Page 1

Page 2

This manual is an integral part of the motorcycle and must remain with it for its entire life.

The manual must accompany the motorcycle if it is sold or transferred to a new owner.

Please store this manual in a safe a place. In case of damage or loss, request a new copy by contacting:

Ducati North America, Inc.

10443 Bandley Drive

Cupertino, California, 95014

Tel: 001.408.253.0499

Fax: 001.408.253.4099

E-mail: customerservice@ducatiusa.com

Web site: www.ducatiusa.com

Quality and safety standards of Ducati motorcycles are constantly being updated consequent to the

development of new design solutions, equipment and accessories. Although the manual includes fully

updated information at the time of print, Ducati Motor Holding S.p.A. therefore reserves the right to make

changes without prior notification or without incurring obligations. For this reason, you may note

discrepancies when comparing some illustrations with your motorcycle.

Any and all reproduction or dissemination of the contents in whole or in part is strictly prohibited. All rights

are reserved by Ducati Motor Holding S.p.A. Requests for authorizations shall be made in writing to this

company with specification of the reason.

Page 3

Owner's Manual

US/CANADA

1

Page 4

Introduction

We'd like to welcome you among Ducati enthusiasts

and congratulate you on your excellent choice of

motorcycle. We imagine you'll be riding your Ducati

motorcycle for long trips as well as short daily

excursions. Ducati Motor Holding S.p.A. wishes you

smooth and enjoyable riding.

Your motorcycle is the result of constant research

and development by Ducati Motor Holding S.p.A., so

it's important that the standard of quality is upheld

through careful observance of the scheduled

maintenance chart and the use of original spare parts.

In the Owner's Manual you'll find instructions for

performing small maintenance procedures.

The most important servicing and maintenance

procedures are contained in the Service Manual

available at Authorized Service Centers of Ducati

Motor Holding S.p.A..

2

In your own interest, for your safety and in order to

guarantee product reliability, we strongly

recommend that you go to an Authorized Dealer or

Service Center for any servicing included on the

scheduled maintenance chart (see page 124)

Our highly skilled staff has access to the special tools

and equipment needed to perform any servicing

procedure with expertise. They use only Ducati

original spare parts as the best guarantee for full

interchangeability, smooth running and long life.

All Ducati motorcycles come with a Warranty

Booklet.

The Warranty does not extend to motorcycles used

in competitions or competitive trials.

Any tampering or even partial modification of the

components will result in automatic invalidation of

Warranty rights.

Incorrect or insufficient servicing procedures, use of

non-original spare parts or parts not explicitly

approved by Ducati may lead to the invalidation of the

Warranty, besides potential damage and reduced

performance.

Page 5

Table of contents

Introduction 2

Safety guidelines 6

Warning symbols used in the manual. 6

Permitted use 7

Rider's obligation 7

Reporting safety defects 9

Rider education 10

Clothing 10

“Best Practices” for safety 11

Refueling 13

Carrying the maximum load allowed 15

Dangerous products - warnings 16

Vehicle ID number 18

Engine ID number 19

Plate positioning 20

Noise and exhaust emission control system

information

California emission control warranty statement Your

warranty rights and obligations

Manufacturer’s warranty coverage 27

Owner's warranty responsibilities: 27

California evaporation emission system 28

Ducati limited warranty on emission control

system

26

27

28

Instrument Panel (Dashboard) 31

Dashboard 31

LCD unit functions 33

LCD – How to set/display parameters 35

Total distance covered indicator: “Odometer“ 37

Air temperature indicator 38

Vehicle speed indication 39

Engine coolant temperature indicator 40

Partial trip meter “TRIP A” 41

Partial trip meter “TRIP B“ 42

Distance traveled on fuel reserve: “TRIP FUEL“ 43

Maintenance indicator (SERV) 44

Battery voltage indicator (BATT). 45

Engine idle RPM setting (RPM) 46

LAP timer 47

Stored data display (LAP Memory) 49

DDA data acquisition 51

Erase DDA 52

Clock setting function 53

Dashboard diagnosis 55

Instrument panel backlighting 61

Headlight “smart” auto-off 61

Headlight “smart” switch-on 61

The Immobilizer system 63

Keys 63

Code card 64

Immobilizer override procedure 65

Operation 67

3

Page 6

Duplicate keys

Service menu - unit of measurement (UNIT SET) 68

67

Controls 70

Position of motorcycle controls 70

Key-operated ignition switch and steering lock 71

LH switch 72

Clutch lever 73

RH switch 74

Throttle twistgrip 74

Front brake lever 75

Rear brake pedal 76

Gear change pedal 76

Setting the gear change and rear brake pedals 77

Main components and devices 79

Position on the vehicle 79

Fuel tank plug 80

Seat lock 81

Side stand 82

Steering damper 83

Front fork adjusters 84

Rear shock absorber adjusters 86

4

Riding the motorcycle 88

Break-in recommendations 88

Pre-ride checks 90

Starting the engine 91

Moving off 93

Braking 93

Stopping the motorcycle 95

Parking 95

Refueling 96

Tool kit and accessories 97

Main maintenance operations 98

Removing the fairing 98

Changing the air filter 102

Checking and topping up coolant level 103

Checking brake and clutch fluid level 104

Checking brake pads for wear 106

Lubricating cables and joints 107

Adjusting throttle control free play 108

Charging the battery 109

Checking drive chain tension 110

Chain lubrication 111

Replacing the high and low beam bulbs 112

Replacing the parking light bulb 114

Rear turn indicators 115

Number plate light 115

Beam setting 116

Page 7

Rear view mirror adjustment

Tubeless tires 118

Checking engine oil level 120

Cleaning and replacing the spark plugs 121

Cleaning the motorcycle 122

Storing the motorcycle 123

Important notes 123

117

Maintenance 124

Scheduled maintenance chart: operations to be

performed by the Dealer

Scheduled maintenance chart: operations to be

performed by the customer

124

127

Technical data 128

Overall dimensions (mm) 128

Weights 128

Engine 130

Timing system 130

Performance data 131

Spark plugs 131

Fuel system 131

Brakes 132

Transmission 133

Frame 134

Wheels 134

Tires 134

Suspensions 135

Exhaust system 136

Available colors 136

Electrical system 136

Routine maintenance record 142

5

Page 8

Safety guidelines

Your safety and that of others are very important.

Ducati Motor Holding S.p.A. urges you to ride your

motorcycle responsibly.

Before using your motorcycle for the first time,

please read this manual carefully from start to finish

and closely follow the guidelines. This will allow you

to obtain all information regarding a correct use and

maintenance.

If you have any doubts or questions, consult a Dealer

or Authorized Service Center.

6

Warning symbols used in the manual.

Different forms of information regarding potential

hazards that may affect you or others have been

used. These include:

- Safety stickers on the motorcycle;

- Safety warnings preceded by a warning symbol

and by one or the two words Caution or

Important.

Warning

Failure to observe these instructions may lead

to a hazardous situation and cause severe injury to

the rider or others, or even death.

Important

Possibility of damaging the motorcycle and/or

its components.

Note

Additional information regarding the job being

performed.

The terms RIGHT and LEFT are referred to the

motorcycle viewed from the riding position.

Page 9

Permitted use

This motorcycle must be used only on road surfaces

with asphalt or flat and even pavement.

This motorcycle may not be used on dirt roads or for

off-road riding.

Warning

Using the bike off-road may cause the rider to

lose control, which in turn may lead to vehicle

damage, injury or death.

Warning

This motorcycle must not be used for towing or

for the addition of a sidecar, since this may cause a

loss or control and consequent accident.

Warning

The total weight of the motorcycle in running

order with rider, passenger, baggage and additional

accessories must not exceed 882 lb (400kg).

Rider's obligation

All riders must hold a driver's license.

Warning

Riding without a license is illegal and punishable

by law. Make sure you always have your license on

you when setting out on the motorcycle. Do not

allow inexpert riders or those not in possession of an

authorized driver's license to ride the motorcycle.

Do not ride the motorcycle when under the influence

of alcohol or drugs.

Warning

Riding under the influence of alcohol or drugs is

illegal and punishable by law.

Avoid taking medication before riding the motorcycle

if you have not consulted your doctor about potential

side effects.

Warning

Some medications may induce sleepiness or

other effects that impair reflexes and the ability of the

rider to control the motorcycle, which may lead to

accident.

7

Page 10

Some countries require mandatory insurance

coverage.

Warning

Check the laws applicable to your country. Take

out an insurance policy and keep the policy in a safe

place along with the other motorcycle documents.

To protect the safety of the rider and/or passenger,

some countries have made it a law to wear a

homologated helmet.

Warning

Check the laws applicable to your country.

Riding without a helmet may be punishable by a fine.

Warning

Failure to be wearing a helmet in case of

accident increases the chance of serious injury and

even death.

Warning

Make sure that the helmet is in compliance with

safety specifications, provides excellent visibility, is

the correct size for the head, and has the DOT

(Department of Transportation) label affixed to the

helmet surface.

8

Laws regulating traffic vary from country to country.

Check the laws in force in your country before riding

the motorcycle and pay strict adherence to them .

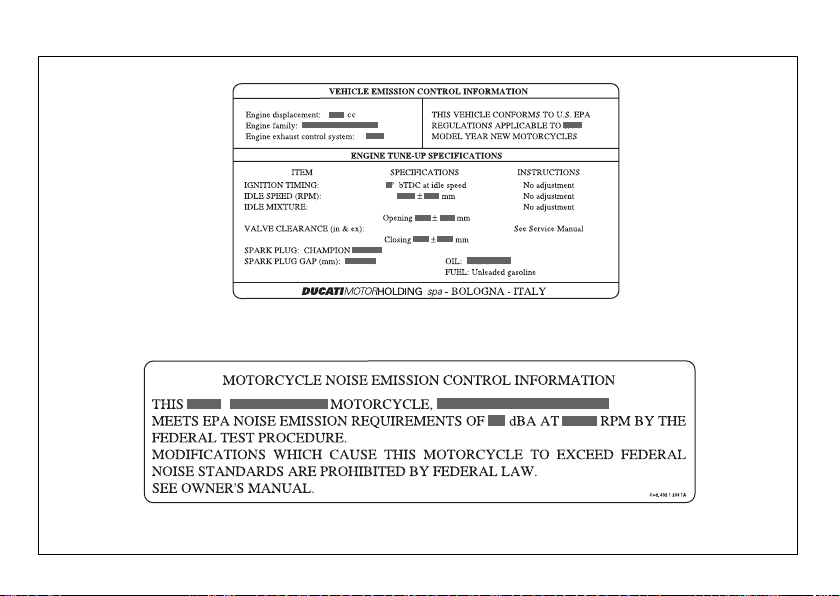

Warning

Tampering with Noise Control System

Prohibited. Federal Law prohibits the following acts

or causing thereof:

1) the removal or rendering inoperative by any

person, other than for purposes of maintenance,

repair, or replacement, of any device or element

of design incorporated into any new vehicle for

the purpose of noise control prior to its sale or

delivery to the ultimate purchaser or while it is in

use; or

2) the use of the vehicle after such device or

element of design has been removed or

rendered inoperative by any person.

Among the acts presumed to constitute tampering

are those listed below:

1) Removal of, or puncturing the muffler, baffles,

header pipes or any other component that

conducts exhaust gases.

2) Removal or puncturing of any part of the intake

system.

3) Lack of proper maintenance.

Page 11

4) Replacing any moving part of the vehicle, or parts

of the exhaust or intake system, with parts other

than those specified by the manufacturer.

This product should be checked for repair or

replacement if the motorcycle noise has increased

significantly through use. Otherwise, the owner may

become subject to penalties under state and local

ordinances.

Reporting safety defects

If you believe your vehicle has a defect that could

cause a crash or cause injury or death, you should

immediately inform the National Highway Traffic

Safety Administration (NHTSA), in addition to

notifying Ducati North America, 10443 Bandley Drive

Cupertino, California, 95014, Tel: 001.408.253.0499,

Fax: 001.408.253.4099. If NHTSA receives similar

complaints, it may open an investigation, and if it

finds that a safety defect exists in a group of vehicles,

it may order a recall and remedy campaign. However,

NHTSA cannot become involved in individual

problems between you, your dealer, or Ducati North

America. To contact NHTSA, you may either call the

Auto Safety Hotline toll-free at 1-800-424-9393 (or

366-0123 in Washington, D.C. area) or write to:

NHTSA, 1200 New Jersey Avenue SE W43-488,

Washington, D.C. 20590. You can also obtain other

information about motor vehicle safety from the

Hotline.

9

Page 12

Rider education

Accidents are frequently due to inexperience. Riding,

maneuvering and or braking are carried out differently

from other vehicles.

Warning

A rider's lack of preparation or an inappropriate

use of the vehicle may result in a loss of control,

death or serious damage.

Be sure you know the “RULES OF THE ROAD“,

carefully read and familiarize with the contents of the

M.O.M. (Motorcycle Operator Manual) for

information on your State and which can be viewed

on the M.S.F. (Motorcycle Safety Foundation)

website (www.msf-usa.org).

You are strongly recommended to take a riding

course approved by the M.S.F. (Motorcycle Safety

Foundation).

10

Clothing

Clothing in the use of the motorcycle plays an

important role in safety, as the motorcycle provides a

person no protection from impact in the same way as

an automobile.

Suitable clothing includes: helmet, eye protection,

gloves, boots, long-sleeved jacket and long pants.

- The helmet must have the requisites as listed on

page 8, if the helmet model has no visor, use

suitable goggles;

- Gloves must have five fingers and be made of

leather or other abrasion-resistant material;

- Boots or shoes used for riding must have non-slip

soles and ankle protection;

- Jacket and pants, or even riding suits, must be

made of leather or abrasion-resistant material and

in a color with inserts that are very visible.

Important

In any case, avoid wearing loose or floppy

clothing that can become stuck in the motorcycle

parts.

Page 13

Important

For your safety this type of clothing must be

used in both summer and winter.

Important

For the safety of the passenger, make sure that

he or she also wears appropriate clothing.

“Best Practices” for safety

Before, during and after use, remember to follow

some simple rules that are extremely important for

safety and for maintaining the motorcycle at top

efficiency.

Important

During the break-in period, carefully observe the

instructions contained on page 88. Failure to follow

these instructions releases Ducati Motor Holding

S.p.A. from any liability whatsoever for any engine

damage or shorter engine life.

Warning

Do not ride the motorcycle unless you are well

familiarized with the controls to be used during the

ride.

Before starting the motorcycle, always performs the

checks detailed in this manual (see page 90).

Warning

Failure to perform checks may cause damage to

the vehicle and serious injury to the rider and/or

passenger.

11

Page 14

Warning

Start the engine when outdoors or in a well

ventilated place. Never start the engine in a closed

environment.

Exhaust gases are poisonous and may lead to loss of

consciousness or even death within a short time.

During the ride, assume a correct body position and

make sure the passenger does the same.

Important

The rider should ALWAYS keep both hands on

the handlebar.

Important

Both rider and passenger should keep their feet

on the footpegs when the motorcycle is in motion.

Important

The passenger should always hold on to the

strap on passenger seat with both hands.

12

Important

Be very careful when maneuvering

intersections or when riding in areas near exits from

private grounds, parking lots or access roads to

highways.

Important

Be sure you are clearly visible and do not ride in

the blind spot of the vehicles ahead.

Important

ALWAYS signal your intention to turn or pull

over to the next lane with due warning using the turn

indicators.

Important

Park your motorcycle where no one is likely to

hit it, and use the side stand.

Never park on uneven or soft ground or your

motorcycle may fall over.

Page 15

Important

Visually inspect the tires at regular intervals for

cracks and cuts, especially on sidewalls, bulges or

large spots which are indicative of internal damage.

Replace them if badly damaged.

Remove any stones or other foreign bodies caught in

the tread.

Warning

The engine, exhaust pipes and mufflers stay hot

for a long time after the engine has been turned off.

Be especially careful not to touch the exhaust system

with any part of the body and never park the

motorcycle near flammable materials (wood, leaves,

etc.).

Warning

When you leave the motorcycle unattended,

always remove the ignition key and make sure it is

inaccessible to anyone unsuitable to ride the

motorcycle.

Refueling

Refuel the motorcycle in an open area and with the

engine switched off.

Do not smoke or ever use flames during refueling.

Be careful never to drop fuel on the engine or

exhaust pipe.

When refueling, do not fill the tank completely: fuel

should never be touching the rim of filler recess.

When refueling, avoid inhaling fuel vapors and take

care that they do not come in contact with eyes, skin

or clothing.

13

Page 16

Warning

The vehicle is compatible only with fuel having

a maximum content of ethanol of 10% (E10). Using

fuel with ethanol content over 10% is prohibited.

Using it could result in severe damage of the engine

and motorcycle components. Using fuel with ethanol

content over 10% will render the Warranty null and

void.

Warning

In case of malaise caused by prolonged

inhalation of fuel vapors, stay outdoors and consult a

physician. In case of contact with eyes, rinse eyes

thoroughly with water. In case of contact with skin,

wash the area immediately with soap and water.

Warning

Fuel is highly flammable. If it accidentally spills

onto clothes, change them.

14

Page 17

Carrying the maximum load allowed

Your motorcycle is designed for long-distance riding

with the maximum load allowed carried in full safety.

Even weight distribution is critical to preserving these

safety features and avoiding difficulties when

performing sudden maneuvers or riding on bumpy

roads.

Warning

Do not exceed the total permitted weight for

the motorcycle and pay attention to the information

below regarding load capacity.

Information about carrying capacity

Important

Arrange your luggage or heavy accessories in

the lowest possible position and close to motorcycle

center.

Important

Never fix bulky or heavy objects to the steering

head or front mudguard, as this would affect stability

and be dangerous.

Important

Be sure to secure the luggage to the supports

provided on the motorcycle as firmly as possible.

Improperly secured luggage may affect stability.

Important

Do not insert any objects you may need to carry

into the gaps of the frame, as these may interfere

with moving parts.

Warning

Make sure tires are inflated to the correct

pressure indicated at page 118 and that they are in

good condition.

15

Page 18

Dangerous products - warnings

Brake fluid

Used engine oil

Warning

Prolonged or repeated contact with used engine

oil may cause skin cancer. If exposed to used engine

oil on a daily basis, make it a rule to wash your hands

thoroughly with soap immediately after use. Keep

away from children.

Brake lining debris

Never attempt to clean the brake assembly using

compressed air or a dry brush.

16

Warning

Avoid spilling brake fluid onto plastic, rubber or

painted parts of the motorcycle to avoid the risk of

damage. Protect these parts with a clean shop rag

before servicing the motorcycle. Keep away from

children.

Warning

The brake fluid used in the brake system is

corrosive. In the event of accidental contact with

eyes or skin, wash the affected area with generous

quantities of running water.

Coolant

Engine coolant contains ethylene glycol, which may

ignite under particular conditions, producing invisible

flames. Although the flames from burning ethylene

glycol are not visible, they are still capable of causing

severe burns.

Warning

Take care not to spill engine coolant on the

exhaust system or engine parts. These parts may be

hot and ignite the coolant, which will subsequently

burn with invisible flames.

Page 19

Coolant (ethylene glycol) is an irritant and is

poisonous when ingested. Keep away from children.

Never remove the radiator cap when the engine is

hot. The coolant will be scalding hot and is under high

pressure.

The cooling fan operates automatically: keep hands

well clear and make sure your clothing does not get

caught in the fan.

Battery

Warning

The battery gives off explosive gases; keep it

away from any source of ignition such as sparks,

flames and cigarettes. Charge the battery in a wellventilated area.

17

Page 20

Vehicle ID number

DUCATI

TYPE OF

MOTORCYCLE

MODEL

YEAR

PLANT OF

MANU FACTURE

SEQUENTIAL

NUMBER

{

{

{

Varies-can be Ø thru 9 or X (Check digit)

ZDM 1 X B M V X B 0 0 0 0 0 0

fig. 1

fig. 2

Note

These numbers identify the motorcycle model

and should always be indicated when ordering spare

parts.

We recommend that you note the frame number of

your motorcycle in the space below.

Frame number

18

Page 21

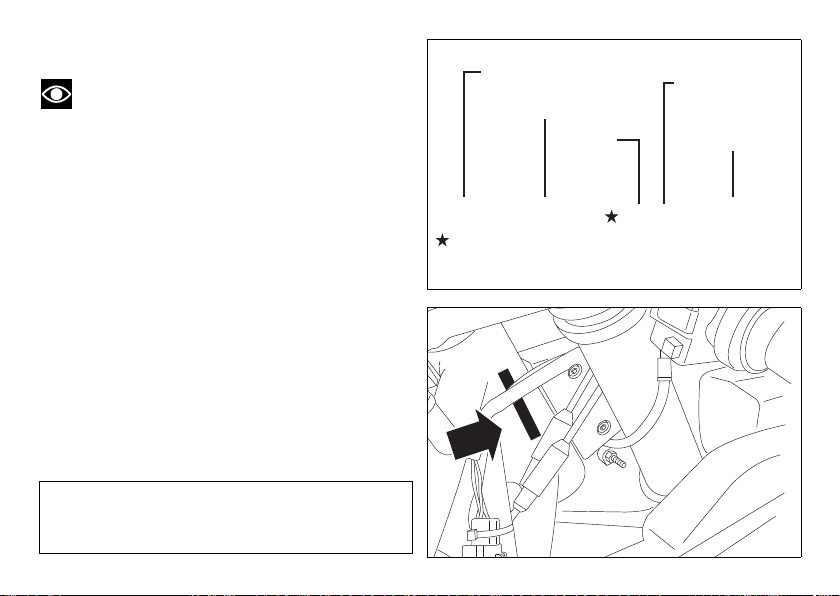

Engine ID number

XBG ? *000000*

ENGINE

TYPE

MODEL

YEAR

SEQUENTIAL

NUMBER

fig. 3

fig. 4

Note

These numbers identify the motorcycle model

and should always be indicated when ordering spare

parts.

We recommend that you note the engine number of

your motorcycle in the space below.

Engine number

19

Page 22

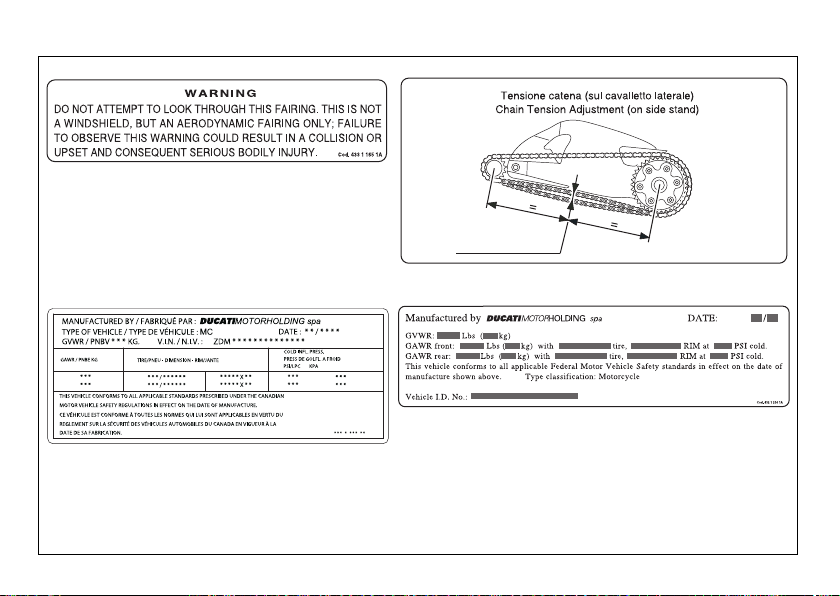

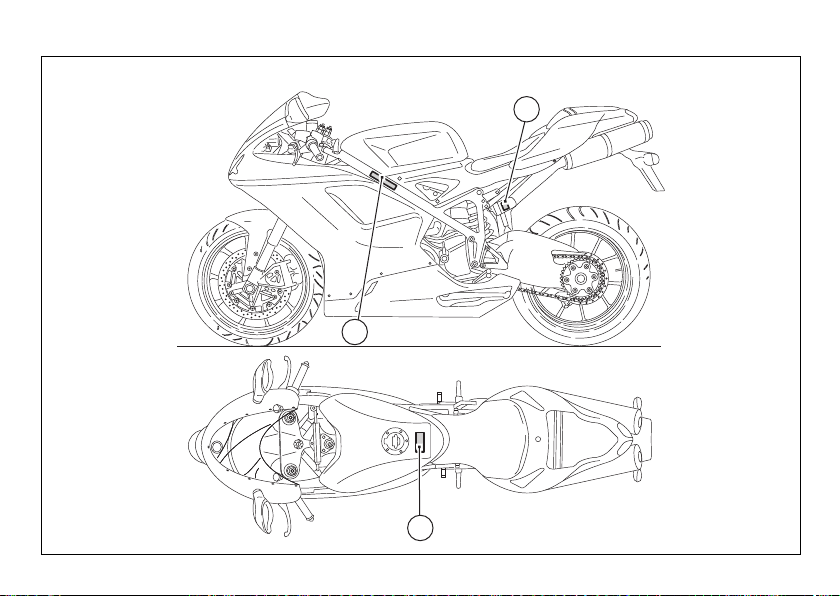

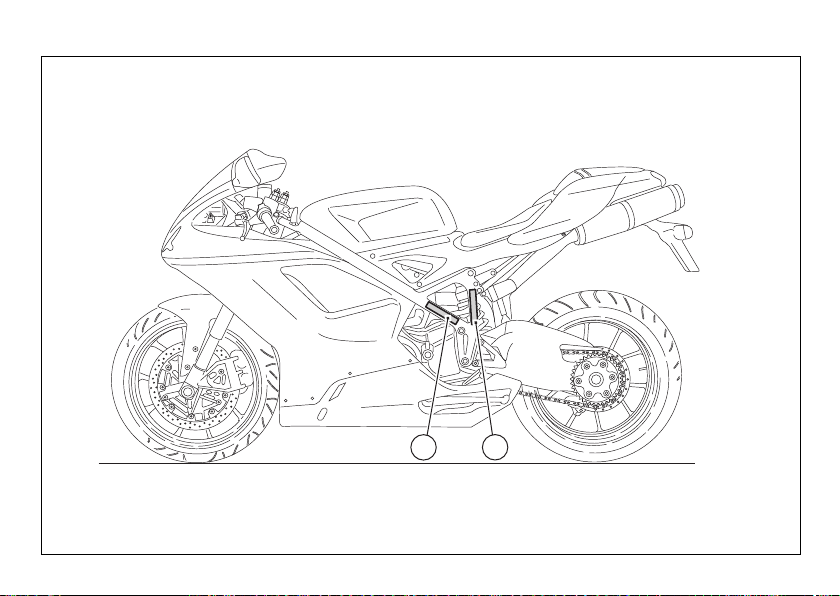

Plate positioning

1

3

2

3

Canada only

fig. 5

20

Page 23

31

1.2 ÷ 1.3 in

÷ 33 mm

1

2

3

3

(Canada Only)

fig. 6

21

Page 24

4

5

6

fig. 7

22

Page 25

6

5

4

fig. 8

23

Page 26

7

8

fig. 9

24

Page 27

7

8

fig. 10

25

Page 28

Noise and exhaust emission control system information

combustion chamber through the air cleaner and the

throttle body.

Source of Emissions

The combustion process produces carbon monoxide

and hydrocarbons. Control of hydrocarbons is very

important because under certain conditions, they

react to form photochemical smog when subjected

to sunlight.

Carbon monoxide does not react in the same way,

but is toxic. Ducati utilizes lean carburetor settings

and other systems to reduce carbon monoxide and

hydrocarbons.

Exhaust Emission Control System

Exhaust Emission Control System is controlled by an

Electronic Control Unit (ECU), and no adjustments

should be made except idle speed adjustments with

the throttle stop screw. The Exhaust Emission

Control System is separate from the crankcase

emission control system.

Crankcase Emission Control System

The engine is equipped with a closed crankcase

system to prevent discharging crankcase emissions

into the atmosphere. Blow-by gas is returned to the

26

Evaporative Emission Control System

The motorcycles are equipped with an evaporative

emission control system which consists of a charcoal

canister and associated piping. This system prevents

the escape of fuel vapors from the engine and fuel

tank.

Problems that may affect motorcycle

emissions

If you are aware of any of the following symptoms,

have the vehicle inspected and repaired by your local

Ducati dealer.

Symptoms:

Hard starting or stalling after starting.

Rough idle.

Misfiring or backfiring during acceleration.

After-burning (backfiring).

Poor performance (drivability) and poor economy.

Page 29

California emission control warranty statement Your warranty rights and obligations

The California Air Resources Board is pleased to

explain the emission control system warranty on your

MY 2013 motorcycle. In California, new motor

vehicles must be designated, built and equipped to

meet the State's stringent anti-smog standards.

Ducati North America, Inc. must warrant the

emission control system on your motorcycle for the

periods of time listed below provided there has been

no abuse, neglect or improper maintenance of your

motorcycle.

Your emission control system may include parts such

as fuel-injection system, the ignition system, catalytic

converter, and engine computer. Also included may

be hoses, belts, connectors and other emissionrelated assemblies. Where a warrantable condition

exists, Ducati North America, Inc. will repair your

motorcycle at no cost to you including diagnosis,

parts and labor.

Manufacturer’s warranty coverage

- 5 years or 30,000 kilometers (18641 miles),

whichever first occurs.

Owner's warranty responsibilities:

- As the motorcycle owner, you are responsible for

the performance of the required maintenance

listed in your owner's manual. Ducati North

America, Inc. recommends that you retain all

receipts covering maintenance on your

motorcycle, but Ducati North America, Inc. cannot

deny warranty solely for the lack of receipts or for

your failure to ensure the performance of all

scheduled maintenance.

- You are responsible for presenting your

motorcycle to a Ducati dealer as soon as a

problem exists. The warranty repairs should be

completed in a reasonable amount of time, not to

exceed 30 days.

- As the motorcycle owner, you should also be

aware that Ducati North America, Inc. may deny

you warranty coverage if your motorcycle or a part

has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

If you have any questions regarding your warranty

rights and responsibilities, you should contact Ducati

North America, Inc. at 001.408.253.0499 or the

California Air Resource Board at 9528 Telstar

Avenue, El Monte, CA 91731.

27

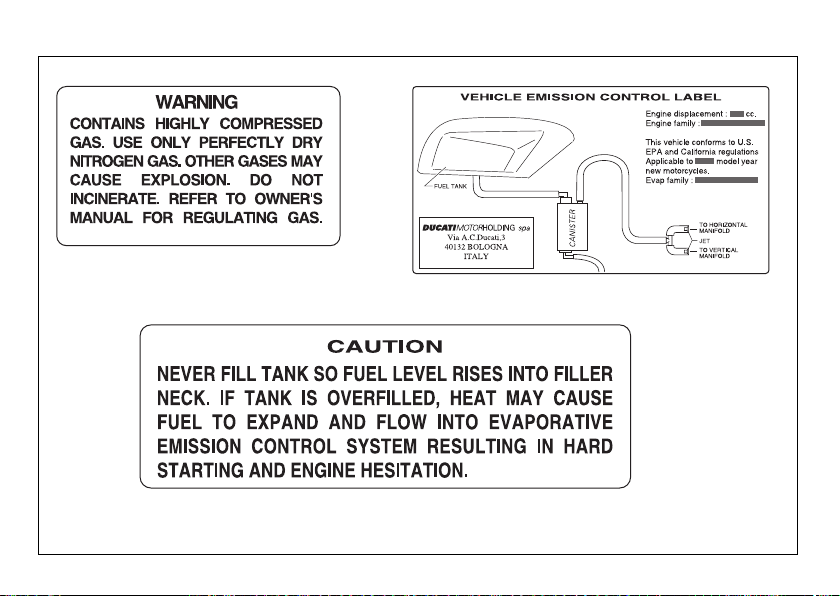

Page 30

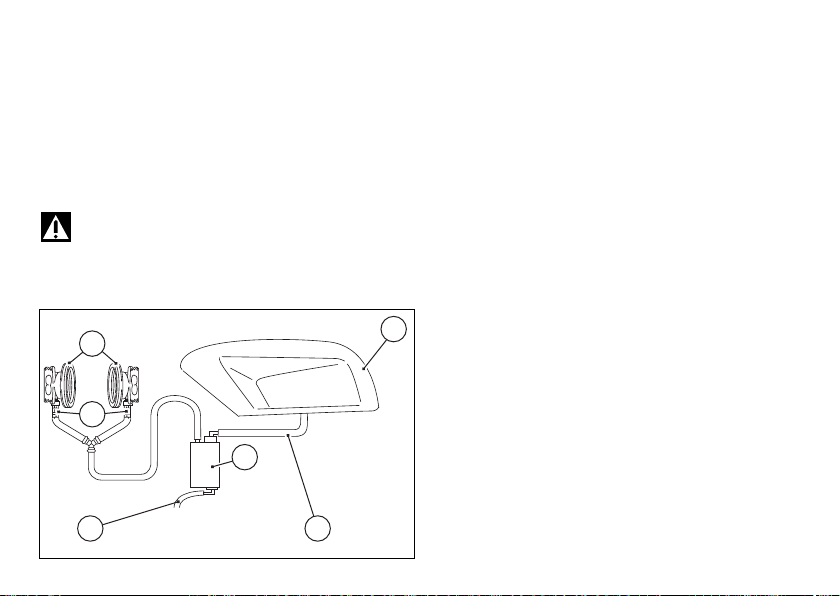

California evaporation emission system

1 5

3

6

2

4

CANISTER

fig. 11

This system consists of (fig. C):

1) Warn air inlet;

2) Canister;

3) Dell’Orto jet;

4) Fuel tank;

5) Breather pipe;

6) Intake manifolds.

Important

In the event of a fuel system malfunction,

contact a Ducati Authorized Service Center.

28

Ducati limited warranty on emission control system

Ducati North America, Inc., 10443 Bandley Drive

Cupertino, California, 95014 warrants that each new

1998 and later Ducati motorcycle, that includes as

standard equipment a headlight, taillight and

stoplight, and is street legal:

A) is designed, built and equipped so as to conform

at the time of initial retail purchase with all applicable

regulations of the United States Environmental

Protection Agency, and the California Air Resources

Board; and

B) is free from defects in material and workmanship

which cause such motorcycle to fail to conform with

applicable regulations of the United States

Environmental Protection Agency or the California Air

Resources Board for a period of use of 30,000

kilometers (18,641 miles) or 5 (five) years from the

date of initial retail delivery, whichever first occurs.

I. Coverage

Warranty defects shall be remedied during

customary business hours at any authorized Ducati

motorcycle dealer located within the United States of

America in compliance with the Clean Air Act and

applicable regulations of the United States

Environmental Protection Agency and the California

Page 31

Air Resources Board. Any part or parts replaced

under this warranty shall become the property of

Ducati.

In the state of California only, emissions related

warranted parts are specifically defined by that

state’s Emissions Warranty Parts List. These

warranted parts are: carburetor and internal parts;

intake manifold; fuel tank, fuel injection system;

spark advance mechanism; crankcase breather; air

cutoff valves; fuel tank cap for evaporative emission

controlled vehicles; oil filler cap; pressure control

valve; fuel/vapor separator; canister; igniters; breaker

governors; ignition coils; ignition wires; ignition

points, condensers, and spark plugs if failure occurs

prior to the first scheduled replacement, and hoses,

clamps, fittings and tubing used directly in these

parts. Since emission related parts may vary from

model to model, certain models may not contain all of

these parts and certain models may contain

functionally equivalent parts.

In the state of California only, Emission Control

System emergency repairs, as provided for in the

California Administrative Code, may be performed by

other than an authorized Ducati dealer. An

emergency situation occurs when an authorized

Ducati dealer is not reasonably available, a part is not

available within 30 days, or a repair is not complete

within 30 days. Any replacement part can be used in

an emergency repair. Ducati will reimburse the

owner for the expenses, including diagnosis, not to

exceed Ducati’s suggested retail price for all

warranted parts replaced and labor charges based on

Ducati’s recommended time allowance for the

warranty repair and the geographically appropriate

hourly labor rate. The owner may be required to keep

receipts and failed parts in order to receive

compensation.

II. Limitations

This Emission Control System Warranty shall not

cover any of the following:

A. Repair or replacement required as a result of

(1) accident,

(2) misuse,

(3) repairs improperly performed or replacements

improperly installed,

(4) use of replacement parts or accessories not

conforming to Ducati specifications which adversely

affect performance and/or

(5) use in competitive racing or related events.

B. Inspections, replacement of parts and other

services and adjustments required for routine

maintenance.

C. Any motorcycle on which odometer mileage has

been changed so that actual mileage cannot be

readily determined.

29

Page 32

III. Limited liability

A. The liability of Ducati under this Emission Control

Systems Warranty is limited solely to the remedying of

defects in material or workmanship by an authorized

Ducati motorcycle dealer at its place of business during

customary business hours. This warranty does not cover

inconvenience or loss of use of the motorcycle or

transportation of the motorcycle to or from the Ducati

dealer. Ducati shall not be liable for any other expenses,

loss or damage, whether direct, incidental, consequential

or exemplary arising in connection with the sale or use of

or inability to use the Ducati motorcycle for any purpose.

Some states do not allow the exclusion or limitation of

any incidental or consequential damages, so the above

limitations may not apply to you.

B. No express emission control system warranty is given

by Ducati except as specifically set forth herein. Any

emission control system warranty implied by law,

including any warranty of merchantability or fitness for a

particular purpose, is limited to the express emission

control systems warranty terms stated in this warranty.

The foregoing statements of warranty are exclusive and

in lieu of all other remedies. Some states do not allow

limitations on how long an implied warranty lasts so the

above limitation may not apply to you.

C. No dealer is authorized to modify this Ducati Limited

Emission Control Systems Warranty.

30

IV. Legal rights

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to

state.

V. This warranty is in addition to the Ducati limited

motorcycle warranty.

VI. Additional information

Any replacement part that is equivalent in

performance and durability may be used in the

performance of any maintenance or repairs.

However, Ducati is not liable for these parts. The

owner is responsible for the performance of all

required maintenance. Such maintenance may be

performed at a service establishment or by any

individual. The warranty period begins on the date the

motorcycle is delivered to an ultimate purchaser.

Ducati North America, Inc..

10443 Bandley Drive

Cupertino, California, 95014

Tel: 001.408.253.0499

Fax: 001.408.253.4099

E-mail: customerservice@ducatiusa.com

Web site: www.ducatiusa.com

Page 33

Instrument Panel (Dashboard)

2

1

5 8 6 3 4 57

fig. 12

Dashboard

1) LCD (see page 33)

2) REVOLUTION COUNTER (rpm).

Indicates engine revs per minute

3) NEUTRAL LIGHT N (GREEN).

Comes on when in neutral position.

4) LOW FUEL LIGHT (YELLOW).

Comes on when fuel is low and there is about a

gallon (3 liters) of fuel left in the tank.

5) TURN INDICATOR LIGHTS (GREEN).

Illuminates and flashes when the turn indicator is in

operation.

6) ENGINE OIL PRESSURE LIGHT (RED).

Comes on when engine oil pressure is too low. It

briefly comes on when the ignition is switched to ON

and normally goes out a few seconds after engine

starts.

May come on briefly when the engine is hot, but

should go off as the engine revs up.

Important

If this light (6) stays on, stop the engine or it may

suffer severe damage.

7) HIGH BEAM LIGHT (BLUE).

Comes on when high beam is on.

8) “ENGINE DIAGNOSIS - EOBD” LIGHT

(AMBER YELLOW).

The engine ECU illuminates this light to indicate

errors and consequent engine lock.

31

Page 34

9) “VEHICLE DIAGNOSIS” LIGHT.

9

10B 10C10A

fig. 13

A

12

B

11

fig. 14

Illuminates when the motorcycle diagnostics detects

a problem.

10)OVER REV LIGHT.

Light 10A: This light comes on steady at 800 rpm

below the limiter threshold.

Lights 10A steady + 10B: These lights come on

steady at 400 rpm below the limiter threshold.

Lights 10A + 10B + 10C: These lights come on

flashing when the limiter threshold is reached.

11) CONTROL SWITCH.

Button used to display and set dashboard parameters

with two positions A “▲“ and B “▼“.

12) HIGH-BEAM FLASH BUTTON FLASH (fig. 14).

The high-beam flash button may also be used to

control the LAP functions and the instrument panel

DDA data logger.

32

Page 35

LCD unit functions

fig. 15

Warning

Adjustments/settings on the dashboard are

strictly to be carried out when the motorcycle is

stationary. Never operate the dashboard controls

while riding the motorcycle.

1) SPEEDOMETER.

Indicates road speed

2) ODOMETER.

Gives total distance covered.

3) TRIP METER.

Indicates distance covered since the meter (TRIP A

and TRIP B) was last reset.

4) TRIP FUEL METER.

Gives total distance traveled on fuel reserve.

5) CLOCK.

6) LAP TIMER.

7) ENGINE RPM INDICATOR (RPM).

8) LAP TIME, TOP SPEED AND MAXIMUM RPM

RECORDING (LAP).

9) BATTERY VOLTAGE INDICATOR (BATT).

10)AIR TEMPERATURE INDICATOR.

11)WATER TEMPERATURE INDICATOR.

Indicates engine coolant temperature.

7

2 3 4

5

1 6

12

8

9

10

11

Important

Stop riding if the temperature reaches the

maximum value, otherwise the engine might be

damaged.

12)SERVICE WARNING (SERV).

The “SERV” message indicates that the vehicle has

covered the distance corresponding to a Scheduled

Maintenance interval. The message is displayed only

at Key-On for 5 seconds. The service indicator will be

reset at an Authorized Ducati Service center during

servicing.

33

Page 36

Important

The instrument panel allows the diagnosis of

the electronic ignition/injection system. Never use

the menus reserved for trained personnel for any

reason. If this function is accidentally accessed, turn

the key to OFF and contact a Ducati Dealer or

Authorized Service center for the necessary checks.

34

Page 37

LCD – How to set/display parameters

ENGINE OFF

ENGINE OFF

ENGINE OFF ENGINE OFF

ENGINE OFF

ENGINE ON

fig. 16

At key-on (key turned from OFF to ON) the

Dashboard activates all the digits of the LCD for 1

second and switches on the indicator lights in

sequence.

It then switches to “normal“ display mode showing

the model indication in place of the odometer readout

and the version (EU, UK, USA, CND, FRA, JAP) for 2

seconds, in place of the road speed readout.

Model is displayed as “scrolling“ text until the engine

is started.

35

Page 38

At Key-On, the Dashboard always shows the

A

B

1

fig. 17

following information (de-activating any previously

activated functions):

ODOMETER

AIR TEMPERATURE.

CLOCK

SPEED

COOLANT TEMPERATURE

ENGINE RPM

At this point, with the button (1, fig. 8) in position B

“▼“, the Odometer readout (TOT) will cycle through

the following functions:

TRIP A

TRIP B

TRIP FUEL (only if active)

until cycling back to the ODOMETER (TOT) function.

ERASE USB

TIME SET

CODE (only if active)

Pressing button (1, fig. 8) in position A “▲“ gives

access to the MENU and the following functions are

displayed one after another:

ERROR (only if at least one error is present)

BATT

RPM

LAP (OFF or ON)

LAP MEM

USB (OFF or ON)

36

Important

This menu is active only if the speed of the

motorcycle is less than 12.4 mph (20 km/h). If this

MENU is open and the speed of the motorcycle

exceeds 12.4 mph (20 km/h), the instrument panel

automatically exits the menu and returns to the initial

display. It is possible to exit the MENU at any time,

however, by pressing button (1, fig. 8) in position A

“▲“, for 3 seconds.

Page 39

Total distance covered indicator:

fig. 18

vs. EU, CND, FRA, JAP

vs. UK, USA

“Odometer“

This function shows the total distance covered by the

vehicle.

This function shows the total distance covered by the

vehicle.

At Key-On the system automatically enters this

function.

The odometer reading is stored permanently and

cannot be reset.

If the distance traveled exceeds 99999 mi (or 99999

km), the value “99999” will be displayed

permanently.

37

Page 40

Air temperature indicator

fig. 19

Diagnosis

Engine

Diagnosis

Engine

vs. EU, CND, FRA, JAP

vs. UK, USA

This function shows the external temperature.

Display limits: -38.2°F to +255.2°F (-39°C to +124°C)

In the event of a sensor FAULT (-40°F/-40°C, 257°F/

+125°C or disconnected), a string of dashes “- - -”

(not flashing) is displayed and the “Engine Diagnosis

- EOBD” light comes on (8, fig. 4).

38

Page 41

Vehicle speed indication

fig. 20

vs. EU, CND, FRA, JAP

vs. UK, USA

This function shows vehicle speed.

The instrument panel receives the actual speed value

(expressed in km/h) from the ECU and displays the

value increased by 8%.

Maximum speed displayed is 186 mph (299 km/h).

Over 186 mph (299 km/h) the instrument panel

displays the dashes “- - -” (not flashing).

39

Page 42

Engine coolant temperature indicator

fig. 21

Engine

Diagnosis

STEADY READING

STEADY READING

STEADY READING

FLASHING DATUM

FLASHING DATUM

STEADY READING

STEADY READING

STEADY READING

FLASHING DATUM

FLASHING DATUM

Engine

Diagnosis

vs. EU, CND, FRA, JAP

vs. UK, USA

Indicates engine coolant temperature.

- If reading is -40 °F (-40 °C) or less, the display

shows a string of flashing dashes (“- - -“) and the

“Engine diagnosis - EOBD“ light (8, fig. 4) comes

on;

- if the reading is between -38°F and +102°F (-39°C

and +39°C) “LO” is shown on the dashboard

(steady);

- if the reading is between +104°F and +248°F

(+40°C and +120°C) the reading appears on the

dashboard (steady);

- if the reading is between +250°F and +255°F

(+121°C and +124°C) “HI” is shown on the

dashboard (flashing);

- If reading is +257 °F (+125 °C) or more, the

display shows a string of flashing dashes (“---“)

and the “Engine diagnosis - EOBD“ light (9, fig. 4)

comes on;

- In the event of a sensor “error“, a string of

flashing dashes (“---“) is shown and the “Engine

diagnosis - EOBD“ light comes on (8, fig. 4).

40

Page 43

Partial trip meter “TRIP A”

fig. 22

vs. EU, CND, FRA, JAP

vs. UK, USA

This function shows the partial distance covered by

the vehicle.

Holding the button (1, fig. 8) pressed for 3 seconds in

position B “▼” when this function is displayed resets

the trip meter.

When the reading exceeds 999.9, distance traveled

is reset and the meter automatically starts counting

from 0 again.

41

Page 44

Partial trip meter “TRIP B“

fig. 23

vs. EU, CND, FRA, JAP

vs. UK, USA

This function shows the partial distance covered by

the vehicle.

Holding the button (1, fig. 8) pressed for 3 seconds in

position B “▼” when this function is displayed resets

the trip meter.

When the reading exceeds 999.9, distance traveled

is reset and the meter automatically starts counting

from 0 again.

42

Page 45

Distance traveled on fuel reserve:

fig. 24

vs. EU, CND, FRA, JAP

vs. UK, USA

“TRIP FUEL“

This function shows the distance traveled on fuel

reserve.

When the fuel light comes on, the display

automatically switches to the “TRIP FUEL“ indicator.

Trip fuel reading remains stored even after Key-Off

until the vehicle is refueled.

Count is interrupted automatically as soon as fuel is

topped up to above minimum level.

When the reading exceeds 999.9, the counter is

reset and the count restarts automatically.

43

Page 46

Maintenance indicator (SERV)

fig. 25

It shows service intervals (service).

The message “SERV” is displayed at the following

intervals:

after the first 621 mi (1000 km) on the odometer;

every 7456 mi (12000 km) on the odometer.

The message is displayed only at Key-On for 5

seconds.

When the service indicator appears, contact a Ducati

Dealer or Authorized Service center.

44

Page 47

Battery voltage indicator (BATT).

STATUS 1

STATUS 2

STATUS 3

STEADY STEADY

FLASHING FLASHING

FLASHING FLASHING

fig. 26

This function describes the battery voltage indicator.

To display this function, go into the menu and select

the “BATT” page.

The dashboard displays the battery voltage

information as follows:

- if voltage is between 12.1 and 14.9 Volt, the

reading is on steady;

- if voltage is between 10.0 and 12.0 Volt or

between 15.0 and 16.0 Volt, the reading will be

flashing;

- if battery voltage is equal or less than 9.9 Volt,

“LO“ is shown flashing and the “Vehicle

Diagnosis“ light comes on (9, fig. 4);

- if battery voltage is equal or greater than 16.1 Volt,

“HI“ is shown flashing and the “Vehicle

Diagnosis” light comes on (9, fig. 4).

45

Page 48

Engine idle RPM setting (RPM)

fig. 27

This function describes engine idle setup.

To display this function, go into the menu and select

the “RPM” page.

In addition to the upper rev counter scale, the

instrument panel also displays engine rpm

numerically so that you can adjust the idle speed

more precisely.

46

Page 49

LAP timer

fig. 28

This function lets you display lap times.

To enable this function, enter the menu and set the

LAP function to “On“ by holding button (1, fig. 8) in

position B “▼“ pressed for 3 seconds.

The lap timer is started and stopped using the highbeam flasher button FLASH (12, fig. 5) on the LH

switch.

When the LAP function is active, each time you press

the FLASH button, the display will show the lap time

for 10 seconds, before reverting to normal mode.

You can save a maximum of 30 laps in the memory.

Once the memory is full, the display no longer stores

lap times when the FLASH headlight button is

pressed, and the flashing message “FULL” is shown

on the display for 3 seconds until the times are reset.

47

Page 50

When the LAP function is set to Off in the menu, the

fig. 29

Press Flash

After 10 secs.

Press Flash

After 10 secs.

current “lap“ is not stored.

If the LAP function is active and the display is

suddenly turned off (Key-Off), the LAP function will

be automatically disabled (even if the lap timer was

active, the current “lap“ is not stored).

In case the time is never “stopped“, after 99

minutes, 59 seconds, 99 hundredths, the timer starts

from 0 (zero) and the time counting continues until

the function is disabled.

If however the LAP function is switched on and the

memory has not been cleared, but fewer than 30 laps

have been saved (e.g. 18 laps), the instrument panel

will store any remaining laps until the memory is full

(in this case, it will store an additional 12 laps).

This function only displays lap times; but other data

are also saved (MAX speed, MAX rpm, rev limiter if

reached) for viewing at a later date in the Lap

Memory function.

48

Page 51

Stored data display (LAP Memory)

A

B

B

A

A

A

B

B x 19

B x 19

fig. 30

B = ON for 3

secs.

Resets lap

times in

memory

It displays data stored using the LAP function: lap

time, MAX speed and MAX rpm.

To view stored lap times, enter the menu and go to

page “LAP MEM“.

Holding button (1, fig. 8) in position B “▼“ pressed

for 3 seconds in this menu page accesses the “1st

lap“ view mode. The display will show the lap

number, lap time, the MAX speed and the MAX rpm

reached for the lap in question.

Press button (1, fig. 8) in position B “▼“ repeatedly

to scroll through the 30 laps stored until returning to

the 1st lap.

If you press button (1, fig. 8) in position B “▼“ for 3

seconds while the saved times are displayed, the

display immediately resets all the saved times and

the LAP function is disabled automatically, if active.

The MAX speed saved is the maximum speed

indicated on the display in Lap function.

If MAX speed reading exceeds 186 mph (299 Km/h)

while the information is stored, actual speed reading

is displayed (example: 316 Km/h).

If the memory is empty, the display shows the 30 lap

times with the lap timer reading “00.00.00”, MAX

RPM = 0 and MAX speed = 0.

49

Page 52

If the engine reached one of the two thresholds

before the limiter or the limiter threshold during a lap,

the corresponding lights (10, fig. 4) come on while

viewing stored lap times.

50

Page 53

DDA data acquisition

fig. 31

This function activates the DDA analyzer (not fitted

for this model, but available at Ducati sales network):

the data logger must be connected to vehicle wiring.

To enable this function, enter the menu and set the

“DDA“ data acquisition to “On“ by holding the

button (1, fig. 8) in position B “▼“ pressed for 3

seconds. The START/STOP control for the data

logger lap separator is the high-beam flash button

FLASH (12, fig. 5) on the LH switch. If the DDA

function is active and the display is suddenly

switched off (Key-Off), the function is switched off

automatically.

Note

Online assistance is available to Ducati Data

Analyzer (DDA) owners (http://dda.prosa.com). This

service will provide anything necessary to correctly

use the DDA with your PC: both for the device and

the software for analyzing the recorded data.

Warning

After use, disconnect the DDA from the main

wiring harness.

51

Page 54

Erase DDA

DDA = ON

fig. 32

Displayed for 2 secs.

Displayed for 10 secs.

Displayed for 2 secs.

B = ON for 3 secs.

YES

NO

This function deletes all data from the DDA (not fitted

for this model, but available at Ducati sales network):

the data logger must be connected to vehicle wiring.

To erase data, enter the menu page “Erase DDA“.

If you press button (1, fig. 8) in position B “▼“ for 3

seconds and the DDA is not acquiring data, the

message “WAIT…” is shown on the display for 10

seconds; after these 10 seconds, message “Erase

OK“ is displayed for 2 seconds to confirm that the

data in the DDA data logger have been erased.

If the button (1, fig. 8) is pressed in position B “▼“

for 3 seconds while the DDA data logger is acquiring

data, the data logger memory is not erased and the

display shows message “FAIL“ for 2 seconds.

52

Page 55

Clock setting function

fig. 33

B = ON for 3 secs.

Flashing

Flashing

Flashing

Flashing

Flashing

Flashing

This function is used to set the clock time.

To set the clock, select the “TIME SET” page from

the menu.

Holding button (1, fig. 8) in position B “▼“ pressed

for 3 seconds in this menu page gives access to the

setup mode.

When you access this function, the text “AM“

flashes; if you press button (1, fig. 8) in position B

“▼” the text “PM” flashes; if you press button (1,

fig. 8) in position B “▼” mode will go back to

previous setting (if it is 00:00, when toggling from

“AM” to “PM”, 12:00 will be displayed).

pressing button (1, fig. 8) in position A “▲” accesses

the hour setting mode; the hours start to flash. Each

time you press the button in position B “▼“ the digit

will increase by 1 hour; if the button is held pressed

down in position B “▼“, the digit will increase by 1

hour every second (when the button is held pressed,

the hours do not flash).

B

B

B

B

B

B

A

A

A

A

A

Pressing button (1, fig. 8) in position A “▲”, gives

access to the minute setting mode; minutes start to

flash. Each time you press the button in position B

“▼“, the digit will increase by 1 minute. If you hold

the switch down in position B “▼”, the count

increases cyclically in steps of 1 minute every

A

53

Page 56

second. If the button is held depressed in position B

“▼“ for over 5 seconds, minutes will increase by 1

minute every 100 ms (while the button is held

depressed in position B “▼“ seconds do not flash).

Pressing the button in position A “▲” exits setup

mode and the new time is displayed.

54

Page 57

Dashboard diagnosis

Important

The instrument panel runs system diagnostics

after 60 seconds from the last Key-Off.

Any abnormal vehicle behavior is displayed.

If more errors are present, they are displayed one by

one every 3 seconds.

The table below shows the errors that can be

displayed.

Warning

When one or more errors are displayed, always

contact a Ducati Dealer or Authorized Service Center.

WARNING

LIGHT

ERROR MESSAGE ERROR

COIL 8.1 Horizontal cylinder coil error

COIL 8.2 Horizontal cylinder coil error

COIL 9.1 Vertical cylinder coil error

COIL 9.2 Vertical cylinder coil error

COIL 10.1 Horizontal cylinder coil error

55

Page 58

WARNING

LIGHT

56

ERROR MESSAGE ERROR

COIL 10.2 Horizontal cylinder coil error

COIL 11.1 Vertical cylinder coil error

COIL 11.2 Vertical cylinder coil error

INJE 12.1 Horizontal cylinder injector error

INJE 12.2 Horizontal cylinder injector error

INJE 13.1 Vertical cylinder injector error

INJE 13.2 Vertical cylinder injector error

INJE 14.1 Horizontal cylinder injector error

INJE 14.2 Horizontal cylinder injector error

INJE 15.1 Vertical cylinder injector error

Page 59

WARNING

LIGHT

ERROR MESSAGE ERROR

INJE 15.2 Vertical cylinder injector error

PUMP 16.0 Fuel pump relay error

FAN 18.1 Fan relay error

FAN 18.2 Fan relay error

STRT 19.1 Solenoid starter error

STRT 19.2 Solenoid starter error

STEP. 21.1 Stepper motor error

STEP. 21.2 Stepper motor error

STEP. 21.3 Stepper motor error

LAMB. 22.1 Lambda heaters error

57

Page 60

WARNING

LIGHT

58

ERROR MESSAGE ERROR

LAMB. 22.2 Lambda heaters error

EXVL 23.1 Exhaust valve motor error

EXVL 23.2 Exhaust valve motor error

EXVL 23.3 Exhaust valve motor error

EXVL 23.4 Exhaust valve motor error

TPS 1.1 Throttle position sensor error

TPS 1.2 Throttle position sensor error

PRESS 2.1 Pressure sensor error

PRESS 2.2 Pressure sensor error

T. WAT 3.1 Water temperature sensor error

Page 61

WARNING

LIGHT

ERROR MESSAGE ERROR

T. WAT 3.2 Water temperature sensor error

AIR 4.1 Air temperature sensor error

AIR 4.2 Air temperature sensor error

BATT 5.1 Battery voltage error

BATT 5.2 Battery voltage error

LAMB 6.1 Lambda sensor error

TILT 6.2 Lambda 2 sensor error

DTC 8.0 Traction control unit error

ECU 30.0 Engine control unit error

PK.UP 34.0 pick up sensor error

59

Page 62

WARNING

LIGHT

60

ERROR MESSAGE ERROR

SPEE. 36.0 Speed sensor error

IMMO 37.0 Immobilizer error

IMMO 37.1 immobilizer error

IMMO 37.3 Immobilizer error

IMMO 37.5 Immobilizer error

CAN 38.0 CAN communication line error

Page 63

Instrument panel backlighting

The instrument panel backlighting is always activated

by Key-On.

The instrument panel is equipped with sensors that

detect the ambient light level and at night reduce the

maximum backlighting level by 20% to prevent glare.

Headlight “smart” auto-off

This function allows you to reduce current

consumption from the battery by automatically

managing headlight switching-off. The device is

enabled in three instances:

- In case 1, when the key is turned from OFF to ON

and the engine is not started within 60 seconds,

the headlight is turned off and will be turned back

on next time you start the engine.

- In case 2, after the vehicle has been running with

the headlights on and the engine is stopped using

the RUN-STOP button on the RH switch.

In this case, 60 seconds after stopping the engine,

the headlight is turned off and will be turned back

on next time you start the engine.

- In case 3, when starting up the engine, the

headlight is turned off and back on as soon as the

engine is started.

Headlight “smart” switch-on

This function allows programmed activation of the

headlight even with the motorcycle off (Key-Off).

The instrument panel stays active for 60 seconds

soon after Key-Off, and the headlight can be

switched on by pressing switch (1, fig. 8) in position

B “▼”.

During these 60 seconds, each time the button (1,

fig. 8) is pressed in position B “▼“, the instrument

panel allows to activate the headlight for 30 seconds;

each time the button is pressed, the activation time

will be added up, up to a maximum of 180 seconds,

corresponding to pressing the button (1, fig. 8) in

position B “▼” 6 times.

After the first time you press switch (1, fig. 8) in

position B “▼”, the period of 30 seconds starts, thus

switching on the headlight. Further switch-on time

can be added only if you press the switch again

within these 30 seconds. If the 30 seconds have

elapsed, no further time can be added, and the

instrument panel will switch off the headlight.

61

Page 64

To reset this function, you must perform at least one

Key-On/ Key-Off cycle.

If there is a sudden battery cutoff while the function

is active, the instrument panel will disable the

function when the voltage is restored (the instrument

panel is disabled for 60 seconds).

62

Page 65

The Immobilizer system

B

1

fig. 34

For improved antitheft protection, the motorcycle is

equipped with an IMMOBILIZER, an electronic

system that inhibits engine operation whenever the

ignition switch is turned off.

Housed in the handgrip of each ignition key is an

electronic device that modulates an output signal.

When the ignition is turned on this signal is

generated by a special antenna incorporated in the

switch and changes every time. The modulated

signal represents the “password” (which is changed

at each start-up) by which the ECU recognizes the

ignition key. The ECU will only allow the engine to

start if it recognizes this password.

Keys (fig. 34)

The Owner receives a set of keys comprising:

- 2 (BLACK) keys B

These keys contain the “immobilizer system code“.

Note

Your Ducati dealer may ask you to produce your

Code Card in order to carry out certain servicing

operations.

The black keys (B) are regular ignition keys and are

used to:

- start up the engine.

- open the fuel tank filler plug.

- open the seat lock.

Note

The two keys have a small plate (1) attached

that reports their identification number.

Warning

Keep the keys separate, and store the tag (1) in

a safe place.

It is also advisable to use only one of the keys to start

the motorcycle.

63

Page 66

Code card

fig. 35

A

fig. 36

The CODE CARD (fig. 35) supplied with the keys

reports an electronic code (A, fig. 36) to start the

engine in the event it fails to start after KEY-ON

because the immobilizer system inhibited the

ignition.

Warning

Keep the CODE CARD in a safe place. However,

it is advisable to keep the electronic code printed on

the CODE CARD handy when you ride your

motorcycle, in case it is necessary to enable the

engine through the procedure described below. This

procedure lets you disable the “engine block”

function - indicated by the amber “Vehicle diagnosis“

light (9,fig. 12) coming on - in the event of problems

with the immobilizer system.

This operation is only possible if the electronic code

indicated on the code card is known.

Warning

Your dealer will ask you to produce the Code

Card in order to reprogram or replace a key.

64

Page 67

Immobilizer override procedure

A

A

A

A

A

B

B

B

B

B

B

B

B

B

fig. 37

B = ON for 3

secs.

Entered

code

OK?

No

Ye

Should the immobilizer LOCK (disable) the engine,

you can perform the “Immobilizer Override”

procedure from the instrument panel by entering the

relevant function as described below.

Enter the menu and go to page “CODE“.

Note

This menu should only be active when at least

one Immobilizer error is present.

This menu page shows a default “00000“ code. If

you press button (1, fig. 8) in position B “▼“ for 3

seconds, you will access the procedure for entering

the electronic code given on the Code Card.

65

Page 68

Entering the code:

when you access this function, the first digit on the

left will flash.

Button (1, fig. 8):

Each time you press the button in position B “▼“ the

digit will increase by one unit every second;

pressing the button in position A “▲” accesses

setting mode of the second digit which will start to

flash. Each time you press the button in position B

“▼“ the digit will increase by one unit every second;

pressing the button in position A “▲” accesses

setting mode of the third digit which will start to

flash. Each time you press the button in position B

“▼“ the digit will increase by one unit every second;

pressing the button in position A “▲” accesses

setting mode of the fourth digit which will start to

flash. Each time you press the button in position B

“▼“ the digit will increase by one unit every second;

pressing the button in position A,▲” accesses

setting mode of the fifth digit which will start to flash.

Each time you press the button in position B “▼“ the

digit will increase by one unit every second;

press in position A “▲” to confirm the code.

66

If the code has been entered correctly, the word

“CODE” and the code you just entered will flash for

4 seconds. The “Vehicle diagnosis“ light (9, fig. 4)

will turn off; the instrument panel automatically exits

the menu and the engine start-up inhibition is

temporarily overridden.

If the error is still present, at the next Key-On the

instrument panel error and the inhibited status will

persist.

If the code is not entered correctly, the instrument

panel reverts to the “CODE“ menu and displays the

default “00000“ code.

Page 69

Operation

When the ignition key is turned to OFF, the

immobilizer inhibits engine operation. When the

ignition key is turned back to ON to start the engine,

the following happens:

1) if the code is recognized, the immobilizer enables

engine ignition. Press the START button (2, fig. 43),

to start the engine;

2) if the “Vehicle diagnosis “ light (9, fig. 4) comes on

and the page with the message “Error IMMO“ is

displayed when you press button (1, fig. 8) in position

“▼“ it means that the code was not recognized.

When this is the case, turn the ignition key back to

OFF and then to ON again. If the engine still does not

start, try with another black key. If the other key does

not work out either, contact the Ducati Service

network.

Warning

Any important shock might damage the

electronic components fitted into the key.

Use only one key during the procedure. Failure to do

so might prevent the system from recognizing the

code of the key in use.

Duplicate keys

If you need any duplicate keys, contact the Ducati

Service network with all the keys you have left and

the CODE CARD.

The Ducati Service Center will program all the new

keys as well as any keys you already have.

You may be asked to provide proof that you are the

legitimate owner of the motorcycle.

The codes of any keys not submitted will be wiped

off from the memory to make those keys

unserviceable in case they have been lost.

Note

If you sell your motorcycle, do not forget to give

all keys and the CODE CARD to the new owner.

67

Page 70

Service menu - unit of measurement (UNIT SET)

This function allows you to select the units of

measurement displayed on the instrument panel.

To enter the service menu, push button (1, fig. 17) in

position A“▲” while turning the key from “Off“ to

“On“.

Note

Within this menu all other functions are

excluded and motorcycle starting is disabled.

The first function displayed is the “Immobilizer

Reprogramming” procedure (Cod REPR). Press the

button (1, fig. 17) in position A “▲” or B “▼” to

select the “Setting Special” (Set UNIT) function.

Now press button (1, fig. 17) in position B “▼“ for

3 seconds.

Each time you press button (1, fig. 17) in position B

“▼“ the instrument panel scrolls through the

following sequence of options, which flash on the

display:

68

UNIT OF MEASUREMENT

Country

standard

EU Km/h °C Km

EN Mph °C miles

USA Mph °F miles

CND Km/h °C Km

FRA Km/h °C Km

JAP Km/h °C Km

ECU ld. The instrument panel sets units of

If you press the button (1, fig. 17) in position B “▼“

for 3 seconds, the option currently displayed will be

saved to memory and the word “MEM” will appear.

Upon the following Key-On the instrument panel will

be set to the new settings.

Speed Air

temperature

measurement according to ECU

information

Odometer/

trip meters

Page 71

fig. 38

Key OFF to quit

press B for 3 sec.

Press A

Press B

press B for 3 sec.

press B for 3 sec.

press B for 3 sec.

press B for 3 sec.

press B for 3 sec.

press B for 3 sec.

Press B

Press B

Press B

Press B

Press A

Press A

Press A

Press A

Press A

69

Page 72

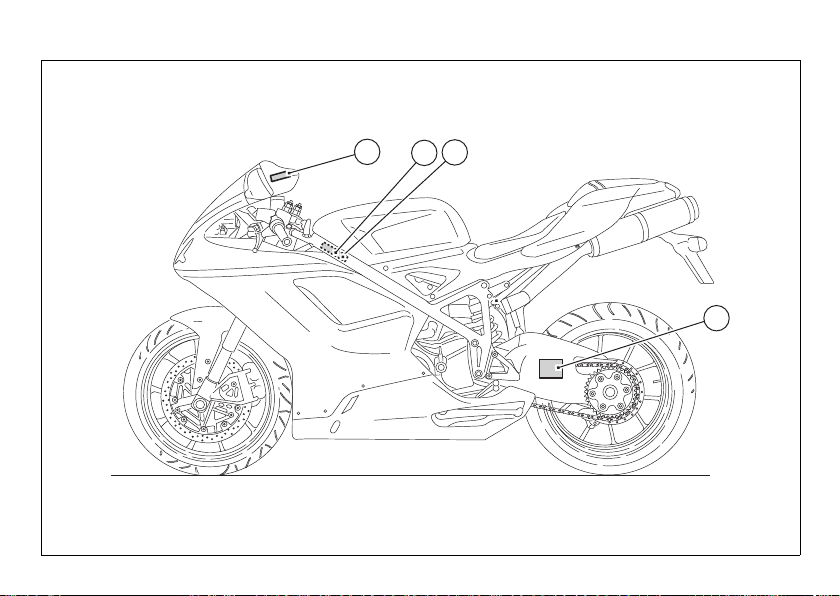

Controls

1

4

3

2

9

8

5

7

6

fig. 39

Warning

This section shows the position and function of

the controls used to ride the motorcycle. Be sure to

read this information carefully before you use the

controls.

Position of motorcycle controls (fig. 39)

1) dashboard.

2) Key-operated ignition switch and steering lock.

3) Left hand handlebar switch.

4) Clutch lever.

5) Rear brake pedal.

6) Right hand handlebar switch.

7) Throttle twistgrip.

8) Front brake lever.

9) Gear change pedal.

70

Page 73

Key-operated ignition switch and

A

B

C

D

fig. 40

steering lock

It is located in front of the fuel tank and has four

positions:

A) ON: enables lights and engine operation;

B) OFF: disables lights and engine operation;

C) LOCK: the steering is locked;

D) P: parking light on and steering locked.

(fig. 40)

Note

To move the key to the last two positions, press

it down before turning it. The key can be removed in

positions (B), (C) and (D).

71

Page 74

LH switch (fig. 41)

1 2

4

3 5

fig. 41

1) Dip switch, two-position light selector switch:

position = low beam on;

position = high beam on.

2) Button = three-position turn indicator:

central position = off;

position = left turn;

position = right turn.

To cancel turn indicators, push in once switch returns

to central position.

3) Button = warning horn.

4) Button = high-beam flasher (FLASH) and

instrument panel control.

5) Two-position instrument panel control switch:

position “▲”;

position “▼”.

72

Page 75

Clutch lever

2 1

fig. 42

Lever (1) disengages the clutch. It features a dial

adjuster (2) for lever distance from the twistgrip on

handlebar.

The lever distance can be adjusted through 10 clicks

of the dial (2). Turn clockwise to increase lever

distance from the twistgrip. Turn the adjuster counter

clockwise to decrease lever distance.

When the clutch lever (1) is operated, drive from the

engine to the gearbox and the drive wheel is

disengaged. Using the clutch properly is essential to

smooth riding, especially when moving off.

Warning

Set clutch lever when motorcycle is stopped.

Important

Using the clutch properly will avoid damage to

transmission parts and spare the engine.

Note

It is possible to start the engine with the side

stand down and the gearbox in neutral. When

starting the bike with a gear engaged, pull the clutch

lever (in this case the side stand must be up).

73

Page 76

RH switch (fig. 43)

3

1

2

fig. 43

1) ENGINE STOP switch, two positions:

position “ ” (RUN) = run;

position “ ” (OFF) = stop.

Warning

This switch is mainly intended for use in

emergency cases when you need to stop the engine

quickly. After stopping the engine, take the switch

back to the “ ” position to enable starting.

Important

Stopping the engine using switch (1) after riding

with the lights on and leaving the ignition key in the

ON position, may run the battery flat as the lights will

remain on.

2) Button = engine start.

Throttle twistgrip (fig. 43)

The twistgrip (3) on the right handlebar opens the

throttles. When released, it will spring back to the

initial position (idling speed).

74

Page 77

Front brake lever (fig. 44)

21

fig. 44

Pull in the lever (1) towards the twistgrip to operate

the front brake. The system is hydraulically operated

and you just need to pull the lever gently.

The control lever (1) features a dial adjuster (2) for

lever distance from the twistgrip on handlebar

adjustment.

The lever distance can be adjusted through 10 clicks

of the dial (2). Turn clockwise to increase lever

distance from the twistgrip. Turn the adjuster counter

clockwise to decrease lever distance.

75

Page 78

Rear brake pedal (fig. 45)

1

fig. 45

6

5

4

3

2

1

N

fig. 46

Push down on the pedal (1) to apply the rear brake.

The system is hydraulically operated.

Gear change pedal (fig. 46)

When released, the gear change pedal automatically

returns to rest position N in the center. This is

indicated by the dashboard light N (3, fig. 12) coming

on.

The pedal can be moved:

down = press down the pedal to engage the 1

and to shift down. The N light will go out;

upwards= lift the pedal to engage 2

rd

3

, 4th, 5th and 6th gears.

Each time you move the pedal you will engage the

next gear.

st

gear

nd

gear and then

76

Page 79

Setting the gear change and rear brake

2 1 3

fig. 47

pedals

The gear change and rear brake pedals can be

adjusted to suit the preferred riding position of each

rider.

To adjust the position, proceed as follows:

hold the linkage (1) and slacken the lock nuts (2) and

(3).

(fig. 47 and fig. 48)

Note

Nut (2) has a left hand thread.

Fit an open-end wrench to hexagonal element of

linkage (1) and rotate until setting pedal in the desired

position.

Tighten both check nuts onto linkage.

77

Page 80

To adjust the position, proceed as follows:

7

4

5

6

fig. 48

Loosen counter nut (4).

Turn pedal stroke adjusting screw (5) until pedal is in

the desired position.

Tighten the check nut (4) to 1.7 lbf-ft (2.3 Nm).

Operate the pedal by hand to check that there is

0.05÷0.07 in (1.5÷2 mm) of free play before the

brake bites.

If not so, set the length of cylinder linkage as follows.

Loosen the check nut (6) on cylinder linkage.

Tighten linkage into fork (7) to increase play, or

unscrew linkage to reduce it.

Tighten the check nut (6) to 5.5 lbf-ft (7.5 Nm) and

check free play again.

78

Page 81

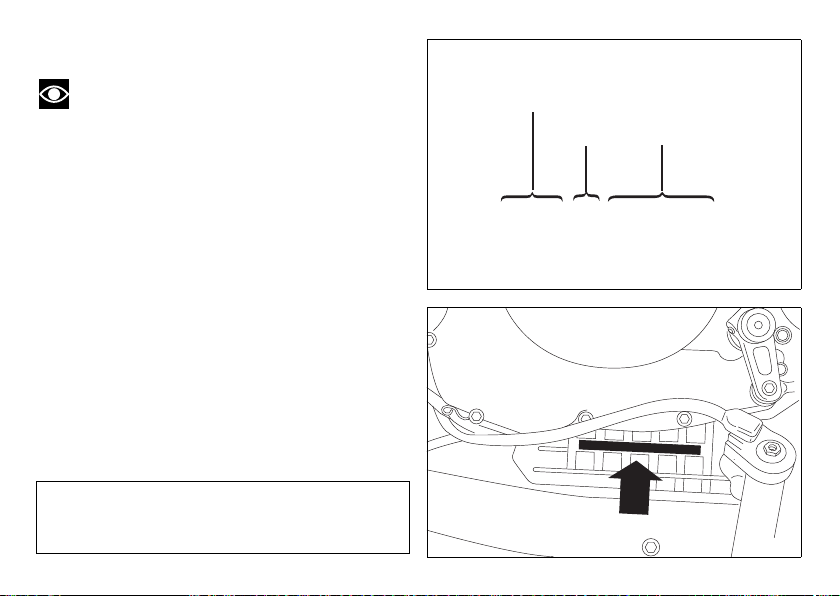

Main components and

3

4

15

6

5 2

8

6

7

9

fig. 49

devices

Position on the vehicle (fig. 49)

1) Tank filler plug.

2) Seat lock.

3) Side stand.

4) Steering damper

5) Rearview mirrors.

6) Front fork adjusters.

7) Rear shock absorber adjusters.

8) Exhaust muffler (see “Warning” on page 95).

9) Catalytic converter.

79

Page 82

Fuel tank plug (fig. 50)

1

fig. 50

Opening

Lift the protection lid (1) and fit the ignition key into

the lock. Turn the key clockwise 1/4 turn to unlock.

Lift the plug.

Closing

Refit the plug with the key in it and push it down into

its seat. Turn the key counter-clockwise to the initial

position and remove it. Close the lock protection lid

(1).

Note

The plug can only be closed with the key in.

Warning

Always make sure you have properly refitted

(see page 96) and closed the plug after refueling.

80

Page 83

Seat lock

2

1

1

1

0

0

fig. 51

3

4

5

fig. 52

Opening (fig. 51)

Insert the key into the seat lock (1) and turn it

clockwise until the seat catch disengages with an

audible click.

Moderately pull the rear end of the seat (2) up and

raise until it can be extracted.

Closing (fig. 52)

Insert the hooks (3) on the base of the seat under the

rear subframe.