DualSaw RS1200 Owner's Manual

WARNING: Read, understand and follow all safety rules and

operating instructions in this manual before using this product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

RS1200

OWNERS’

MANUAL

1

TABLE OF CONTENTS

Introducon ......................................................................................................... 1

Warranty .............................................................................................................. 1

Product Registraon ............................................................................................ 2

General Safety Rules ............................................................................................ 2

Specic Safety Rules ............................................................................................ 5

Symbols ............................................................................................................... 8

Features ............................................................................................................. 9

Assembly ............................................................................................................ 11

Operaon ........................................................................................................... 14

Maintenance ...................................................................................................... 19

Parts List .............................................................................................................. 20

Customer Service ............................................................................................... 22

INTRODUCTION

The DUALSAW® RS1200 has many special features that make this tool dierent

from other reciprocang saws. Please read and understand this manual before

using this product.

WARRANTY

DUALSAW® – LIMITED ONE YEAR WARRANTY

This warranty covers all defects in workmanship or materials in your DUALSAW®

for a period of one year from the date of purchase. This warranty does not

cover blades.

HOW TO GET SERVICE

Return the DUALSAW® RS1200, properly packaged and postage prepaid to our

Authorized Service Center. You can obtain the locaon of the Center by calling

1‑855‑382‑5729. When you request warranty service, you also must present proof

of purchase documentaon, which includes the date of purchase (sales receipt).

We will repair any faulty workmanship, and either repair or replace any defecve

part, at our opon. We will do so without any charge to you. We will complete the

work within 90 days or less.

WHAT IS NOT COVERED

This warranty applies only to the original purchaser and may not be transferred.

This warranty only covers defects arising under normal usage and does not

cover any malfuncon, failure, or defects resulng from misuse, abuse, neglect,

alteraon, modicaon, or repairs by other than the Authorized Service Center.

Infusion Brands, Inc. makes no warranes, representaon, or promises as to the

quality or performance of its power tools other than those specically stated in

this warranty.

2

3

PRODUCT REGISTRATION

To get informaon on product updates, special oers, and warranty claims,

register your DUALSAW® RS 1200 on our website www.DualSaw.com

Here is what you will need:

• Sales Receipt

• Machine Serial Number (located on the underside of the saw body)

GENERAL SAFETY RULES

WARNING!

Read, understand, and follow all safety rules and operating instructions

in this manual before using this product. Failure to follow all rules and

instructions listed below may result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Always keep your work area clean and well lit. Cluered benches and dark

areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence

of ammable liquids, gases, or dust. Power tools create sparks, which may

ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operang a power tool.

Distracons can cause you to lose control.

GENERAL SAFETY RULES

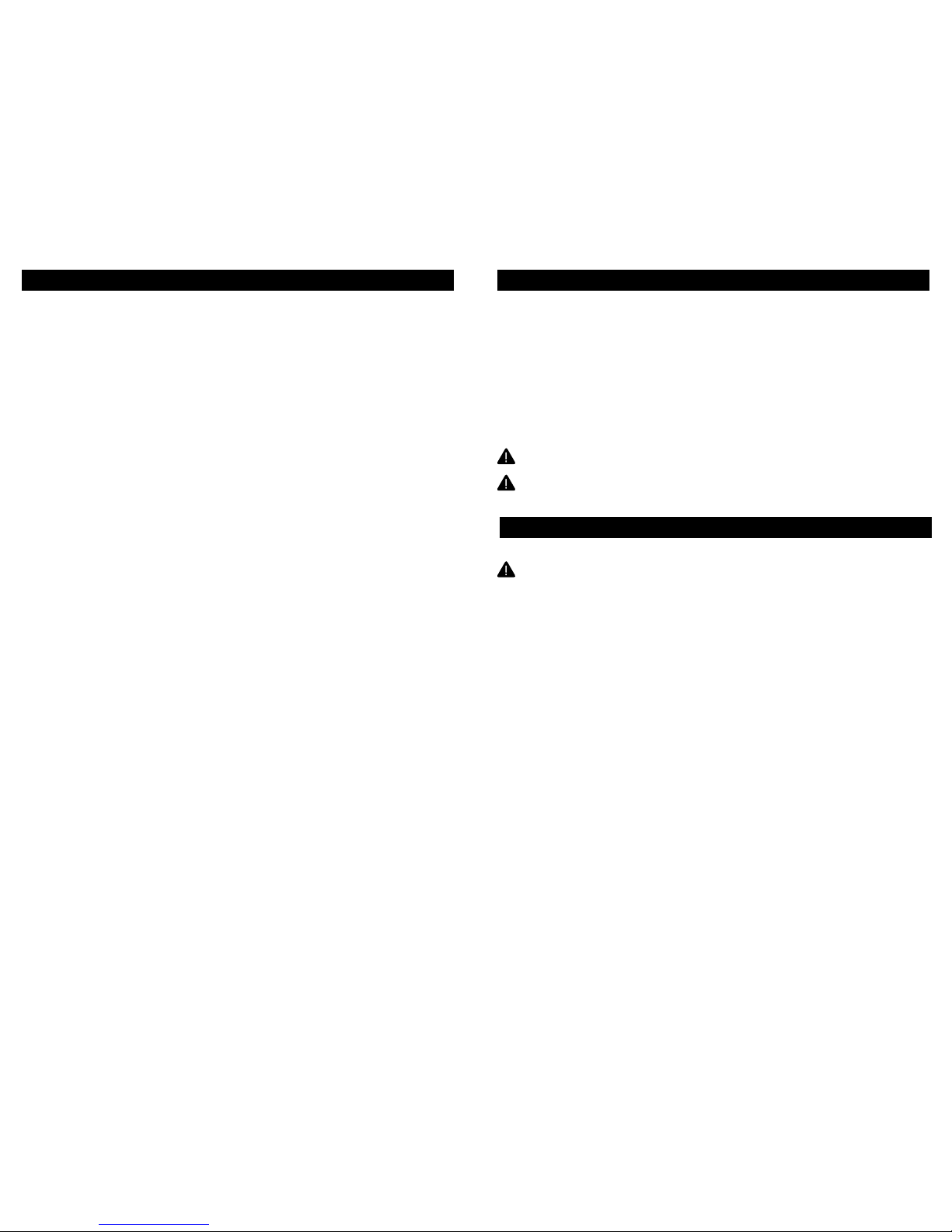

Note: The extension cord must have adequate wire size AWG (American Wire Gauge)

for safe, efficient use. Smaller gauge wires have greater capacity (16 gauge wire has

more capacity than 18 gauge wire).

ELECTRICAL SAFETY

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges,

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

• Do not expose power tools to rain or wet condions. Water entering a power

tool will increase the risk of electric shock. If operang the power tool in

damp locaons is unavoidable, a Ground Fault Circuit Interrupter must be

used to supply the power to your tool. Use electrician’s rubber gloves and

footwear to further enhance your personal safety in damp condions.

• Do not abuse the cord. Never use the cord to carry the tool or to pull the

plug. Keep cord away from heat, oil, sharp edges, or moving parts. Contact

Customer Service if cord is damaged and do not use the saw. Damaged cords

increase the risk of electric shock.

• Do not use tool if saw does not turn “ON” or “OFF”. Any tool that cannot be

controlled with the trigger switch is dangerous and must be repaired.

• When operang a power tool outside, always use an outdoor extension

cord with a minimum 13 amperes fuse. These cords are rated for outdoor

use and reduce the risk of electric shock. The use of any extension cord will

cause some loss of power. To keep the loss at a minimum and to prevent

overheang, use an extension cord that is heavy enough to carry the current

that the tool will draw. For recommended sizes of extension cords refer to the

following table.

serial number

Minimum Gauge Extension Cord (AWG)

Volts Total Length of Cord

120v 0 to 25 26 to 50 51 to 100 101 to 150

240V 0 to 50 51 to 100 101 to 200 201 to 300

Ampere Rang AWG AWG AWG AWG

More than 0

Not more than 6

18 16 16 14

More than 6

Not more than 10

18 16 14 12

More than 10

Not more than 13

16 16 14 12

More than 13

Not more than 16

14 12 Not Recommended

4

5

PERSONAL SAFETY

• Stay alert. Watch what you are doing and use common sense when operang

a power tool. Do not use the tool while red or under the inuence of drugs,

alcohol, or medicaon. A moment of inaenon while operang power tools

may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts. Wear protecve hair covering to contain long hair.

• Keep handles dry, clean and free from oil and grease. Rubber gloves and non‑

skid footwear are recommended when working outdoors.

• Avoid accidental starng. Carrying tools with your nger on the switch or

plugging in tools that have the switch in the “ON” posion invites accidents.

• Do not overreach. Keep proper foong and balance at all mes. Proper foong

and balance enables beer control of the tool in unexpected situaons.

• Use safety equipment. Always wear eye protecon. Dust mask, non‑skid

safety shoes, hard hat, or hearing protecon must be used for appropriate

condions.

TOOL USE AND CARE

• Always use clamps or other praccal ways to secure and support the

workpiece to a stable plaorm. Holding the material in your hand or against

your body is dangerous and may lead to loss of control. Hold the tool rmly to

prevent loss of control.

• Do not force the tool. Use the correct tool for your applicaon. The correct

tool will do the job beer.

• Disconnect the plug from the power source before making any inspecons or

adjustments, changing blades, or storing the tool. Such preventave safety

measures reduce the risk of starng the tool accidentally.

• Store idle tools in a dry and secure place, out of reach of children and other

untrained persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Properly maintained tools with sharp cung edges

are less likely to jam and are easier to control. Develop a periodic maintenance

schedule for your tool.

• Check for misalignment or binding of moving parts, breakage of parts, and

any other condion that may aect the tool’s operaon. If damaged, contact

Customer Service before using. Any alteraon or modicaon is a misuse and

may result in a dangerous condion.

GENERAL SAFETY RULES

KEEP HANDS AWAY FROM CUTTING AREA AND BLADE

• Always keep both hands on the saw. When both hands are holding the saw,

they cannot be cut by the blade.

• Keep your body posioned to either side of the saw blade, but not in line with

the saw blade. Hold the saw rmly to prevent loss of control. Do not reach

underneath the material being cut.

• While operang, always keep the cord away from the cung area.

• Never hold the workpiece being cut in your hands or across your leg. It is

important to support the material properly to minimize body exposure, blade

jamming, or loss of control.

• Always hold tool by the insulated gripping surfaces when performing an

operaon where the cung tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal parts of the tool “live” and

shock the operator.

• Do not turn the saw on while carrying it. Accidental contact with the saw

blade could result in serious personal injury.

• Periodically remove the blades, clean the saw with a cloth or blow it clean

with compressed air.

GENERAL SAFETY RULES

SPECIFIC SAFETY RULES

SERVICE

• Tool service must be performed only by qualied repair personnel. Service

or maintenance performed by unqualied personnel could result in a risk of

injury. Contact Customer Service for informaon for repairs.

• When servicing a tool, always use only idencal replacement parts. Follow

instrucons in the maintenance secon of this manual. Use of unauthorized

parts or failure to follow maintenance instrucons may create a risk of electric

shock or injury. Certain cleaning agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plasc parts.

DO NOT TOUCH ANY MOVING PART WHEN THE SAW IS RUNNING

BLADES MAY BE HOT AFTER USE. USE CAUTION WHEN CHANGING BLADES

6

7

SPECIFIC SAFETY RULES SPECIFIC SAFETY RULES

WARNING!

• Do not let familiarity with your saw make you careless. Remember that a

careless fraction of a second is sufficient to cause severe injury.

• Only use blades specially designed for this saw. Other blades will not

operate safely and could result in serious personal injury.

• If the blades come in contact with the workpiece before they reach

full speed, it could cause the saw to kickback toward you resulting in

serious injury.

HOW TO AVOID KICKBACK

Kickback is a sudden reacon to a pinched, bound, or misaligned saw blade,

causing the saw to li up and out of the workpiece and toward the operator.

When the blade is pinched or bound ghtly by the kerf closing down, the blade

stalls and the motor reacon drives the unit rapidly back toward the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back edge

of the blade can dig into the workpiece causing the blade to kickback.

Kickback is the result of tool misuse and/or incorrect operang procedures or

condions and can be avoided by taking proper precauons as given below:

• Maintain a firm grip with both hands on the saw and position your body

and arm to allow you to resist kickback forces. Kickback forces can be

controlled by the operator, if proper precautions are taken.

• Support large panels to minimize the risk of blade pinching and

kickback. Large panels tend to sag under their own weight. Supports must

be placed under the panel on both sides, near the line of cut and near the

edge of the panel.

• Do not use dull or damaged blades. Unsharpened or improperly set blades

produce a narrow kerf causing excessive friction, blade binding, and

kickback.

• Use extra caution when making a “plunge cut” into existing walls or other

blind areas. The protruding blade may cut objects that can cause kickback.

• Guard against kickback if the blade binds or the saw stalls and is rapidly

driven back towards the operator, release trigger switch immediately. Do

not force tool. Stay alert and exercise control.

ADDITIONAL SAFETY RULES

• Be sure to read and understand all instrucons. Failure to follow all

instrucons listed below may result in electric shock, re, and/or serious

personal injury.

• Know your power tool. Read operator’s manual carefully. Learn the

applicaons and limitaons, as well as the specic potenal hazards related to

this tool.

• Always wear safety glasses or eye shields when using this saw. Everyday

eyeglasses have only impact‑resistant lenses; they are NOT safety glasses.

• Always protect your lungs. Wear a face mask and dust mask if the operaon is

dusty.

• Always protect your hearing. Wear protecon during extended periods of

operaon.

• Inspect the tool’s cord periodically and if damaged, contact Customer Service.

• Check for damaged parts. Before using the tool, inspect all parts for damage to

determine if it will operate properly and perform its intended funcon. Check

for misalignment or binding of moving parts, breakage of parts, and any other

condion that may aect the tool’s operaon. A guard or other part that is

damaged should be properly repaired or replaced. Contact Customer Service.

WARNING!

Some dust created by using power tools contains chemicals that may

cause cancer, birth defects, or reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products,

• Arsenic and chromium from chemically treated lumber.

To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as those dust mask

that are specially designed to filter out microscopic particles.

Loading...

Loading...