Dual Pumps CF12150PHR, CT15250PHR, CT12150PHR, CT13200PHR, CT16200PHR Operating Instructions Manual

...

Model

Serial No.

Engine No.

Year of Manufacture

CE

Pressure Washer

Operating Instructions

793-1200

pumps

Pressure Washer

Operating Instructions

This manual and any other literature supplied should be read

thoroughly before attempting to operate the Power Washer. Pay

particular attention to any instructions relating to safety, and the

starting, stopping and maintenance of petrol and diesel engines.

This manual has been compiled to give all of the necessary information

to operate the Dual Pumps range of Pressure Washers safely and

effectively. It is recommended the manual and its accompanying

literature be read and understood before attempting to assemble

or operate the equipment. Following these simple instructions will

ensure operator safety and prolong the life of the power washer.

Our policy is to improve our products continuously and we therefore

reserve the right to discontinue or change specications, models or

designs without notice or obligation.

THESE INSTRUCTIONS SHOULD BE KEPT

WITH THE MACHINE AT ALL TIMES.

2. Equipment Variants and Options

This equipment has been designed and manufactured for the high pressure

washing of machinery, buildings etc, using water and detergent. Use only a

recommended detergent.

It should not be used for washing electrical equipment, people, animals and

surfaces that are loose and easily damaged.

This manual deals with the following variants of pressure washers,

Power input Petrol and diesel engines.

4bhp – 18bhp

High-pressure Multi cylinder plunger

Pump 8 lpm–30 lpm

100bar – 250bar pump pressure.

Transport frame Rigid steel frames in either static or

wheeled options.

EC DECLARATION OF CONFORMITY

Dual Pumps Ltd

Unit 8, Hudson Road

Saxby Road Ind. Est.

Melton Mowbray

Leicestershire LE13 1BS

Declares that this equipment conforms to the following directives,

2000/14/EC, 2006/42/EC, 2004/108/EEC

Tom Herridge

Technical Manager

1. Index

Equipment Variants and Options .........................................................section 2

Safety ..................................................................................................section 3

Description of Main Features...............................................................section 4

Installation ..........................................................................................section 5

Operation .............................................................................................section 6

Maintenance ........................................................................................section 7

Storage ................................................................................................section 8

Fault Finding ........................................................................................section 9

Warranty ............................................................................................section 10

Lance Variations .............................................................................. appendix 1

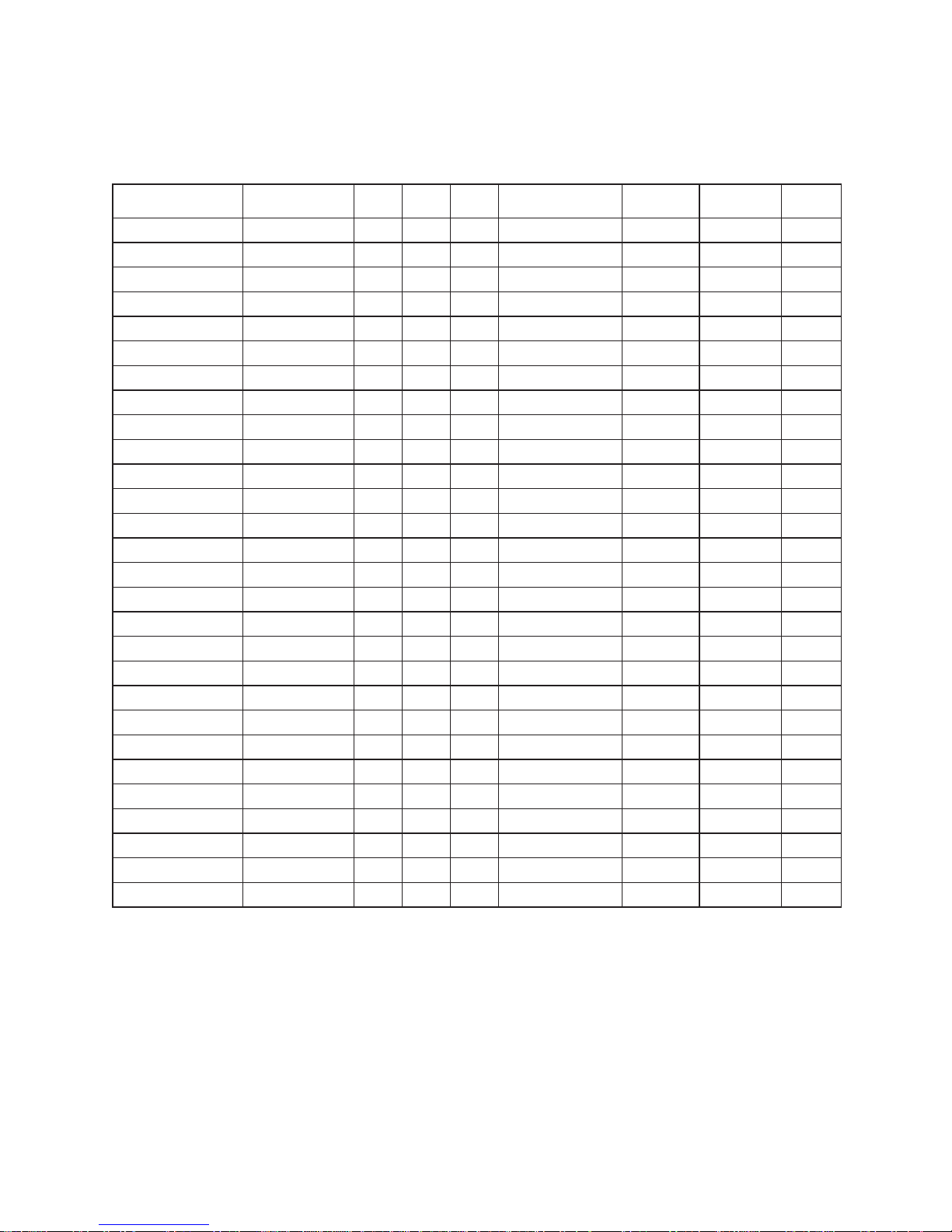

Variants and Options (g 1)

SPL = Sound Power Level on equipment representative for this type.

GSPL = Guaranteed Sound Power Level for this equipment.

Part No Engine Lpm Bar Kg L x W x H

SPL

LwA dB

GSPL

LwA dB

Group

CF10135PHR Petrol 5.5Hp 10 135 24 460x370x460 107 111 1-C

CF12150PHR Petrol 5.5Hp 12 150 31 580x410x455 107 111 1-C

CT12150PHR Petrol 5.5Hp 12 150 36 940x600x890 107 111 1-C

CT13200PHR Petrol 8Hp 13 200 48 940x600x890 105 111 1-E

CT16200PHR Petrol 11Hp 16 200 55 940x600x890 107 111 1-F

CT15250PHR Petrol 11Hp 15 250 60 970x630x850 107 111 1-G

CT13185DLR Diesel 6.8Hp 13 185 71 970x630x850 109 115 2-J

DT12140PHR Petrol 5.5Hp 12 140 43 910x565x890 107 111 1-C

DT14150PHR Petrol 6.5Hp 14 150 43 910x565x890 106 111 1-D

DT15200PHR Petrol 11Hp 15 200 70 970x630x850 107 111 1-F

DT15250PHR Petrol 13Hp 15 250 71 970x630x850 107 111 1-F

DF14150PHR Petrol6.5Hp 14 150 38 580x410x455 106 111 1-D

DS14150PHR Petrol 6.5 Hp 14 150 45 680x580x820 106 111 1-D

DT14150DLR Diesel 6.8Hp 14 150 73 970x630x850 109 115 2-J

RT15200PHR Petrol 11Hp 15 200 82 1060x620x710 107 111 1-F

RT15250PHR Petrol 13Hp 15 250 82 1060x620x710 107 111 1-F

RT21170PHR Petrol 13Hp 21 170 82 1060x620x710 107 111 1-G

RT15200DYE Diesel 10Hp 15 200 113 1060x620x725 111 112 2-O

RT21170DYE Diesel 10Hp 21 170 113 1060x620x725 111 112 2-O

RTT-C101 Petrol 11Hp 15 250 60 970x630x850 107 111 1-G

RTT-D201 Petrol 5.5Hp 12 140 43 910x565x890 107 111 1-C

RTT-D203 Petrol 6.5Hp 14 150 43 910x565x890 106 111 1-D

RTT-D204 Petrol 11Hp 15 200 70 970x630x850 107 111 1-F

RTT-D205 Petrol 13Hp 15 250 71 970x630x850 107 111 1-F

RTT-D202 Diesel 6.8Hp 14 150 73 970x630x850 109 115 2-J

WBU8150P-LC Petrol 5.5Hp 8 150 53 1520x680x740 107 111 1-C

WBU8150P Petrol 4.8Hp 8 150 58 1520x680x740 107 111 1-C

WBU8200P Petrol 5.5Hp 8 200 58 1520x680x740 107 111 1-C

*NOTE: Models prexed RTT- are supplied with Return To Tank by-pass system.

3. Safety

Power washers should only be used by fully trained, competent persons. They

should not be used by untrained or inexperienced users.

Care should be taken when handling the pressure washers as they have uneven

centres of gravity and may topple over when lifted.

3.1 Suitable Persons

Operators should be physically t and free from the inuences of drugs or

alcohol.

Prolonged periods of operation are strenuous and operators should be

encouraged to take regular breaks. If you have any doubts about your tness

to operate this equipment, seek professional advice before proceeding.

3.2 Protective Clothing

Operators and assistants should wear the following Personal Protective

clothing and equipment: -

Waterproof boots with good non-slip soles

Waterproof overalls

Waterproof gloves

*Goggles or full-face protection to at least BS EN166

**Ear Muffs or Ear Plugs to give protection to at least EN352-1. EN352-2

3.3 Use in conned spaces

Diesel and Petrol engines produce fumes and toxic gases, use only in wellventilated spaces.

To prevent the build up of ammable vapours the charging of petrol and

diesel tanks should not be done in conned spaces. Any spillages should

be cleaned up and any absorbent material used should be disposed of in

a proper manner.

3.4 General Safety

Check all hoses and couplings for tightness and damage, loose connections

should be tightened and damaged hoses replaced.

Ensure the workspace is clear and free from obstructions; consideration

should be given to the erection of fences or sheeting to prevent injury to

others.

High-pressure lances react ‘Kick Back’ when the operating trigger is pulled.

Ensure you have a good rm footing and anticipate this reaction.

Extra care should be taken when working at heights, scaffolding should be

in good condition, secure and properly fenced, working from ladders is not

recommended.

The high-pressure stream can be dangerous, do not point the stream directly

at others or submit them to the ne over-spray.

3.5 Control of Vibration at Work Regulations 2005

This machine in its standard form does not exceed the 2.5 m/s² vibration action

value and should not require any daily limitations to it use. Periodic equipment

checks and servicing will maintain the characteristics and efciency of this

machine.

Warning:

Any modications or accessories added or use with this machine may affect

the vibration levels. Under the Control of Vibration at Work Regulations it

is the employers duty to manage the exposure to vibration and implement

training and health surveillance for employees.

Under the Supply of Machinery (Safety) Regulations1992 (SMSR),

you should ensure equipment is in good condition and maintained in

accordance with the manufacturers instructions, any modications or

accessories added to this machine should be assessed for safe operation

and vibration, then implement appropriate measures.

* Note: Goggles or Full Face Protection.

The wearing of eye and face protection in hazardous areas is a requirement under regulation

4 of the personal protective equipment at work regulations 1992.

Regulation 4 requires employers to provide suitable personal protective equipment to

employees who may be exposed to risks affecting their health and safety.

Full Face Protection.

High speed flying partials or chemical splashes are rarely aimed directly at the eyes. A full

face visor offers the maximum protection in extreme conditions. Full face shields offer a wide

area of protection and because of the all round ventilation, remain mist free even in wide

temperatures swings.

Chemical Splash.

Chemical splashes and vapours can hit you from all sides. It’s important that full eye

enclosure is selected, e.g. Unvented goggles. Full face shields will also protect the whole

face from liquid splashes. Those with chin guards should be selected where there is a

danger of splash deflecting up from work surfaces.

Impact.

Impact hazards are caused by fast moving particles from the cleaning operation. The

potential impact speed must be assessed before selecting the most appropriate protection.

Safety glasses could be dislodged by high velocity impacts, in which case goggles or face

shield should be selected.

** Note: Ear Muffs or Ear Plugs.

The noise at work regulations require that from February 2006 persons working in noise

levels between 80dBA and 85dBA must be provided with suitable hearing protection on

request. If noise levels are above 85dBA then hearing protection must be supplied and worn.

4. Description of Main Features (g 2)

1. Detergent Hose 11. Operating Trigger and Safety Catch

2. Detergent Hose Connection 12. Pressure Hose Connection

3. Detergent Rate Control 13. Pressure Regulator

4. Drive Engine 14. Pump Dipstick

5. Gearbox Dipstick

(Depending on Model) 15. Pump Sight Glass

6. Gearbox Sight Glass

(Depending on Model) 16. Return (external return to water supply

depending on model)

7. Hand Lance 17. Suction Filter

8. High/Low Pressure Nozzle 18. Typical Transport Frame

9. High Pressure Hose 19. Water Inlet

10. High Pressure Pump 20. Water Inlet Filter

ALTERNATIVE

VALVE ASSEMBLY

RETURN TO TANK BY-PASS

(Depending on Model)

NOTE:

Typical Example of

Pressure

Washer Layout

5. Installation

5.1 From the pump and gearbox (if tted) remove the ‘Red’ travel plugs,

replacing them with the yellow-topped dipsticks. Check all oil levels, top

up if necessary.

5.2 Fill engine with oil and fuel, see engine manufacturers handbook

for details of oil and fuel types.

5.3 Connect the battery leads. (Electric start models only).

5.4 Connect the suction hose to the Power Washer (g 3). Ensure the

connection has no air leaks. Air leaks on the suction hose connection

will impair the performance of the machine.

5.5 Connect the water return line to its connector and place the other end in

the water supply container. (Bypass to tank models only)

(Fig 2 item 16 & Fig 4).

5.6 Submerge the opposite end of the suction hose and its suction lter in a

suitable container containing the water supply (g 4). Ensure the lter is

always kept below the water level.

5.7 Connect the high-pressure hose to the power washer (g 5) and to the

lance (g 6). Tighten as appropriate, do not over tighten.

Ensure that the trigger safety catch is in the ON position whilst making

these connections.

Fig 3. Connect the suction hose.

Fig 4. Submerge the suction hose.

Fig 5. Connect the High-Pressure Hose

to the Power Washer.

Fig 6. Connect the High-Pressure

Hose to the Lance.

NOTE

KEEP SUCTION FILTER CLEAN

Return

Suction

Return Hose

depending on

model

6. Operation

6.1 Start engine (Note: Depress the lance trigger to release water pressure

before starting the engine).

Refer to accompanying booklet relating to the type of engine tted.

6.2 Using High Pressure Lance

(Note: See Appendix 1 for lance type and operation)

Release the lance safety catch, which is located behind the trigger.

6.2.2 Point the lance downwards and towards the object being cleaned.

6.2.3 Squeeze, the trigger to start the high-pressure jet, proceed to

wash the object. Adjust the working pressure by turning the

pressure regulator knob + or - to suit the application (g 2, item 13).

Never direct the high-pressure stream at the engine or pump as

this could cause irreparable damage.

WARNING: - High-pressure lances react ‘Kick Back’ when the operating

trigger is pulled. Ensure you have a good rm footing and anticipate this

reaction.

6.2.4 Release the trigger to stop the high-pressure jet.

6.3 Washing using detergent

Attach the detergent induction pipe to the power washer,

(g 2, item 1) placing the opposite lter end into the detergent container.

Select the low pressure setting on the lance, (see appendix 1 for details

of your lance) and spray the water/detergent mixture onto the object

being cleaned. Leave the detergent for the period recommended by the

chemical manufacturer allowing it time to work, washing off with clean water.

The volume of detergent used can be controlled by means of the regulator

on the suction valve (see g 2. item 3).

6.4 Switching Off

Release trigger.

Stop drive engine, (refer to additional literature / handbook supplied,

relating to the type of engine tted, remembering to switch off ignition after

use to prevent draining the battery, electric start models only).

Depress the high-pressure lance’s trigger to release the pressure in the

high-pressure hose.

Disconnect water supply.

WARNING: Do not let the pump idle in By-Pass for lengthy periods, if you

intend to break from work for more than 5 minutes, switch the machine off.

Should the machine run for longer period, the temperature of the recirculating water will increase rapidly and could risk damaging the pump

seals. (Models with internal by-pass only).

Running power washers should never be left unattended.

8. Storage

Disconnect pressure hose and lance, draining water from the hose.

Disconnect water feed hose, draining water from the hose.

Wash out detergent hose with clean water, draining water from the hose.

Turn over the engine by hand to expel water from pump.

Ensure the equipment is clean and dry before storage.

The equipment should be stored in a dry and frost proof place.

7. Maintenance

Activity Each/ 3 months 12 months or

First Use or 50 Hours 100 hours

Inspect / top up oil levels

Engine *

Gearbox *

Pump *

Change Oil

Gearbox (EP90 Gear Oil) * *

Pump (SAE30 Pump Oil) * *

(Change engine oil in-line with the engine First 3

manufacturers recommendation), or at - months or *

50hrs only)

Clean water inlet lter *

Inspect and or change, engine/gearbox drive key

Inspect *

Change *

(It is recommended that you consult your dealer (if required)

before performing this item of maintenance)

Inspect high-pressure hose and its connection for *

tightness and damage

Inspect suction hose and its connections for *

tightness and damage

High pressure jet

Inspect *

Change *

Pneumatic tyres *

Check/Inate tyre pressures (0.7bar, 10psi) *

9. Fault Finding

Symptom Possible Cause Remedy

Pump running normally Lance in low pressure mode Check and adjust

but pressure low. Pressure Regulator valve Check and adjust

Pump sucking air. Check water supply and

possible air ingress.

Nozzle badly worn Check and/or replace

Worn piston packing Seek professional advice

Fluctuating pressure Blocked water lter Check lter, clean or

replace if necessary.

Pump sucking air Check integrity of suction

hose and connections.

Pressure low after a long Nozzle badly worn Check and/or replace

period of normal use.

Pump noisy. Pump sucking air Check integrity of suction

hose and connections.

Excessive temperature of Reduce temperature to

liquid in pump below 60ºC, do not allow

pump to idle for long

periods.

Worn bearing or valves Seek professional advice

Presence of water in oil. Ingress through breathers Replace oil, do not wash

engine or pump

Worn oil seals Seek professional advice

Water dripping from under pump. Worn piston packing Seek professional advice

Oil dripping from Worn oil seal Seek professional advice

pump/gearbox/engine.

Excessive vibration in Water supply low Check adequacy of water

lance/delivery line. supply. Ensure suction

lter is below water level.

Ingress of air into suction Check integrity of suction

line hose and connections.

Irregular functioning of Seek professional advice

valves

10. Warranty

Limited Warranty Supplied by Dual Pumps Ltd

Dual Pumps Ltd as suppliers warrants to the original purchaser, each new unit

or other product supplied from its factory, for the period of twelve (12) months

from the date of shipment from the factory, six (6) months for equipment on hire

or rental), to be free from defects in material and workmanship under normal use

and service. “Normal Use and Service” means not to exceed recommendations on

maximum speeds, pressures and temperatures or handling uids not compatible

materials, as noted in the applicable Dual Pumps catalogue, technical literature

and instructions. This warranty shall not apply to any pump or other product, which

has been repaired or altered, to adversely affect the performance or reliability of

the pump or product. Lance or hoses are not covered by this warranty due to the

adverse conditions of their use.

Neither this warranty nor any implied warranty apply to damage caused by any

of the following:

1. Freight damage

2. Frost or freezing damage

3. Damage caused by parts and/or accessories or components not obtained

from or approved by Dual Pumps Ltd.

4. Any consequential or incidental damage arising from the use of any, pump or

other products supplied by Dual Pumps Ltd.

5. Damage due to misapplication and/or misuse. The normal wear of moving

parts or components affected by moving parts.

The liability of Dual Pumps Ltd under the foregoing warranty is limited to the repair

or replacement at Dual Pumps Ltd option without charge for labour, mileage costs

or materials of any parts upon return of the entire pump or other product or of

the particular part to the Dual Pumps Ltd factory within the warranty period at

the sole expense of the purchaser, which part shall upon examination appear to

Dual Pumps Ltd satisfaction to have been defective in material or workmanship.

The liability of Dual Pumps Ltd under any theory or recovery (except any express

warranty where the remedy is set forth in the above paragraph) for loss, harm or

damage, shall be limited to the lesser of the actual cost, harm or damage, or the

purchase price of the involved pump or other product when sold by Dual Pumps

Ltd to its customer. Dual Pumps Ltd expressly warrants its pumps or other products

as above stated.

There are no other express warranties. Any implied warranties, including implied

warranty of merchantability or of tness for a particular purpose, are limited in

duration to twelve (12) months from the date of the purchase by the original

purchaser, (six (6) months for the equipment on hire or rental). There is no implied

warranty of tness for a particular purpose or merchantability when this product

is put to rental use.

No person including any dealer or representative of Dual Pumps Ltd is authorised

to make any representation or warranty concerning Dual Pumps Ltd products

on behalf of Dual Pumps Ltd, or to assume for Dual Pumps Ltd the obligations

contained in this warranty. Dual Pumps Ltd reserves the right to make changes in

design and other changes and improvements upon its products without imposing

any obligation on itself to install the same, in its existing products or products then

in process or manufacture.

This warranty does not affect any statutory rights that you may have.

Procedure for claiming under this warranty

The claimant must despatch the unit, product or part at his own expense to the

Dual Pumps Ltd factory with a full detailed report for inspection, upon receipt

Dual Pumps Ltd will inspect and decide whether the unit, product or part is in

fact a genuine warranty claim. Upon this decision the pump, product or part will

be replaced either free of charge under this warranty or despatched and charged

to the original customer together with a full report should it be found not to be

covered by this warranty.

Warranty claimed items, if required urgently will be despatched to the customer

and charged for, on receipt of the claimed defective item Dual Pumps Ltd will

decide whether the claim is valid and if so will issue a credit for the item. Should

Dual Pumps Ltd nd the claimed item to be out of warranty declarations the said

charge will stand and be paid by the customer as normal.

The copyright of this manual belongs to Dual Pumps Ltd and must not be copied

or reproduced without the express permission of the company.

Appendix 1. Lance variations

LOW PRESSURE JET

HIGH PRESSURE JET

Unit 8, Hudson Road

Saxby Road Ind. Est.

Melton Mowbray

Leicestershire LE13 1BS

Telephone: +44 (0)1664 567226 Fax: +44 (0)1664 410127

E-mail: info@dualpumps.co.uk www.dualpumps.co.uk

pumps

Loading...

Loading...