” extension studs, washers,

fasteners, “Do Not Obstruct” stickers, and

installation instructions

1.12 lbs.

OP_UL*

INSERT SIZE

Kit 2: UL Door Outer Plate

Consult

Factory

* Insert S4 for Stainless Steel (provided with Stainless Steel hex bolts).

* Insert BI for Black Iron.

Items in Bold refer to hinged doors.

Custom Sizes Available Upon Request - Additional leadtimes may apply

Unlike the ULtimate Sandwich® style door, the ULtimate II weld on

door requires minimal additional clearance. The duct only needs to be

large enough to accommodate the frame and satisfy the NFPA 96

Standard.

Although the frame only extends 1” past each side of the

opening, the NFPA 96 standard requires a minimum of 1.5”

clearance between the opening and all seams or edges. Therefore, a

minimum of 1.5” clearance is recommended on each side of the

opening. In order to use the minimum duct height, the door must be

installed with its longest dimension running horizontally along the

length of the duct.

PACKAGING INFORMATION AND SIZING GUIDELINES

Listed

Fittings for Hood and Duct Penetration

Duct Access Door

88VF

Grease

Loading...

Loading...