Gasoline Pressure Washer

OPERATOR’S MANUAL

Model: GSW01A

Original Instructions

CAUTION: Read the instructions before using the machine

Chongqing Dajiang power Equipment Co.,Ltd

Qinggang Industrial Zone,

Chongqing 402767, P.R.China

TABLE OF CONTENTS

Introduction ..............................................................................................................................................................................3

Safety Rules .............................................................................................................................................................................5

Safety Symbols .............................................................................................................................................................5

Safety Instructions .......................................................................................................................................................5

Pressure Washer Features .....................................................................................................................................................8

Pressure Washer Parts Assembly..........................................................................................................................................8

Pressure Washer Parts List ....................................................................................................................................................8

Assembly ...............................................................................................................................................................................11

Packing List ................................................................................................................................................................11

Unpacking ...................................................................................................................................................................11

Attaching Foot Assembly............................................................................................................................................12

Install Handle..............................................................................................................................................................12

Attaching Upper and Lower Gun Hooks .....................................................................................................................12

Attaching Accessory Hook ..........................................................................................................................................12

Attaching Spray Gun...................................................................................................................................................13

Adding Engine Oil and Fuel .........................................................................................................................................14

Operation ................................................................................................................................................................................16

How to Start Pressure Washer ...................................................................................................................................16

How to Turn Off Pressure Washer ..........................................................................................................................17

How to Use Spray Gun ...............................................................................................................................................17

Using Spray Nozzle ....................................................................................................................................................17

How to Apply Detergent ...........................................................................................................................................18

Maintenance ..........................................................................................................................................................................19

Pre Operation Steps ...................................................................................................................................................19

After Each Use ...........................................................................................................................................................19

Maintenance Schedule ...............................................................................................................................................19

Changing Oil ..............................................................................................................................................................20

Engine Maintenance ..................................................................................................................................................20

How to Store .............................................................................................................................................................21

Troubleshooting ....................................................................................................................................................................22

Diagrams ................................................................................................................................................................................23

Ec Declaration of Conformity ...............................................................................................................................................24

SAVE THIS MANUAL FOR FUTURE REFERENCE

This manual contains important information regarding safety, operation, and maintenance.

INTRODUCTION

Thank you for purchasing this superior quality pressure washer from Ducar. When operating and maintaining this product

as instructed in this manual, your pressure washer will give you many years of reliable service.

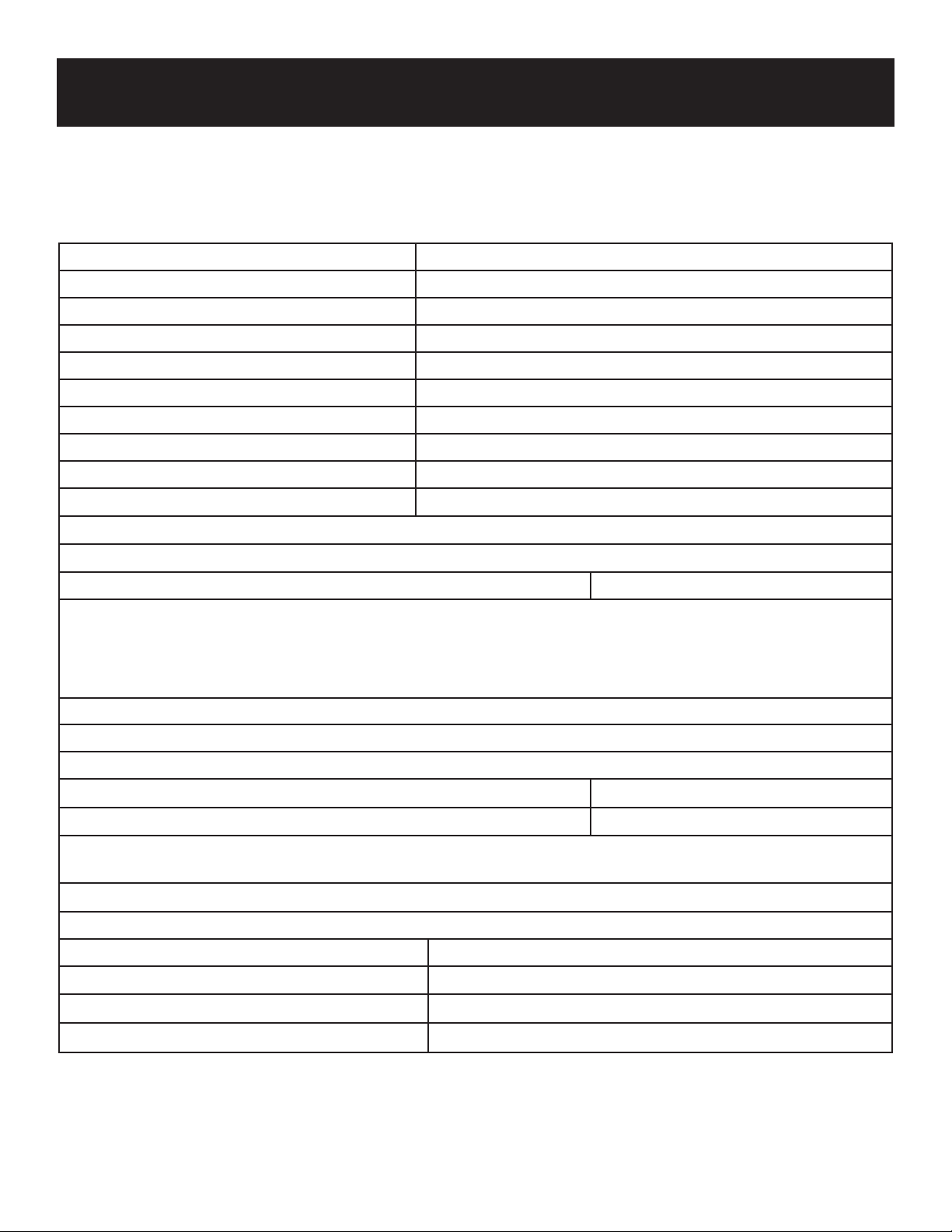

Product Specifications:

Type GSW01A

Rated pressure 22.8 MPa

Allowable pressure

Rated flow

Max. flow 590 l/h

Max. water intake temperature

Max. inlet water pressure

Net weight

Water hose diameter

Kickback force on lance 28 N

DECLARED SINGLE-NUMBER NOISE EMISSION VALUES (In accordance with EN ISO 4871:1996)

The guaranteed A-Weighted sound power level, L

Values determined according to noise test code given in Annex CC of EN 60335-2-79:2012, using the basic standard

EN ISO 3744:2010.

NOTE: Declared single-number noise emission values are the sum of measured values and the associated uncertainty,

and they represent upper boundaries of the range of values which is likely to occur in measurements.

DECLARED VIBRATION EMISSION VALUES OF A SINGLE MACHINE (In accordance with EN ISO 12096:1997)

24.8 MPa

590 l/h

50°C

0.55 MPa

35 kg

Min. ø12.7mm

(ref. 1 pW) 105 dB(A)

WAd

Measured vibration emission value α

Handle of trigger gun

Middle of trigger gun

Values determined according to vibration test code given in Annex DD of EN 60335-2-79:2012, using the basic standard

ISO 5349-1:2001.

Engine

Model DH212

Displacement 212cc

Power 4.5kW/3600rpm

Fuel tank capacity 3.6 L

3

0.828 m/s²

2.068 m/s²

INTRODUCTION

The emissions control system for this pressure washer is compliant with all standards set by the Environmental Protection

Agency.

Product Applications:

•

This pressure washer is designed to remove dirt and mold from house siding, decks, garage floors, brick patios, and

cement walkways.

• This unit can be used to clean cars, motorcycles, boats, RV’s outdoor furniture, lawn equipment, and grills.

How to contact us:

You can write to us at:

Chongqing Dajiang power Equipment Co.,Ltd

Qinggang Industrial Zone,

Chongqing 402767, P.R.China

Record the following information bellow for service or warranty assistance.

Date of Purchase:

Model Number:

Serial Number:

4

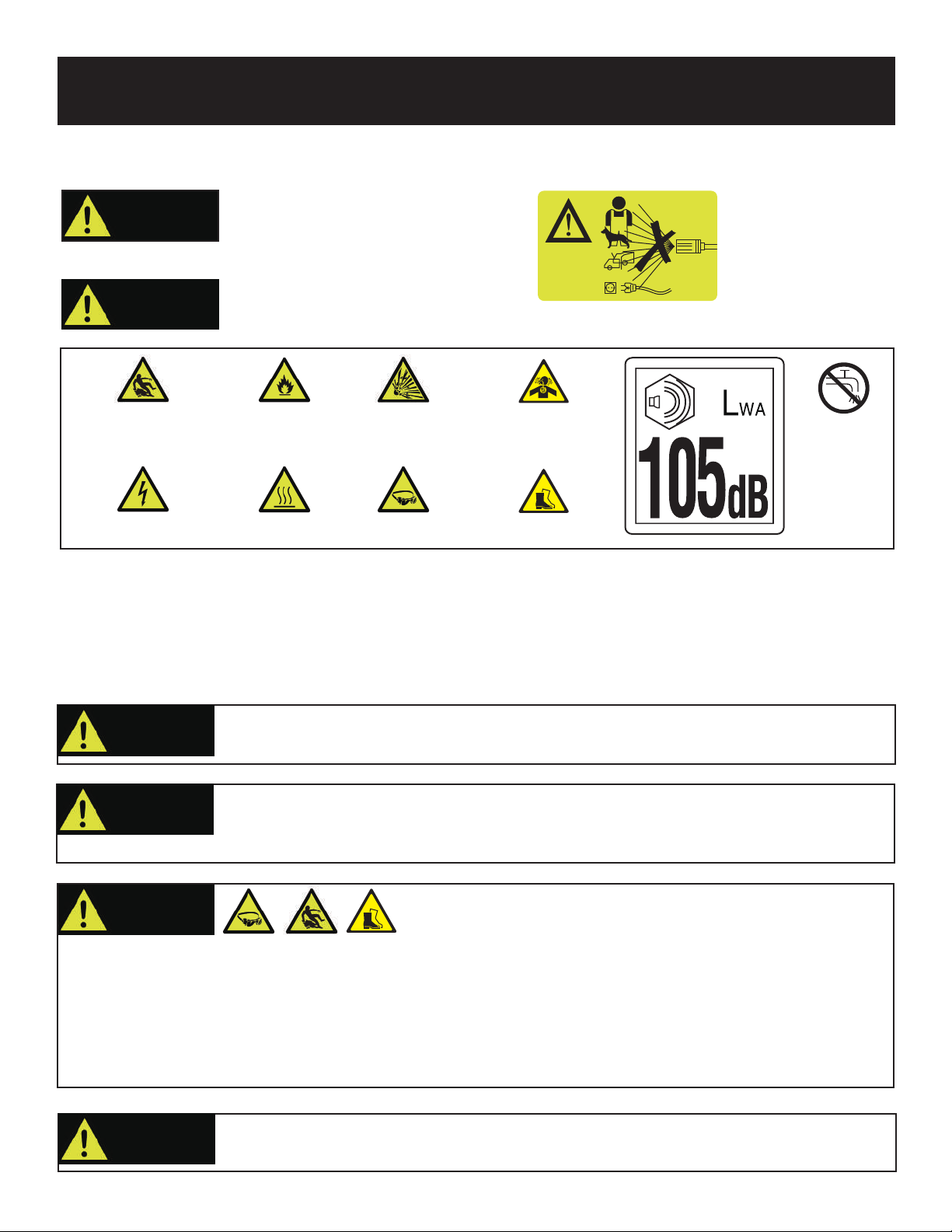

Safety Symbols

WARNING!

CAUTION!

SAFETY RULES

Indicates a potentially hazardous

situation which could result in

serious injury or death if not avoided.

Indicates a potentially hazardous

situation which could result in

damage to equipment or property.

Never point the jet at

people, animals, the

device itself or live

electrical devices.

Slippery surface Risk of explosionRisk of fire

Risk of electric shock Hot surface Eye protection

Carbon monoxide

Safety footwear

The unit is

not suitable

for use with

a drinking

water supply!

Safety Instructions

This machine must be attended during operation. The manufacturer cannot anticipate every possible hazardous

circumstance that the user may encounter. Therefore, the Warning!s in this manual, on tags, and on affixed decals are not

all-inclusive. To avoid accidents, the user must understand and follow all manual instructions and use common sense.

WARNING!

WARNING!

Read and understand this manual in its entirety before operating this pressure washer.

Improper use of this pressure washer could result in serious injury or death.

This machine has been designed for use with the cleaning agent supplied or recommended

by the manufacturer. The use of other cleaning agents or chemicals may adversely affect

the safety of the machine.

WARNING!

• Spray from this unit has extreme pressure and can ricochet back splashing water or propelling objects towards eyes.

• Never substitute eye protection with dry condition goggles.

• Pressure washer can create puddles and slippery surfaces. Never wear sandals, always wear protective footwear.

• Operate pressure washer from a level and stable surface.

• Do not operate from a ladder, scaffolding, or uneven surface as recoil from spray gun could cause you to fall.

• Do not over-extend yourself in attempt to reach a little further.

WARNING!

Do not direct the jet against yourself or others in order to clean clothes or foot-wear.

Do not use the machine within range of persons unless they wear

protective clothing.

5

SAFETY RULES

WARNING!

WARNING!

WARNING!

WARNING!

WARNING!

WARNING!

Risk of explosion - Do not spray flammable liquids.

High pressure cleaners shall not be used by children or untrained personnel.

High pressure hoses, fittings and coupling are important for the safety of the machine. Use

only hoses, fittings and couplings recommended by the manufacturer.

To ensure machine safety, use only original spare parts from the manufacturer or approved

by the manufacturer.

Water that has flowed through backflow preventers is considered to be non-potable.

The machine shall be disconnected from its power source during cleaning or maintenance

and when replacing parts or converting the machine to another function.

WARNING!

WARNING!

• Carbon monoxide gas is a poisonous, odorless gas that can cause headache, confusion, fatigue, nausea, fainting,

sickness, seizures, or death. If you start to experience any of these symptoms, IMMEDIATELY get fresh air and seek

medical attention.

Never use indoors, in a covered area, or in a confined space, even if doors and windows are open.

•

WARNING!

WARNING!

WARNING!

Do not use the machine if a supply cord or important parts of the machine are damaged,

e.g. safety devices, high pressure hoses, trigger gun.

Do not use combustion engine powered machines indoors unless adequate

ventilation is assessed by national labour authorities.

Ensure that any exhaust emissions are not in the vicinity of air intakes.

For gas or oil-heated machines it is important to provide adequate ventilation and make

sure that the flue gases are properly discharged.

Incorrect fuels shall not be used as they may prove hazardous

WARNING!

Never spray near a power source such as an electrical outlet. Making contact with

a power source could cause an electric shock or burn.

6

SAFETY RULES

WARNING!

WARNING!

• The high pressure stream of water produced can cut through skin and underlying tissue. Never squeeze the trigger or

point the spray gun at other people, animals, plants, or fragile objects such as glass, even if the engine is stopped.

• This unit is not a toy. Keep unit away from children and pets.

• Do not leave spray gun unattended while unit is running.

• Make sure the spray gun, nozzle, and accessories are attached correctly.

• Never attempt to repair high pressure hose, always replace.

• Never attempt to repair leaks with sealant, always replace O-ring or seal.

• Never attempt to connect or disconnect hose from pump or spray gun while system is pressurized.

• Always release water pressure from unit every time you stop the engine.

WARNING!

•

• Allow hot components to cool before touching.

Stay alert and use common sense. Do not operate this unit if you are under the influence of

alcohol, drugs, medication or you feel tired.

High pressure jets can be dangerous if subject to misuse. The jet must not be directed at

persons, live electrical equipment or the machine itself.

Avoid contacting hot areas of this unit.

WARNING!

• Do not wear loose clothing or gloves.

• Remove jewelry or anything else that could be caught in moving parts.

• Tie back or wear protective head covering to contain long hair.

Moving parts can catch on clothing, jewelry, and hair.

WARNING!

•

death.

•

on the unit before starting the engine.

• Never smoke while operating or fueling this unit.

•

•

• When adding or draining fuel, unit should be turned off for at least 2 minutes to cool before removing fuel cap. If unit

has been running the fuel cap is under pressure, remove slowly.

• To keep fuel from spilling, secure unit so it cannot tip while operating or transporting.

• When transporting unit, disconnect the spark plug wire and make sure the fuel tank is empty with the fuel shutoff

valve turned to the off position.

WARNING!

This machine can be used by people with reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they have been given supervision or instruction

concerning use of the machine in safe way and understand the hazards involved.

7

PRESSURE WASHER FEATURES

A - High Pressure Hose

B - Fuel Tank

C - Choke

D - Fuel Valve Lever

E - Soap Tank

F - Handle

G - Spray Gun

H - Locking Trigger

I - Pull Cord

J - Engine Switch

K - Dipstick

L - No Flat Foam Filled Tires

M - High Pressure Hose Outlet

N - Water Inlet

8

PRESSURE WASHER PARTS ASSEMBLY

9

PRESSURE WASHER PARTS LIST

NUMBER ITEM NAME QTY

1 Engine 1

2 Bolt M6 7

3 Shim 9

4 M6 Self-Lock Nut 9

5 Lower "A" Frame assembly 1

6 M8 Self-Lock Nut 1

7 Rubber Feet 1

8 Cap, Soap Tank 1

9 Soap Tank 1

10 Lower "A" Frame assembly Board 1

11 Gun Hook 1

12 M6 Self-Lock Nut 8

13 Engine Mount, Vibration Isolator 4

14 Wheels 2

15 Axle 2

16 Hair Pin 2

17 Handle Pivot Lock 2

18

19 Panel 1

21 Gun Hook 2

22 Nozzle Holder 4

23 Handle 1

24 Foam Grip 1

25 Bungee Cord Knob 1

26 Bungee Cord 1

27 Siphone Tube 1

28 Pump 1

29 Bolt M8 4

30 Shaft Key 1

31 Wand 1

32 Spray Gun 1

33 Nozzle Cleaner 1

34 Smart cover 1

35 High Pressure Hose 1

36

37

38

39 Black Soap Nozzle 1

40 Spark plug wrench 1

41 funnel 1

Plastic expansion screw

Red Nozzle 0°

Green Nozzle 25°

White Nozzle 40°

2

1

1

1

10

ASSEMBLY

Packing List

• Pressure washer

• Spark plug wrench

• Operator’s manual and product registration card

• Engine manual

• Spray gun

Extension wand with quick-connect fitting High

•

pressure hose

•

• Spray nozzles (5) - 0°, 15°, 25°, 40° and soap nozzle

• funnel

• Nozzle cleaner

WARNING!

WARNING!

Do not attempt to assemble or operate this pressure washer until you have read and

understood this entire manual. If you have any problems assembling or operating this unit

Do not operate this pressure washer if any of the parts are damaged or missing until the

part is replaced. Using this product with damaged or missing parts can cause damage to

the machine or result in serious injury or death.

Unpacking

1. Remove the high pressure hose from box.

2. After the high pressure hose has been removed, carefully open product by cutting down the sides of the box.

3. Remove the product, parts, and all accessories. Make sure all items listed on the packing list are included and not

damaged.

11

ASSEMBLY

Install Handle (See fig 1)

• Install upper frame (handle) onto the lower frame by sliding the handle over the two upright tubes on the lower frame

and pressing down firmly until the handle is seated and the two detent pins snap in place.

FIG 1

Attaching the Spray Gun (See fig 2 & 3)

• Screw the spray wand and the trigger handle together until they are secure.

•

nut on by turning clockwise until it is hand tight.

FIG 2

FIG 3

12

ASSEMBLY

Adding / Checking Engine Oil (See fig 4)

• Place pressure washer on a level surface.

•

• Carefully add between 520 ml (17.6 oz) of 4-Cycle engine oil (SAE10W30) to empty reservoir until oil reaches

• Be sure to replace both dipsticks before attempting to start the engine.

• To check oil, set pressure washer on a level surface, wipe dipstick clean, then reinsert dipstick without re-threading.

FIG 4

Adding Fuel (See fig 5)

• Set pressure washer on a clean and level surface in an area that is well ventilated.

• Remove fuel cap.

• Insert a funnel into the fuel tank and carefully pour gasoline into the tank until fuel level reaches 1 1/2 inches below the

top of the neck.

CAUTION!

CAUTION!

FIG 5

14

ASSEMBLY

Connecting Garden Hose to Pressure Washer (See fig 6)

• Inspect inlet screen and remove any debris.

• Connect hose to water inlet and tighten by hand. There must be a minimum of 10 feet of unrestricted hose between

pressure washer and faucet or shut off valve.

• Turn on water.

• Purge the system’s pump of air by releasing the safety and squeezing the trigger of the spray gun.

CAUTION!

Do not run pump without connecting to the water supply and turning water on. Failure to

do so could damage the pressure washer. Failure to follow these instructions will void

product warranty. The unit is not suitable for use with a drinking water supply!

FIG 6

Connect High Pressure Hose to Pump (See Fig 7)

• Attach end of high pressure hose to the high pressure outlet on pump.

• Follow the same procedure with opposite end to attach high pressure hose to spray wand.

FIG 7

15

OPERATION

Pre-Operation Check List

• Read and understand this operator manual in its entirety before operating pressure washer.

• Check oil level and add oil to the proper level if low.

• Check fuel level and add fuel if needed.

• Check connections of handle and all hoses to make sure they are secure.

• Check all hoses for kinks and damage.

•

Check flow of water supply and make sure it is adequate (2.8 - 5.6bar).

WARNING!

from dissipating.

• Carbon monoxide gas is a poisonous, odorless gas that can cause headache, confusion, fatigue, nausea, fainting,

sickness, seizures, or death. If you start to experience any of these symptoms, IMMEDIATELY get fresh air and seek

medical attention.

•

•

• When working in areas where vapors could be inhaled, use a respirator mask according to all of its instructions.

CAUTION!

Do not run pressure washer with a damaged hose. Do not run pressure washer without

result. FAILURE TO FOLLOW THESE INSTRUCTIONS WILL VOID PRODUCT WARRANTY.

Starting Pressure Washer (See Fig 8-9)

• Place pressure washer on a level surface.

• Turn on water.

• Purge the system’s pump of air by releasing the safety and squeezing the trigger of the spray gun.

• Attach wand/lance to spray gun.

• Turn fuel valve to the ON position.

• Slide the choke lever to the “Choke” position.

• Turn the engine OFF/ON switch to the “ON” position.

• Holding the machine with your hand, pull the recoil handle (starter cord) slowly until resistance is felt, then pull rapidly.

Squeeze the Gun trigger and release the pressure after every failed attempt to start the pressure washer (This will

reduce the back pressure).

• Let engine run for several seconds and then gradually slide the choke lever to the RUN position as the engine warms

up until the choke is fully slid to the RUN position.

CHOCK

RUN

OFF

ON

OFF

ON

FIG 8 FIG 9

16

OPERATION

WARNING!

Pull cord recoils rapidly and pulls arm towards engine faster than you can let go which

could result in injury.

• Always relieve pressure from spray gun before pulling starter cord, including every failed attempt to start engine.

• To avoid recoil, pull starter cord slowly until resistance is felt, then pull rapidly.

Stopping Pressure Washer (See Fig 10)

• Turn the on/stop switch to the OFF position.

• Turn the fuel valve to the OFF position.

• Turn off water and squeeze the trigger handle to release all water pressure.

OFF

ON

FIG 10

Using the Spray Gun (See Fig 11 - 12)

• Flip the lock tab behind the trigger up or down until it clicks to apply or remove the safety. Pull back on the trigger to

begin operating pressure washer.

•

To stop water flow, release trigger.

SLOT

LOCK OUT

WARNING!

FIG 11 FIG 12

Kickback forces result from pressing the trigger! Therefore, always hold the spray gun with

both hands! Pay attention to safe posture! Improper handling can lead to injuries!

TRIGGER

Using Spray Nozzle (See fig 13-14)

• To connect or disconnect spray tip, pull back on the quick-connect collar. Insert or remove spray tip then release collar.

• When spray tip is connected, pull on the spray tip to make sure it is secured.

• For general cleaning use the 40° spray tip. This option is for cement walkways.

17

OPERATION

• For stripping, spot cleaning, blasting, and hard to reach areas use the 25° spray tip. This option is for removing paint,

rust, mildew, marine growth off boats, or grease stains. This option can be used for reaching second story surfaces, or

for the removal of paint, rust, oil stains, tar, gum, and other stubborn substances. Use extreme caution when using this

nozzle.

• For applying pressure washer safe detergent, use the black soap nozzle.

• The angle of the nozzles shown indicates the spray “fan shape” projected from the nozzle when the trigger of the spray

gun is pulled and high pressure water is passing through the nozzle. The pressure and flow will not change significantly

due to the various fan patterns (Nozzles).

SPRAY

WAND

“CLICK”

NOZZLE

FIG 13

0°

25° 40°

Soap

FIG 14

Applying Detergent

• Rinse surface with cool water before applying cleaner.

• Prepare detergent as required by job. For best results follow detergent directions as supplied from manufacturer.

• Remove cap from detergent container and fill.

• Spray detergent on surface. For best results use long, even, and overlapping strokes. Allow detergent to set for about

3 minutes before rinsing, but do not allow detergent to dry on surface or it may cause streaking or cause damage to the

surface. Use good judgment.

•

a bucket of clean water to remove detergent.

WARNING!

Only use mild, environmentally friendly detergents intended for use in pressure washers.

Ask at your specialist dealer about these special products. Never use aggressive chemicals

(eg bleach), abrasive detergents or similar to avoid damage to your health, the product and

the environment.

WARNING!

Avoid skin contact with detergents, in particular contact with eyes! If detergents gets in

your eyes flush your eyes with clean water and seek immediate medical attention!

Rinsing with the Pressure Washer

Test a small area first to avoid surface damage.

•

• Rinse from top to bottom using long, overlapping strokes.

Moving the Pressure Washer

• Turn the pressure washer off.

• Tilt unit towards you until it is balanced on its wheels.

• Roll machine to desired location.

18

MAINTENANCE

Regular maintenance will extend the life of this pressure washer and improve its performance. The warranty does not

cover items that result from operator negligence, misuse, or abuse. To receive full value from the warranty, operator must

maintain the pressure washer as instructed in this manual, including proper storage.

WARNING!

Before inspecting or servicing this machine, make sure the engine is off and no parts are

moving. Disconnect the spark plug wire and move it away from the spark plug.

Pre-operation Steps

Before starting the engine, perform the following pre-operation steps:

• Check the level of the engine oil and the fuel tank level

•

• Remove any debris that has collected on the pressure washer.

• Check water inlet screen for damage. Clean inlet screen if it is clogged.

• Check high pressure hose for damage.

•

Briefly run garden hose to flush out any debris or insects.

• Inspect the work area for hazards.

Remove Debris

•

• Use a damp cloth to wipe exterior surfaces. If dirt is caked on, use a soft bristle brush.

After Each Use

Follow the following procedure after each use:

• Shut off engine and turn off water supply. Release water pressure by pointing spray gun in a safe direction and

squeezing the trigger.

• Disconnect high pressure hose, spray gun, and nozzle. Drain water from items and use a rag to wipe down the outside

of the hose and spray gun.

• Empty the water from the pump by pulling the recoil starter 6 times.

• Store unit in a clean and dry area.

• Use of a pressure washer pump conditioner is recommended, follow the instructions provided by the manufacturer of

the pump conditioner.

Maintenance Schedule

After First 5 Hours Change Engine Oil

After Each Use Check and Clean Water Inlet screen

Check High Pressure Hose

Check and Clean Detergent Siphoning Tube

Check Spray Gun for Leaks

Clean Debris

Check Engine Oil Level before starting

Annually (20 hr Use) Change Engine Oil (Service more often under dirty or dusty conditions)

Annually (50 hr Use) Check and Clean Air Filter

Annually (100 hr Use) Service or Replace Spark Plug

19

MAINTENANCE

Changing Engine Oil

Engine oil will drain better if the engine is still warm, but not hot.

• Shut off engine.

Clean the area around the oil fill cap/dipstick to keep out debris then remove oil fill cap/dipstick.

•

• Place an oil pan on the ground to catch oil. Remove oil plug then tilt pressure washer back and to the side to empty out

the oil from the crankcase.

•

Once oil is completely drained, return the pressure washer to a level position and install the oil drain plug. Refill the

engine with new oil as instructed earlier in this manual under Adding/Checking Oil.

Oil Drain Plug

Checking Detergent Siphoning Tube

• Check the detergent siphoning tube for clogs, leaks, or tears.

•

• Replace siphoning tubes if damaged.

WARNING!

Never repair high pressure hose or use unit if hose is damaged. If hose is damaged replace

with identical Ducar part.

High Pressure Hose

• Inspect hose for cuts, bulges, or leaks which can develop from kinking or wear. If damage is found, immediately replace

hose.

• Inspect couplings for damage. Immediately replace hose if damage is found.

Spray Gun

• Make sure the spray gun is connected securely.

• Inspect the spray gun safety and make sure the spray gun trigger springs back upon release.

Spray Nozzle

If a pulsing sensation is felt while squeezing the trigger, the spray nozzle may be dirty or clogged and should be cleaned

immediately.

• To clean the nozzle, shut off the engine and turn off the water.

• Remove the nozzle from the spray wand making sure that the nozzle is pointing away from you and in a safe direction.

• Use the nozzle cleaner or a small paper clip to dislodge any foreign materials which are clogging or restricting the

spray tip.

•

• Reconnect the nozzle to the spray wand.

• Turn the water supply back on and start engine.

Nozzle Cleaner

20

MAINTENANCE

Checking Spark Plug

• Disconnect the spark plug wire from the spark plug.

• Before removing the spark plug, clean the area around its base to prevent debris from entering the engine.

• Clean carbon deposits off the electrode with a wire brush.

• Check the electrode gap and slowly adjust to 0.80mm (0.031in.) if necessary.

• Reinstall spark plug and tighten to Torque 22.0 – 26.9 Nm (16-20 ft-lb).

• Reconnect spark plug wire.

• If spark plug is worn replace only with an equivalent replacement part. Spark plug should be replaced annually.

WARNING!

• Never attempt to repair high pressure hose, always replace.

• Never attempt to repair leaks with sealant, always replace O-ring or seal.

Water pressure produced by this unit can cut through skin and tissue leading to serious

injury and possible amputation.

Repairing Leaking Connections

• Purchase O-Ring / Maintenance kits through the nearest authorized service center and follow instructions provided with

kit.

Air Filter

•

•

•

• .

WARNING!

.

Storing Pressure Washer

If storing pressure washer for 30 days or more follow the procedures below:

• Add fuel stabilizer to gasoline to keep gasoline from going stale and to prevent gum deposits from forming on the

carburetor. Run engine for a couple of minutes to circulate the fuel stabilizer.

• Add PumpSaver to protect pump from freezing or damage caused by mineral deposits.

•

• Disconnect the spark plug wire and clean the spark plug. Leave spark plug wire disconnected.

•

• Cover unit with a suitable protective cover to keep unit dry.

• Store unit in a frost-free area.

21

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Engine does not start 1. Out of fuel

2. Engine oil low

3. Spark plug wire disconnected

from spark plug

4. Bad spark plug

5. Spark plug wire has shorted

6. Ignition inoperative

Engine hard to start

Engine lacks power and vibrates

excessively

Engine quits during operation

Engine loses power when load is

added

1. Stale fuel or water in fuel

2. Spark plug producing weak spark

3. Excessively rich fuel mixture

1.

1. Out of fuel

1. Engine speed is too slow

1. Fill fuel tank

2. Add engine oil

3. Connect spark plug wire

4. Replace spark plug

5. Contact service center

6. Contact service center

1.

gasoline.

2. Contact service center

3. Contact service center

1.

1. Fill fuel tank

1. Move throttle to fast. If this does

not correct problem, contact

service center.

Water pressure is weak 1. Water supply is restricted.

2. Water not turned on to full power

3. Not using high pressure nozzle

Detergent and spray do not mix

Pump fails to produce pressure or

pressure is inconsistent

1. Detergent hose is not submerged

or has disconnected

2. Black soap nozzle needed

1. Water supply is restricted

2. Water not turned on full power

3. Nozzle is clogged

4. Spray gun leaks

5. Air in line

6. Inlet hose screen is clogged

7. Water supply is over 100°F

8. Pump is faulty

1. Inspect garden hose for kinks or

leaks. Make sure you are using

a large enough garden hose

(min. ¾ inch diameter)

2. Open water source all the way.

3. Change nozzle

1. Make sure hose is connected

and submerged in the detergent.

2. Install soap nozzle

1. Inspect garden hose for kinks or

leaks. Make sure you are using a

large enough garden hose (Min.

¾ inch diameter)

2. Open water source all the way.

3. Clean nozzle

4. Check spray gun connection or

replace spray gun

5. Squeeze trigger handle to

remove air

6. Clean inlet

7. Use cool water supply

8. Contact service center

22

DIAGRAMS

23

Loading...

Loading...