Dual Pumps CF12150PHR, CT15250PHR, CT12150PHR, CT13200PHR, CT16200PHR Operating Instructions Manual

...

Model

Serial No.

Engine No.

Year of Manufacture

CE

Pressure Washer

Operating Instructions

793-1200

pumps

Pressure Washer

Operating Instructions

This manual and any other literature supplied should be read

thoroughly before attempting to operate the Power Washer. Pay

particular attention to any instructions relating to safety, and the

starting, stopping and maintenance of petrol and diesel engines.

This manual has been compiled to give all of the necessary information

to operate the Dual Pumps range of Pressure Washers safely and

effectively. It is recommended the manual and its accompanying

literature be read and understood before attempting to assemble

or operate the equipment. Following these simple instructions will

ensure operator safety and prolong the life of the power washer.

Our policy is to improve our products continuously and we therefore

reserve the right to discontinue or change specications, models or

designs without notice or obligation.

THESE INSTRUCTIONS SHOULD BE KEPT

WITH THE MACHINE AT ALL TIMES.

2. Equipment Variants and Options

This equipment has been designed and manufactured for the high pressure

washing of machinery, buildings etc, using water and detergent. Use only a

recommended detergent.

It should not be used for washing electrical equipment, people, animals and

surfaces that are loose and easily damaged.

This manual deals with the following variants of pressure washers,

Power input Petrol and diesel engines.

4bhp – 18bhp

High-pressure Multi cylinder plunger

Pump 8 lpm–30 lpm

100bar – 250bar pump pressure.

Transport frame Rigid steel frames in either static or

wheeled options.

EC DECLARATION OF CONFORMITY

Dual Pumps Ltd

Unit 8, Hudson Road

Saxby Road Ind. Est.

Melton Mowbray

Leicestershire LE13 1BS

Declares that this equipment conforms to the following directives,

2000/14/EC, 2006/42/EC, 2004/108/EEC

Tom Herridge

Technical Manager

1. Index

Equipment Variants and Options .........................................................section 2

Safety ..................................................................................................section 3

Description of Main Features...............................................................section 4

Installation ..........................................................................................section 5

Operation .............................................................................................section 6

Maintenance ........................................................................................section 7

Storage ................................................................................................section 8

Fault Finding ........................................................................................section 9

Warranty ............................................................................................section 10

Lance Variations .............................................................................. appendix 1

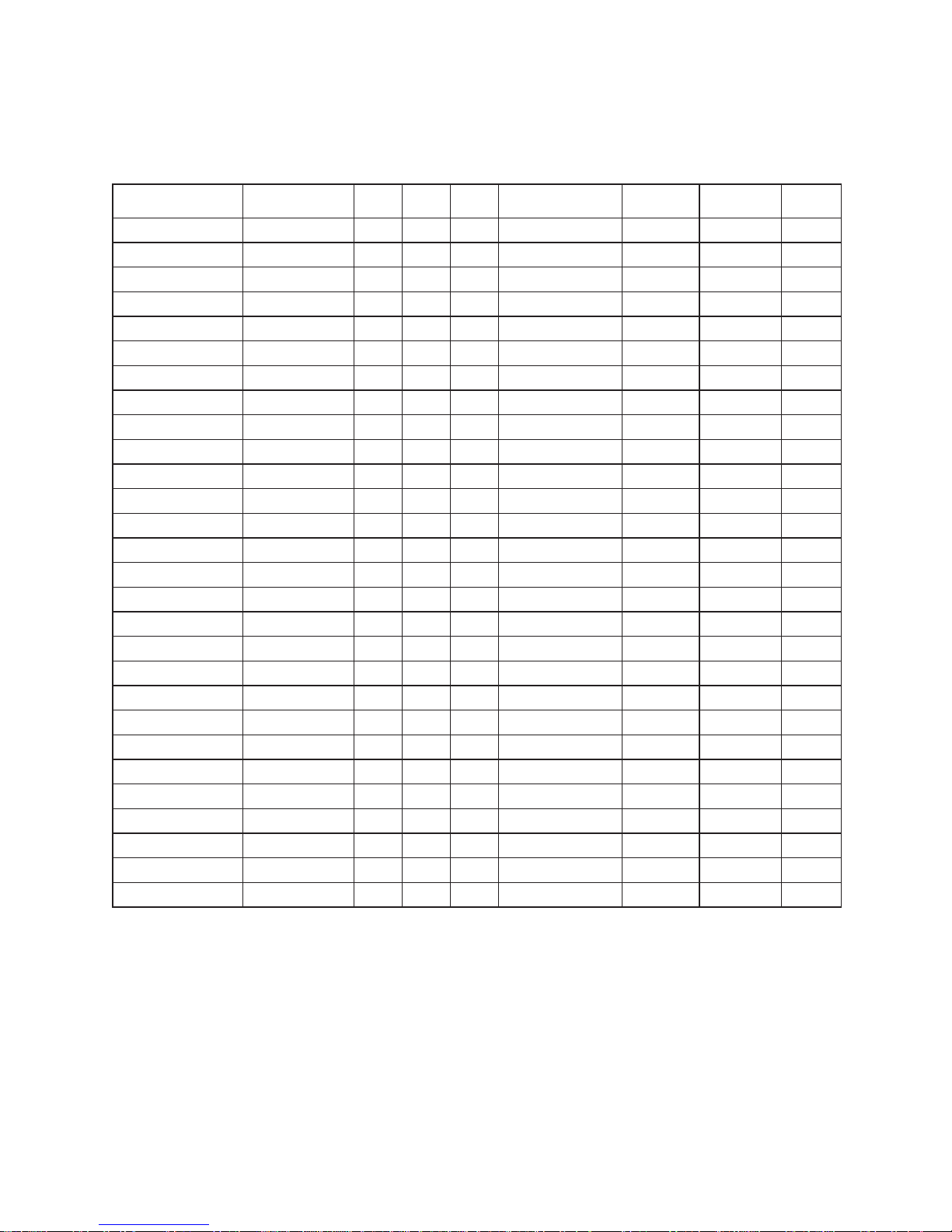

Variants and Options (g 1)

SPL = Sound Power Level on equipment representative for this type.

GSPL = Guaranteed Sound Power Level for this equipment.

Part No Engine Lpm Bar Kg L x W x H

SPL

LwA dB

GSPL

LwA dB

Group

CF10135PHR Petrol 5.5Hp 10 135 24 460x370x460 107 111 1-C

CF12150PHR Petrol 5.5Hp 12 150 31 580x410x455 107 111 1-C

CT12150PHR Petrol 5.5Hp 12 150 36 940x600x890 107 111 1-C

CT13200PHR Petrol 8Hp 13 200 48 940x600x890 105 111 1-E

CT16200PHR Petrol 11Hp 16 200 55 940x600x890 107 111 1-F

CT15250PHR Petrol 11Hp 15 250 60 970x630x850 107 111 1-G

CT13185DLR Diesel 6.8Hp 13 185 71 970x630x850 109 115 2-J

DT12140PHR Petrol 5.5Hp 12 140 43 910x565x890 107 111 1-C

DT14150PHR Petrol 6.5Hp 14 150 43 910x565x890 106 111 1-D

DT15200PHR Petrol 11Hp 15 200 70 970x630x850 107 111 1-F

DT15250PHR Petrol 13Hp 15 250 71 970x630x850 107 111 1-F

DF14150PHR Petrol6.5Hp 14 150 38 580x410x455 106 111 1-D

DS14150PHR Petrol 6.5 Hp 14 150 45 680x580x820 106 111 1-D

DT14150DLR Diesel 6.8Hp 14 150 73 970x630x850 109 115 2-J

RT15200PHR Petrol 11Hp 15 200 82 1060x620x710 107 111 1-F

RT15250PHR Petrol 13Hp 15 250 82 1060x620x710 107 111 1-F

RT21170PHR Petrol 13Hp 21 170 82 1060x620x710 107 111 1-G

RT15200DYE Diesel 10Hp 15 200 113 1060x620x725 111 112 2-O

RT21170DYE Diesel 10Hp 21 170 113 1060x620x725 111 112 2-O

RTT-C101 Petrol 11Hp 15 250 60 970x630x850 107 111 1-G

RTT-D201 Petrol 5.5Hp 12 140 43 910x565x890 107 111 1-C

RTT-D203 Petrol 6.5Hp 14 150 43 910x565x890 106 111 1-D

RTT-D204 Petrol 11Hp 15 200 70 970x630x850 107 111 1-F

RTT-D205 Petrol 13Hp 15 250 71 970x630x850 107 111 1-F

RTT-D202 Diesel 6.8Hp 14 150 73 970x630x850 109 115 2-J

WBU8150P-LC Petrol 5.5Hp 8 150 53 1520x680x740 107 111 1-C

WBU8150P Petrol 4.8Hp 8 150 58 1520x680x740 107 111 1-C

WBU8200P Petrol 5.5Hp 8 200 58 1520x680x740 107 111 1-C

*NOTE: Models prexed RTT- are supplied with Return To Tank by-pass system.

3. Safety

Power washers should only be used by fully trained, competent persons. They

should not be used by untrained or inexperienced users.

Care should be taken when handling the pressure washers as they have uneven

centres of gravity and may topple over when lifted.

3.1 Suitable Persons

Operators should be physically t and free from the inuences of drugs or

alcohol.

Prolonged periods of operation are strenuous and operators should be

encouraged to take regular breaks. If you have any doubts about your tness

to operate this equipment, seek professional advice before proceeding.

3.2 Protective Clothing

Operators and assistants should wear the following Personal Protective

clothing and equipment: -

Waterproof boots with good non-slip soles

Waterproof overalls

Waterproof gloves

*Goggles or full-face protection to at least BS EN166

**Ear Muffs or Ear Plugs to give protection to at least EN352-1. EN352-2

3.3 Use in conned spaces

Diesel and Petrol engines produce fumes and toxic gases, use only in wellventilated spaces.

To prevent the build up of ammable vapours the charging of petrol and

diesel tanks should not be done in conned spaces. Any spillages should

be cleaned up and any absorbent material used should be disposed of in

a proper manner.

3.4 General Safety

Check all hoses and couplings for tightness and damage, loose connections

should be tightened and damaged hoses replaced.

Ensure the workspace is clear and free from obstructions; consideration

should be given to the erection of fences or sheeting to prevent injury to

others.

High-pressure lances react ‘Kick Back’ when the operating trigger is pulled.

Ensure you have a good rm footing and anticipate this reaction.

Extra care should be taken when working at heights, scaffolding should be

in good condition, secure and properly fenced, working from ladders is not

recommended.

The high-pressure stream can be dangerous, do not point the stream directly

at others or submit them to the ne over-spray.

Loading...

Loading...