Duco IQ-unit Quick Start Manual

IQ-unit

Quick Start

L1020200-D 21.06.2017

ENGLISH

DUCO, HANDELSSTRAAT 19

VEURNE, B8630

09

Raadpleeg www.duco.eu voor meer informatie omtrent garantie, onderhoud,

technische gegevens enz.

Installatie, aansluiting, onderhoud en herstellingen dienen door een erkend

ins

tallateur te gebeuren. De elektronische onderdelen van dit product kunnen

onder spanning staan. Vermijd contact met water.

Naviguez vers www.duco.eu pour plus d’informations sur la garantie, l’entretien,

des fiches techniques etc.

L’installation, le raccordement, l’entretien et les réparations doivent être effectués

par un ins

tallateur agréé. Les éléments électroniques de ce produit peuvent être

sous tension. Éviter tout contact avec l’eau.

See www.duco.eu for information regarding warranty, maintenance, technical data,

etc.

Installation, connection, maintenance and repairs are to be carried out by an

accredited installer. The electronic components of this product may be live. Avoid

contact with water.

75

ENGLISH

Table of contents

1 Application ...................................................................................................................................................76

Centrally controlled exhaust

..............................................................................................77

Zonally controlled exhaust

....................................................................................................78

2

Connectors and buttons ................................................................................................................79

3

Cabling .............................................................................................................................................................81

Cabling diagram

..............................................................................................................................82

RF (wireless communication)

............................................................................................84

Wired (cabled communication)

.........................................................................................85

Various cabling options

............................................................................................................86

4

Installation ..................................................................................................................................................88

Mounting

.................................................................................................................................................88

Air duct connections

...................................................................................................................89

5

Zonal control options .......................................................................................................................90

6

Installation ..................................................................................................................................................92

Installer / User mode

.................................................................................................................92

Installing components

...............................................................................................................94

Other operations

.............................................................................................................................98

7

Configuration ............................................................................................................................................99

Setting exhaust vents

.................................................................................................................99

Configuration

...................................................................................................................................102

8

Settings ....................................................................................................................................................... 106

Setting the time

.............................................................................................................................108

NightBoost

..........................................................................................................................................109

ModBus

..................................................................................................................................................110

76

ENGLISH

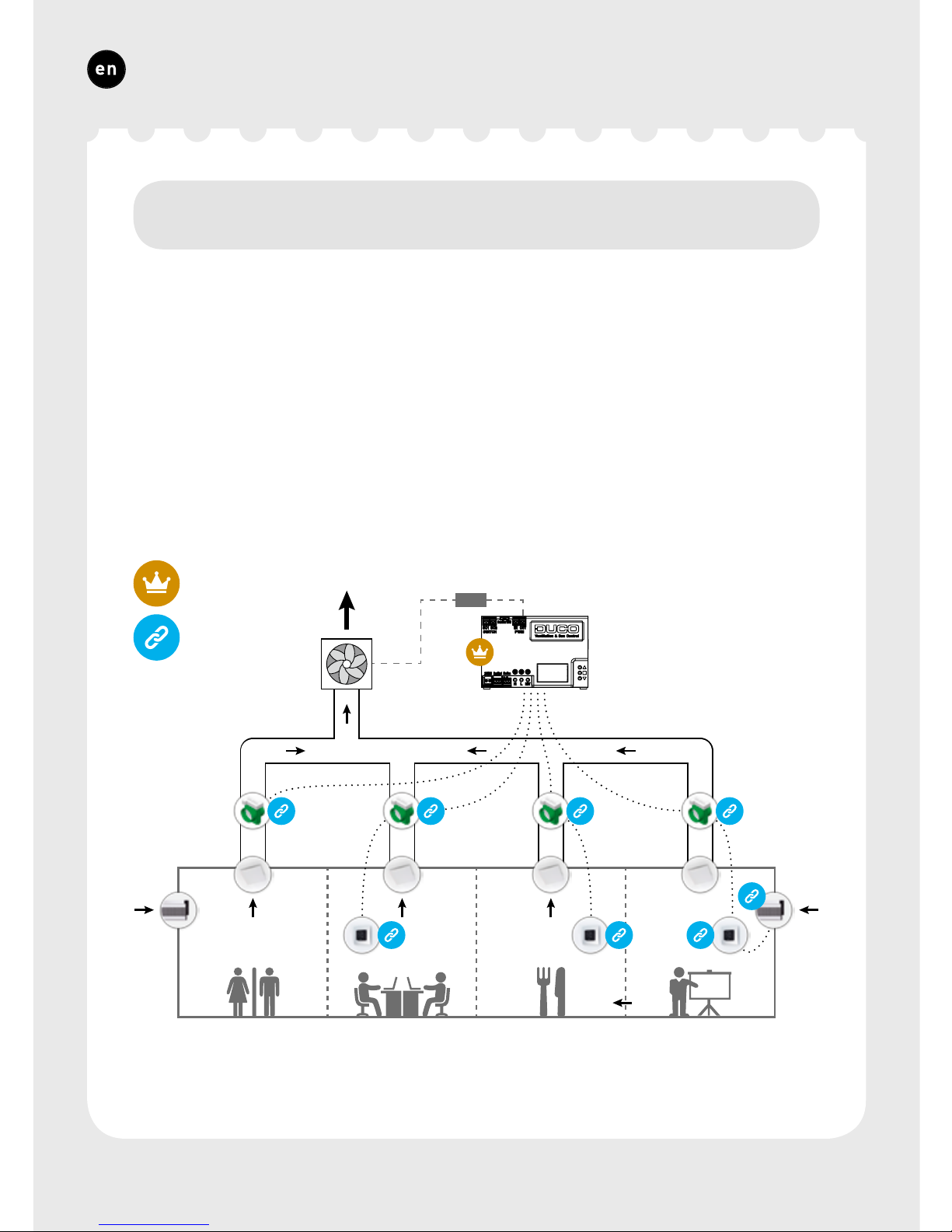

The IQ-unit operates as a ‘master’ or brain within Duco's Demand-Controlled Natural Ventilation Systems.

It receives and interprets signals from the ‘slave’ components (measurements from a sensor or manual input), based on which it controls

the ventilation system and any external unit. The IQ-unit thus ensures

that stale air, with excessive CO2 or moisture content, is exhausted.

The IQ-unit boasts smart functions such as NightBoost and ventilative

cooling, and can also be connected to a building management system

via ModBus.

The IQ-unit can be used in different situations and can perform different functions depending on requirements and the type of central

extract unit:

DucoBox WTW

The IQ-unit controls the DucoBox WTW via the WTW connection.

Pressure-controlled fan

With this the IQ-unit is not connected to the central extract unit. In this

case, the IQ-unit is only required to utilise functions such as ModBus,

NightBoost and ventilative cooling.

Non-pressure-controlled fan

The IQ-unit controls the fan via a PWM connection.

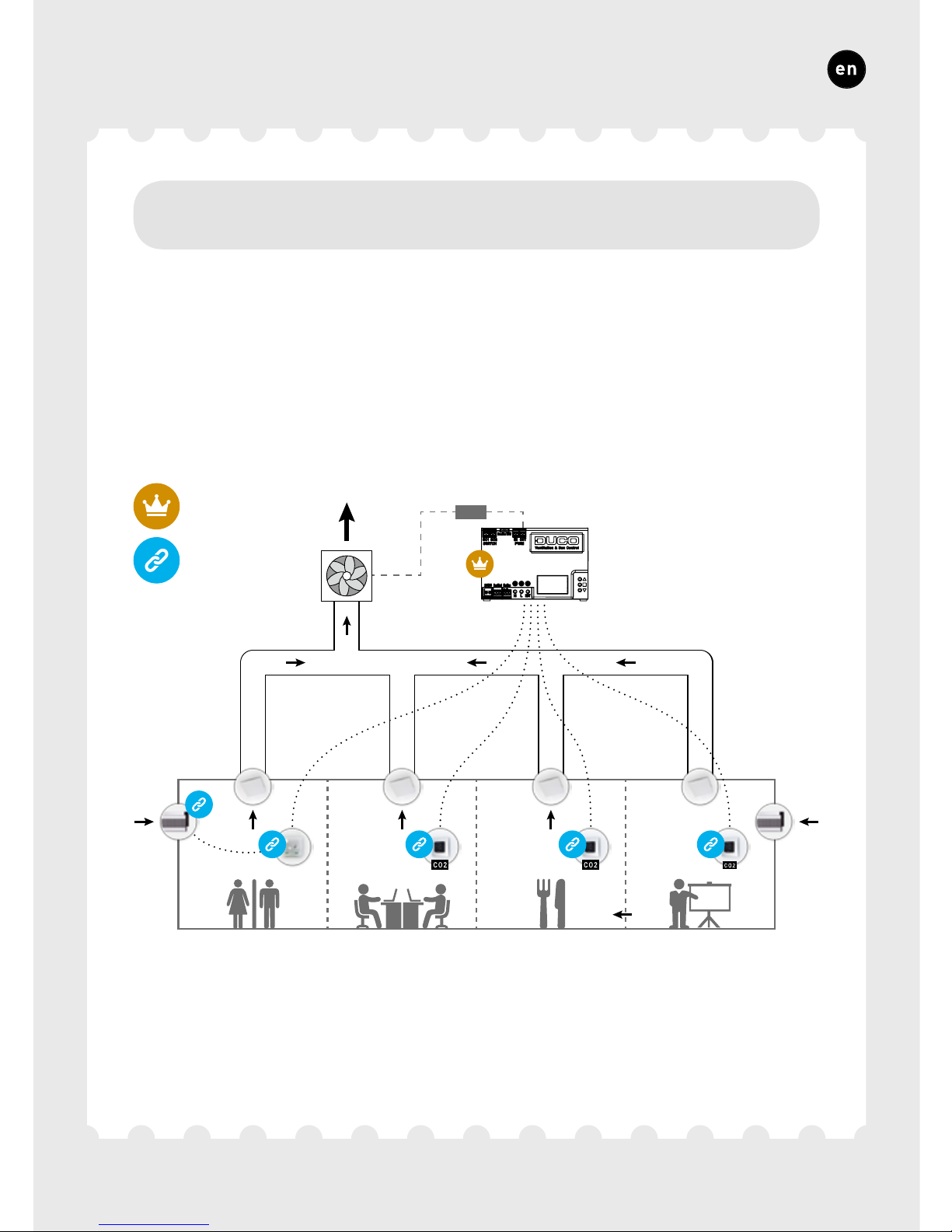

With the IQ-unit, both centrally and zonally controlled exhaust is

available.

1

Application

77

ENGLISH

*

PWM

With centrally (= not locally) controlled exhaust, air is exhausted in

every air duct connected.

1A.

Centrally controlled exhaust

Master

Slave

* Connection between IQ-unit and fan (via PWM) is only applicable when using a non-pressure-

controlled fan.

78

ENGLISH

1B.

Zonally controlled exhaust

With zonally (= locally) controlled exhaust, stale air is exhausted only

where necessary, which is conducive to optimum energy-efficiency and

quietness in the ventilation system. This requires a component to be

provided for each zone that acts as a control valve to regulate the exhaust air flow rate in that zone. This can be done by providing an Intelli

Air Valve — Duco’s smart control valve — in the duct of each zone, or

using another component with actuator control if the maximum flow

rate through an Intelli Air Valve is insufficient, such as a DucoGrille

Close.

PWM

*

Master

Slave

* Connection between IQ-unit and fan (via PWM) is only applicable when using a non-pressure-

controlled fan.

79

ENGLISH

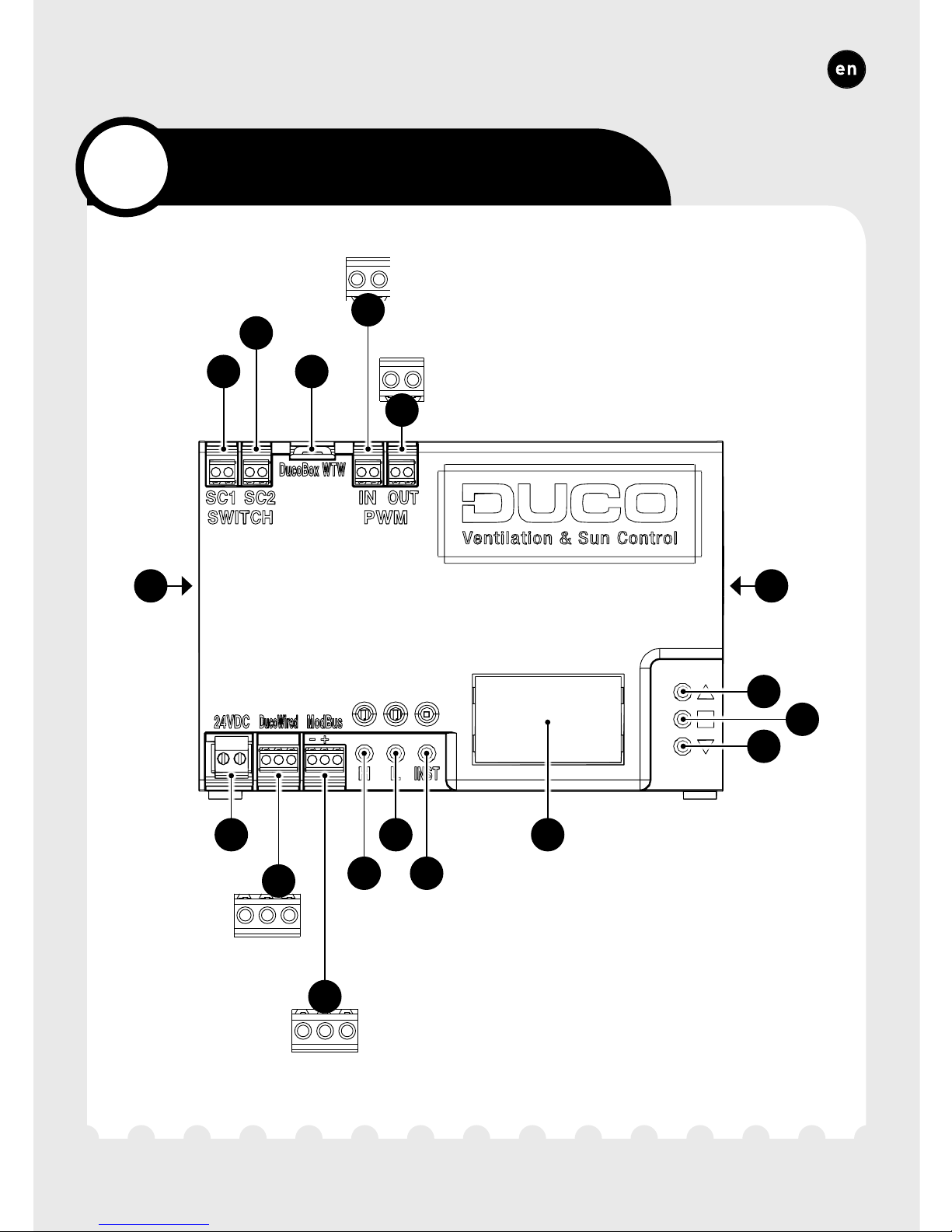

4

1

5

2

6

3

10

7

A

8

B

C

F

E

D

119

AABBGND

GND

- +

- +

- +

2

Connectors and buttons

80

ENGLISH

CONNECTORS

1 Power 24 VDC

2 DucoBus (A, B, GND)

3 ModBus (A/-,

B/+, GND)

4 Switch contact 1 -

onboard (n132)

5 Switch contact 2 -

onboard (n133)

6 DucoBox WTW

7 PWM IN

8 PWM OUT

9 Duco Network Tool

BUTTONS

A HIGH

B LOW

C INST

(installer mode)

D UP

E ENTER

F DOWN

DIVERS

10 Display

11 SD card

(software update)

81

ENGLISH

The IQ-unit is able to communicate with slave components via a wireless (RF) or wired link. Both types of communication can be combined

in one system. Wired connections are to be recommended in all cases

of non-residential and other projects where large distances or various

walls and/or building levels need to be spanned.

In addition, connections can also be made via a Switch Sensor (quantity

of 2), PWM-IN and PWM-OUT, WTW and ModBus.

3

Cabling

82

ENGLISH

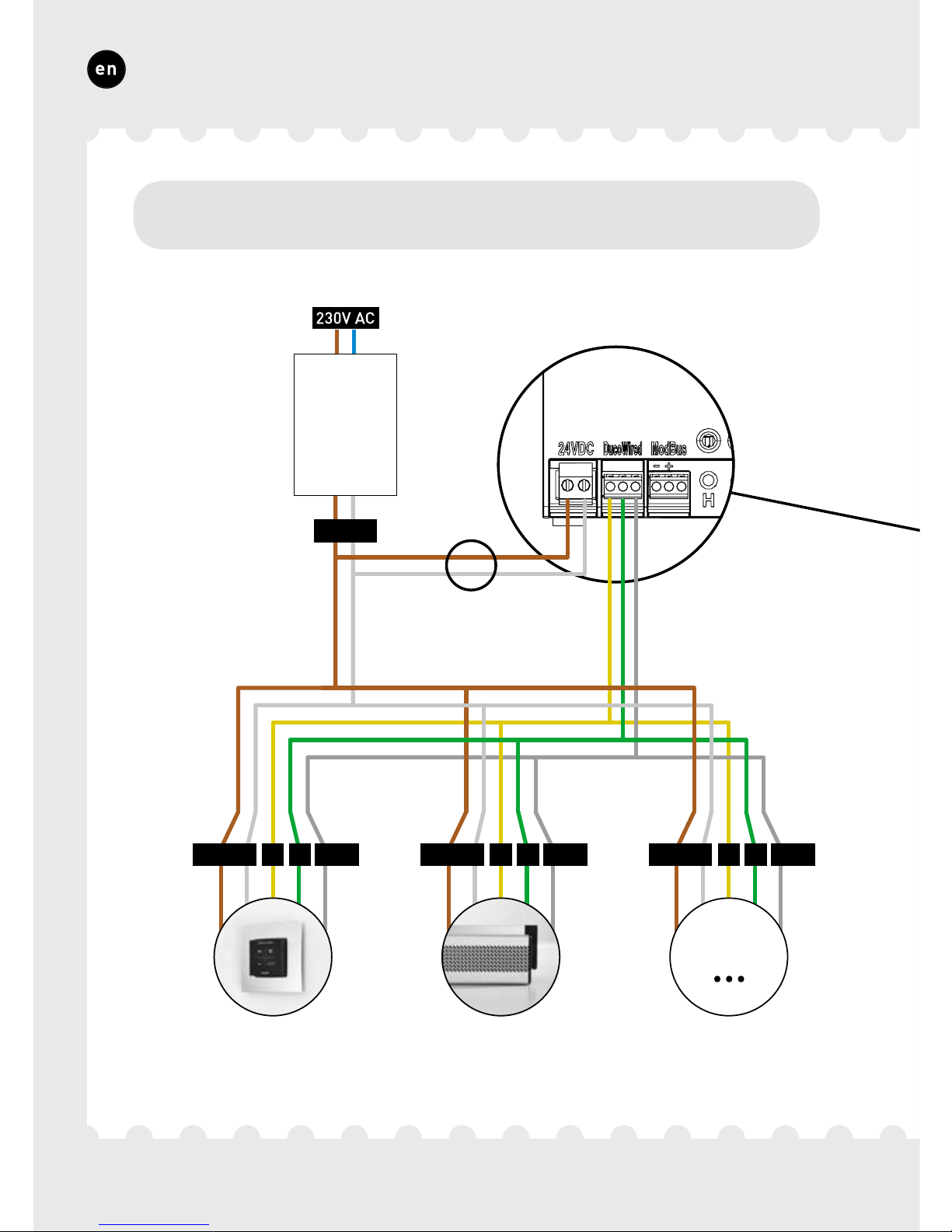

Wired

24 VDC

24 VDC

A B GND

POWER

SUPPLY

User controller

User controller

User controller

Tronicwindow ventilator

Tronicwindow ventilator

Tronicwindow ventilator

24 VDC A B GND 24 VDC A B GND

Not with DucoBox WTW

xxx

xxx

Max. of 99 Wired

3A.

Cabling diagram

83

ENGLISH

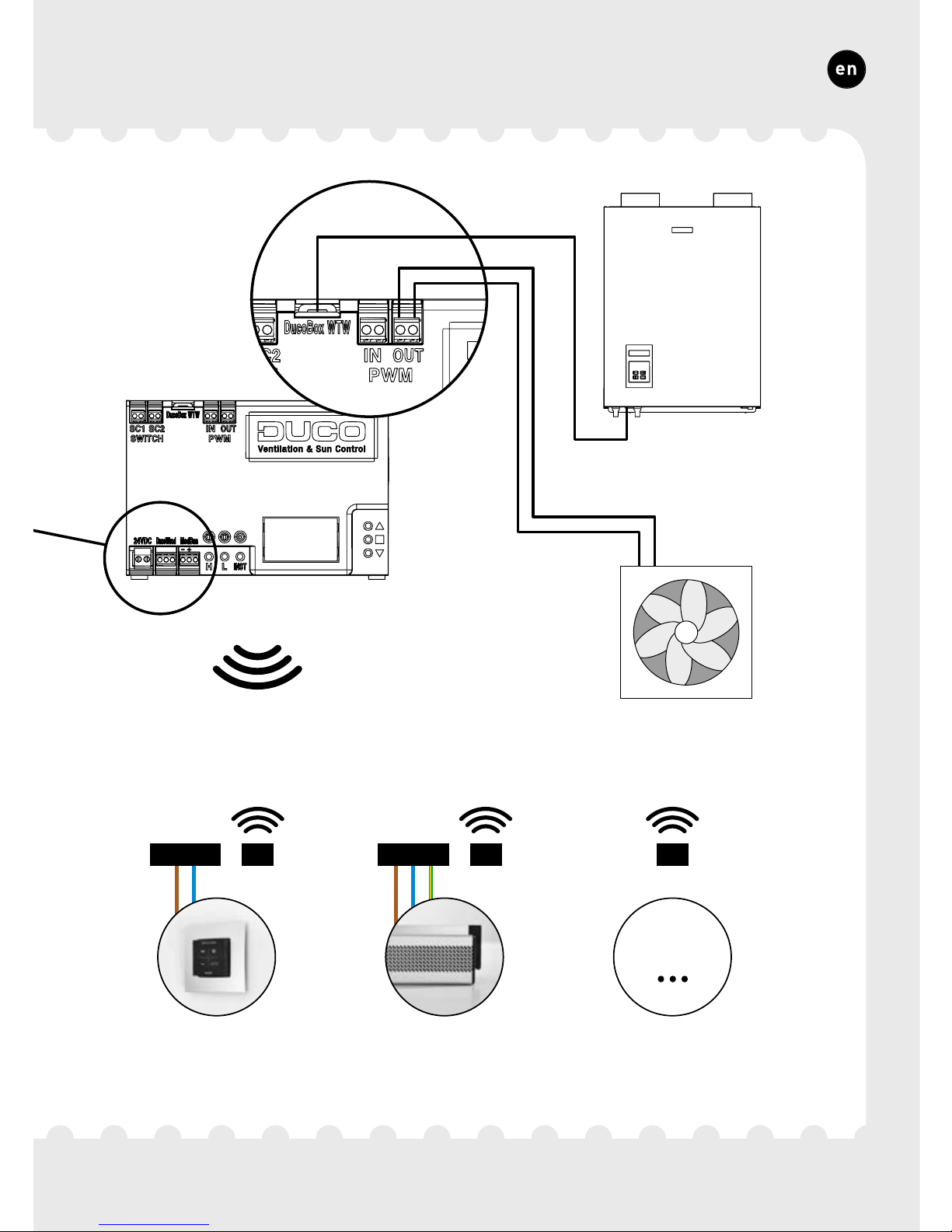

Max. of 30 RF

RF230 VAC

User controller

User controller

User controller

RF230 VAC

Tronic window ventilator

Tronicwindow ventilator

Tronicwindow ventilator

DUCOBOX

WTW

Externalcentral extract

unit

xxx

xxx

OF

OU

OR

RF

RF

84

ENGLISH

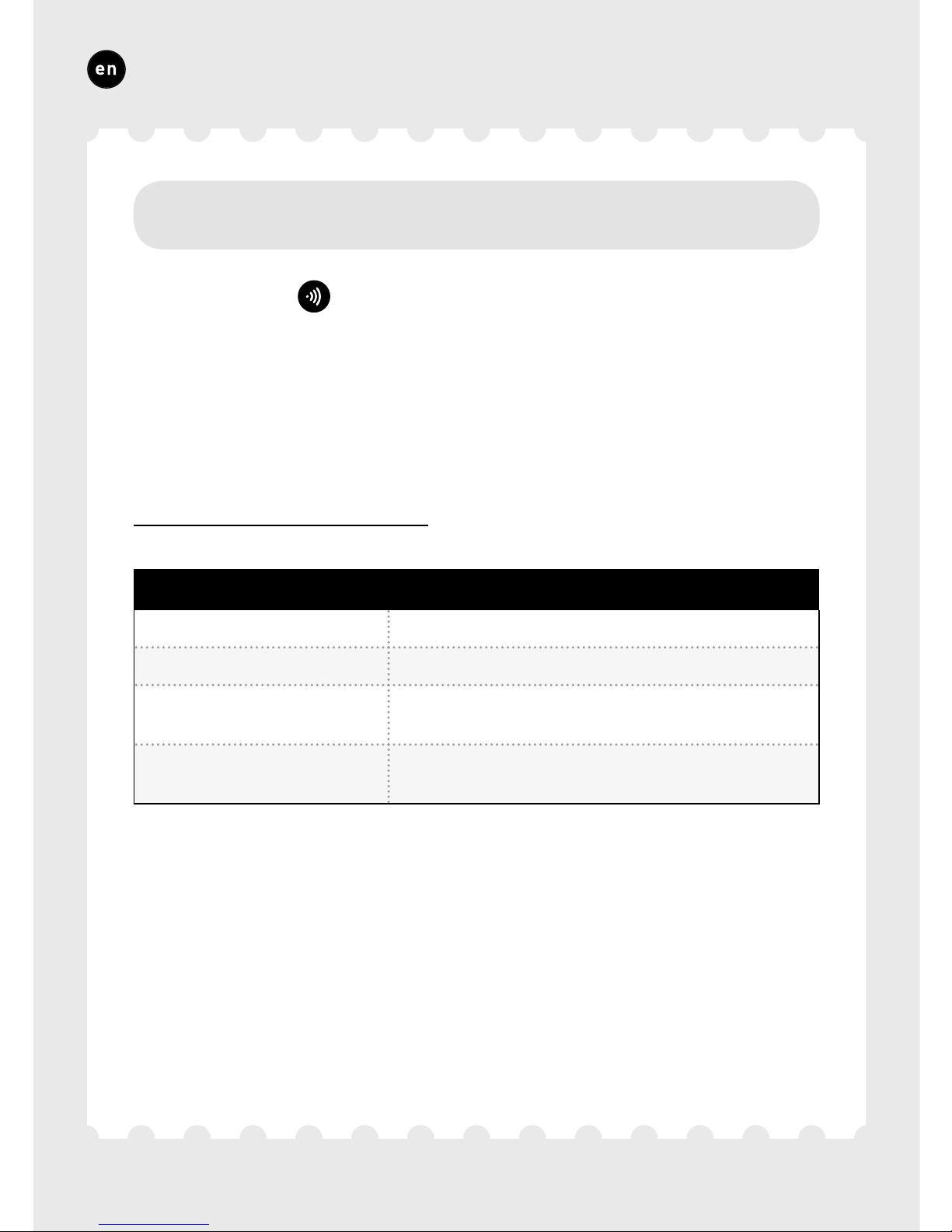

3B.

RF (wireless communication)

RF components ( ) have a maximum free-field range of 350 metres.

This distance will be much less in a building because of obstacles

so you will need to allow for features such as walls, concrete and

metal. All slave components (except those which are battery powered)

also act as repeaters. Signals from components that are unable to

make a (strong) connection with the master component are forwarded automatically via no more than one other non-battery-powered component (= hop point). Please refer to information sheet

RF communication (L8000001) at www.duco.eu for further information.

DUCO RF

Power supply 230 VAC

Frequency 868 MHz

Maximum distance

350 m, free field

(less through obstacles)

Maximum number

of components

Up to 25 wireless components in a single system

Loading...

Loading...