Ductmate DC25 Service manual

DUCTMATE

Industries, Inc.

®

‘25’/‘35’/‘45’

CONNECTION SYSTEMS

RECTANGULAR

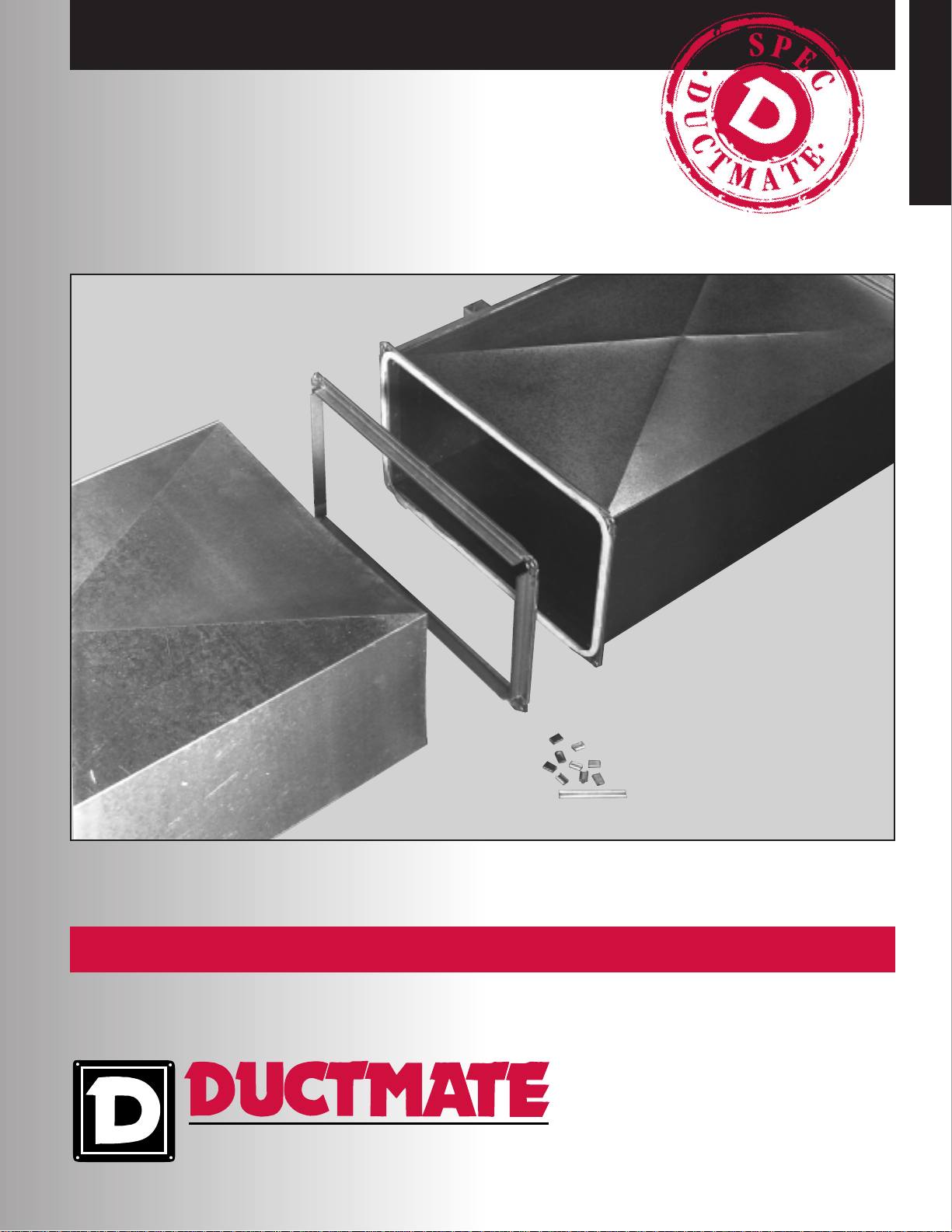

Rectangular Duct Connection System

Strong and Virtually Leak-Free

• Simple to install

• No additional sealing required

Visit our on-line information center at www.ductmate.com

• Available in specialty metals

• Consistent connections

Rectangular Duct

‘25’/‘35’/‘45’

DESCRIPTION PRODUCT GUARANTEE

Ductmate 25/35/45 connection systems consist of roll-formed flanges, corner

pieces, gasket and cleat. The flanges attach to the duct wall and have an integral

mastic which allows the flange to seal itself to the duct. Corner pieces are used

to add rigidity to the flange; hold the ductwork together and provide a sealing

surface for the gasket. The gasket serves as a seal between the flanges. The cleat

insures even compression of the gasket along the length of the flange.

BASIC USE

Ductmate 25/35/45 are used to connect rectangular ducts when a rigid, leakfree connection is required.

SPECIAL CHARACTERISTICS

Patented downset in corner insures proper sealing (excludes Ductmate ‘45’)

Patented corner clips ease installation (excludes Ductmate ‘45’)

Sealing materials meet NFPA 90A & B Class 1 requirements

The Ductmate ‘45’ system is not recommended for applications with duct

gauges heavier than 10 or lighter than 22.

The Ductmate ‘35’ system is not recommended for applications with duct

gauges heavier than 16 GA, or lighter than 26 GA.

The Ductmate ‘25’ is not recommended for applications with duct gauges

heavier than 20 GA or lighter than 26 GA.

TECHNICAL INFORMATION

Ductmate ‘45’ was tested in accordance with SMACNA testing procedures. No

external sealant was employed and the test results reveal: the Ductmate ‘45’

system is comparable to a SMACNA Class K transverse joint; the Ductmate ‘35’

system is comparable to the SMACNA Class “J” transverse joint and the

Ductmate ‘25’ system is comparable to the SMACNA Class “F” joint. Ductmate

‘35’ in stainless steel exhibits the same performance as galvanized. Aluminum

DM35 is comparable to a SMACNA H connection. DM25 is not available in

aluminum or stainless. DC35 corner pieces must be used with aluminum.

Aluminized or PVC cleats are used with aluminum flanges. Cleat is not available

in aluminum. Do not notch the corners when fabricating ductwork for the

Ductmate System.

PACKAGING INFORMATION

The Ductmate Systems consist of the following components:

a. Ductmate ‘45’ flange is roll-formed from 18 GA galvanized steel, with an

integral sealant.

b. Ductmate ‘35’ flange is roll-formed from 20 GA galvanized steel, with an

integral sealant.

c. Ductmate ‘25’ flange is roll-formed from 24 GA galvanized steel, with an

integral sealant.

d. Ductmate ‘45’ electroplated, bolt corner pieces insert into the hollow

web of the ‘45’ angle.

e. Ductmate DCIIIA, DCIIIB or DC35 corner pieces insert into the hollow

web of the ‘35’ Angle.

f. Ductmate DC25 clip or DC25 bolt corner pieces insert into the hollow

web of the ‘25’ Angle.

g. Ductmate ‘45’ metal cleat is roll-formed from 22 GA galvanized steel.

h. Metal cleat is roll-formed from 20 GA galvanized steel.

(PVC Cleat is available upon request).

i. Gasket is extruded butyl for use between mating flanges.

(Neoprene gasket is available upon request).

j. Corner clips are 16 GA galvanized steel. (Use of nuts and bolts

optional: 3/8" x 1" for DCIIIB, 5/16" x 1" for Ductmate DC25 corners).

All component parts of the Ductmate Systems are guaranteed against defective

material.

CLEAT

PVC CLEAT:

Polyvinyl chloride (PVC) is an organic polymer derived from petroleum and

salt.

PERFORMANCE PROPERTIES:

Relative high ignition resistance flash ignition 391º/735ºF

Low fuel contribution

Lack of flaming drips

High external heat necessary to maintain combustion

UL94-Passes

UL723 (ASTM E-84) Test Data: Flame Spread:10

Service Temp: +32ºF to +150ºF

PVC Cleat is used around perimeter of transverse joint. Not recommended for

roof top applications.

METAL CLEAT:

DM Metal Cleat is roll-formed of 20 GA galvanized steel for application around

perimeter of transverse joint.

INSTALLATION INSTRUCTIONS

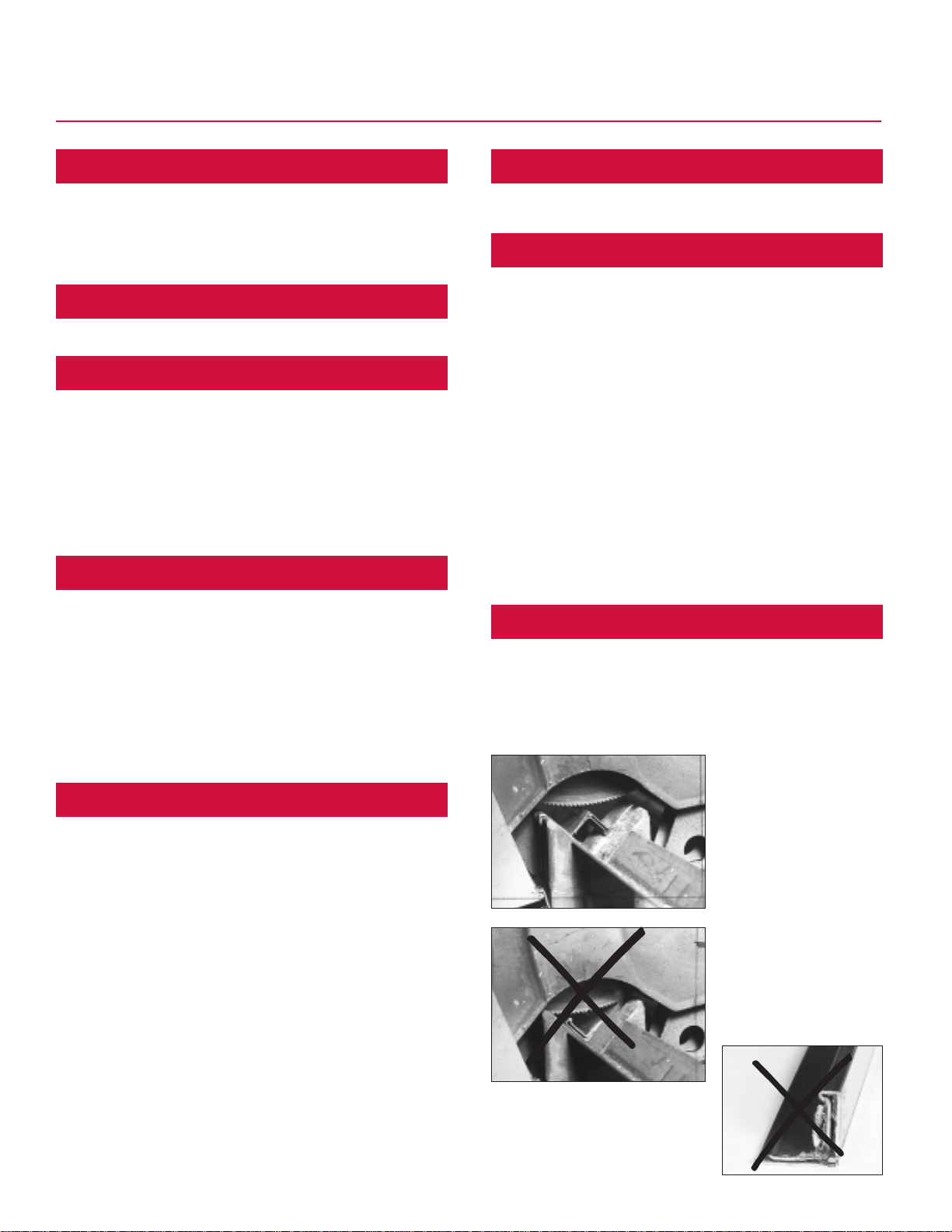

Do not notch the corners when fabricating ductwork for

the Ductmate System.

* Marks deviations from the original instructions when installing

Ductmate “45”.

C

UTTINGDUCTMATEANGLE

Connection System

self ignition 454ºC/850ºF

Fuel Contribution: 0

Smoke Density: 10

1. Always cut Ductmate angle

1 1/4" — 1 3/8" shorter than

duct dimension. Slam the blade

through the Angle as quickly as

possible. Saw must have

sufficient horsepower. Always use

a metal friction saw blade. A

band saw or hack saw can be

substituted.

2. Never cut Ductmate angle with

legs up as chips may fall into the

mastic.

Never use an abrasive blade to

cut Ductmate angle as the heat

can melt out the mastic.

Loading...

Loading...