DT Swiss F 535 ONE operation manual

FORKS

F 535 ONE

TECHNICAL MANUAL

V2018.09

1. GENERAL ..................................................................................................... 3

2. DESCRIPTION .............................................................................................. 6

3. SMALL SERVICE .......................................................................................... 11

4. CONVERTING THE CONTROL ELEMENTS FROM MANUAL TO REMOTE .21

5. CONVERT THE CONTROL ELEMENTS FROM REMOTE TO MANUAL ........ 27

6. ADDING / REMOVING APT VOLUME SPACERS........................................... 33

2

1. GENERAL

1.1 VALIDITY

This manual describes the component specied on the front page and the footer. It is valid for the

construction level of the component on the 26.09.18. Deviations are possible and all items are subject to

technical changes.

1.2 SAFETY

The safety instructions are classied as follows:

DANGER

...indicates a hazardous situation that, if not avoided, will result in death or serious injury.

CAUTION

… indicates a hazard with a medium level of risk which, if not avoided, may result in minor or moderate

injury.

NOTE

… indicates a potentially hazardous situation that may result in damage to property.

1.3 TARGET GROUP

This manual is intended for end users and dealers. It offers the possibility for experienced users to carry out

small maintenance works on their own. If there are any doubts concerning the own skills, a DT Swiss service

center should be contacted.

If the work is not carried out properly, any warranty claims expire.

1.4 LAYOUT

The cover page and the footing provide information about the type of product and manual as well as the

version of the manual. On the back you will nd the DT Swiss contact details. A list of all DT Swiss service

centers can be found at www.dtswiss.com.

This manual is intended for being printed as an A5 booklet. Only print this manual if electronic usage is not

possible.

F 535 - technical manual 3

1.5 DT SWISS MANUAL CONCEPT

The DT Swiss manuals are split into the following types of manuals:

• User Manual: Information for the end user on how to install and use the component.

• Technical Manual: Detailed information for the end user and the dealer on how to maintain the

component, spare parts and technical data.

1.6 USING THIS MANUAL

The steps described in this manual must be carried out in the order they are shown. If steps are ignored or

executed in a wrong order, the function of the component cannot be guaranteed.

Instructions begin with the table «Preparatory Steps» and end with the table «Closing Steps». The instructions

in these tables must be carried out.

1.7 GENERAL MAINTENANCE INFORMATION

Unless otherwise specied, moving parts, threads, O-rings and seals must be greased before assembly.

CLEANING

For an optimal result of the maintenance works, every component that will be disassembled must be cleaned.

Only use cleaners which do not damage the components. Especially the cleaning of O-rings and sealings

requires mild cleaners. Observe the instructions for use of the respective cleaning agent.

DT Swiss recommends the following cleaning products:

• Motorex Rex

• Motorex Swissclean

• Motorex OPAL 2400, 3000 OPAL, OPAL 5000

Use soap water or similar mild cleaners for external cleaning.

TOOLS

To ensure a damage-free mounting and dismounting of the components, only use the tools which are

mentioned in this manual. Special tools are indicated at the beginning of a chapter in the table "Required

material".

The use of different tools is at the discretion of the user. If components are damaged by the usage of differing

tools, the user is liable.

DT Swiss special tools are precision tools. Damage-free mounting and dismounting of the components can

only be ensured if the tools are working properly and if the conditions of the tools are perfect. Always keep the

tools in their original packaging or adequate devices to save them from damages.

4

1.8 ENVIRONMENTAL PROTECTION

The statutory regulations shall apply. Whenever possible, waste has to be avoided. Waste, especially carbon,

lubricants, cleaners and any other uids must be disposed in an environmentally compatible manner.

Only print this manual if electronic usage is not possible.

1.9 EXCLUSION OF LIABILITY

The activities listed in this manual may only be carried out by persons with sufcient specialist knowledge.

The user is liable for any damage or consequential damage caused by wrong maintained or wrong installed

components. If you have doubts, please contact your allocated DT Swiss pro level service center.

1.10 WARRANTY (EUROPE)

In addition to the general guarantee required by law, DT Swiss AG based in Biel/Switzerland, provides a

guarantee for 24 months from the date of purchase. DT Swiss AG shall reject any liability for both indirect

damage caused by accidents and consequential damage.

Any contradictory or extended national rights of the purchaser are not affected by this warranty. Place of

performance and jurisdiction is Biel/Switzerland. Swiss law shall apply.

Submit any warranty claims to your retailer or a DT Swiss service center. Any defects recognized by DT Swiss

AG as a warranty claim will be repaired or replaced by a DT Swiss service center.

Warranty and guarantee claims can only be made by the original purchaser with a valid sales receipt.

There shall be no claim under the guarantee for:

• Normal wear and tear caused by use of the components

• Incorrect assembly

• Incorrect or nonexistent maintenance

• Incorrectly completed repairs

• Use of unsuitable products

• Modication of components

• Incorrect use or misuse

• Carelessness

• Leasing, commercial use or use in competitions

• Damage caused by accidents

• Delivery and transport damage

• Modication, defacing or removal of the serial number

F 535 - technical manual 5

2. DESCRIPTION

The damping unit controls the compression and rebound speed of the fork. During compression and rebound movements of

the suspension fork, oil is pressed through holes with adjustable cross section and through small spring plates (shims) which

allow more oil to pass through as the oil pressure increases (the faster the movement of the suspension fork, the higher the

oil pressure).

The damping unit is a closed system. The damping oil is separated from the air in the fork by a preloaded oating piston. This

prevents the oil from foaming and ensures a constant damping performance even on long, rough downhills.

2.1 COMPRESSION

The damping unit was rethought right from the start in the design of the F 535 suspension fork. A system was realized

that allows different damping characteristics over the stroke of the fork. In the rst third of the travel, the suspension fork

responds extremely sensitively, with a rmer characteristic after the rst third of the travel. This system provides maximum

traction and at the same time high control and feedback on the ground.

The low-speed compression (LSC) can be pre-adjusted in three steps «OPEN», «DRIVE» and «LOCK» for different terrain and

different demands.

OPEN

Full functionality and sensibility of the fork can be attained in the mode «OPEN». This setup is mostly suitable for downhills,

technical and rough uphills and comfortable rides on at trails.

In order to meet the requirements of all riders, the low-speed compression can be set in “OPEN”mode with the setup tool

(Torx T10). The fork is very sensitive and comfortable when the compression damping is fully open (counterclockwise to the

stop). To use the full potential of the fork, we recommend using it with the compression damping fully open regardless of the

rider's weight and the bicycle. The compression damping can be incrementally increased for a less sensitive response.

DRIVE

The «DRIVE» mode sets the fork into a very rm mode. The fork moves, but is very rm. Movements from pedaling are mostly

eliminated. This setting is mostly advantageous for sporty and efcient pedaling on at trails and uphills.

LOCK

The «LOCK» mode blocks the fork in fully extended position. This is mostly suitable for situations where no suspension is

needed (for example riding on the road or connecting trails). The lockout in the «LOCK» mode is hard and dened. A blow-off

valve protects rider and material from unexpected hits.

High speed compression (HSC)

The setup of the high-speed compression leads to a controlled feeling even on hard hits, jumps or steps. The high-speed

compression is pre-set and is not adjustable.

6

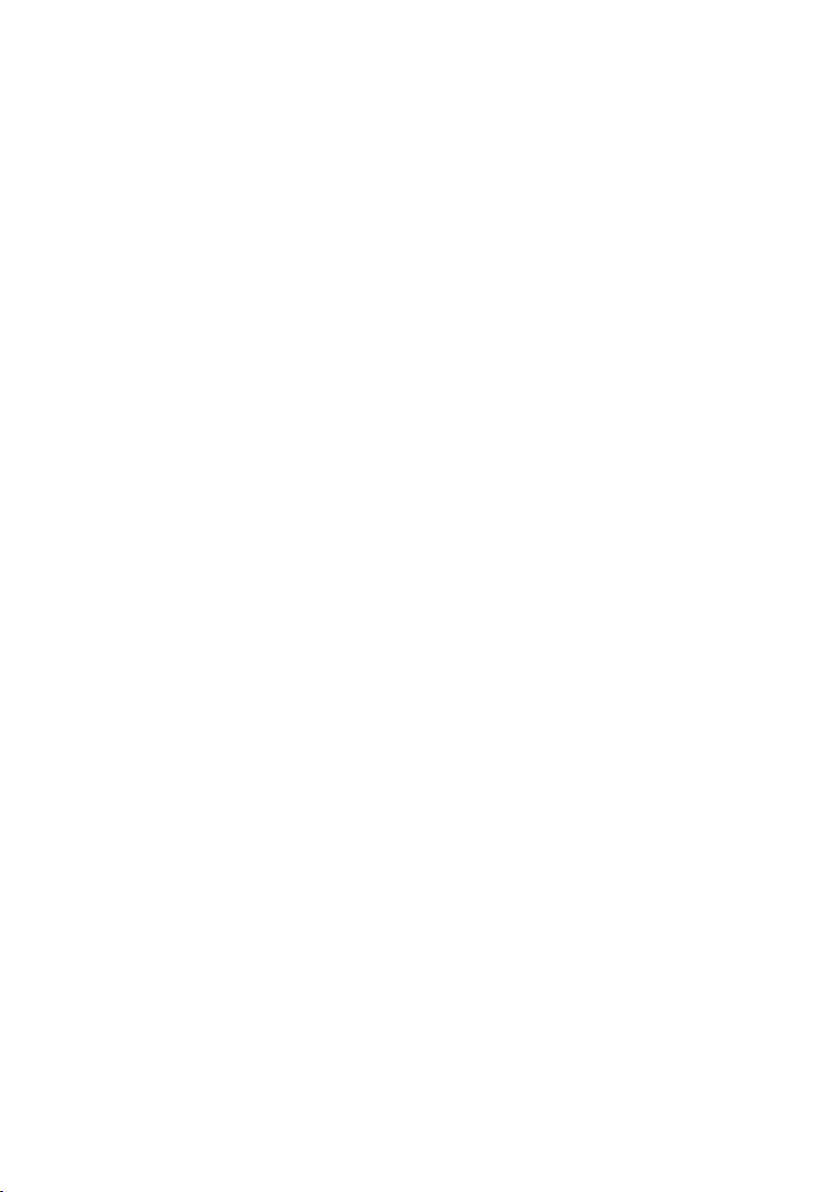

COMPRESSION - FUNCTION IN DETAIL

OPEN 1

OPEN 2

C

DRIVE

LOCK

LSC HSC

gure 1: Compression - function in detail

When the fork compresses, the piston inside the oil chamber is pushed upwards. Some of the oil passes through a one way

valve past the piston (see gure 1) into the lower part of the oil chamber. Thus the volume beneath the piston is smaller than

above, only part of the displaced oil can ow into the space beneath the piston. This excess oil is pushed through the damping

circuit into the upper part of the damping unit. The preloaded oating piston creates a counter pressure to the inowing oil.

Low Speed Compression (LSC)

In the «OPEN» mode the oil ows through the oil channel of the low-speed compression (LSC) and thus over the adjusting

needle, which position can be adjusted with the external compression adjuster (see gure 1/OPEN 1). The position of the

adjusting needle controls the ow resistance of the oil and thus the intensity of damping. The higher the ow resistance, the

higher the damping.

The oil ows through the channel of the low-speed compression into an area where the oil presses a preloaded piston

downwards (see gure 1/OPEN 1). The piston can be pressed down until the oil channel of the incoming oil is closed by a

sliding bushing. From this position, the oil can only ow through the channels of the high speed compression (see gure 1/

OPEN 2). This function gives the suspension fork its characteristic property: The damping responds very sensitively over the

rst third of the travel. After exceeding the rst third of the spring travel, the damping becomes rmer and thus prevents too

rapid and deep immersion in the travel.

F 535 - technical manual 7

High speed compression (HSC)

Additionally, the oil ows through the oil channel of the high-speed compression (HSC). Shims are placed at the end of the oil

channel. These shims only open when a dened oil pressure is attained. Oil which cannot ow through the oil channels of the

LSC (because of fast deection of the fork, and thus big displacement of the oil generated by the piston), ows through the oil

channels of the HSC. This ensures separate damping characteristics on small and medium or on fast compression speeds.

In «DRIVE» mode, the oil channel of the «OPEN» mode is closed. The oil ows through a separate oil channel onto a special

shim stack (see gure 1DRIVE).

In mode «LOCK» (see gure 1LOCK), a slider closes the oil channels of the low-speed compression (LSC) and high-speed

compression (HSC). The oil can only ow through the blow-off channel. Shims at the end of the blow-off channel open the

access to the HSC channel at a dened oil pressure. The blow-off itself does not represent a damping function, it protects

rider and material from big hits.

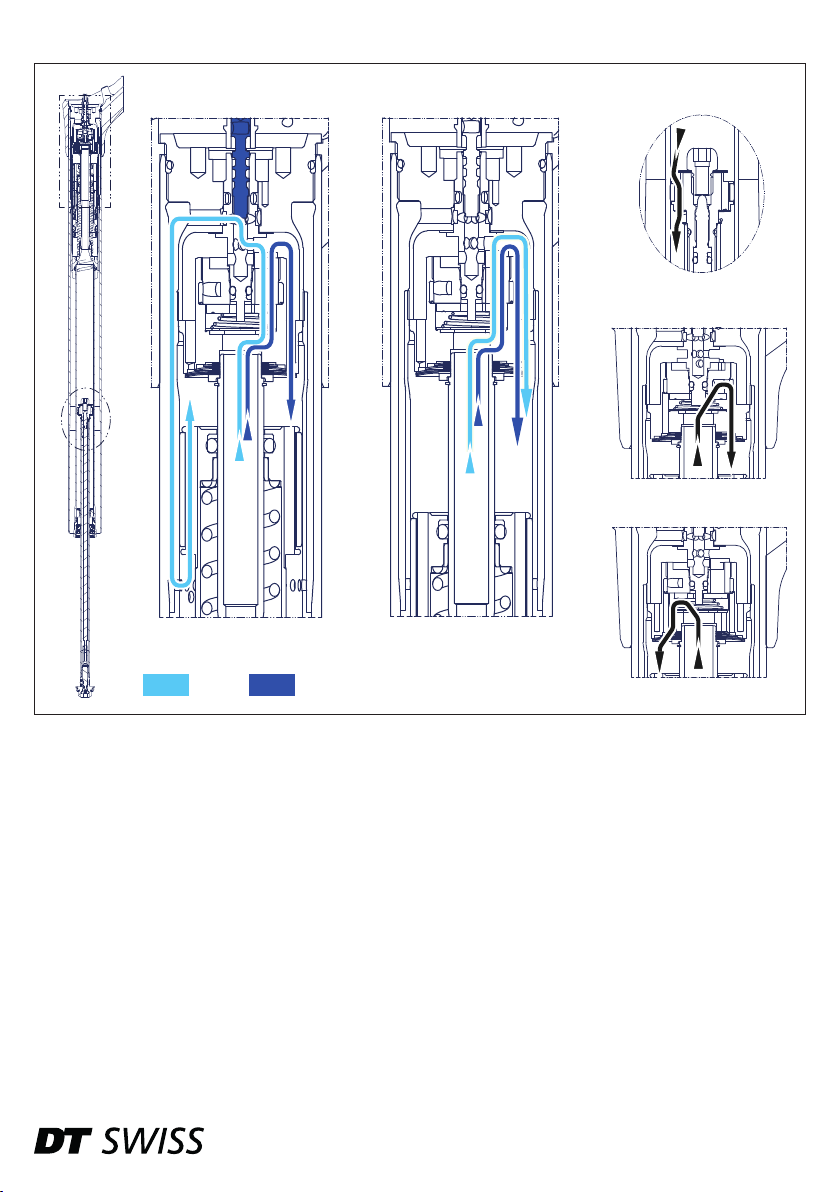

2.2 REBOUND

The preloaded oating piston pushes the oil from the

upper part of the damping unit into the oil chamber when

the fork is released. The oil can ow directly from the

upper unit of the damping unit into the oil chamber.

The rebound damping happens in the damping piston.

Low-speed rebound (LSR)

When the fork rebounds slowly, the oil ows through the

oil channel of the low-speed rebound (LSR). An adjusting

needle, which position can be adjusted with the red

rebound adjuster, controls the owing resistance through

the LSR oil channel. The position of the adjusting needle

controls the ow resistance of the oil and thus the intensity

of damping. The higher the ow resistance, the higher the

damping.

High speed rebound (HSR)

Additionally, the oil ows through the oil channel of the

high-speed rebound (HSR). Shims are placed at the end

of the oil channel. These shims only open when a dened

oil pressure is attained. Oil which cannot ow through the

oil channels of the LSR (because of fast rebound speed of

the fork and thus big displacement of the oil generated by

the piston) ows through the oil channels of the HSR. This

ensures separate damping characteristics on small and

medium or on fast rebound speeds.

LSR HSR

gure 2: Rebound - Function in Detail

8

2.3 SPRING

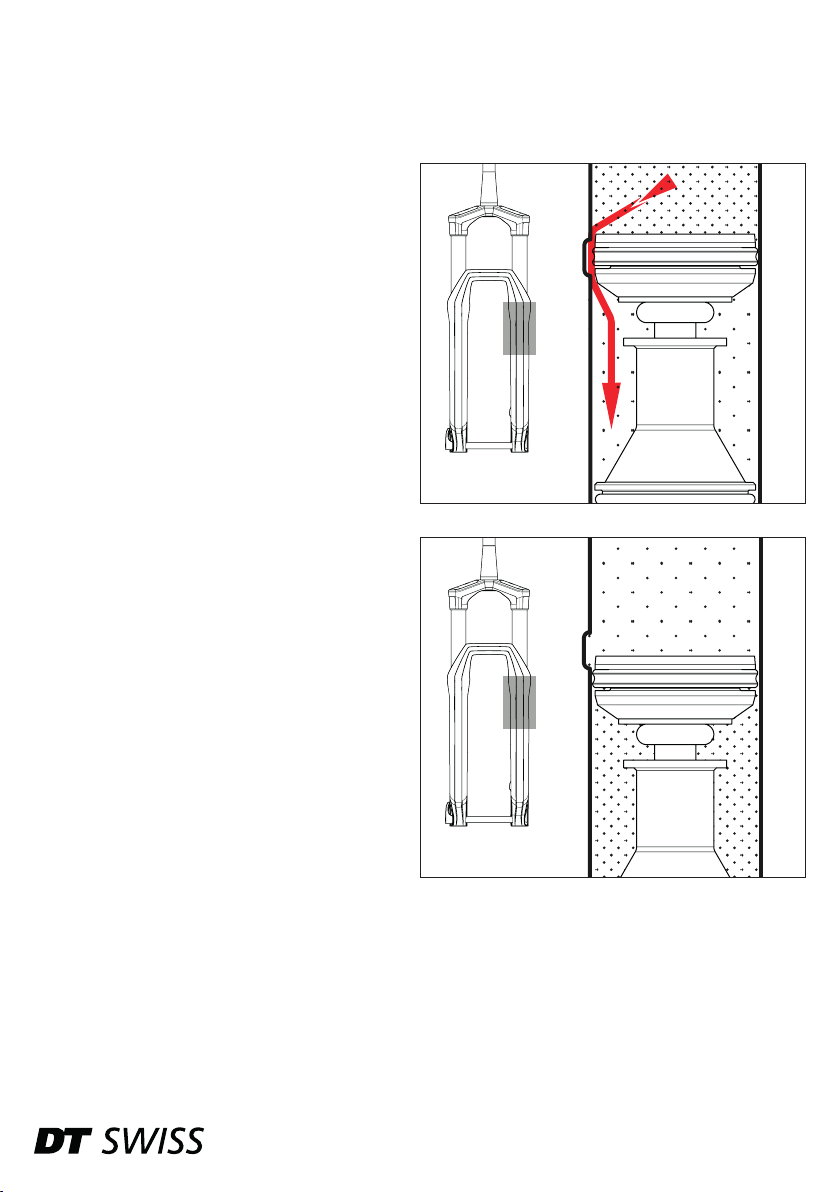

The Line Air system consists of a bypass located in the air chamber. The bypass ensures that the pressure inside the negative

air chamber is higher than in the positive air chamber when the fork is fully extended. This reduces the force of the beginning

stroke. The fork responds very smooth and offers more comfort and traction.

FUNCTION IN DETAIL

After inating or changing the air pressure:

When the fork compresses, the piston moves over the bypass

of the air chamber.

When the piston is located on the bypass, the bypass ensures

a pressure equalization of the positive and negative air

chamber (see red arrow).

gure 3: Pressure compensation via the bypass valve

Function during operation:

Due to the pressure equalization, the pressure in the negative

air chamber is higher than in the positive air chamber when

the fork is fully extended. This increased pressure inside the

negative air chamber counteracts to the breakaway torque

and improves the response characteristics drastically.

When the fork is compressed further, only the air inside the

positive air chamber is compressed.

When the fork extends again, a pressure builds up in the

negative air chamber and the cycles starts again.

gure 4: Pressure conditions with unloaded fork

F 535 - technical manual 9

2.4 SPRING CONNECTOR

B C D

The spring unit is connected to the lower unit of the fork via a spring

connector.

The spring connector basically consists of a coil spring and a guide

bushing.

The steel spring of the spring connector absorbs minor impacts before

they can be transferred to the spring unit. Since the spring unit with its

sliding seals is more inert than a steel spring, the slightest unevenness

is absorbed by the steel spring of the spring connector without the seals'

static friction having to be overcome.

In the event of major impacts or sustained force on the lower unit, the steel

spring in the spring connector is compressed to such an extent that the

force is transmitted directly to the spring unit. The cycle starts anew when

the fork is relieved and loaded again.

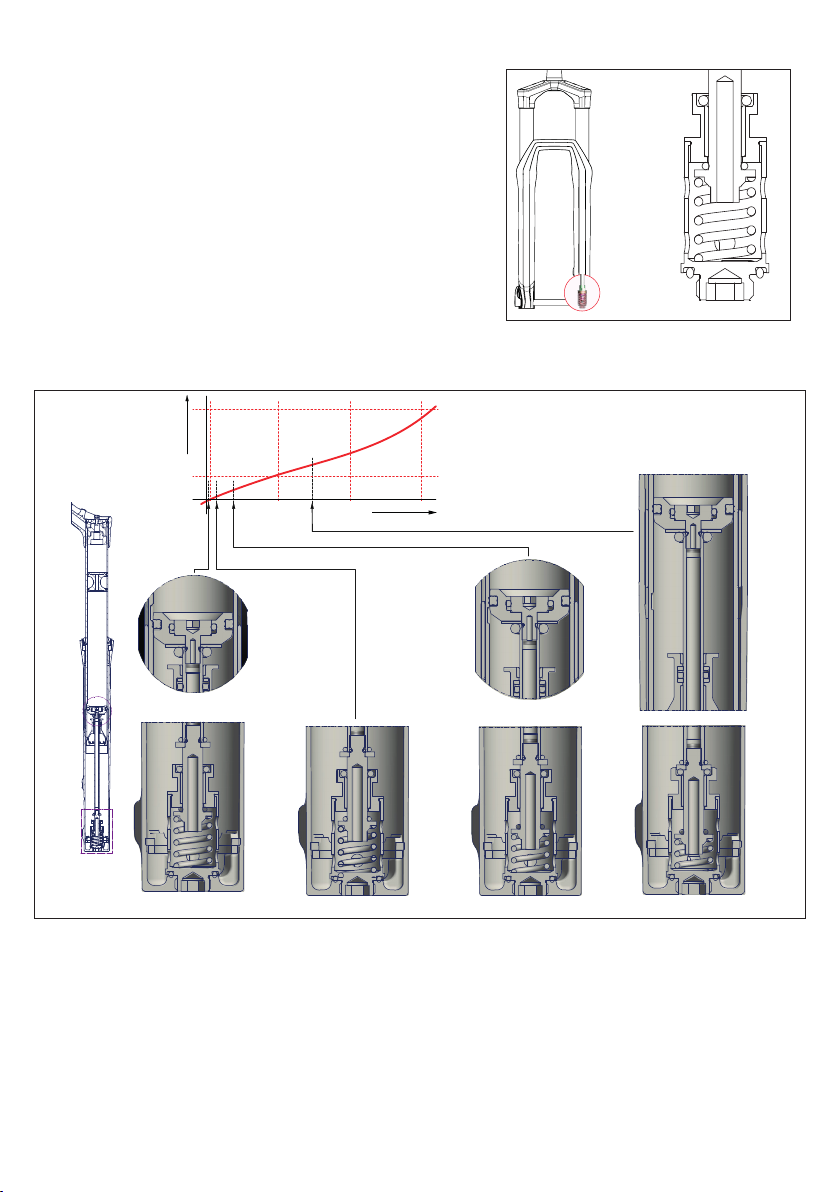

FUNCTION IN DETAIL

1750

Kraft [N]

450

50 100 150

Federweg [mm]

gure 5: Close-up spring connector

A

gure 6: Spring connector- function in detail

A The fork is fully extended. No force is applied to the spring connector.

B The fork starts to compress. On the rst millimetres of the travel, the entire force is absorbed by the spring connector

without air being compressed in the air chamber (static friction of the seals).

C The force acting on the fork compresses the spring connector further. The piston of the air chamber starts to move and

compresses the air in the air chamber.

D After approx. 30 mm of travel, the spring in the spring connector is completely compressed. The entire force acting on

the suspension fork is transmitted directly to the piston of the air chamber.

10

3. SMALL SERVICE

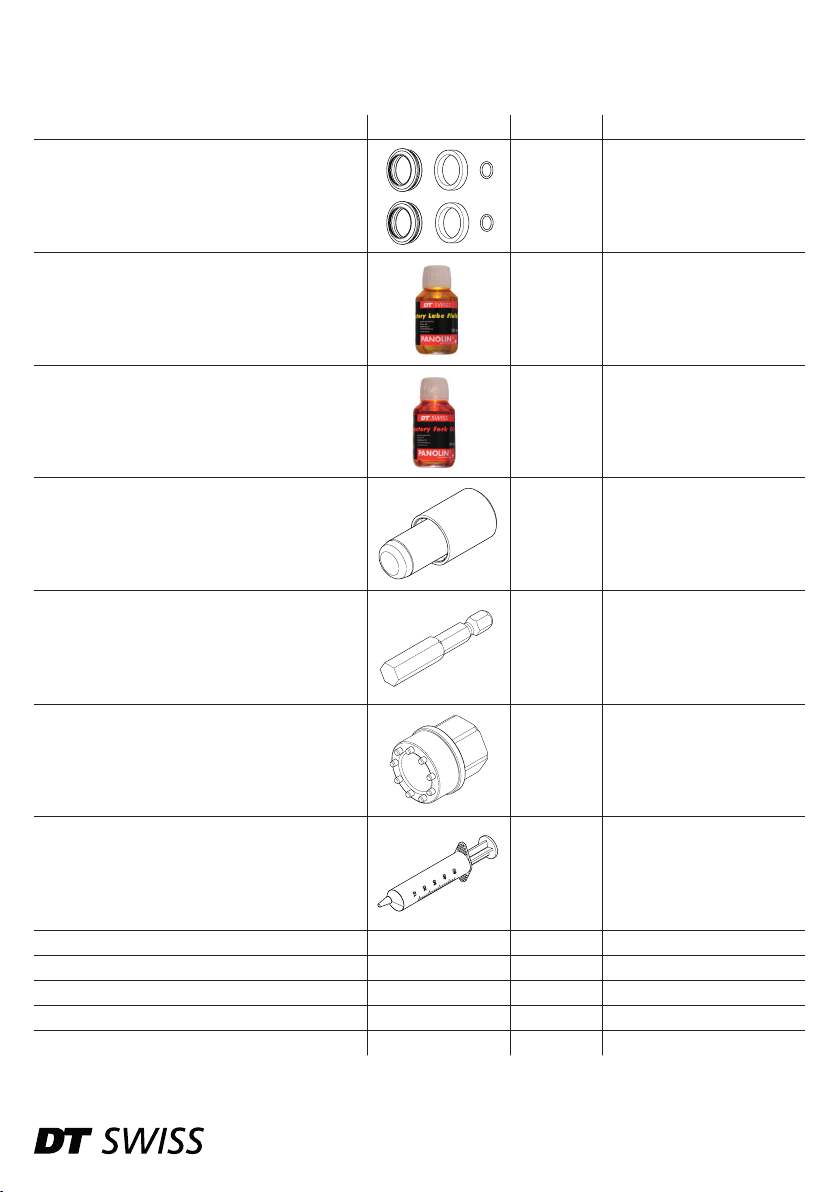

3.1 REQUIRED TOOLS AND MATERIALS

Required tools and materials Specication Quantity Article number

Wiper seal kit Ø35

• 2 x wiper

• 2 x foam ring

• 2x O-ring

1 FWKXXXXXXXXX20369S

DT Swiss Lube Fluid

DT Swiss Fork Oil

Wiper seal mounting tool

Reworked 8 mm hex bit

Mounting tool for spring unit

Syringe (minimum volume 20 ml)

100 ml 4064XXXXXXXX000026

100 ml 4064XXXXXXXX000024

1 FWTXXXXXX10015661S

1 FXTXXXXXXXX018482S

1 FWTXXXXXXXX014126S

1 -

Tire lever 1 Degreaser - Torque wrench 25 Nm 1 Plastic hammer 1 Shock pump 1 -

F 535 - technical manual 11

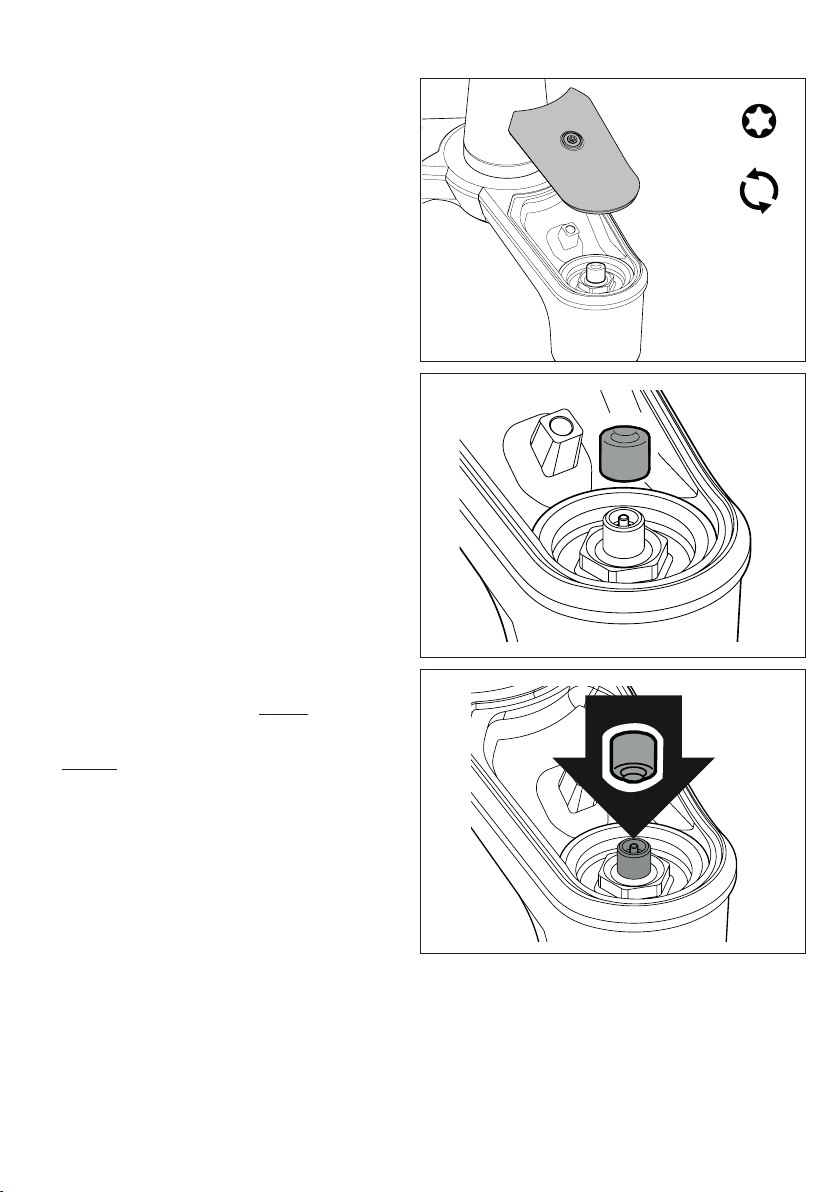

3.2 RELEASING THE AIR

1. Unscrew the xing screw of the cover on the

spring side.

2. Remove the cover.

3. Unscrew the valve cap.

T10 Torx

4. Carefully press the back of the valve cap

onto the valve insert and slowly release the

air.

5. Slowly compress the fork two times about

10 mm with the valve insert pressed and

pull it apart again.

→ This balances the positive and negative

air chambers.

12

Loading...

Loading...