Page 1

Use and maintenance manual

S2R 1000

E

1

Page 2

E

2

Page 3

We would like to welcome you among Ducati enthusiasts,

and congratulate you for choosing a Ducati motorcycle.

We are sure that you will use your Ducati motorcycle for

longer journeys as well as short daily trips, but however

you use your motorcycle, Ducati Motor Holding S.p.A

wishes you an enjoyable ride.

We are continuously working to improve our Technical

Assistance service. For this reason, we recommend

that you follow strictly the instructions in this manual,

especially those regarding the running-in period. In this

way, you can be sure your Ducati motorcycle will

continue to be a pleasure to ride.

For repairs or advice, please contact one of our authorized

service centres.

There is also an information service available to all

Ducati owners and enthusiasts for any advice and

suggestions you might need.

Notes

Ducati Motor Holding S.p.A. cannot accept any

liability for errors that may have occurred in the preparation

of this manual. All information in the manual was valid at

the time of going to print. Ducati Motor Holding S.p.A.

reserves the right to make any modifications required

due to the ongoing development of their products.

For safety and reliability, to avoid invalidating the warranty

and to maintain the value of your motorcycle, use only

original Ducati spare parts.

E

Enjoy the ride!

Warning

This manual is an integral part of the motorcycle and,

if ownership is transferred to a third party, must always

be passed to the new owner.

3

Page 4

Table of contents

E

General indications 6

Warranty 6

Symbols 6

Useful road safety information 7

Riding with a full load 8

Identification data 9

Front brake lever

Rear brake pedal

Gearchange pedal

Adjusting the position of the gearchange pedal

Adjusting the position of the rear brake pedal

23

24

24

25

26

Main components and devices 27

Position on motorcycle 27

Fuel tank filler cap

Seat lock and helmet holder

Sidestand

Front fork adjusters 31

Rear shock absorber adjusters

Changing motorcycle track alignment

30

28

29

33

35

Controls 10

Position of the motorcycle controls 10

Instrument panel

LCD functions 13

The immobilizer system 16

16

Keys

Code card 17

Procedure to override the immobilizer using the throttle

twistgrip 18

Duplicate keys 19

Ignition switch and steering lock

Left-hand handlebar switch

Clutch lever

Right-hand handlebar switch

Throttle twistgrip

4

21

11

20

21

22

22

Riding the motorcycle 37

Running-in recommendations 37

Pre-ride checks 38

Starting the engine 39

Moving off 41

Braking 42

Stopping the motorcycle 43

Refuelling 43

Parking 44

Toolkit and accessories

45

Main Maintenance Operations 46

Removing the fairing panels 46

Lifting the fuel tank

47

Page 5

Changing the air filter 48

Checking the brake and clutch fluid level

Checking the brake pads for wear

Lubricating cables and joints

Adjusting the throttle control cable

Charging the battery

Checking the drive chain tension

Lubrication of the drive chain 55

Replacing bulbs 56

Headlight aim

Tyres 61

Checking the engine oil level

Cleaning and renewing the spark plugs

General cleaning 65

Storing the motorcycle 66

Important notes 66

60

51

53

63

50

52

54

49

64

Maintenance 67

Programmed maintenance plan: operations to be carried out

by the dealer 67

Programmed maintenance plan: operations to be carried out

by the dealer 70

Technical data 71

Dimensions (mm) 71

Weights 71

Fuel, lubricants and other fluids 72

Engine 73

Timing system 73

Performance data 74

Spark plugs 74

Fuel system 74

Brakes 75

Transmission 76

Frame 77

Wheels 77

Tyres 77

Suspension 77

Exhaust system 78

Available colours 78

Electrical system 78

Routine servicing record 82

For United States of America

Version Only 83

Reporting of safety defects 83

Safety warnings 83

Noise emission warranty 83

Noise and exhaust emission control system information 83

Tampering warning 84

Riding safety 85

Protective apparel 86

Vehicle identification number (VIN) 86

Label location

California evaporation emission system

Ducati limited warranty on emission control system 89

87

89

Routine maintenance record 92

E

5

Page 6

General indications

E

Symbols

Ducati Motor Holding S.p.A. advises you to read this

manual carefully in order to familiarise yourself with your

motorcycle. If in doubt, please contact a Ducati Dealer or

Authorized Service Centre. The information in this manual

will help ensure that your riding experience is trouble-free

and enjoyable, and it will help you obtain top performance

from your motorcycle for a long time. This booklet uses a

set of symbols with special meanings:

Warranty

In your own interest, and in order to guarantee product

reliability, you are strongly advised to refer to a

Ducati Dealer or Authorized Workshop for servicing

that requires any particular technical expertise.

Our highly qualified staff have access to the specialised

tools required to perform any servicing job to the highest

professional standards, using only Ducati original spare

parts as the best guarantee for perfect interchangeability,

smooth running and long service life.

All Ducati motorcycles come with a “Warranty Booklet”.

However, the warranty does not apply to motorcycles

used in competitions. If any motorcycle part is tampered

with, modified, or replaced with parts other than original

Ducati spare parts during the warranty period, the

warranty will be automatically invalidated.

6

Warning

Failure to comply with these instructions may put

you at risk, and lead to severe injury or even death.

Important

Risk of damage to the motorcycle and/or its

components.

Notes

Additional information about the current operation.

References to the right or left side of the motorcycle

assume you are sitting on the seat, facing forward.

Page 7

Useful road safety information

Warning

Read this section before riding your motorcycle.

Many accidents are the result of the inexperience of the

rider. Always make sure you have your licence with you; you

need a valid licence that entitles you to ride a motorcycle.

Do not lend your motorcycle to persons that are

inexperienced or do not hold a valid licence.

Riders and passengers must always wear appropriate

clothing and a safety helmet.

Do not wear loose clothes or accessories that could

become tangled in the controls or limit your field of vision.

Never start or run the engine in an enclosed space.

Exhaust gases are poisonous and may lead to loss of

consciousness or even death within a short time.

The rider should keep his/her feet on the footrests when

the motorcycle is in motion.

Always hold the handlebars firmly with both hands so

you will be ready for sudden changes in direction or in the

road surface. The pillion passenger should always hold on

to the grabhandles under the seat with both hands.

Obey the legal requirements and observe national and

local regulations.

Always respect speed limits where these are indicated

and always adapt your speed to suit the current visibility,

road and traffic conditions.

Always signal your intention to turn or change lane in

good time, using the appropriate turn signal indicators.

Be sure you are clearly visible and avoid riding within the

blind spot of the vehicle in front of you.

Be very careful at road junctions, or when riding in areas

near exits from private land or car parks, or on the slip roads

to motorways.

Always turn off the engine when refuelling. Be extremely

careful not to spill fuel on the engine or on the exhaust

pipe when refuelling.

Do not smoke when refuelling.

While refuelling, it is possible to inhale noxious fuel vapours.

Should any fuel drops be spilled on your skin or clothing,

immediately wash with soap and water and change your

clothing.

Always remove the key if leaving your motorcycle

unattended.

The engine, exhaust pipes, and silencers remain hot for a

long time.

Warning

The exhaust system might still be hot even if the

engine is switched off; take special care not to touch

exhaust system with any part of your body and do not

park the motorcycle next to inflammable material (wood,

leaves etc.).

Park your motorcycle where no one is likely to knock

against it, and use the side stand.

Never park on uneven or soft ground, or your motorcycle

may fall over.

E

7

Page 8

Riding with a full load

Your motorcycle is designed for travelling over long

distances with a full load in complete safety.

Even weight distribution is critical for maintaining safety

standards, and to avoid getting into difficulties when

making sudden manoeuvres or riding on bumpy roads.

Information on load capacity

The total weight of the motorcycle in running order with

E

rider, luggage and additional accessories should not exceed

390 kg.

Arrange your luggage or heavy accessories in the lowest

possible position and close to the centre of the motorcycle.

Secure the luggage firmly to the motorcycle structure.

Luggage incorrectly secured may cause the motorcycle

to become unstable.

Never fix bulky or heavy objects to the top yoke or front

mudguard, as this would cause dangerous instability.

Do not insert objects into gaps in the frame, where they

could interfere with moving parts.

Check that the tyres are inflated to the pressure indicated

on page 61 and that they are in good condition.

8

Page 9

Identification data

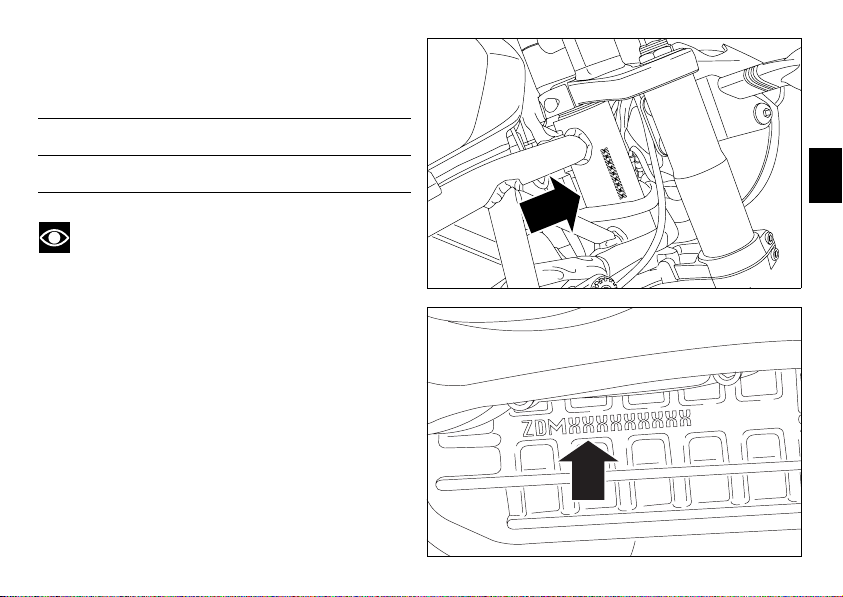

All Ducati motorcycles have two identification numbers,

one for the frame (fig. 1) and one for the engine (fig. 2).

Frame number

Engine number

Notes

These numbers indicate the motorcycle model, and

should be quoted when ordering spare parts.

E

fig. 1

fig. 2

9

Page 10

Controls

E

1

4

7

Warning

This section shows the position and function of the

controls used to drive the motorcycle. Be sure to read this

information carefully before you use the controls.

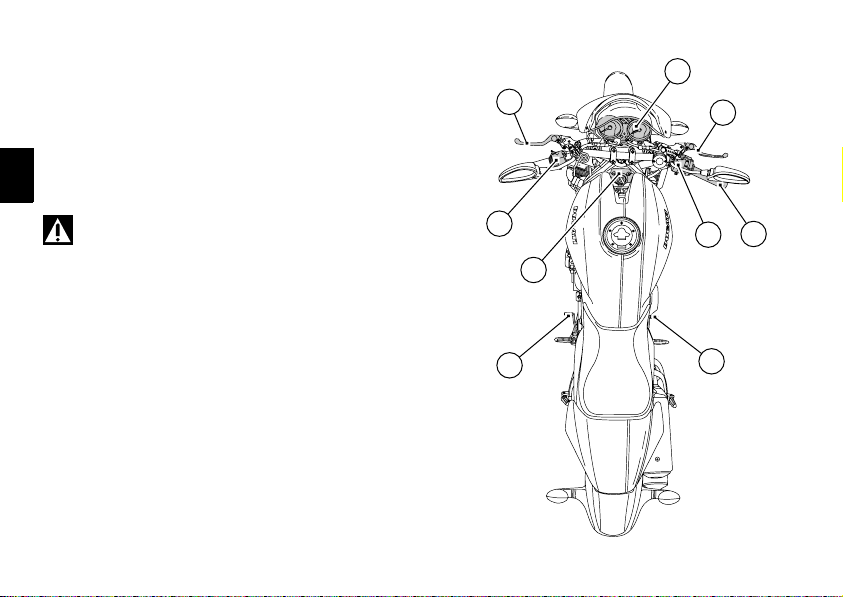

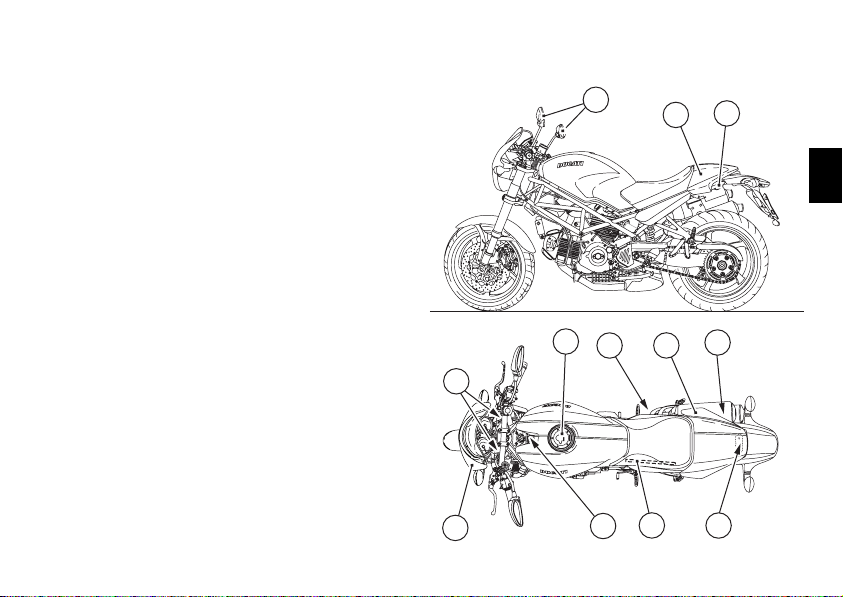

Position of the motorcycle controls (fig. 3)

1) Instrument panel.

2) Ignition switch and steering lock

3) Left-hand handlebar switch.

4) Clutch lever.

5) Right-hand handlebar switch.

6) Throttle twistgrip.

7) Front brake lever.

8) Gearchange pedal.

9) Rear brake pedal.

10

3

2

8

6

5

9

fig. 3

Page 11

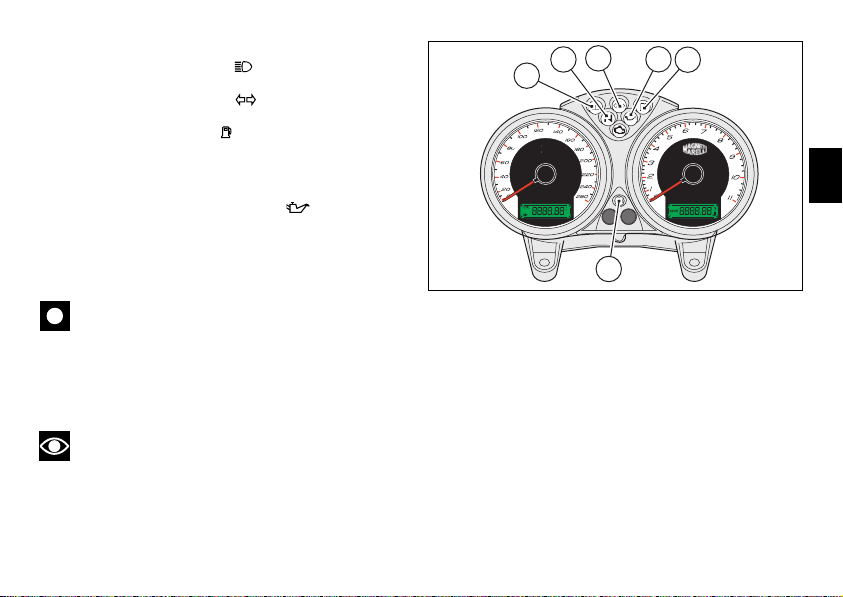

Instrument panel (fig. 4.1)

1) High beam warning light (blue).

Illuminates when the high beam headlight is on.

2) Turn signal warning light (green).

Flashes when a turn signal is on.

3) Low fuel warning light (yellow).

Illuminates when there are approximately 3 litres of fuel left

in the tank.

4) Neutral light N (green).

Illuminates when the gearbox is in neutral.

5) Engine oil pressure warning light (red).

Illuminates when engine oil pressure is too low. This light

comes on when the ignition is switched to ON and should

go out a few seconds after the engine starts.

It may come on briefly if the engine is very hot, but should

go out again as engine speed increases.

Important

Do not use the motorcycle if this light stays on,

otherwise the engine could be damaged.

6) Amber warning light

Comes on and flashes when the motorcycle is parked

(immobilizer on); also used for immobilizer diagnostics.

Notes

When the immobilizer is activated, the light flashes

for 24 hours after which it goes off, but the immobilizer

remains active.

2

4

1

5

3

E

6

fig. 4.1

11

Page 12

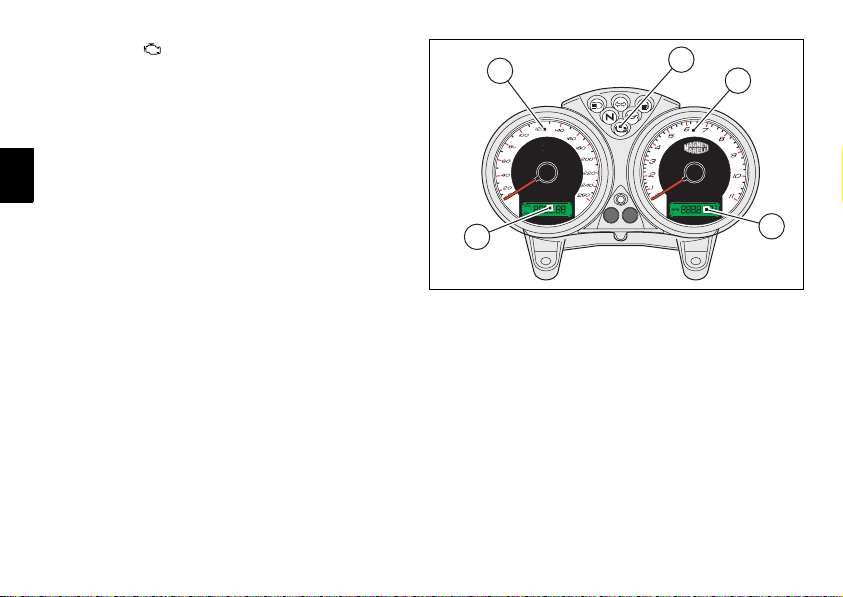

7) EOBD light (yellow amber).

Comes on when the engine is locked. Switches off after a

few seconds (normally 1.8 - 2 sec.).

8) Speedometer (km/h).

Indicates road speed.

a) LCD (1):

- Odometer (km).

Shows total distance travelled.

- Trip meter (km).

E

Shows distance travelled since last reset.

- Fuel reserve trip counter.

When the fuel level warning light is on, displays the

number of kilometres travelled in reserve.

9) Tachometer (rpm).

Indicates engine revs per minute.

b) LCD (2):

- Clock

- Oil temperature

12

8

a

7

9

b

fig. 4.2

Page 13

LCD functions

When the engine is switched on (key turned from OFF to ON),

the instrument panel checks all instruments (dials, display,

warning lights), see (fig. 5 and fig. 6).

LCD unit functions (1)

By pressing button (A, fig. 6) with the key turned to ON,

you can cycle between display of the trip counter and the

odometer and, if the fuel level warning light is on, the fuel

reserve trip counter.

Resetting the trip meter

If button (A, fig. 6) is held pressed for more than 2 seconds

while the TRIP (trip meter) is active, the display is reset

(LCD 1).

LCD unit functions (2)

If button (B, fig. 6) is pressed with the ignition key at ON,

the display shows the clock and the oil temperature.

Setting the clock

Press (B, fig. 6) for at least 2 seconds and the time will be

shown in display (b, fig. 4.2).

Select AM/PM by pressing button (A, fig. 6). Press button (B)

to select the hour setting function. Press (A) repeatedly to

change the hour indication. Press button (B) to change to

the minute setting function.

Press button (A) to increase the minutes; hold the button

pressed for more than 5 seconds to increase the rate of

change. Press button (B) to exit the clock setting function.

OFF

Km/h

-1

min

x1000

E

fig. 5

CHECK

1

A

B

2

fig. 6

13

Page 14

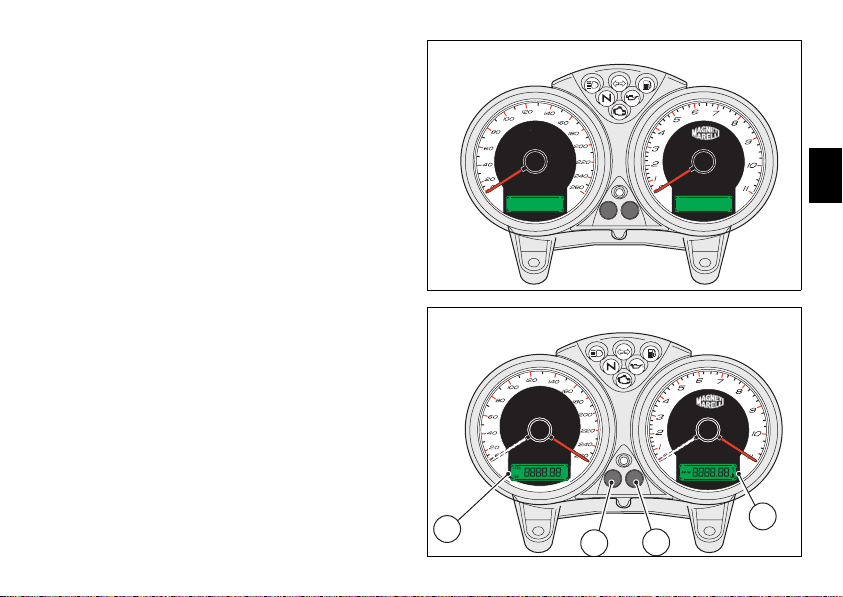

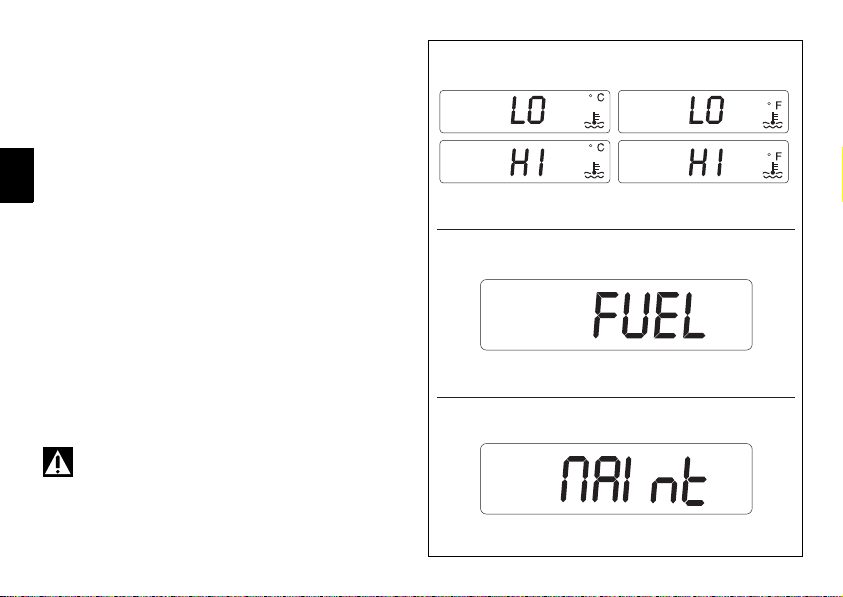

Oil temperature function

If the oil temperature falls below 50 °C /122 °F the word

“ LO” will be displayed, whereas if the temperature rises

above 170 °C/338 °F, the word “ HI” will appear.

Fuel level warning light

When the fuel level warning light illuminates the word

“ FUEL” appears on display (2, fig. 6) and the fuel

reserve trip counter function will be activated and indicate

E

on display (1, fig. 6) the number of kilometres travelled in

reserve preceded by the letter “F” (FUEL).

Maintenance indicator function

The “ MAInt” message on display (1, fig. 6) indicates that

the service interval has been reached: it will be displayed

for 5 seconds each time the ignition is switched ON.

When the “ MAInt” message is displ ayed, contact an

authorised dealer or service centre.

Display backlight

Press button (B, fig. 6) within 5 seconds after the ignition

key is turned to the ON position to adjust the brightness

of the backlight. The brightness changes at each press of

the button.

Warning

Any adjustments to the instrument panel must only be

carried out when the motorcycle is stationary. Never operate

the instrument panel controls while riding the motorcycle.

14

Page 15

Automatic headlight switch-off

This function helps reduce battery use by automatically

switching off the headlight.

The device is triggered in two cases:

- in the first case, if you turn the key from OFF to ON and

do not start the engine. After 60 seconds the headlight

will be deactivated and will only be reactivated the next

time the key is turned from OFF to ON or the engine is

started.

- in the second case, after normal use of the motorcycle

with the lights on, if the engine is killed using the

ENGINE STOP switch (1, fig. 12). In this case,

60 seconds after the engine is stopped, the headlight

will be turned off and will only be turned on again the

next time the engine is started.

Notes

Also during engine starting, the system turns the

headlight off and turns it back on once the engine has

started.

E

15

Page 16

The immobilizer system

For additional anti-theft protection, the motorcycle is

equipped with an IMMOBILIZER, an electronic system

that locks the engine automatically whenever the ignition

switch is turned off.

The handgrip of each ignition key contains an electronic

device that modulates the output signal from a special

antenna in the switch when the ignition is switched On.

The modulated signal represents the “password”

E

(which is changed at each start-up) by which the ECU

recognizes the ignition key. The ECU will only allow the

engine to start if it recognises this password.

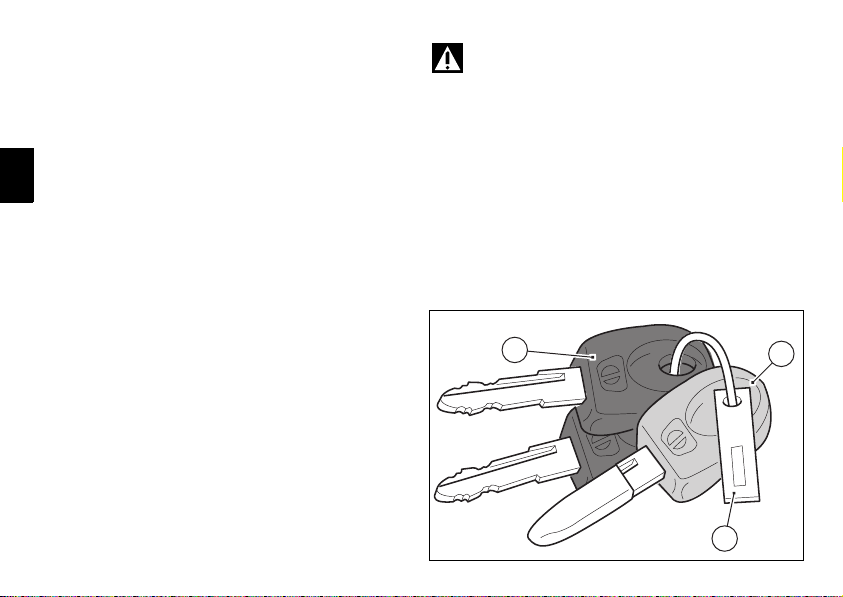

Keys (fig. 7)

The owner receives a set of keys, comprising:

- 1 key A (RED)

The red key is a service tool and is part of the

motorcycle’s immobilizer system. It contains the code

of the immobilizer system and should not be used for

normal everyday use of your motorcycle. Your dealer

may ask you to produce the red key in order to carry

out certain service operations. For security reasons,

the red key cannot be replaced. In cases where the red

key is required for servicing purposes and the owner is

unable to produce it, it will be necessary to renew the

motorcycle’s electronic control unit, instrument panel

and ignition switch assembly, and the cost of these

operations will be met by the owner. It is therefore

important to keep the red key in a safe place.

- 2 keys B (BLACK)

16

Warning

The red key (A) has a rubber sleeve to keep it in

perfect condition and to prevent contact with other keys.

Never remove this protection unless absolutely necessary.

The B keys are the keys for normal use, and are used to:

- start the engine

- open the lock on the fuel tank filler cap

- open the seat lock.

The A key performs all the same functions as the B keys

and it can also be used to reset and re-program other

black keys if necessary.

B

A

1

fig. 7

Page 17

Notes

The three keys have a small tag (1) attached, which

shows their identification number.

Warning

Keep the keys separate, and store the tag (1) and key A

in a safe place.

It is also advisable to use only one of the black keys to

start the motorcycle.

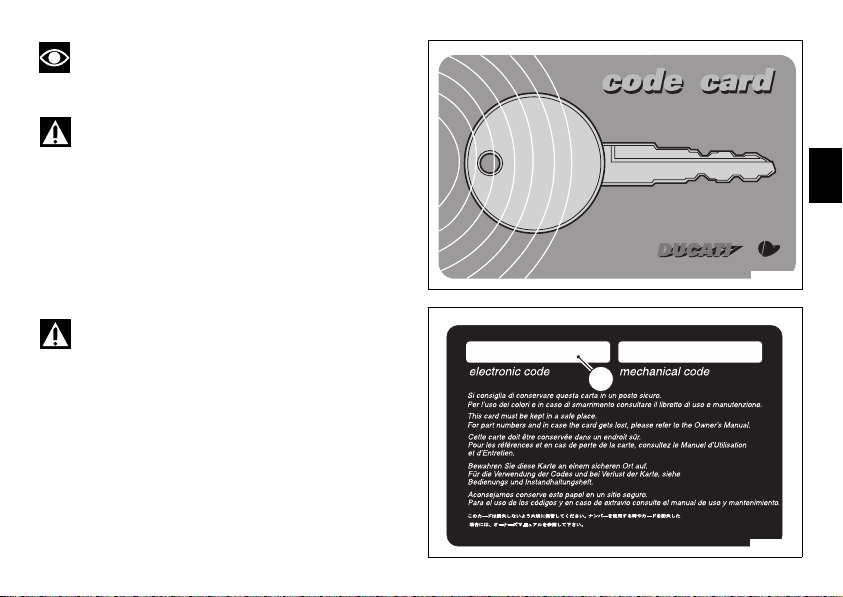

Code card

The keys come with a CODE CARD (fig. 8), which shows: the

electronic code (A, fig. 9) to be used if the engine is locked,

and if the engine fails to start when the key is at On.

Warning

Keep the CODE CARD in a safe place. It is advisable to

always carry the electronic code shown on the CODE CARD

with you when using the motorcycle, in case it is necessary

to override the engine immobilizer by means of the

procedure that uses the throttle twistgrip.

In the event of faults in the immobilizer system, the following

procedure makes it possible to disable the “engine lock”

function, which is indicated by the yellow-amber EOBD

warning light (7, fig. 4.1).

This operation is only possible with the electronic code

shown on the code card.

E

fig. 8

A

fig. 9

17

Page 18

Procedure to override the immobilizer

using the throttle twistgrip

1) Turn the key to ON, fully open the throttle and hold it open.

The EOBD warning light (7, fig. 4.1) goes off after the pre-set

time of 8 seconds.

2) Release the throttle twistgrip as soon as the EOBD light

goes off.

3) The EOBD light flashes. Now enter the electronic release

E

code shown on the CODE CARD given to the customer

when the motorcycle was handed over by the dealer.

4) Count a number of flashes of the EOBD (7, fig. 4.1)

light equal to the first number of the secret code.

Open the throttle twistgrip, hold fully open for 2 seconds,

then release it. The digit entered is acknowledged, and

the EOBD light comes on and stays on for the pre-set

time of 4 seconds. Repeat the operation until you have

entered the final digit.

If no operation is performed with the throttle twistgrip, the

EOBD light will flash 20 times and then illuminate steadily.

In this case, repeat the procedure from step (1).

5) When you release the throttle, if the code was entered

correctly, the EOBD light flashes to indicate that the

engine is unlocked. The EOBD light returns to its normal

state (off) after 4 seconds.

6) If the code has NOT been entered correctly, the EOBD

light remains lit and the procedure can be repeated as

many times as necessary by turning the key to OFF,

then re-starting from step (1).

18

Notes

If you release the twistgrip too soon, the warning

light comes on again. Return the ignition key to OFF and

repeat the procedure from step (1).

Page 19

Operation

When the ignition key is turned from ON to OFF, the

immobilizer system activates the engine lock. When the

ignition key is turned back to ON to start the engine, the

following happens:

1) if the code is recognized, the warning light (6, fig. 4.1) on

the instrument panel flashes briefly; the protection system

has recognized the code and disables the engine lock.

When you press the START (3, fig. 12) button, the engine

will start up.

2) If either the warning light (6, fig. 4.1) or the EOBD light

(7, fig. 4.1) remain lit, the code has not been recognized.

In this case, it is advisable to turn the ignition key back

to OFF and then to ON again. If the engine still does not

start, try using another black key.

If the engine still does not start, contact the DUCATI Service

network.

3) If the warning light (6, fig. 4.1) keeps flashing, it means that

an error signal from the immobilizer system has been cleared

(e.g. with the override procedure using the throttle twistgrip).

Turn the key to OFF and back to ON; the immobilizer light

should return to its normal state (see step 1).

Warning

Sharp knocks can damage the electronic components

inside the key.

Always use the same key during the procedure. The use of

different keys could prevent the system from recognizing

the code in the inserted key.

Duplicate keys

If you need additional keys, contact your DUCATI Service

Centre with all the keys you have in your possession and

your CODE CARD.

DUCATI Service will program new keys and re-program

your original keys (up to a maximum of 8 keys).

DUCATI Service may ask for proof that you are the

legitimate owner of the motorcycle.

The codes for any keys not present during the memory

programming procedure are cancelled, to ensure that any

keys that may have been lost can no longer be used to

start the engine.

Notes

If you sell your motorcycle, it is essential to transfer

all keys and the CODE CARD to the new owner.

E

19

Page 20

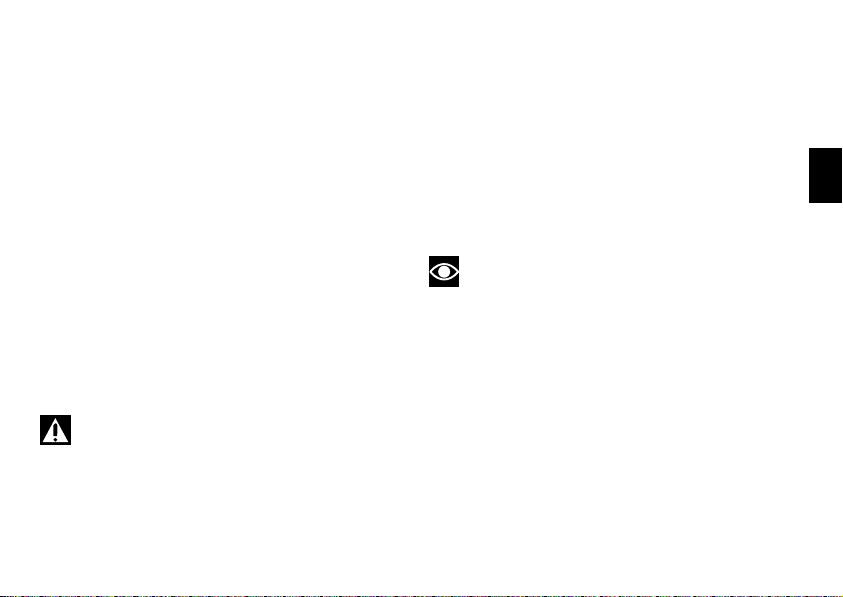

Ignition switch and steering lock (fig. 10)

This is located in front of the fuel tank and has four positions:

A) ON: enables lights and engine operation;

B) OFF: disables lights and engine operation;

C) LOCK: the steering is locked;

D) P: sidelight and steering lock.

E

Notes

To move the key to the last two positions, push it in

before turning. The key can be removed in positions (B), (C)

and (D).

20

B

C

D

A

fig. 10

Page 21

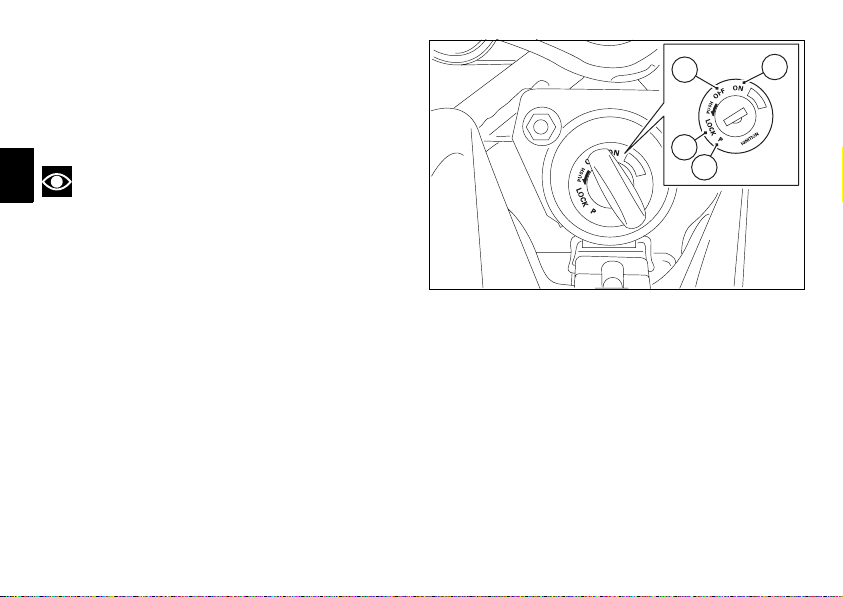

Left-hand handlebar switch (fig. 11)

1) Dip switch, two-position light selector switch:

position = low beam on;

position = high beam on.

2) Button = three-position turn signal:

centre position = off;

position = left turn;

position = right turn.

To cancel the turn signals, press the control switch once it

has returned to the central position.

3) Button = horn.

4) Button = high beam flasher.

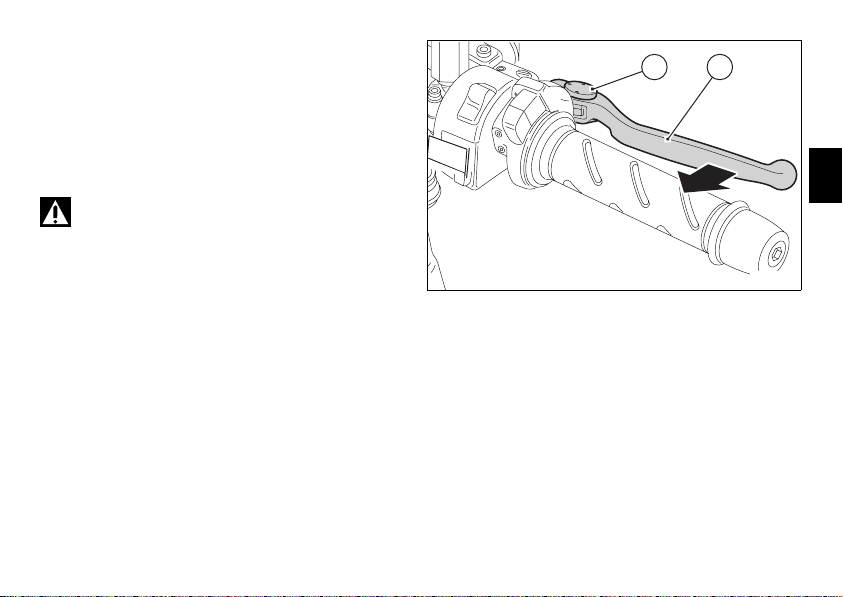

Clutch lever (fig. 11)

Lever (5) disengages the clutch. It features an adjuster

knob (6) to alter the distance of the lever from the

twistgrip on handlebar.

To make the adjustment, keep the lever (5) full forward and

adjust the knob (6), turning it to one of the four preset

positions, taking account of the fact that:

position n° 1 corresponds to the maximum distance

between the lever and grip, while position n° 4

corresponds to the minimum distance.

When the clutch lever (5) is operated, drive from the

engine to the gearbox and the rear wheel is disengaged.

Correct use of the clutch lever is very important in all

riding situations, especially when moving off.

6

4

5

1

2

3

fig. 11

Important

Using the clutch properly will prolong the life of the

engine and prevent any damage to components in the

transmission.

Notes

The engine can be started with the sidestand down

and the gearbox in neutral. If starting with a gear engaged,

pull in the clutch lever (in this case the sidestand must be up).

E

21

Page 22

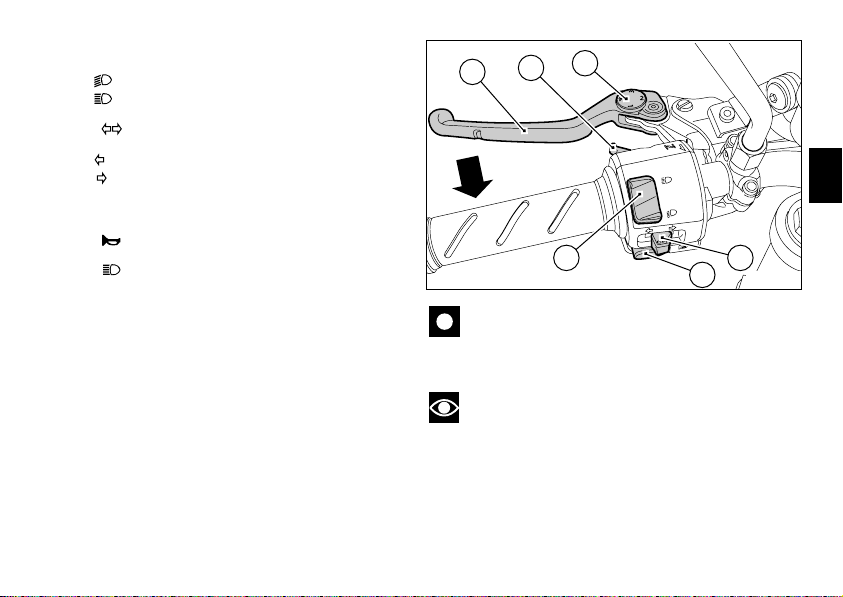

Right-hand handlebar switch (fig. 12)

1) Two-position ENGINE STOP switch:

position (RUN) = run;

position (OFF) = stop engine.

Warning

This switch is mainly intended for use in

emergencies when you need to stop the engine quickly.

E

After stopping the engine, return the switch to the

position to enable starting.

Important

Travelling with the headlight, switching off the engine

with switch (1) and leaving the ignition key in the ON position

can drain the battery, as the headlight remains on.

2) Button = engine start.

Throttle twistgrip (fig. 12)

The twistgrip (1) on the right handlebar opens the butterfly

valves in the throttle body. When released, the twistgrip

returns automatically to the initial position (idling speed).

22

1

2

3

fig. 12

Page 23

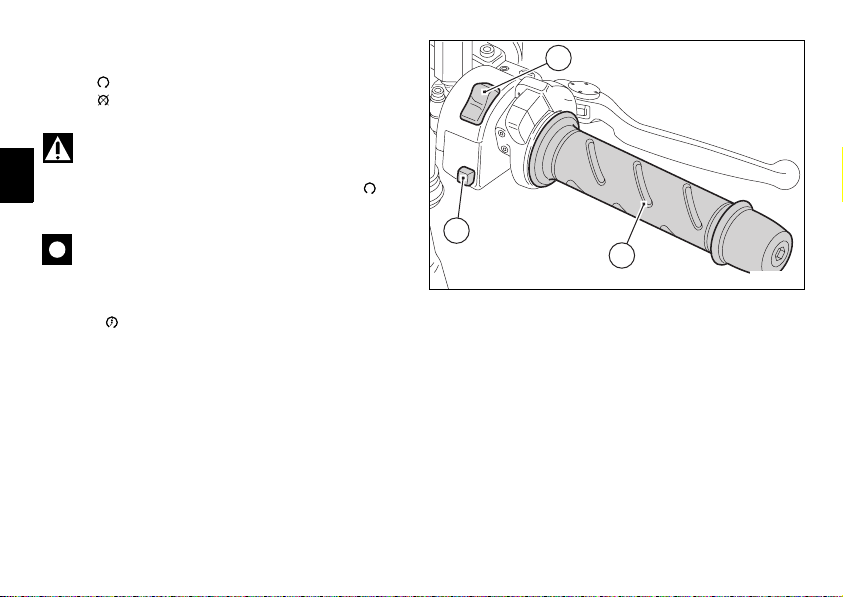

Front brake lever (fig. 13)

Pull in the lever (4) towards the twistgrip to operate the

front brake. The system is hydraulically assisted and you

only need to pull the lever gently.

The brake lever is provided with an adjuster (5) to alter the

distance between the lever and the twistgrip on handlebar.

Follow the same procedure as for the clutch control lever

(page 21).

Warning

Before using these controls, read the instructions on

page 41.

5

4

E

fig. 13

23

Page 24

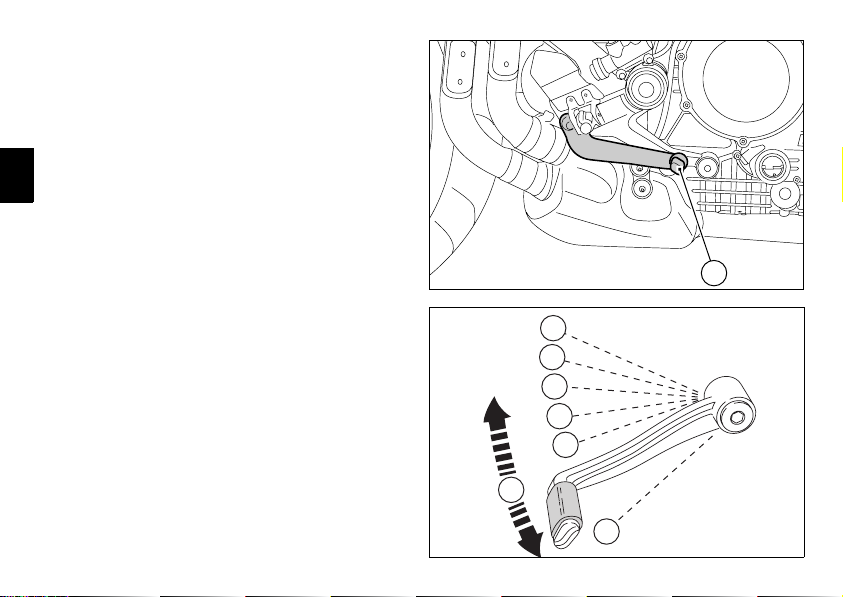

Rear brake pedal (fig. 14)

Push down on the pedal (1) with your foot to operate the

rear brake.

The system is controlled hydraulically.

E

1

fig. 14

Gearchange pedal (fig. 15)

The gearchange pedal has a central position N, with

automatic return, and two directions of movement:

down = push down on the pedal to engage 1

to shift down. At this point the N warning light on the

instrument panel will go off;

up = lift the pedal to engage 2

th

and 6th gears.

5

Each time you move the pedal you engage the next gear,

one gear at a time.

nd

gear and then 3rd, 4th,

24

st

gear and

6

5

4

3

2

N

1

fig. 15

Page 25

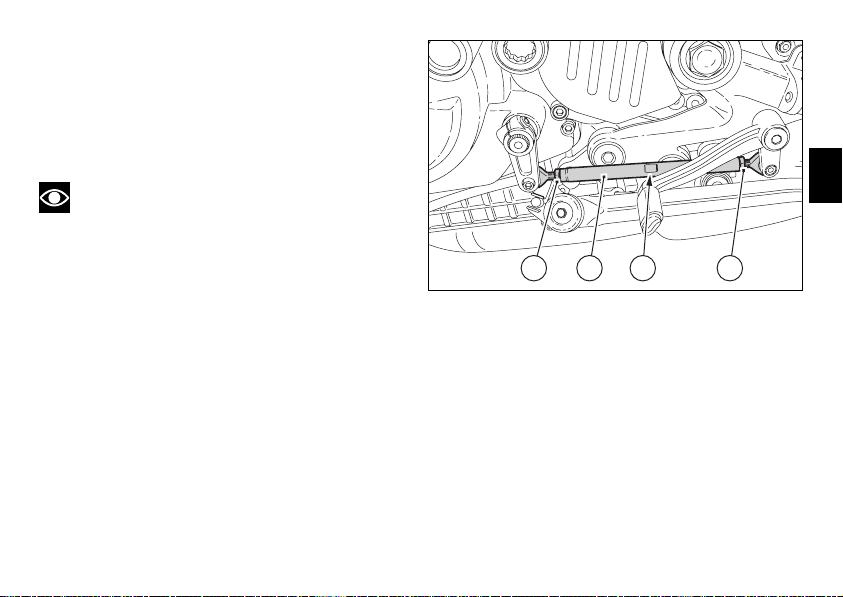

Adjusting the position of the gearchange

pedal (fig. 16)

The position of the gearchange pedal relative to the footrest

can be adjusted to suit the requirements of the rider.

To adjust the position, proceed as follows:

Hold the rod (1) using an open-ended wrench (2) and

slacken off the locknuts (3) and (4).

Notes

The locknut (4) has a left-hand thread.

Turn the rod (1) and move the pedal to the required position.

Tighten both nuts against the rod.

31

E

2

4

fig. 16

25

Page 26

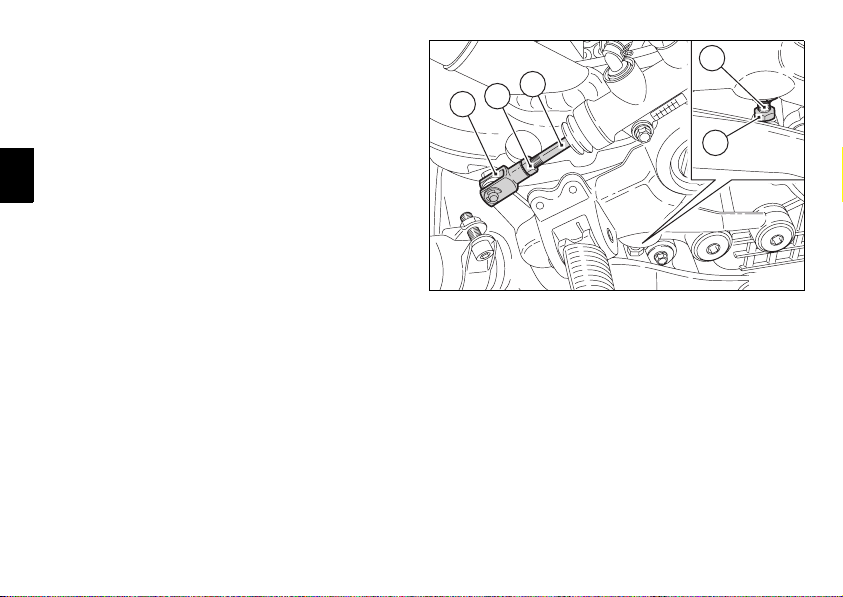

Adjusting the position of the rear brake

pedal (fig. 17)

The position of the rear brake lever relative to the footrest

can be adjusted to suit the requirements of the rider.

To adjust the position of the rear brake pedal, proceed as

follows:

Loosen the locknut (5).

Turn the pedal travel adjustment bolt (6) until the pedal is in

E

the desired position.

Tighten the locknut (5).

Operate the pedal by hand to check that there is 1.5 - 2 mm

of freeplay before the brake bites.

If not, adjust the length of the master cylinder pushrod as

follows.

Slacken off the locknut (7) on the pushrod.

Screw the pushrod (8) into the clevis (9) to increase the

freeplay, or screw it out to reduce it.

Tighten the locknut (7) and recheck the pedal freeplay.

26

6

8

7

9

5

fig. 17

Page 27

Main components and devices

Position on motorcycle (fig. 18)

1) Fuel tank filler cap.

2) Seat lock.

3) Helmet cable pin.

4) Passenger grabhandle.

5) Sidestand.

6) Rearview mirrors.

7) Rear shock absorber adjusters.

8) Front fork adjuster.

9) Tank support strut.

10) Seat cover

11) Fuel tank release lever.

12) Headlight fairing.

13) Catalytic converter.

12

6

10

4

E

1

7

8

11

9

13

2

3

fig. 18

27

Page 28

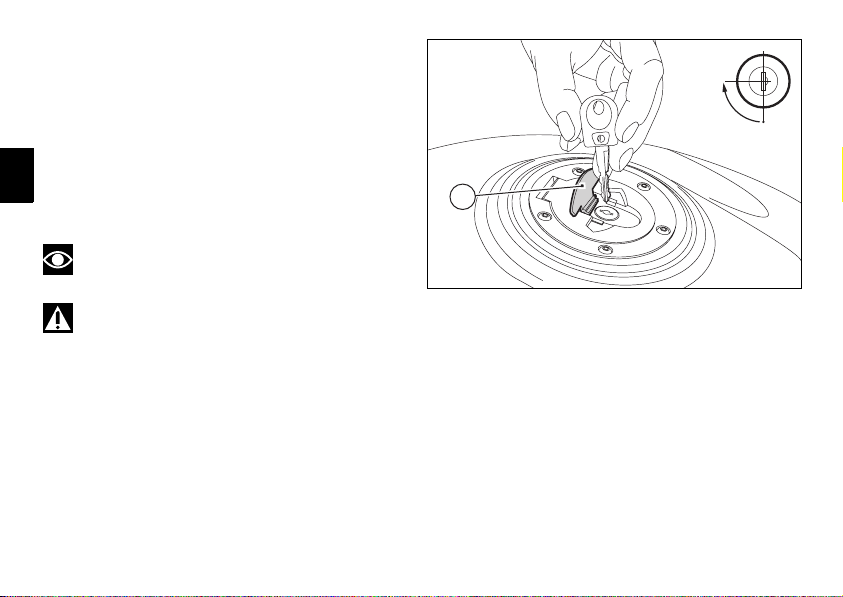

Fuel tank filler cap (fig. 19)

Opening

Raise the cover (1) and insert the key into the lock.

Give the key a 1/4 turn clockwise to unlock.

Lift the cap.

Closing

Close the cap with the key inserted and push it into its seat.

E

Turn the key anticlockwise to the initial position and

remove it. Replace the lock cover (1).

Notes

The cap can only be closed with the key inserted.

Warning

Always make sure you have properly closed the

fuel filler cap after refuelling (see page 43).

28

1/4

OPEN

1

0

fig. 19

Page 29

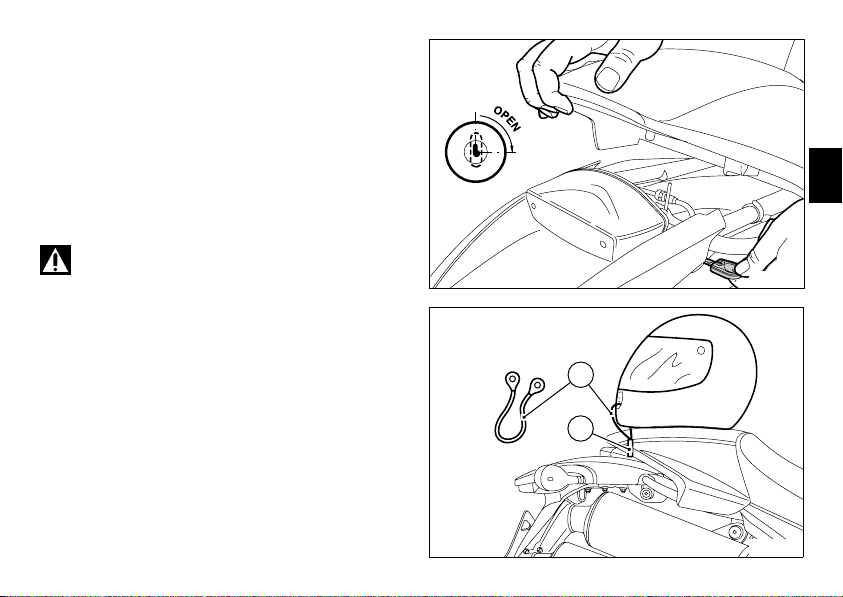

Seat lock and helmet holder (fig. 20 - fig. 21)

Opening

Insert the key in the lock and turn it clockwise to release the

seat from the frame. Pull the seat backwards to release it

from the front catches.

The helmet cable (1) is located at the rear of the

compartment under the seat (see page 45). Pass the

cable through the helmet and insert the end of the cable

in the pin (2). Leave the helmet hanging and refit the seat

to hold it in place.

Warning

This device protects the helmet against theft when

the motorcycle is parked. Do not leave the helmet attached

in this way when riding the motorcycle, as it can interfere

with your movements and cause loss of control of the

motorcycle.

Closing

Make sure all parts are correctly arranged and secured in

the underseat compartment. Insert the front ends of the

seat base under the U bolt in the frame, then push the

rear end of the seat until you hear the bolt in the lock click

into place. Check that the seat is firmly secured to the

frame and remove the key from the lock.

0

1

E

fig. 20

1

2

fig. 21

29

Page 30

Sidestand (fig. 22)

Important

Before lowering the sidestand, check that the ground

is sufficiently even and hard.

Do not park on soft or pebbled ground or on asphalt melted

by the sun etc. or the motorcycle may fall over.

E

When parking on a slope, always park with the rear wheel

on the downhill side.

To lower the sidestand, hold the motorcycle handlebars

with both hands and push down on the stand (1) with your

foot until it is fully extended. Tilt the motorcycle until the

sidestand is resting on the ground.

Warning

Do not sit on the motorcycle when it is supported on

the sidestand.

To raise the sidestand to the rest position (horizontal position),

tilt the motorcycle to the right and, at the same time, lift the

stand (1) with your foot.

Notes

It is advisable to check periodically that the stand

mechanism (consisting of two springs, one inside the other)

and safety sensor (2) are working properly.

Notes

The engine can be started with the sidestand down

and the gearbox in neutral. If starting with a gear engaged,

pull in the clutch lever (in this case the sidestand must be up).

30

2

1

fig. 22

Page 31

Front fork adjusters

The front forks can be adjusted for both rebound damping

and compression damping.

The settings are adjusted by way of external adjuster screws:

1) (fig. 23) to adjust rebound damping;

2) (fig. 23) to adjust spring preload;

3) (fig. 24) to adjust compression damping.

To adjust the rebound damping setting, turn the adjuster (1)

on the top of each fork leg with a flat screwdriver. To turn

the adjuster (3, fig. 24), insert a screwdriver through the base

of the fork tube and the hole in the wheel axle as shown.

Adjusters (1) and (3) have click positions corresponding to

different damping settings.

The stiffest damping setting is obtained with the adjuster

turned fully clockwise to the “0” position.

Start with this position and turn counterclockwise. Count the

screw clicks, which correspond to position “1”, “2” and so

forth.

1

2

E

A

fig. 23

31

Page 32

Standard settings:

compression: 6 clicks

rebound: 6 clicks

Spring preload (A, fig. 23): 18 mm

Adjustment range:

compression: 16 clicks

rebound: 14 clicks

Spring preload (A, fig. 23): 10÷25 mm

To change the spring preload for each fork leg, turn the

E

adjuster (2) with a 22 mm hex spanner.

Important

Adjust both fork legs to same setting.

32

3

fig. 24

Page 33

Rear shock absorber adjusters (fig. 25)

The rear shock absorber has external adjusters that allow you

to adjust the rear suspension to suit different load conditions.

The adjuster (1), located on the right-hand side of the shock

absorber at the lower end where it is attached to the

swingarm, is used to set the rebound damping.

Turn the adjuster (1) clockwise to stiffen the damping H and

anti-clockwise to soften it S.

STANDARD setting:

turn adjuster (1) all the way in (clockwise), then slacken by

18 clicks.

Spring preload: 25 mm

The two nuts (2) on the upper part of the shock absorber

serve to adjust the preload on the external spring.

To change the spring preload, turn the upper nut. Preload is

increased or reduced by screwing the lower nut in or out.

Warning

Use a pin wrench to turn the preload adjusting nut.

Take special care when turning the nut, to avoid injuring

your hand by striking it violently against other parts of the

motorcycle if the wrench suddenly slips off the nut while

turning.

2

E

1

SH

fig. 25

33

Page 34

Warning

The shock absorber is filled with gas under

pressure and may cause severe injury if dismantled by

untrained persons.

If you plan to carry a passenger and luggage, adjust the rear

shock absorber spring load to the maximum setting to

improve the handling characteristics of the motorcycle and

to avoid the possibility of ground contact. It may also be

E

necessary to adjust the rebound damping accordingly.

34

Page 35

Changing motorcycle track alignment

(fig. 26 - fig. 27 - fig. 28)

The standard ride height setting is the result of tests carried

out in a wide variety of conditions by our technical staff.

Modifying the frame geometry is a very critical operation,

and can be dangerous if carried out by untrained persons.

Before changing the standard setting, measure the

reference value (H, fig. 26).

The rider can adjust the rear ride height to suit his/her needs

by changing the working position of the rear shock absorber.

To alter the eye to eye length of the tie-rod (1), slacken the

locknuts (3).

Notes

Note that the lower nut (3) has a left-hand thread.

Rotate the tie-rod (2) with an open-ended wrench.

Once the tie-rod length is adjusted correctly, tighten the

nuts (3) to 25 Nm.

Warning

The length of the tie-rod (2) between the centres of

the two eyes (1) should not exceed 272 mm.

E

H

fig. 26

1

3

3

2

2

1

fig. 27

35

Page 36

The maximum distance that the UNIBALL end fitting (A)

can be unscrewed from the tie-rod body is 5 threads, or

7.5 mm (B).

E

B

36

A

fig. 28

Page 37

Riding the motorcycle

Running-in recommendations

Max. rpm (fig. 29)

Rpm limits to be observed during the running-in period and in

normal use:

1) Up to 1000 km;

2) From 1000 to 2500 km.

1.000 Km

1.000 ÷ 2.500 Km

-1

min

x1000

fig. 29

Up to 1000 km

During the first 1000 km, keep an eye on the tachometer.

The revs should never exceed:

5,500-6,000 rpm.

During the first hours of riding, it is advisable to continuously

vary the load on the engine and the rpm, though still keeping

within the above limits.

For this reason, roads with numerous bends and hilly areas

are ideal for running in the engine, brakes and suspension.

For the first 100 km, use the brakes gently. Do not brake

violently or keep brake applied for too long. This will enable a

correct break-in of friction material on brake pads against

brake discs.

To allow all the mechanical moving parts in the motorcycle to

adapt to one another, and to avoid shortening the life of the

main engine components, it is advisable to avoid sudden

acceleration and running the engine at high rpm for too long,

especially uphill.

It is also advisable to check the drive chain frequently and

ensure that it is lubricated as required.

From 1000 to 2500 km

You can take more power from the engine, but you should

never go above 7000 rpm.

E

37

Page 38

Important

Throughout the running-in period, be careful to stick to

the recommended maintenance schedule and periodic

service intervals indicated in the warranty booklet. Failure

to follow these instructions will release Ducati Motor

Holding S.p.A. from any liability for any engine damage or

shortened engine life.

Keeping to the running-in recommendations will ensure longer

E

engine life and reduce the need for overhauls and re-tuning.

Pre-ride checks

Warning

Failure to carry out these checks before starting may

result in damage to the motorcycle and injury to rider.

Before starting, check the following points:

Fuel level in the tank

Check the fuel level in the tank. Re-fuel if necessary

(page 43).

38

Engine oil level

Check the oil level in the sump through the sight glass.

Top up if necessary (page 63).

Brake and clutch fluid

Check the fluid levels in the respective reservoirs.

Tyre condition

Check the pressure and condition of the tyres (page 61).

Controls

Operate the brake, clutch, gearchange and throttle controls

(lever, pedal and twistgrip) and check that they function

correctly.

Lights and indicators

Check that lights, indicators and horn are working properly.

Replace any burnt-out bulbs (page 56).

Key locks

Check that the fuel filler cap and the seat are locked.

Sidestand

Make sure the sidestand operates smoothly and is in the

correct position (page 30).

Warning

If there are any faults or malfunctions, do not start

the motorcycle and contact your DUCATI Dealer or

Authorized Service Centre.

Page 39

Starting the engine

Warning

Before starting the engine, familiarise yourself with

the controls that you will use when riding.

1) Turn the ignition switch to ON (fig. 30). Check that

both the green light N and the red light on the

instrument panel come on.

Important

The oil pressure warning light should go out a

few seconds after the engine has started (page 11).

Notes

The engine can be started with the side stand down

and the gearbox in neutral. If starting with a gear engaged,

pull in the clutch lever (in this case the side stand must be up).

ON

E

fig. 30

39

Page 40

2) Make sure that the stop switch (1, fig. 31) is in the

RUN position, then press the starter button (2, fig. 31).

This model has servo-assisted starting. To use the servoassisted starting feature, press the start button (2) and

release it immediately. When you press button (2) the

starter motor runs automatically for a period of time that

varies according to the engine temperature. The system

disengages the starter motor as soon as the engine starts.

E

If the engine fails to start, wait at least 2 seconds before

pressing the start button (2) again.

Allow the engine to start on its own, without turning the

throttle.

Important

Do not rev the engine when cold. Allow some time for

the oil to warm up and reach all points that need lubricating.

40

1

2

fig. 31

Page 41

Moving off

1) Disengage the clutch by squeezing the clutch lever.

2) Push down the gearchange lever firmly with the tip of

your foot to engage first gear.

3) Raise the engine revs by turning the throttle twistgrip

while gradually releasing the clutch lever. The motorcycle

will start moving.

4) Release the clutch lever completely and accelerate.

5) To change to second gear, close the throttle to reduce

the engine revs, disengage the clutch, lift the gearchange

lever and release the clutch lever.

To change down, proceed as follows: release the twistgrip,

disengage the clutch, briefly accelerate the engine to allow

the gears to synchronize, shift down and release the clutch.

Use the controls intelligently and opportunely: when riding

uphill, change down immediately when the motorcycle

begins to slow down, to avoid abnormal stresses on the

motorcycle structure as well as on the engine.

Important

Avoid sudden acceleration, as this may lead to

misfiring and transmission snatching. The clutch lever should

not be held in longer than necessary after a gear is engaged,

otherwise friction parts may overheat and wear out.

E

41

Page 42

Braking

Slow down in time, change down to use the engine brake,

then apply both brakes. Pull in the clutch lever before the

motorcycle comes to a stop to prevent the engine stalling.

Warning

Use both the brake lever and the brake pedal for

effective braking. Using only one of the brakes will give

E

you less braking power. Never use the brake controls

harshly or suddenly as you may lock the wheels and lose

control of the motorcycle. When riding in the rain or on

slippery surfaces, braking capacity is significantly reduced.

Always use the brakes very gently and carefully when

riding under these conditions. Any sudden manoeuvres

may lead to loss of control.

When riding down long, steep downhill slopes, change

down to use engine braking. Apply the brakes intermittently

for brief periods only. Keeping the brakes applied

continuously causes the friction material to overheat and

dangerously reduces braking effectiveness. Under-inflated

tyres reduce braking efficiency and may adversely affect

handling and road-holding on bends.

42

Page 43

Stopping the motorcycle

Reduce speed, change down and release the throttle

twistgrip. Change down to engage first gear and then

neutral. Apply the brakes and bring the motorcycle to a

complete stop. Switch the engine off by turning the key

to OFF (page 20).

Important

Do not leave the key in the ON position when the

engine is off to avoid damaging the electrical components.

E

fig. 32

Refuelling

Do not overfill the tank when refuelling. The fuel level should

always be below the rim of the filler cap recess (fig. 33).

Warning

Use fuel with low lead content and an original

octane number of at least 95.

Check that no fuel is trapped in the filler cap recess.

Max level

fig. 33

43

Page 44

Parking

Stop and park the motorcycle on the side stand (see page 30).

To prevent theft, turn the handlebar fully left and turn the

ignition key to the LOCK position.

If you park in a garage or other indoor area, make sure that

there is proper ventilation and that the motorcycle is not

near a source of heat.

If necessary, you can leave the side lights on by turning

the key to position P.

E

Important

Do not leave the key at P for long periods or the

battery will run down. Never leave the motorcycle

unattended with the ignition key inserted.

Warning

The exhaust system might still be hot even if the

engine is switched off; take special care not to touch exhaust

system with any part of your body and do not park the

motorcycle next to inflammable material (wood, leaves etc.).

Warning

Using padlocks or other locks designed to prevent

movement of the motorcycle (such as brake disc locks, rear

sprocket locks, and so on) is very dangerous, and may impair

motorcycle operation and the safety of rider and passenger.

44

fig. 34

Page 45

Toolkit and accessories (fig. 35)

The underseat compartment contains:

use and maintenance manual;

helmet fastening cable;

toolkit for routine maintenance operations and checks.

To access the compartment, you need to remove the

seat (page 29) and remove the cover (1) unscrewing the

special screw (2) with a coin.

(fig. 36)

Toolkit

Contains:

3) spark plug wrench;

4) tommy bar for spark plug wrench;

5) double-ended screwdriver;

6) helmet fastening cable.

1

2

E

fig. 35

6

3

4

5

fig. 36

45

Page 46

Main Maintenance Operations

Removing the fairing panels (fig. 37)

Some parts of the motorcycle fairing have to be removed

E

for certain maintenance or repair operations.

Warning

If parts that have been removed are not refitted

correctly they may become loose suddenly while riding

and cause you to lose control of your motorcycle.

Removal of the headlight fairing

Unscrew and remove the two bolts (1) securing the

headlight shell to the headlight support.

Notes

Be careful not to lose the nuts for the bolts (1)

located on the inside of the headlight shell.

Remove the headlight shell (2).

46

1

2

fig. 37

Page 47

Lifting the fuel tank (fig. 38)

Warning

To prevent fuel from spilling out through the filler

cap breather hole, the quantity of fuel in the tank should

be less than 5 litres.

Remove the seat (page 29), release the catch (1).

Lift the tank and release the support strut (2, fig. 39)

from its holder under the seat.

Rest the tank on the support strut.

To replace the tank, perform the above operations in the

reverse order.

Warning

When lowering the fuel tank, take care to position

the hoses correctly so they are not pinched or crushed.

E

1

2

3

fig. 38

fig. 39

47

Page 48

Changing the air filter (fig. 40)

The air filter must be renewed at the intervals indicated in the

periodic maintenance table shown in the Warranty Booklet.

To access the airbox, lift the fuel tank as described in

(page 47).

To remove the filter, release the clips (1) on both sides of

the airbox cover and remove the cover (2, fig. 40).

Remove the old filter cartridge (3, fig. 41) and fit a new one.

E

Important

A dirty filter reduces the amount of intake air, which

increases fuel consumption, reduces engine power and

causes deposits to form on the spark plugs.

Do not use the motorcycle without a filter; as impurities in

the air could get into the engine and cause damage.

Reinstall the filter correctly in its housing in the airbox, as

shown in the figure, and refit all the parts originally removed.

Important

If using the machine on wet or dusty roads, the air

filter cartridges should be renewed more frequently than

the intervals in the periodic maintenance table in the

Warranty Booklet.

48

2

1

fig. 40

3

fig. 41

Page 49

Checking the brake and clutch fluid level

(fig. 42)

The levels should not fall below the MIN marks on the

respective reservoirs.

If the level is too low it can allow air to get into the circuit,

thus impairing the efficiency of the relative system.

Brake and clutch fluid must be topped up and changed at

the intervals specified in the periodic maintenance table

(see Warranty Booklet) by a Ducati Dealer or Authorized

Service Centre.

Important

It is recommended that all brake and clutch hoses

be renewed every four years.

Clutch system

If there is too much play at the control lever and the

motorcycle jumps or stops when a gear is engaged, this

indicates air in the system. Contact a Ducati Dealer or

Authorized Service Centre to have the system inspected

and the air bled from the system.

fig. 42

Brake system

If there is excessive play at the brake lever or pedal even

though the brake pads are still in good condition, contact a

Ducati Dealer or Authorized Service Centre to have the

system inspected and any air expelled from the circuit.

E

Warning

The level of clutch fluid tends to increase in the reservoir

as the friction material on the clutch plates wears out. Do not

exceed the specified level (3 mm above the minimum level).

Warning

Brake and clutch fluid is harmful to paintwork and plastic

parts, so do not allow it to come into contact with them.

Hydraulic oil is corrosive and can cause damage and injuries.

Never mix different quality oils.

Check that the seals are in good condition.

49

Page 50

Checking the brake pads for wear (fig. 43)

Front brake

The brake pads are marked with wear indicators so that

they can be checked without removing them from the

calipers. If the grooves in the pad friction material are still

visible, the pad is still in good condition.

Rear brake

E

The thickness of the friction material on each pad must be at

least 1 mm.

Important

Have the brake pads replaced at a Ducati Dealer or

Authorized Service Centre.

50

fig. 43

MIN

1 mm

Page 51

Lubricating cables and joints (fig. 44)

The condition of the outer cables of the throttle and starter

cables should be checked at regular intervals. There should be

no signs of pinching or cracking on the outer plastic sheath.

Operate the control to check that the inner cable slides

smoothly: if you feel any rubbing or catching, have the cable

replaced by a Ducati Dealer or Authorized Service Centre.

To prevent problems, periodically lubricate the ends of each

control cable with SHELL Advance Grease or Retinax LX2.

In the case of the throttle cable, open the twistgrip housing

by unscrewing the two screws (1, fig. 44) and grease the

end of the cable and the race.

E

1

Warning

Close the twistgrip housing carefully, inserting the

cable in the race.

Refit the housing and tighten the screws (1) to 1.8 Nm.

To ensure smooth operation of the pivot on the sidestand,

remove any dirt and apply SHELL Alvania R3 to all points

subject to friction.

fig. 44

51

Page 52

Adjusting the throttle control cable (fig. 45)

In all steering positions, the throttle twistgrip should have

about 2 – 4 mm of free travel, measured at the outer edge

of the twistgrip housing. Adjust if necessary, using the

adjuster (1, fig. 45) located on the twistgrip.

E

52

➤

➤

1

fig. 45

Page 53

Charging the battery (fig. 46)

Before charging the battery, it is best to remove it from

the motorcycle.

First disconnect the black negative terminal (-), then the

red positive terminal (+).

Release the clips (1) and remove the battery.

Warning

The battery produces explosive gases: keep it away

from heat sources and flames.

Charge the battery in a well-ventilated area.

Connect the battery charger leads to the battery terminals: red

to the positive terminal (+), black to the negative terminal (-).

Important

Connect the battery to the charger before switching

on to prevent sparks at the battery terminals that could

ignite the gases inside the cells.

Always connect the red positive terminal first.

Warning

Keep the battery out of the reach of children.

Charge the battery at 1 A for 5 to 10 hours.

1

-

+

E

fig. 46

53

Page 54

Checking the drive chain tension (fig. 47)

Move the motorcycle slowly until you find the point at

which the upper section of the chain is most taut.

Place the motorcycle on its sidestand.

Push the chain upwards with a finger in correspondence

with the centre of the swingarm (see adhesive label).

The bottom run of the chain must be able to deflect 30 to

32 mm.

If not, have the chain tensioned at a Ducati Dealer or

E

Authorized Service Centre.

Warning

For the safety of the rider, it is essential that the

eccentric hub clamp bolts are correctly tightened.

Important

An incorrectly tensioned chain will cause the rapid

wear of transmission parts.

54

=

30 ÷ 32 mm

=

fig. 47

Page 55

Lubrication of the drive chain

The chain fitted on your motorcycle has O-rings that keep

dirt out of and lubricant inside the sliding parts.

So as not to damage these seals when cleaning the chain,

use special solvents and avoid aggressive washing with

high-pressure steam cleaners. After cleaning, blow the

chain dry with compressed air or wipe with an absorbent

material, then lubricate each link with SHELL Advance Chain

or Advance Teflon Chain.

Important

Using non-specific lubricants may cause severe

damage to the chain and the front and rear sprockets.

E

55

Page 56

Replacing bulbs

Before replacing a burnt-out bulb, make sure that the new

one complies with voltage and wattage as specified in

the “Electrical System” paragraph on page 78.

Headlight

To carry out maintenance on the headlight, it is advisable to

remove the headlight fairing as described in the paragraph

“Removing the headlight shell” on page 46.

E

To access the headlight bulbs, loosen the lower screw (1)

that attaches the lens/reflector assembly to the shell.

Disconnect the wiring connector (2, fig. 49) from the

headlight bulb. Release the bulb retaining clip (3, fig. 49)

and remove the bulb from its housing.

56

(fig. 48 - fig. 49 - fig. 50 - fig. 51)

1

fig. 48

2

3

fig. 49

Page 57

Fit a new bulb (4, fig. 50).

Notes

Do not touch the transparent part of the bulb with your

fingers, this will darken it and cause a loss of brightness.

Insert the tabs on the bulb base into the corresponding slots

in the bulb housing to ensure the bulb is correctly positioned;

hook the end of the clip (3, fig. 49) on to the headlight

mountings. Reconnect the wiring.

To renew the side light bulb, detach the wiring connector.

The bulb (5, fig. 51) is of the bayonet type: push it in and turn

it anti-clockwise to remove it. Push the new bulb in and turn

it clockwise until it clicks into place. Reconnect the wiring

connector and replace the lens/reflector assembly.

4

E

fig. 50

1

fig. 51

57

Page 58

Turn signals (fig. 52)

Loosen the screw (1) and detach the lens (2) from the turn

signal light.

The bulb has a bayonet-type base: to remove it, push it in and

turn it counter-clockwise. Push in the new bulb and turn it

clockwise until it clicks into place. Refit the lens by inserting

the tab (A) in the corresponding slot in the turn signal.

Refit and tighten the screw (1).

E

Brake light

To change the brake light bulb, loosen the two screws (1)

securing the lens (2) and remove it. The bulb has a bayonettype base: to remove it, push it in and turn it counterclockwise. Push in the new bulb and turn it clockwise

until it clicks into place. Refit the lens.

(fig. 53)

A

2

1

fig. 52

58

2

1

fig. 53

Page 59

Number plate light (fig. 54)

To access the bulb in the number plate light (3), pull the bulb

holder out from the light, then pull the bulb out of the holder

and renew it.

E

3

fig. 54

59

Page 60

Headlight aim (fig. 55)

To check the headlight aim, place the motorcycle upright

with the tyres inflated to the correct pressure and one

person sitting astride the motorcycle. The motorcycle

should be perfectly vertical, with its longitudinal axis at

right angles to a wall or screen at a distance of 10 metres.

Draw a horizontal line on the wall at the height of the

centre of the headlight and a vertical one in line with the

longitudinal axis of the motorcycle.

E

If possible, perform this check in conditions of low

ambient light.

Switch on the low beam headlight:

the upper edge between the dark area and the lit area

should not be above 9/10th of the height of the headlamp

centre from the ground.

Notes

Note: this procedure is the one specified by Italian

regulations for checking the maximum height of light beams.

Owners in other countries should adapt this procedure

to the regulations in force in the country where the

motorcycle is used.

The vertical aim of the headlamp is adjusted by turning the

screws (1, fig. 56) that attach it to the side mountings.

60

10 m

9

x

x

10

fig. 55

1

fig. 56

Page 61

Tyres

Front tyre pressure:

2.1 bar – 2.3 kg/cm

Rear tyre pressure:

2.2 bar – 2.4 kg/cm

As tyre pressures are affected by changes in temperature

and altitude, check and adjust them whenever you are

riding in areas where there are large variations in

temperature or altitude.

2

2

Important

Check and adjust the pressures with the tyres cold.

To prevent distortion of the front wheel rim, increase tyre

pressure by 0.2 to 0.3 bar when riding on bumpy roads.

Repairing or renewing tyres

With minor punctures, tubeless tyres take a long time to

deflate, as they tend to hold the air inside. If you find that

one of the tyres is slightly deflated, check the tyre for

slow punctures.

Warning

Punctured tyres must be renewed.

Replace with tyres of the original brand and type.

Be sure to tighten the valve dust caps securely to prevent

leaks while riding. Never fit tyres with inner tubes, as

these can cause the tyre to burst suddenly, with possibly

serious consequences for the rider and passenger.

After renewing a tyre, the wheel must be balanced.

Important

Do not remove or alter the position of the wheel

balancing weights.

Notes

If tyres need changing, contact a Ducati Dealer

or Authorized Service Centre to make sure wheels are

removed and refitted correctly.

E

61

Page 62

Minimum tread depth

Measure the tread depth (S, fig. 57) at the point where the

tread is most worn.

It should not be less than 2 mm, and in any case not less

than the legal limit.

Important

E

Visually inspect the tyres at regular intervals for cracks

and cuts, especially on the side walls, and bulges or large

stains that indicate internal damage. Replace them if badly

damaged.

Remove any stones or other foreign bodies stuck in the

tread.

62

S

fig. 57

Page 63

Checking the engine oil level (fig. 58)

The engine oil level can be seen through the sight glass (1)

on the clutch cover.

Check the oil level with the motorcycle upright and the

engine cold. Allow a few minutes for the oil level to stabilize

after stopping the engine.

The oil level should be between the marks next to the

sight glass. If the level is below the bottom mark, top up

with SHELL Advance Ultra 4 engine oil.

Remove the oil filler cap (2) and top up until the oil reaches

the required level. Replace the filler cap.

Important

To change the engine oil and filters at the intervals

specified in the maintenance table in the Warranty Booklet,

contact a Ducati dealer or Authorized Service Centre.

Oil viscosity

SAE 10W-40

The other viscosity values shown in the table can be used if

the local average temperature is within the limits specified

for that oil viscosity.

10W

Unigrade

15W–40 15W–50

10W–40

10W–30

Multigrade

–10

2

1

fig. 58

20W

20

20W–40 20W–50

0 10 20 30 40 C

30

40

E

63

Page 64

Cleaning and renewing the spark plugs

(fig. 59)

Spark plugs are an important part of the engine and should

be checked at regular intervals.

This is a relatively simple operation and provides a good

indication of how well the engine is running.

Pull the spark plug caps off the spark plugs and remove

the plugs from the cylinder heads using the wrench

E

supplied in the toolkit.

Check the colour of the ceramic insulation around the

central electrode: an even brown colour is a sign that the

engine is in good condition.

If the insulation is any other colour, or if there are dark

deposits, renew the spark plug and describe the condition of

the old plug to a Ducati dealer or Authorized Service Centre.

Also check the central electrode; if it is worn or glazed,

renew the spark plug.

Check the electrode gap, which must be:

0,6÷0,7 mm.

Important

Take care when bending the side electrode to adjust

the gap. A gap outside the specified limits will adversely

affect engine performance and may lead to difficult

starting or erratic idling.

Thoroughly clean the electrode and insulation using a wire

brush, and check the condition of the washer.

Clean the spark plug socket on the head and take care not

to allow foreign bodies to fall into the combustion chamber.

64

0,6÷0,7 mm

fig. 59

Insert the spark plug in the cylinder head and screw in fully

by hand. Tighten to a torque of 20 Nm.

If you do not have a torque wrench, tighten the plug by hand,

then give it a further 1/2 turn with the spark plug wrench

supplied in the toolkit.

Important

Do not use spark plugs with an unsuitable heat rating

or incorrect reach.

The spark plug must be tightened correctly.

Page 65

General cleaning

To preserve the original shine on metal surfaces and

paintwork, wash and clean your motorcycle at regular intervals

depending on the type of use and according to the particular

road conditions. Use specific products, where possible

biodegradable. Avoid aggressive detergents or solvents.

Warning

There may be loss of braking efficiency immediately

after washing the motorcycle. Never grease or lubricate

the brake discs. This will cause loss of braking efficiency.

Clean the discs with an oil-free solvent.

Important

Do not wash your motorcycle immediately after use,

as marks can form due to evaporation of the water on hot

surfaces.

Never clean the motorcycle using hot or high-pressure

water jets.

Cleaning the motorcycle with high-pressure water cleaners

may lead to seizure or serious faults in the front fork,

wheel hub assembly, electric system, front fork seals, air

inlets or exhaust silencers, with subsequent loss of the

required levels of safety.

If parts of the engine are unusually dirty or greasy, use a

degreasing agent, avoiding contact with transmission

components (chain, front and rear sprockets, etc.).

Rinse with warm water and dry all surfaces with chamois

leather.

E

65

Page 66

Storing the motorcycle

If the motorcycle is to be left unused for a long period, it is

advisable to carry out the following operations first:

clean the motorcycle;

empty the fuel tank by removing the drain plug and gasket;

pour a few drops of engine oil into the cylinders through the

spark plug bores, then crank the engine by hand a few times

to form a protective film of oil on the cylinder inner walls;

place the motorcycle on the paddock stand;

E

disconnect and remove the battery. If the motorcycle

has been left unused for more than a month, the battery

should be checked and re-charged if necessary.

Protect the motorcycle with a special motorcycle cover

that will not damage the paintwork or retain moisture.

This type of motorcycle cover is available from Ducati

Performance.

66

Important notes

The legislation in some countries (France, Germany,

Great Britain, Switzerland etc.) sets certain noise and

pollution standards.

Periodically carry out the required checks and renew parts as

necessary, using Ducati original spare parts, in compliance

with the regulations in the country concerned.

Page 67

Maintenance

Programmed maintenance plan: operations to be carried out by the dealer

E

List of operations with type of intervention

(distance or time interval *)

Change the engine oil

Change the engine oil filter

Clean the engine oil pick-up filter

Checking the engine oil pressure

Check and/or adjust the valve clearances (1)

Check the tension of the timing belts (1)

Renew the timing belts

Check and clean the spark plugs. Renew if necessary

Check and clean the air filter (1)

Change the air filter

km x1000 1 12 24 36 48 60

miles x1000 0,6 7,5 15 22,5 30 37,5

Months 6 12 24 36 48 60

••••••

••••••

•

••

•••••

•••

••

••

•••

••

67

Page 68

List of operations with type of intervention

(distance or time interval *)

Check throttle body synchronisation and idle speed setting (1)

Check the brake and clutch fluid levels

Change the clutch and brake fluid

E

Check and adjust the brake and clutch control cables

Check/lubricate the throttle/cold start cable

Check tyre pressure and wear

Check the brake pads. Renew if necessary

Check the steering head bearings

Check the drive chain tension, alignment and lubrication

Check the clutch disc pack. Renew if necessary (1)

Check the rear wheel cush drive

Check the wheel hub bearings

Check the indicators and lighting

Check tightness of nuts and bolts securing the engine to the frame

Check the sidestand

Check tightness of the front wheel axle nut

Check tightness of the rear wheel axle nut

Check the external fuel hoses

Change the front fork oil

68

km x1000 1 12 24 36 48 60

miles x1000 0,6 7,5 15 22,5 30 37,5

Months 6 12 24 36 48 60

•••••

••••••

•

•••••

•••••

••••••

••••••

••

••••••

•••••

••

••

•••••

•••••

•••••

•••••

•••••

•••••

•

Page 69

List of operations with type of intervention

(distance or time interval *)

Check the forks and rear shock absorber for oil leaks

Check the front sprocket retaining bolts

General lubrication and greasing

Check and recharge the battery

Road test the motorcycle

General cleaning

* Service operation to be carried out in accordance with the specified distance or time intervals (km, miles or

months), whichever occurs first.

(1) Operation to be carried out only at the specified distance intervals.

km x1000 1 12 24 36 48 60

miles x1000 0,6 7,5 15 22,5 30 37,5

Months 6 12 24 36 48 60

•••••

•••••

•••••

•••••

••••••

•••••

E

69

Page 70

Programmed maintenance plan: operations to be carried out by the dealer

List of operations with type of intervention

(distance or time interval *)

Check the engine oil level

E

Check the brake and clutch fluid levels

Check tyre pressure and wear

Check the drive chain tension and lubrication

Check the brake pads. If necessary, contact your dealer to renew pads

* Service operation to be carried out in accordance with the specified distance or time intervals (km, miles or

months), whichever occurs first.

70

km x1000 1

miles x1000 0,6

Months 6

•

•

•

•

•

Page 71

Technical data

370

Dimensions (mm) (fig. 60)

Weights

Dry weight (excluding liquids and battery)

178 kg

Fully laden: 390 kg

Warning

Failure to observe weight limits could result in poor

handling and impair the performance of your motorcycle,

and could result in loss of control.

130

780

1440

2120

370

370

1060

500

fig. 60

803

71

E

Page 72

Fuel, lubricants and other fluids Type

3

Fuel tank, including a reserve of 3 dm

Sump and filter SHELL - Advance Ultra 4 3,3

Front/rear brake and clutch circuits SHELL Advance Brake DOT 4 —

E

Protection for electrical contacts SHELL Advance Contact Cleaner —

Front fork SHELL Advance Fork 7.5 or Donax TA 0.465 (each leg)

(litres) Unleaded fuel with at least 95 octane rating 14

dm

Important

Do not use additives in fuel or lubricants.

72

3

(litres)

Page 73

Engine

Longitudinal 90º “L” twin cylinder, four-stroke.

Bore (mm):

94

Stroke (mm):

71,5

Total displacement cm

992

Compression ratio 1:10±0.5

Max power at crankshaft (95/1/EC)

64 kW - 84 HP at 8,250 rpm

Max torque at crankshaft (95/1/EC):

86 Nm (8.5 kgm) at 6,250 rpm.

3

:

Timing system

Desmodromic with two valves per cylinder, operated by four

rocker arms (two opening rockers and two closing rockers)

and one overhead camshaft. Driven by the crankshaft through

spur gears, timing belt pulleys and toothed timing belts.

Desmodromic timing system

1) Opening (or upper) rocker arm;

2) opening shim;

3) half rings;

4) closing (or lower) shim;

5) return spring for closing rocker;

6) closing (or lower) rocker arm;

7) camshaft;

8) valve.

1

2

3

4

6

(fig. 61)

5

7

8

fig. 61

E

73

Page 74

Performance data

Maximum speed in any gear should be reached only after

the correct running-in period with the motorcycle properly

serviced at the recommended intervals.

Important

Failure to follow these instructions will release

Ducati Motor Holding S.p.A. from any liability for any

E

engine damage or shortened engine life.

Spark plugs

Make:

CHAMPION

Type:

RA 6 HC.

Make:

NGK

Type:

DCPR8E.

74

Fuel system

Indirect electronic injection (MARELLI)

Throttle body diameter:

45 mm

Injectors per cylinder: 1

Holes per injector: 1

Fuel supply: 95-98 RON.

Page 75

Brakes

Front

Type:

drilled steel disc.

2 discs.

Braking surface material:

steel.

Flange material:

steel.

Disc diameter:

320 mm.

Hydraulically operated by a control lever on right handlebar.

Braking surface, cm

44 per disc

Differential bore brake calipers.

Make and type:

BREMBO 30/34-4 Piston.

Friction material:

FERIT I/D 450 FF.

Master cylinder type:

PSC 16.

Rear

Type:

with fixed drilled steel disc.

Disc diameter:

245 mm.

Hydraulically operated by pedal on R.H. side.

2

:

Braking surface:

2

25 cm

Brake caliper:

32 mm Ø piston.

Make and type:

BREMBO P 32

Friction material:

FERIT I/D 450 FF.

Master cylinder type:

PS 11 C.

Warning

The brake fluid used in the brake system is corrosive.

In the event of accidental contact with eyes or skin, wash

the affected area with copious amounts of running water.

E

75

Page 76

Transmission

Clutch:

dry multiplate;

operated by control lever on left handlebar.

Transmission from engine to gearbox main shaft via spur

gears.

Front sprocket/clutch sprocket ratio:

32/59

Gearbox:

E

6 speed;

with constant mesh gears, gearchange pedal on left.

Final drive ratio:

15/41

Total gear ratios:

st

15/37

1

nd

17/30

2

rd

20/27

3

th

22/24

4

th

24/23

5

th

28/24

6

76

Drive chain from gearbox to rear wheel:

Make:

RK

Type:

525 GXV

Dimensions:

5/8" x 1/4"

No. of links:

103+1 joining link

Important

The above gear ratios are approved and should not

be modified under any circumstances.

However, if you wish to tune up your motorcycle for

competitions or special tracks, Ducati Motor Holding S.p.A.