DT Swiss DICUT Service Manual

WHEELS

DICUT

Technical Manual

V2017.07

1 General 2

1.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Information on Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Target Group 3

Layout 3

DT Swiss Manual Concept 3

How to Use this Manual 3

Cross References 3

1.3 Warranty (Europe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Limited Equipment Warranty USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 General Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning 5

Tools 5

Environmental Protection 5

Disclaimer 5

2Safety 6

3Maintenance 7

3.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Truing the Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Changing a Single Spoke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.1 DICUT nondisc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loosen the Nipple 11

Changing the Spoke on the Drive Side of the Rear Wheel 12

Replacing a Spoke on the Front Wheel / on the Non Drive Side of the Rear Wheel 13

Putting Nipples on DICUT Wheels with Aluminum Rims 14

Putting Nipples on DICUT Wheels with Carbon Rims 14

3.3.2 DICUT Aero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.3 DICUT Disc Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Rebuilding the Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.1 Lacing the Wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.2 Stress Relieving the Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 Servicing the Freewheel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Removing the End Cap and the Rotor 22

Cleaning and Checking the Parts 23

Putting on the Ratchet System® 23

4 Technical Data 26

4.1 Spoke Tension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Tolerance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

V2017.07

DICUT® Technical Manual

1

1General

DANGER

CAUTION

NOTICE

This manual describes the component specified on the front page and the footer. Deviations are possible

Ge n er a lV2017.07

and all items are subject to technical changes.

1.1 Safety

The safety instructions are classified as follows:

...indicates a hazardous situation that, if not avoided, will result in death or serious injury.

...indicates a hazardous situation that, if not avoided, could result in a minor or moderate injury.

...indicates information considered important, but not hazard-related.

...characterizes further information, or information which supplement the respective steps.

DICUT® Technical Manual

2

1.2 Information on Using this Manual

Target Group

This manual is intended for end users and dealers.

It offers the possibility for experienced users to carry out small maintenance works on their own. If there are

any doubts concerning the own skills, a DT Swiss service center should be contacted.

Warranty will expire if works are not done properly.

Layout

The cover page and the footing provide information about the type of product and manual as well as the

version of the manual.

Information on Using this ManualV2017.07

The backside provides a list of the DT Swiss service centers. A list of all DT Swiss service centers can be

found at www.dtswiss.com.

This manual is intended for being printed as an A5 booklet. Only print this manual if electronic usage is not

possible.

DT Swiss Manual Concept

The DT Swiss manuals are split into the following types of manuals:

•User Manual

Information for the end user on how to install and use the component.

• Technical Manual

Detailed information for the end user and the dealer on how to maintain the component, spare parts

and technical data.

How to Use this Manual

The steps described in this manual must be carried out in the order they are shown. If steps are ignored or

executed in a wrong order, the function of the component cannot be guaranteed.

Instructions begin with the table «Preparatory Steps» and end with the table «Closing Steps». The instructions in these tables must be carried out.

Moving parts, threads, O-rings and sealings must be greased before assembling.

Cross References

To simplify the use of this manual, some text is edited as hypertext. Whenever the text is formatted blue and

underlined, it is a reference to a chapter. If the text is formatted black and underlined, it is a reference to a

figure. After clicking you will be automatically redirected to the target of the reference.

Example: Click here:

chap. 1, page 2 to jump to the beginning of this chapter.

DICUT® Technical Manual

3

1.3 Warranty (Europe)

In addition to the general guarantee required by law, DT Swiss AG based in Biel/Switzerland, provides a

guarantee for 24 months from the date of purchase. DT Swiss AG shall reject any liability for both indirect

damage caused by accidents and consequential damage.

Any contradictory or extended national rights of the purchaser are not affected by this warranty. Place of

Warranty (Europe)V2017.07

performance and jurisdiction is Biel/Switzerland. Swiss law shall apply.

Submit any warranty claims to your retailer or a DT Swiss service center. Any defects recognized by DT

Swiss AG as a warranty claim will be repaired or replaced by a DT Swiss service center.

Warranty and guarantee claims can only be made by the original purchaser with a valid sales receipt.

There shall be no claim under the guarantee for:

• Normal wear and tear caused by use of the components

• Incorrect assembly

• Incorrect or nonexistent maintenance

• Incorrectly completed repairs

• Use of unsuitable products

• Modification of components

• Incorrect use or misuse

• Carelessness

• Leasing, commercial use or use in competitions

• Damage caused by accidents

• Delivery and transport damage

• Modification, defacing or removal of the serial number

1.4 Limited Equipment Warranty USA

DT Swiss LTD makes every effort to assure that its product meets high quality and durability standards and

warrants to the original retail consumer/purchaser of our product that each product is free from defects in

materials and workmanship as follows:

2 YEAR LIMITED WARRANTY ON THIS DT SWISS PRODUCT. This warranty does not apply to defects due

directly or indirectly to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities

or to a lack of maintenance.

DT SWISS LTD LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF TWO YEARS FROM THE DATE OF

INITIAL PURCHASE AT RETAIL. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES MAY NOT ALLOW LIMITATIONS ON HOW LONG THE

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. DT SWISS LTD SHALL IN

NO EVENT BE LIABLE FOR DEATH, INJURIES TO PEOPLE OR PROPERTY OR FOR INCIDENTAL,

CONTINGENT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.

SOME STATES MAY NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage prepaid,

to the dealer where you bought the product or to a DT Swiss service center. Proof of purchase date and an

explanation of the complaint must accompany the product. If our inspection discloses a defect, DT Swiss will

either repair or replace the product or refund the purchase price, if we cannot readily and quickly provide a

repair or replacement. DT Swiss will return repaired product or replacement at DT Swiss expense, but if it

is determined there is no defect, or that the defect resulted from causes not within the scope of this

warranty, then the user must bear the cost of shipping. This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state. Legal venue and place of performance is Biel

(Switzerland). Swiss law shall apply. Subject to technical changes. Please keep the user manual and

warranty for future use.

DICUT® Technical Manual

4

1.5 General Maintenance Information

Cleaning

For an optimal result of the maintenance works, every component that will be disassembled must be

cleaned. Only cleaners which do not damage the components may be used. Especially the cleaning of Orings and sealings requires mild cleaners. Always consider the instructions of the respective cleaner.

DT Swiss recommends the following cleaners:

• Motorex Rex

• Motorex Swissclean

• Motorex OPAL 2400, OPAL 3000, OPAL 5000

General Maintenance InformationV2017.07

Use soap water or similar mild cleaners for external cleaning.

Tools

If special materials like grease or oil are needed, they will be specified in the table «Required Material» at

the beginning of a chapter.

Environmental Protection

Whenever possible, waste should be avoided. Waste, especially carbon, lubricants, cleaners and any other

fluids must be disposed in an environmentally compatible manner.

Only print this manual if electronic usage is not possible.

Disclaimer

The operations described in this manual should only be performed by experts. The user is liable for any

damage or consequential damage caused by wrong maintained or wrong installed components. If you have

doubts, please contact a DT Swiss service center.

DICUT® Technical Manual

5

2Safety

DANGER

DANGER

DANGER

NOTICE

SafetyV2017.07

Incorrect handling, installation, maintenance or servicing can lead to accidents causing severe

injuries or death!

• Compliance with the following provisions is a prerequisite for accident-free use and faultless functioning.

• Assembly and maintenance of the component requires a basic knowledge of handling bicycle components. If in any doubt, consult your retailer.

• Components should only be used in accordance with their intended use,otherwise the user shall

assume full responsibility.

• The component must be compatible with all parts of the bicycle.

• Only use original spare parts.

• The components must not be changed or modified.

• The component must not be used if it is damaged or there are any signs of damage. If in any doubt,

consult your retailer.

Risk of death caused by incorrectly assembled or faulty wheels!

• Check that the wheel is connected correctly before each ride.

• Check the wheel for damage before and after each ride.

• Regularly check the spoke tension, rotation and wear of the wheel.

Risk of death caused by failure or reduction of the brake performance when using wheels for rim

brakes!

• Brake with both brakes!

• When riding down hill only brake briefly with pauses in between.

• Avoid sliding and permanent braking, as the wheel will overheat thus causing the failure of the rim,

tyre or inner tube.

• If using new wheels or brake pads, the braking power is also reduced in wet conditions. Adjust the

manner of cycling accordingly.

• Do not expose the wheel to temperatures above 90°C during transport or storage.

Risk of damaging the wheel by selecting incorrect components or tools!

• Do not use metal tire levers. These can damage the surface of the rim, tyre or inner tube.

• Only use valves with a diameter of 6.5 mm and of an adequate length.

• The maximum tyre pressure of the wheel and of the tyre used must not be exceeded.

• Only use rim tapes, inner tubes and tyres which fit the dimensions of the wheel.

• Carbon rims must not be used with tubeless kits and tubeless tyres.

• Carbon rims must not be used with latex tubes.

DICUT® Technical Manual

6

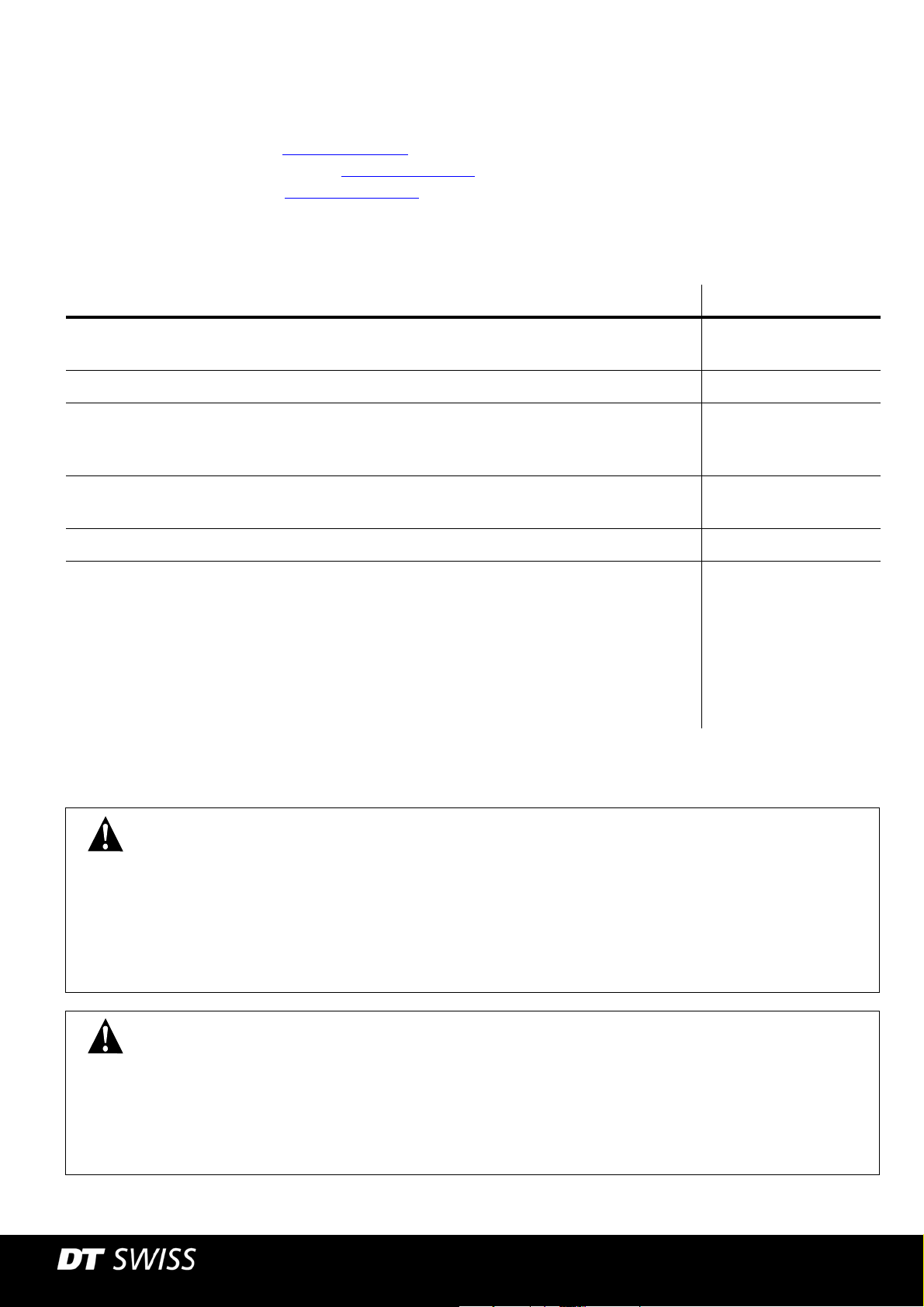

3Maintenance

DANGER

CAUTION

This chapter describes activities which are concerning the whole wheel:

MaintenanceV2017.07

• Truing the wheel, see

• Changing a single spoke, see chap. 3.3, page 12

• Rebuilding the wheel, chap. 3.4, page 18

Maintenance works of the hub can be found in the technical manual at www.dtswiss.com.

DT Swiss recommends the following service works:

Action Interval

Maintenance of the hub (see Technical Manual at www.dtswiss.com). annually

Check spoke tension, run-out and wear of the wheel. 10 hours of use

Check the wheel for damages.

Clean the wheel with a soft cloth and an appropriate cleaner.

Do not use high pressure cleaners and aggressive cleaners!

Check the proper fixation of the wheel. before each ride

Check the braking surface and the brake pads:

chap. 3.2, page 9

or as required

before and after each

ride

after each ride

before each ride

• Remove any contaminations (especially oil and grease) from the brake sur-

faces.

• Check the degree of wear of the brake pads.

• Remove any entrenched impurities (grit, swarf, etc.).

• Check the degree of wear of the rim brake surfaces. In case of any doubts or

viewable wear, contact a skilled professional.

3.1 Safety

Danger to life due to wrong maintenance!

Incorrect maintenance or assembly can lead to unpredictable errors!

• Maintenance and assembly may only be done by a skilled professional.

• In case of any doubt, contact a DT Swiss service center.

Risk of injury due to wrong spare parts!

Incorrect spare parts can lead to unpredictable errors!

• Only use original spare parts.

DICUT® Technical Manual

7

3.2 Truing the Wheel

NOTICE

Preparatory Steps

Remove the wheel from the bike.

Truing the WheelV2017.07

Remove the rim strip, the inner tube and the tire.

Clean the wheel and check for damages.

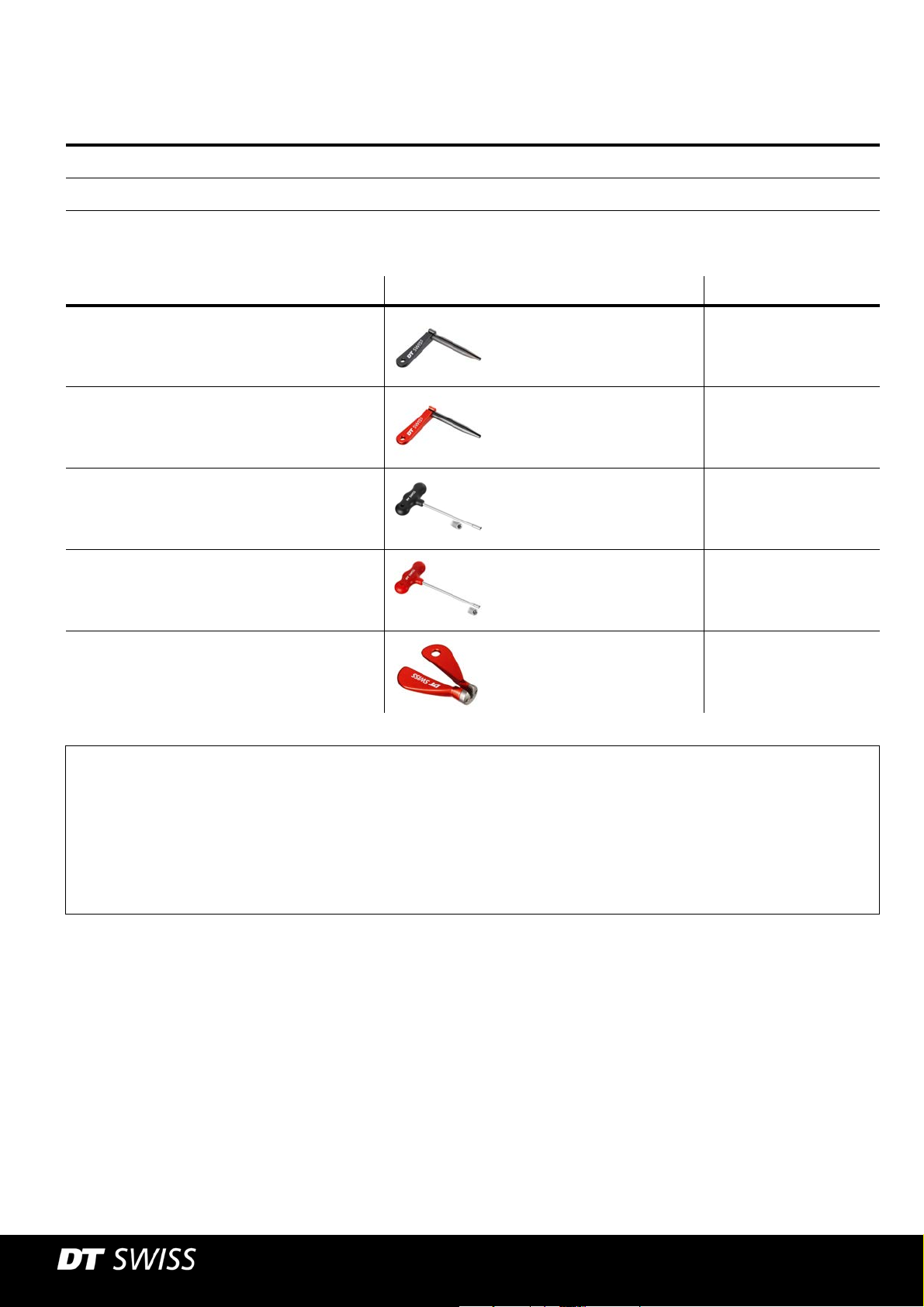

Required Material Specification Amount

spoke holder 1.0 - 1.3 mm TTSXXXXS05644S 1

spoke holder 0.8 - 1.0 mm TTSXXXXR05641S 1

nipple wrench TORX TTSXXXXS05630S 1

nipple wrench square TTSXXXXR05631S 1

spokey square TTSXXXXR05664S 1

Risk of damaging the bladed spokes and the nipples!

• Bladed spokes must be hold with the spoke holder while turning the nipple.

• There are used different spokes types. Ensure that the correct tool is being used.

• When holding the spoke, push the spoke holder as far as possible in direction of the rim.

DICUT® Technical Manual

8

Loading...

Loading...